Patents

Literature

83results about How to "Fast activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

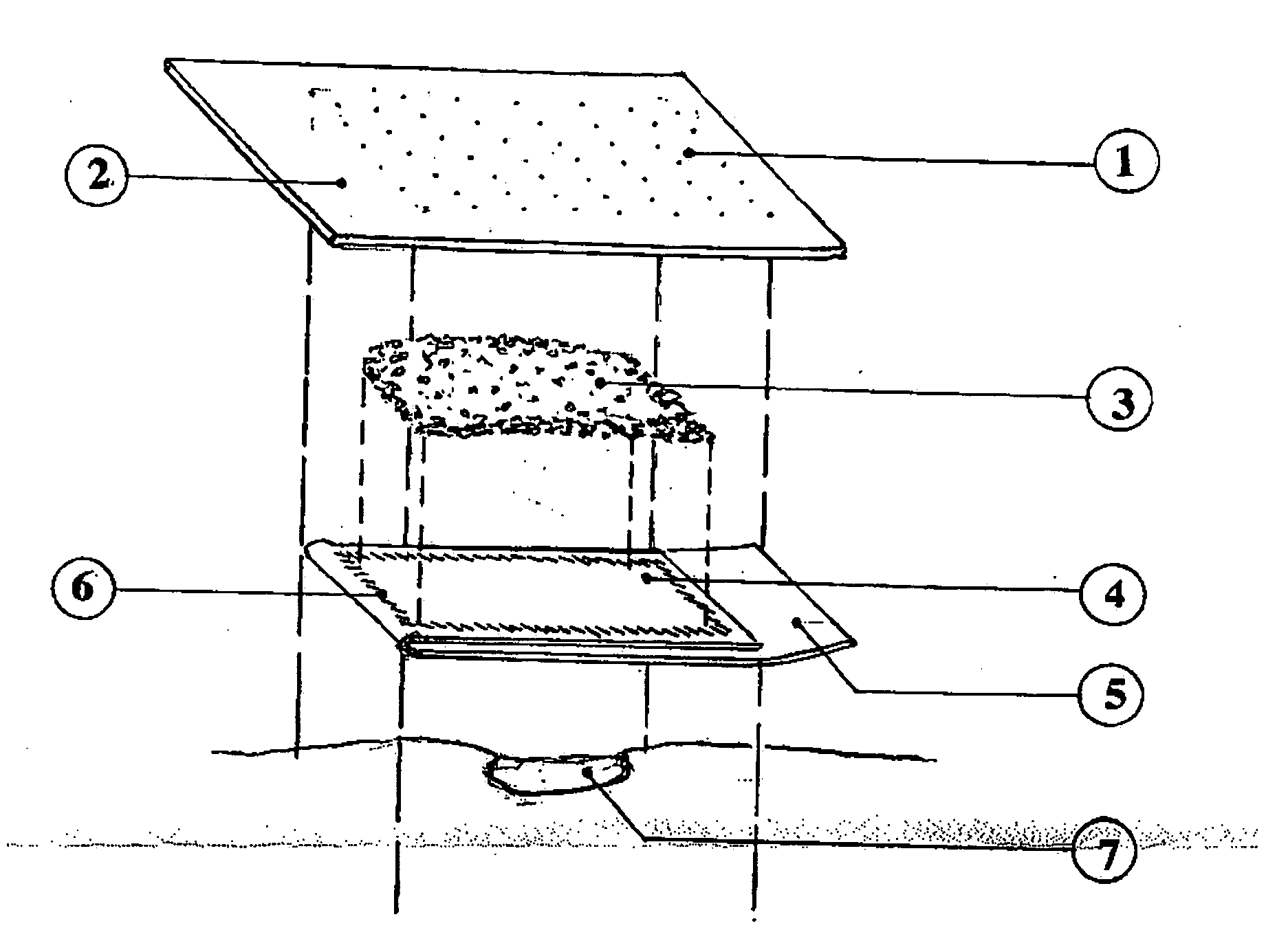

Hemostatic compression bandage

InactiveUS20060155235A1Continuous woundFast activationAdhesive dressingsEngineeringMechanical engineering

A hemostatic compression bandage includes a flexible backing element, a powdered hemostatic substance, and a flexible film element. The backing element includes a first containment region. The film element includes a second containment region corresponding to the first containment region. The film element is removably attached to the backing element so as to contain the hemostatic substance between the backing element and the film element within a volume defined by the first containment region and the second containment region. The backing element includes a pressure region located outside of the first containment region. The film element includes a pull-tab region located outside of the second containment region and at a first side of the bandage. The pull-tab region has sufficient length to be folded back across the second containment region and extending beyond a second side of the bandage that is opposite the first side of the bandage.

Owner:SAWYER EVELYN S

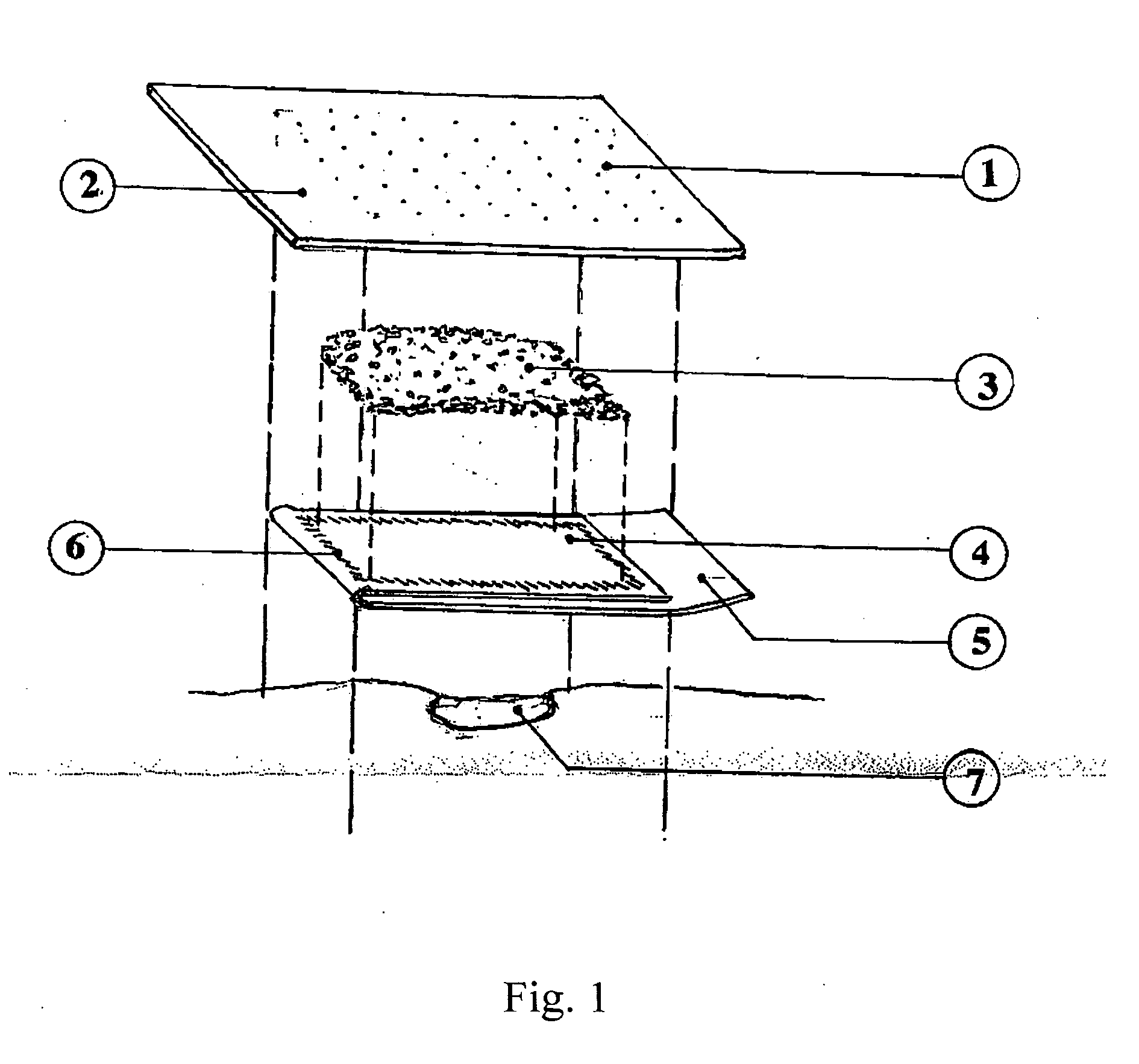

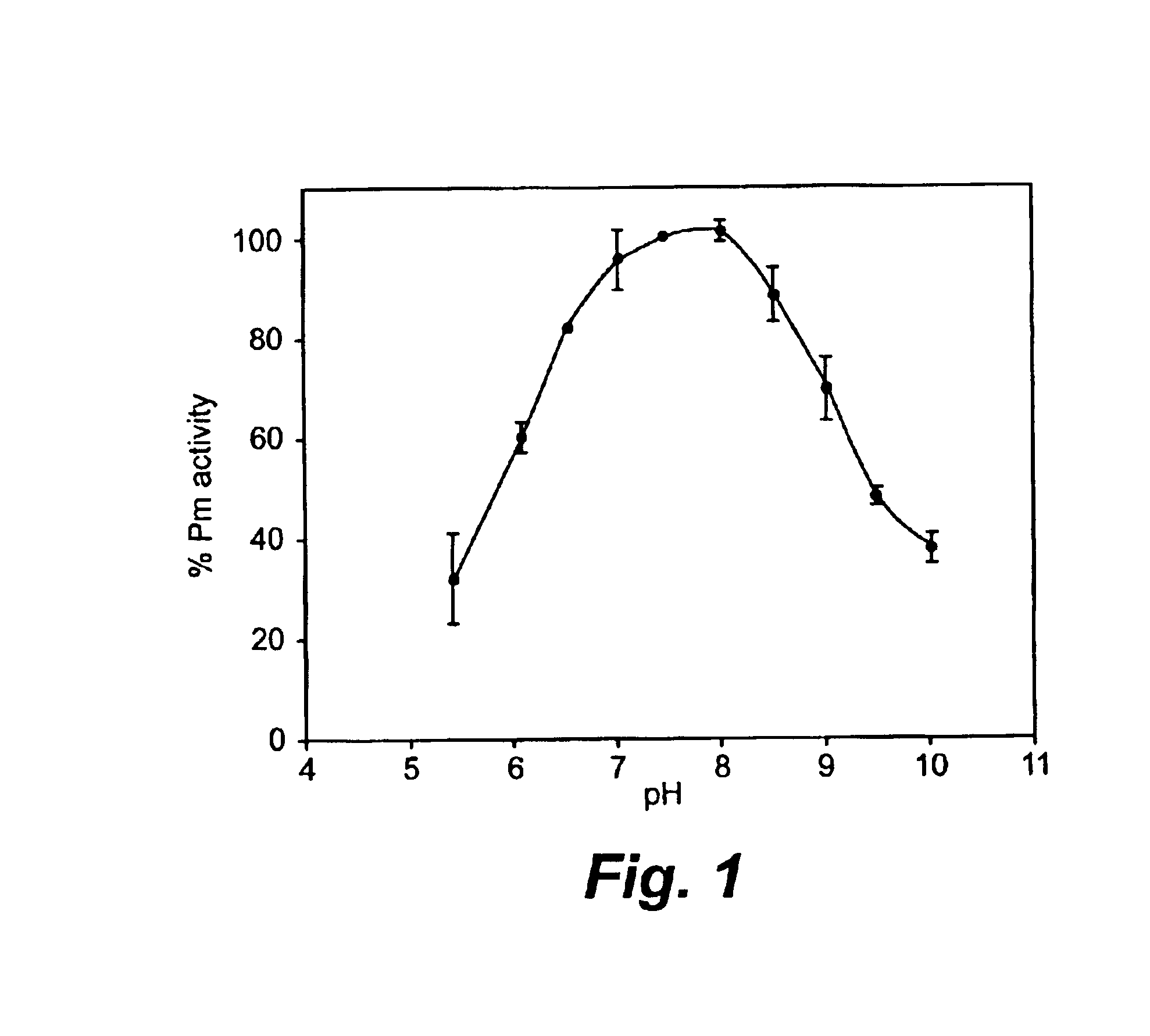

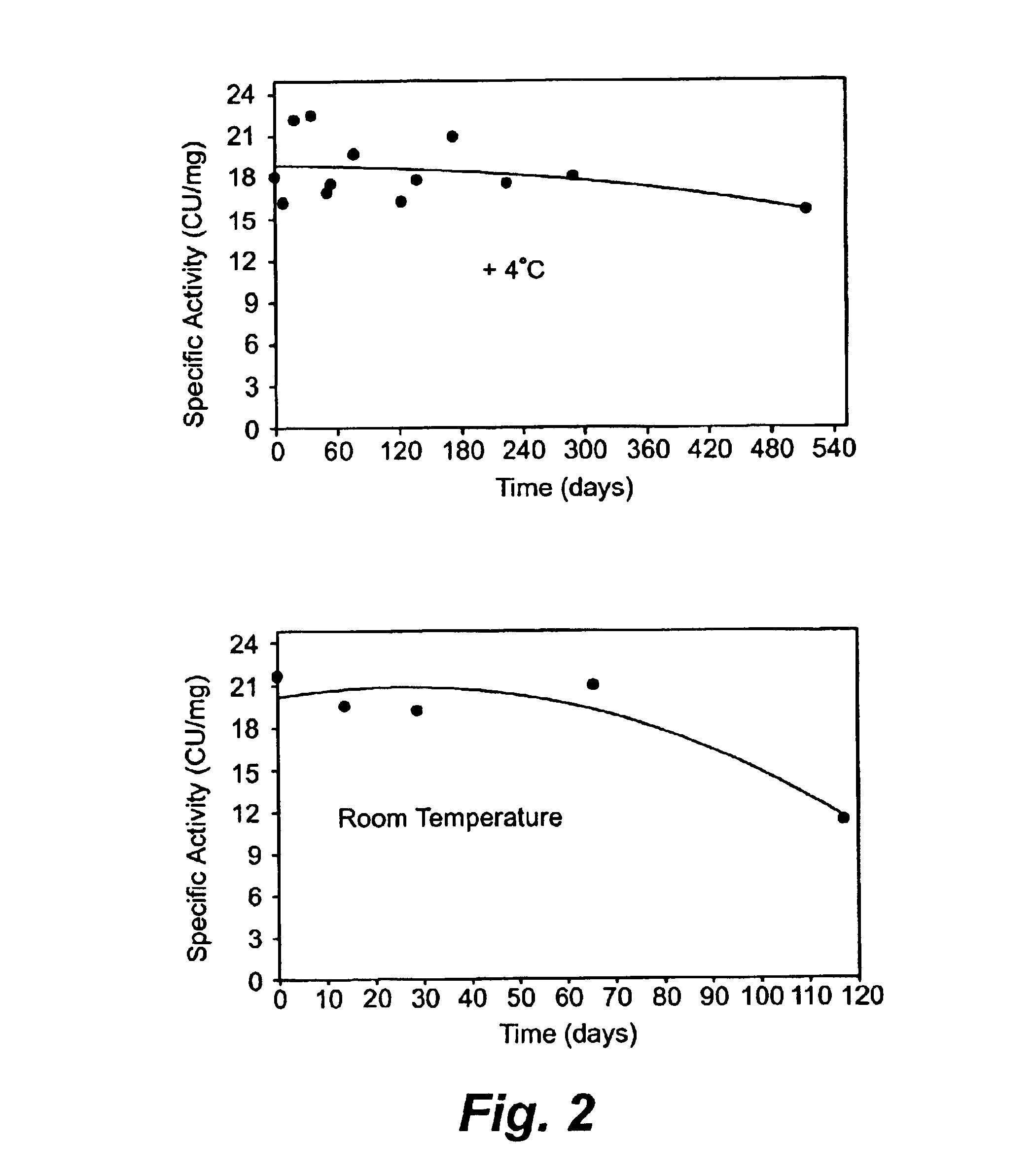

Method of thrombolysis by local delivery of reversibly inactivated acidified plasmin

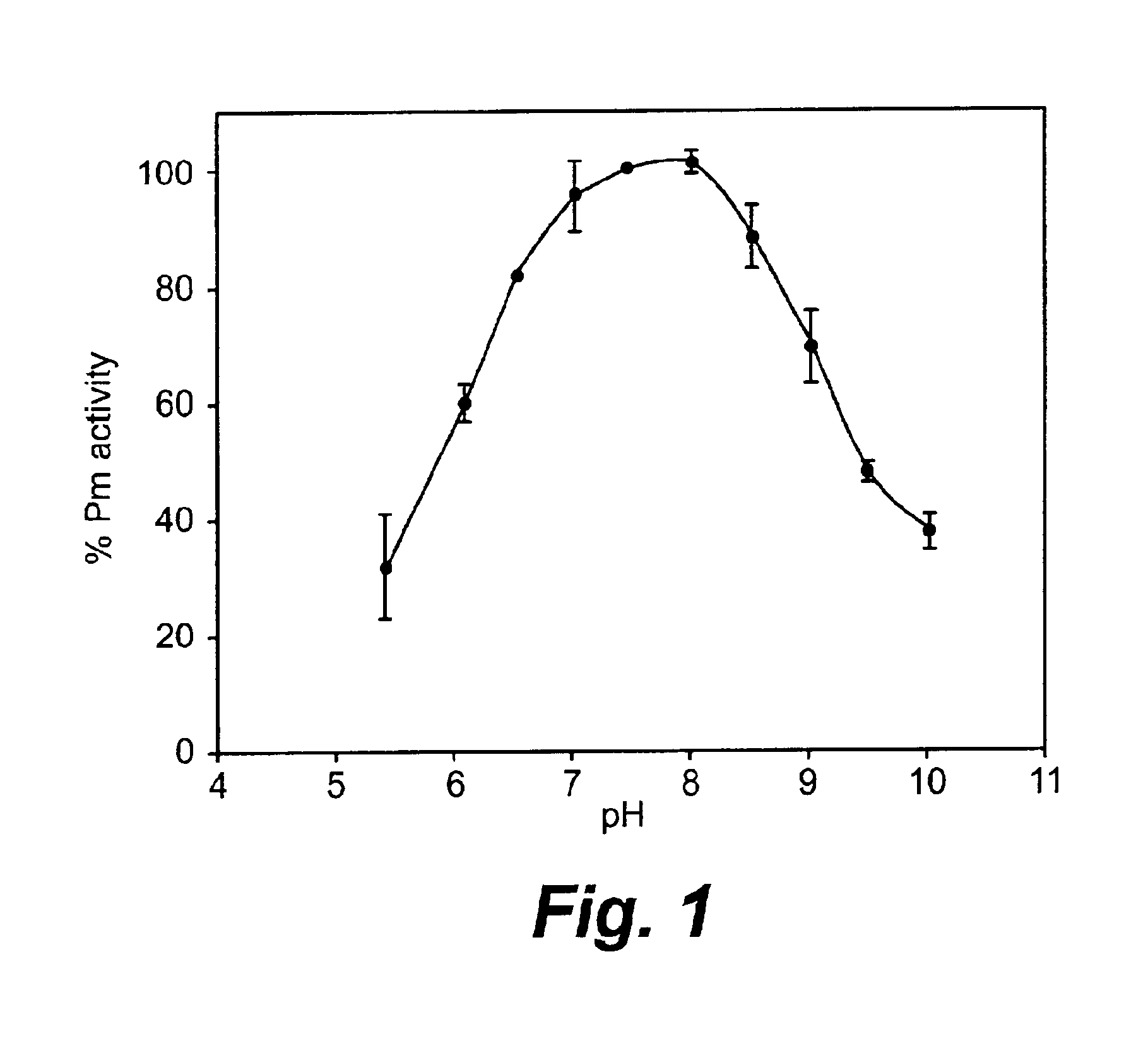

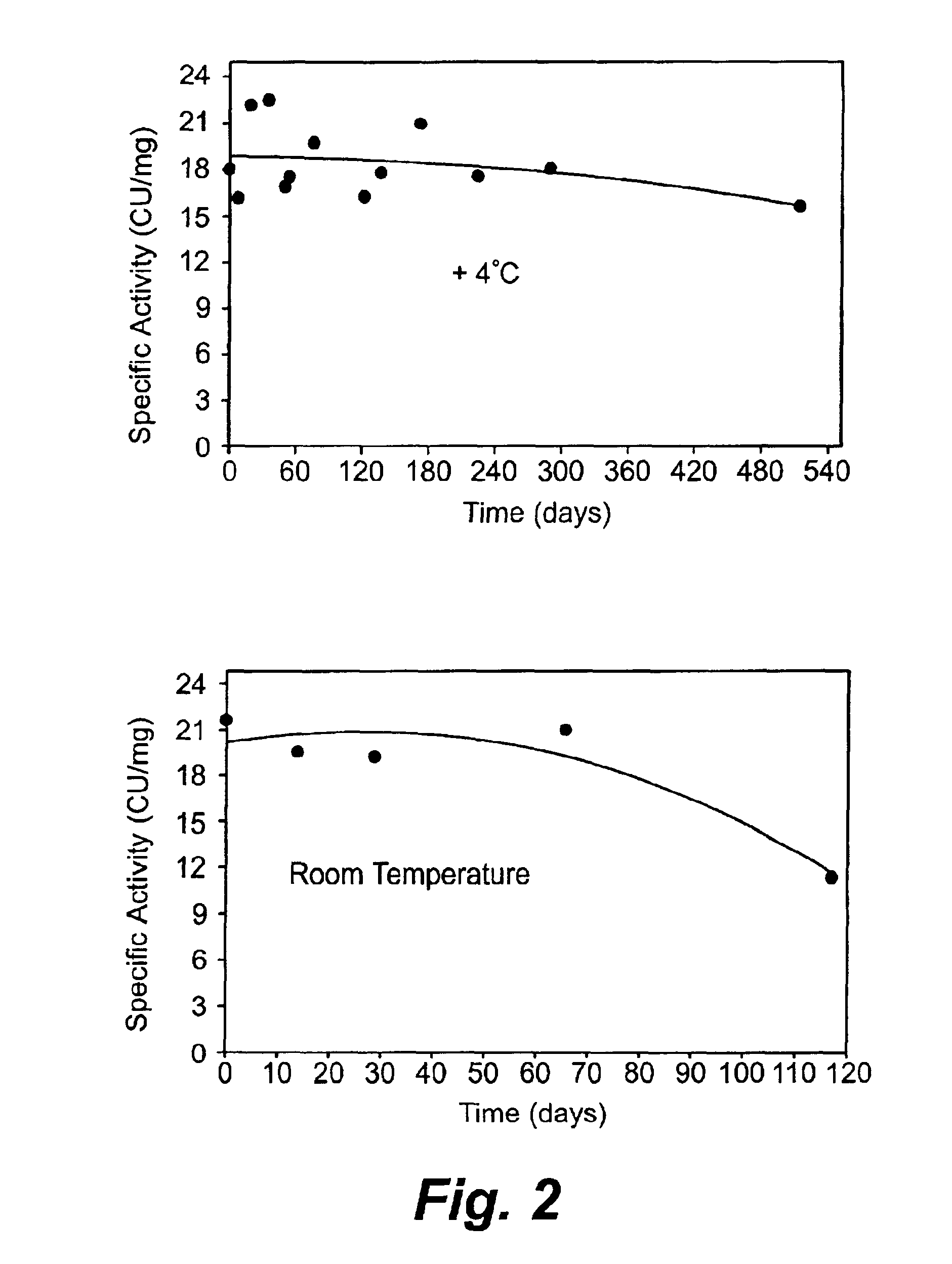

InactiveUS6969515B2Optimize lytic activityOptimize applicationPeptide/protein ingredientsInorganic non-active ingredientsThrombolysisThrombotic occlusion

Methods of thrombolysis that allow the use of a fibrinolytic composition comprising reversibly inactivated acidified plasmin and the localized delivery of the plasmin to a vascular thrombotic occlusion are disclosed. Further disclosed is a method for administering a therapeutic dose of a fibrinolytic composition substantially free of plasminogen activator to a human or animal having a vascular thrombotic occlusion. The fibrinolytic composition includes a reversibly inactivated acidified plasmin substantially free of plasminogen activator. Intravascular catheter delivery of the fibrinolytic composition directly into or in the immediate vicinity of the thrombus is disclosed to minimize the systemic degradation of fibrin while retaining the maximum plasmin activity against the thrombus. The method is applicable to the dissolution of thrombi in artificial devices, e.g., hemodialysis grafts.

