Patents

Literature

207 results about "Microprocessor controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

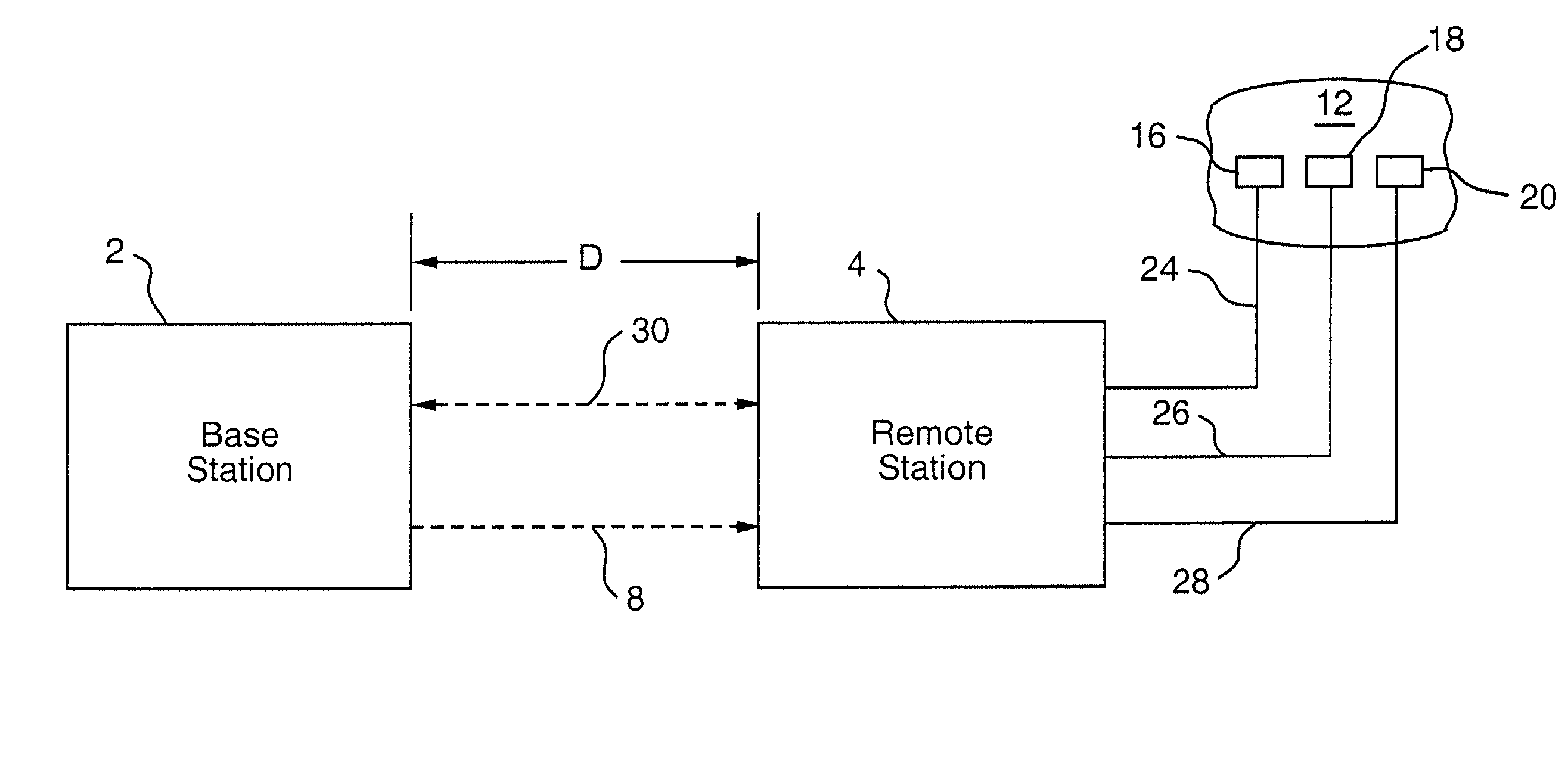

Apparatus for energizing a remote station and related method

InactiveUS6615074B2Eliminate needEasy to useElectrotherapyTelemetry/telecontrol selection arrangementsStored energyMiniaturization

Owner:PITTSBURGH UNIV OF

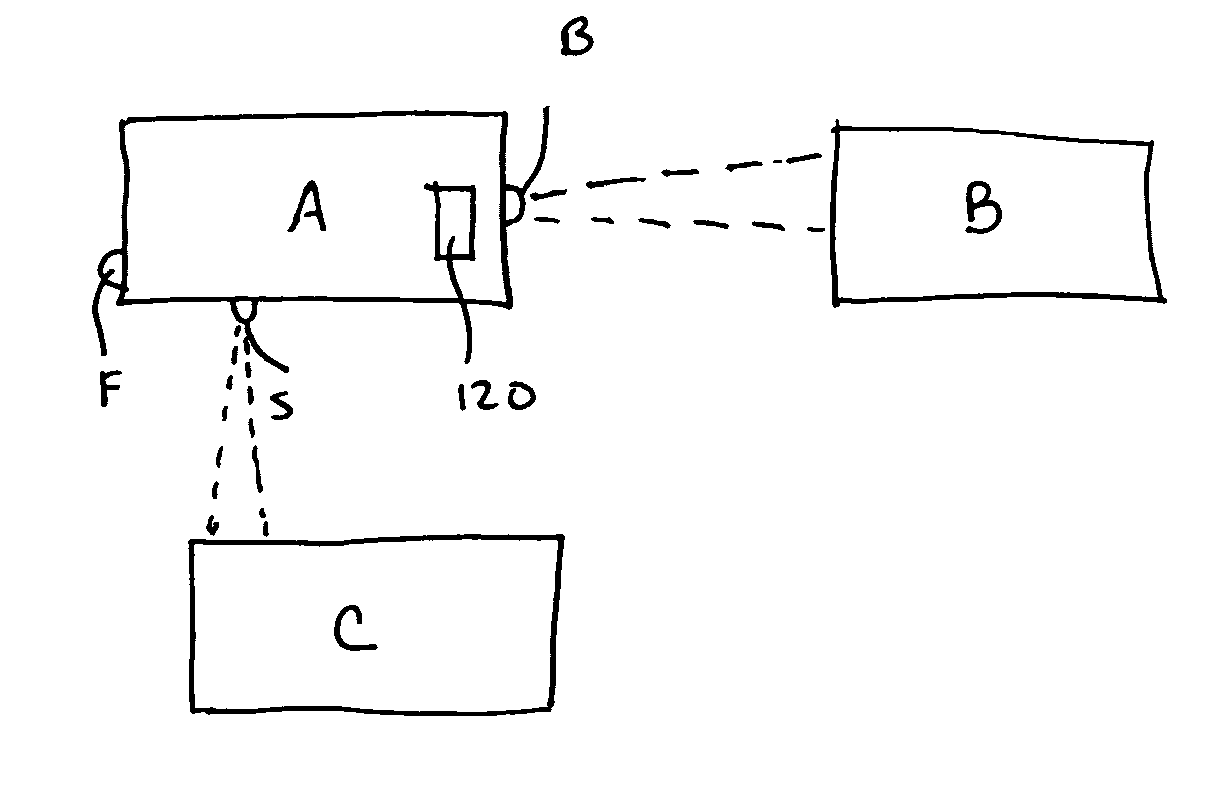

Apparatus for energizing a remote station and related method

InactiveUS6289237B1Eliminate needTelemetry/telecontrol selection arrangementsElectromagnetic wave systemStored energyMicroprocessor controller

