Rice husk cellulose adsorbent, and preparation method and application thereof

An adsorbent and cellulose technology, which is applied in the field of rice husk cellulose adsorbent and its preparation and application, can solve the problems of wasting resources and not being able to give full play to the performance of rice husk, and achieve no energy consumption, abundant raw materials, and reduced processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of rice husk cellulose adsorbent

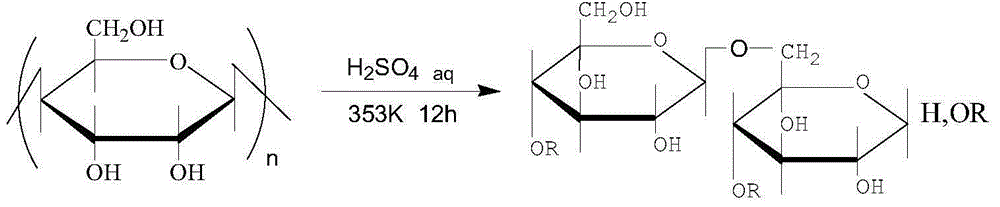

[0025] Take 100 g of raw rice husk (RH), wash it with deionized water, put it into a constant temperature drying oven, dry it at 50° C. for 12 hours, take it out, crush it until it is powdery, and set it aside. Take 20g of rice husk powder and slowly add 80mL of 17.4mol / L sulfuric acid, heat in a water bath, control the temperature at about 80°C, and acidify for 24h. The acidified rice husk powder was mixed with 250mL concentration of 0.2mol L -1 Wash with sodium bicarbonate, then wash with deionized water until neutral, filter, dry at a constant temperature of 60°C for 24 hours, grind and sieve, and select an adsorbent with a particle size of 100-150 μm, which is designated as ORH. The yield is about 73.15%.

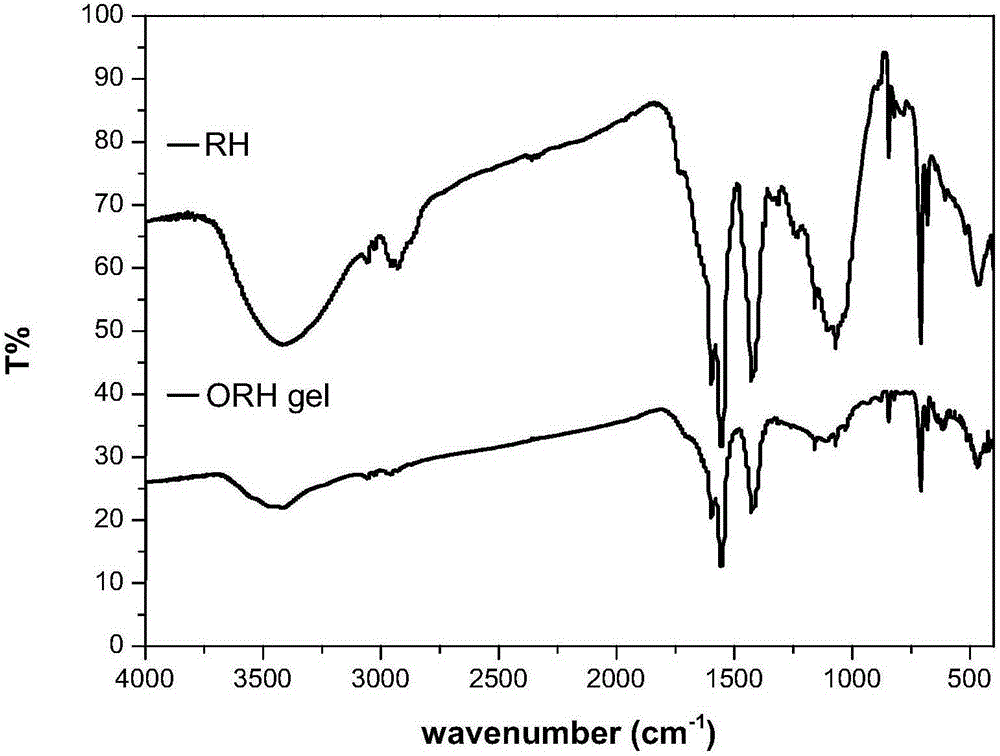

[0026] The infrared spectra of the obtained rice husk cellulose adsorbent were as follows: figure 1 shown at 3700–3100cm -1 The hydroxyl stretching vibration peak at 2950cm is obviously weakened -1 and 1...