Owner:GRIFOLS THERAPEUTICS LLC

Method of thrombolysis by local delivery of reversibly inactivated acidified plasmin

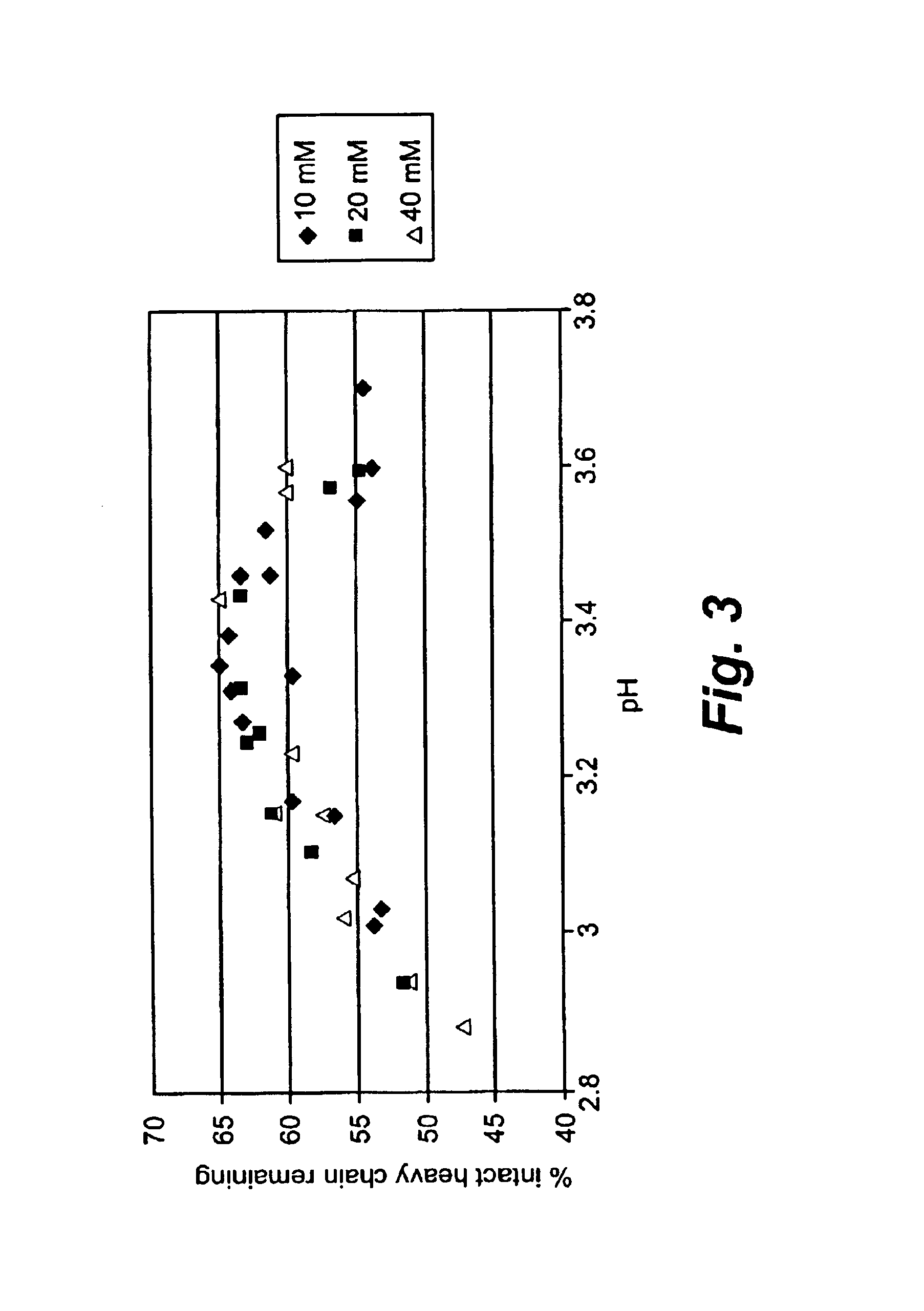

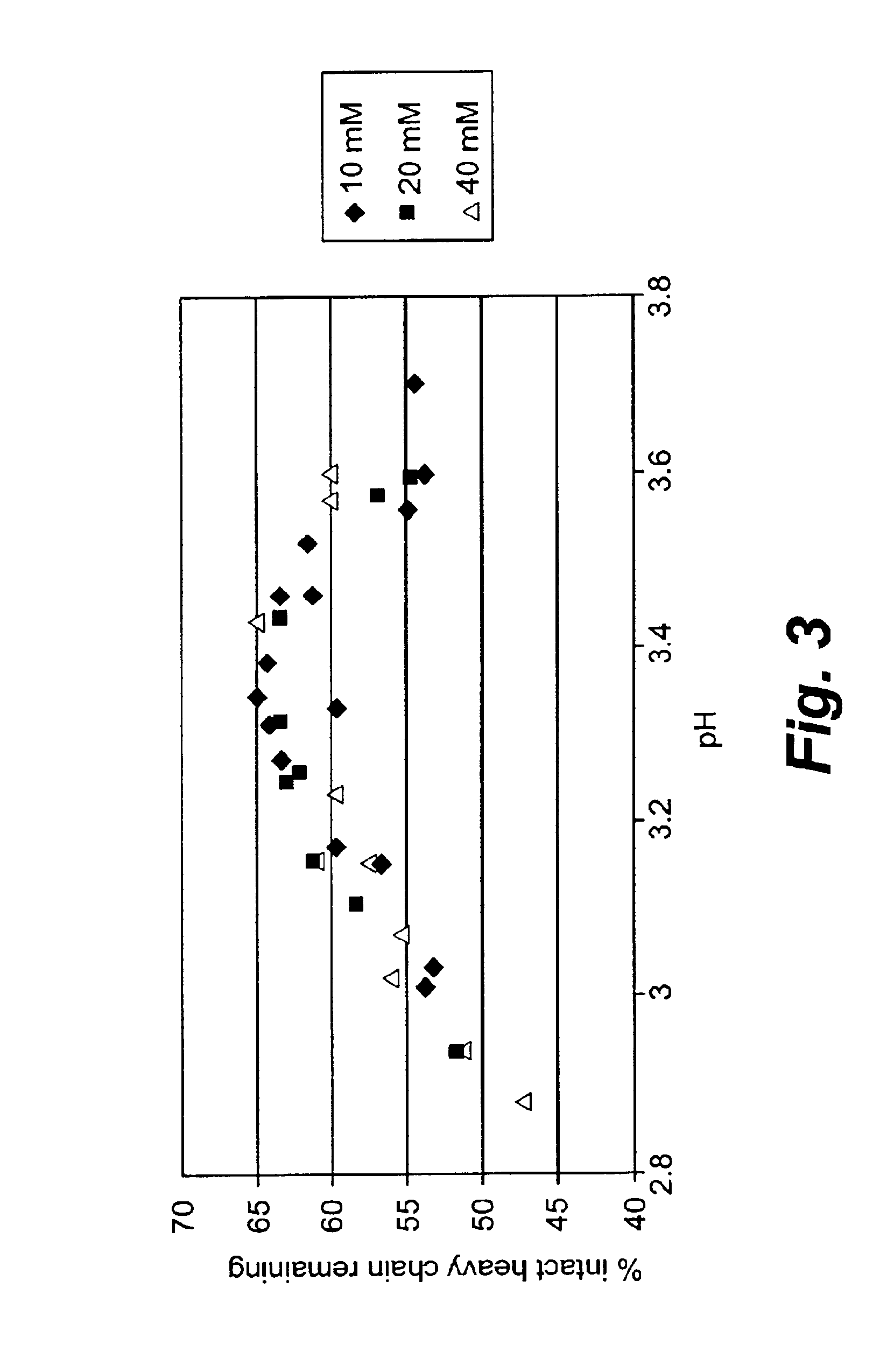

InactiveUS6964764B2Formula stableReduce capacityPeptide/protein ingredientsInorganic non-active ingredientsWhole bodyThrombus

Methods of thrombolysis that allow the use of a fibrinolytic composition comprising reversibly inactivated acidified plasmin and the localized delivery of the plasmin to a vascular thrombotic occlusion are disclosed. Further disclosed is a method for administering a therapeutic dose of a fibrinolytic composition substantially free of plasminogen activator to a human or animal having a vascular thrombotic occlusion. The fibrinolytic composition includes a reversibly inactivated acidified plasmin substantially free of plasminogen activator. Intravascular catheter delivery of the fibrinolytic composition directly into or in the immediate vicinity of the thrombus is disclosed to minimize the systemic degradation of fibrin while retaining the maximum plasmin activity against the thrombus.

Owner:GRIFOLS THERAPEUTICS LLC

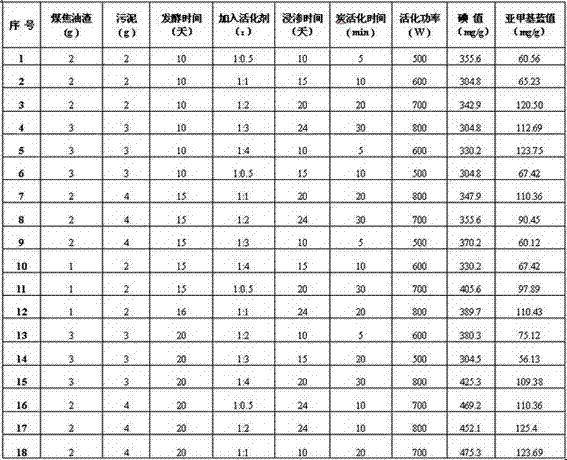

Method for producing activated carbon by thermally activating coal tar dreg/ sludge fermentation body by using microwaves

ActiveCN102381705ALower activation energyReduce manufacturing costActivated carbonIndustrial effluent

The invention discloses a method for producing activated carbon by thermally activating a coal tar dreg / sludge mixed fermentation body by using microwaves. The method comprises the steps of: firstly crushing and grinding coal tar dreg into more than 200 meshes, then, mixing the ground coal tar dreg with sludge, and performing aerobic fermentation for 10-20 days; then, adding zinc chloride servingas an activator into the mixed fermentation body, and infiltrating for 12-24h at 70-80 DEG C, wherein the added zinc chloride is 0.5-4 times more than the mixed fermentation body in mass; and finally, carbonizing and activating for 30-120min in a microwave carbonization furnace under a N2 protection condition to obtain coal tar dreg / sludge mixed activated carbon, washing with water till a neutralcondition is achieved, and drying to obtain a product disclosed by the invention. The method disclosed by the invention has the advantages of simplicity and convenience for operation, easiness for control, low cost, high product synthesis rate and favorable product performance, and can be widely applied to industrial wastewater treatment, refractory wastewater treatment, sound insulation, noise reduction, deodorization, oil absorption, lipid suction and other industries.