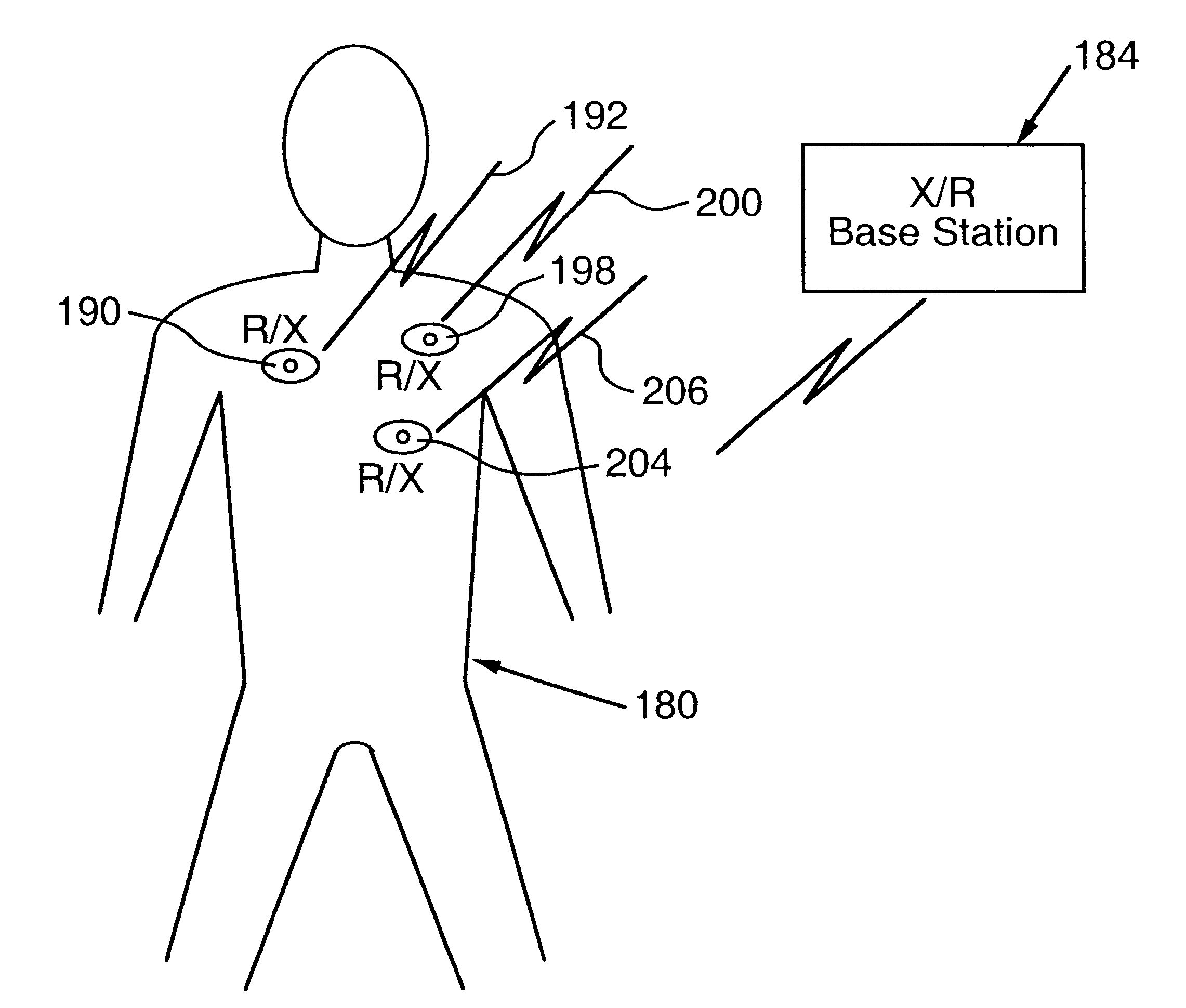

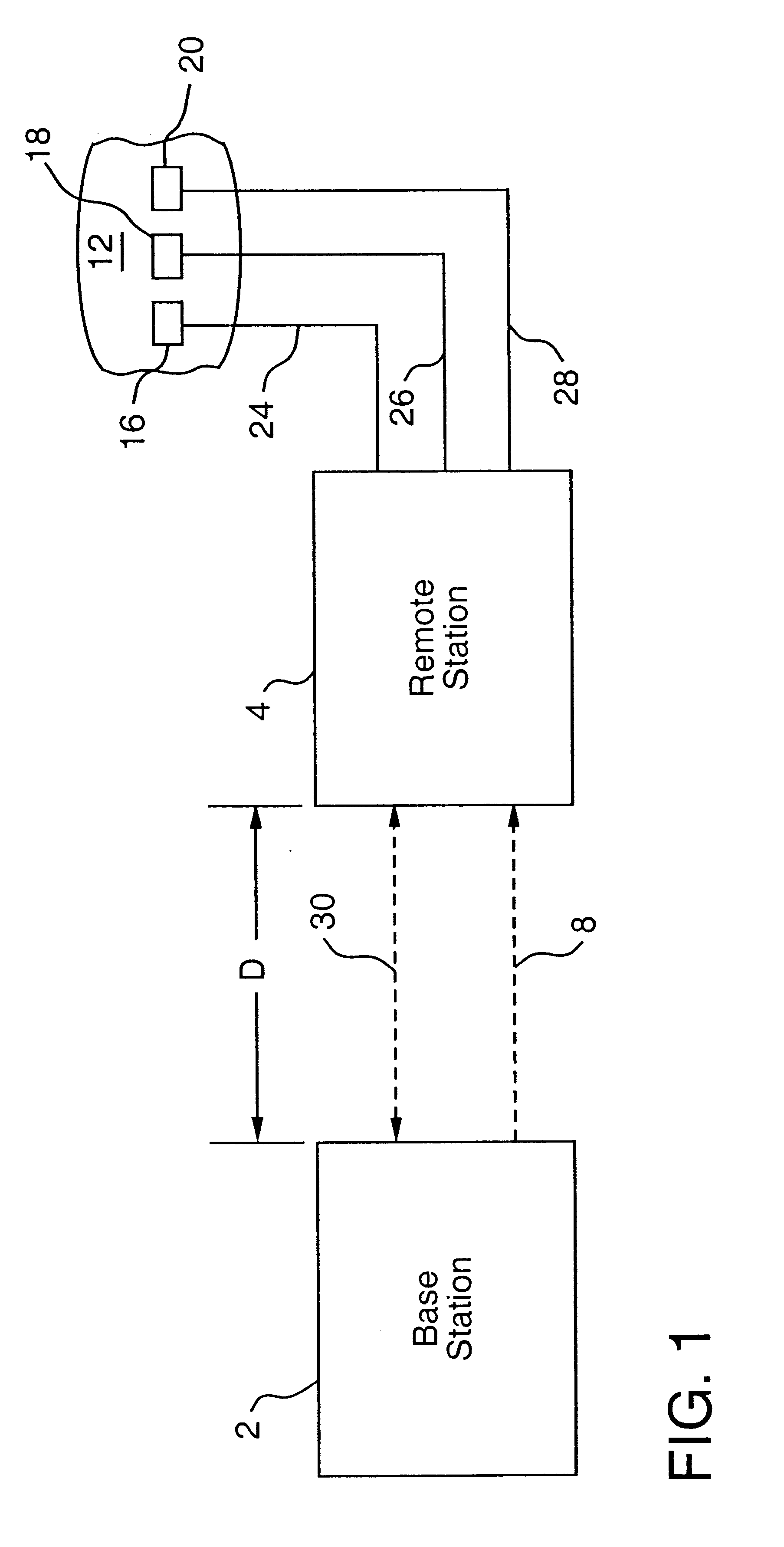

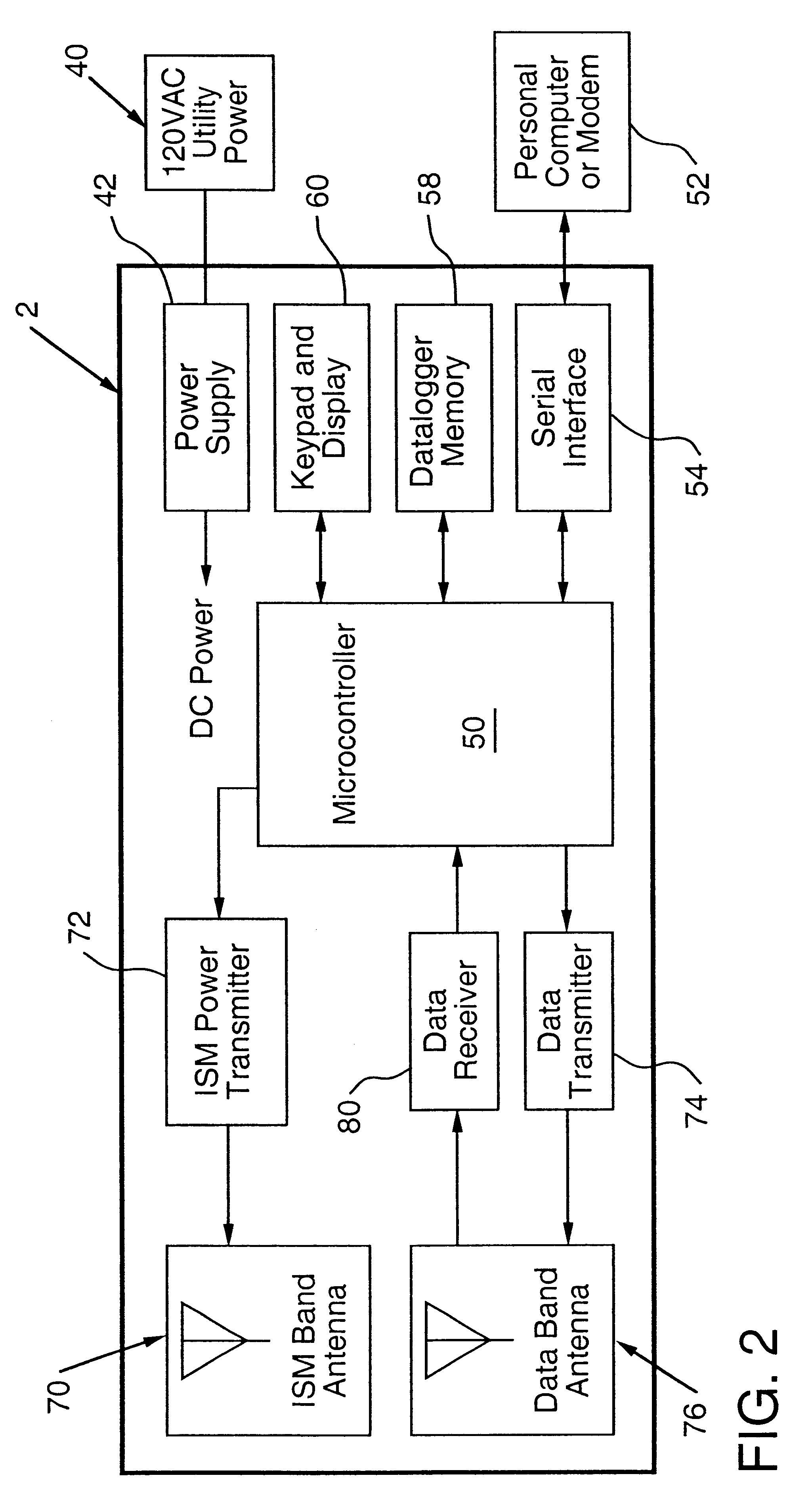

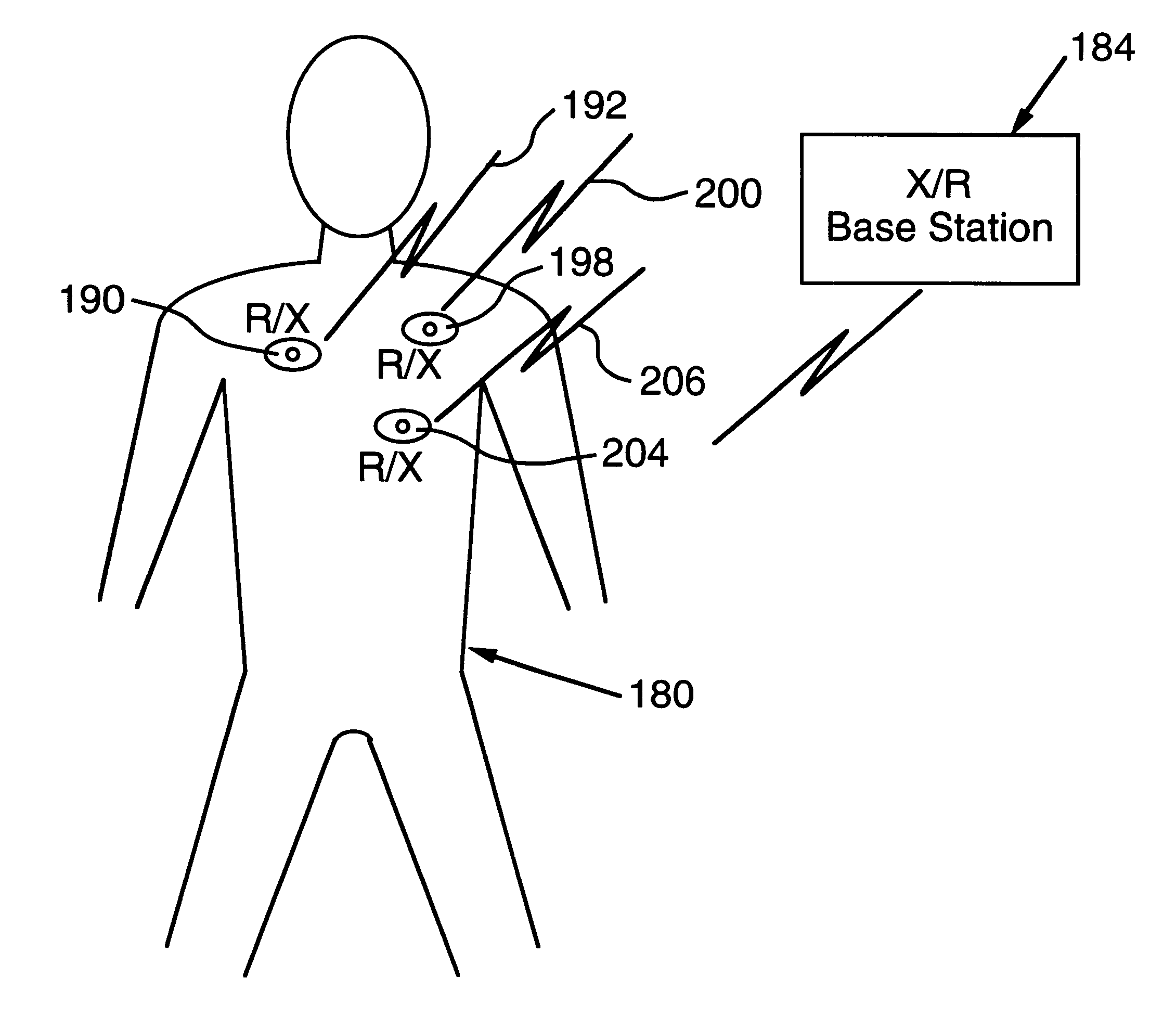

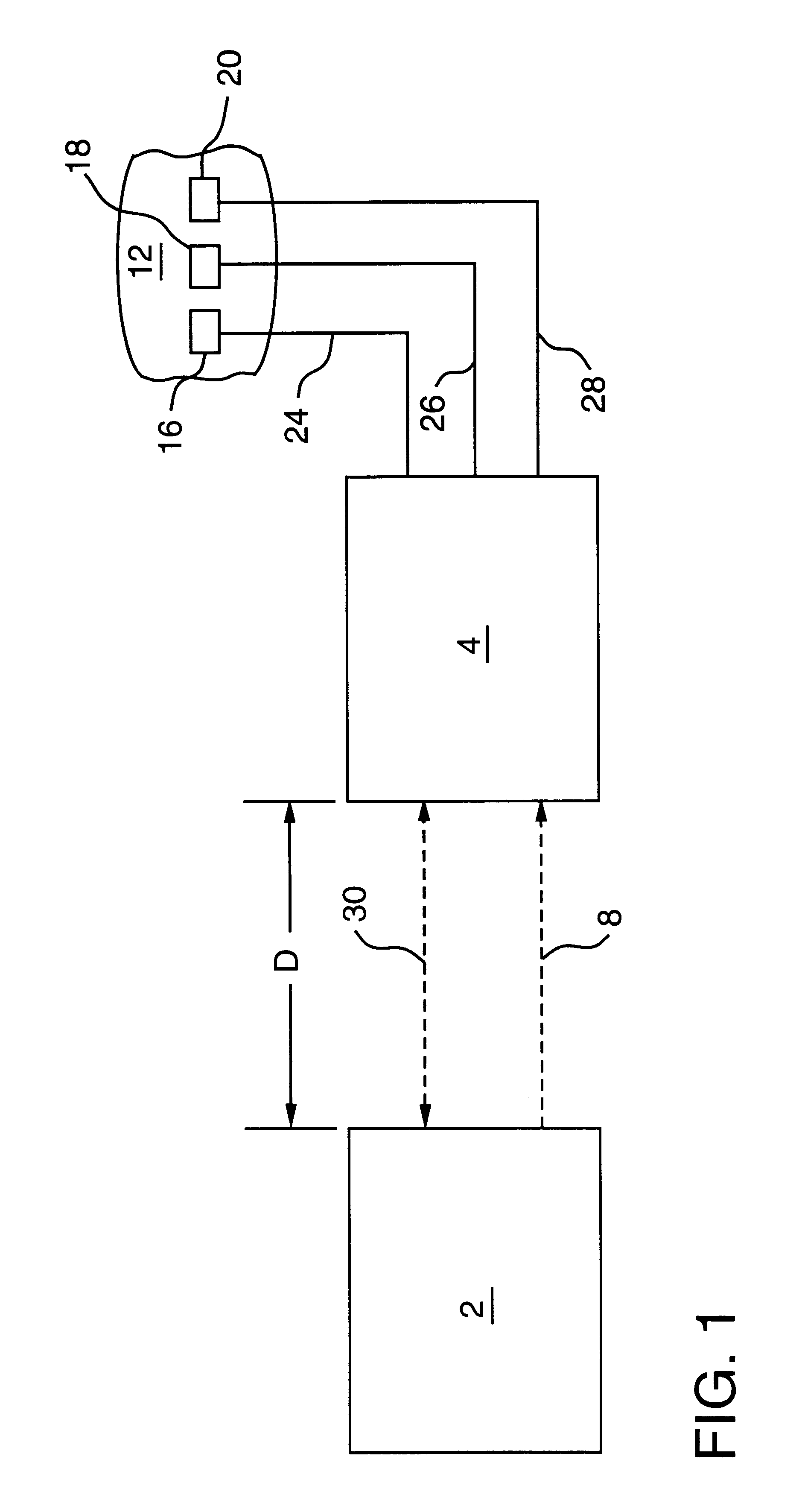

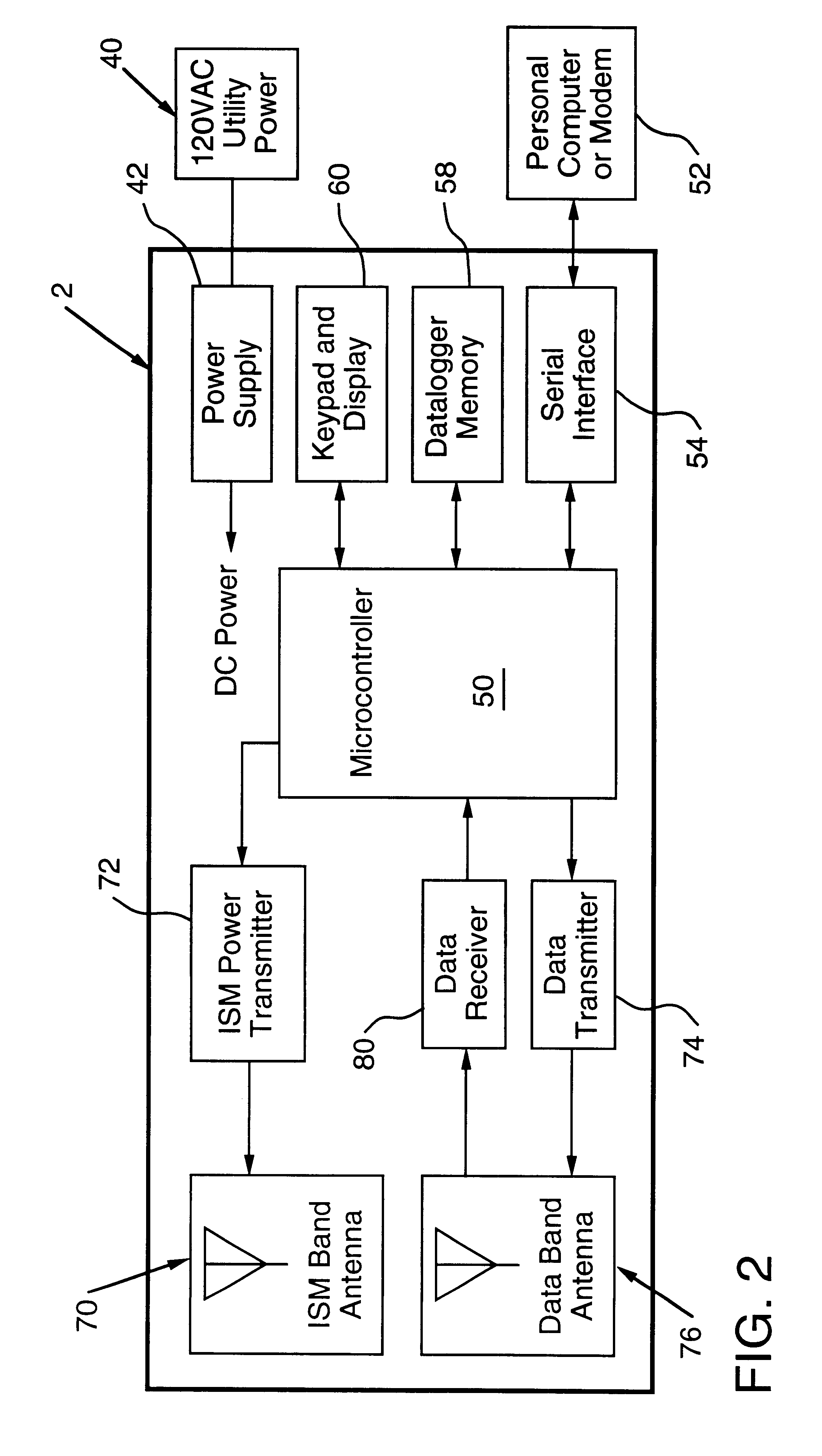

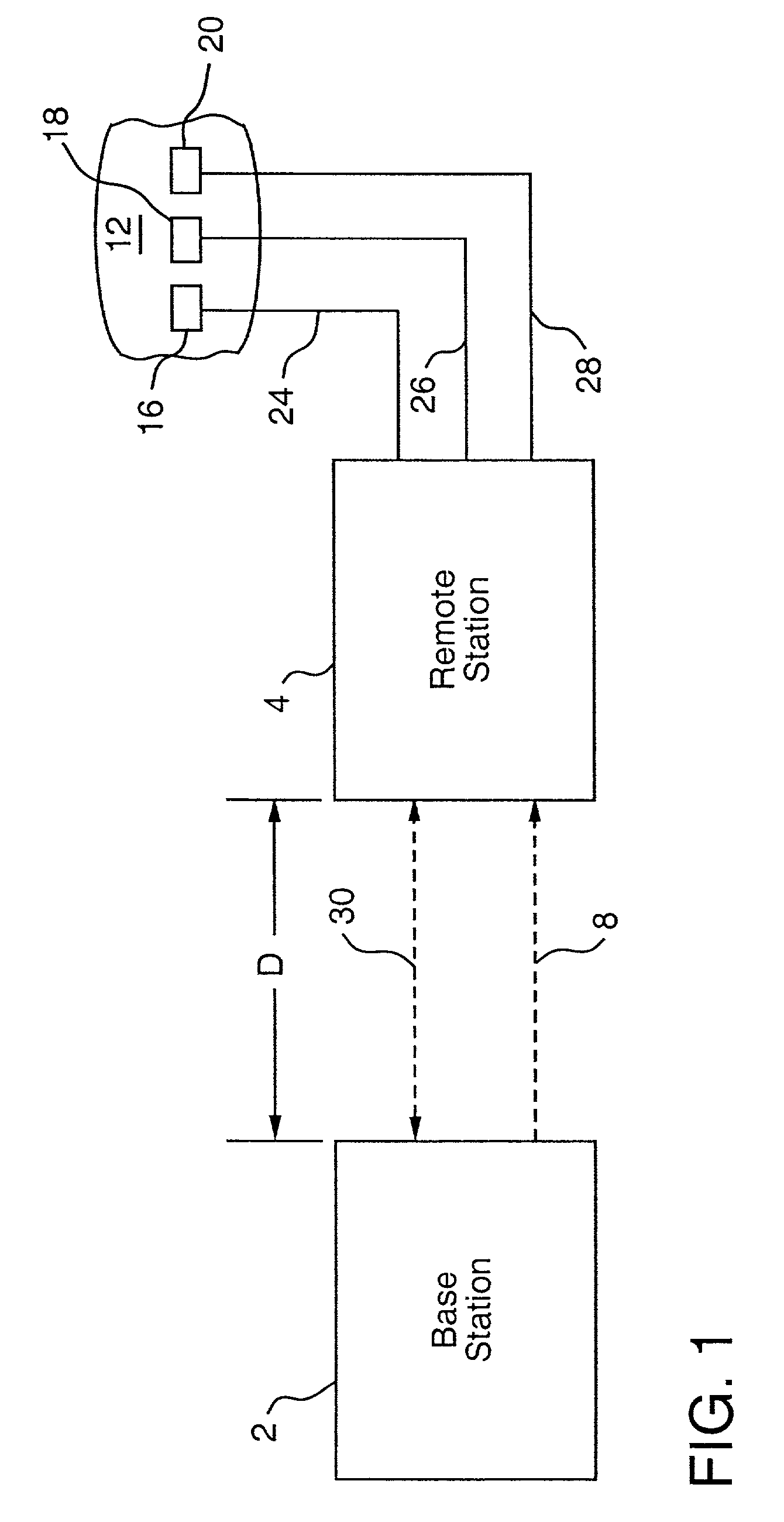

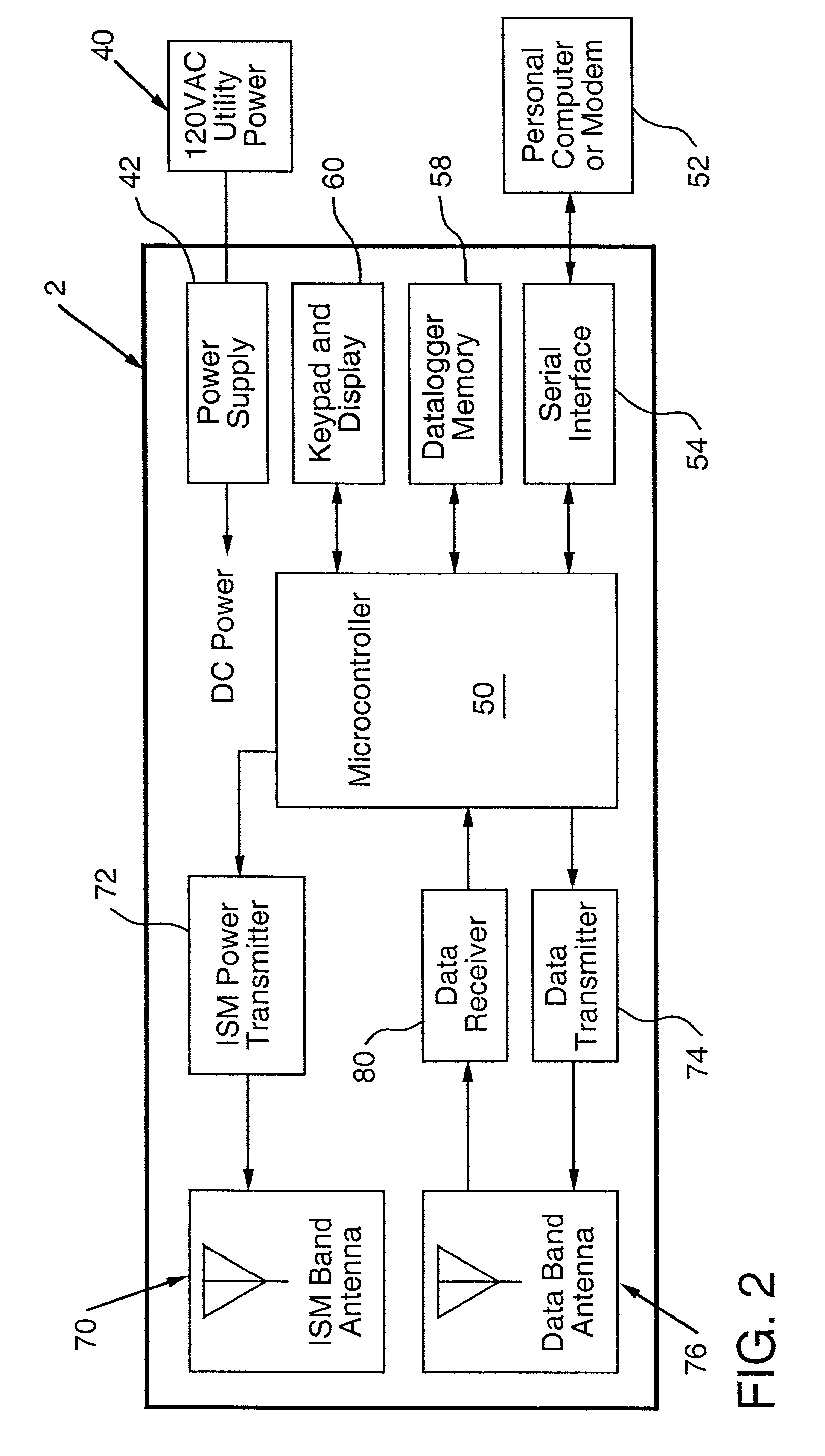

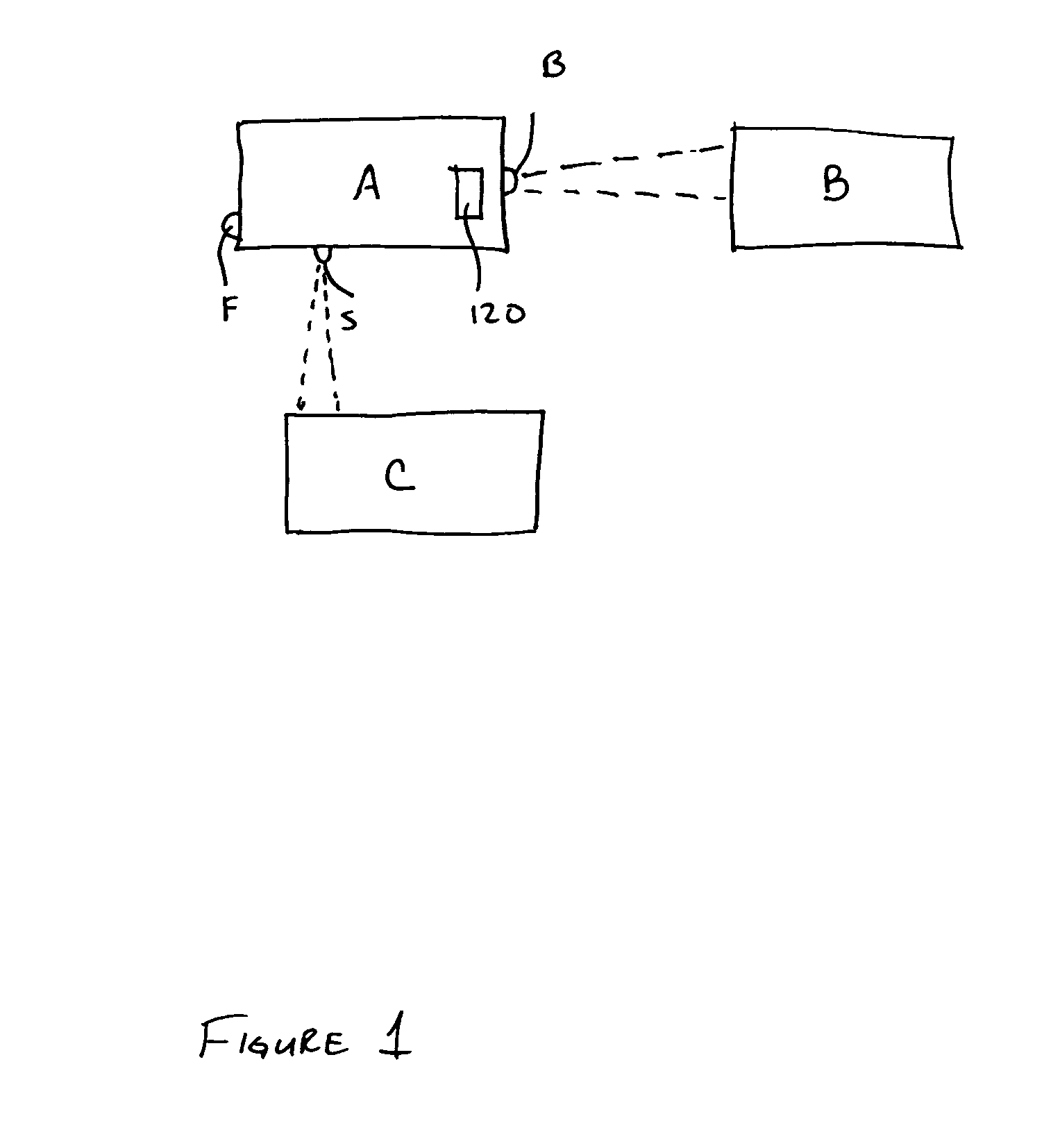

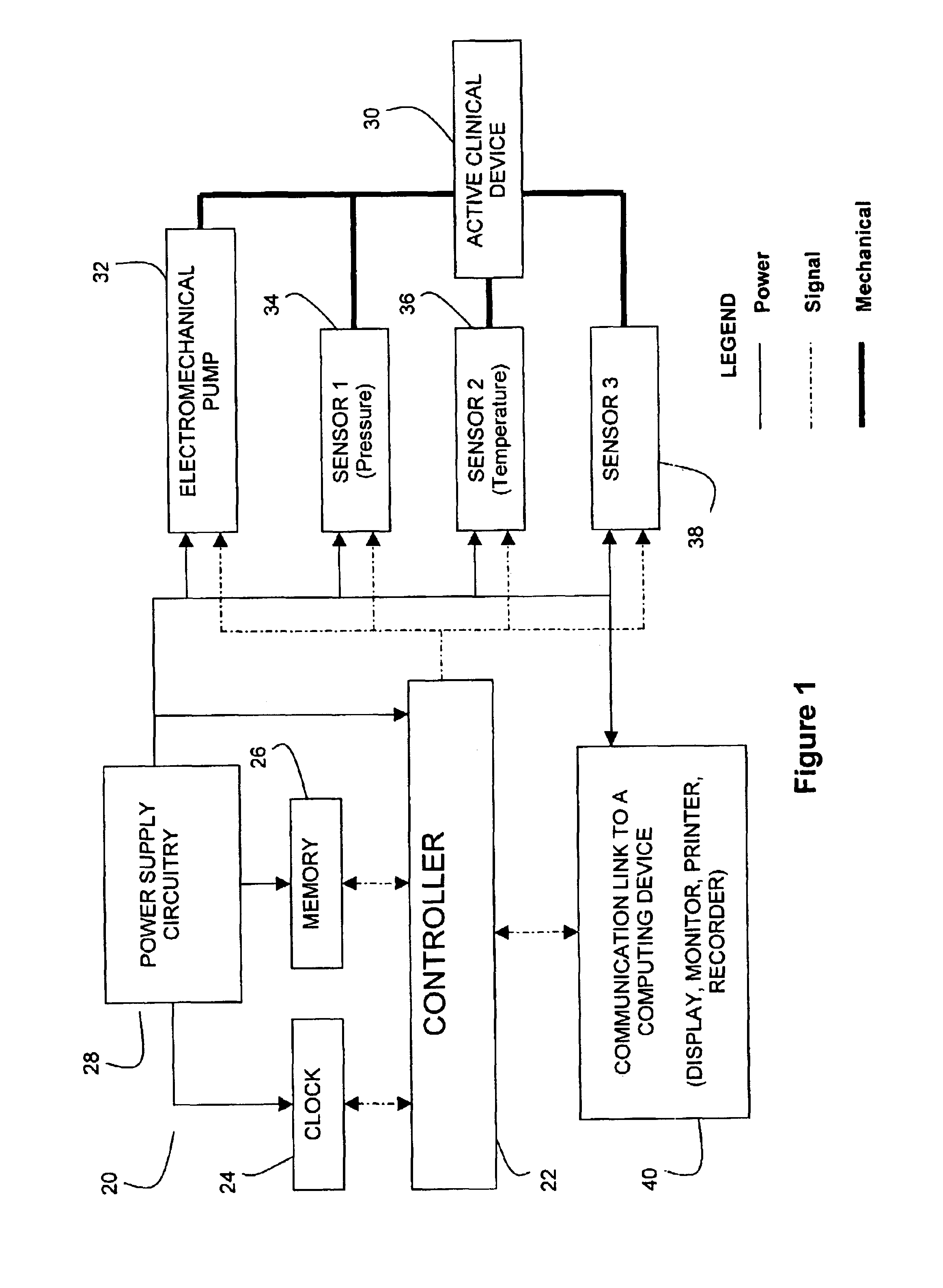

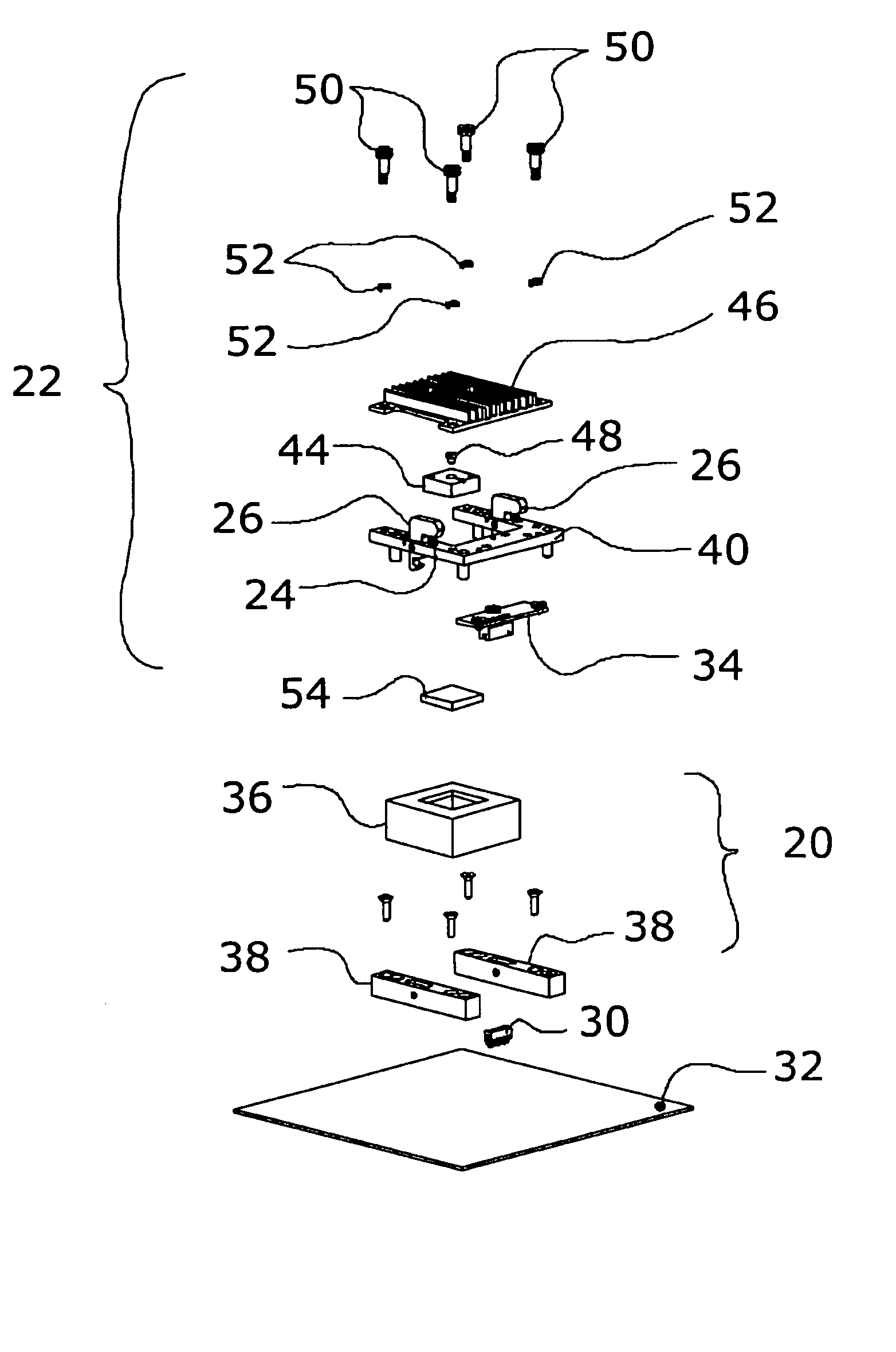

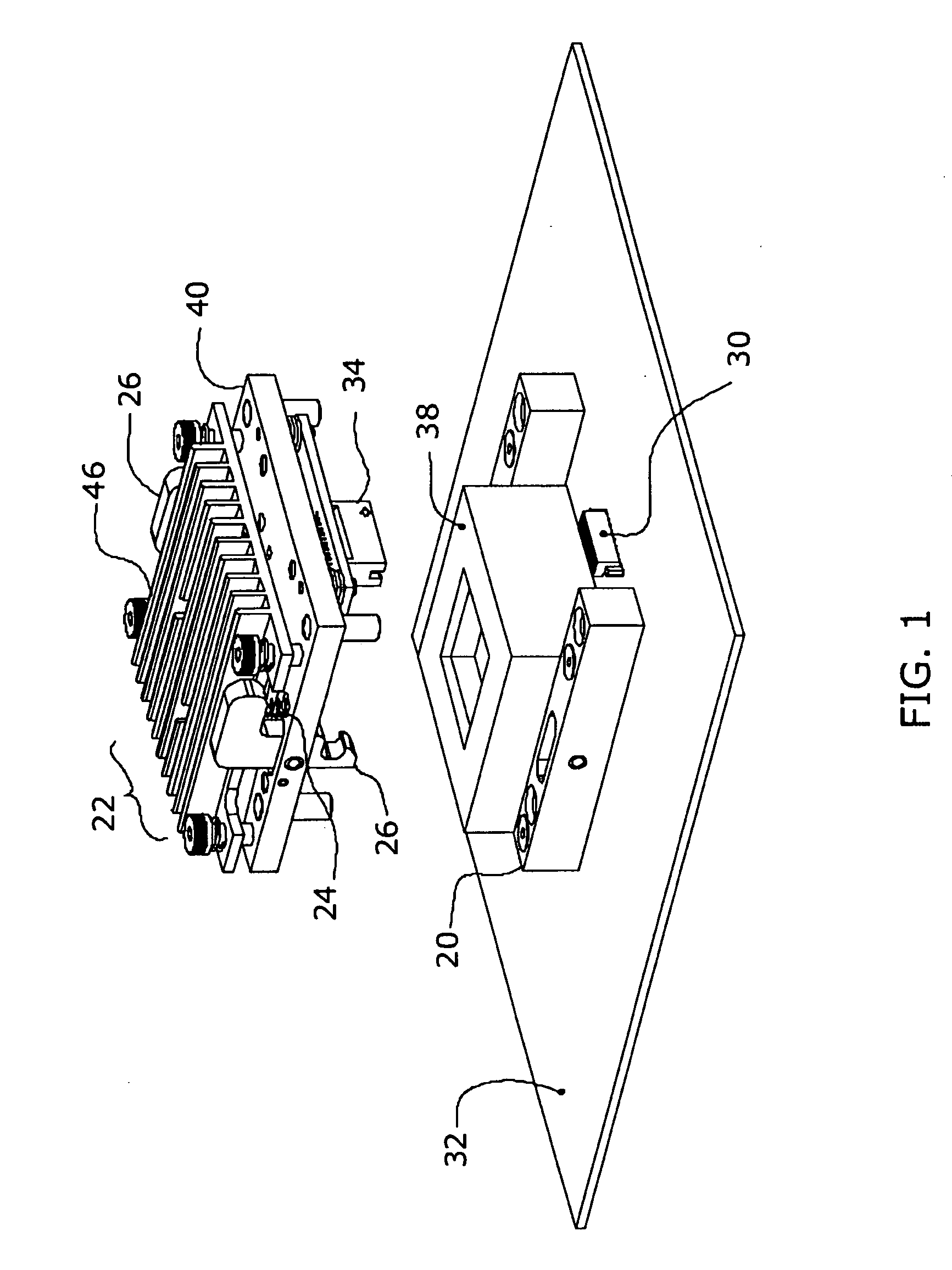

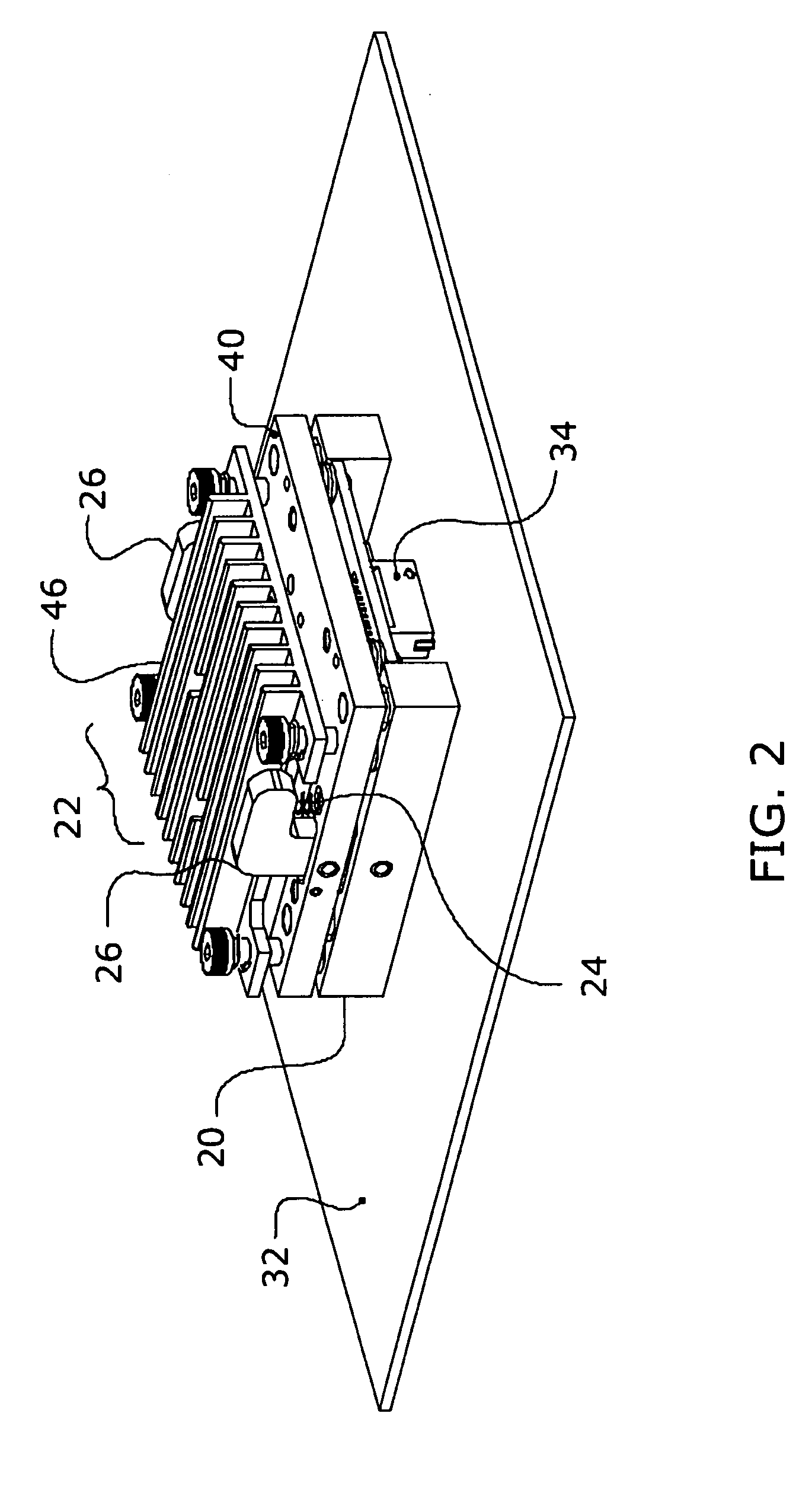

Apparatus for remote interaction with an object of interest includes a remote station for obtaining information from the object of interest, a base station for transmitting energy in space to and communicating with the remote station and the remote station having a conversion device for energizing the remote station responsive to receipt of the transmitted energy. The energy may be of any suitable type including RF power, light, acoustic, magnetic energy or other form of space transmitted or "radiant" energy. The remote station does not have to contain a source of stored energy or a wired connection to a source of energy. The remote station receives the energy transmission and data transmission from the base station and transmits data to the base station. Microprocessor controllers may be provided for the base station and the remote station. The remote station may receive information from sensors and through one or more transponders sequentially communicate information to the base station. An associated method is provided.

