Rapid low-cost activation method for membrane electrode of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell membrane technology, which is applied in the field of fast and low-cost activation of membrane electrodes of proton exchange membrane fuel cells, can solve the problems of high activation cost, use of a large amount of hydrogen, and energy consumption, so as to reduce activation cost, reduce consumption, The effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

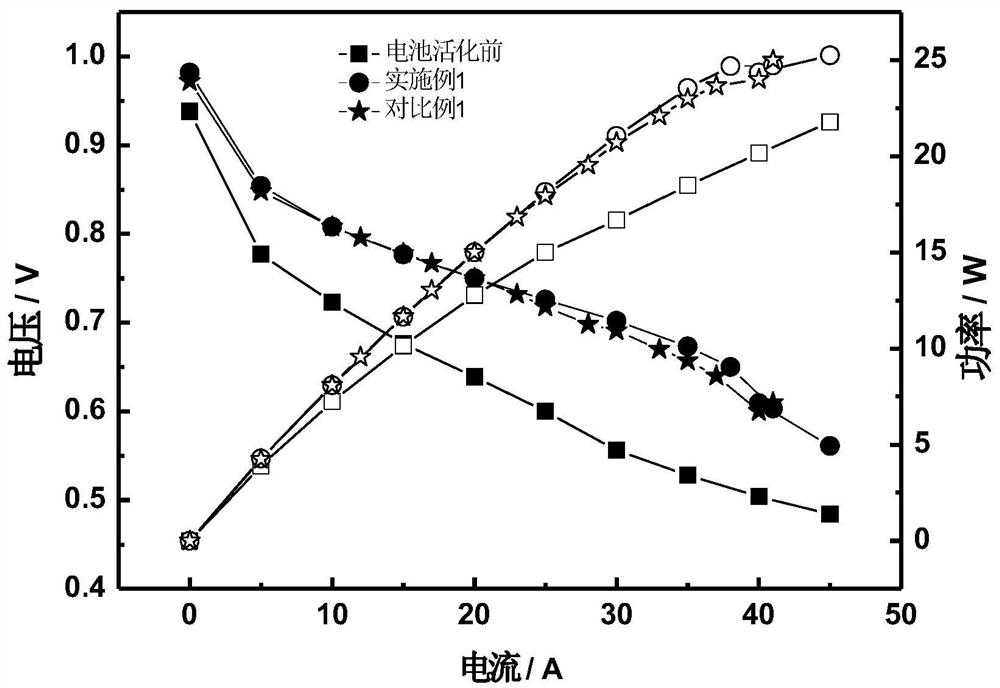

Embodiment 1

[0026] Embodiment 1 (non-discharge wet hydrogen method)

[0027] The research object of this embodiment is a fuel cell, and the effective active area of the membrane electrode is 25cm 2 , using the non-discharge wet hydrogen method to activate the battery, including the following steps:

[0028] (1) Put the newly assembled 25cm 2 The single cell of the proton exchange membrane fuel cell is installed on the fuel cell test bench, and the dry nitrogen gas of 0.3 NL / min is passed through the positive and negative poles of the single cell for 10 minutes to remove the air and impurities in the fuel cell;

[0029] (2) Turn on the heating device and set the temperature of the single battery to 55°C;

[0030] (3) Pass hydrogen with a relative humidity of 80% to the anode, and pass hydrogen with a relative humidity of 80% to the cathode, and the flow rate of hydrogen at the cathode and anode is 0.3 NL / min;

[0031] (4) Keep the flow rate of hydrogen in step (3) for 2 minutes;

[0...