Owner:SOUTHWEAT UNIV OF SCI & TECH

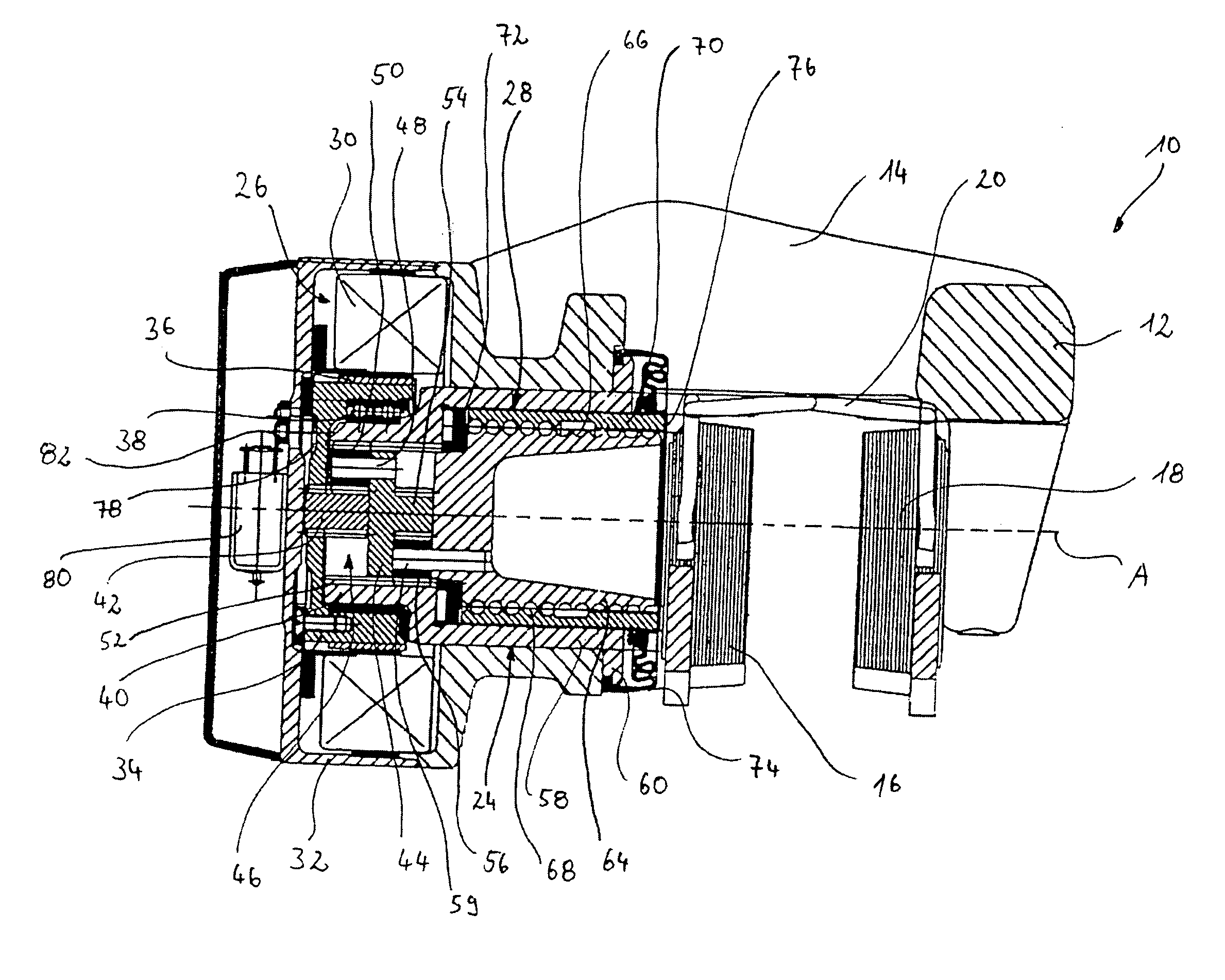

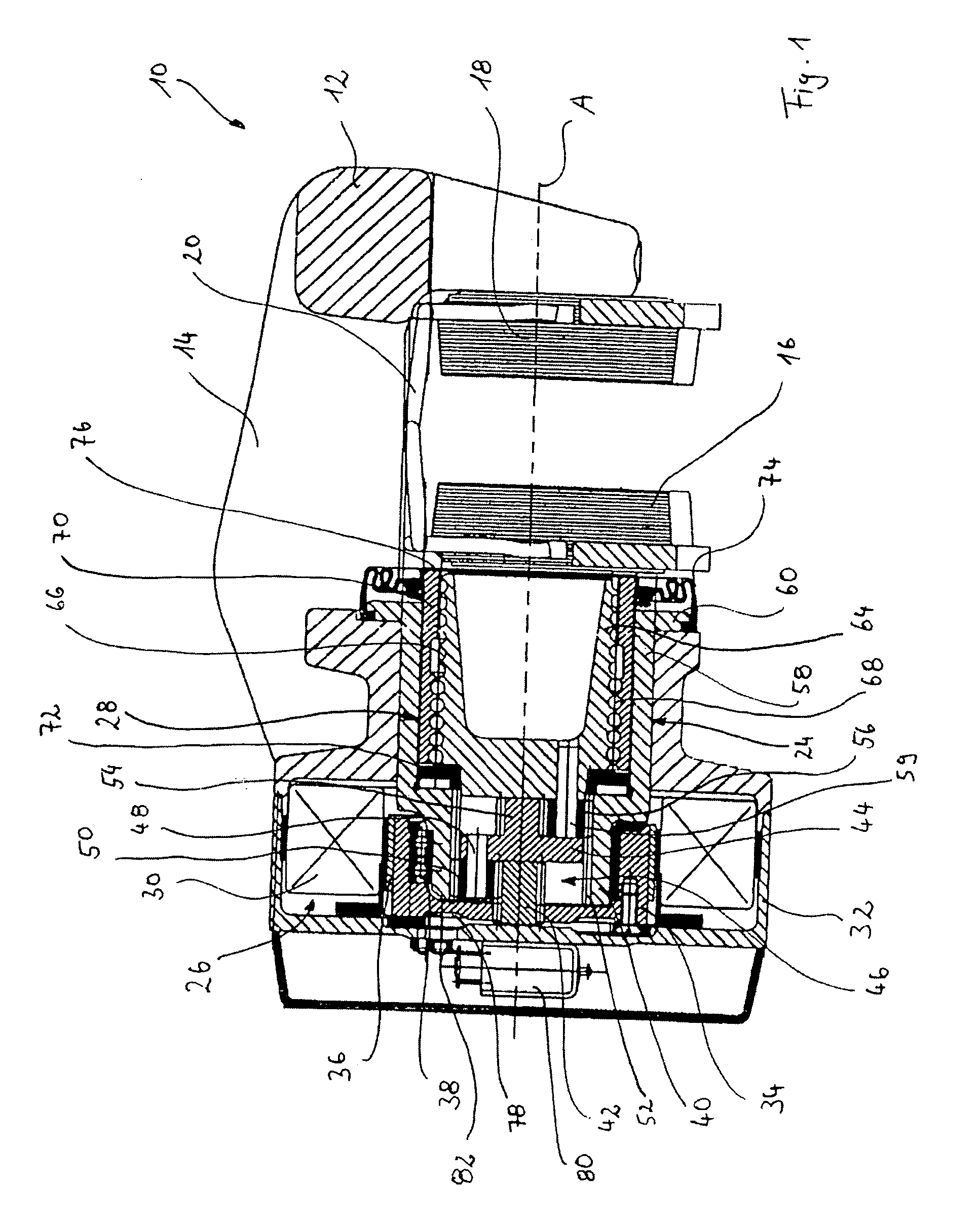

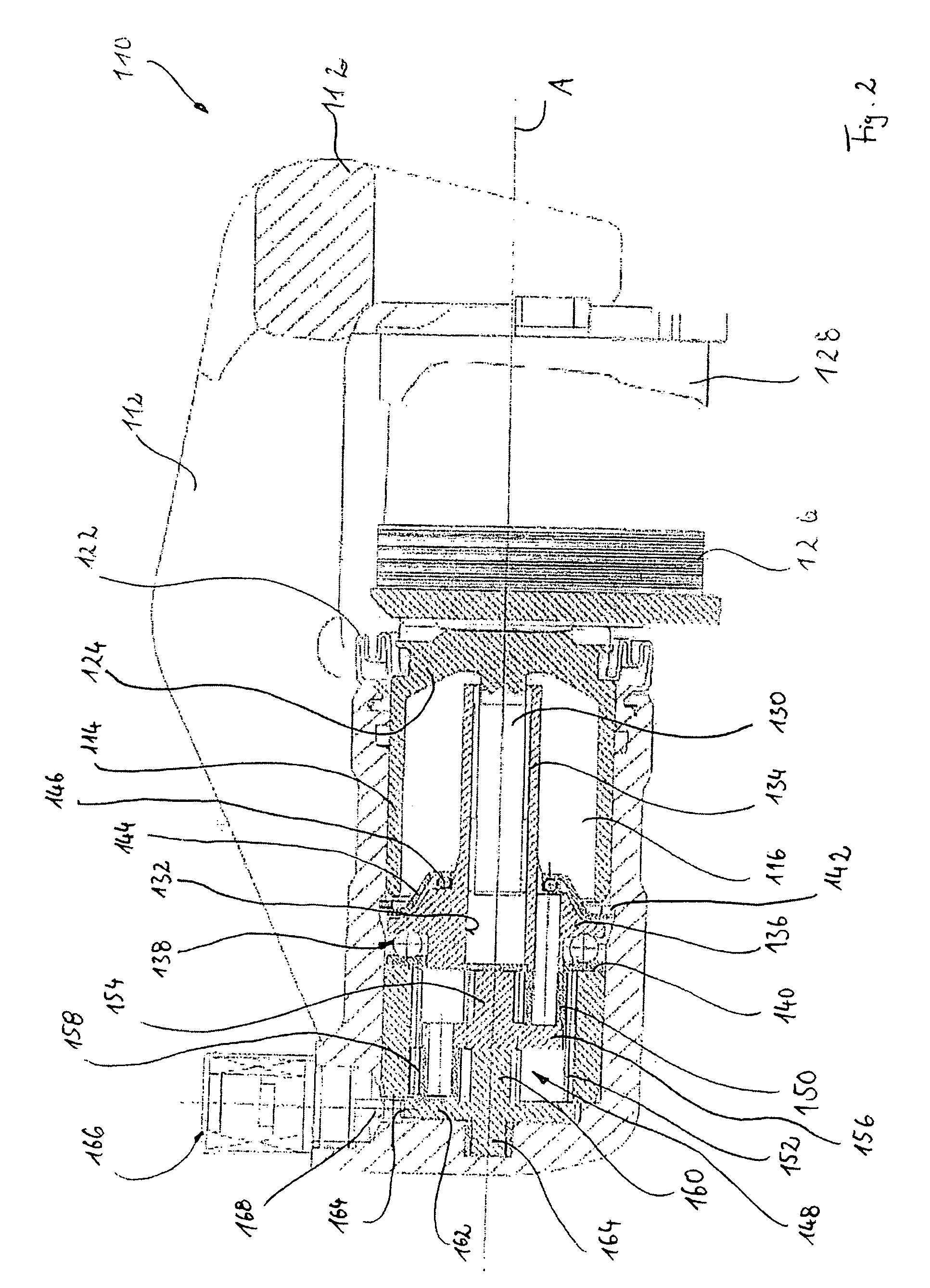

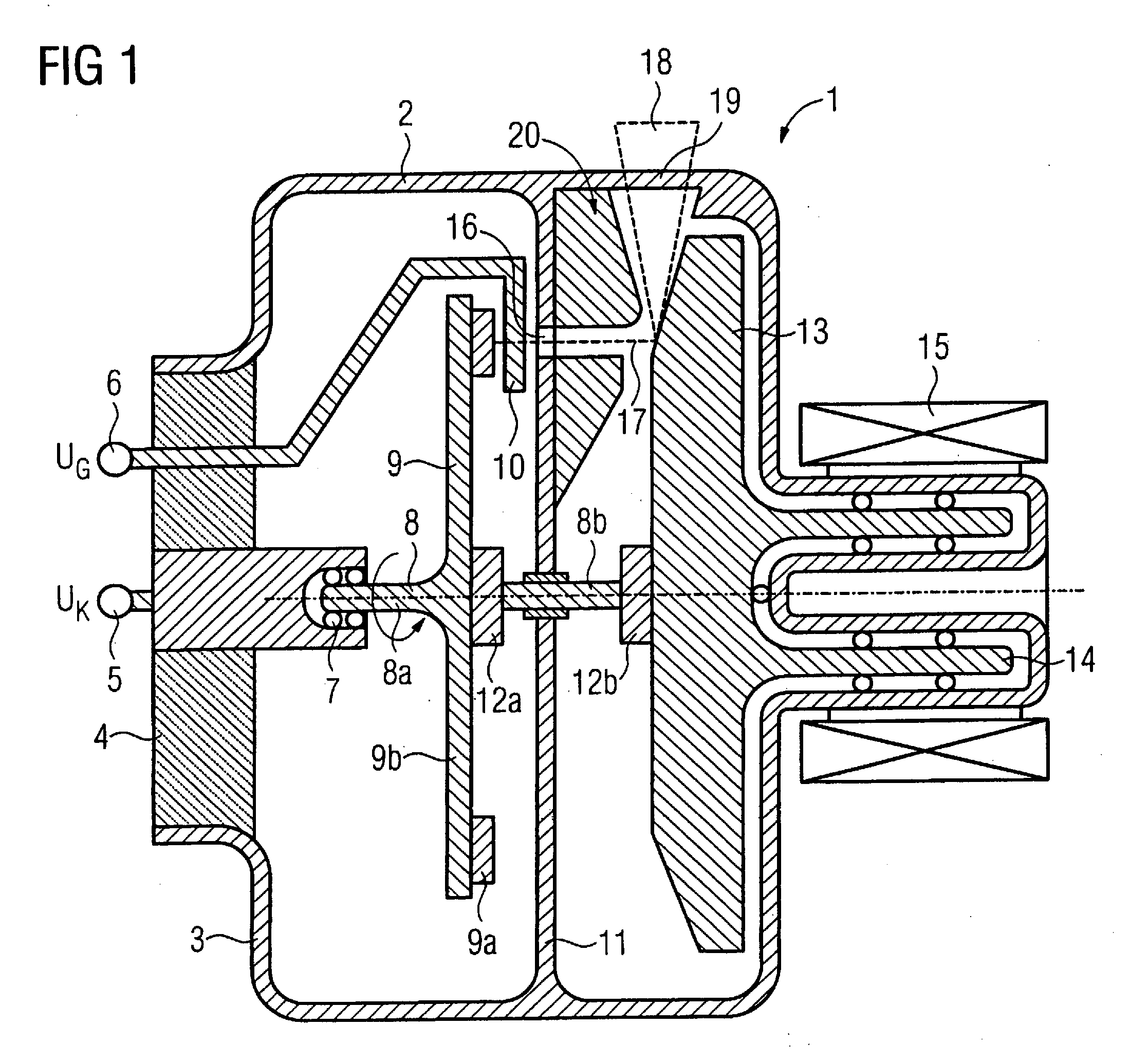

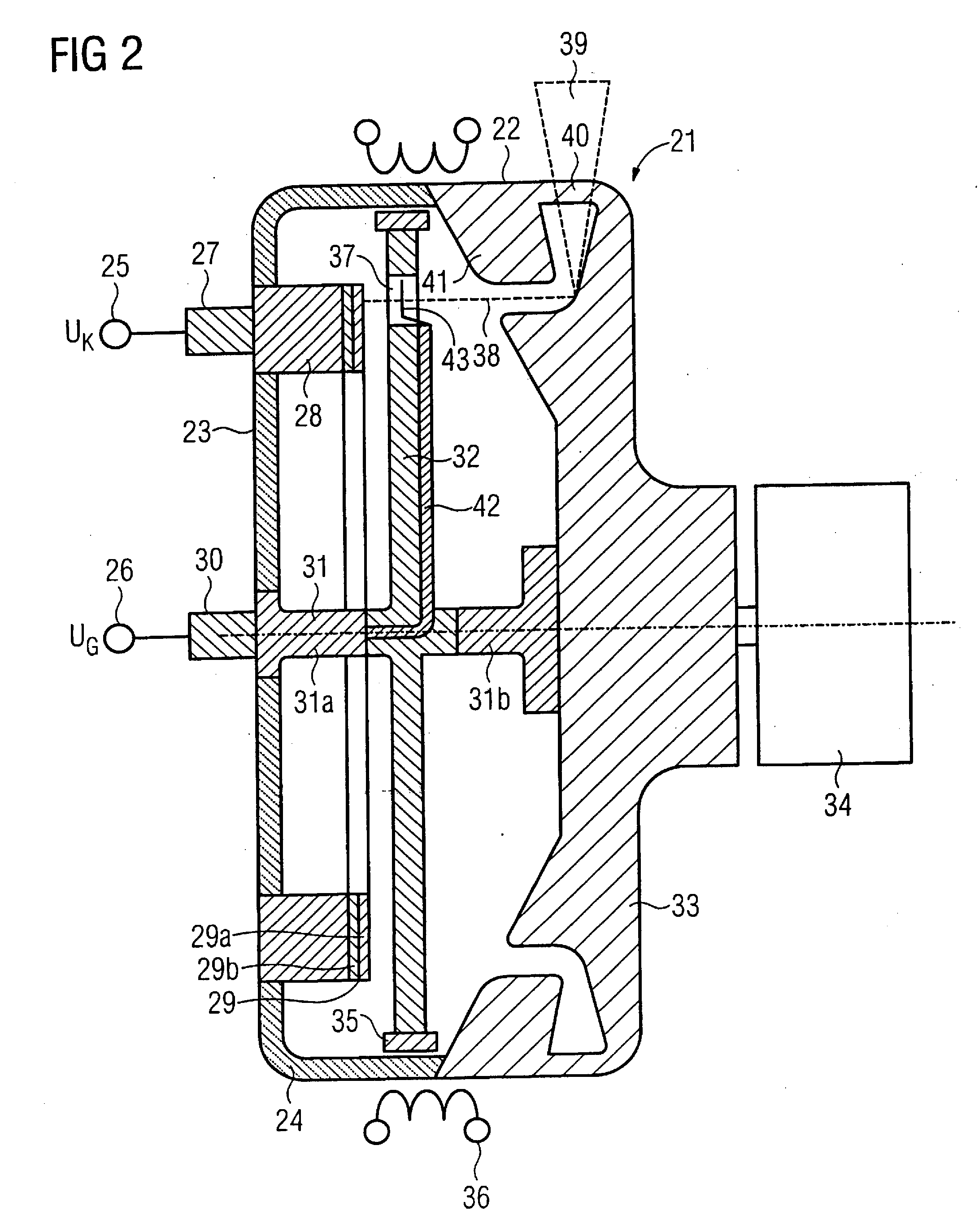

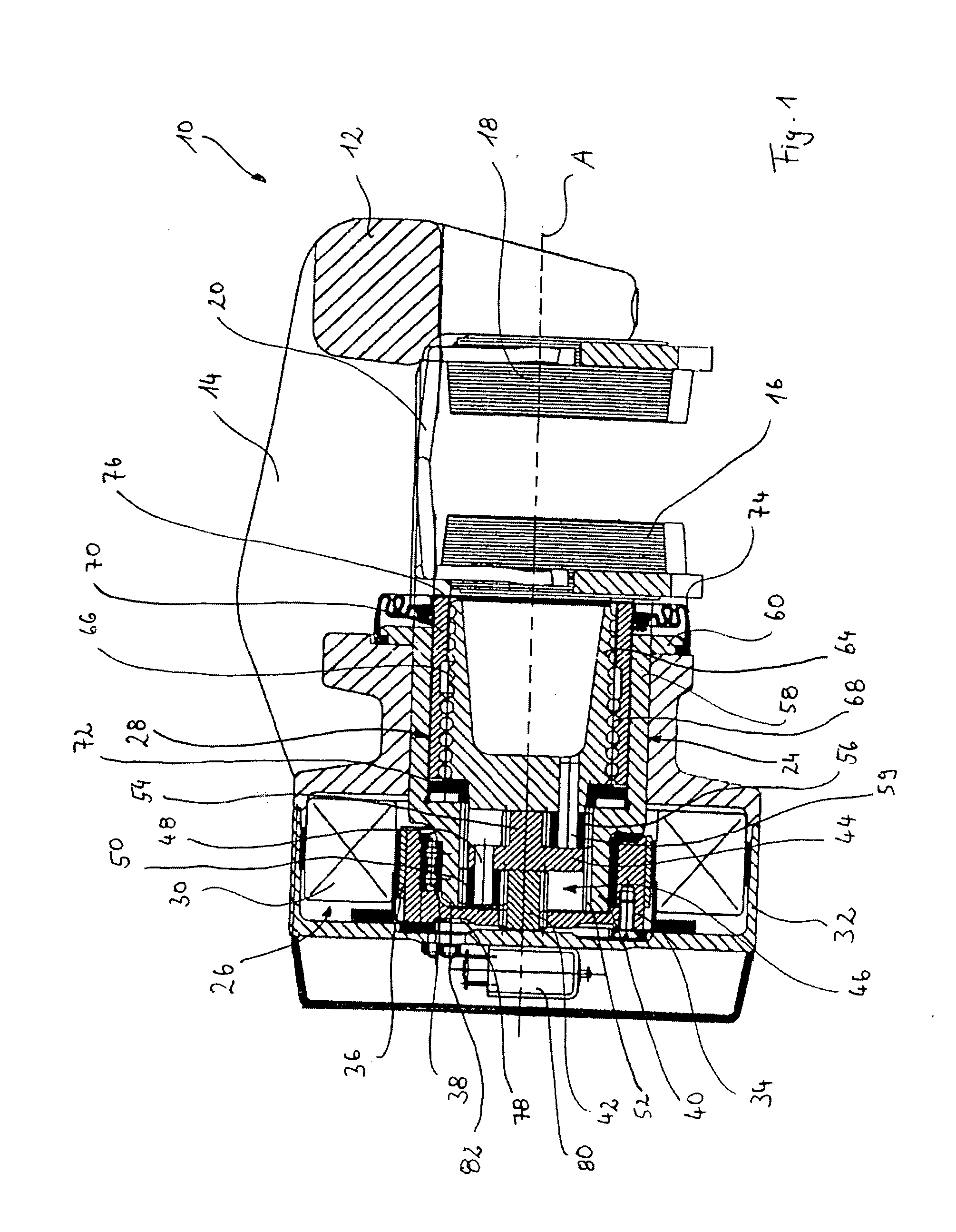

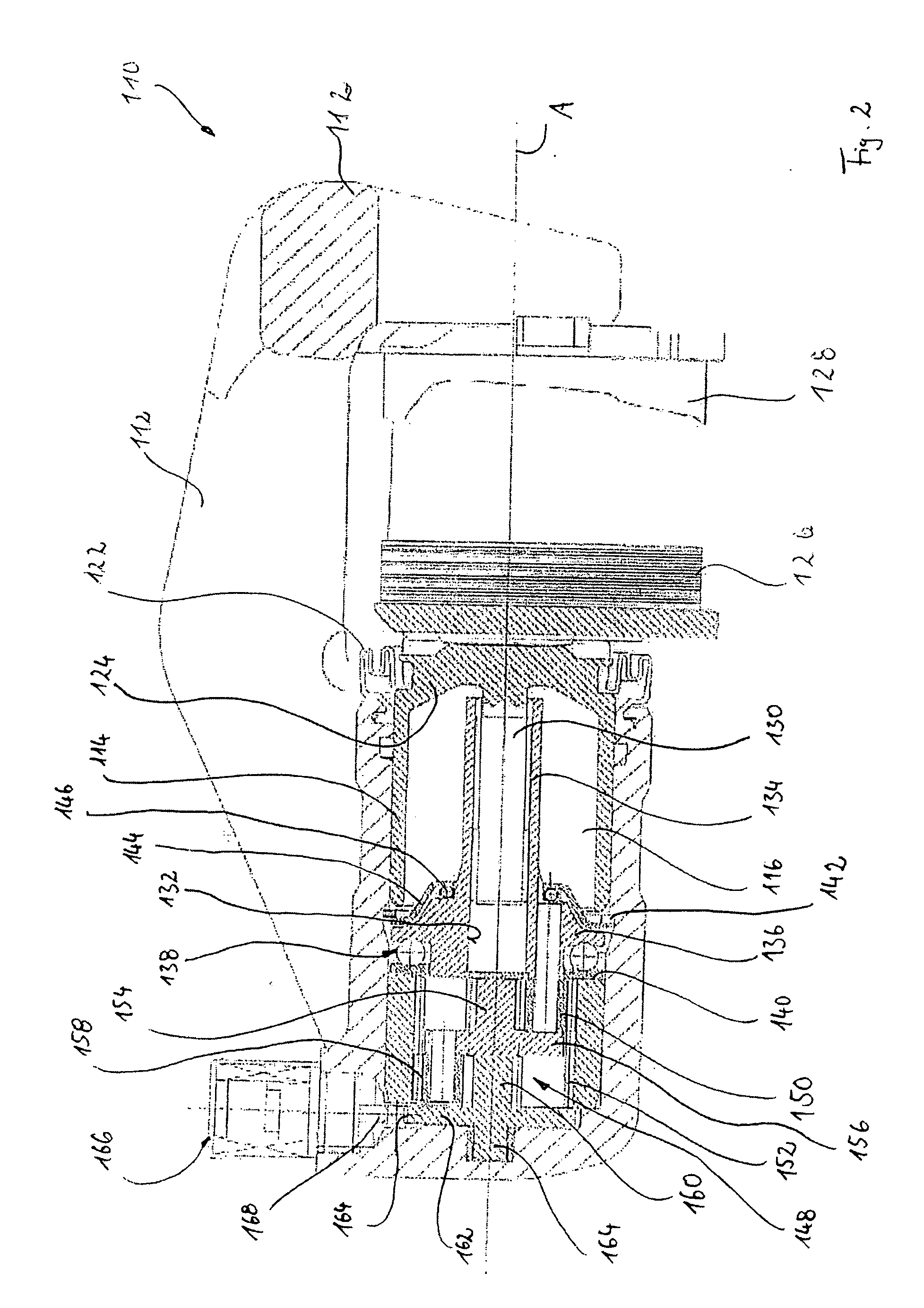

Vehicle brake and method for actuating a vehicle brake

InactiveUS7316300B2Fast activationAvoid displacementBraking element arrangementsBraking action transmissionBrake liningPiston

Owner:LUCAS AUTOMOTIVE GMBH

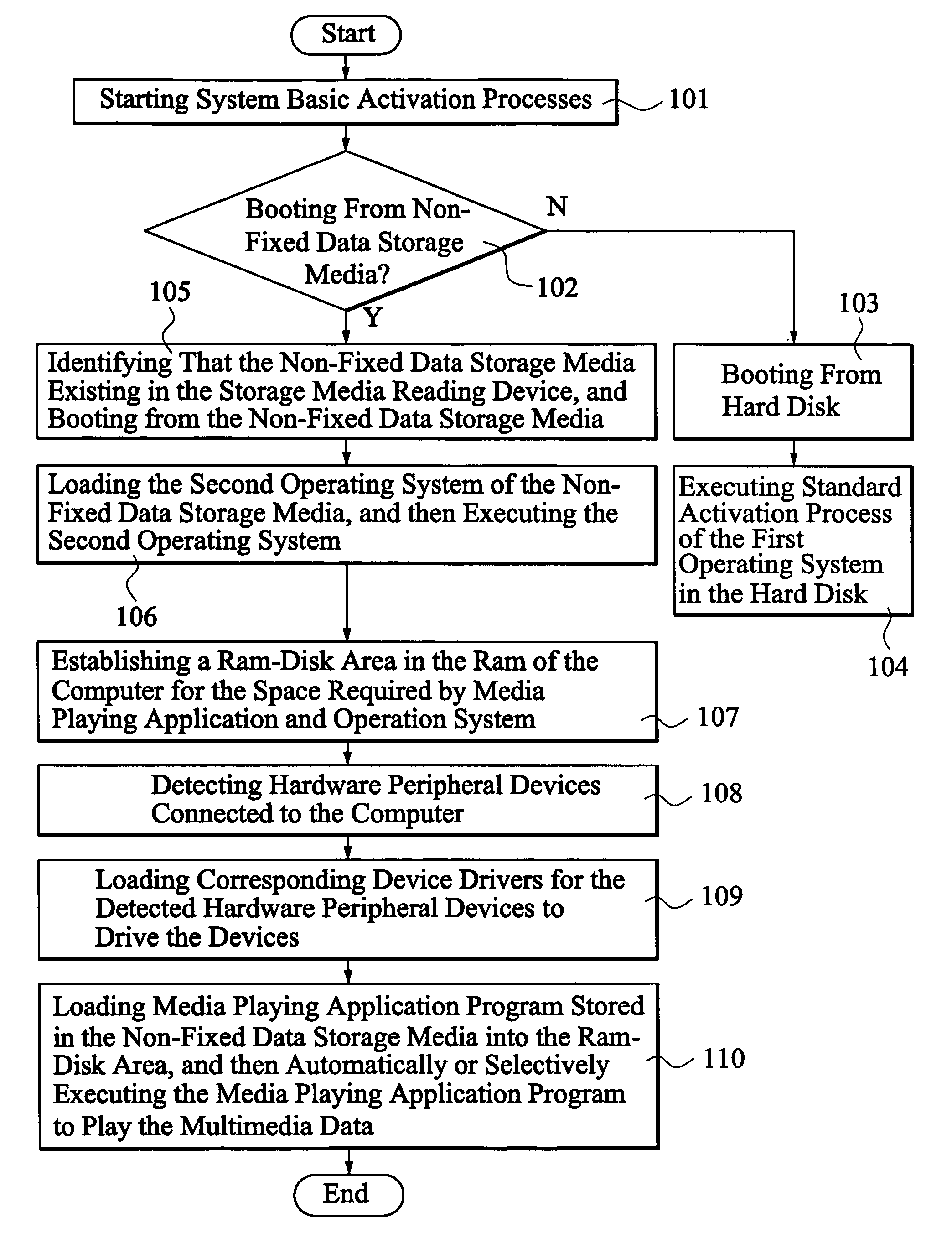

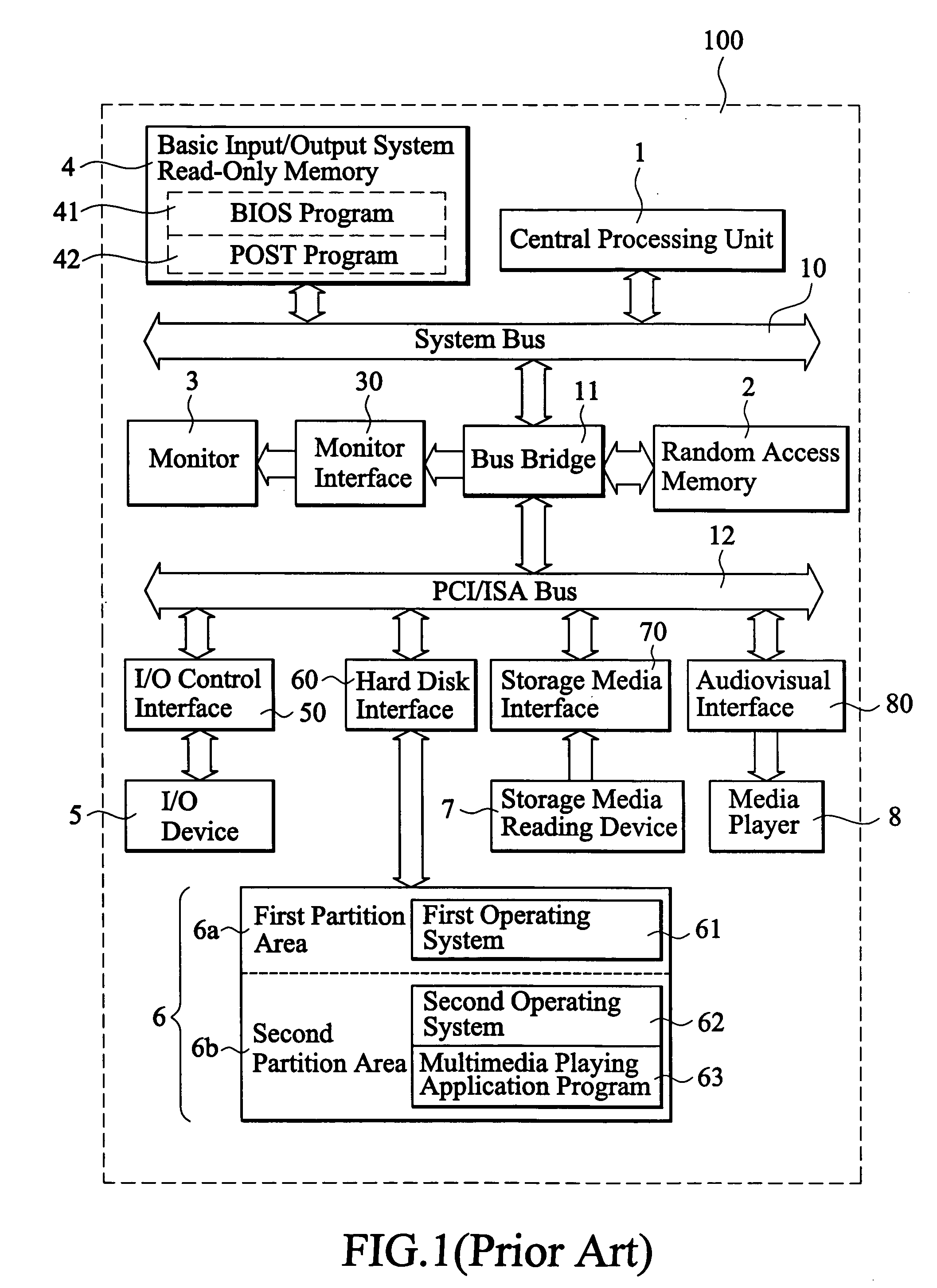

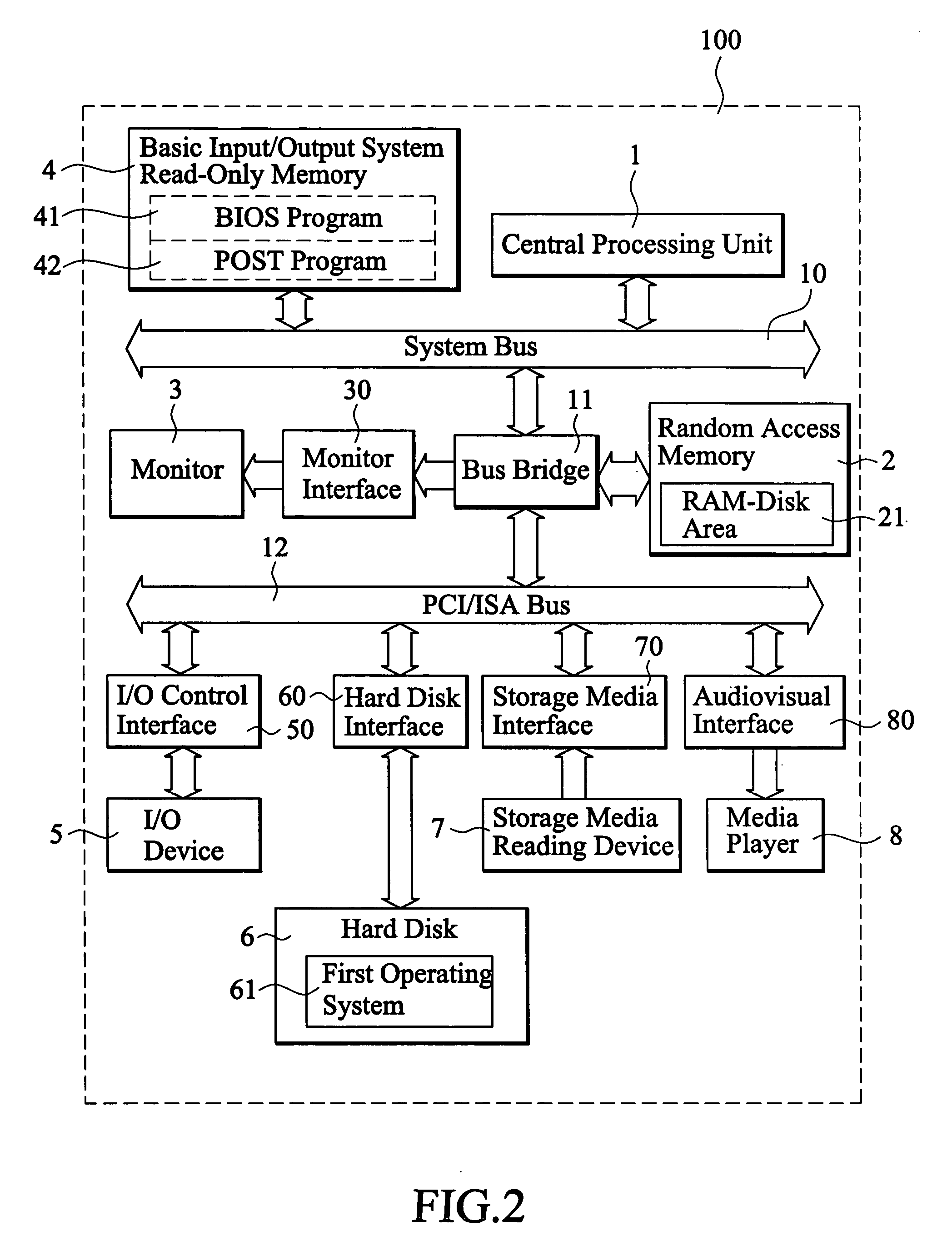

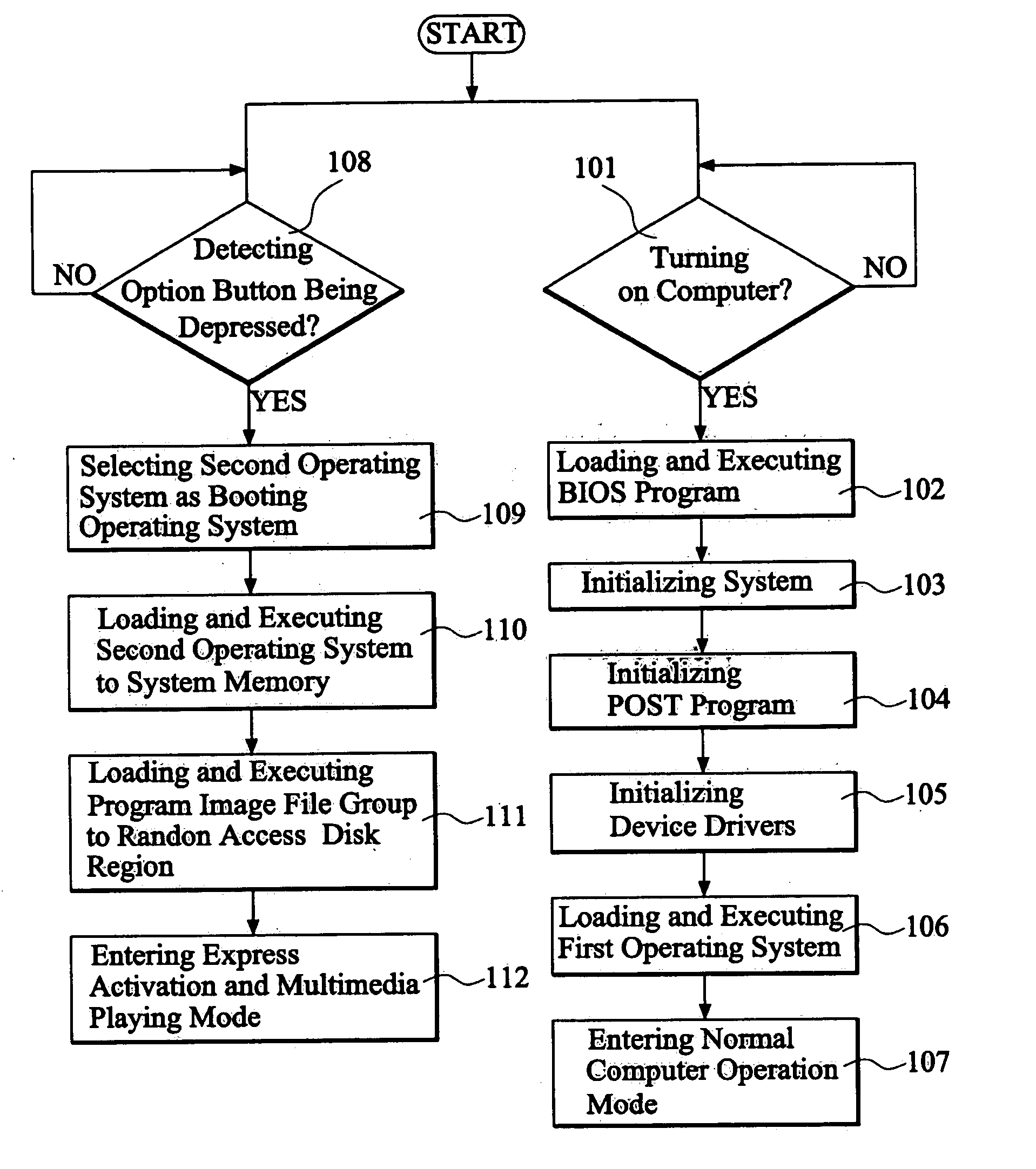

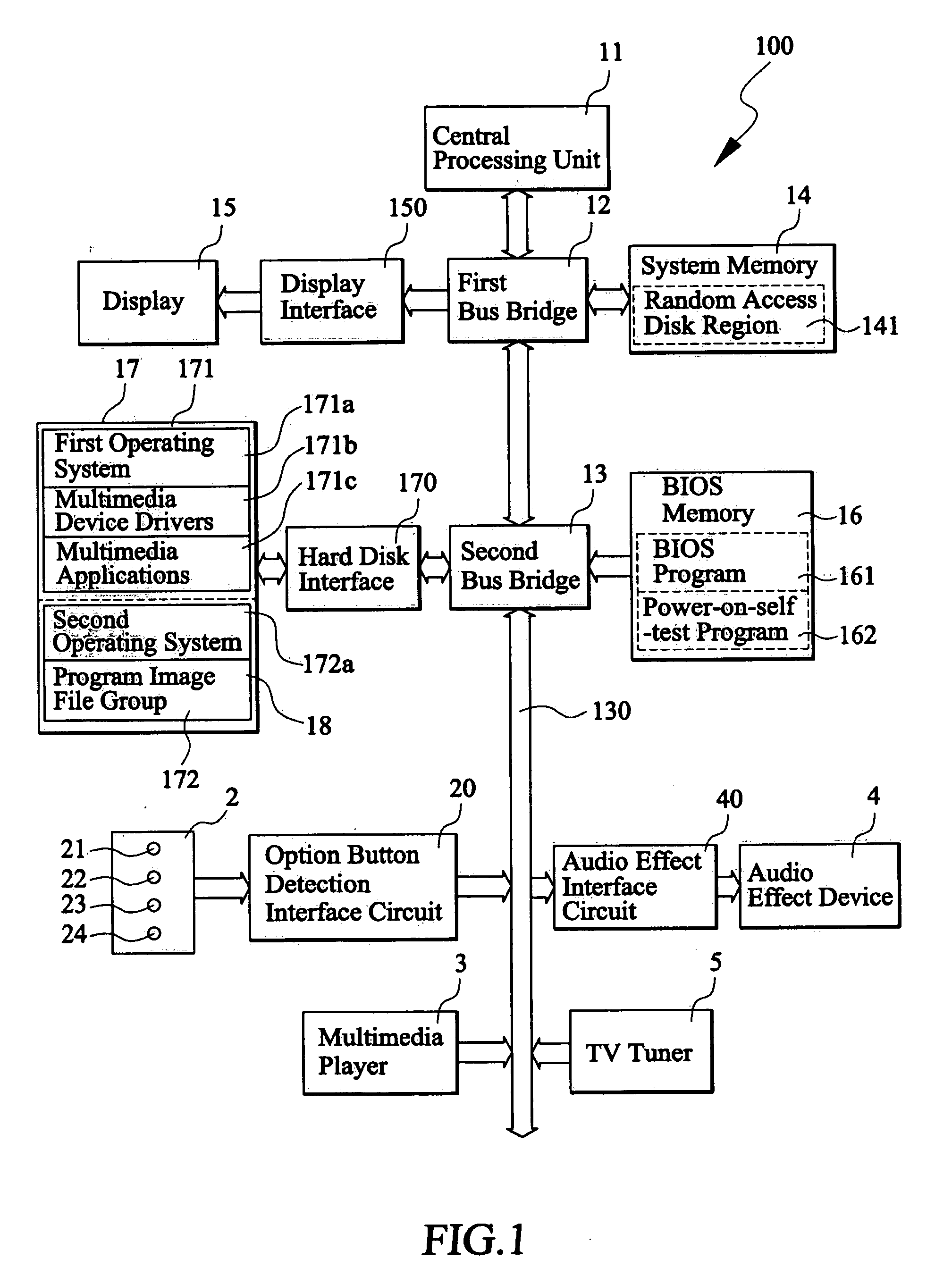

Method for fast activation and playing of multimedia data with non-fixed data storage media

ActiveUS20060026612A1Quick activationOvercomes drawbackCarrier constructional parts dispositionDigital computer detailsOperational systemBiological activation

A method for fast activation and playing of multimedia data with a non-fixed data storage media, such as compact disk, is provided. The storage media, pre-installed with an operating system, is used to activate the computer. Then the media player connected to the computer is detected, and a device driver for the detected media player and a corresponding media playing application in the storage media are executed. The process further includes establishing a RAM disk area in the RAM of the computer for the space required by executing the operating system, device driver for the media player, and the media playing application programs.

Owner:MITAC TECH CORP

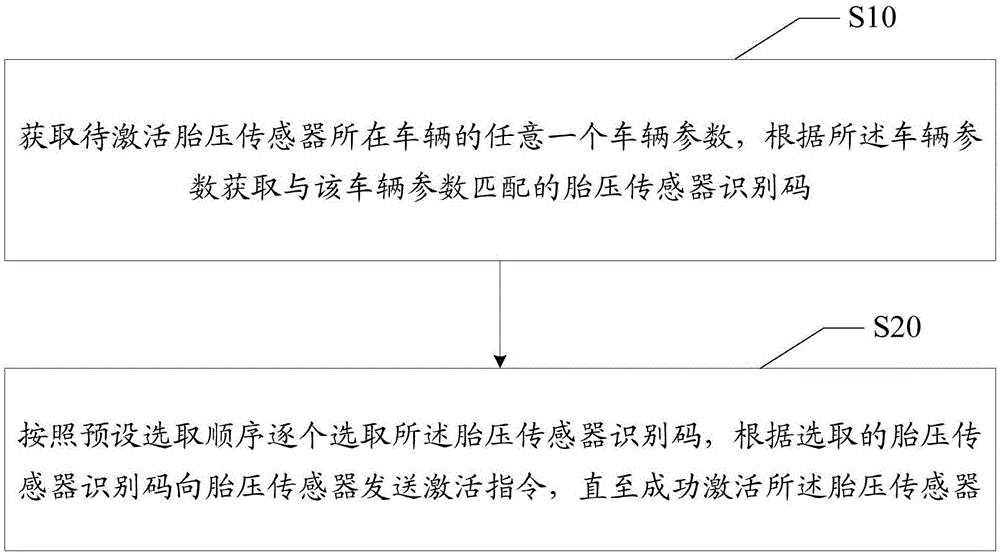

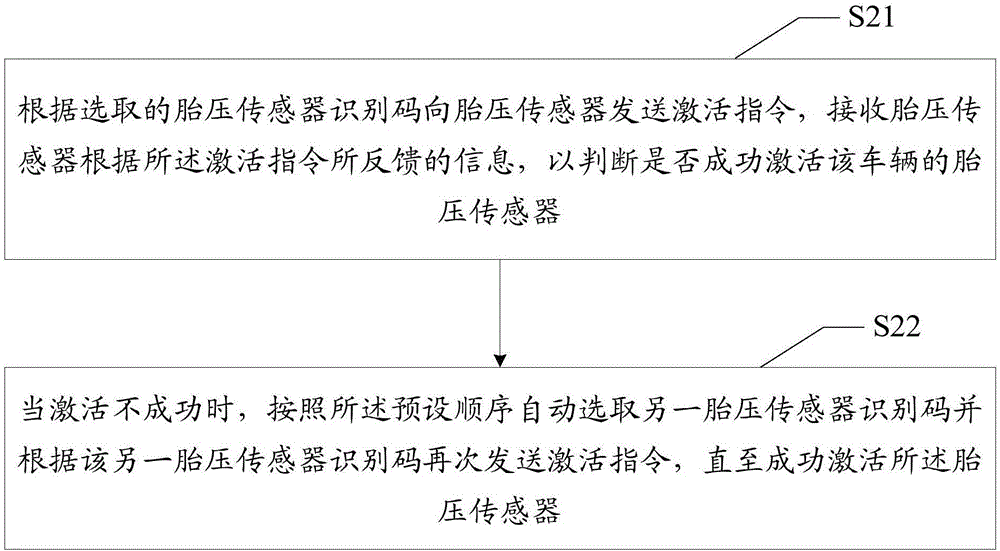

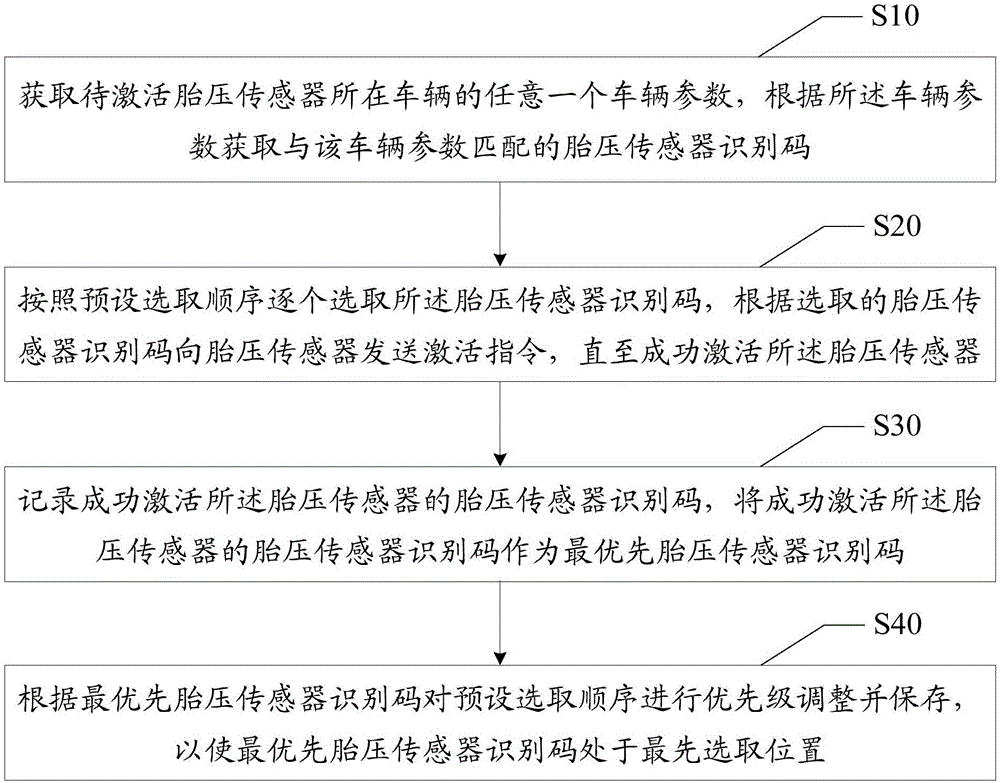

Tire pressure sensor activating method and device thereof

The invention discloses a tire pressure sensor activating method and a device thereof. The method comprises the following steps: obtaining the any vehicle parameter of the vehicle of the to-be-activated tire pressure sensor, obtaining an identification code of the tire pressure sensor matched with the vehicle parameter according to the obtained vehicle parameter; selecting the identification code of the tire pressure sensor one by one according to a pre-selection order, and sending an activation command to the tire pressure sensor according to the selected identification code of the tire pressure sensor until the tire pressure sensor is successfully activated. The problem that the tire pressure sensor arranged on the vehicle is activated through time and labor consuming in the prior art, so that the user experience can be influenced is solved.