Owner:UNIVERSITY OF PITTSBURGH +1

Assessing and/or determining of user authorizations using a transponder, a finger print recognition routine or the like

InactiveUS7523069B1Easy to carryUser identity/authority verificationUnauthorized memory use protectionControl systemEngineering

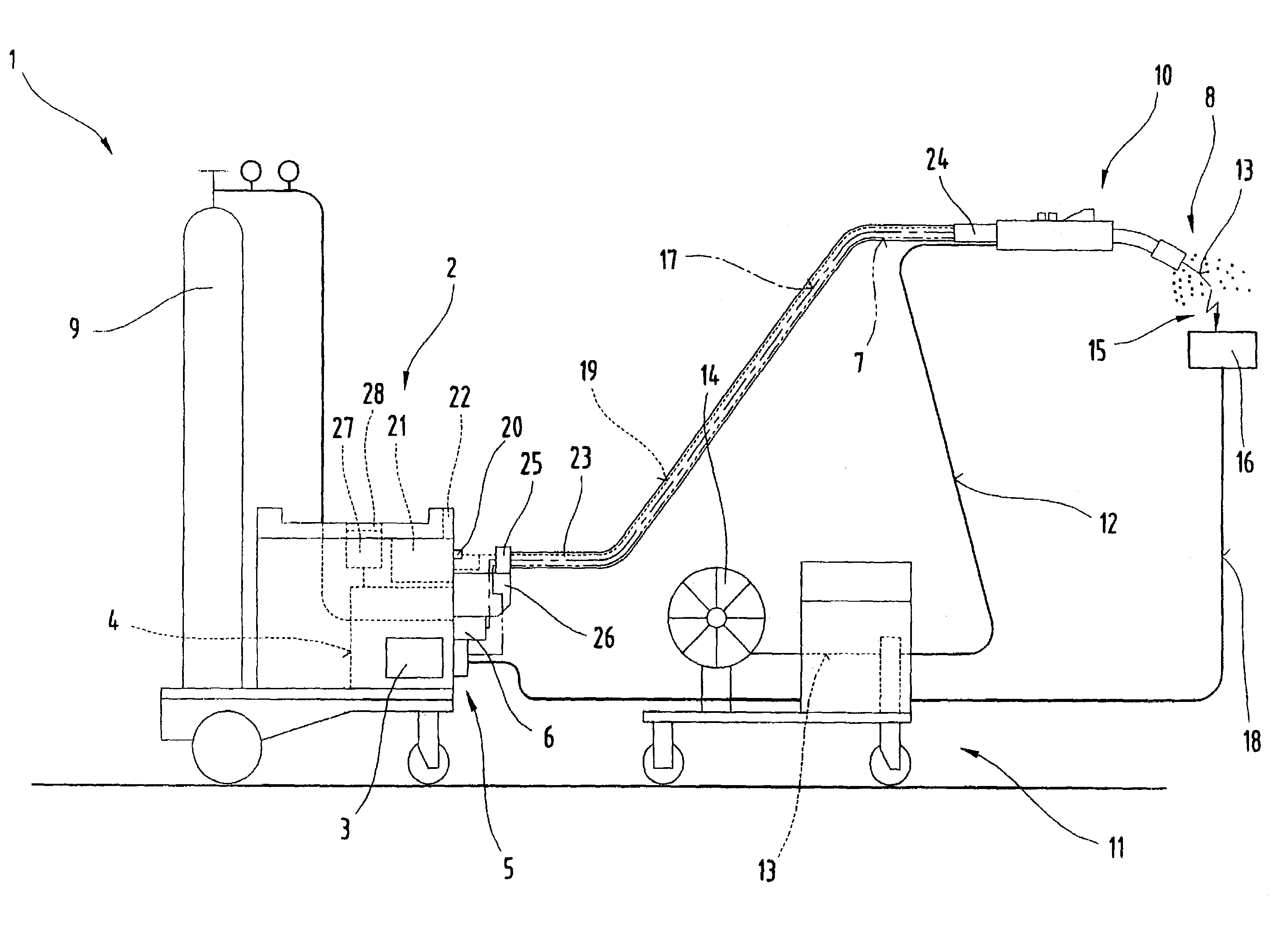

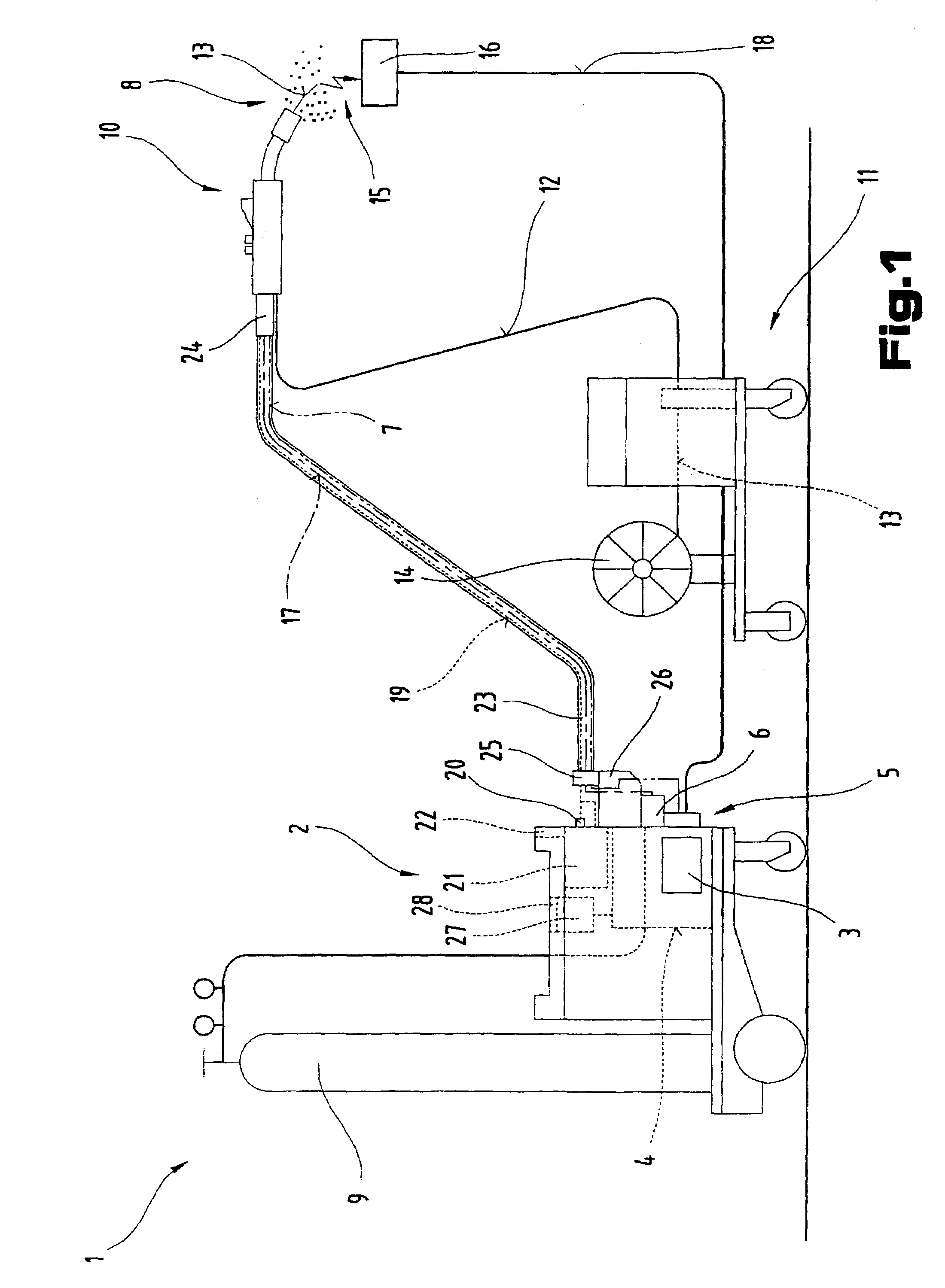

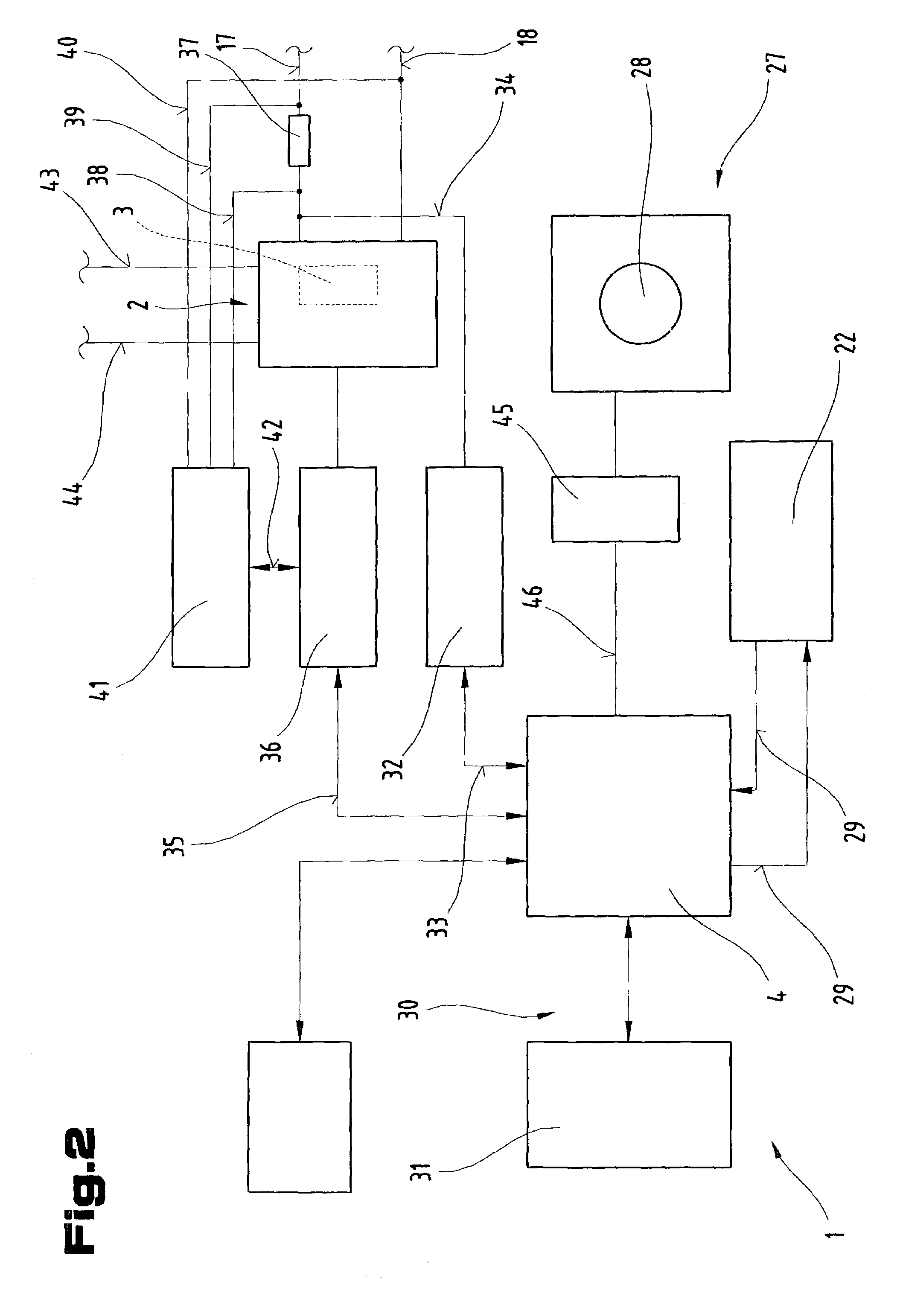

The invention describes a welding device (1) or a current source (2), with a control system (4), preferably comprising a microprocessor controller with a memory unit, a power component (3), in particular a current-inverting source, and additional components such as a welding torch (10), a wire feed device (11), etc., which are connected to the welding device (1) or the current source (2) via appropriate interfaces. An add-on module (27) is connected to the control system (4) or to the current source (2) for identifying a person by means of biometric physical characteristics such as an electronic fingerprint, voice recognition, iris recognition, recognition of a facial shape, recognition of writing, etc. or alternatively a transponder code via a transponder system.

Owner:FRONIUS INTERNATIONAL GMBH

Intelligent dispensing system

ActiveUS7213782B2Improve satisfactionMinimal down timeFilament handlingDomestic applicationsNetwork Communication ProtocolsPulp and paper industry

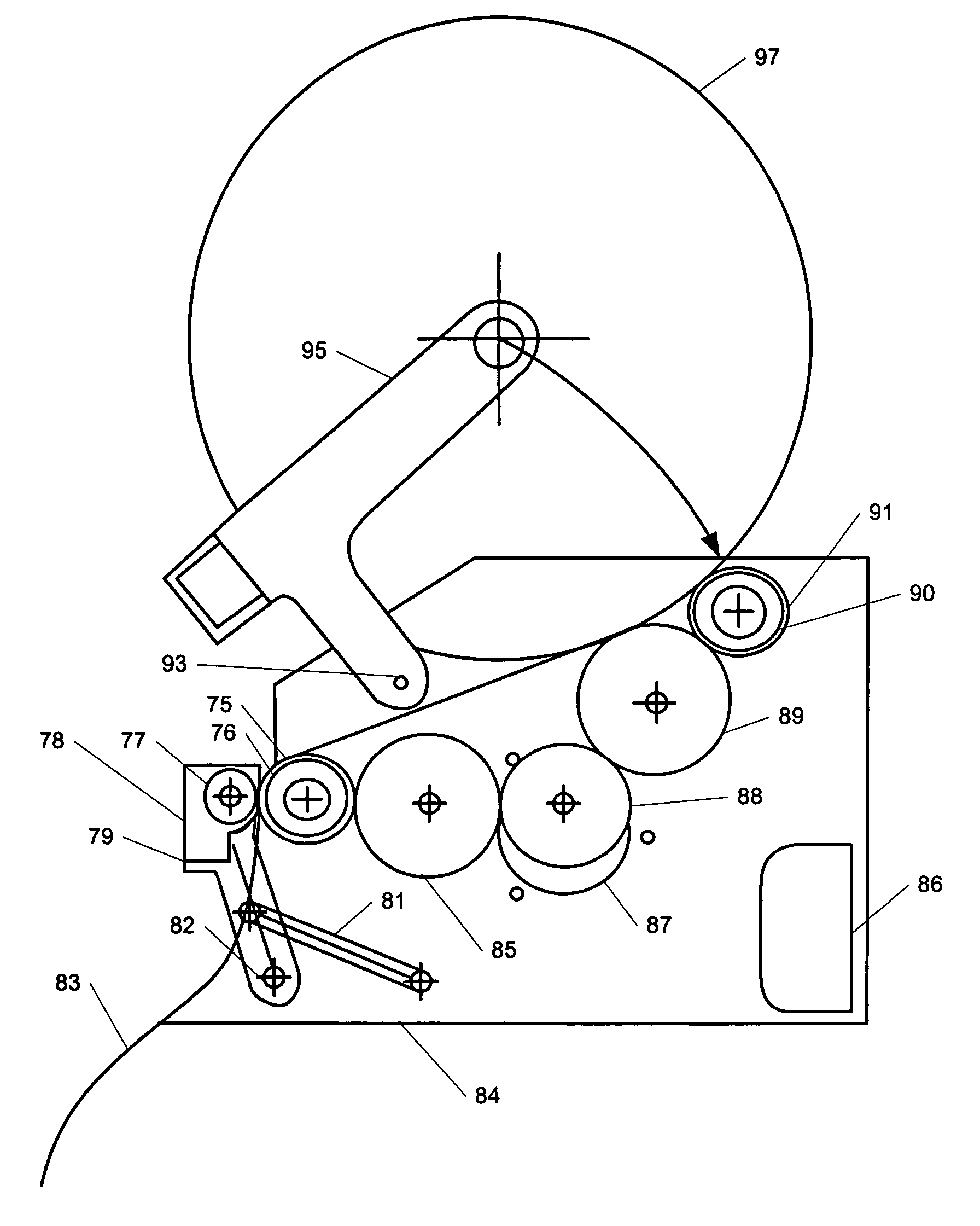

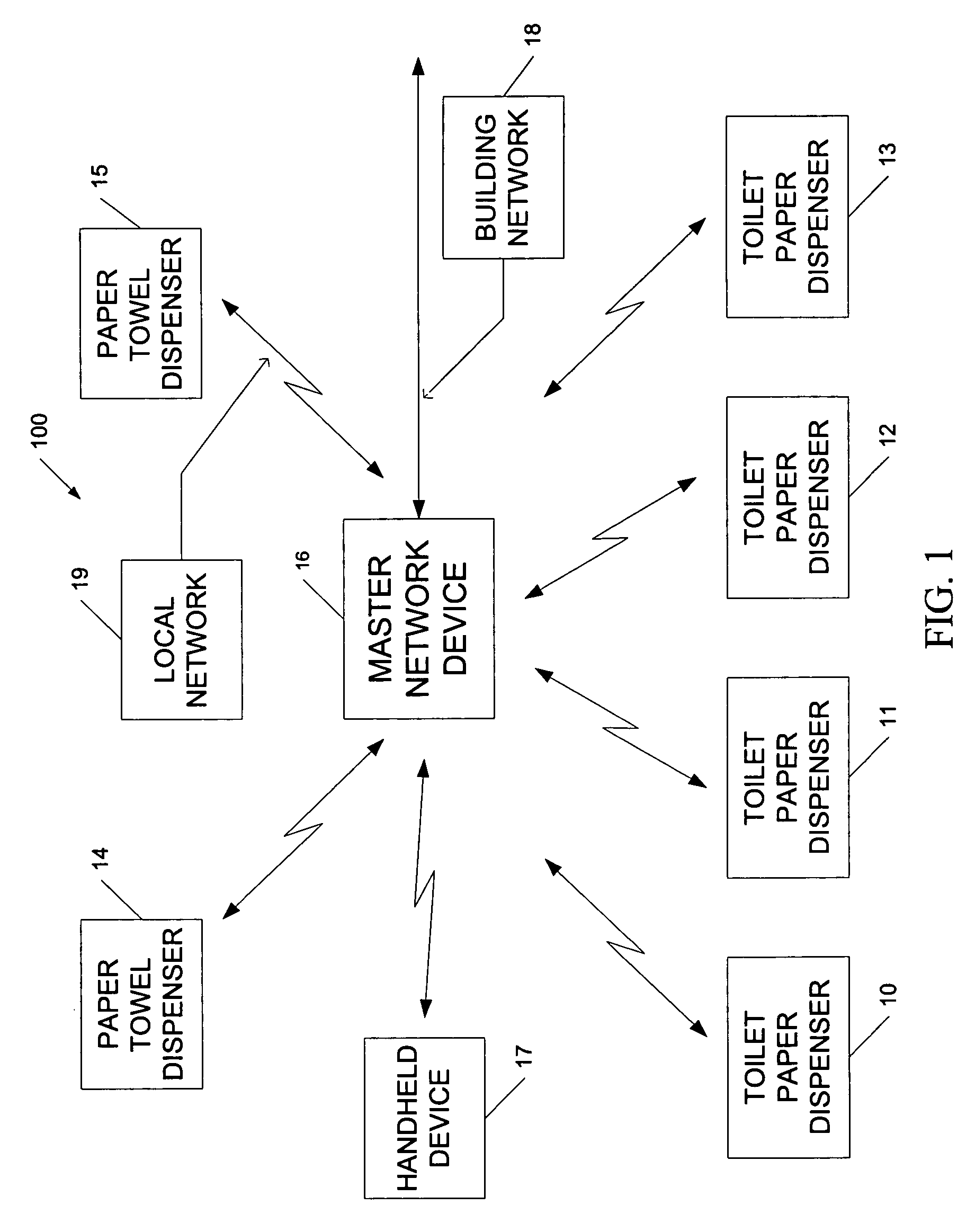

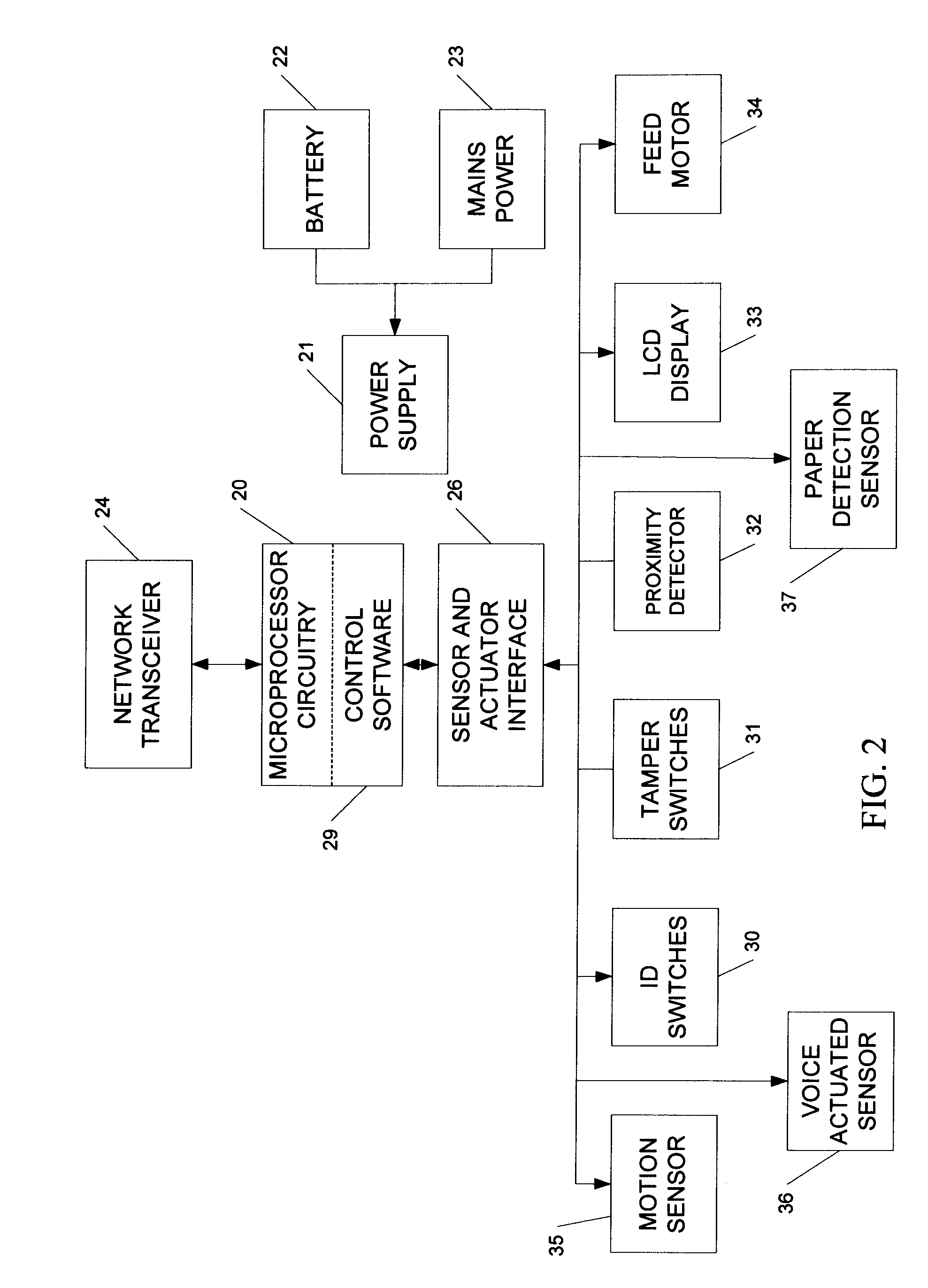

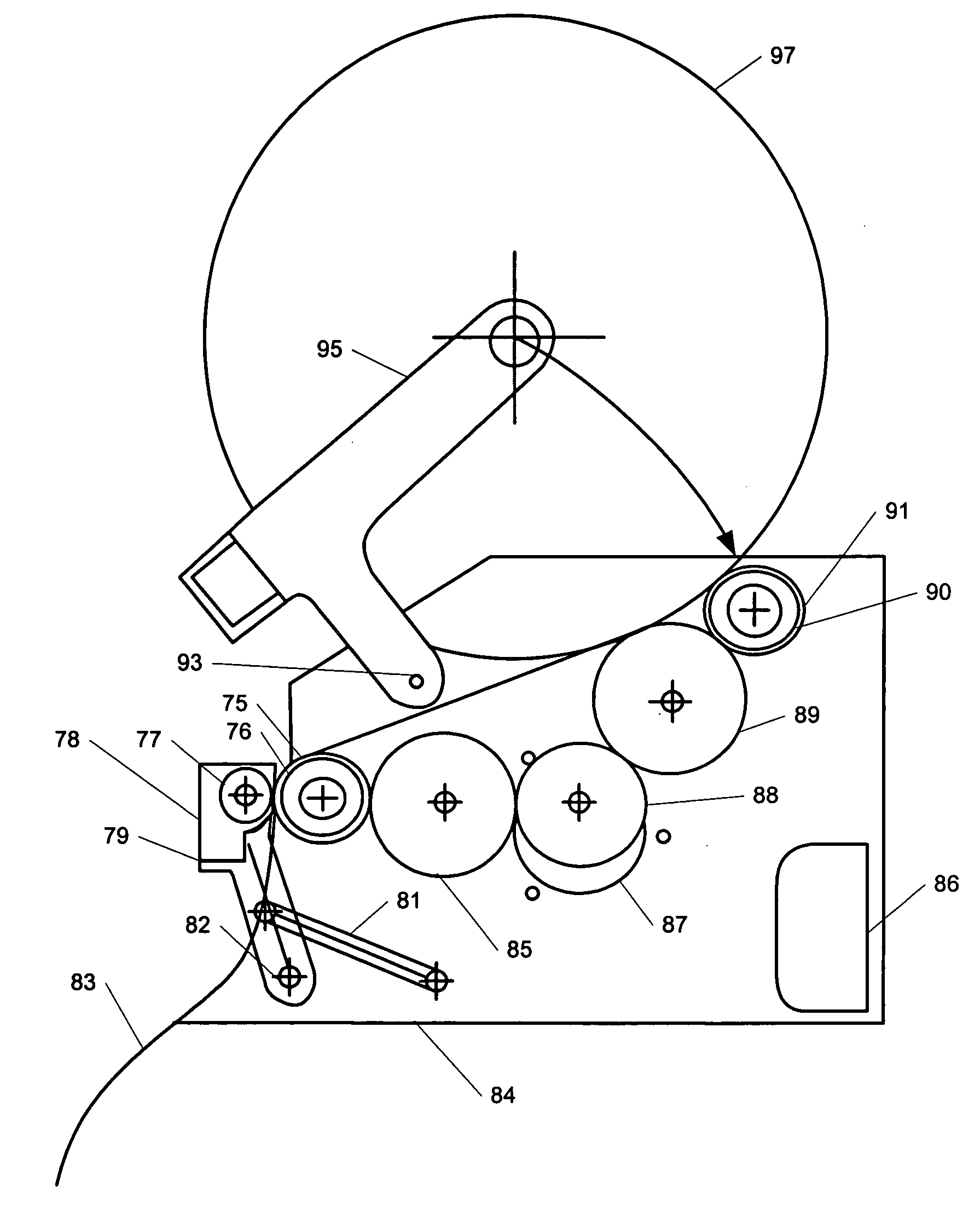

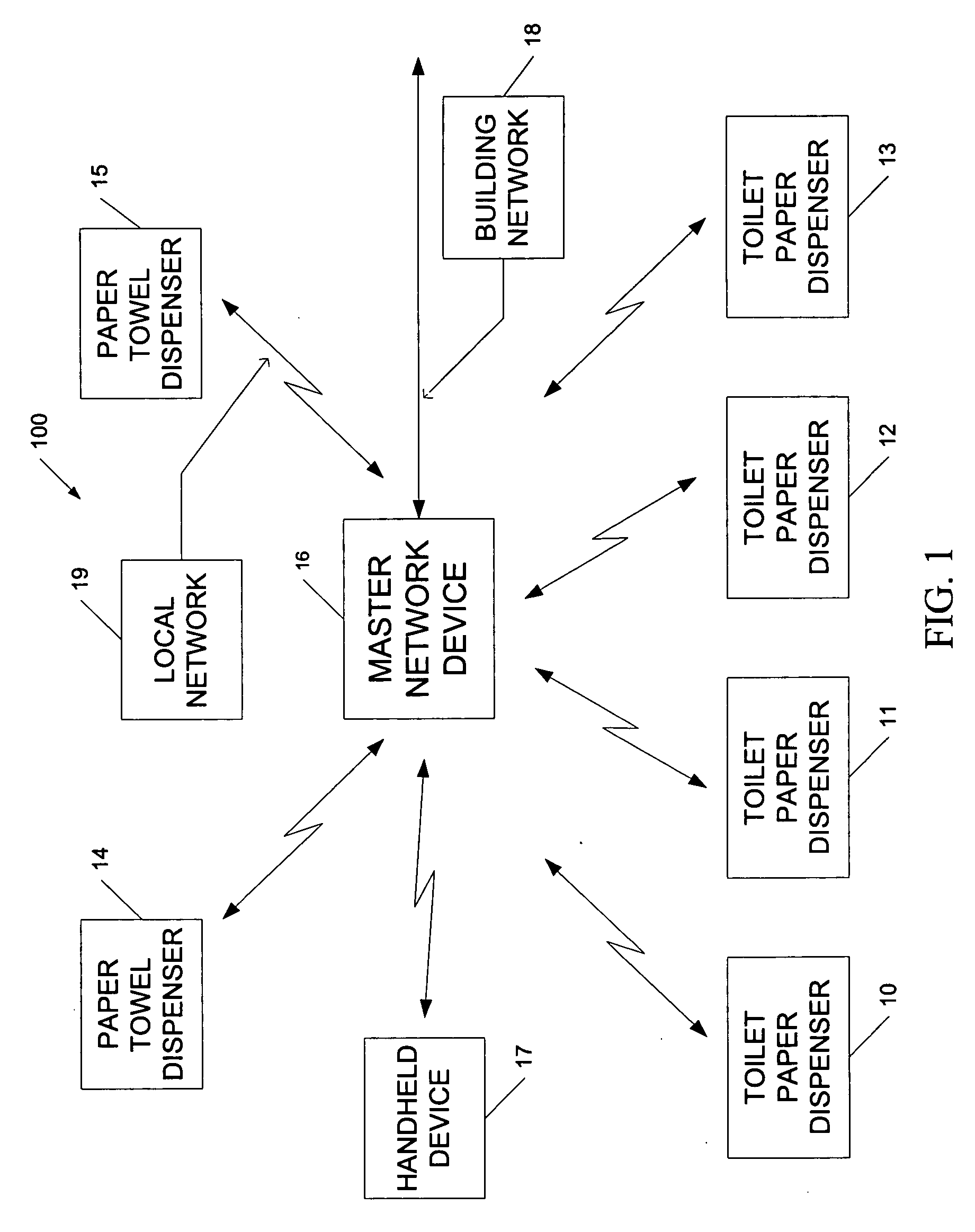

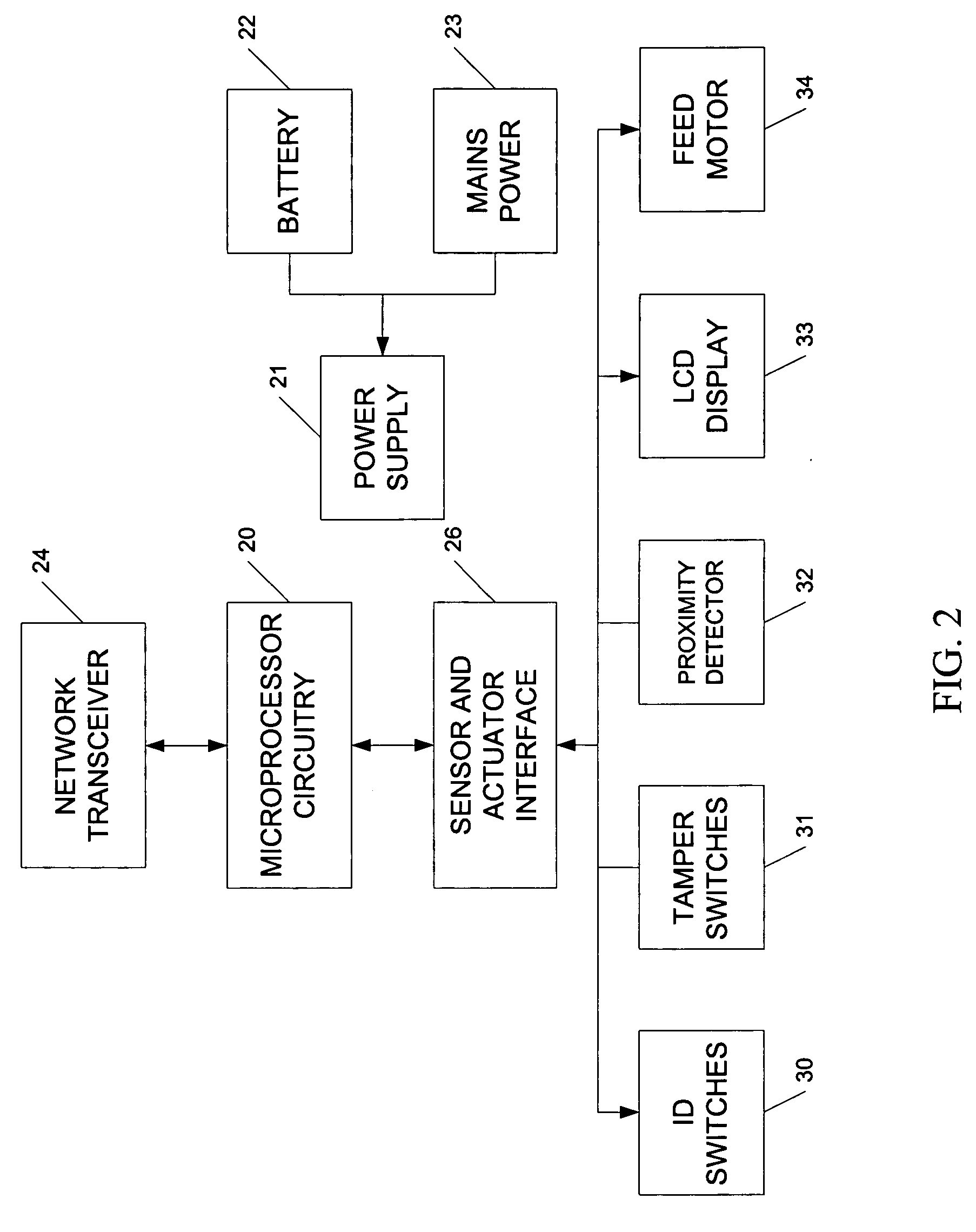

A system and apparatus for automatically dispensing a paper product mounted on a gravity-assisted holder through a dispenser. The apparatus includes an electric motor, a main product roller for automatically rolling a predetermined amount of the paper product from the holder, exit guide rollers for guiding the paper product through a front cover of the dispenser, and a series of interconnected gears that are driven by the electric motor to activate the main product roller and exit guide roller and operate both the main roller and exit roller at the same speed. Operating the rollers at the same speed prevents paper or tissue jamming inside the dispenser. The system monitors usage of each paper product dispenser with each dispenser having a microprocessor controller for determining a corresponding paper product status for the dispenser. Each paper product dispenser communicates with a master network device preferably mounted on a ceiling plane. Paper product status messages are transmitted between each dispenser and master network device unit using a standard data communications protocol. The master network device communicates the paper product status for each individual dispenser to an independent building automation and control network. A central control console that is interoperable with the building automation and control network monitors the status of each paper product dispenser through signals communicated from a master receiver / transmitter unit to the central control console.

