Hand-push type brick paving machine

A brick laying machine, hand-push technology, applied in the field of human-driven hand-push brick laying machine, can solve the problems of time-consuming, laborious, expensive, high cost, etc., and achieve the effect of simple mechanical structure, no energy consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawings and examples.

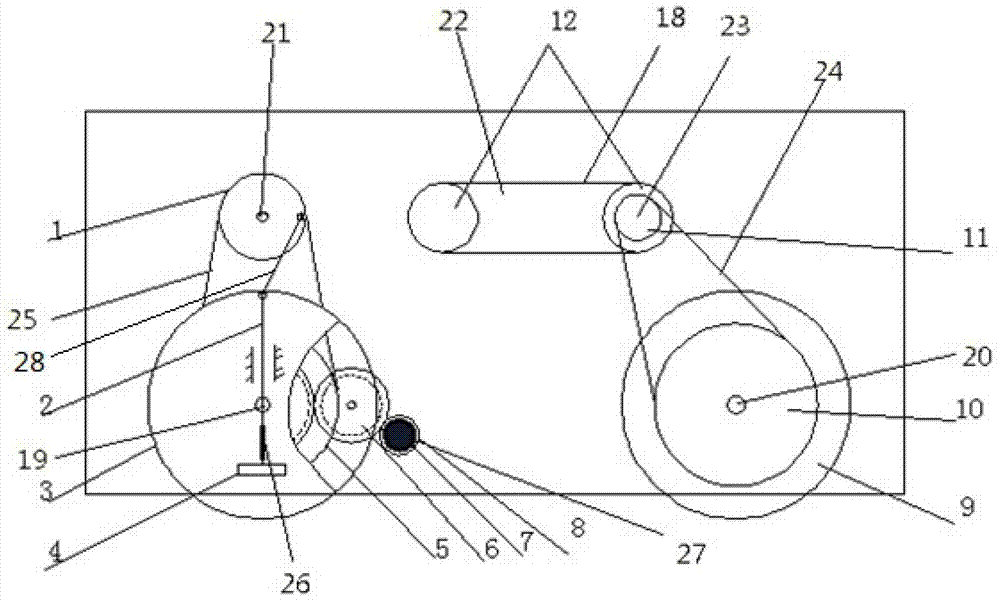

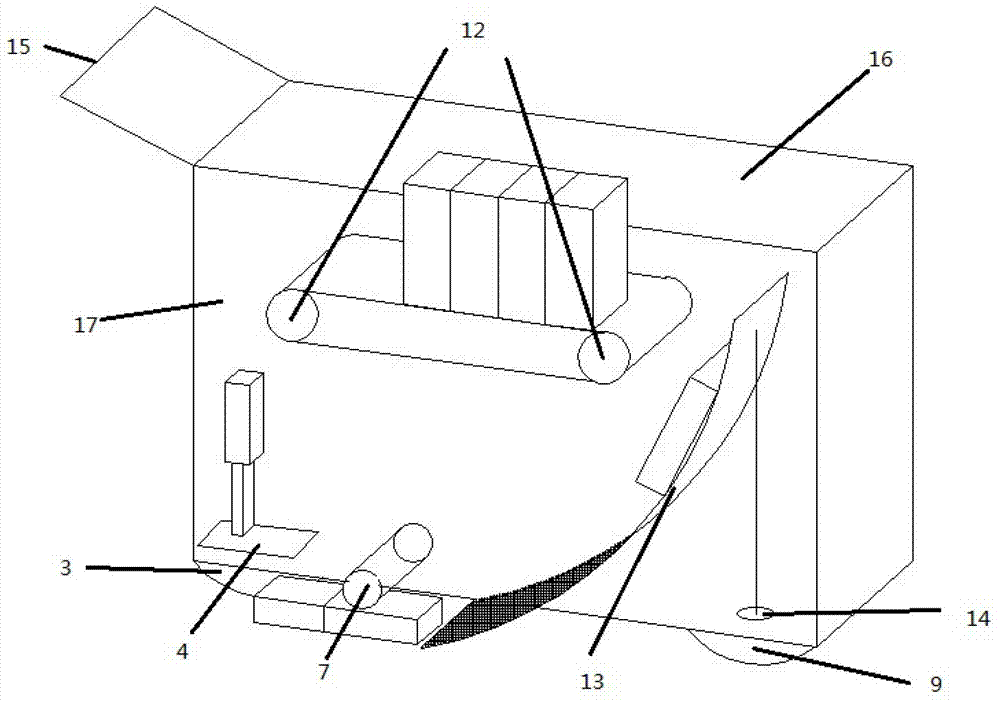

[0017] refer to figure 1 and figure 2 , the hand-push brick laying machine specifically includes 1 body (17), 2 rear wheels (3), 2 front wheels (9), 2 large sprockets (10), 2 small sprockets (11), 2 large pulleys (5), 2 small pulleys (1), 1 conveyor belt (18), 2 rollers (12), 1 brick tray (16), 1 slideway (13), 2 1 rubber roller (7), 1 tamping hammer (4), 1 cover plate, 3 gears of specific size (8), 1 secondary crank slider mechanism (2), 1 rear axle (19), 1 front axle (20), 1 crankshaft (21), 1 bearing plate (22), 1 roller axle (23), 2 direction guide wheels (14).

[0018] The front wheel shaft (20) and the front wheel (9) are interference fit, and are placed on the front and bottom of the body (17); the large sprocket (10) is welded on the connecting shaft between the front wheels (9), and the front wheel (9) Drive the rotation; the small sprocket (11) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com