Owner:LAUNCH SOFTWARE DEV

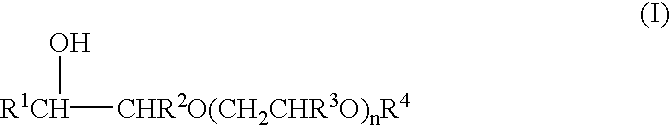

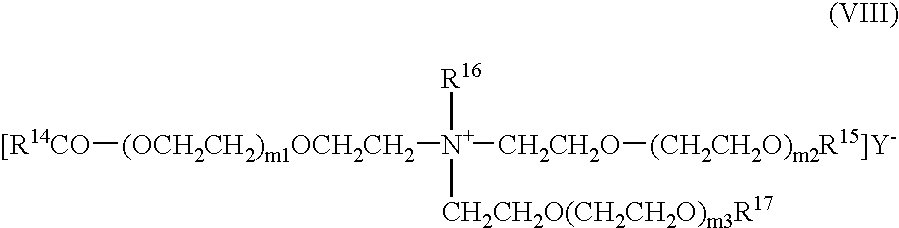

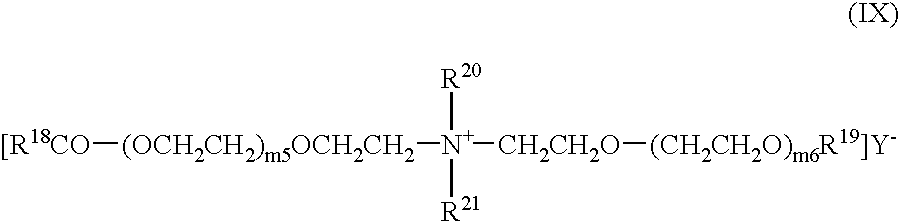

Tenside granules with improved disintegration rate

InactiveUS20030144172A1Easy to cleanHigh dissolution rateNon-ionic surface-active compoundsOrganic detergent compounding agentsEtherSurface-active agents

The invention relates to tenside granules with an improved disintegration rate that are obtained by granulating nonionic tensides of the hydroxy mixed ether type in the presence of disintegrants and compacting the products obtained.

Owner:COGNIS DEUT GMBH & CO KG

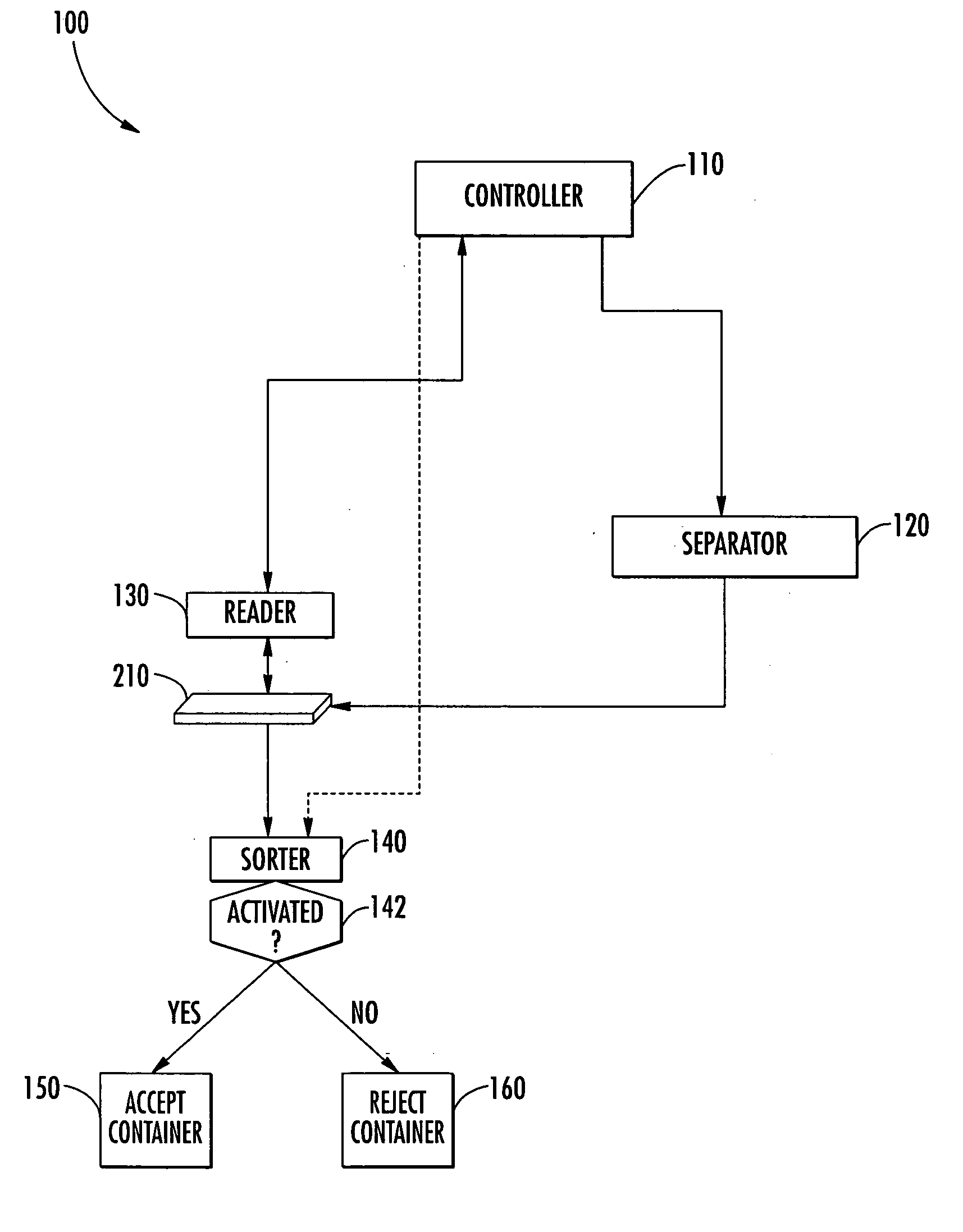

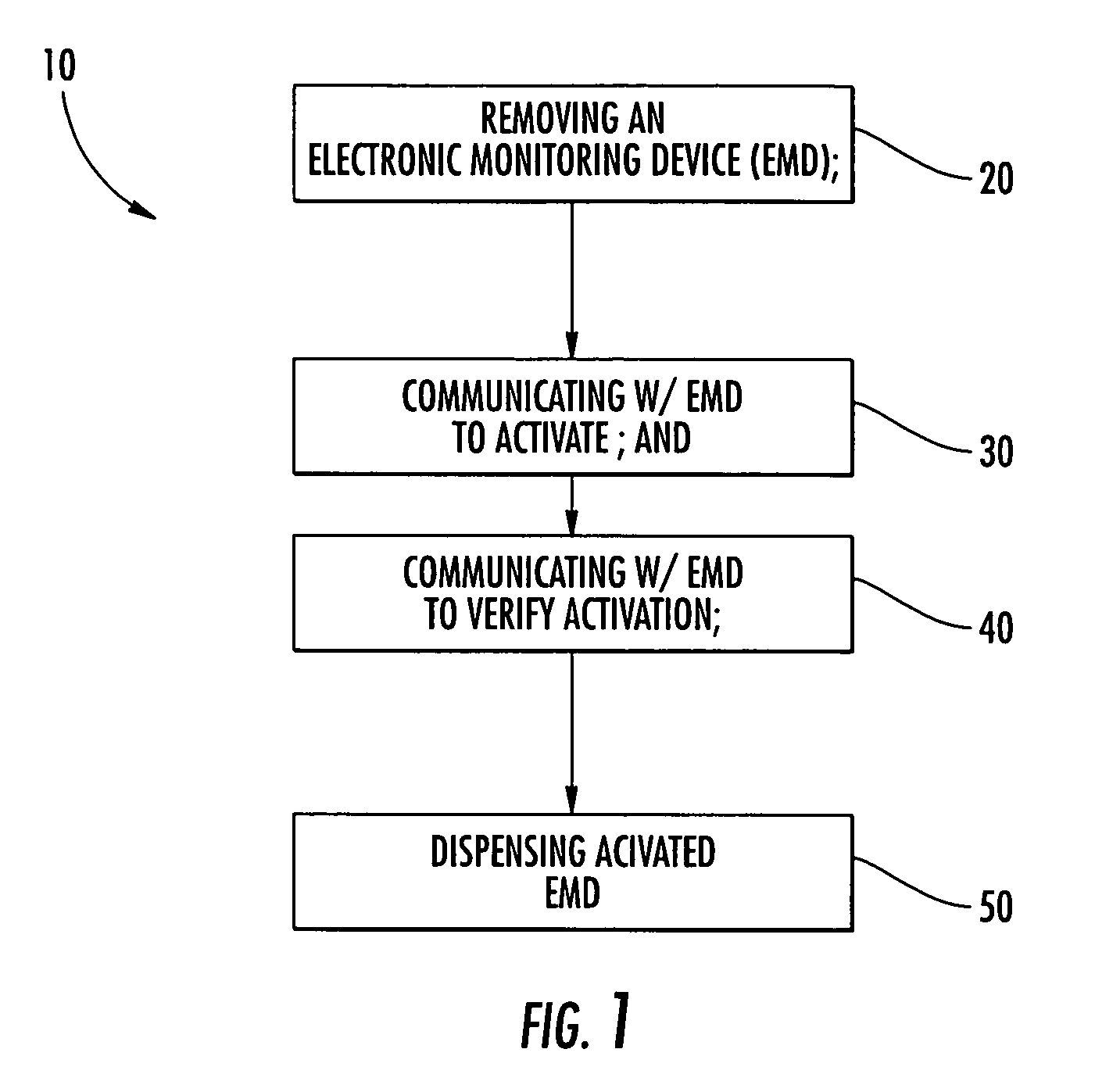

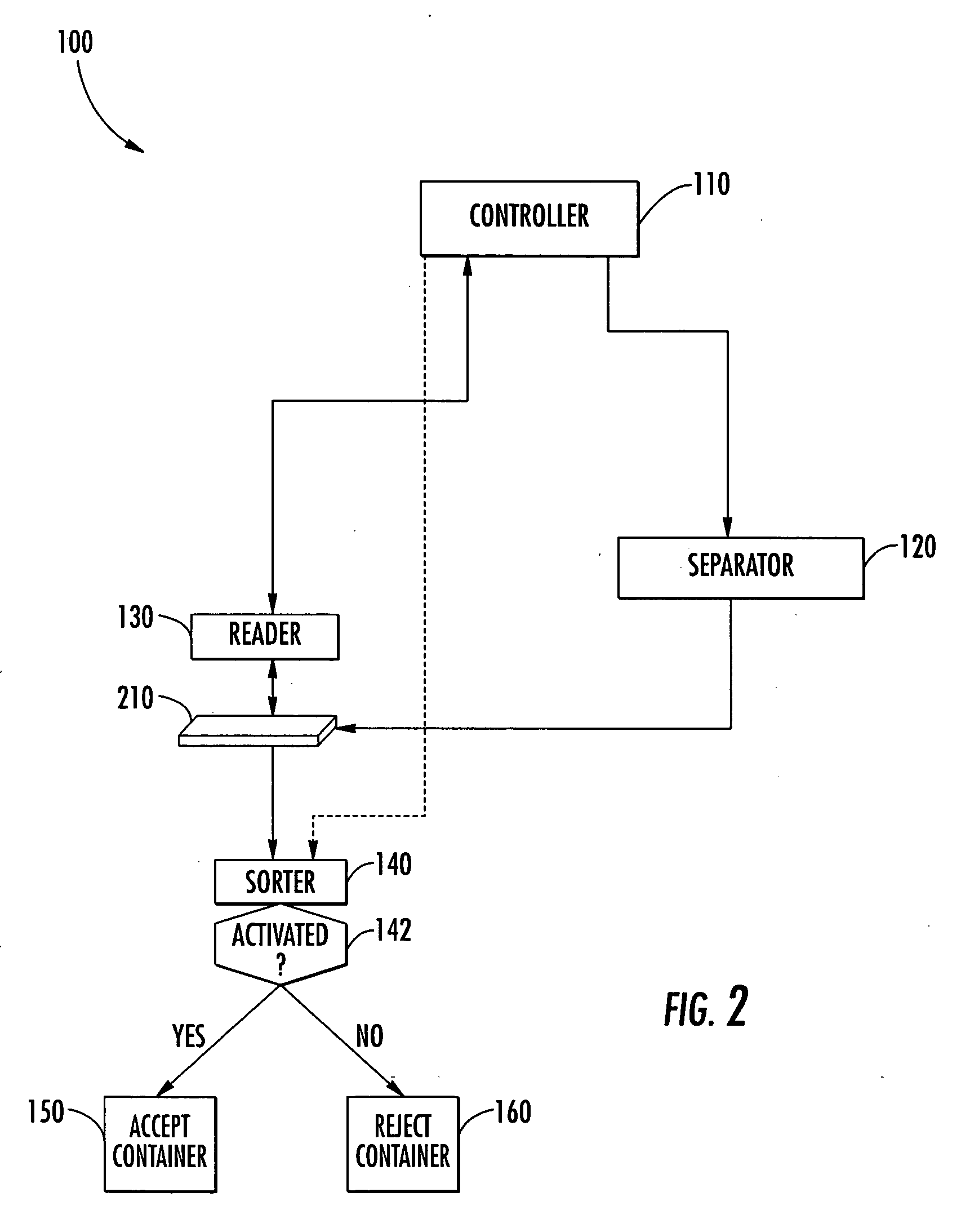

Apparatus for dispensing activated monitoring devices

ActiveUS20050283272A1Rapidly and efficiently activateFast activationRecording measured valuesSpecial data processing applicationsEngineeringMicroprocessor controller

The invention is a method and apparatus for dispensing an activated electronic monitoring device (EM device), such as a data logger. The invention can activate an EM device and verify activation before dispensing the EM device. The invention comprises a receptacle for storing a plurality of unactivated EM devices, a separator for separating an indivdual EM device, a reader for activating and verifying activation of the EM device, and a sorter for dispensing activated EM devices into an accept container that is readily accessible. EM devices that fail to activate can be dispensed into a reject container. In some embodiments, the apparatus includes a controller that typically comprises a microprocessor having stored instructions. The controller can typically communicate with the EM device via the reader to activate the EM device and verify activation. The controller may also be used to program or write instructions to the EM device.

Owner:CRYOVAC ILLC

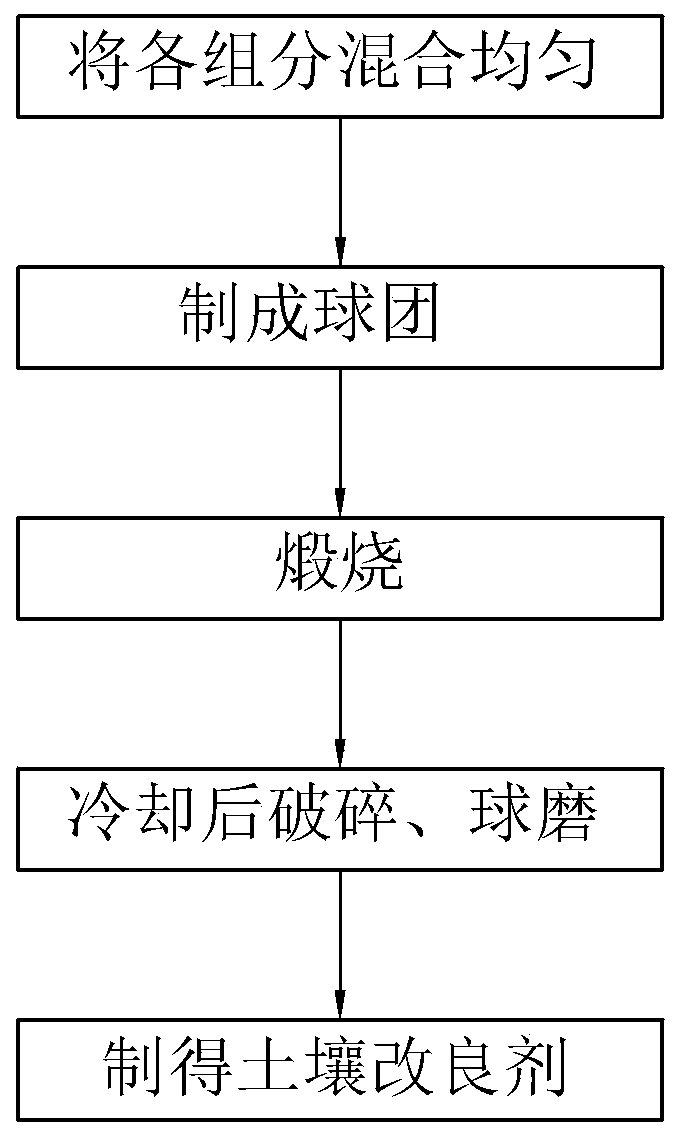

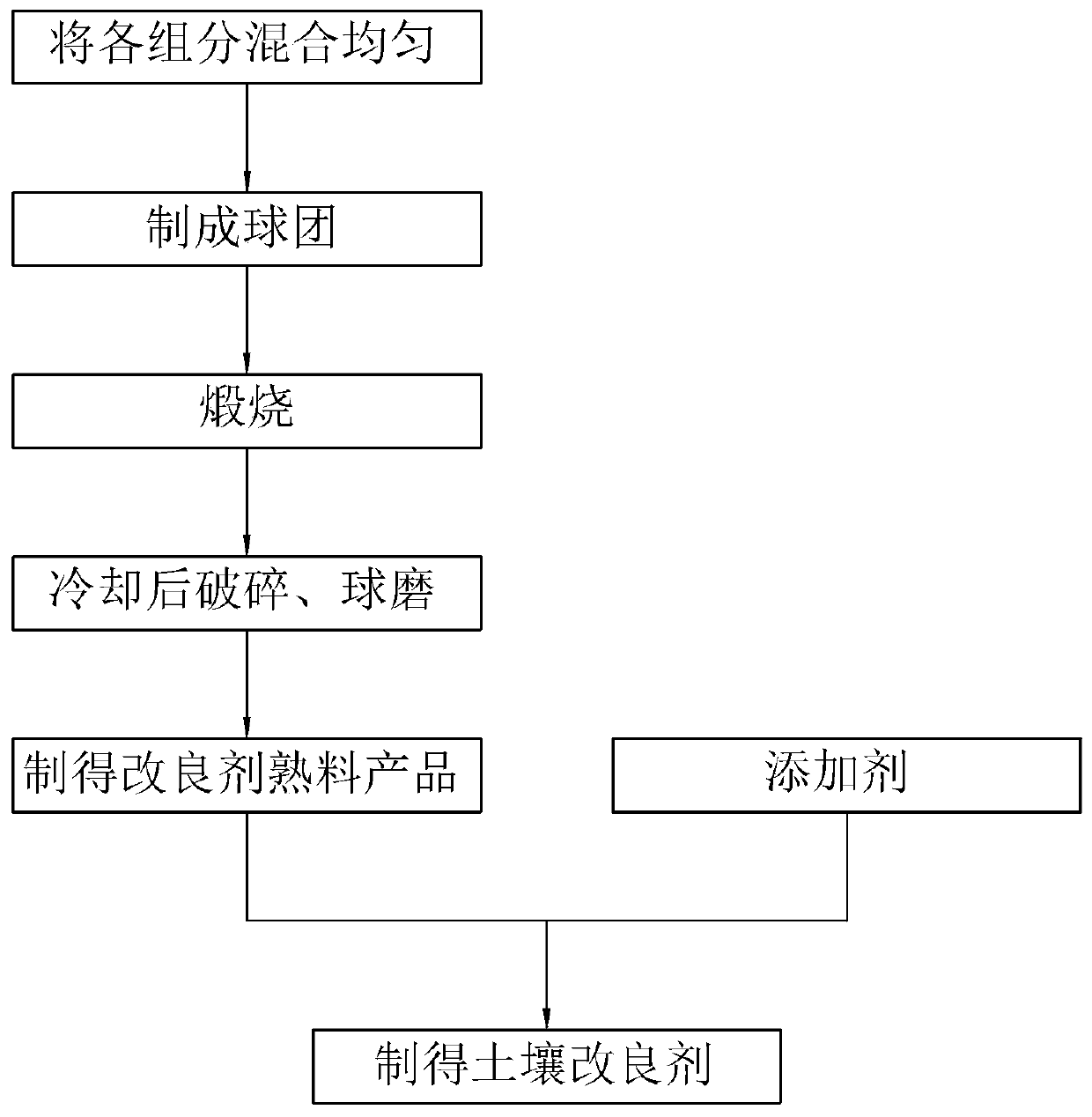

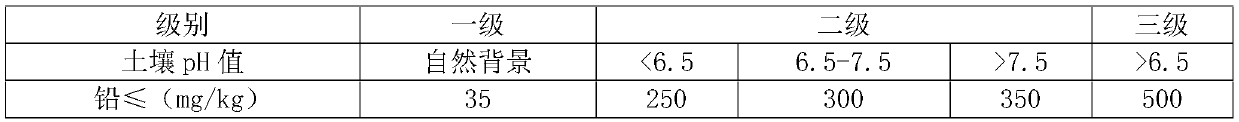

Soil conditioner as well as preparation method and use method thereof

ActiveCN110079332AWide variety of sourcesReduce typesCalcareous fertilisersAgriculture tools and machinesDickiteAlunite

The invention relates to the technical field of soil remediation, in particular to a soil conditioner as well as a preparation method and use method thereof. The soil conditioner comprises the following components in percentage by weight: 40-60% of copper tailings, 20-40% of fluorite tailings or limestone, 6-20% of talc, serpentine or dolomite, and 2-5% of a pellet curing agent, wherein the totalweight is 100%; and the copper tailings include quartz, alunite and dickite. The preparation method comprises the following steps: step 1, weighing the components and mixing the components uniformly;sep 2, preparing the mixture obtained in the step 1 into pellets; step 3, calcining the pellets at a temperature of at least 1000 DEG C for at least 1.5 hours; and step 4, cooling activated pellets and performing ball milling to obtain the soil conditioner. The soil container contains non-ferrous metal and non-metallic ores, various major, medium and trace elements necessary for the growth of crops, fruit trees and seedlings, and basically no additional major, medium and trace elements need to be added.