Owner:VALVE SOULTIONS INC

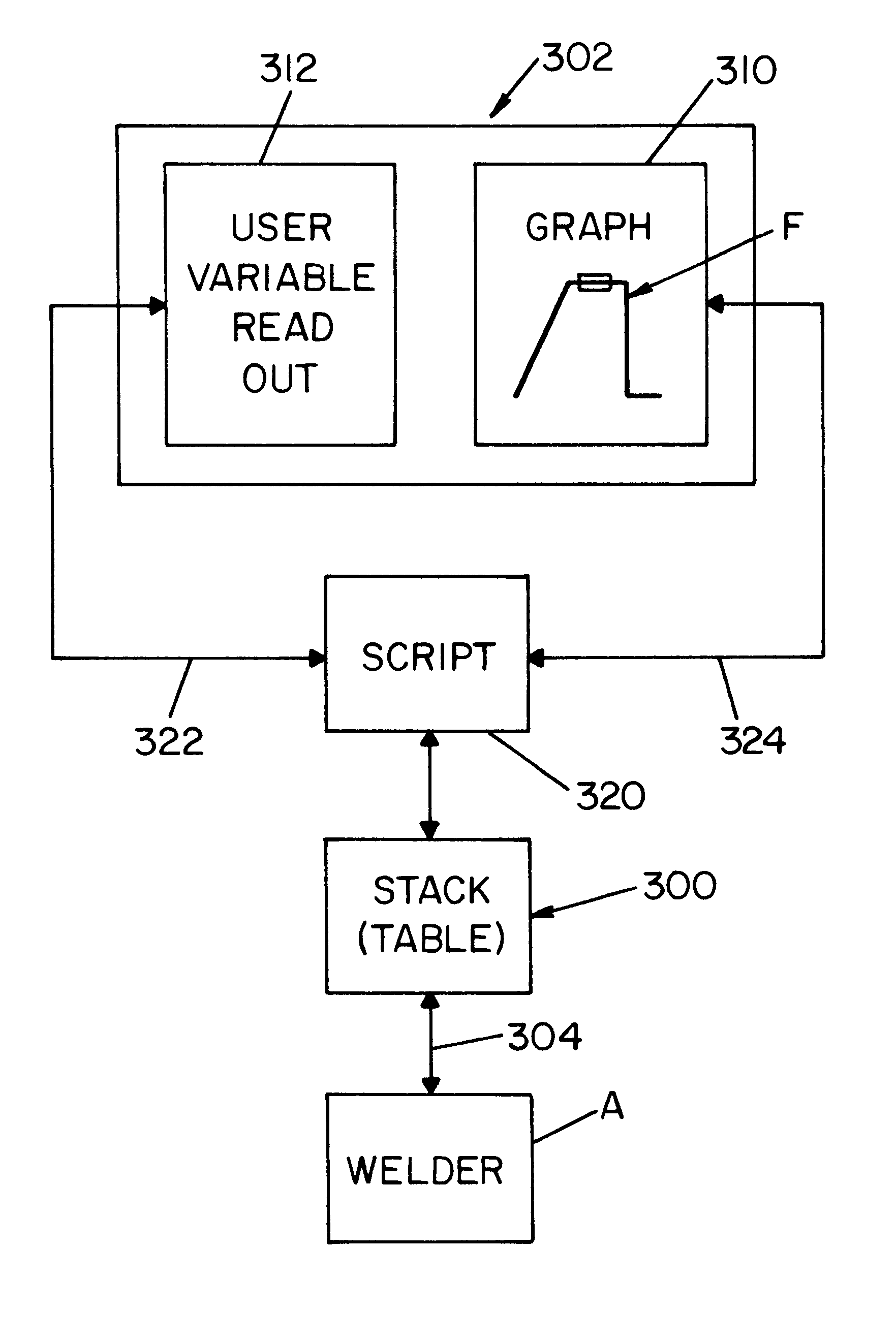

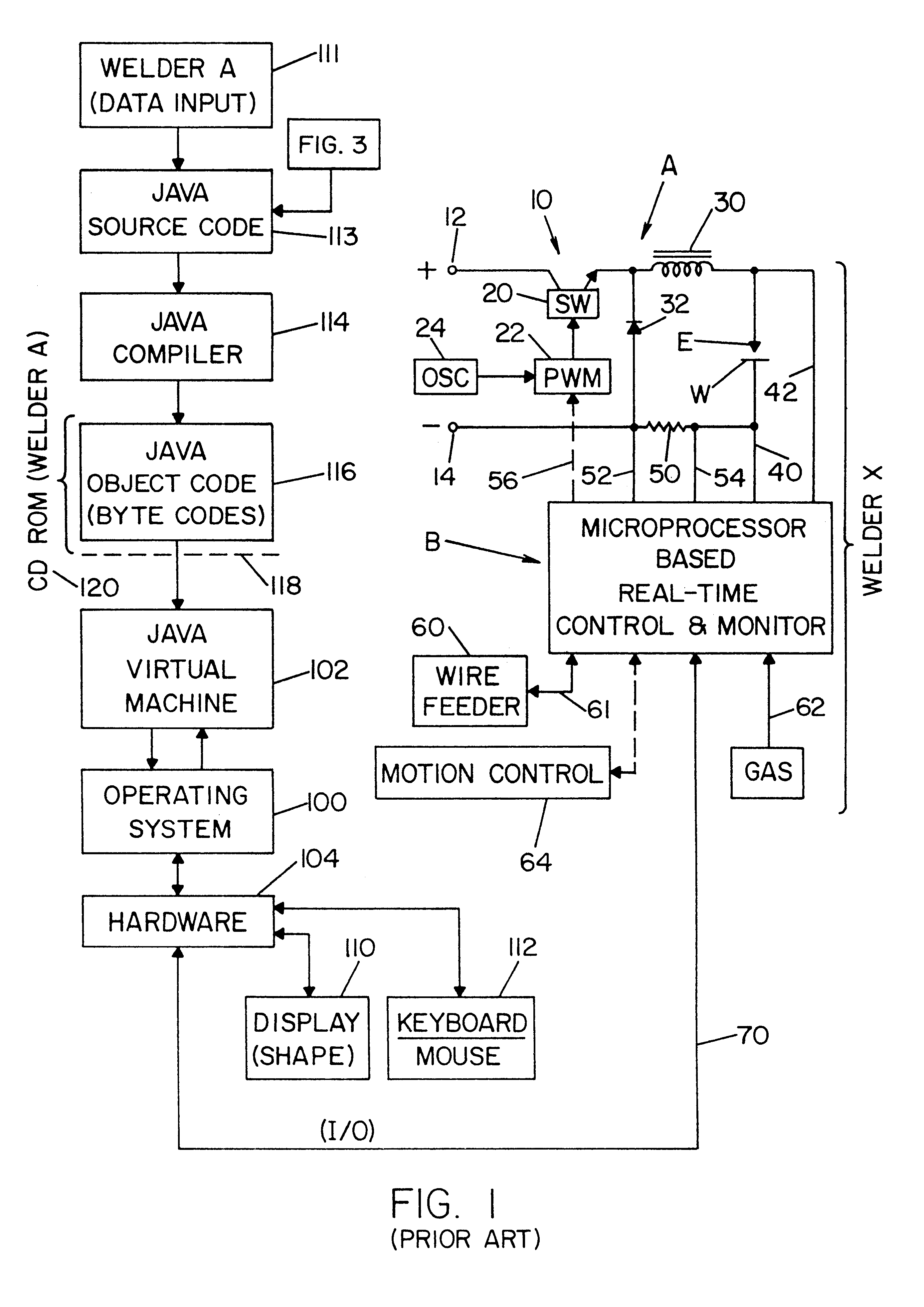

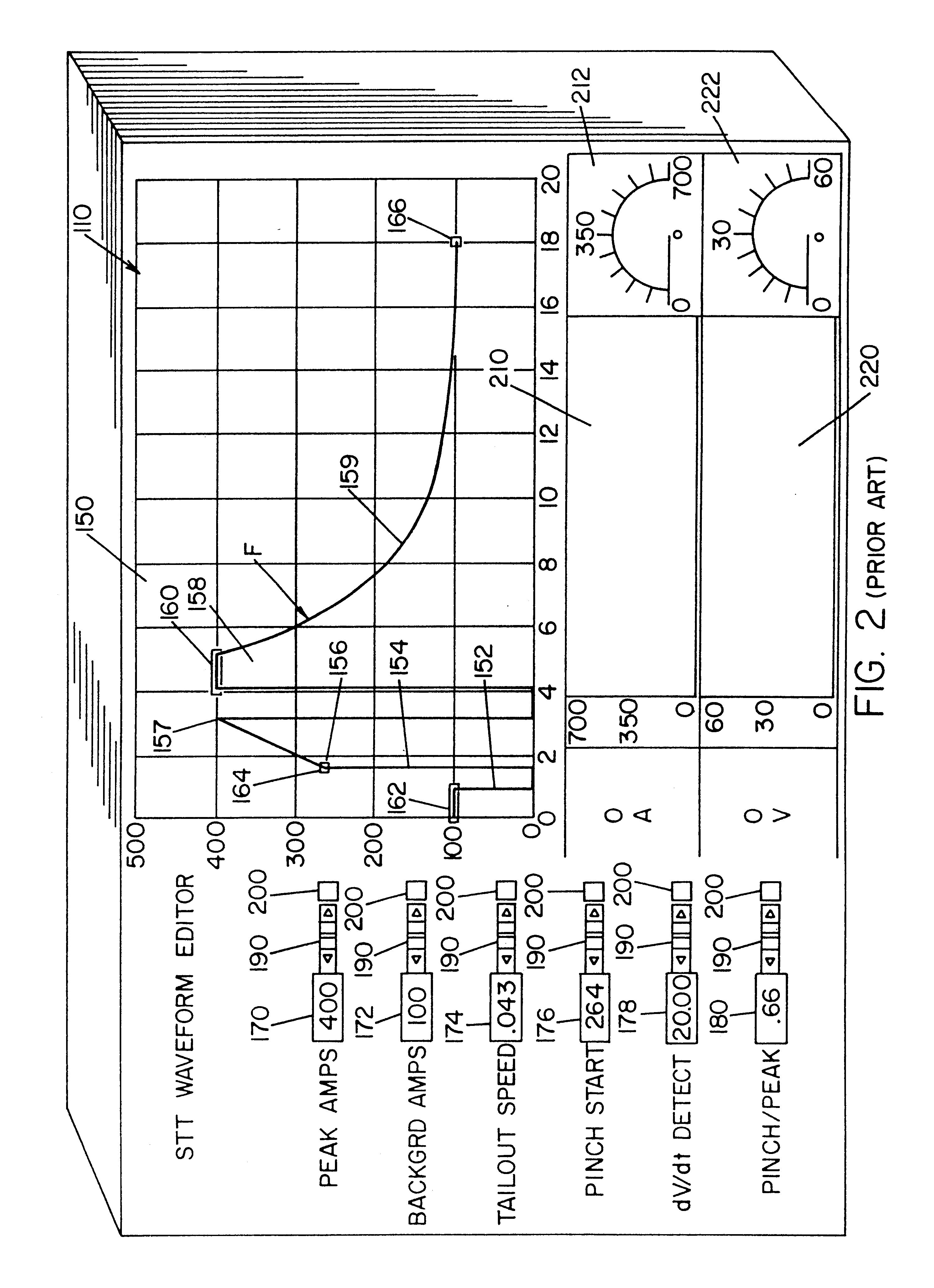

Electric ARC welder and controller to design the waveform therefor

InactiveUS6700097B1Simplified operator manipulationSimplify manipulationArc welding apparatusTelecommunications linkDisplay device

An electric arc welder for creating a welding cycle with a real time current waveform constituting several control parameters by a microprocessor that controls a power supply by a signal so the output of the power supply traces a desired waveform and dynamic reaction behavior to arc conditions defined by the control parameters. The welder has a controller for creating the signal and reading the parameters, a graphic user interface program controlled by input from a graphic user interface computer, a system with a first interface for an interactive display for displaying the desired waveform and dynamic behavior and at least one manipulative control parameter, a second interface for a manual data entry device to change the waveform and / or the parameters and a digital communication link from the graphic user interface to the welder microprocessor controller for causing the welder to perform the desired waveform by controlling the signal. A number of script language files each defining a given type of waveform logic and containing a user manipulative variable table of control parameters and graphical descriptive language to display a waveform to be implemented by the welder is used with an input stage for processing a selected one of the script files into graphic user interface components (readouts, charts, and / or panels) for operating the welder.

Owner:LINCOLN GLOBAL INC

Apparatus for energizing a remote station and related method

InactiveUS20030032993A1Eliminate needEasy to useElectrotherapyTelemetry/telecontrol selection arrangementsStored energyMiniaturization

Apparatus for remote interaction with an object of interest includes a remote station for obtaining information from the object of interest, a base station for transmitting energy in space to and communicating with the remote station and the remote station having conversion means for energizing the remote station responsive to receipt of the transmitted energy. The energy may be of any suitable type including RF power, light, acoustic, magnetic energy or other form of space transmitted or "radiant" energy. The remote station does not have to contain a source of stored energy or a wired connection to a source of energy. The remote station receives the energy transmission and data transmission from the base station and transmits data to the base station. Microprocessor controllers may be provided for the base station and the remote station. The remote station may receive information from sensors and through one or more transponders sequentially communicate information to the base station. An associated method is provided. In other embodiments which are suited for use in miniaturized electronic chip systems, power enhancement and increased effective antenna size are provided.

Owner:PITTSBURGH UNIV OF

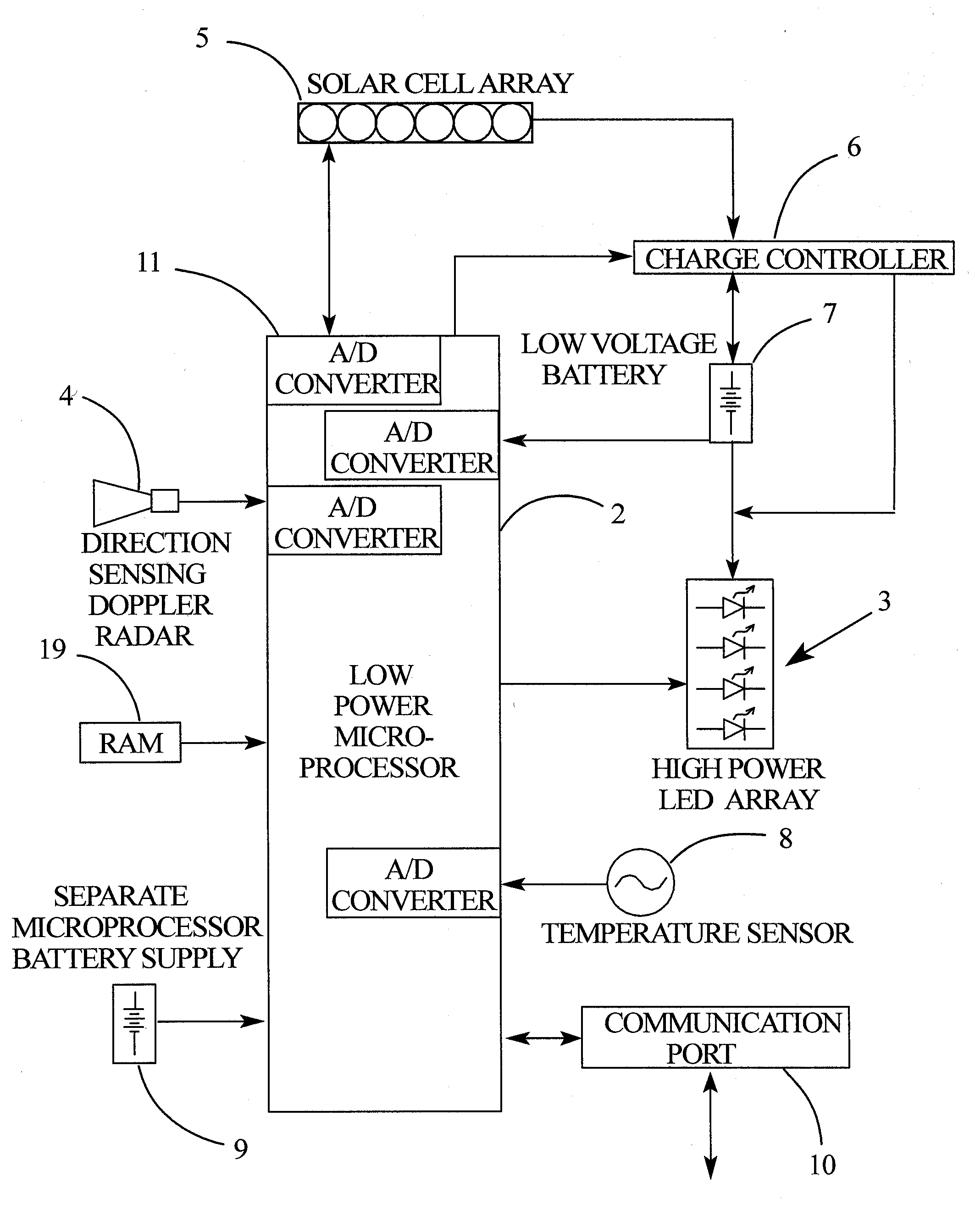

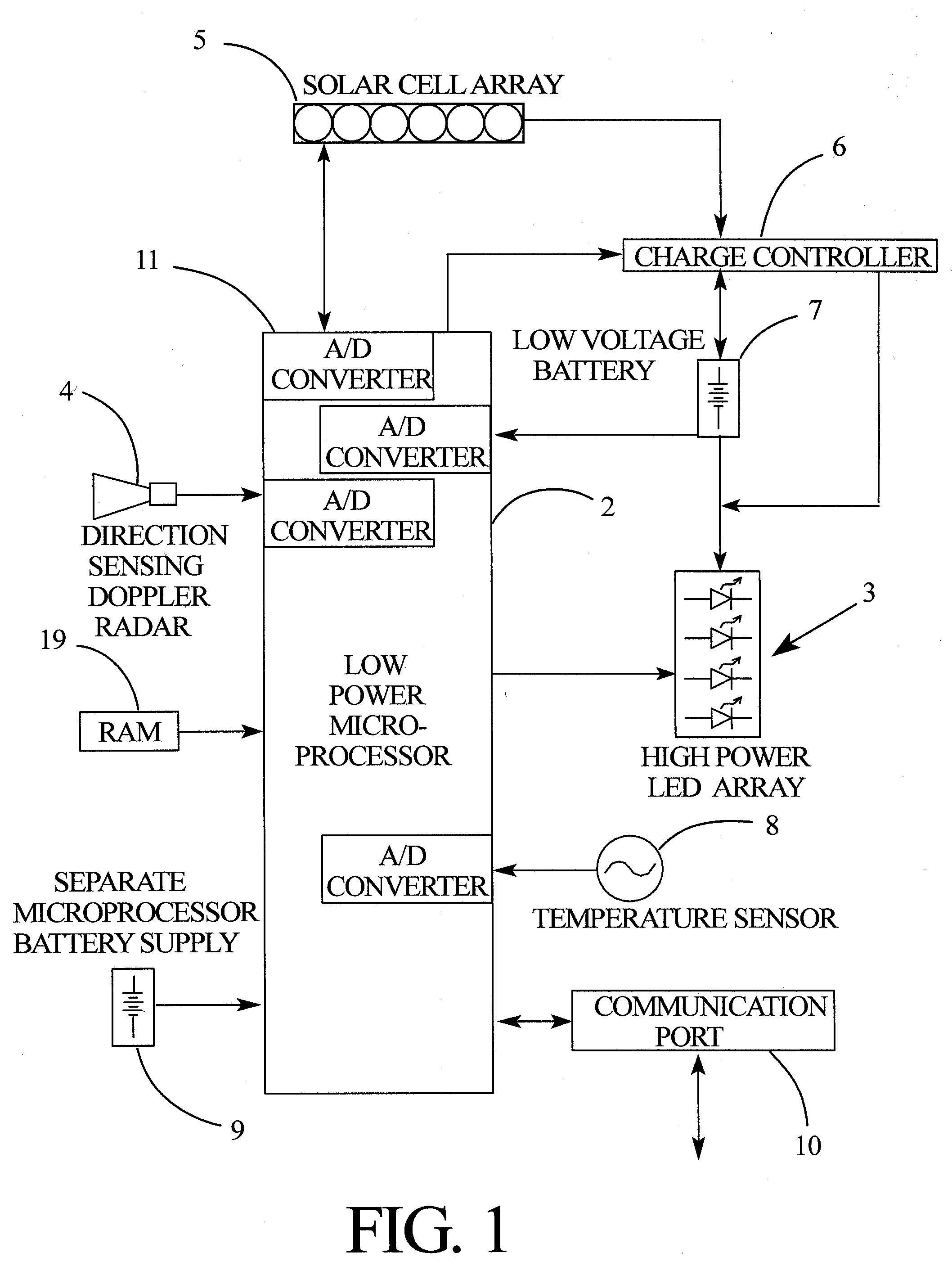

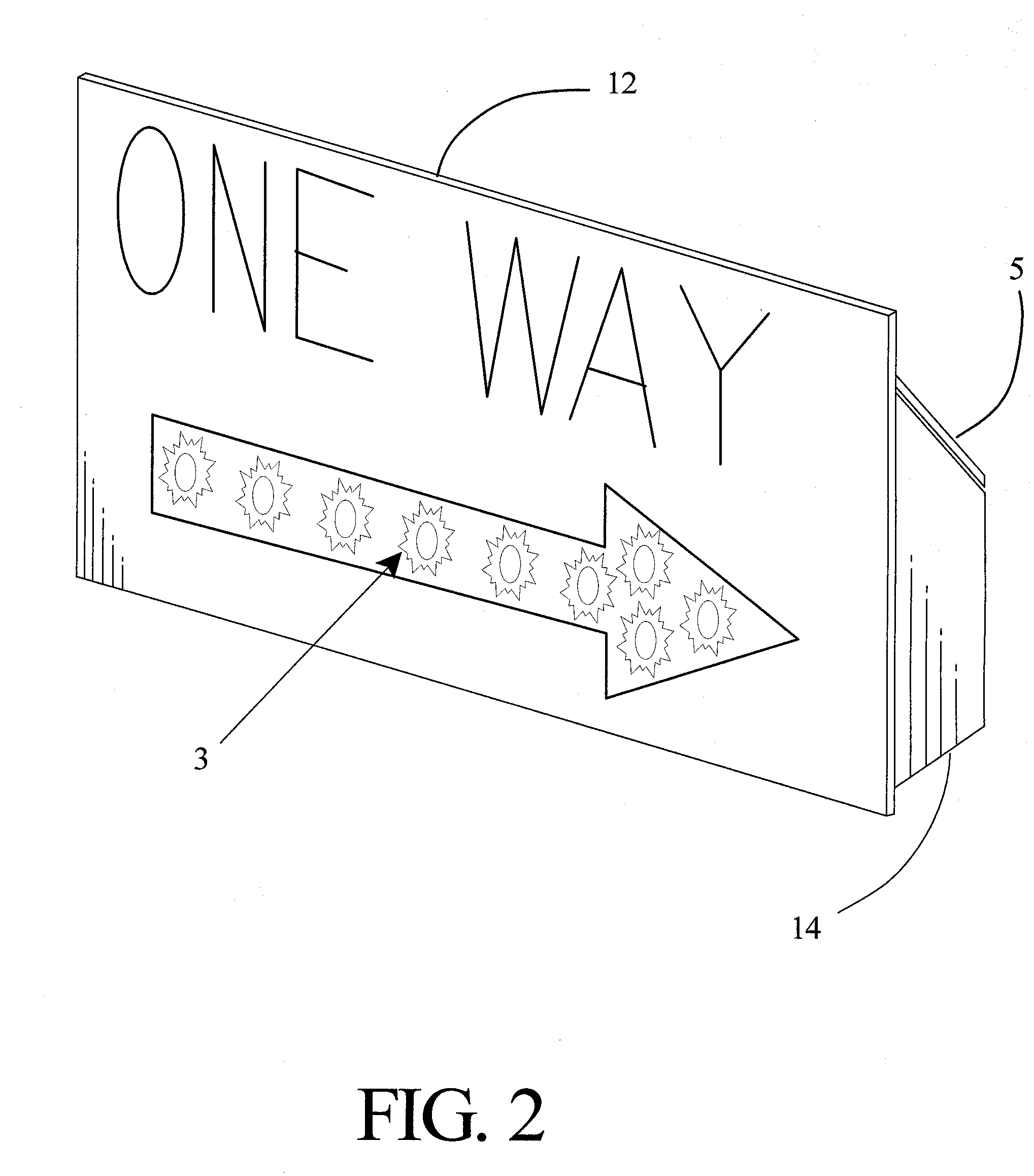

Solar powered sign annunciator

InactiveUS20050046595A1Avoid disadvantagesRetain its shapeRoad vehicles traffic controlElectric/electromagnetic visible signallingLow voltageCharged current

A solar powered sign annunciator comprised of a plurality of high intensity light emitting diodes (LED); a microprocessor controller to regulate power consumption and annunciator characteristics, battery charging and sensor response with an integrated software charge controller; a minimalized solar panel array sized to produce sufficient power for battery charging under normalized solar radiation to latitudes as far north as 45 degrees; a direction sensing Doppler radar to determine the approach of traffic; a low voltage battery to minimize power control losses to the LED array; a temperature sensor to determine proper charging battery status and battery capacity; and a plurality of analog to digital (A / D) converters incorporated in the microprocessor to sense solar power output, temperature input, battery voltage and charging current and Doppler phase shift differential. The system also includes a housing arrangement to incorporate all aforementioned items in a weathertight enclosure providing sufficient horizontal surface for solar cell attachment yet in a package compact enough to easily attach to existing designed signs.