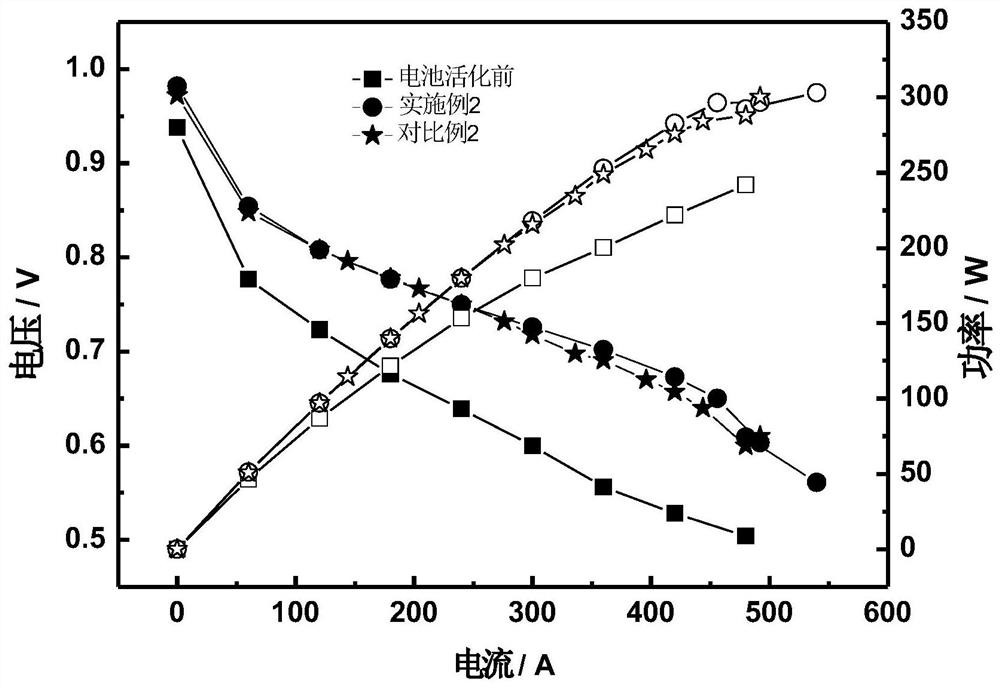

Embodiment 2

[0045] Embodiment 2 (non-discharge wet hydrogen method)

[0046] The research object of this embodiment is a fuel cell, and the effective active area of the membrane electrode is 300cm 2 , using the non-discharge wet hydrogen method to activate the battery, including the following steps:

[0047] (1) Put the newly assembled 300cm2 The proton exchange membrane fuel cell single cell is installed on the fuel cell test bench, and 2.2 NL / min of dry nitrogen is safely purged to the positive and negative poles of the single cell for 10 minutes to remove the air and impurities in the fuel cell;

[0048] (2) Turn on the heating device and set the temperature of the single battery to 55°C;

[0049] (3) Pass hydrogen gas with a relative humidity of 80% to the anode, and pass hydrogen gas with a relative humidity of 80% to the cathode, and the hydrogen flow rate at the cathode and anode is 3.6 NL / min;

[0050] (4) Keep the flow rate of hydrogen in step (3) for 5 minutes;

[0051] (5)...

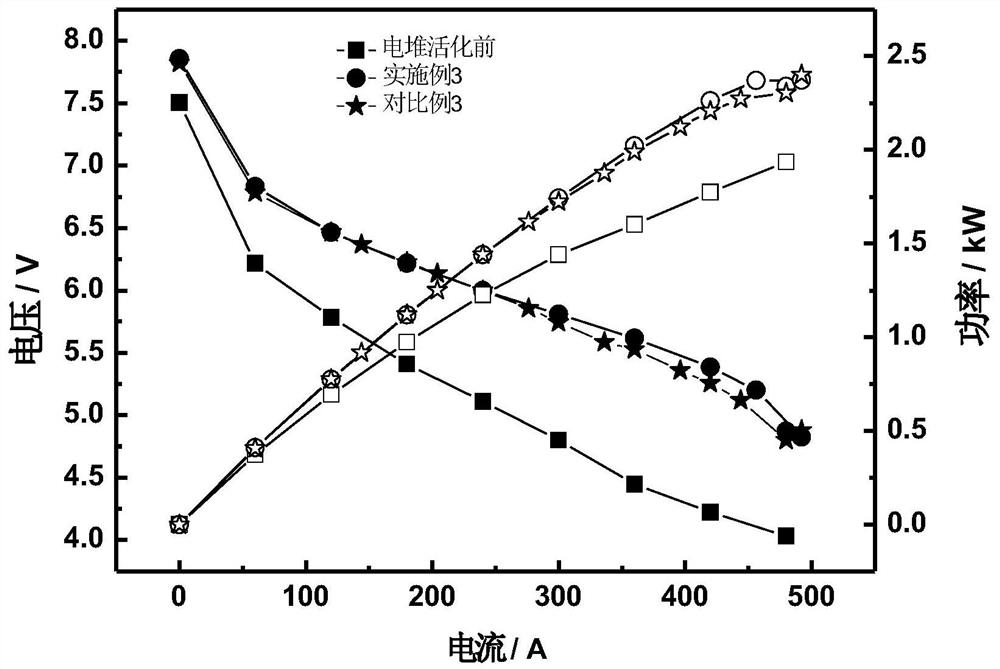

Embodiment 3

[0064] Embodiment 3 (non-discharge wet hydrogen method)

[0065] The research object of this embodiment is a stack assembled with 8 membrane electrodes, and the effective active area of the membrane electrodes is 300cm 2 , using the non-discharge wet hydrogen method to activate the stack, including the following steps:

[0066] (1) Install the newly assembled 8-cell stack on the fuel cell test bench, and safely purge 17.5 NL / min of dry nitrogen to the positive and negative poles of the stack for 15 minutes to remove the air and impurities in the fuel cell;

[0067] (2) Turn on the heating device and set the stack temperature to 65°C;

[0068] (3) Pass hydrogen with a relative humidity of 90% to the anode, and pass hydrogen with a relative humidity of 90% to the cathode, and the hydrogen flow rate at the two poles is 28.8 NL / min;

[0069] (4) Keep the flow rate of hydrogen in step (3) for 15 minutes;

[0070] (5) Close the solenoid valve at the outlet end of the two poles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com