Owner:SHENZHEN MPD HITECH CO LTD

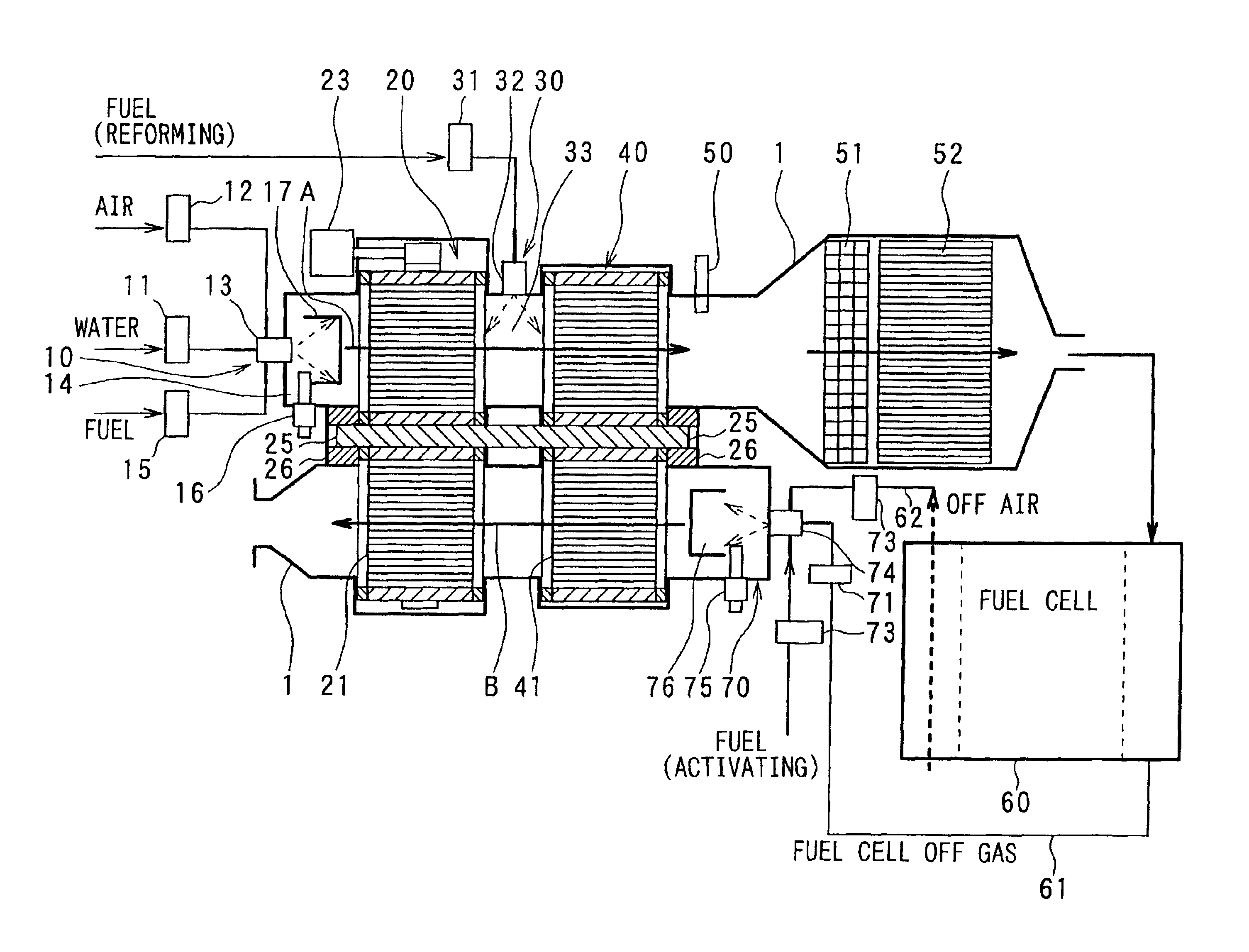

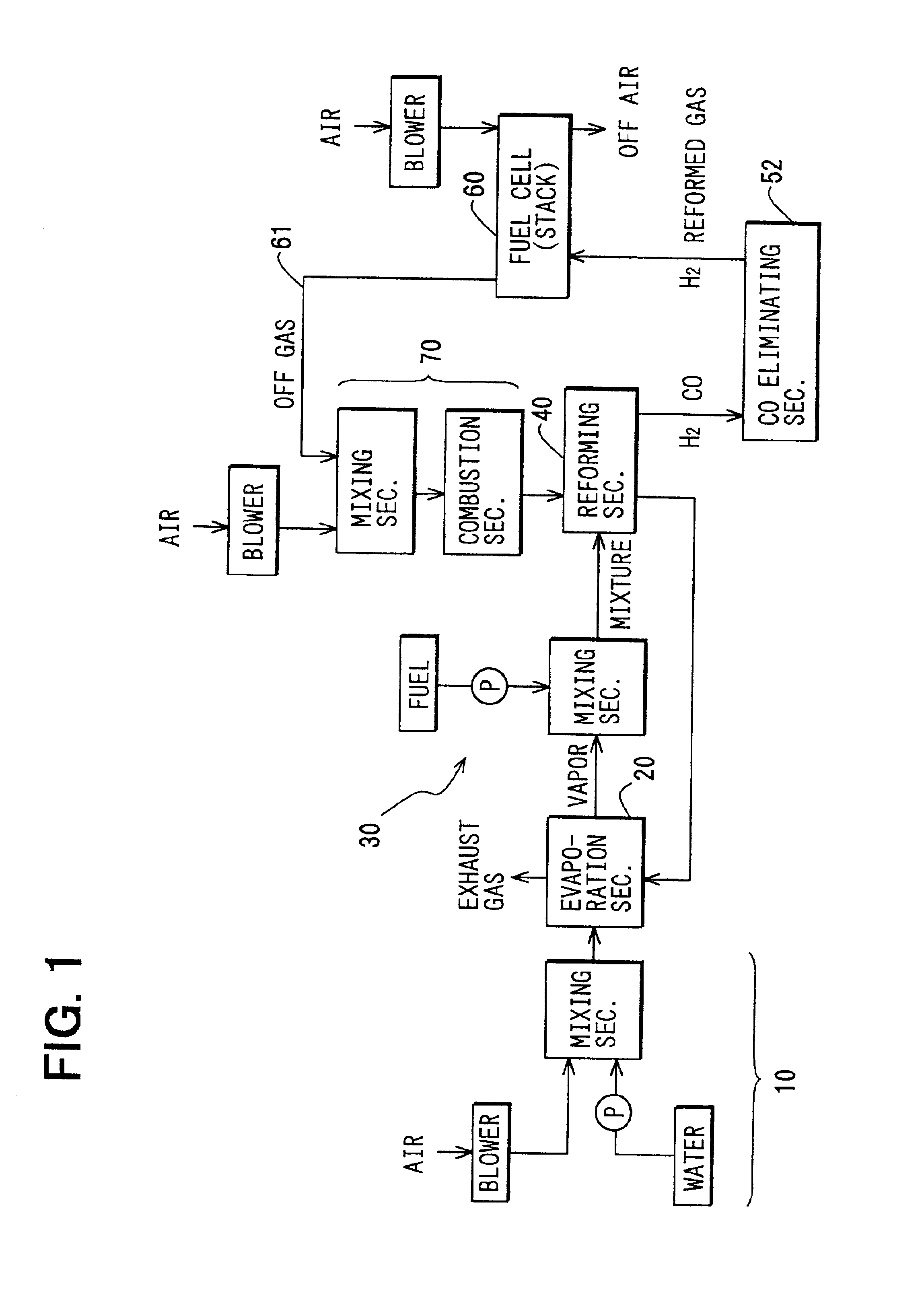

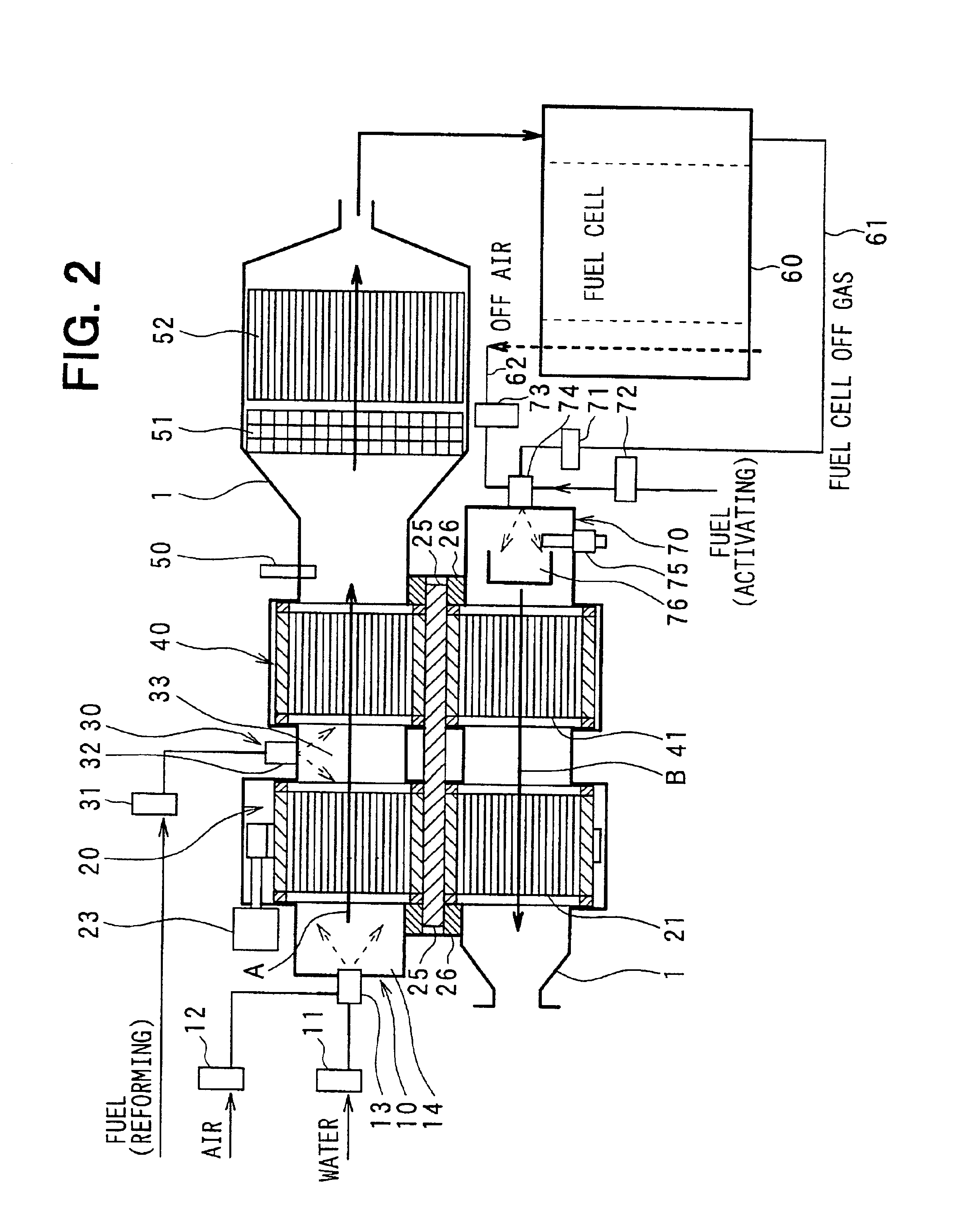

Hydrogen supply device

InactiveUS6838063B2Fast activationImprove responsivenessProcess control/regulationHydrogen/synthetic gas productionCombustionProduct gas

In the hydrogen supply device for producing and supplying hydrogen to a fuel cell, a reforming section has a rotary thermal storage through which low and high temperature passages pass. Reforming material is supplied to the low temperature fluid passage on an upstream side of the first rotary thermal storage. A combustion gas supply section for generating and supplying a combustion gas is located in the high temperature fluid passage on a downstream side of the first rotary thermal storage. With the hydrogen supply device mentioned above, the first rotary thermal storage rotates to move alternately between the low and high temperature fluid passages so that, in the reforming section, the reforming material flowing in the low temperature fluid passage is catalytically reformed to a reformed gas containing hydrogen upon receiving combustion heat of the combustion gas flowing in the high temperature fluid conduit.

Owner:DENSO CORP

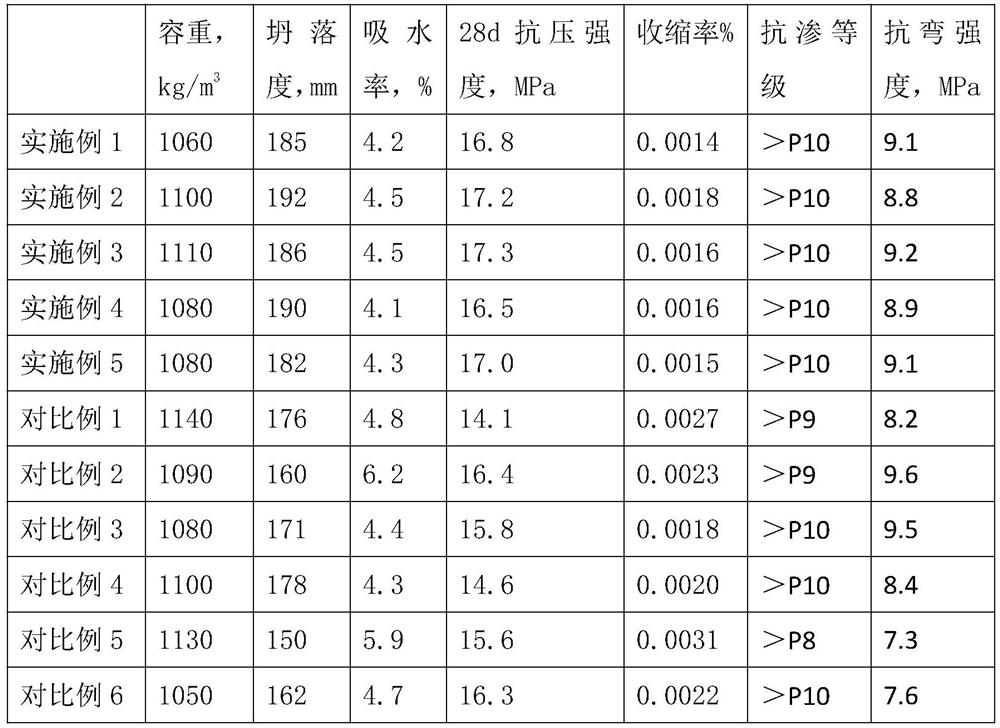

High-strength anti-crack environment-friendly concrete and preparation process thereof

InactiveCN112897947AImprove mechanical propertiesLong-lasting and stable performanceSolid waste managementSodium bicarbonateCrack resistance

The invention provides high-strength anti-cracking environment-friendly concrete and a preparation process thereof. The recycled concrete is prepared from the following components in parts by mass: 350 to 480 parts of PC42.5 cement, 50 to 150 parts of fly ash, 450 to 600 parts of recycled lightweight aggregate, 120 to 180 parts of coated sponge iron, 5 to 20 parts of fluorocarbon modified polyacrylamide copolymer, 40 to 70 parts of sodium bicarbonate, 60 to 120 parts of polyphenyl granules, 1 to 2.5 parts of polycarboxylic acid water reducing agent and 160 to 250 parts of mixing water, wherein the recycled lightweight aggregate comprises waste ceramsite concrete blocks and waste rock wool boards, and the coated sponge iron comprises sponge iron, borax, a polyvinyl alcohol solution and rice husks; through optimization of raw material selection and matching and application of the recycled aggregate, the concrete is green and environment-friendly, prefabricated activation components are specifically arranged, the synergistic effect, high strength, crack resistance and mechanical properties are obviously improved, the performance is lasting and stable, and the method is worthy of popularization and application.

Owner:江苏中砼新材料科技有限公司

Activation method before chemical plating based on photocuring technique

InactiveCN107119459AFast activationIncrease productivityVegetal fibresAnimal fibresActivation methodChemical plating

The invention relates to an activation method before chemical plating based on a photocuring technique. The activation method comprises the following steps: (1) preparing an aqueous photocuring activation liquid; (2) settling the aqueous photocuring activation liquid on a fabric, drying, and performing ultraviolet photocuring. In the activation process, a photocuring technique is adopted to anchor precious metal ions on the surface of the fabric, the operation is simple, green and environment-friendly, the binding fastness of an activated layer and base cloth is improved, meanwhile the amount of the precious metal salts is reduced, and the production cost of the activation process is reduced. The activation method can be applied to activiation treatment before chemical plating of various fabrics and is wide in application range, excellent in activation effect and easy in industrial production.

Owner:SAINTYEAR HLDG GROUP +1

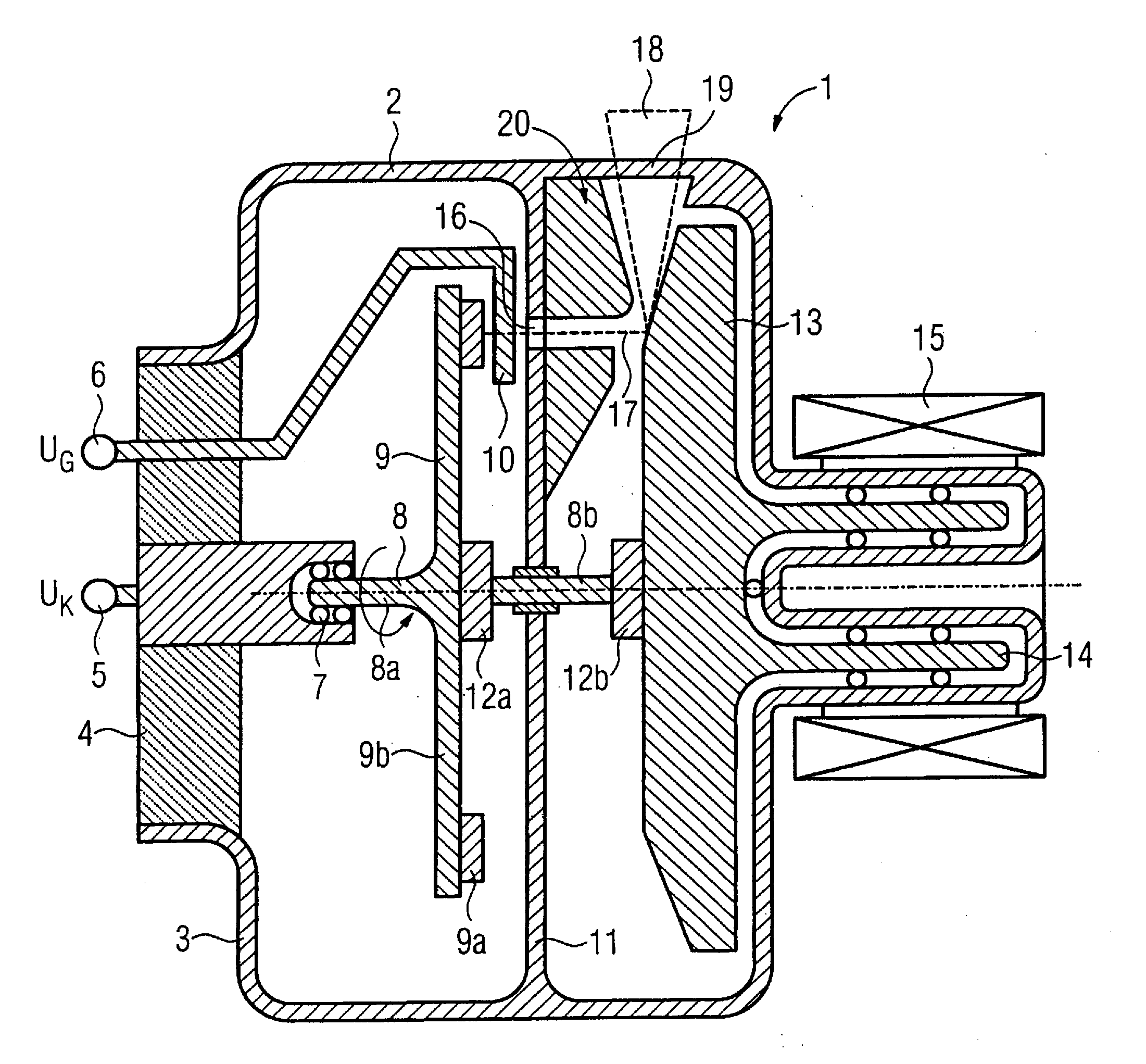

Field emission cathode and x-ray tube embodying same

InactiveUS20090304157A1Easy to useIncreased durabilityX-ray tube electrodesDischarge tube/lamp detailsField emission cathodeAtomic physics

A field emission cathode has a field emitter and an extraction grid, and the field emitter and the extraction grid can be moved relative to one another. Such a field emission cathode is highly durable and exhibits a longer lifespan. An x-ray tube has a field emission cathode composed of a field emitter and an extraction grid that can be moved relative to one another. Such an x-ray tube is highly durable and exhibits a longer lifespan.

Owner:SIEMENS HEATHCARE GMBH

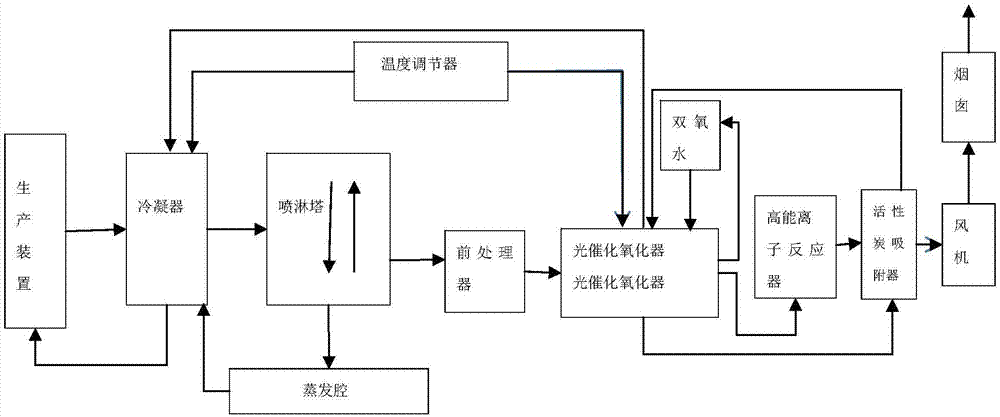

Oxidable volatile organic matter treatment device and use method thereof

InactiveCN107469552AHigh recovery rateReduce secondary pollutionGas treatmentDispersed particle separationFiberActivated carbon

The invention provides an oxidable volatile organic matter treatment device which comprises a condenser. A liquid collecting tank is arranged at the lower portion of the condenser. A liquid returning pump is arranged on the condenser. A liquid inlet pipe of the liquid returning pump is inserted in the liquid collecting tank. A liquid returning pipe of the liquid returning pump is communicated with the interior of a production device or a liquid storage barrel. The bottom of a spray tower is connected with a recycling pipe. The recycling pipe is communicated with an evaporating cavity which is provided with a vapor exhaust pipe. The vapor exhaust pipe is communicated with the condenser. By means of the oxidable volatile organic matter treatment device, workers can conduct condensing and recycling treatment on volatile organic matter in accumulated liquid evaporated in the spray tower through the evaporating cavity after waste gas treatment and can also put an installation frame in an activated carbon adsorber into a photocatalytic oxidizer to conduct activating treatment on activated carbon fiber. By means of the oxidable volatile organic matter treatment device, oxidable volatile organic matter treatment can be conducted step by step, the treatment effect is good, and the recycling rate is high.

Owner:王畅

Method for preparing shrimp sauce by fermenting

InactiveCN106820082AFast activationEnergeticFood ingredient as antioxidantAntifouling/underwater paintsAstaxanthinProteolysis

The invention provides a method for preparing shrimp sauce by fermenting. The method comprises the specific steps of pre-treating, activating, carrying out enzymolysis, fermenting and sterilizing. The method provided by the invention has the beneficial effects that a proteolysis technology is combined with a lactic acid bacterium fermentation technology, so that the preparation time of the shrimp sauce is shortened. The prepared shrimp sauce is purple red, has gloss, rich aroma, rich fresh shrimp flavor and delicious taste, and has sweet taste, no stink odor, high protein content, low fat content and low nitrite content; the shrimp sauce contains rich astaxanthin and calcium citrate; and a coating is formed on a pottery pot sealing film, so that the breeding of bacteria can be inhibited.

Owner:ZHEJIANG OCEAN UNIV

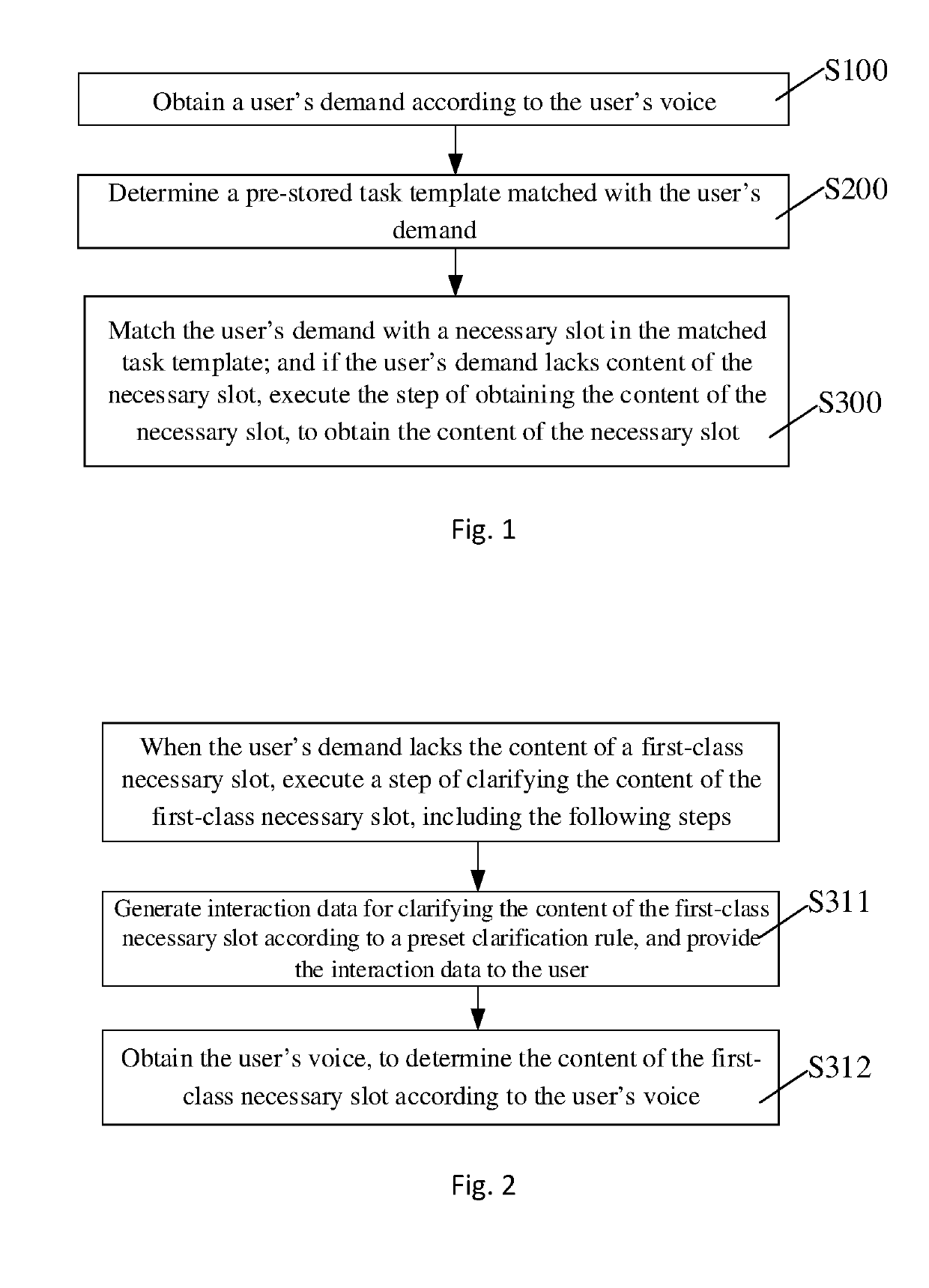

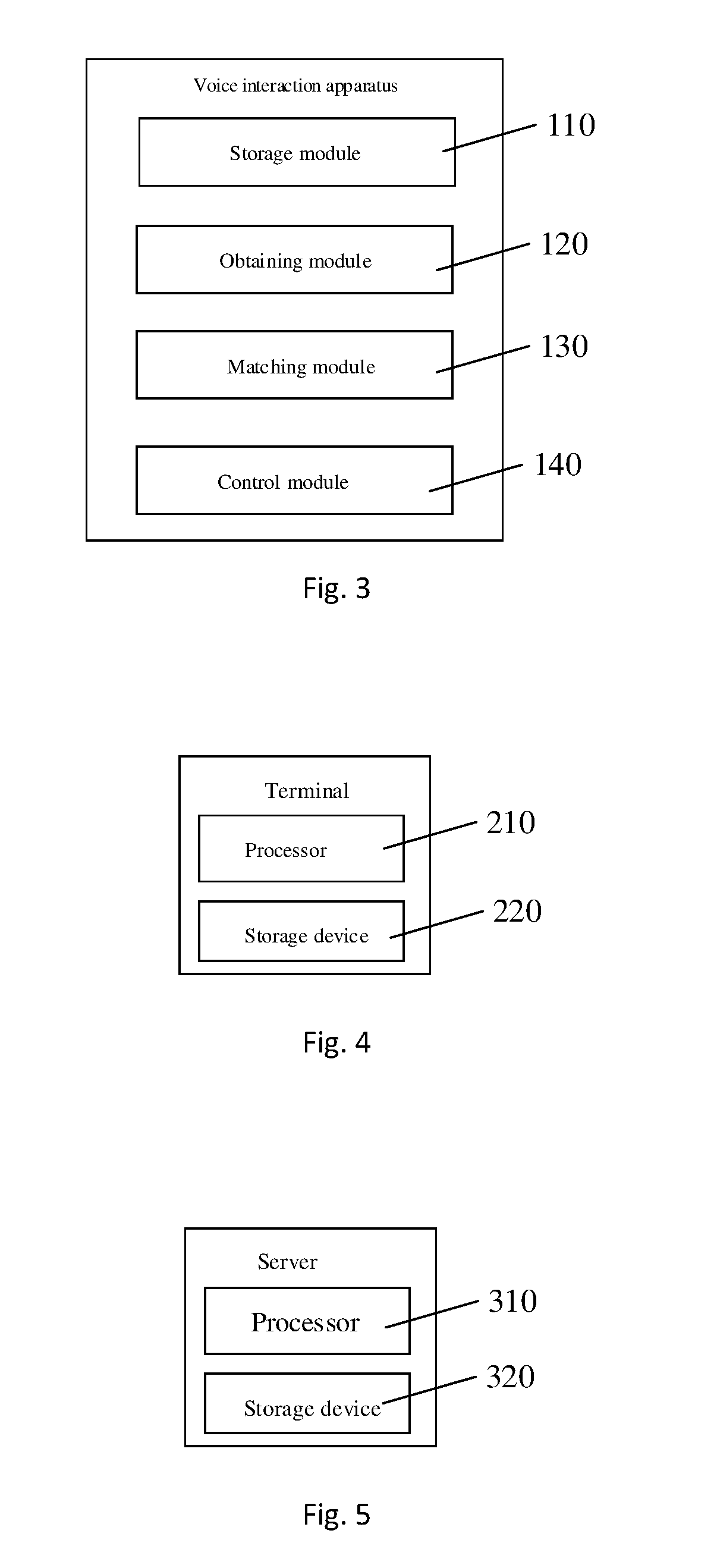

Voice interaction method and apparatus, terminal, server and readable storage medium

ActiveUS20190147869A1Little informationFast activationSpeech recognitionTransmissionUser needsTemplate match