Owner:BLYTH MR JOHN RANDOLPH

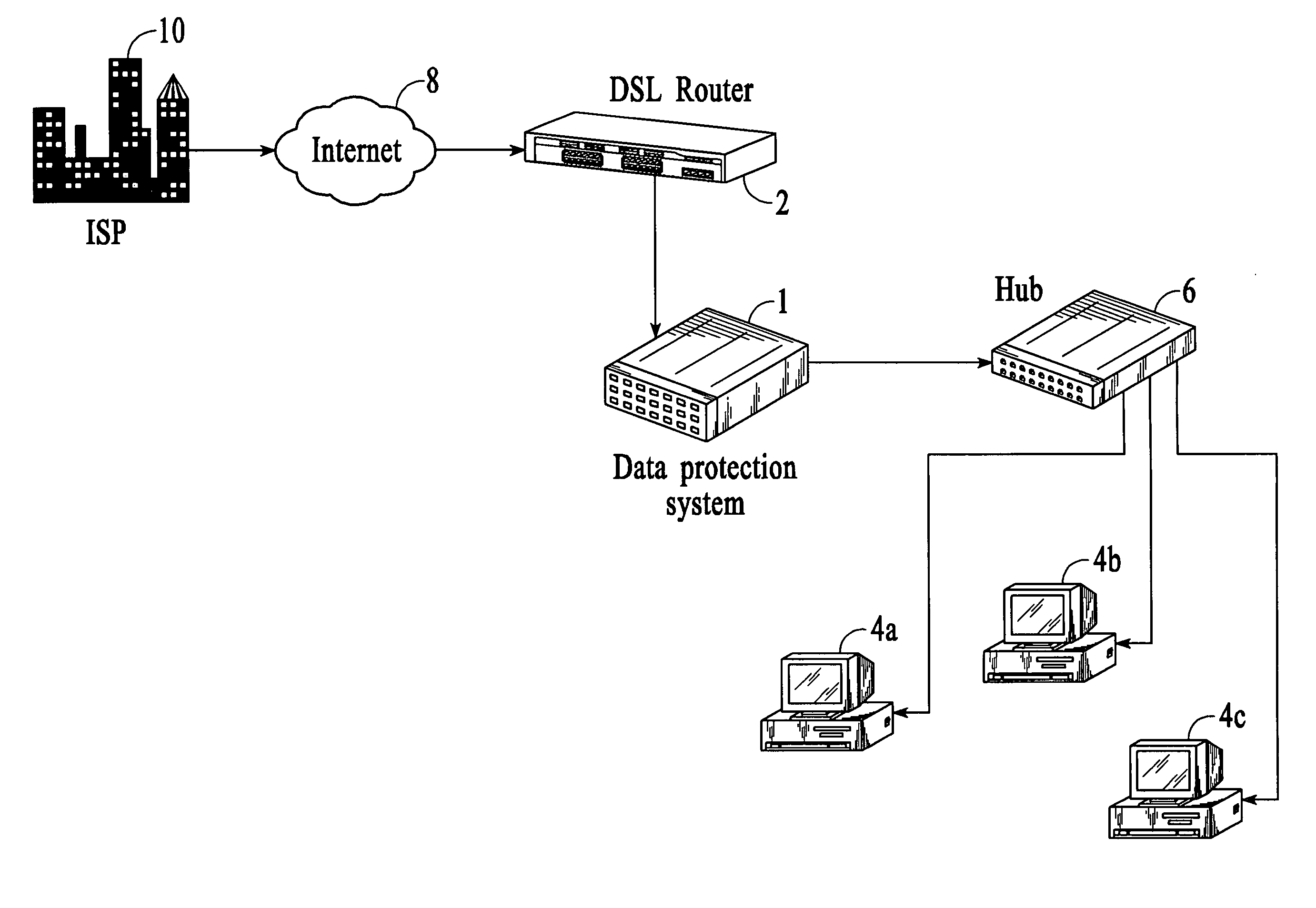

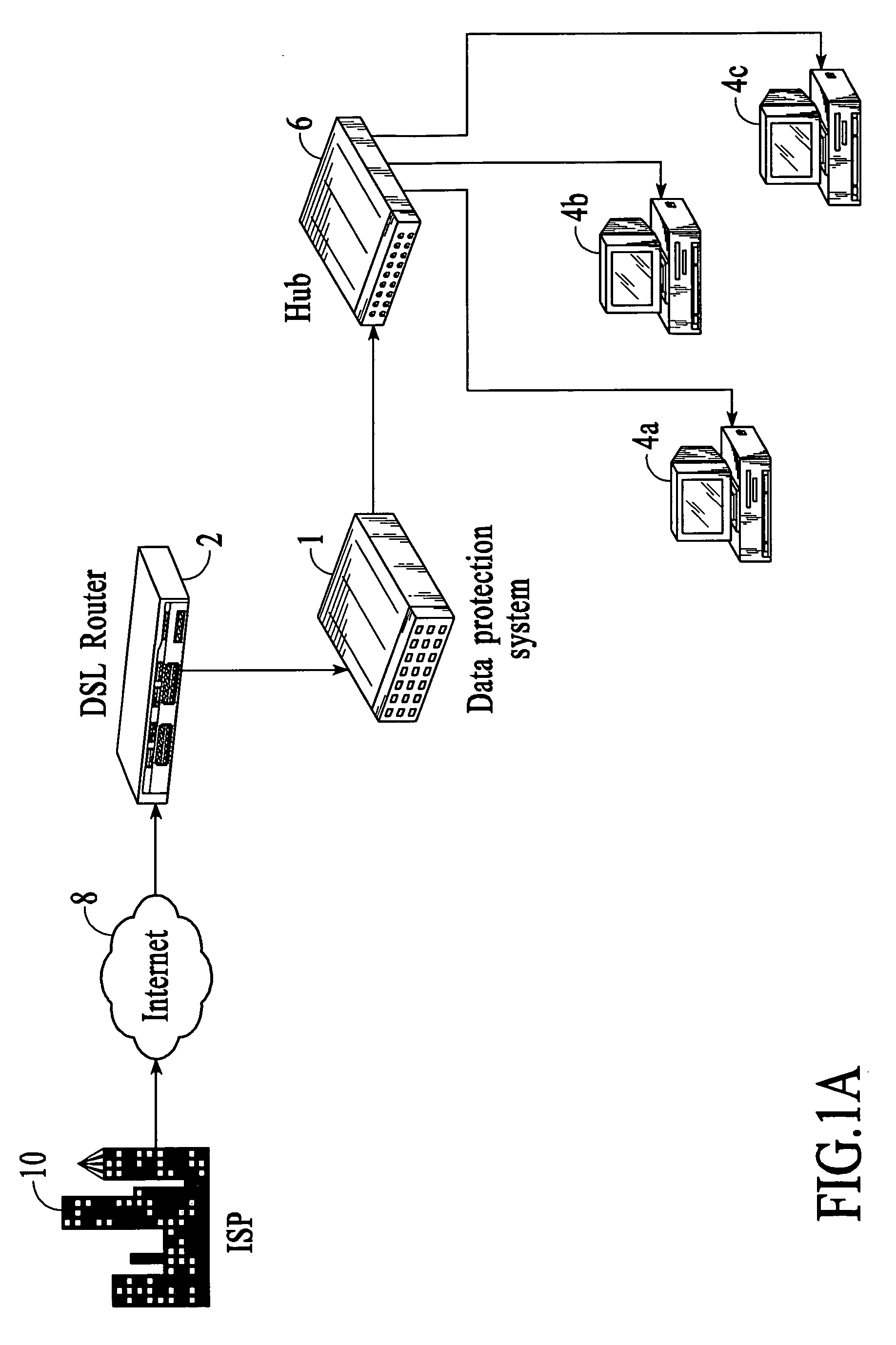

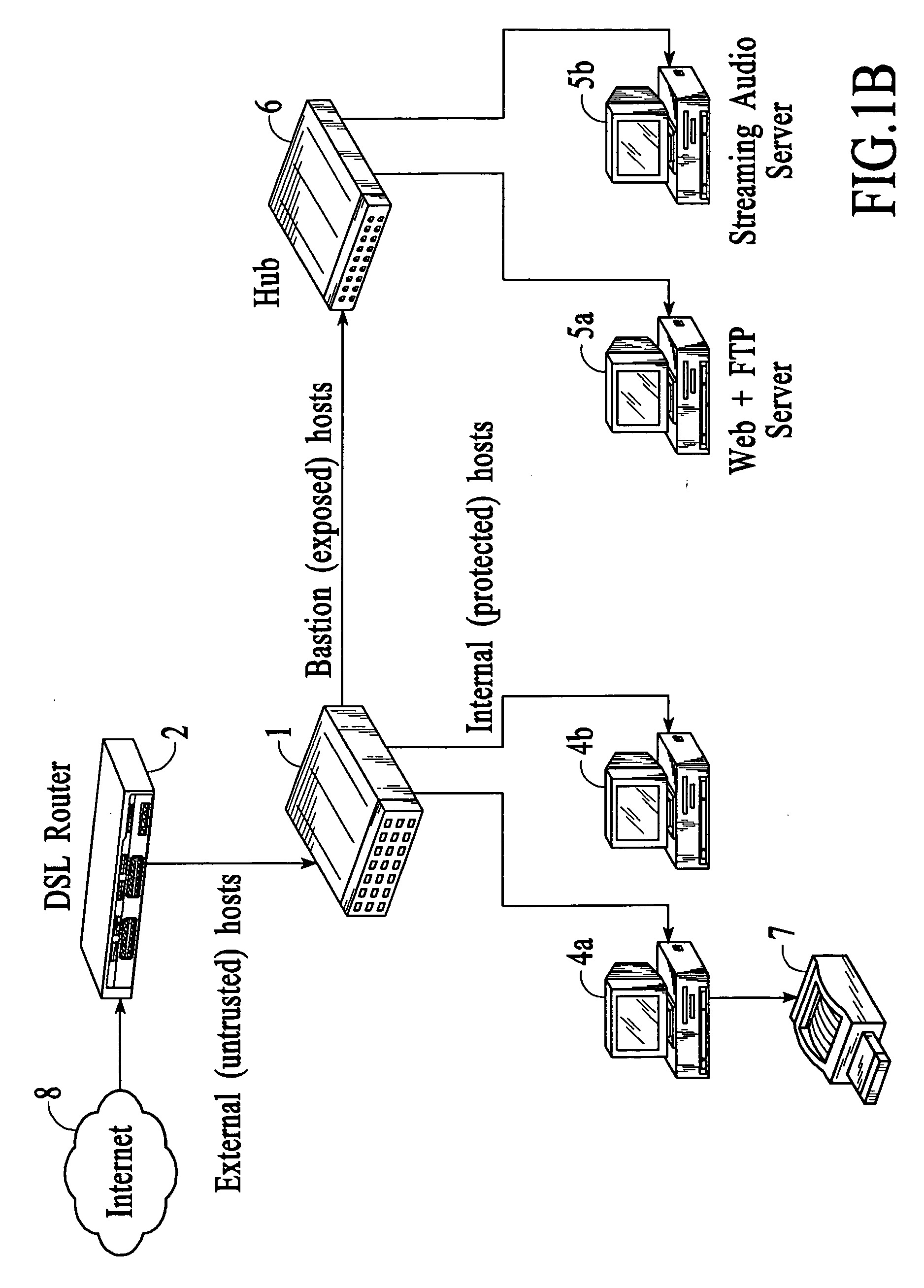

Real time firewall/data protection systems and methods

InactiveUS20060253903A1Easy to switchEliminate requirementsMultiple digital computer combinationsProgram controlData packMicroprocessor controller

Methods and systems for firewall / data protection that filters data packets in real time and without packet buffering are disclosed. A data packet filtering hub, which may be implemented as part of a switch or router, receives a packet on one link, reshapes the electrical signal, and transmits it to one or more other links. During this process, a number of filters checks are performed in parallel, resulting in a decision about whether each packet should or should not be invalidated by the time that the last bit is transmitted. To execute this task, the filtering hub performs rules-based filtering on several levels simultaneously, preferably with a programmable logic or other hardware device. Various methods for packet filtering in real time and without buffering with programmable logic are disclosed. The system may include constituent elements of a stateful packet filtering hub, such as microprocessors, controllers, and integrated circuits. The system may be reset, enabled, disabled, configured, and / or reconfigured with toggles or other physical switches. Audio and visual feedback may be provided regarding the operation and status of the system.

