This centrifugal oil purifier uses the principle of centrifugal purification to remove pollutants greater than the

specific gravity of the oil. Its

advantage is that the machine not only removes 100% of

free water but also has a strong effect on dissolved water while rotating at high speed. The removal ability is conducive to the extension of oil life and

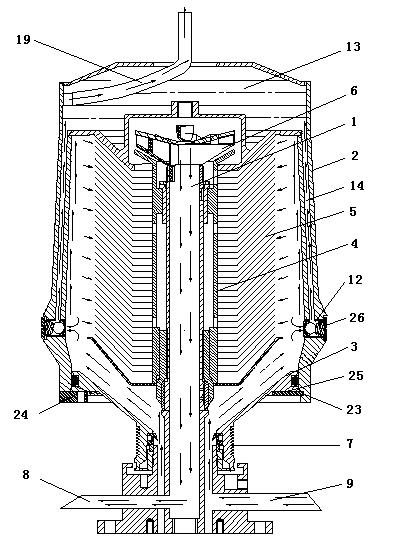

safe operation, and high efficiency. The disadvantages: First, if the speed of the centrifugal cylinder is increased, when the purified oil is input to the inlet of the

impeller at the front end of the centrifugal cylinder, the centrifugal

impeller will be left at a high speed. Rotate, on the one hand, the sucked oil rotates along the circumference under the drive of the impeller; The channel formed is constantly moving upward, and the pollutants in the oil are constantly moving towards the cylinder wall under the action of

centrifugal force, and on the other hand, they are driven upward by the oil. Therefore, the

pollution particles in the oil It is moving according to a

helical synthetic motion trajectory, and large particles of pollutants will be attached to the cylinder wall in this interval. This interval is called the first purification area. The interval from the outflow to the outflow is called the second purification zone

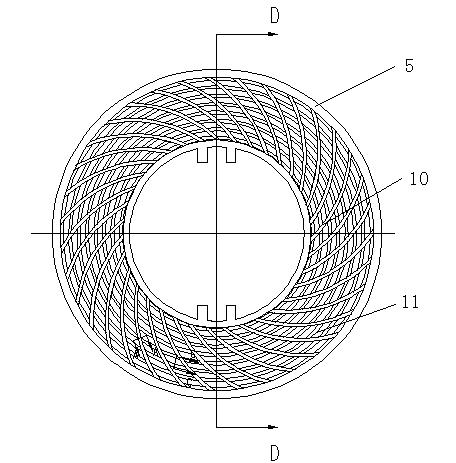

As we all know, in order to obtain a good purification effect, the centrifugal cylinder can be rotated at high speed to establish a high-speed rotating flow field. The higher the rotation speed, the smaller the particle size of the separated pollutants and the higher the purification accuracy. However, this centrifugal The disc-type guide plate in the oil purifier is made of plastic material. After increasing the speed of the centrifugal cylinder, there will be a lot of relative movement between the oil and the edge of the disc-type guide plate just before the oil enters the second purification zone. The disc guide plate rotates the liquid, the higher the speed of the disc guide plate rotating with the centrifugal cylinder, the greater the tangential velocity between the disc guide plate edge and the oil, and the greater the speed pressure, according to Bernoulli The relationship pointed out by the equation: removing the influence of the position head, the static pressure head and the velocity head at this point should be equal to the total water head. Therefore, the static pressure must decrease when the velocity pressure increases. If the static pressure at this point drops to the gas in the liquid When the pressure is separated, the gas dissolved in the oil will be separated. When the oil is about to flow into the gap of the disc guide plate, the air bubbles will be precipitated. Due to the pressure acting on the liquid, there will be air bubbles. It is called

cavitation. Under the action of surrounding pressure, these bubbles will quickly "dissolve" into the oil. There are literatures that the appearance and collapse of

cavitation will produce "knocking". The

impact pressure of 100 atmospheres produces a "

cavitation" phenomenon, which easily destroys the plastic disc guide plate, causing a large number of non-metallic

pollutant particles to appear in the purified oil. Generally, the cleanliness of this oil is measured at 12 Level or so, it will show a state of non-

divergence, which will seriously affect the cleanliness of the oil; second, during the centrifugal rotation of the oil, because the wall of the centrifugal cylinder is in a

closed state, the

solid particles, water and air with large

specific gravity will be separated under the

centrifugal force Under the action, it moves toward the inner wall of the centrifugal cylinder, so that many pollutants,

moisture and air are attached to the inner wall of the centrifugal cylinder. After the centrifugal cylinder stops rotating, these pollutants and

moisture attached to the cylinder wall lose

centrifugal force and are released by gravity. Under the action of the centrifugal cylinder wall and the slope between the blades of the front end cover, it flows into the

dirt receiving box through the

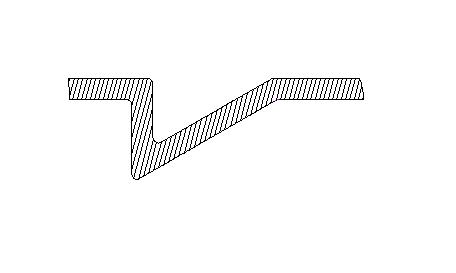

sewage pipe, so that the purification and separation effect of the oil is not obvious. Therefore, the structure of the centrifugal cylinder and the disc guide plate The material, geometric shape and

surface shape are all important links to determine the purification level of the oil purifier; third, during the high-speed rotation of the centrifugal cylinder, due to the connection between the support rod and the sleeve of the rotating skeleton in the prior art Rod connection, the connecting rod and the sleeve and the support rod are in a vertical state, while the oil moves upwards in a

spiral trajectory under the action of centrifugal force, and the structure of the connecting rod and the support rod is applied to the swirl process The opposite resistance of the oil in the center causes the radial partial velocity of the discharged oil to decrease, which reduces the purification effect of the oil; Fourth, because the outer surface of the front end cover is fixed with the

lower half of the centrifugal cylinder, and is sealed by the sealing ring, in After the purifier has been running for a long time, the pollutants separated from the oil, some viscous substances are deposited in the gaps of the disc guide plate, which will reduce the circulation area of the oil and reduce the purification effect. The

front cover needs to be removed frequently Cleaning the

centrifuge, this structure is very difficult to disassemble and install

Login to View More

Login to View More  Login to View More

Login to View More