A voice interaction method and apparatus, a terminal, a server, and a readable storage medium are provided. The method includes the following steps: obtaining a user's demand according to the user's voice; determining a pre-stored task template matched with the user's demand; matching the user's demand with a necessary slot in the matched task template; and if the user's demand lacks content of the necessary slot, executing a step of obtaining the content of the necessary slot, to obtain the content of the necessary slot; wherein the task template is a template generated in advance according to information required for activating a task operation through voice, the slot is information in the task template, and the necessary slot is necessary information in the task template for activating the task operation.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD +1

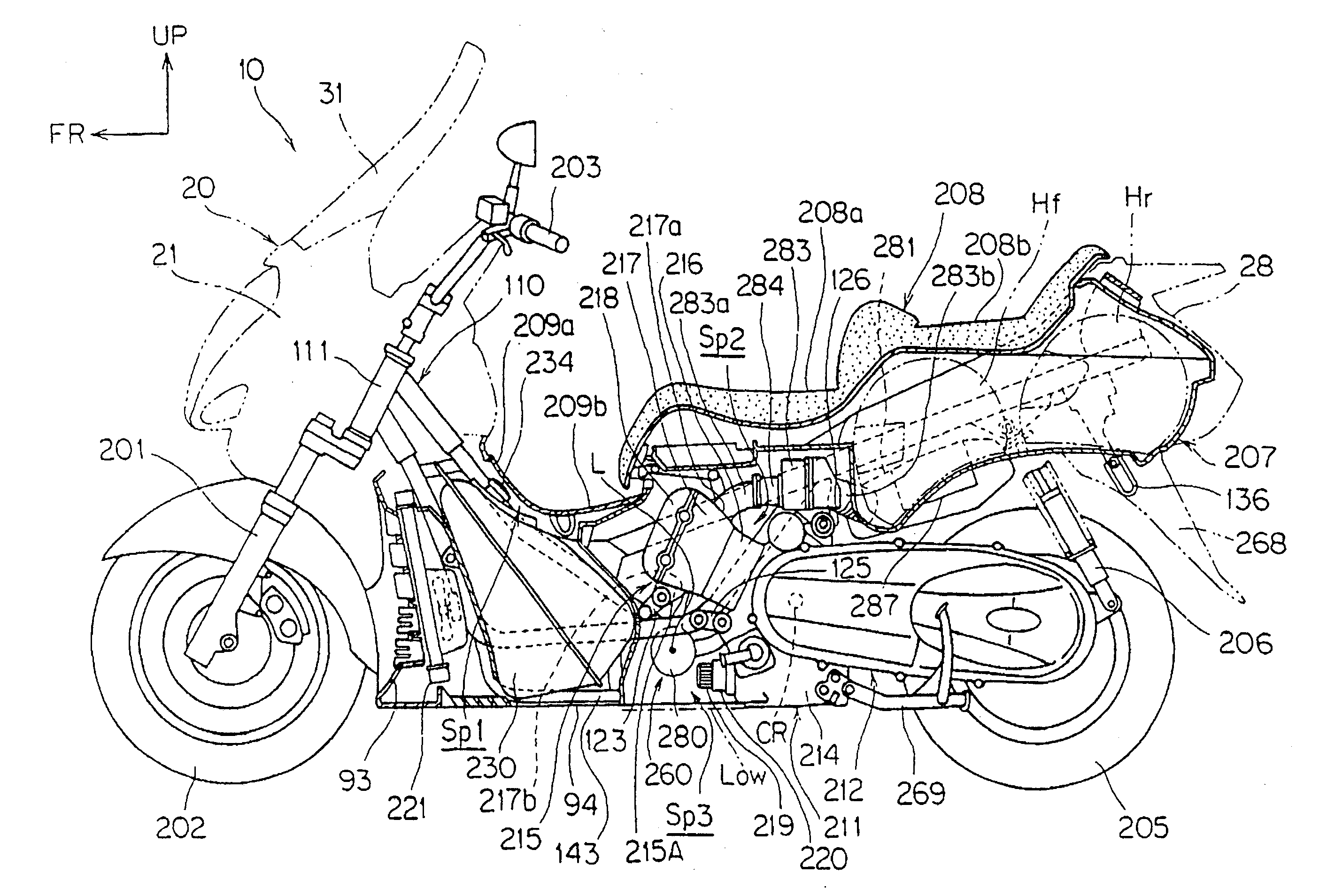

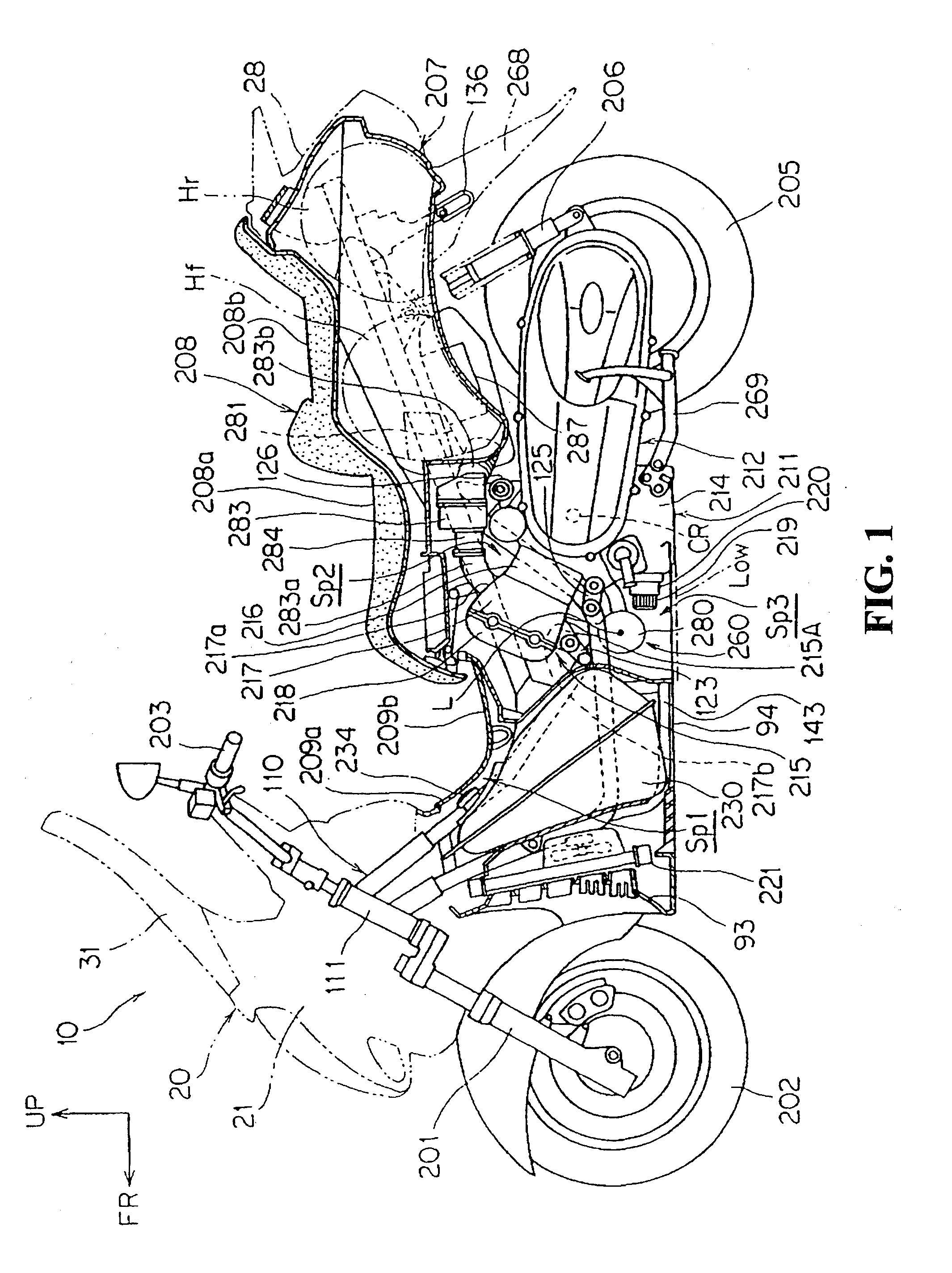

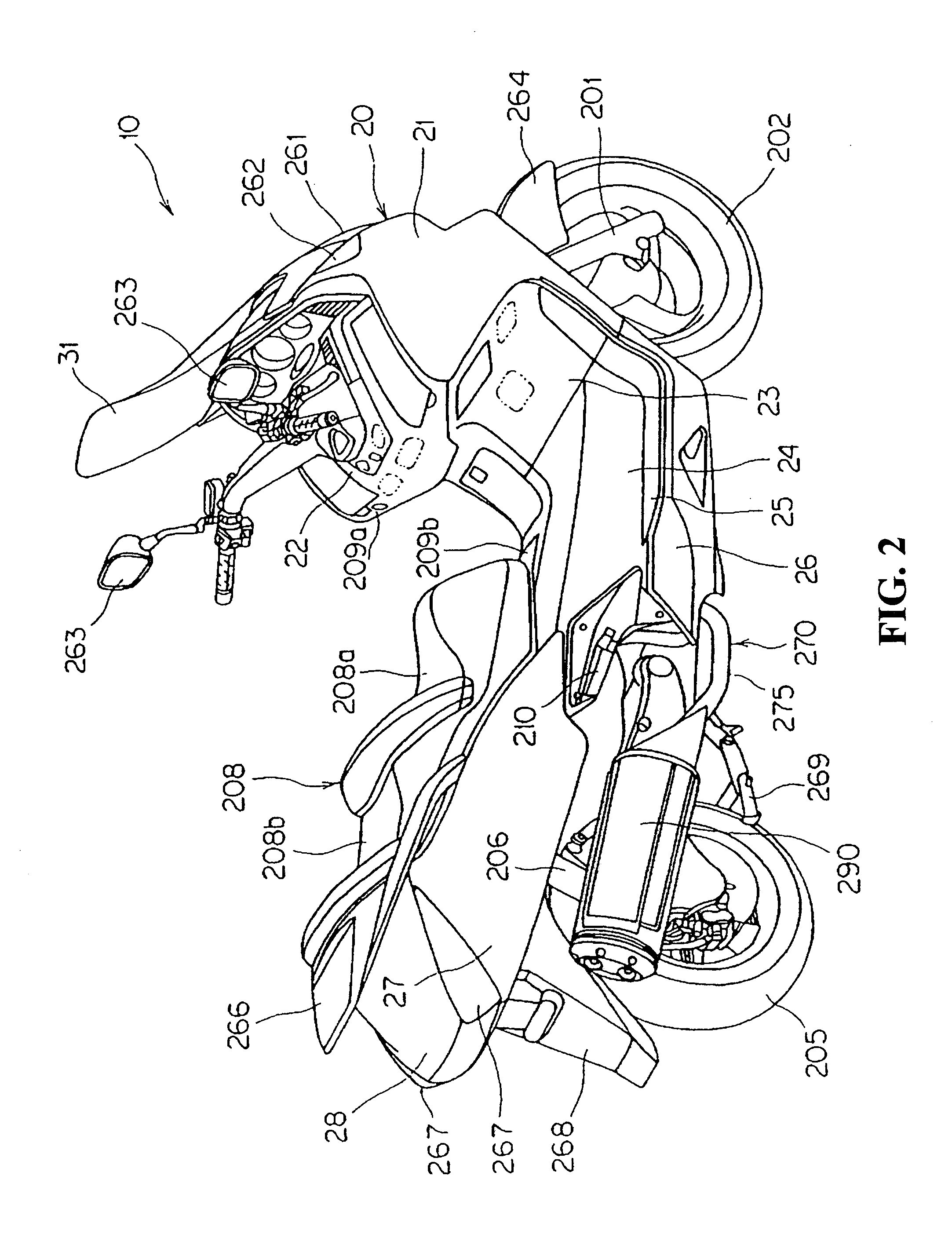

Catalyst arrangement construction of motorcycle

ActiveUS20090165448A1Fast activationCompact constructionSilencing apparatusMachines/enginesEngineeringCrankshaft

An engine has a crankcase, and a cylinder which extends from an upper portion of the crankcase toward a front side. In a space which is formed at an upper side of a horizontal plane which substantially horizontally extends from a bottom surface of the crankcase, a catalyst storage chamber is arranged in such a manner that an axis of the catalyst converter is in a direction of a crankshaft. The space is arranged just below a front surface of the cylinder and forward of a front surface of the crankcase.

Owner:HONDA MOTOR CO LTD

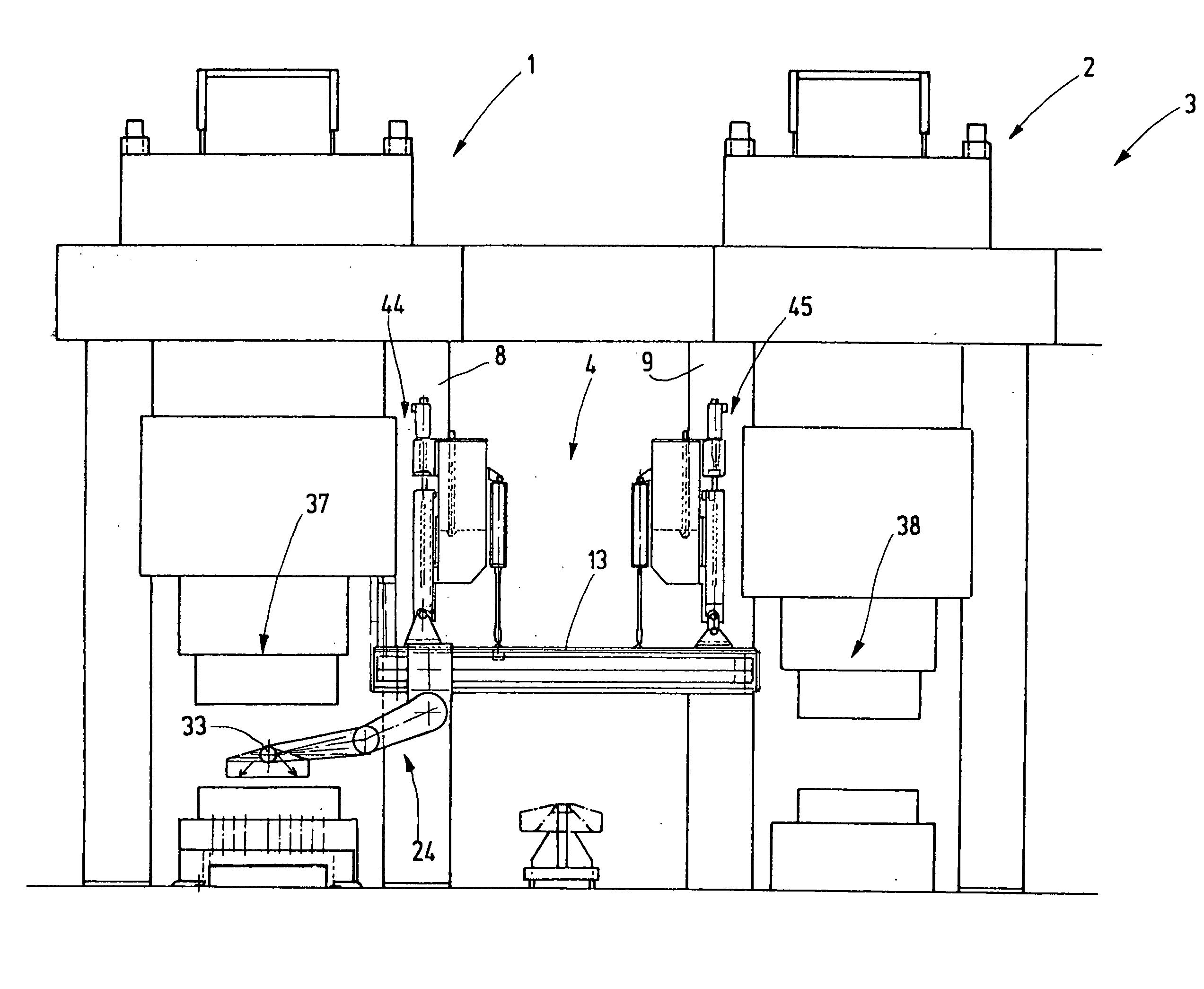

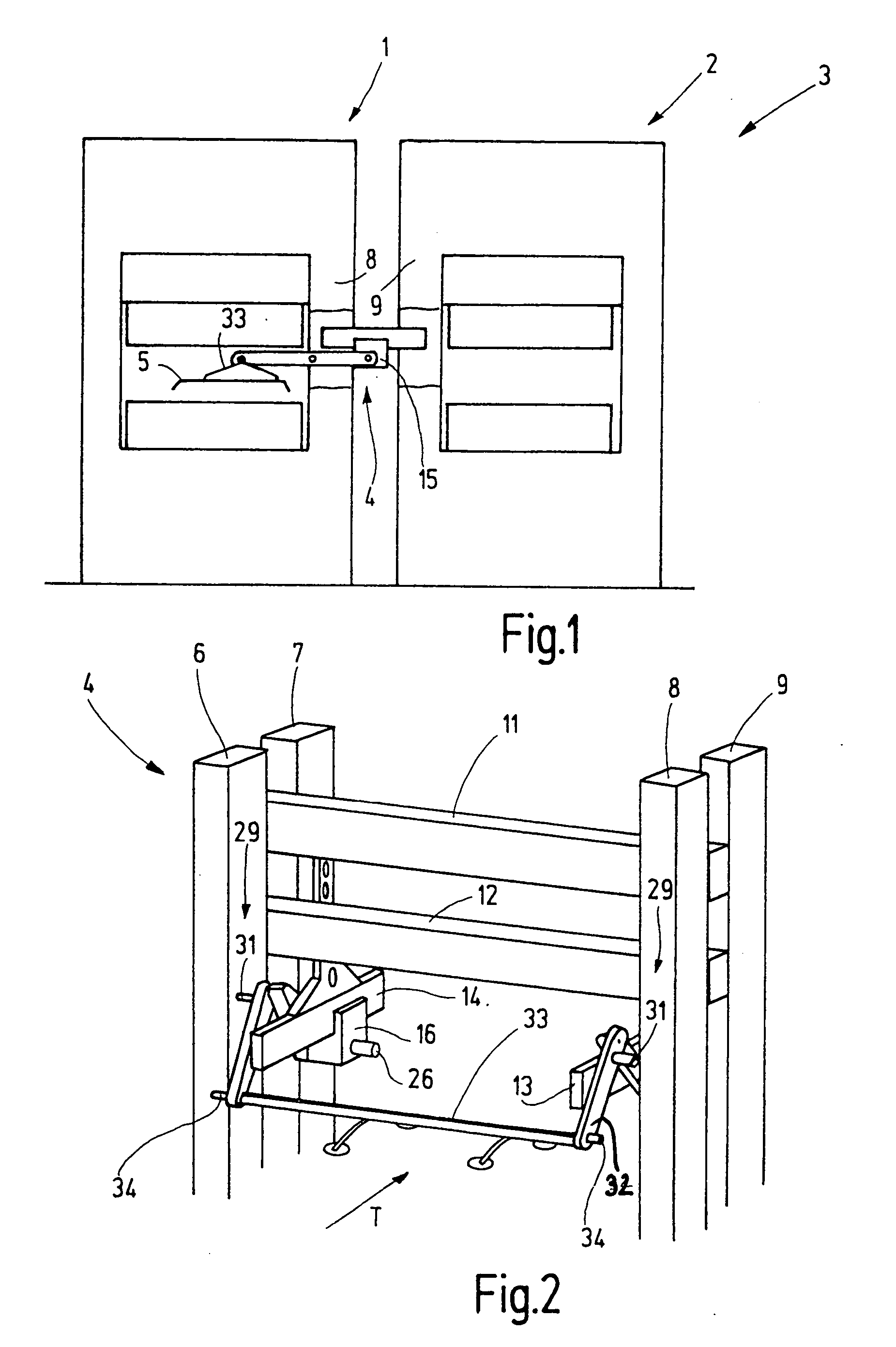

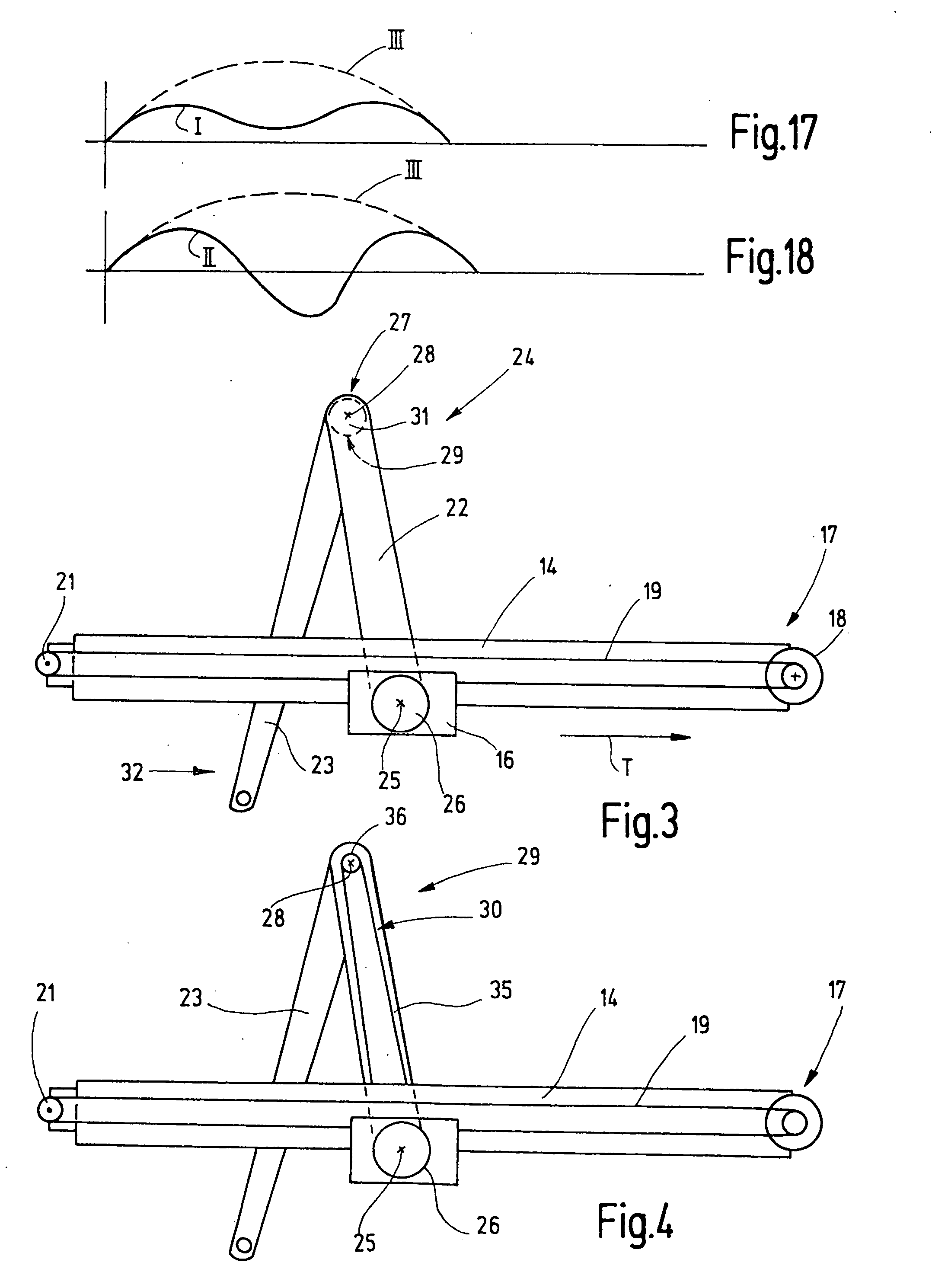

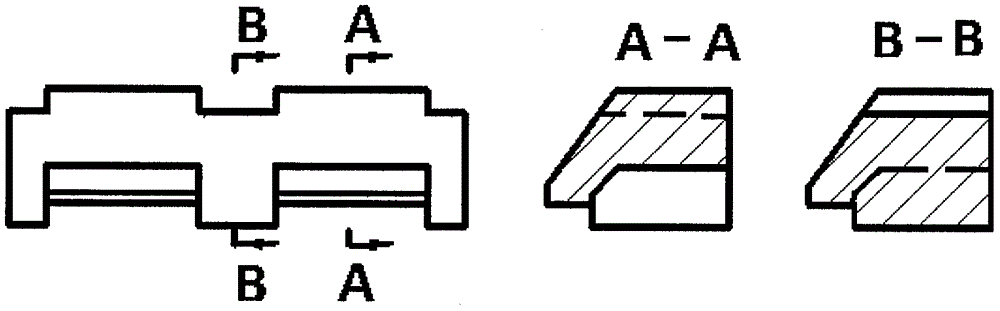

Transfer arrangement and method

InactiveUS20050238473A1Provide powerHigh press stroke rateMetal-working feeding devicesStorage devicesEngineeringMechanical engineering

In a transfer arrangement and method for transferring a workpiece between first and second spaced locations along a guide rail with a carriage movably supported on the guide rail, a transfer arm is pivotally supported on the carriage and carries at its free end a workpiece holder which is accelerated by the carriage with the arm essentially stretched out in the movement direction out of, and decelerated into, the end positions, and, in an intermediate position, the carriage movement is slowed down or even reversed while the workpiece holder is moved along by a pivot movement of the arm.