Owner:802 SYST

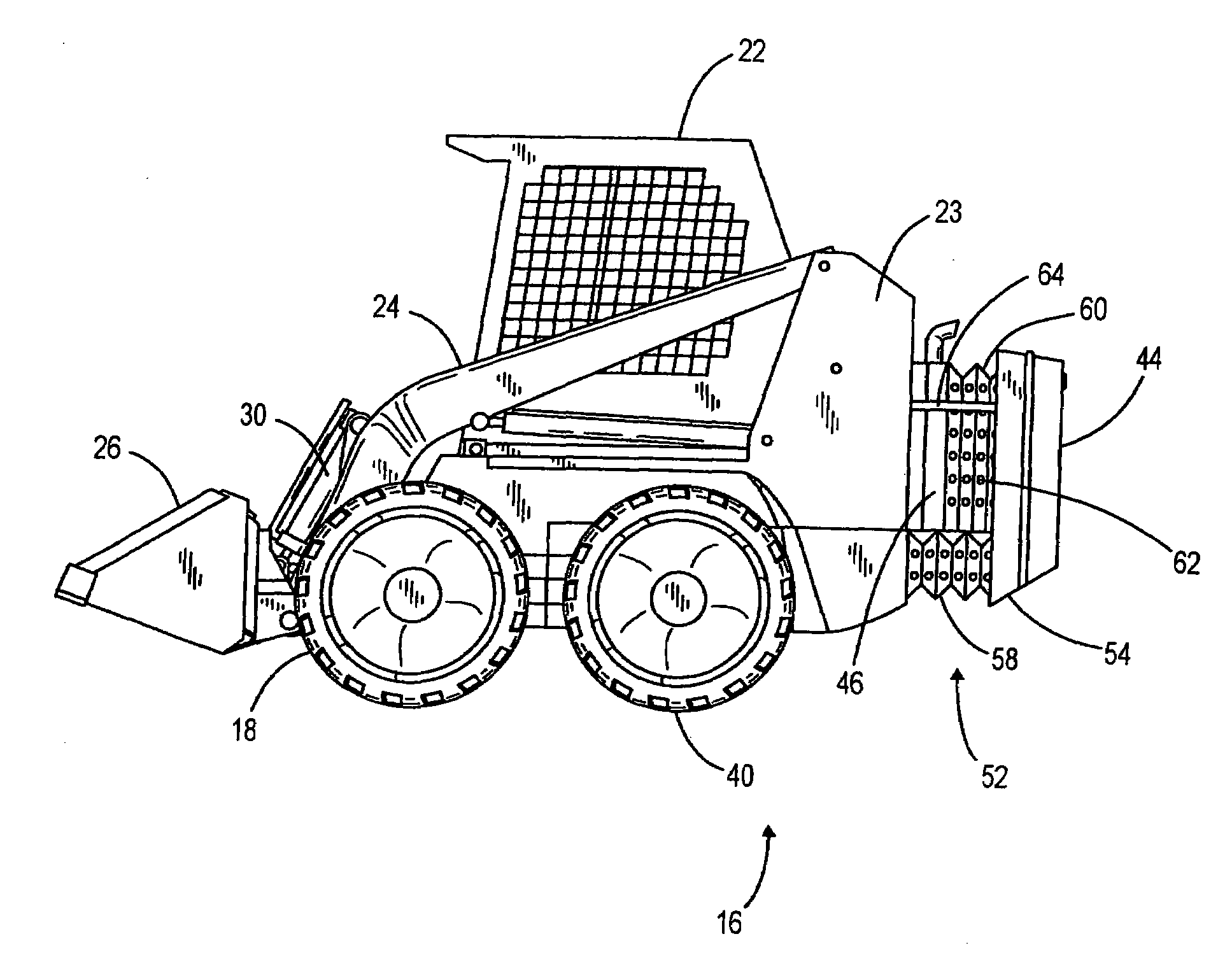

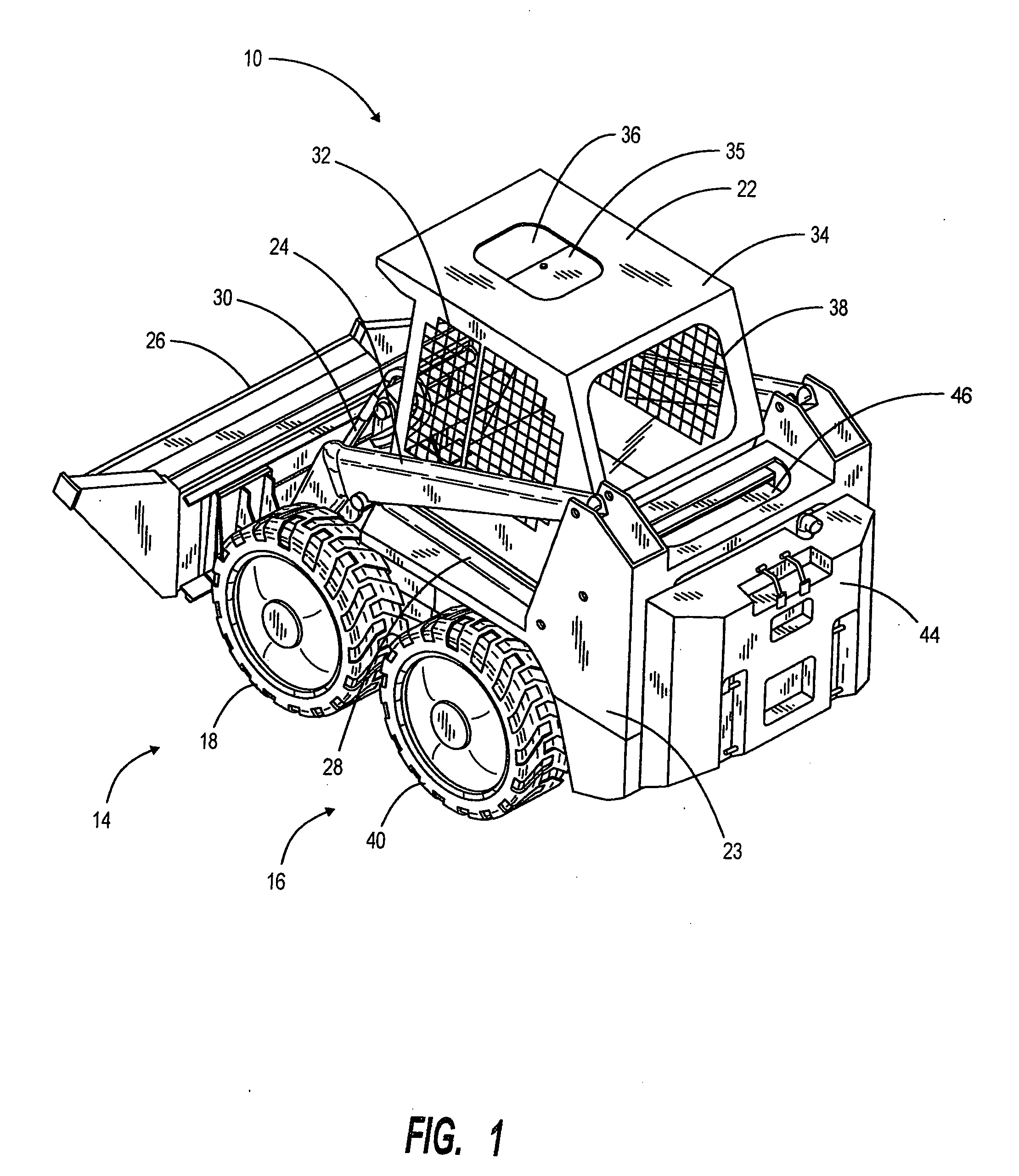

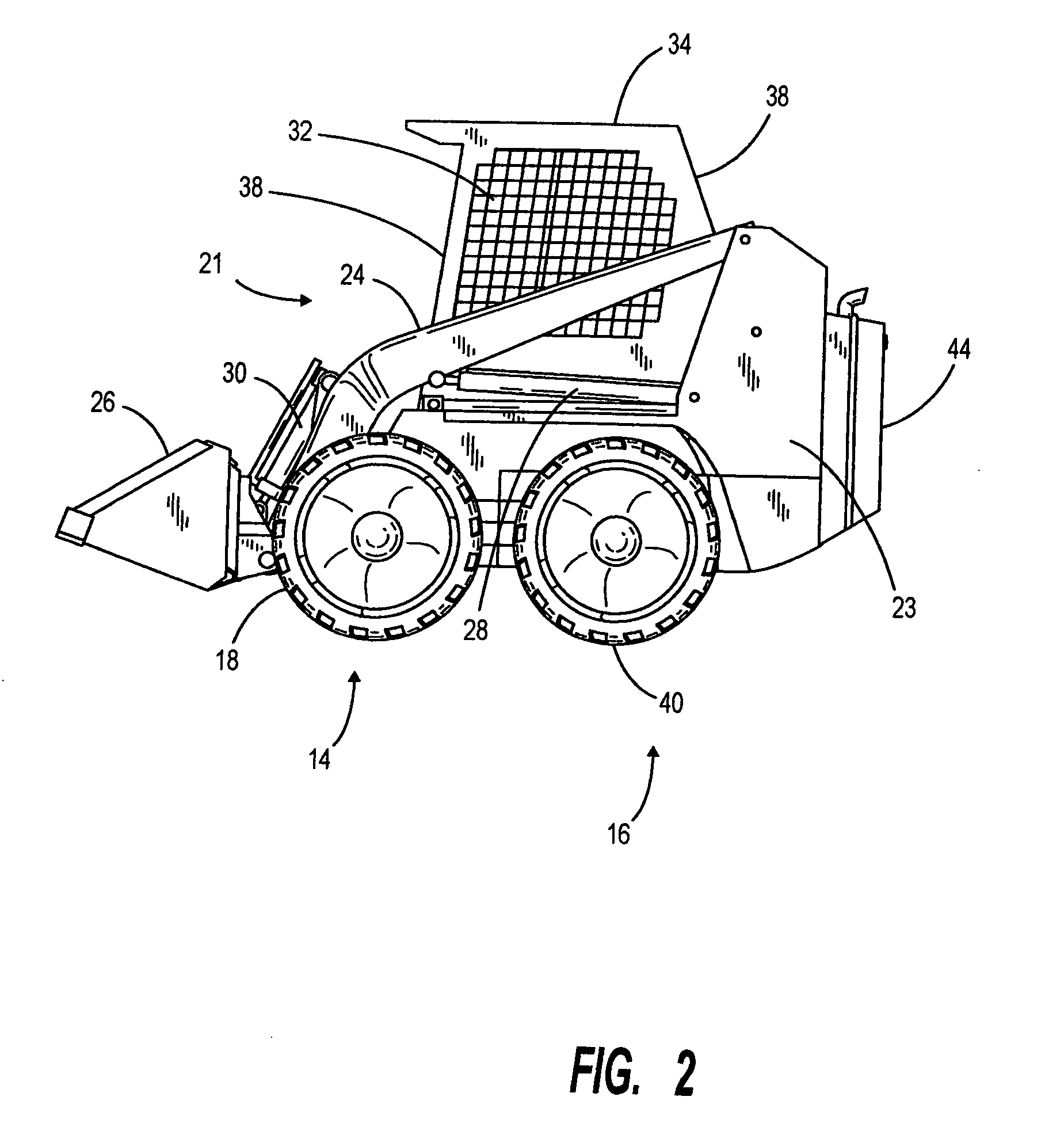

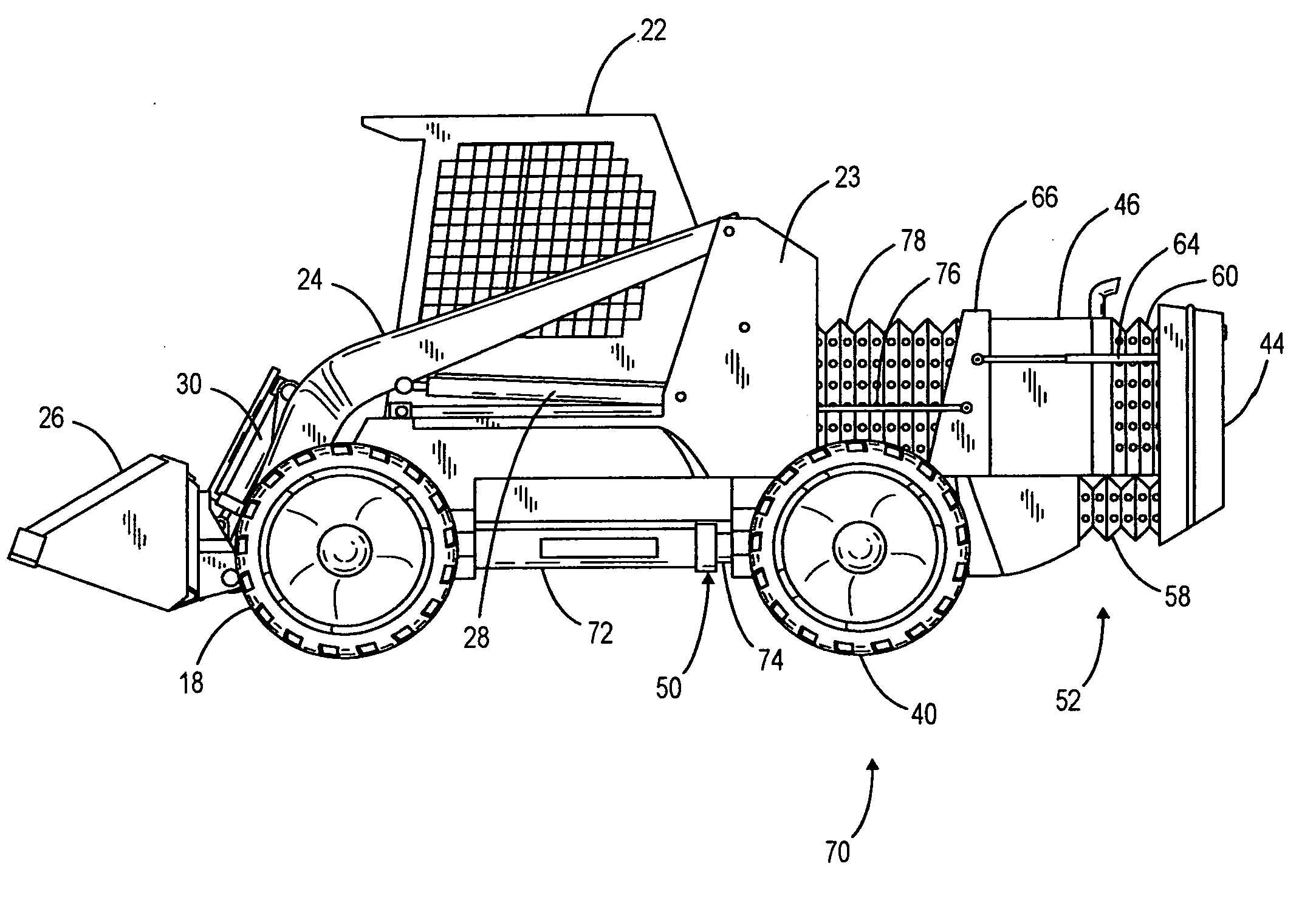

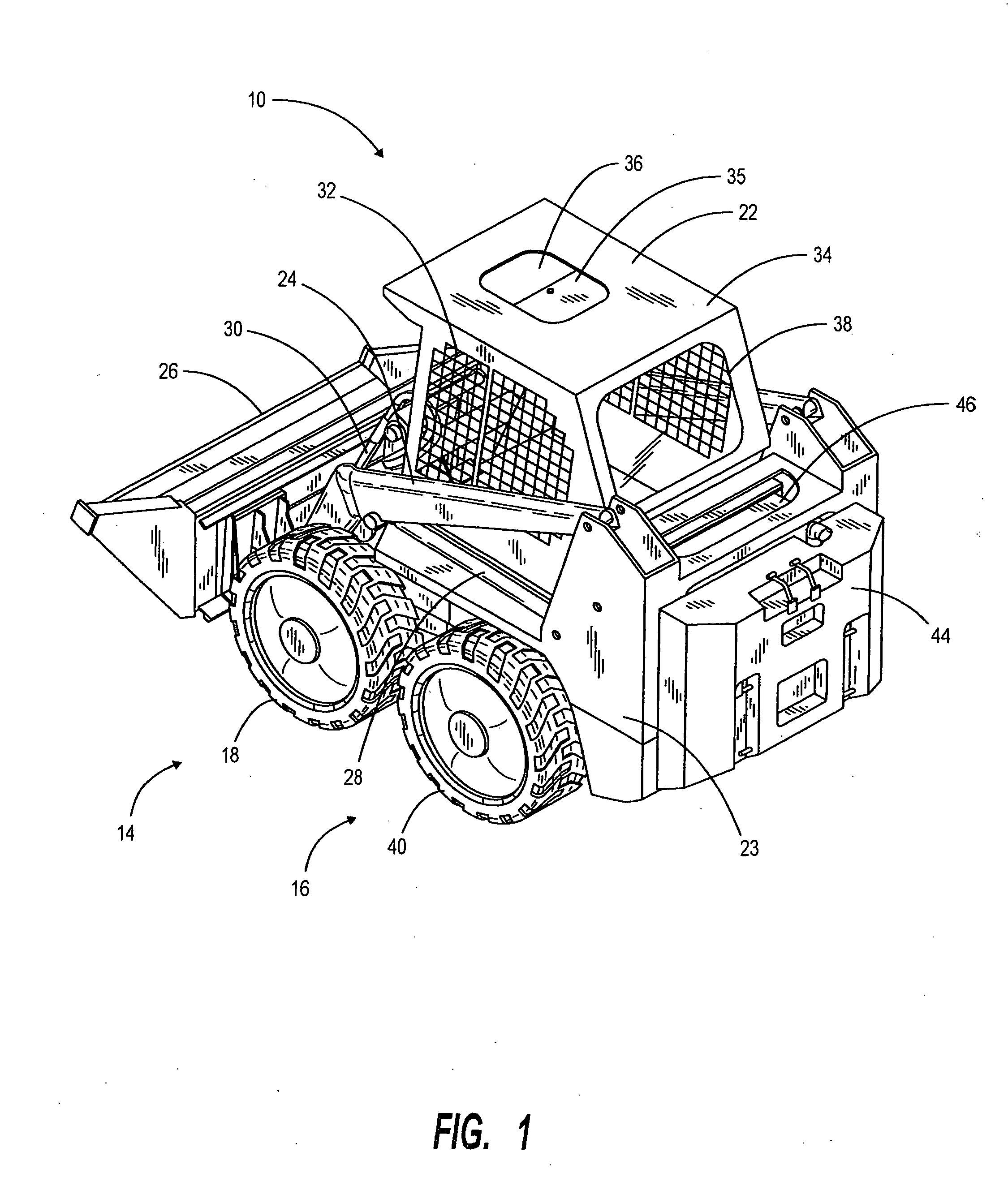

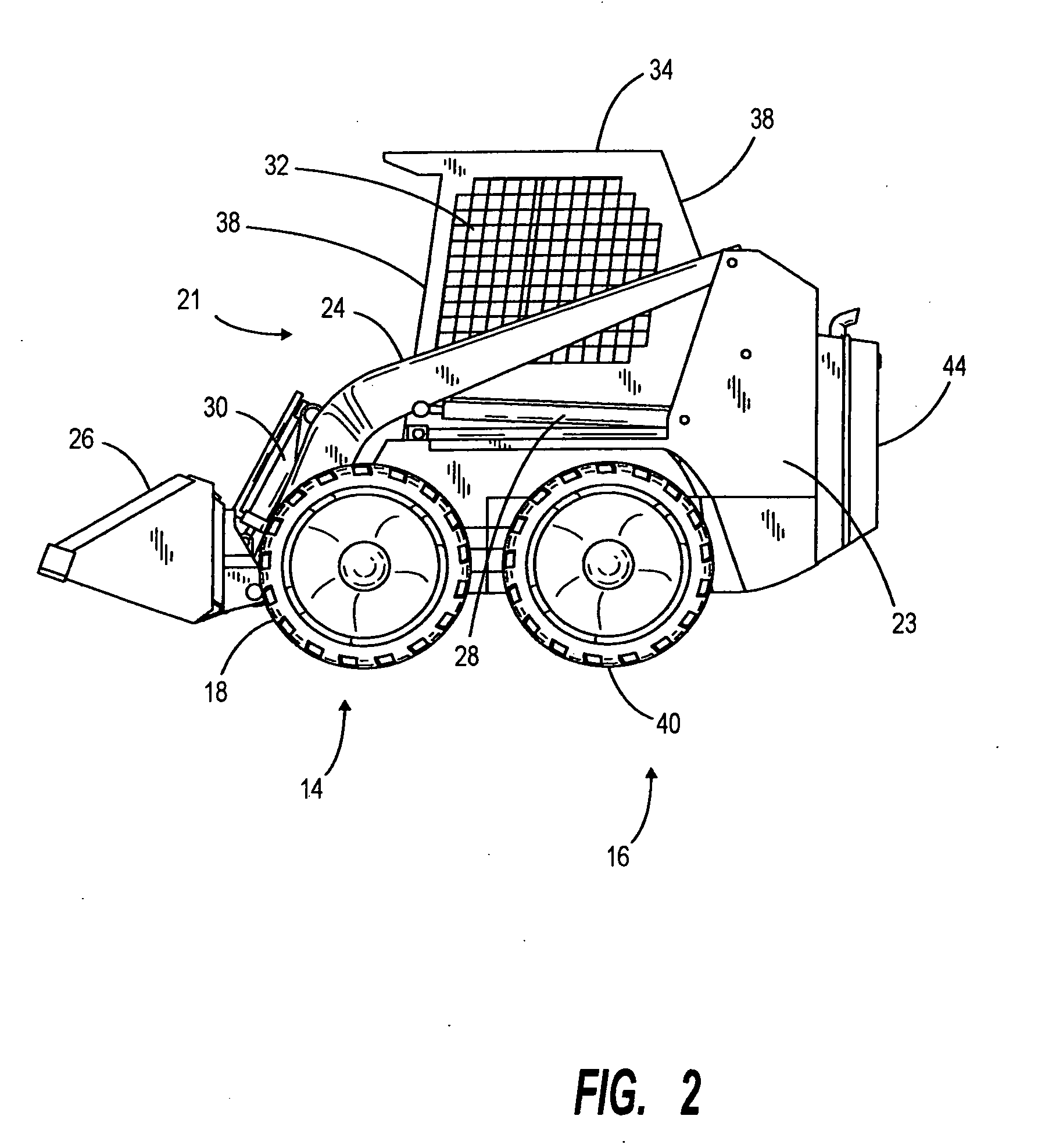

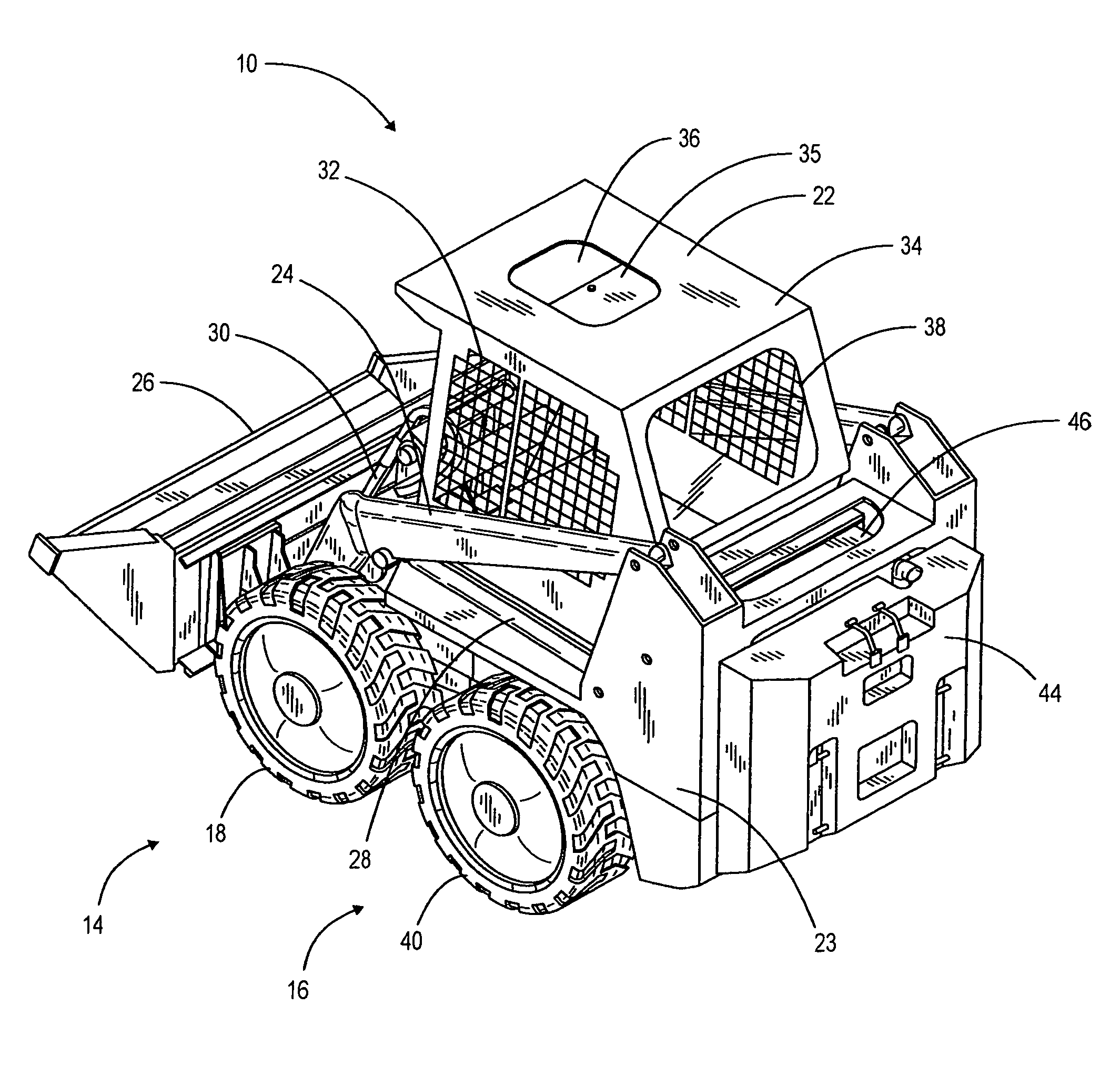

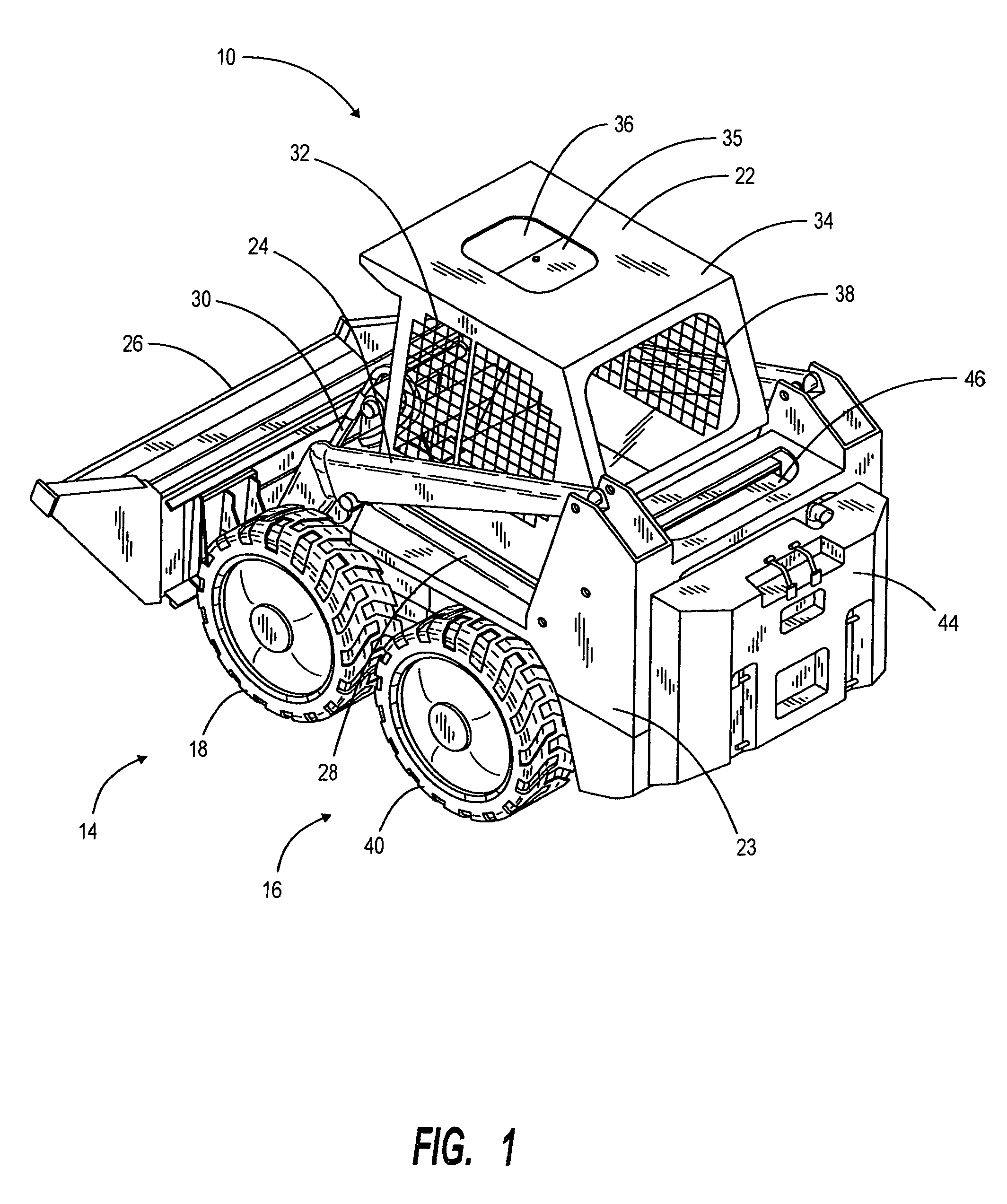

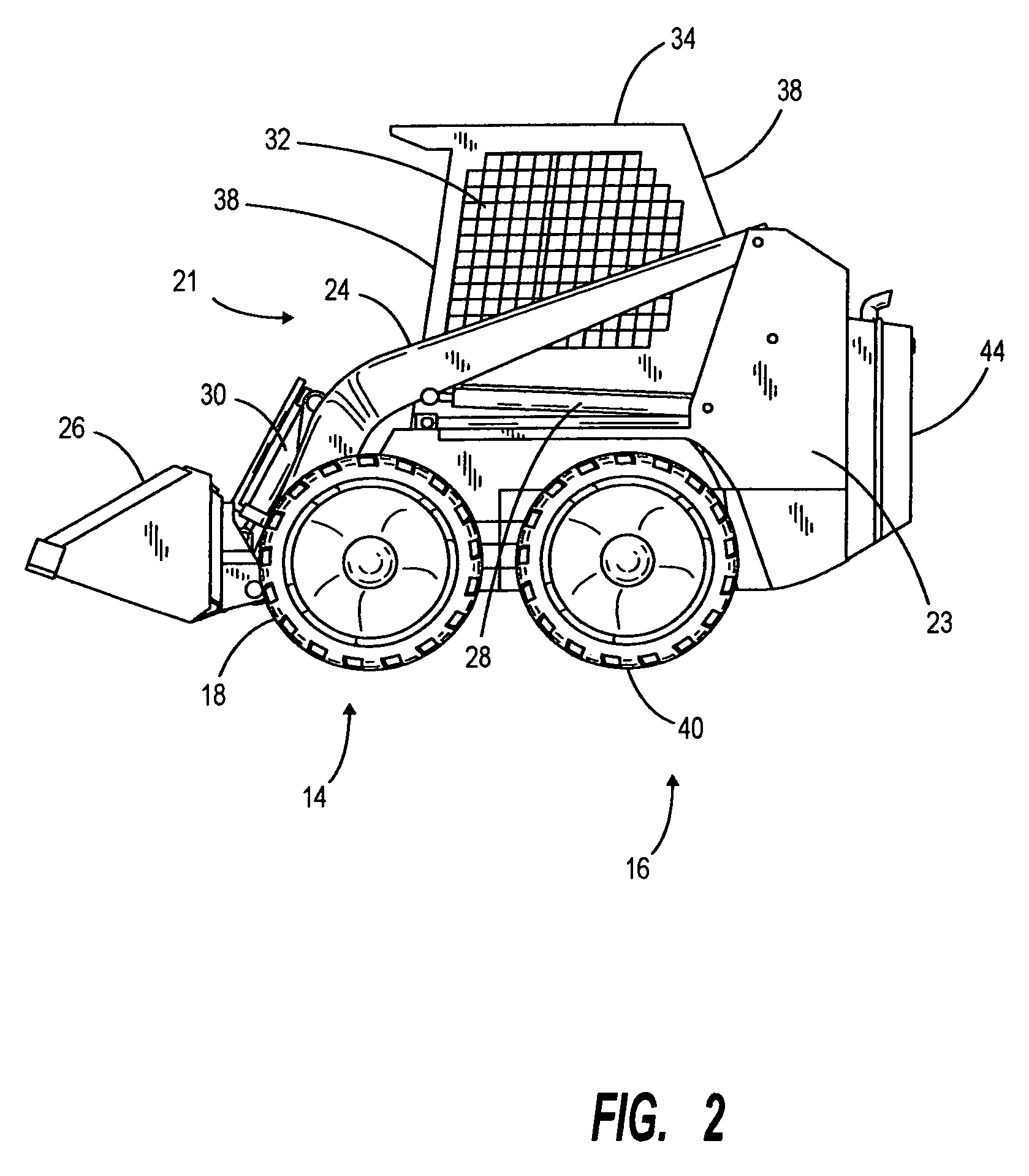

Extendable frame work vehicle

ActiveUS20090038186A1Improve versatilityImprove securitySafety devices for lifting equipmentsAuxillary drivesHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor, and at least one valve network.

Owner:EXTENDQUIP LLC

Vehicle separation warning device

InactiveUS20070159311A1Acoustic signal devicesAnti-collision systemsMicroprocessor controllerSafety zone

A method and apparatus for providing warnings related to vehicle separation. The warning device of the invention generally includes a distance measuring sensor positioned on a rearward facing surface of a first vehicle, the distance measuring sensor being configured to measure a distance between the first vehicle and a second vehicle following the first vehicle, a microprocessor controller in electrical communication with the distance measuring sensor and being configured receive input from the distance measuring sensor and generate outputs therefrom, and a visual warning device positioned on the first vehicle and being in electrical communication with the microprocessor controller. Generally, the controller of the device is configured to execute a program configured to conduct a method, wherein the method includes: a) receiving a distance measurement in the controller from the distance measuring sensor, wherein the distance measurement is representative of the distance from the rear of the first vehicle to the front of the second vehicle; b) determining if the distance measurement is within one of a plurality of predetermined safety zone thresholds; and c) illuminating the visual warning device in accordance with the determined predetermined safety zone thresholds.

