Method for producing activated carbon by thermally activating coal tar dreg/ sludge fermentation body by using microwaves

A technology of coal tar and thermal activation, which is applied in the field of environmentally friendly activated carbon, can solve problems such as difficult solid-liquid separation, and achieve the effects of easy control, uniform heating, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

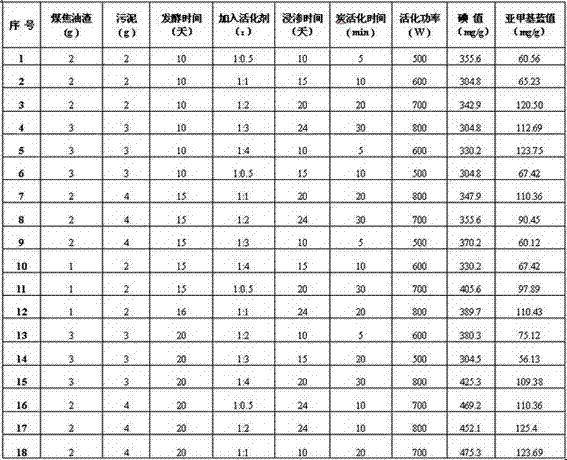

[0023] Below is the specific embodiment of coal tar residue / sludge production gac:

[0024]

[0025] According to above-mentioned each embodiment parameter and can produce the product that reaches the object of the present invention according to following process step. Embodiments of the present invention can be practiced, and the present invention is not limited to these embodiments.

[0026] The technical solution of the present invention is: a method for preparing activated carbon by microwave heat activating coal tar residue / sludge fermentation mixture raw material, which first crushes and grinds coal tar residue to more than 200 meshes, and then mixes it with sludge Aerobic fermentation for 10-20 days, then add 0.5-4 times the mass of zinc chloride as an activator to the mixed fermenter, soak at 70-80°C for 12-24 hours, and finally place it under N 2 The charcoal is activated in a microwave carbonization furnace under protected conditions for 30-120 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com