Owner:SCHULER PRESSEN GMBH & CO KG

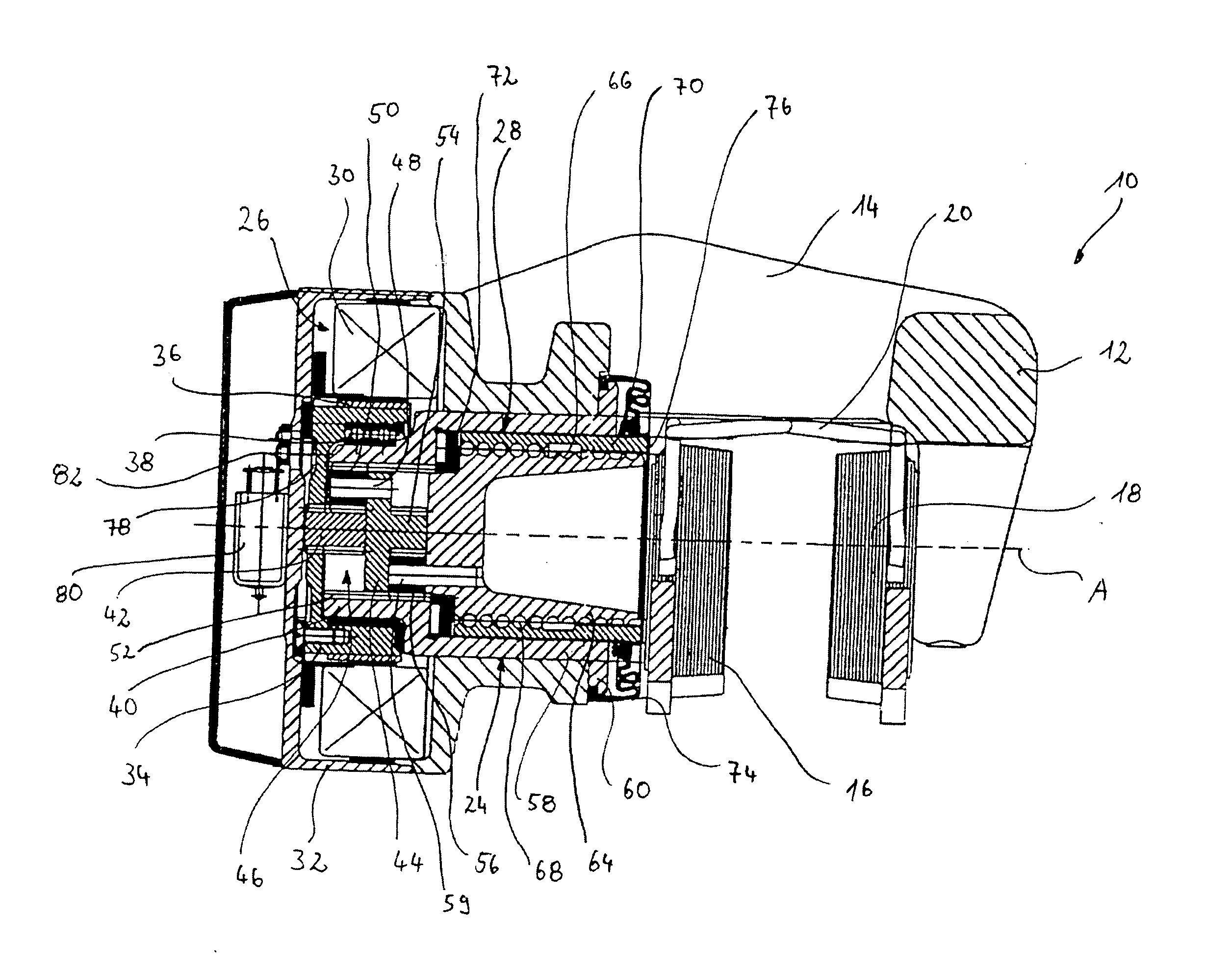

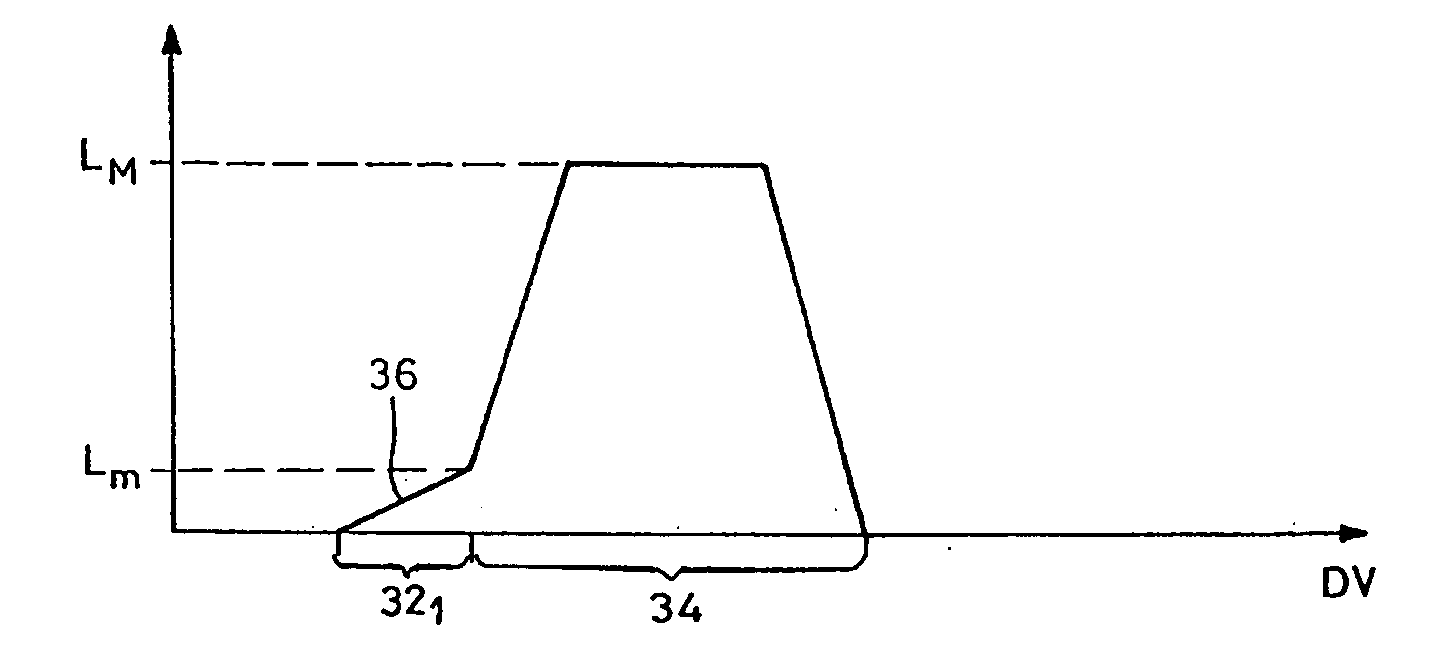

Vehicle brake and method for actuating a vehicle brake

InactiveUS20060054428A1Fast and reliable activationFast activationFluid actuated brakesBraking element arrangementsBrake liningPiston

In a vehicle brake comprising a housing, a brake piston, which is accommodated in the housing and on which a brake lining is fitted, and a blocking device, it is provided that the brake piston is displaceable in the housing by means of an actuating device and that the brake piston is securable relative to the housing by means of the blocking device. In this vehicle brake, it is further provided that the blocking device comprises an electromechanical latching arrangement, which is actuable in such a way that in a latching position it prevents a displacement of the brake piston inside the housing and in a release position it enables a movement of the brake piston in the housing.

Owner:LUCAS AUTOMOTIVE GMBH

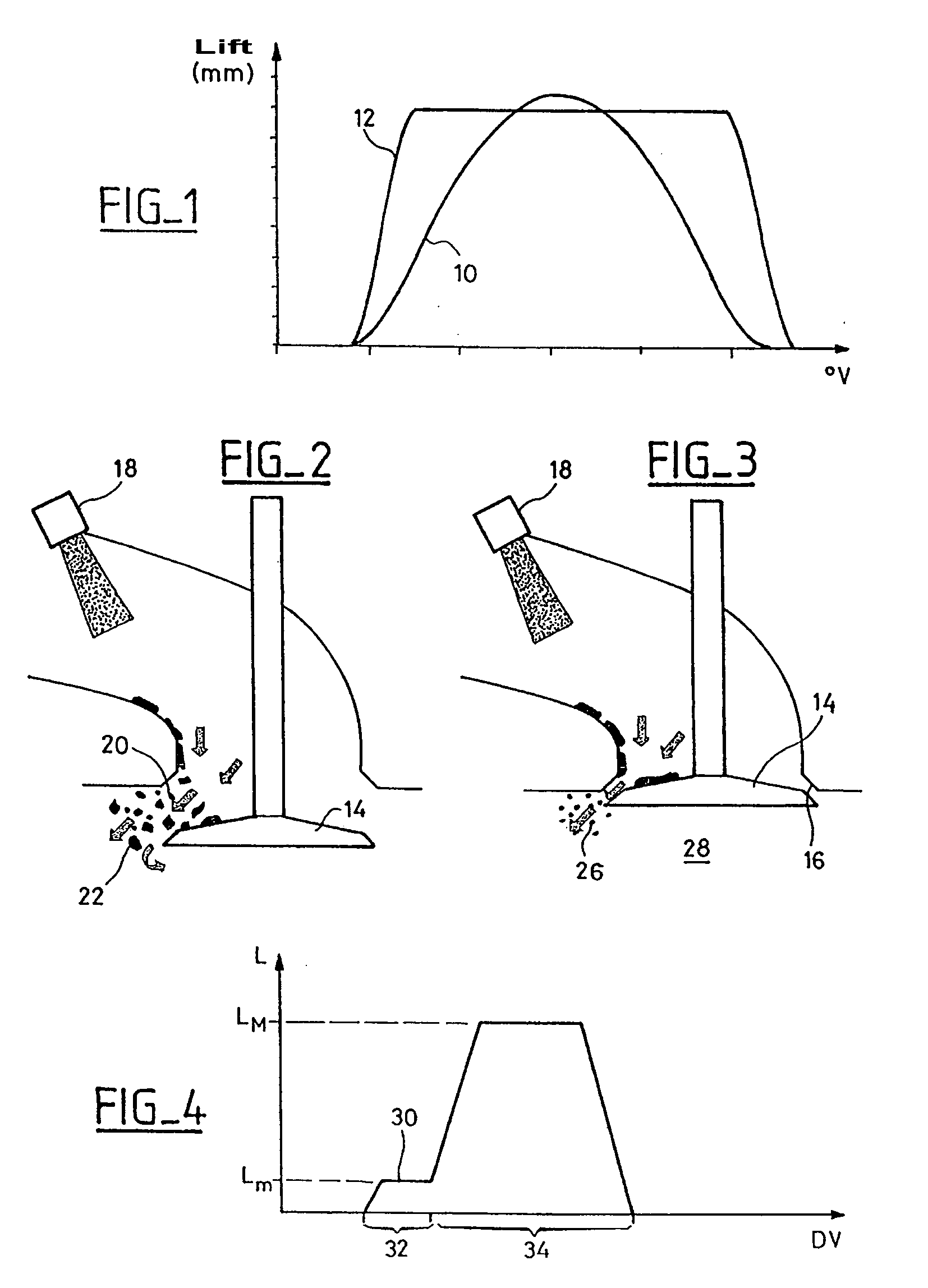

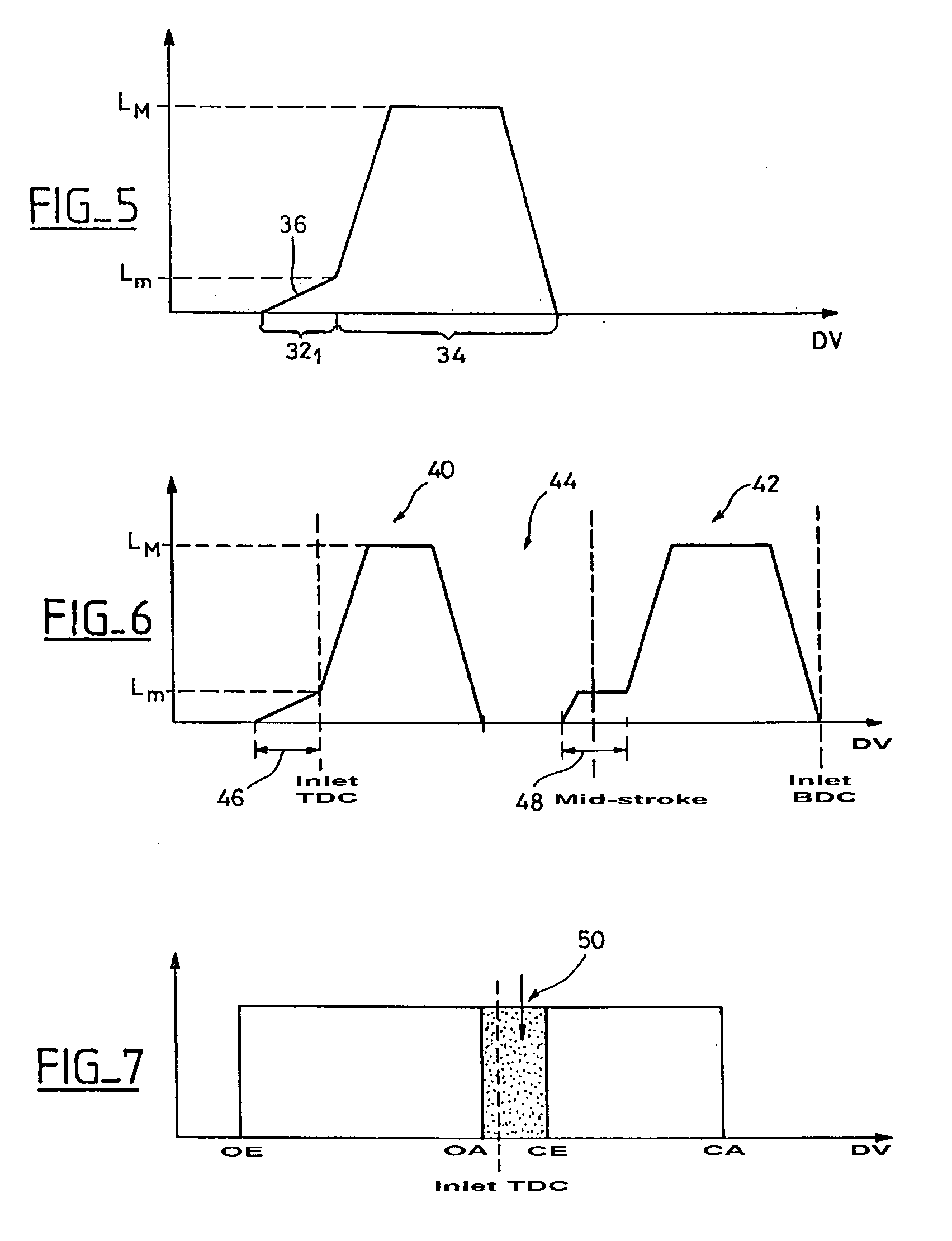

Method of reducing hydrocarbon emissions from a cold engine and device and engine for carrying out this method

InactiveUS20090050085A1Enhanced gas turbulenceHeat up and expandElectrical controlInternal combustion piston enginesInlet valveEngineering

The invention relates to a method of control of an internal combustion engine comprising at least one electrically controlled inlet valve.To reduce hydrocarbon emissions by the cold engine, the opening of the valve is controlled in two successive phases (32, 34), the first phase (32) corresponding principally with the admission of fuel and the second phase (34) mainly corresponding with the air inlet. The opening of the valve is substantially lower during the first phase than during the second phase in order to pulverise the fuel into fine droplets during the first phase.

Owner:PEZHO SITROEN AUTOMOBILS SA

LDS electroless plating process

InactiveCN104561945AReduce manufacturing costControl Nickel FlashingLiquid/solution decomposition chemical coatingMetal layered productsElectroless nickelNickel catalyst

The invention discloses an LDS (Laser Direct Structuring) electroless plating process. The LDS electroless plating process comprising the following steps: firstly, performing pretreatment on an LDS product printed with a copper circuit to remove an oxide film on the surface of copper; secondly, performing nickel dipping processing on the LDS product subjected to pretreatment in nickel dipping liquid to enable metallic nickel to be deposited on the surface of copper so as to obtain a nickel catalyst layer; thirdly, performing activating treatment on the LDS product in an activation solution to active the catalytic activity of nickel dipping copper surface to electroless nickel plating; fourthly, immersing the LDS product in an electroless nickel plating bath to perform electroless nickel plating according to a conventional method. The LDS electroless plating process not only can improve an overflow plating condition, but also can reduce the raw material cost.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

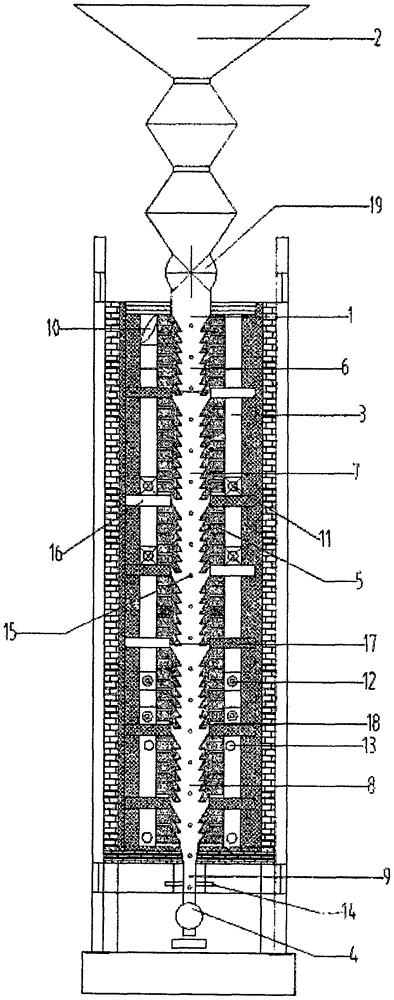

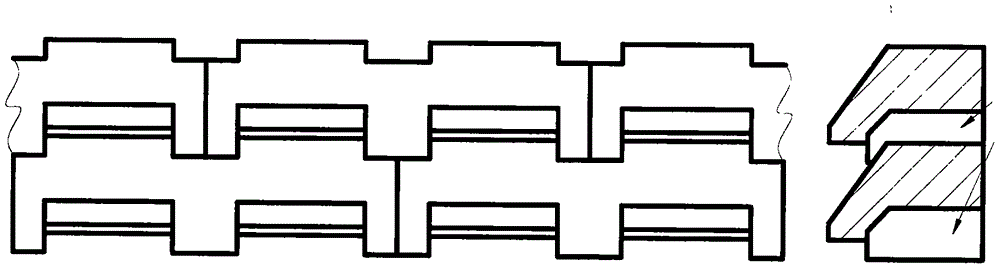

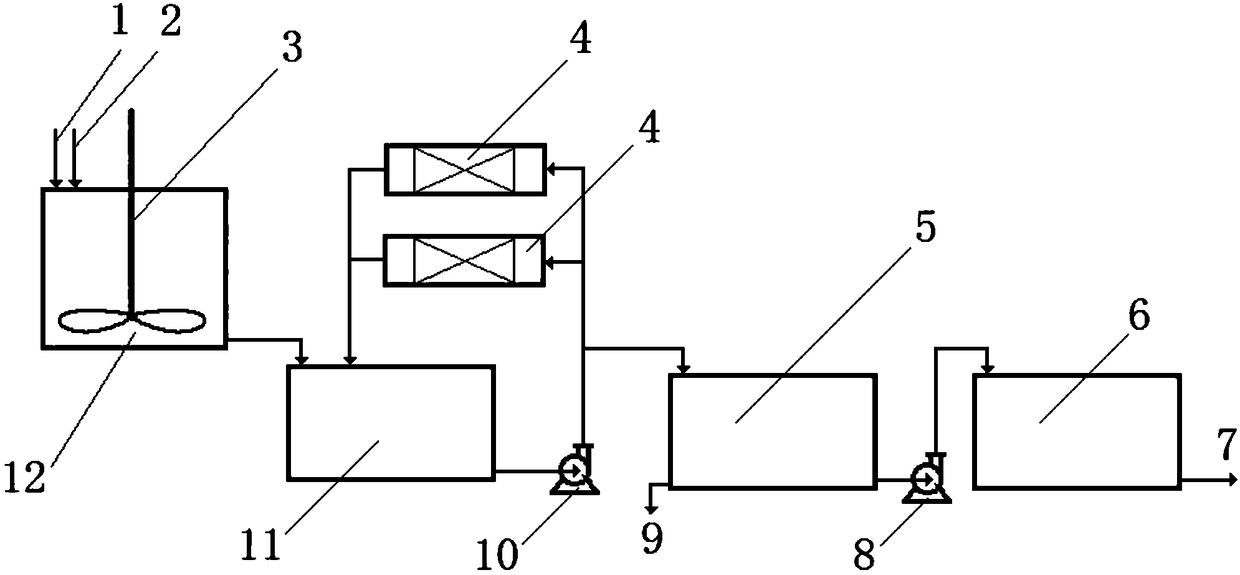

Carbonization and activation device for active coke production

The invention belongs to the field of chemical engineering devices and relates to a carbonization and activation device for active coke production. The device comprises a material channel and flues at two sides of the material channel. The device also comprises a preheating section, a carbonization section, an activation section and a cooling section and the sections are orderly arranged from top to bottom along a vertical direction. The flues in the carbonization and activation sections are respectively provided with gas burners. The flue in the activation section is provided with an activator inlet. The device realizes combination of carbonization and activation, has less processes, uniform and continuous reaction processes, a fast activation rate, a high raw material utilization rate and high production power, greatly reduces power and energy consumption and has a low cost and a high product yield.

Owner:赵英杰

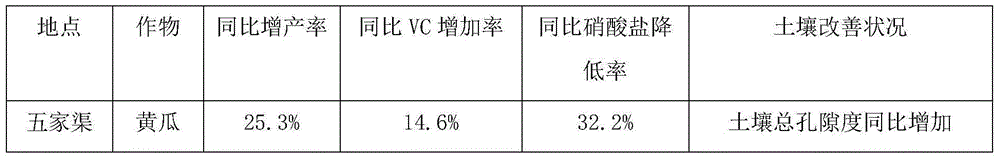

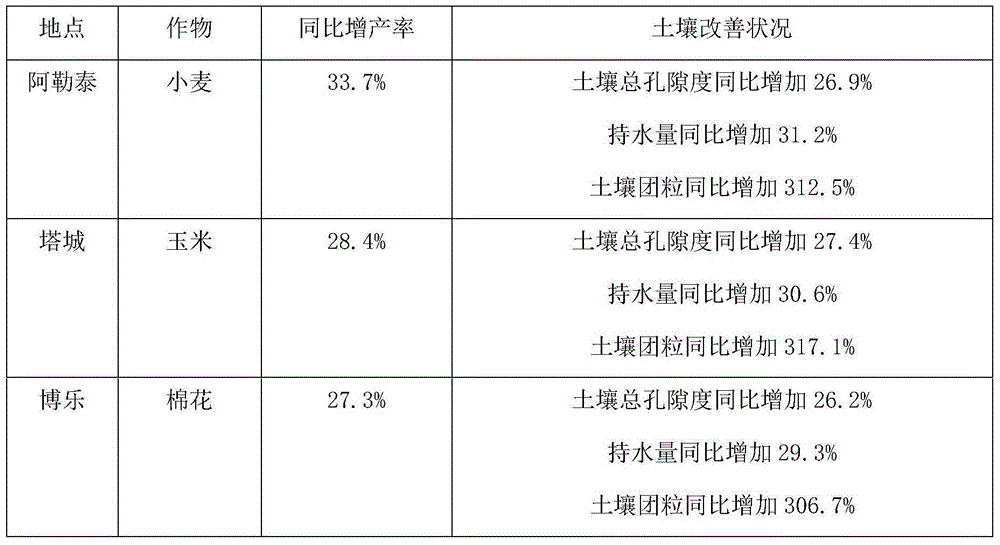

Water-soluble organic humic acid fertilizer and application thereof to promotion of plant yield increment and soil improvement

ActiveCN105198660AHigh porosityImprove water holding capacityFertilizer mixturesNaphthylacetic acidBorax

The invention provides a water-soluble organic humic acid fertilizer and application thereof to promotion of plant yield increment and soil improvement. The preferable water-soluble organic humic acid fertilizer is prepared from compound microorganisms and the following raw materials in parts by weight: 35 parts of water-soluble potassium humate, 16 parts of urea, 9 parts of potassium sulfate, 8 parts of monoammonium sulfate, 3 parts of zinc sulfate, 4 parts of borax, 2 parts of ammonium molybdate, 1.2 parts of hxanoic acid 2-(diethylamino) ethyl ester, 0.9 part of compound sodium nitrophenolate, 0.9 part of alpha-sodium naphthylacetate and 40 parts of water, wherein the total biomass of compound microorganisms in every kg of the water-soluble organic humic acid fertilizer is larger than or equal to 1.2*10<10>cfu. In addition, the invention also provides application of the water-soluble organic humic acid fertilizer to promotion of plant yield increment and soil improvement.

Owner:吉木乃县金世宝农业节水科技有限责任公司

Slurry coating process-based method for preparing thin thermal battery positive electrode and electrolyte combination electrode piece

InactiveCN104681781AAchieve preparationLow costDeferred-action cellsPrimary cell electrodesElectrical batteryCell fabrication

The invention belongs to the field of battery manufacturing, and particularly relates to a slurry coating process-based method for preparing a thin thermal battery positive electrode and electrolyte combination electrode piece. The method comprises the steps: preparing homogeneous thermal battery positive electrode slurry, then coating a conducting substrate with the homogeneous thermal battery positive electrode slurry, drying, solidifying and pressing to obtain a thin thermal battery positive electrode piece; and preparing homogeneous thermal battery fused salt electrolyte slurry, coating the thin thermal battery positive electrode piece with the homogeneous thermal battery fused salt electrolyte slurry in a lamination manner, drying, solidifying and pressing so as to obtain the thin thermal battery positive electrode and electrolyte combination electrode piece. The thin thermal battery positive electrode and electrolyte combination electrode piece prepared by adopting the method has the advantages that the thickness can be reduced by 1 / 3-1 / 2 and is adjustable in the range of tens of micrometers to hundreds of micrometers, and the combination electrode piece has very high values on creating a new way in miniaturizing and thinning thermal batteries and promoting development of national defense industries.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

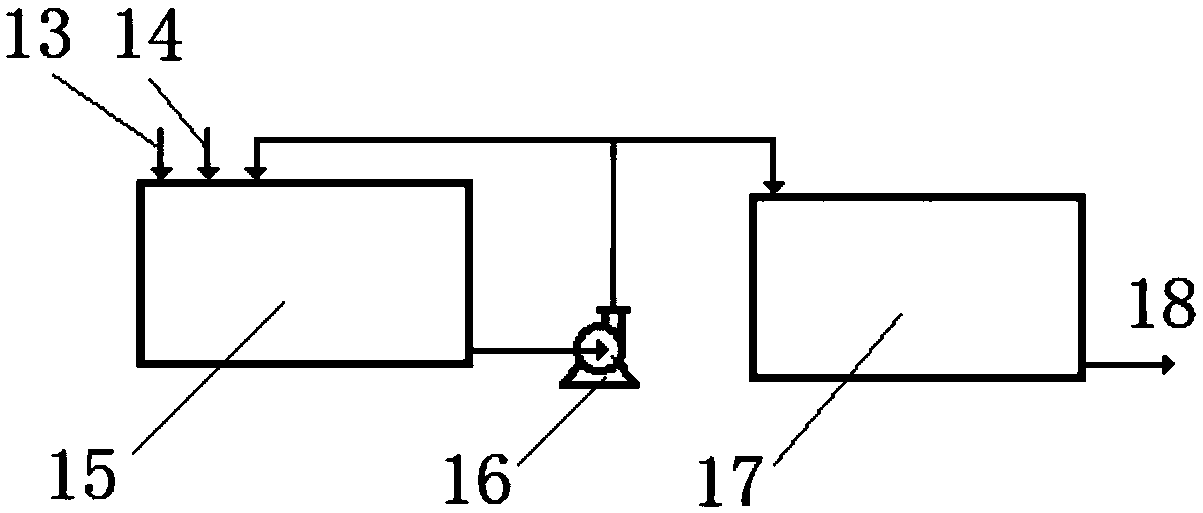

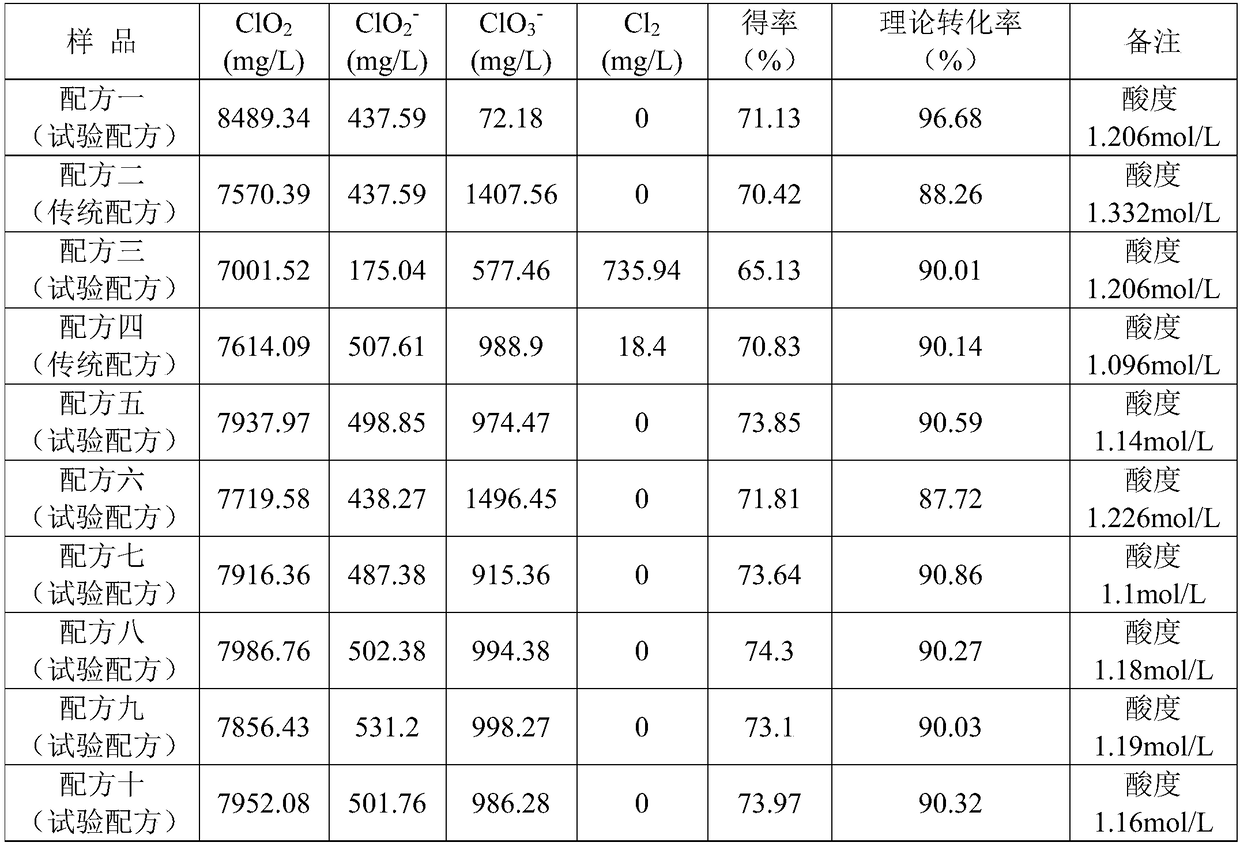

Method for preparing chlorine dioxide disinfectant

PendingCN108439342AImprove conversion rateMeet actual needsChlorine dioxideWater/sewage treatment by oxidationDisinfectantProduct gas

The invention discloses a method for preparing a chlorine dioxide disinfectant. The method comprises the following steps: preparing a sodium chlorite solution and a hydrochloric acid solution respectively; adding the two solutions into equipment and carrying out activation reaction; carrying out continuous aeration to generate high-purity and high-activity chlorine dioxide gas, wherein the purityof the gas is greater than or equal to 99 percent; conveying the chlorine dioxide gas to a drinking water application field. According to the method for preparing the chlorine dioxide disinfectant, disclosed by the invention, reasonable proportioning is carried out through a novel technological formula; the high-purity and high-activity chlorine dioxide gas can be prepared through activation operation.