Owner:SCHOBER SCOTT

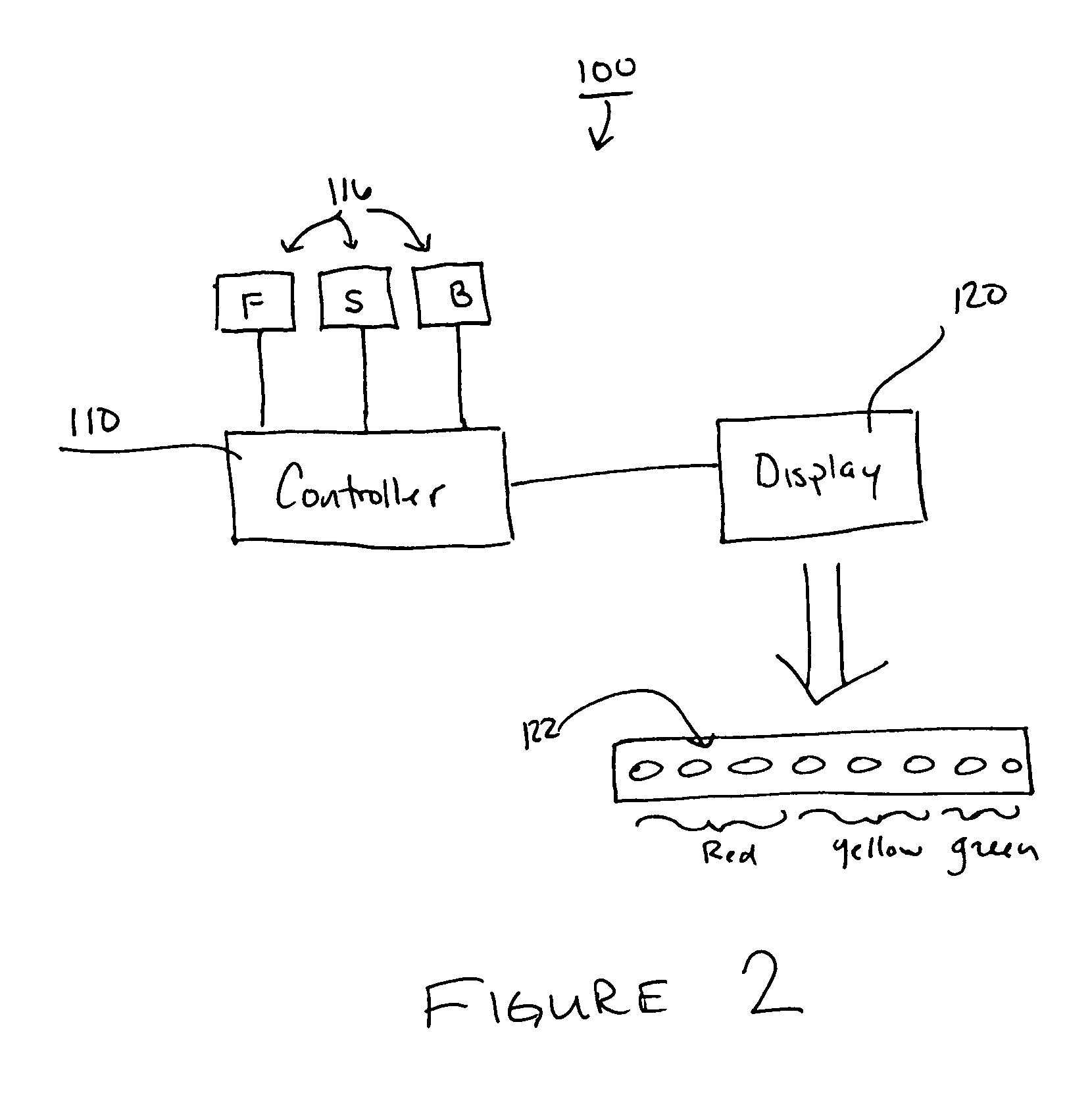

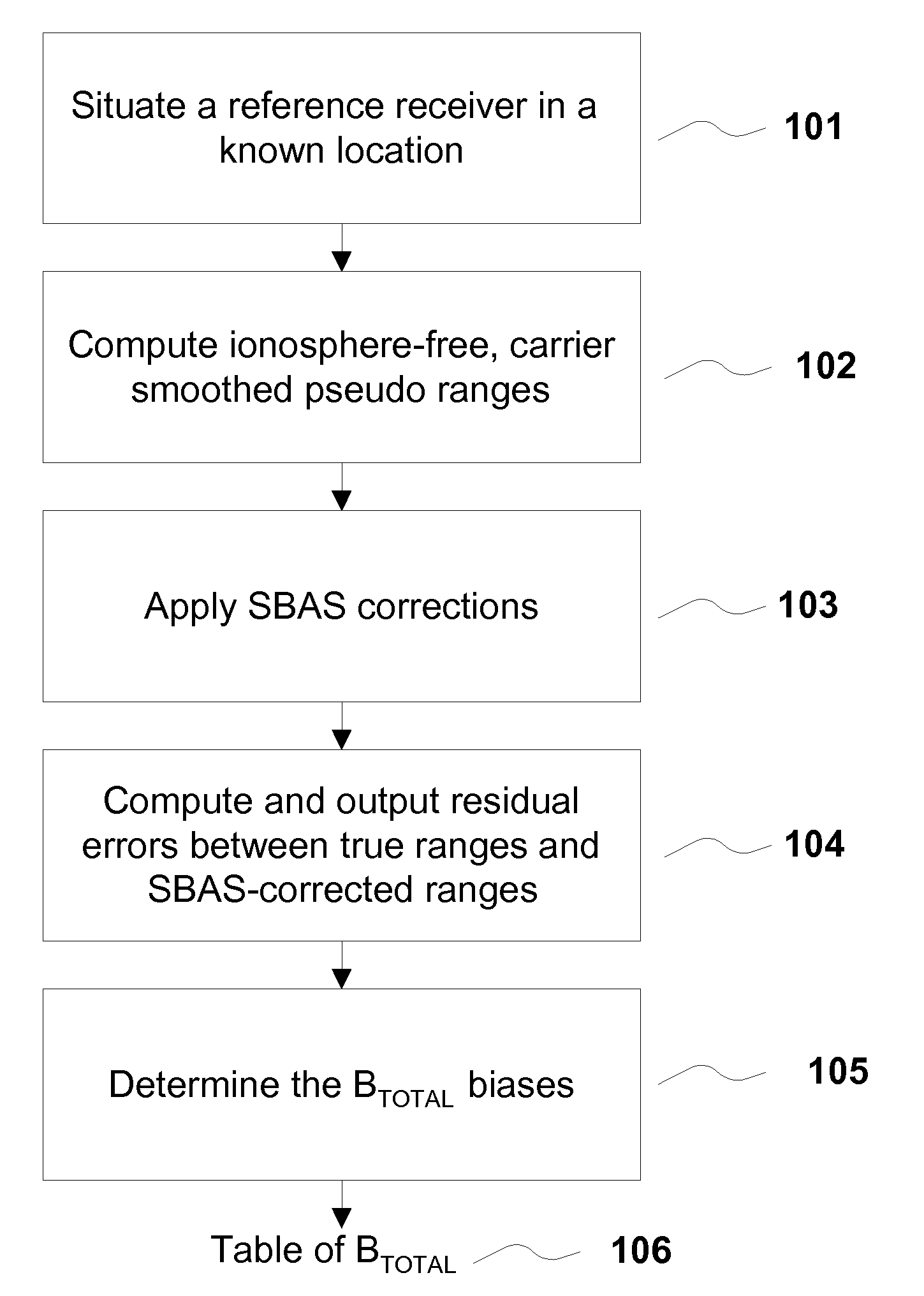

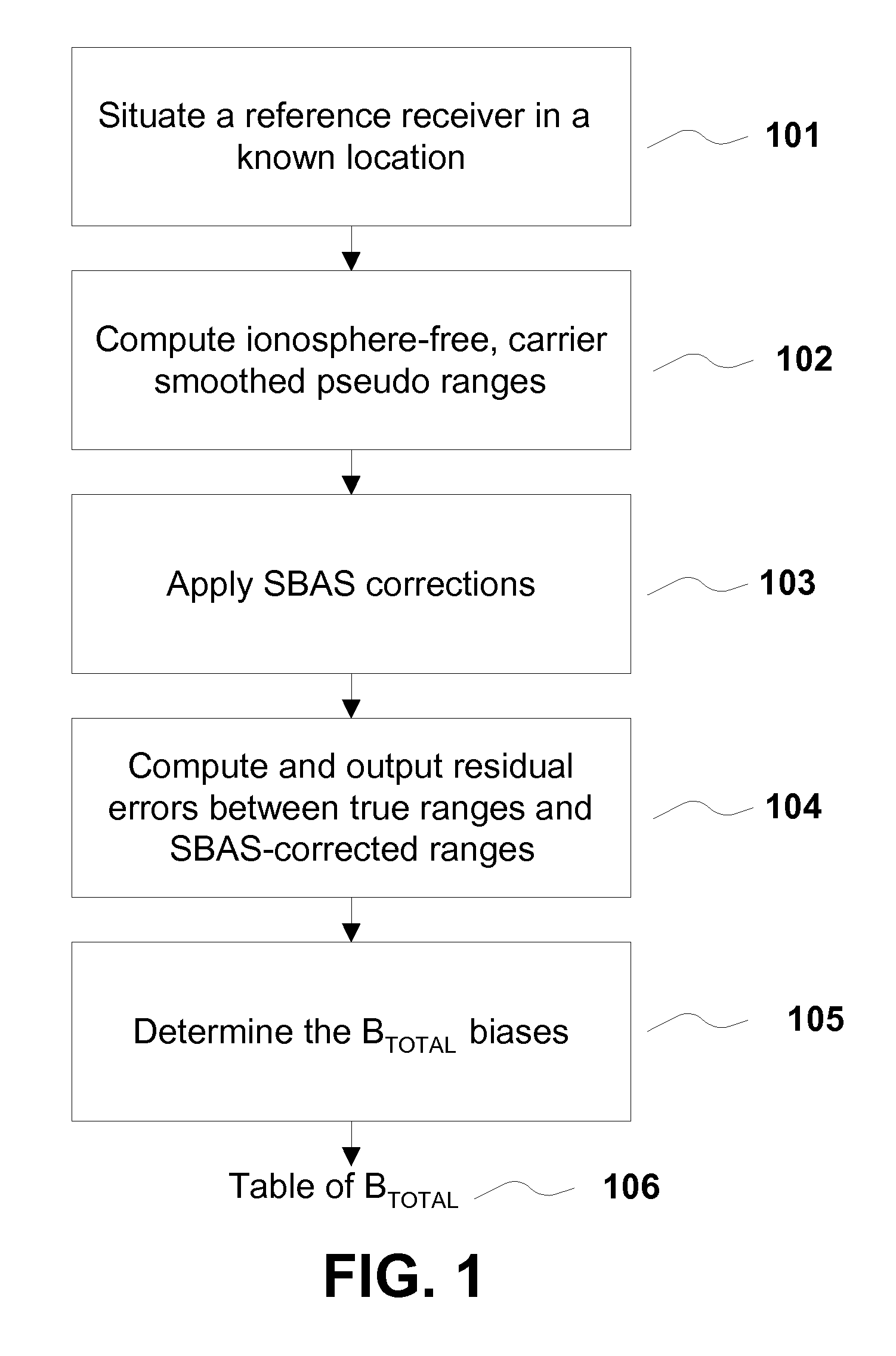

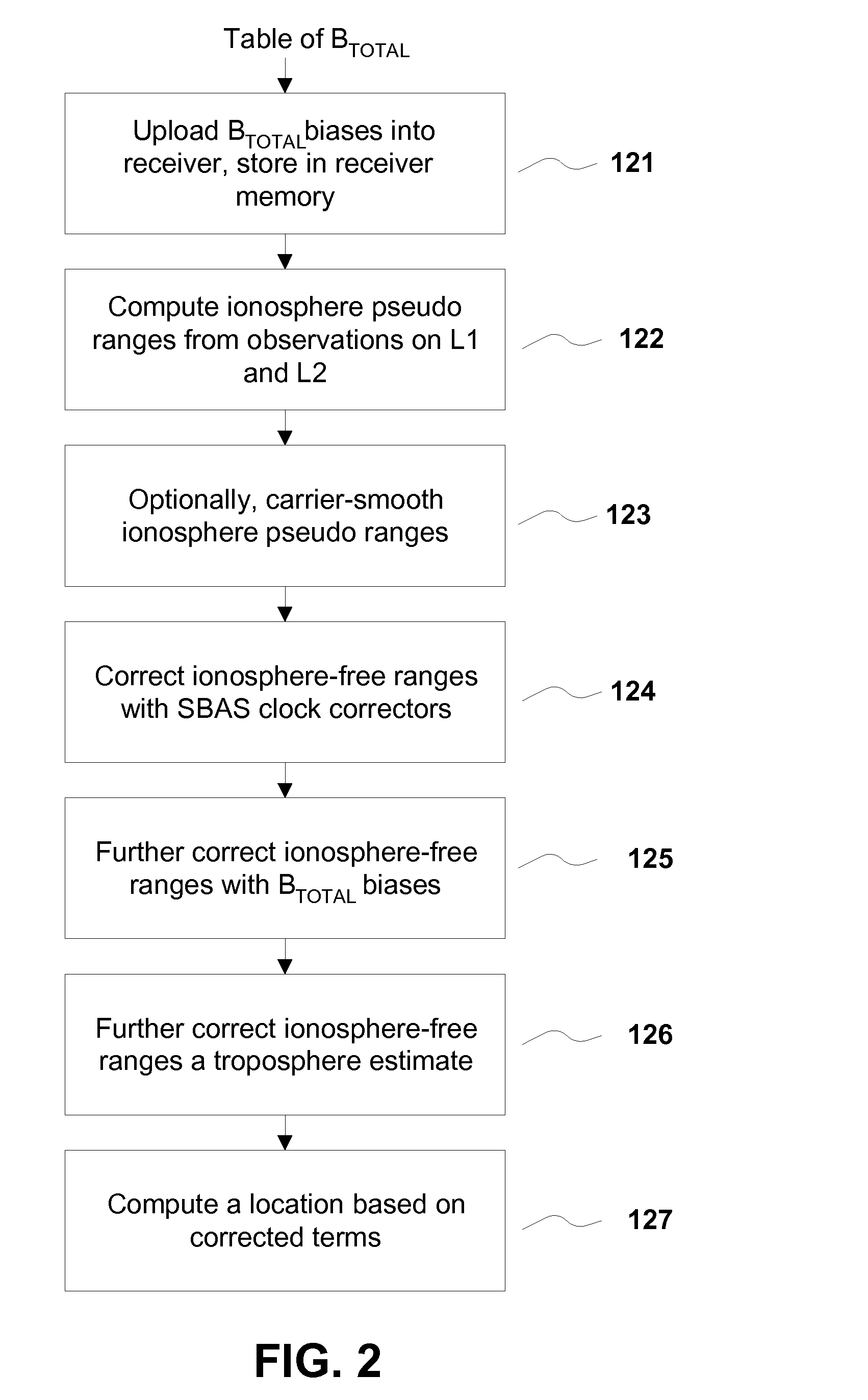

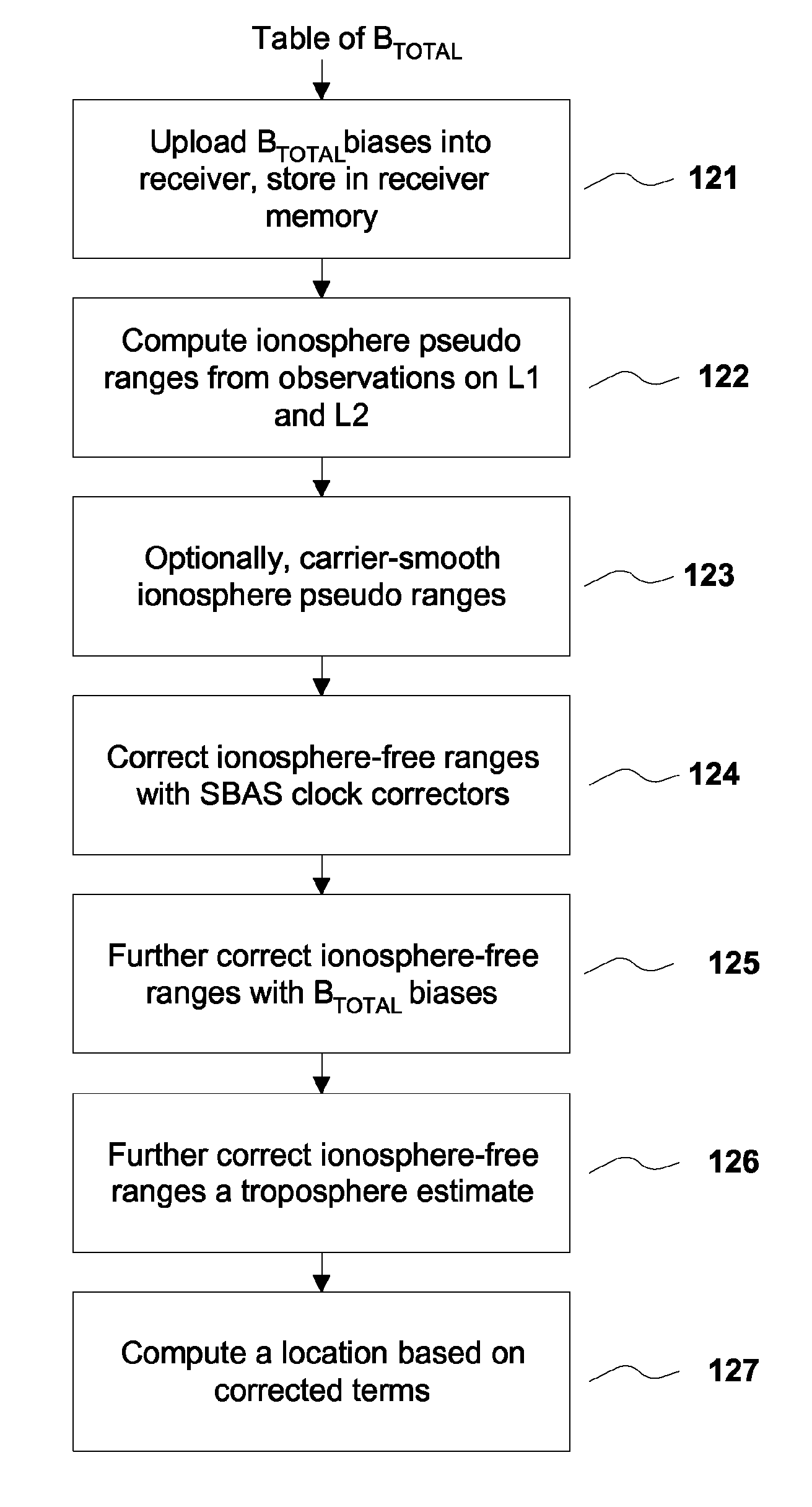

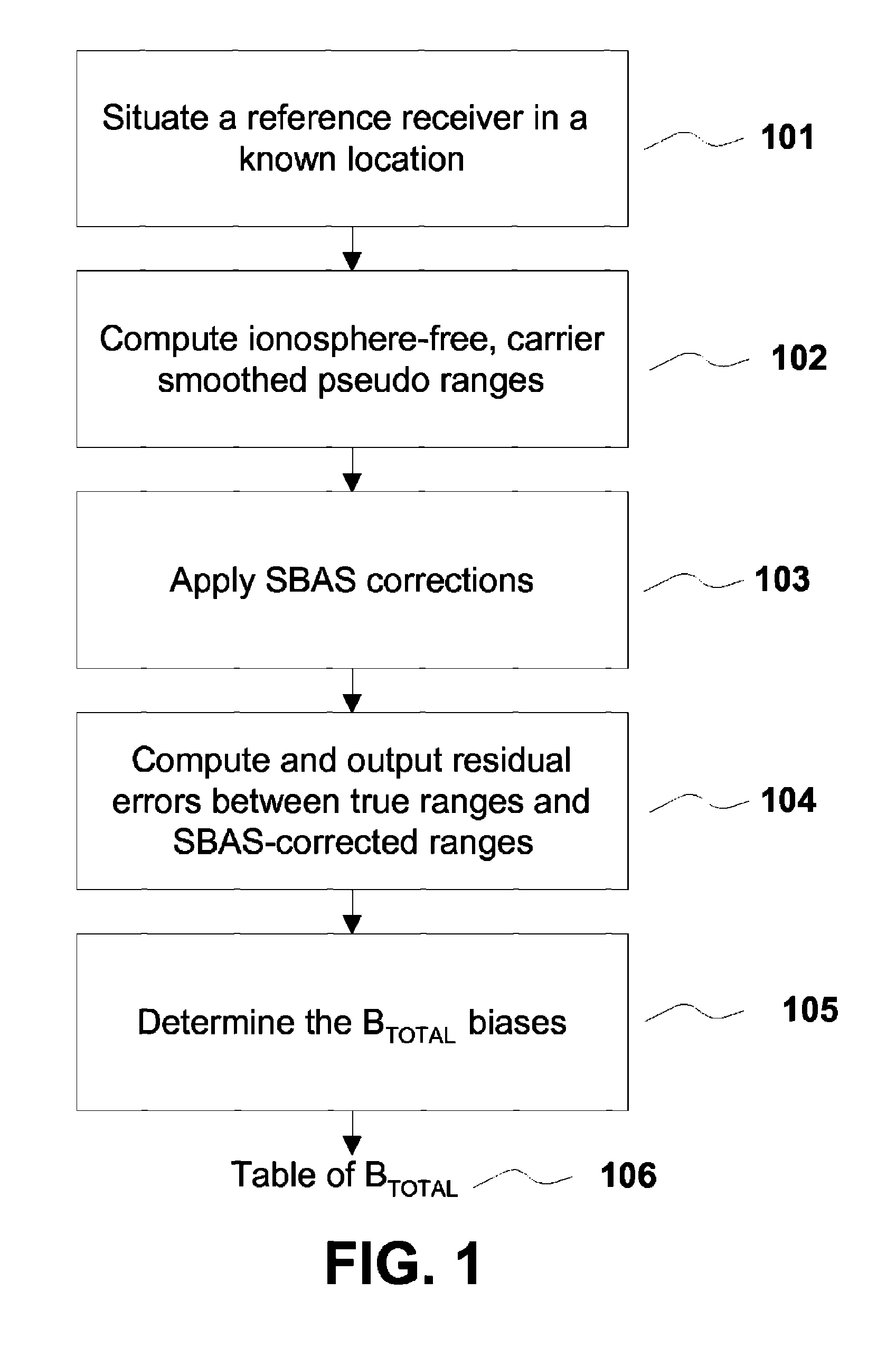

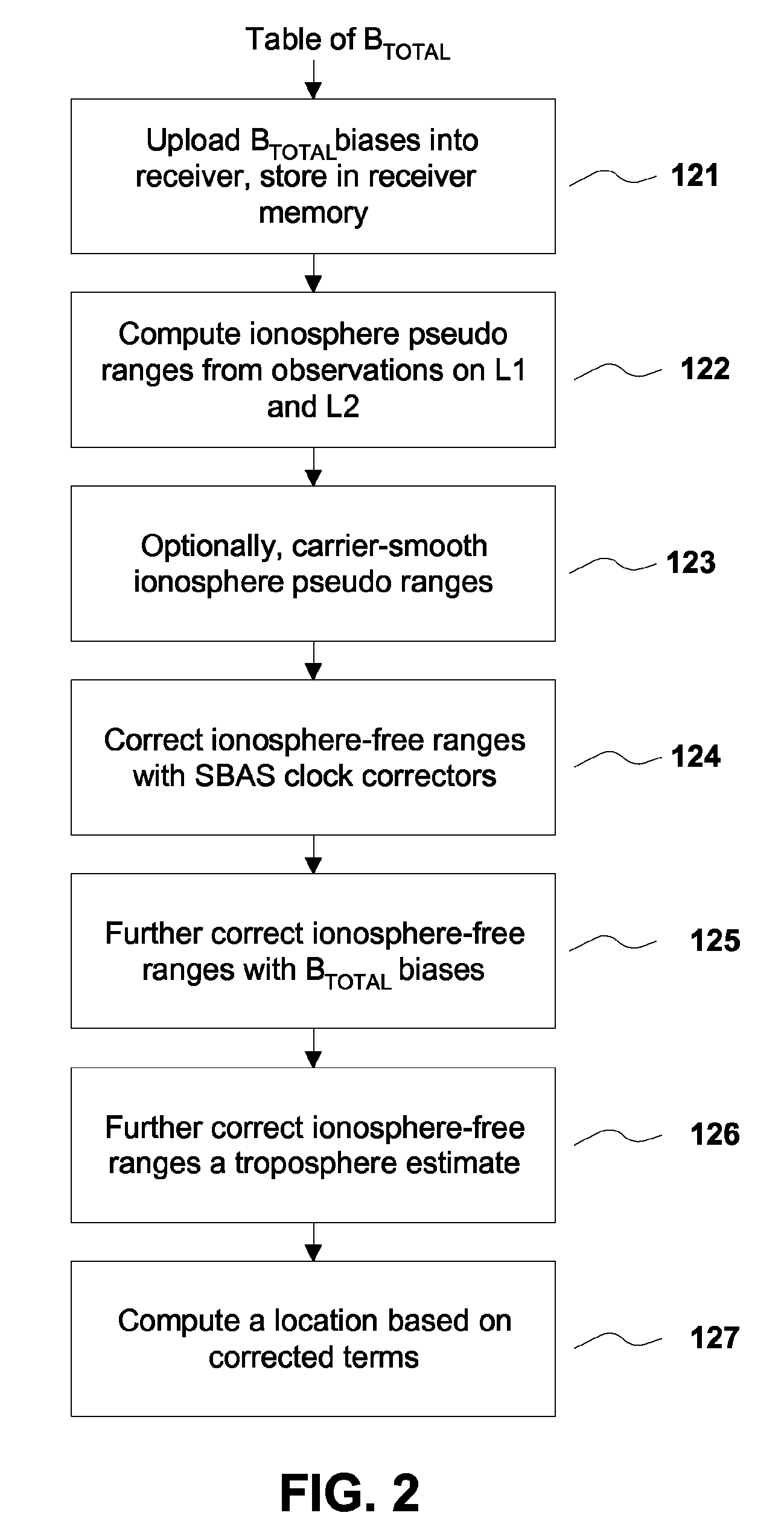

Removing biases in dual frequency GNSS receivers using sbas

ActiveUS20100231443A1Improve performanceImprove navigation accuracySatellite radio beaconingDual frequencyIonosphere

A method for removing biases in dual frequency GNSS receivers circumvents the need for ionosphere corrections by using L2(P) in combination with either L1(P) or L1(C / A) to form ionosphere-free ranges. A table of biases is stored in microprocessor controller memory and utilized for computing a location using corrected ionosphere-free pseudo ranges. A system for removing biases in dual frequency GNSS receivers includes a dual frequency GNSS receiver and a controller microprocessor adapted to store a table of bias values for correcting pseudo ranges determined using L2(P) in combination with either L1(P) or L1(C / A).