Embodiment 2

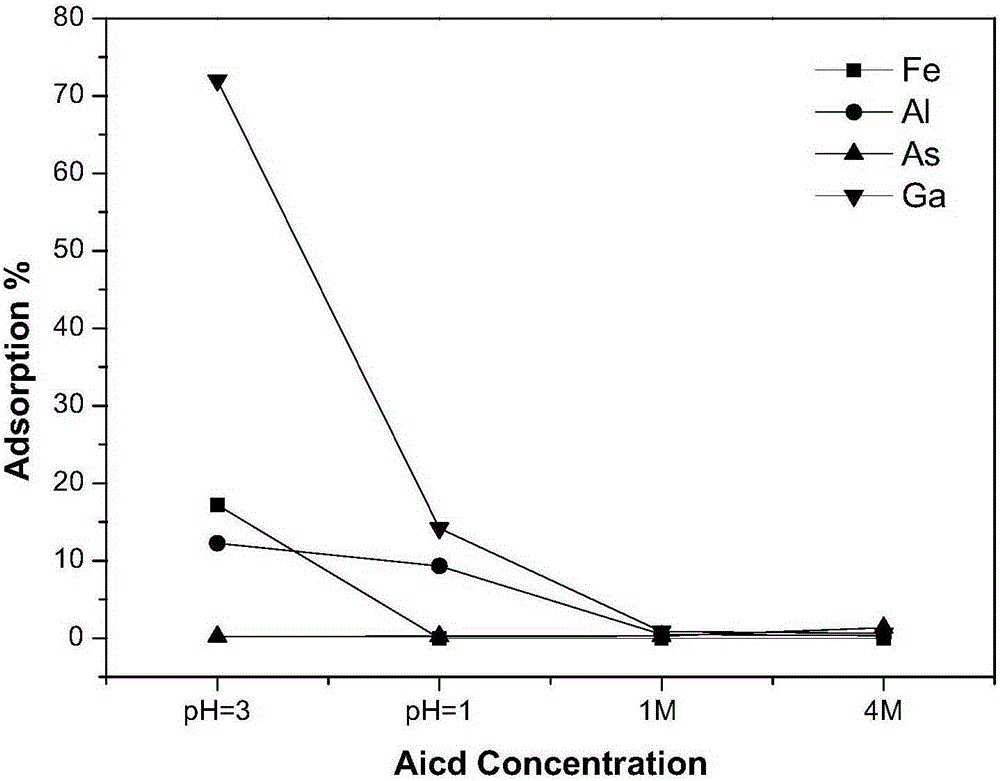

[0030] Embodiment 2 The influence of different acidity and other coexisting ions on gallium adsorption

[0031] Get the solution 10ml that contains Ga20ppm, Al20ppm, Fe20ppm and As20ppm respectively, adjust the pH of solution to be that pH is equal to 1, 3, and [H + ] is 1mol L -1 and 4mol L -1 , and then add 10 mg of the rice husk cellulose adsorbent prepared in Example 1 respectively, and after shaking for 24 hours, measure the concentration of each ion in the solution. The result is as figure 2 shown, from figure 2 It can be seen that in the whole range of acidity, the adsorption rate of the adsorbent for aluminum, iron and arsenic ions is very low, while the adsorption rate for gallium solution can reach more than 72% at pH=3. It shows that the rice husk cellulose adsorbent of the present invention has efficient and selective adsorption of gallium in the solution containing aluminum, iron, arsenic and gallium.

Embodiment 3

[0032] Example 3 Application of Sulfuric Acid Modified Rice Husk Cellulose Adsorbent to the Separation and Enrichment of Gallium

[0033] Take 50mol / L gallium solution, adjust the pH of the solution to pH=3, add 50mg of sulfuric acid modified rice husk adsorbent to 50ml solution containing gallium scattered elements, shake for 24 hours, absorb the gallium scattered elements in the solution, filter The post-loaded gallium adsorbent uses 1mol L -1 The hydrochloric acid solution was analyzed, and the calculated recovery rate was 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com