Owner:四川蒙顶山化工有限公司

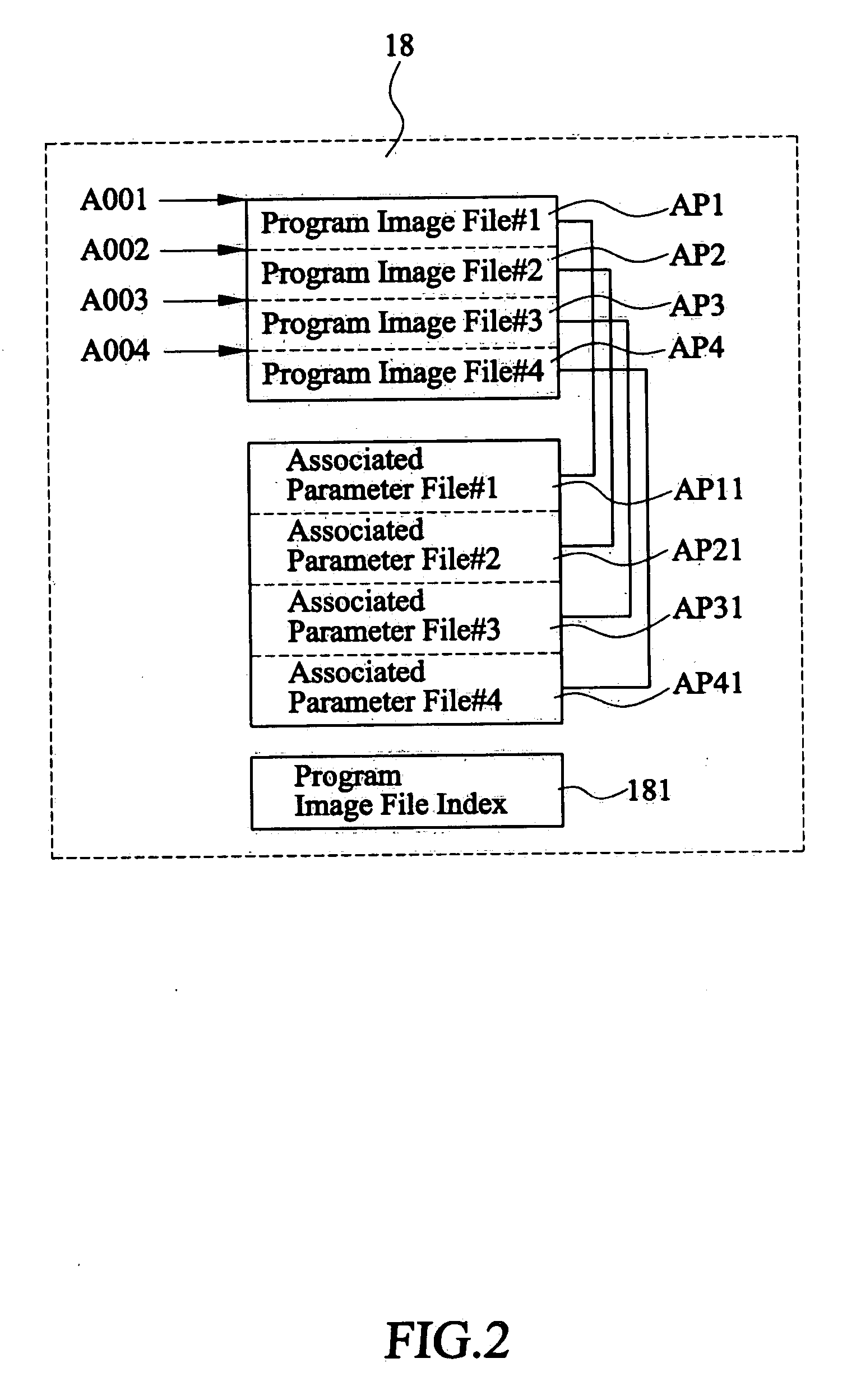

Method for express execution of computer function options by loading program image file

ActiveUS20070067616A1Speed up activationFast extractionDigital computer detailsData resettingOperational systemData memory

A method for fast activating a computer function options by loading program image files is provided, including a data storage pre-installed with at least a program image file. When the user operates an option button, the computer loads and executes the program image file associated with the option button after the basic booting process of the operating system. This activates the multimedia device corresponding to the pressed option button. In the preferred embodiment, the data storage also stores a program image file index in addition to the program image files. The program file index stores the starting addresses and file size of all the program image files.

Owner:MITAC TECH CORP

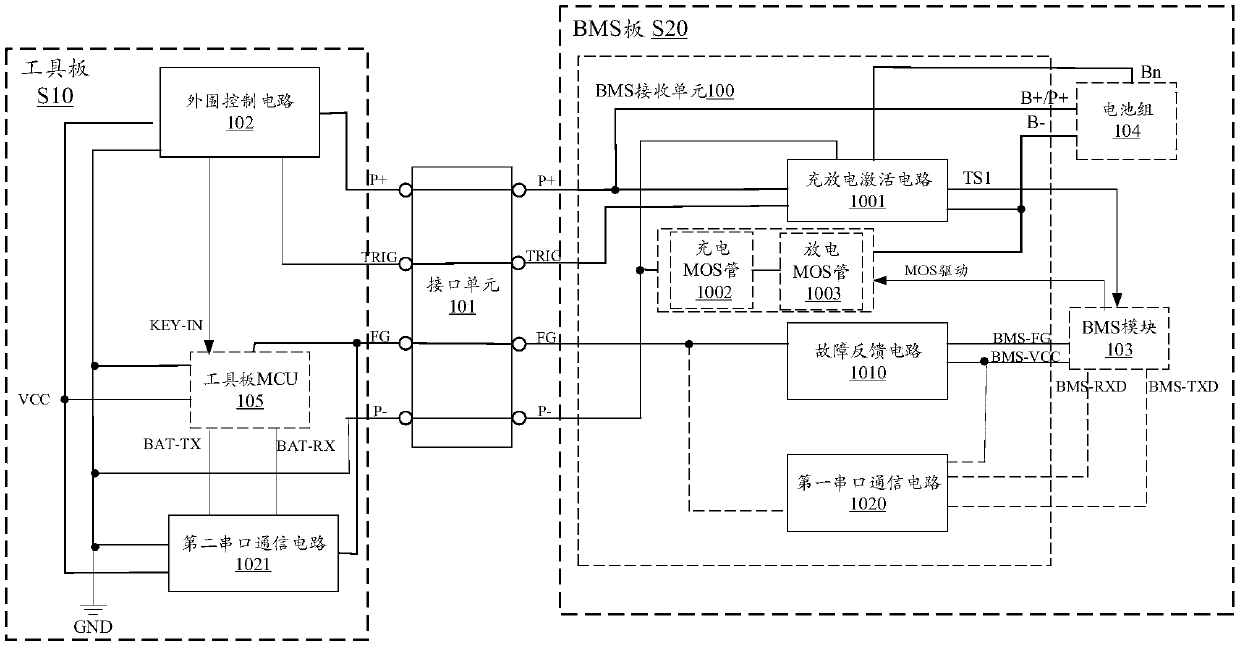

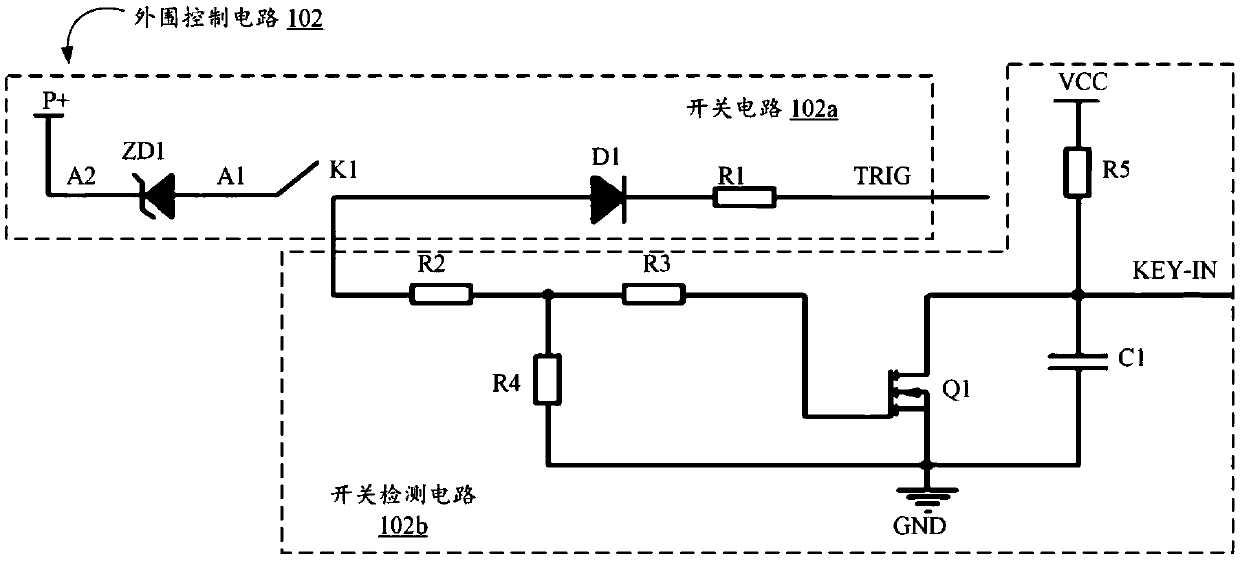

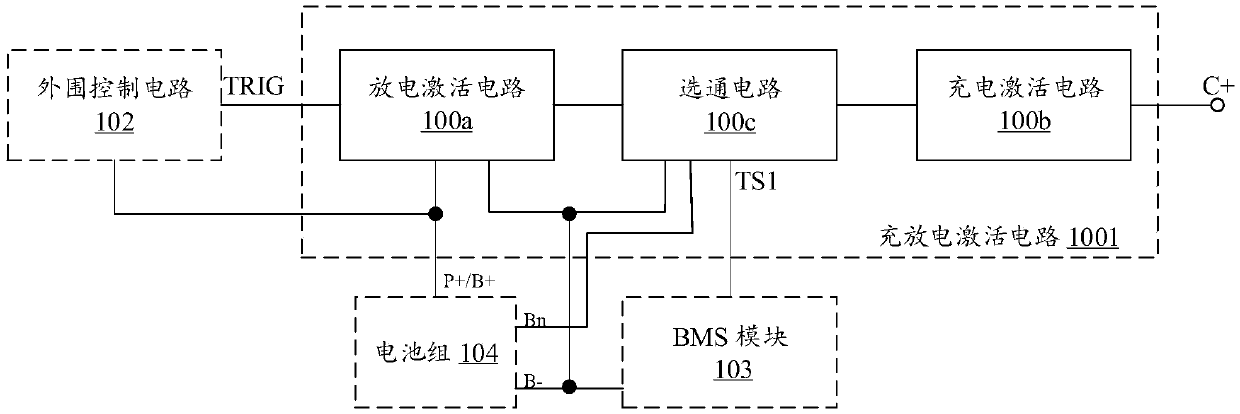

Activation circuit

PendingCN110867911ASimple structureFast activationElectric powerArrangements for several simultaneous batteriesHemt circuitsControl theory

The embodiment of the invention provides an activation circuit. In the embodiment of the invention, the activation circuit comprises a BMS receiving unit, an interface unit and a peripheral control circuit, wherein the BMS receiving unit is electrically connected with the BMS module of the battery pack and is electrically connected with the peripheral control circuit through the interface unit, and the circuit structure is simple. Based on the simple activation circuit, the BMS receiving unit can receive the trigger signal provided by the peripheral control circuit through the interface unit,and perform charging and discharging management on the BMS module of the battery pack according to the trigger signal. Due to the fact that the activation circuit is simple in structure, a complex response mechanism can be avoided, and the activation speed of the BMS can be increased.

Owner:TIANKE INTELLIGENT TECH CO LTD

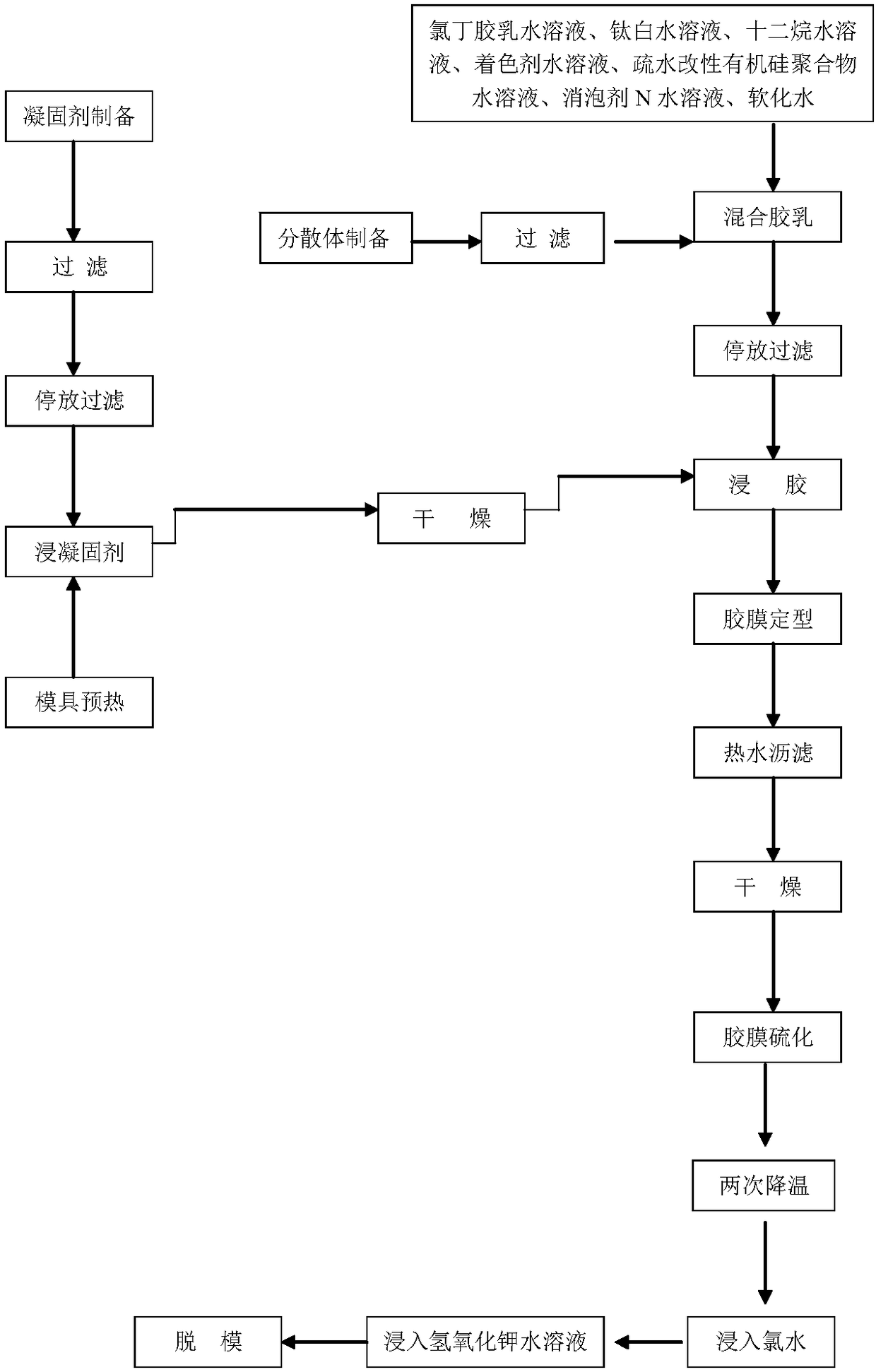

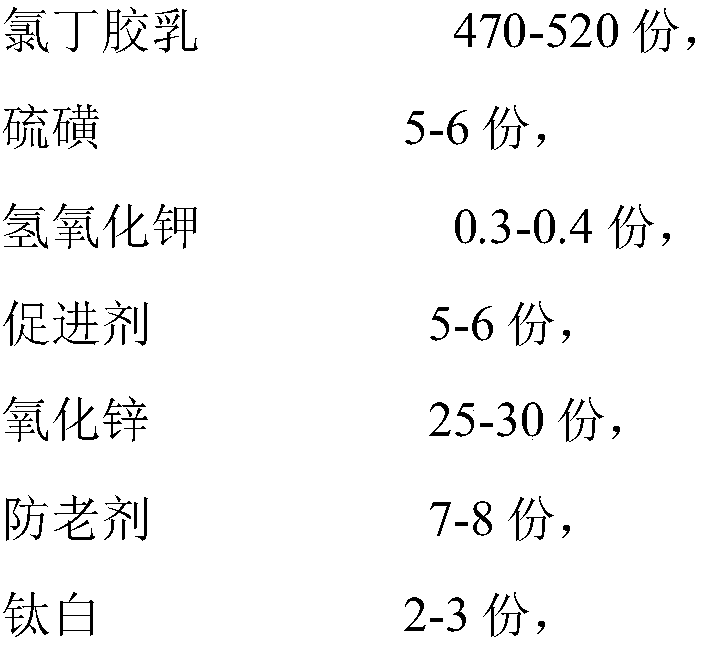

Neoprene medical glove and manufacturing method thereof

The invention discloses a neoprene medical glove, which comprises the following components in parts by weight: 470 to 520 parts of neoprene latex, 5 to 6 parts of sulfur, 0.3 to 0.4 part of potassiumhydroxide, 5 to 6 parts of promoter, 25 to 30 parts of zinc oxide, 7 to 8 parts of anti-aging agent, 2 to 3 parts of titanium dioxide, 1 to 2 parts of dodecane, 3 to 3.5 parts of coloring agent, 1 to1.2 parts of hydrophobic modified organic silicon polymer, 1 to 2 parts of antifoaming agent N, and 510 to 650 parts of softened water. The medical glove has a good anti-aging performance and tensilestrength and prevents the allergy, and the safety of the medical glove is guaranteed.

Owner:BEIJING REAGENT LATEX PRODS

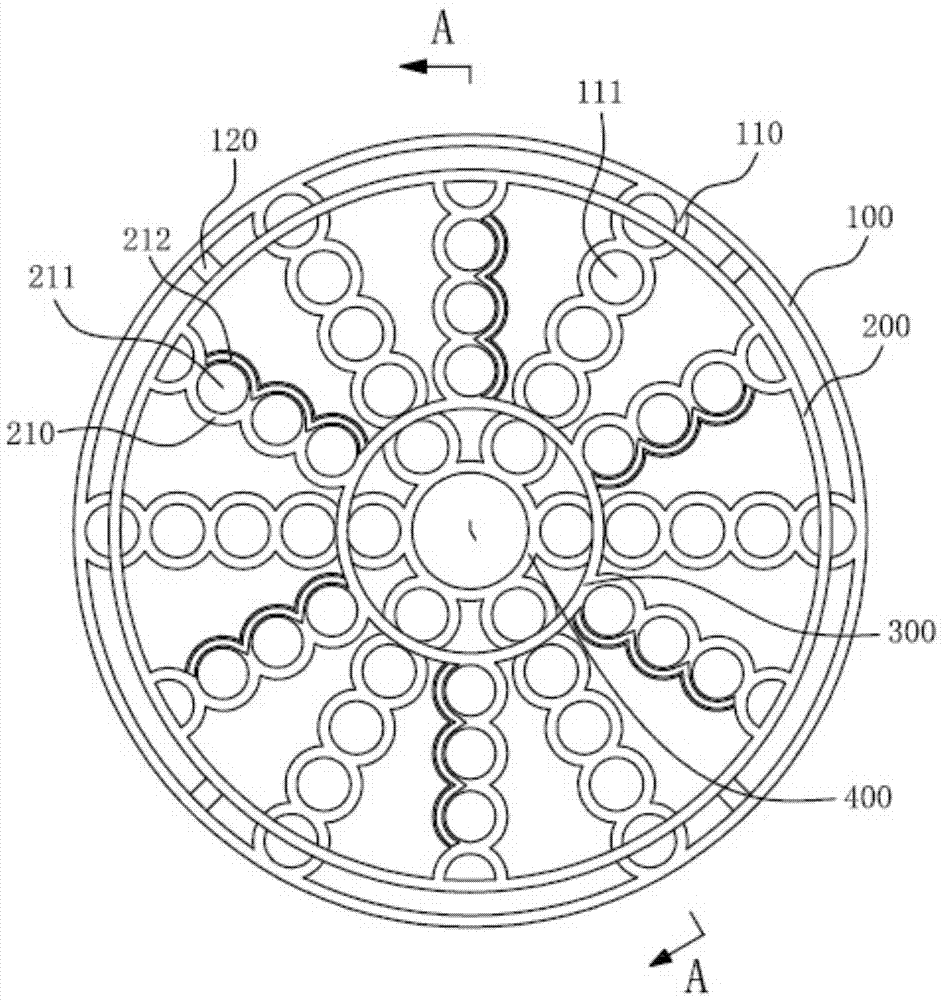

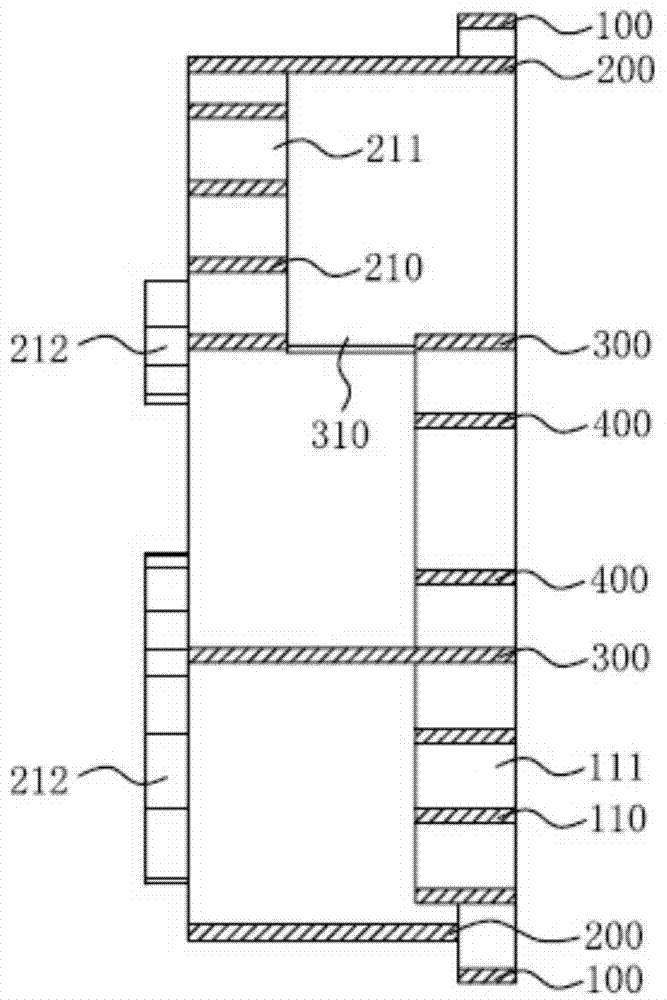

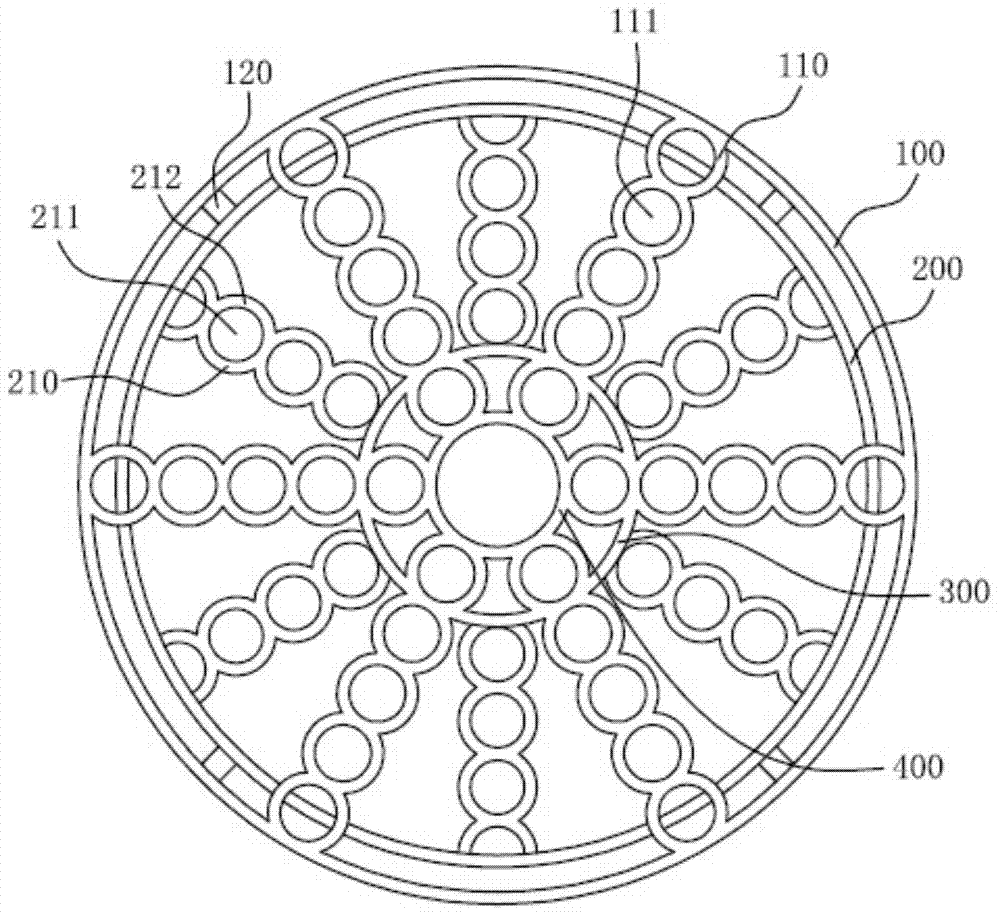

Engine combustion-supporting device

InactiveCN104329192ACompact structureImprove connection strengthFuel re-atomisation/homogenisationMachines/enginesCombustionHydrogen

The invention discloses an engine combustion-supporting device. The engine combustion-supporting device comprises an outer circular ring, and an outer sleeve, an inner sleeve and an inner circular ring which are coaxial with the outer circular ring, wherein the inner circular ring is located in the inner sleeve; the inner sleeve is located in the outer sleeve; the outer side of the outer sleeve winds around the outer circular ring; a plurality of strips of first flow guide belts are connected between the outer sleeve and the inner sleeve; a plurality of strips of second flow guide belts are connected between the outer circular ring and the inner circular ring. According to the engine combustion-supporting device disclosed by the utility model, the air activation speed is accelerated and the combustion-supporting capability of hydrogen and oxygen molecules in the air is improved; the combustion rate of fuel oil is improved and the combustion-supporting effect is generated; the aims of saving energy and protecting the environment, and improving the combustion efficiency are realized; meanwhile, the combustion-supporting device has the advantages of compact structure, high connection strength and high reliability; the service life is effectively prolonged and the combustion-supporting device is convenient for a user to use.

Owner:姚海宁 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com