Owner:HEMISPHERE GNSS

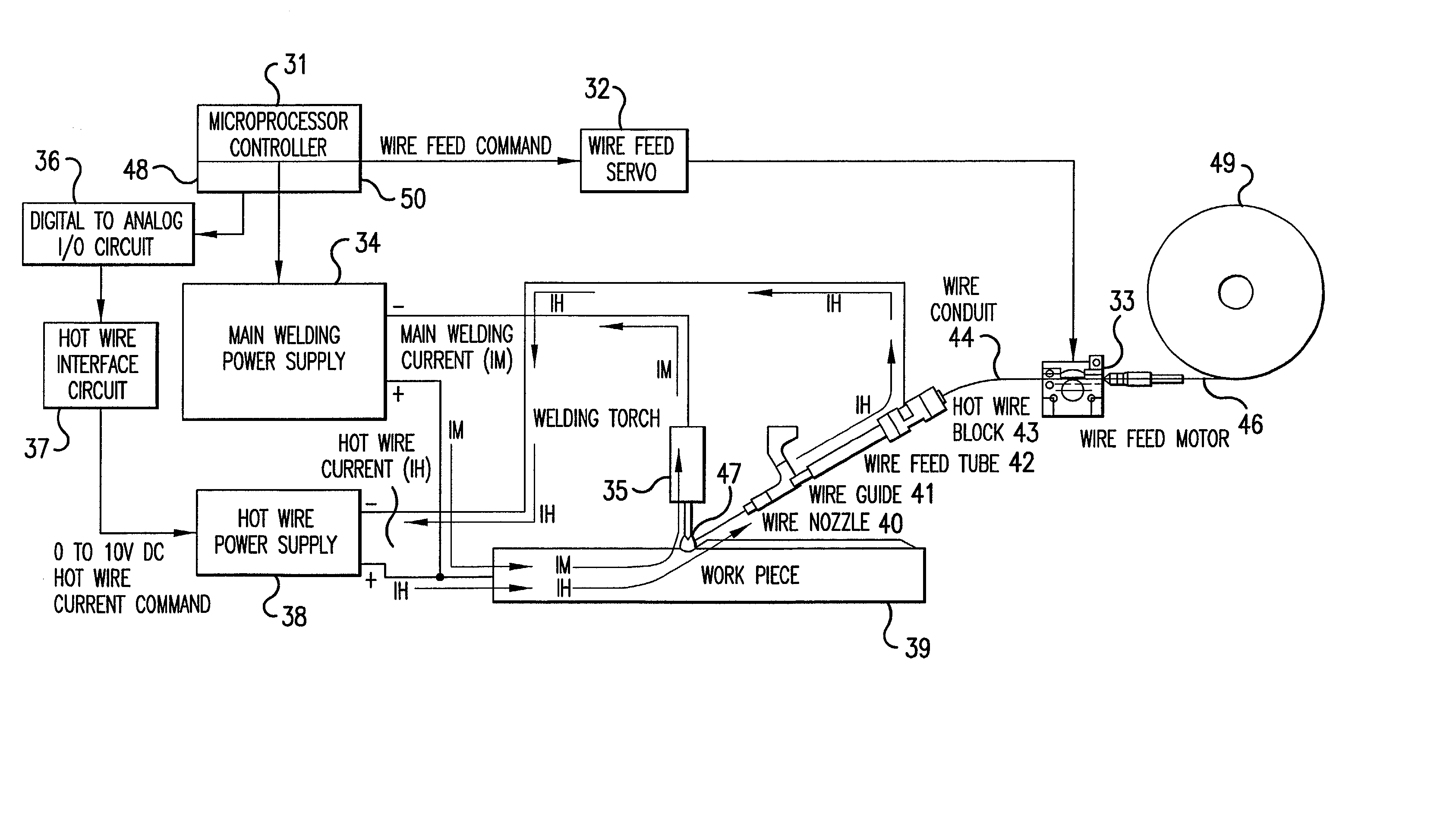

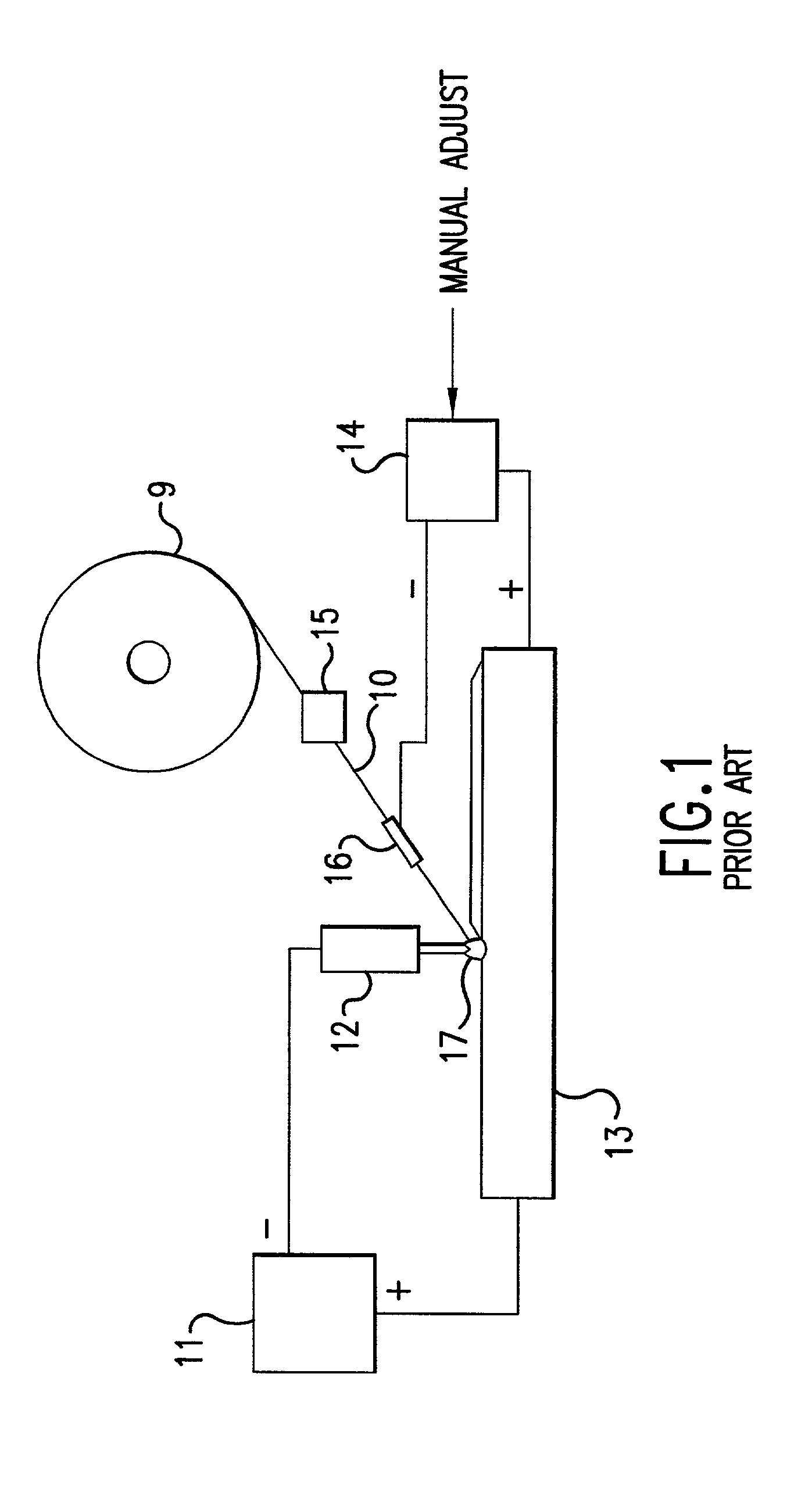

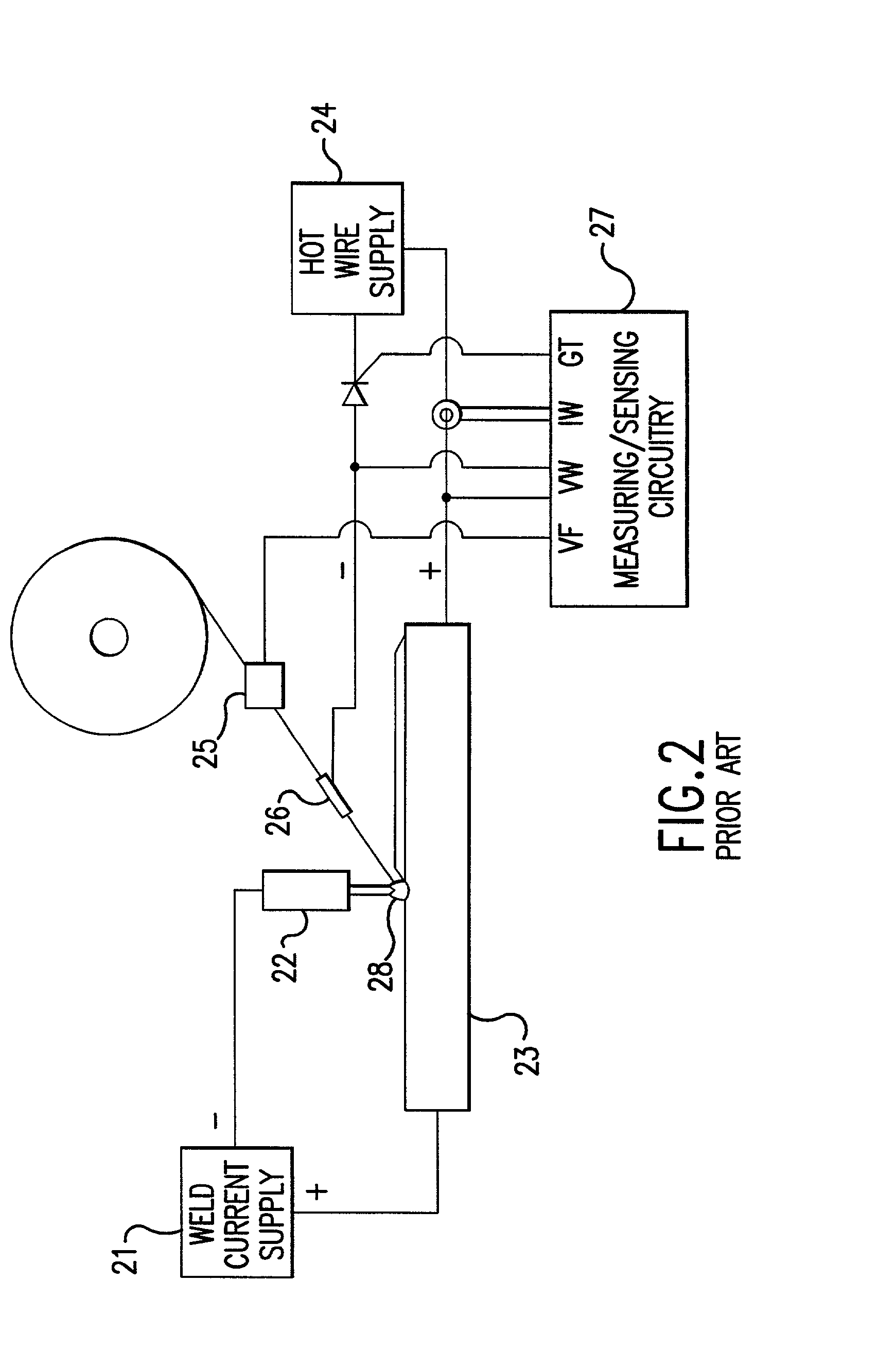

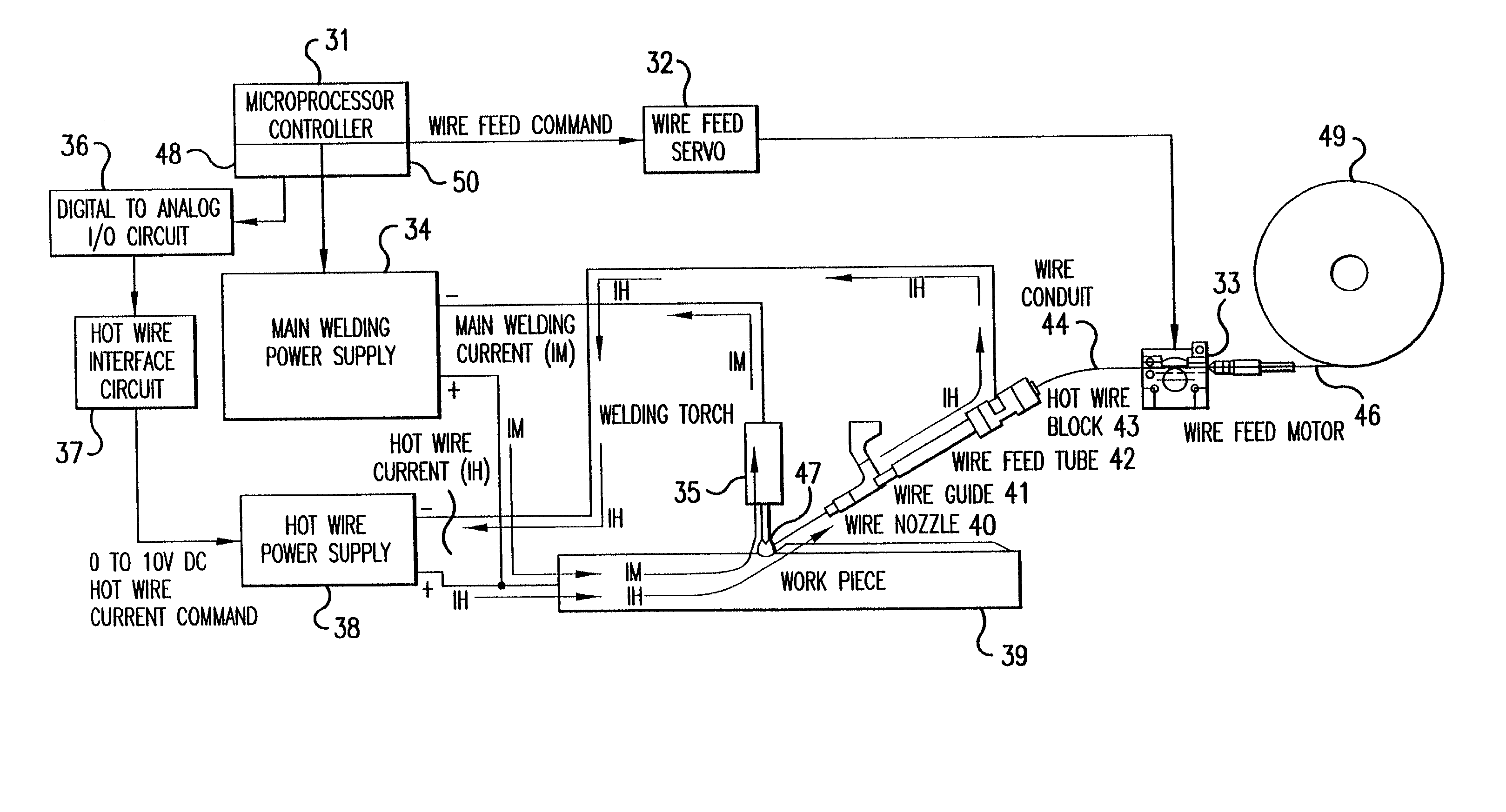

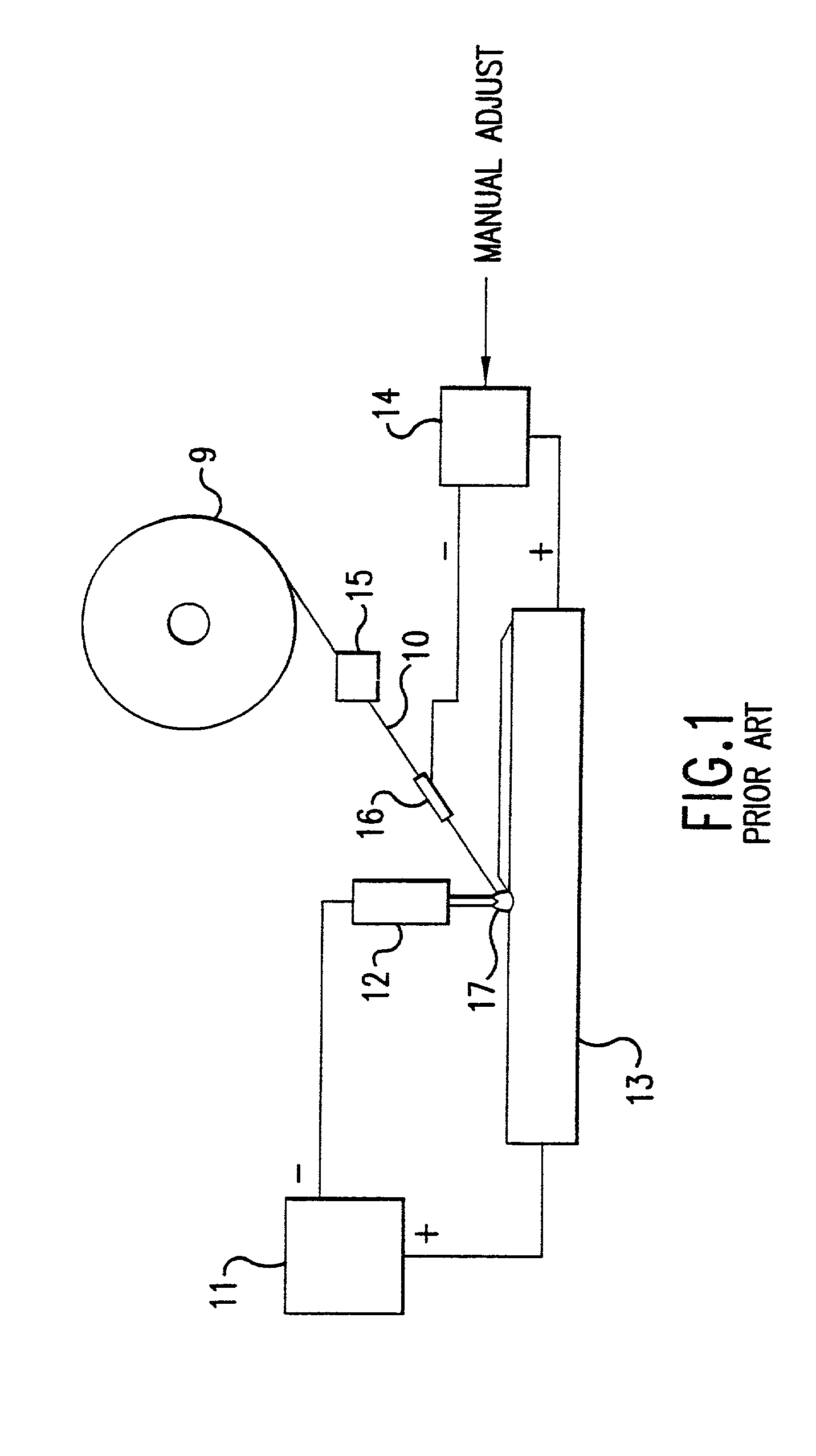

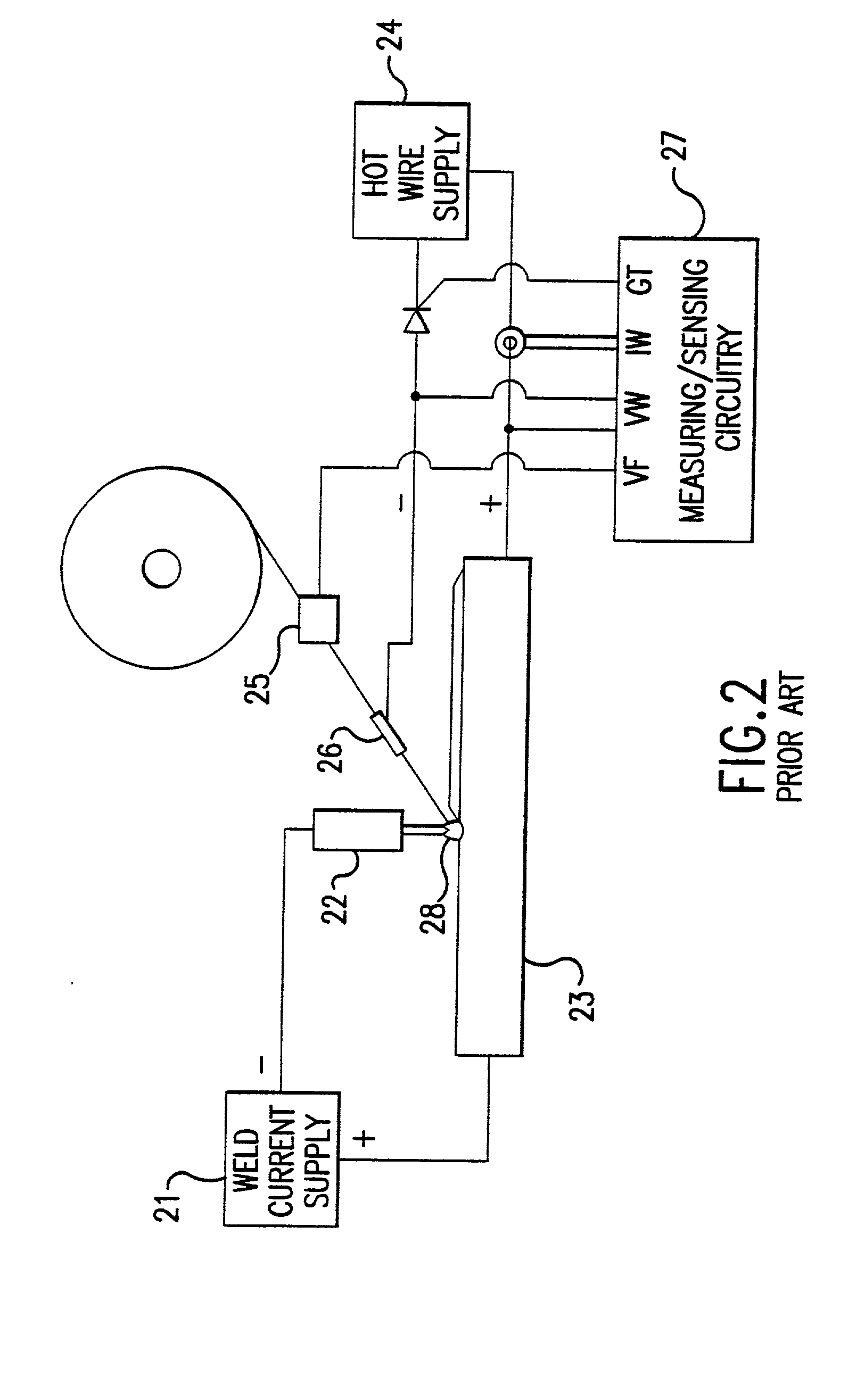

Method and system for hot wire welding

InactiveUS20020117489A1Welding/cutting media/materialsWelding electrode featuresPower flowWelding power supply

A hot wire welding method and system rely upon a welding torch with a non-melting electrode, a melting metal filler wire that is fed into a weld puddle created by welding arc, a microprocessor controller for controlling (i) current of the main welding arc, (ii) filler wire feed speed, and (iii) hot wire current for heating the filler wire. The method and system also rely upon a main welding power supply for supplying the main welding arc and a secondary DC supply for supplying the hot wire current. The hot wire current is automatically controlled by the microprocessor to supply the correct amount of current to the filler wire in response to changes in wire feed speed.

Owner:ARNDT TONY LEE +2

Intelligent dispensing system

ActiveUS20050167541A1Great user satisfactionMinimal down timeFilament handlingDomestic applicationsNetwork Communication ProtocolsPulp and paper industry

A system and apparatus for automatically dispensing a paper product mounted on a gravity-assisted holder through a dispenser. The apparatus includes an electric motor, a main product roller for automatically rolling a predetermined amount of the paper product from the holder, exit guide rollers for guiding the paper product through a front cover of the dispenser, and a series of interconnected gears that are driven by the electric motor to activate the main product roller and exit guide roller and operate both the main roller and exit roller at the same speed. Operating the rollers at the same speed prevents paper or tissue jamming inside the dispenser. The system monitors usage of each paper product dispenser with each dispenser having a microprocessor controller for determining a corresponding paper product status for the dispenser. Each paper product dispenser communicates with a master network device preferably mounted on a ceiling plane. Paper product status messages are transmitted between each dispenser and master network device unit using a standard data communications protocol. The master network device communicates the paper product status for each individual dispenser to an independent building automation and control network. A central control console that is interoperable with the building automation and control network monitors the status of each paper product dispenser through signals communicated from a master receiver / transmitter unit to the central control console.

Owner:VALVE SOULTIONS INC

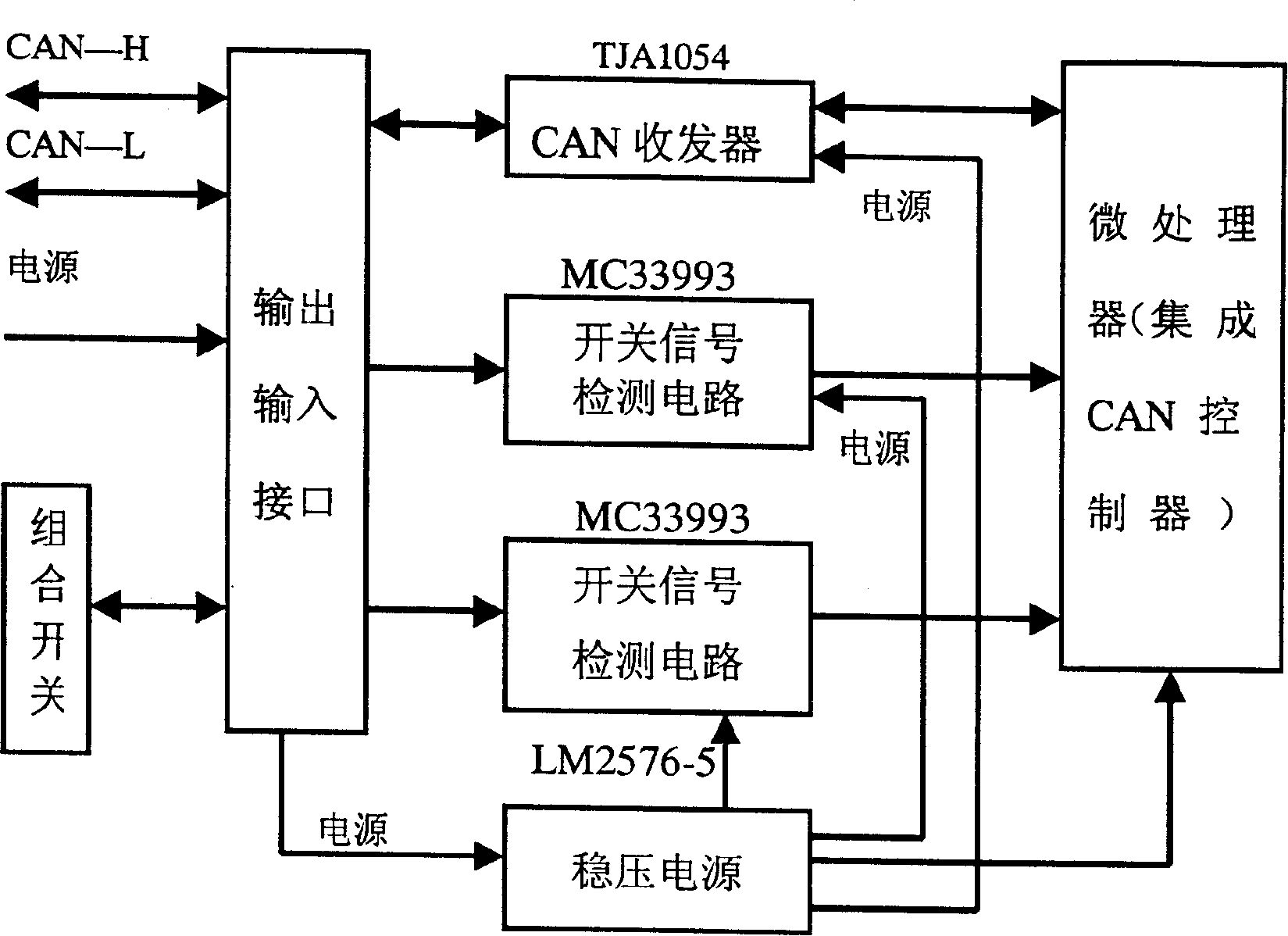

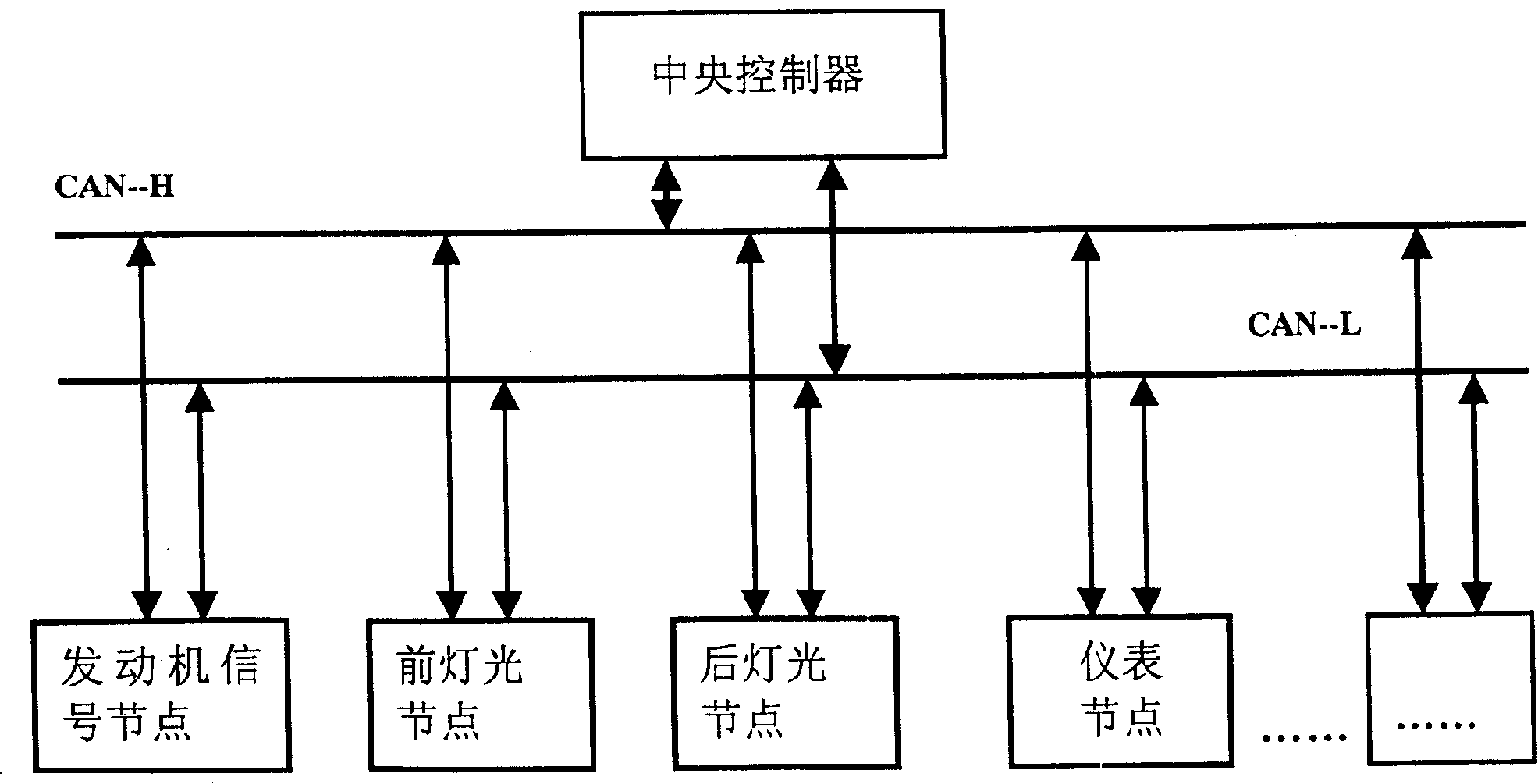

On vehicle network central control unit and its managing and controlling method for on-vehicle network

This invention relates to a central control unit of a car carried network and a method for controlling and managing the car-carried network, among which, the central control unit includes a microprocessor CPU, a CAN T / R device, a CAN controller, a CAN bus, interface, a regulated supply, an input / output interface circuit and a switch signal test circuit. The network system is composed of several electronic control units with CAN interface, the PCU and all nodes of the car-carried network keep communication therefore, the CPU stores node database originally matched, the central control unit and other nodes interact via data communication of matched data request, response and network management request and response to realize the network management of configuration, diagnosis, sleep and awaking.

Owner:袁光辉

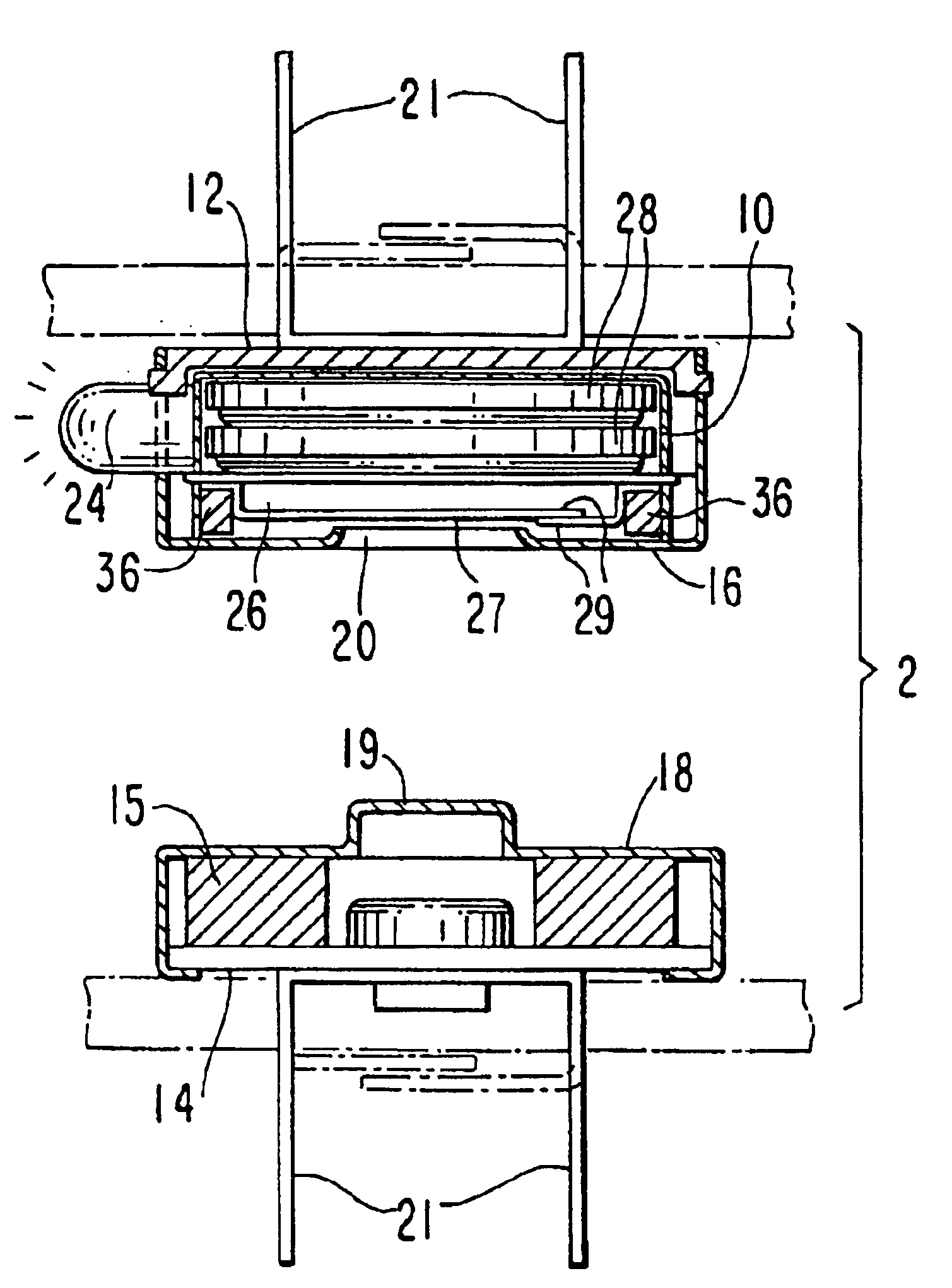

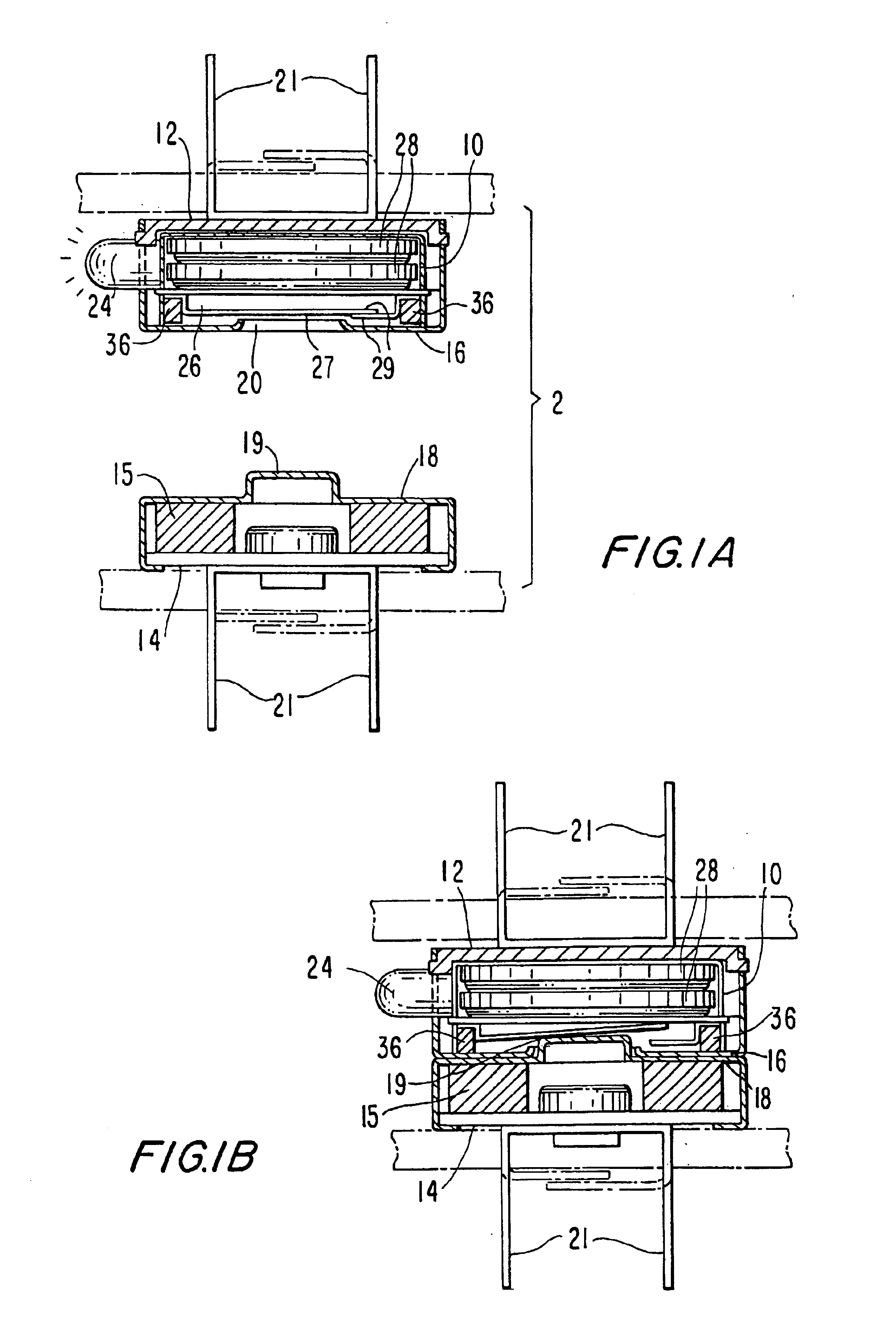

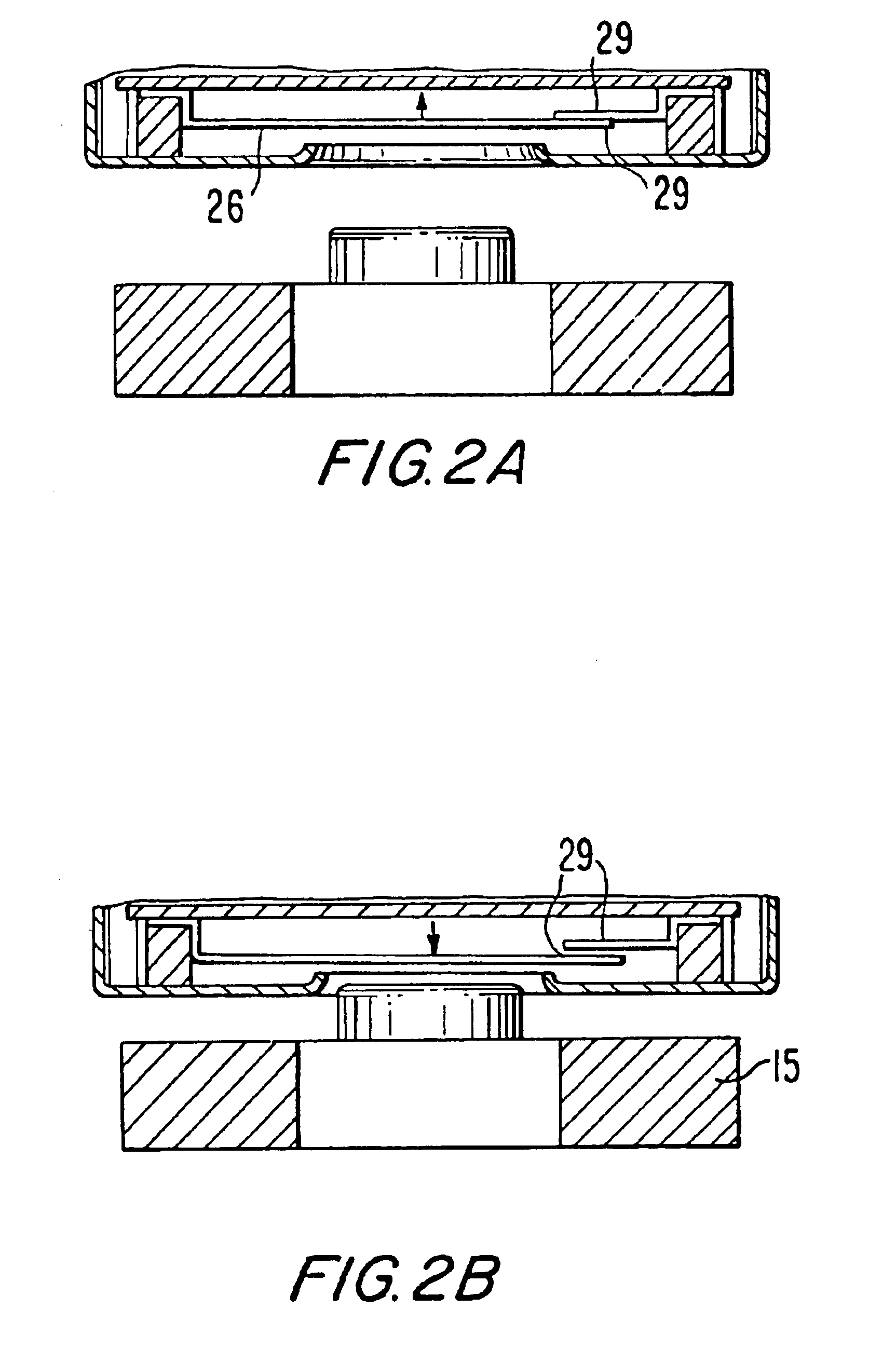

Combination fastener and lighting device

InactiveUS6848808B2Easy to replacePursesLighting support devicesMicroprocessor controllerLight-emitting diode

A combination fastener and separate, manually operable lighting device includes a pair of complimentary fastener members for releasably securing portions of a portable carrying case, such as a lady's handbag, in a closed position when mating surfaces of the complementary members are placed in contact with each other. The lighting device includes a light emitting diode (LED), battery and switch, and an optional programmed microprocessor controller, that is removably secured to a first member of the pair of fastener members. The lighting device is deactivated when the mating surfaces are placed proximate to each other and is activated to illuminate an interior of the accessory when the surfaces are separated. The lighting device utilizes a reed switch which responds to a proximate magnetic force and the complimentary member includes a magnet so that the powers to the LED is turned off when the mating surfaces are brought into contact with each other.

Owner:ACOLYTE SYST

Extendable frame work vehicle having lift member movable in a true vertical fashion

ActiveUS20090206589A1Improve versatilityImprove effectivenessSafety devices for lifting equipmentsVehicle body stabilisationHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor and at least one valve network.

Owner:EXTENDQUIP LLC

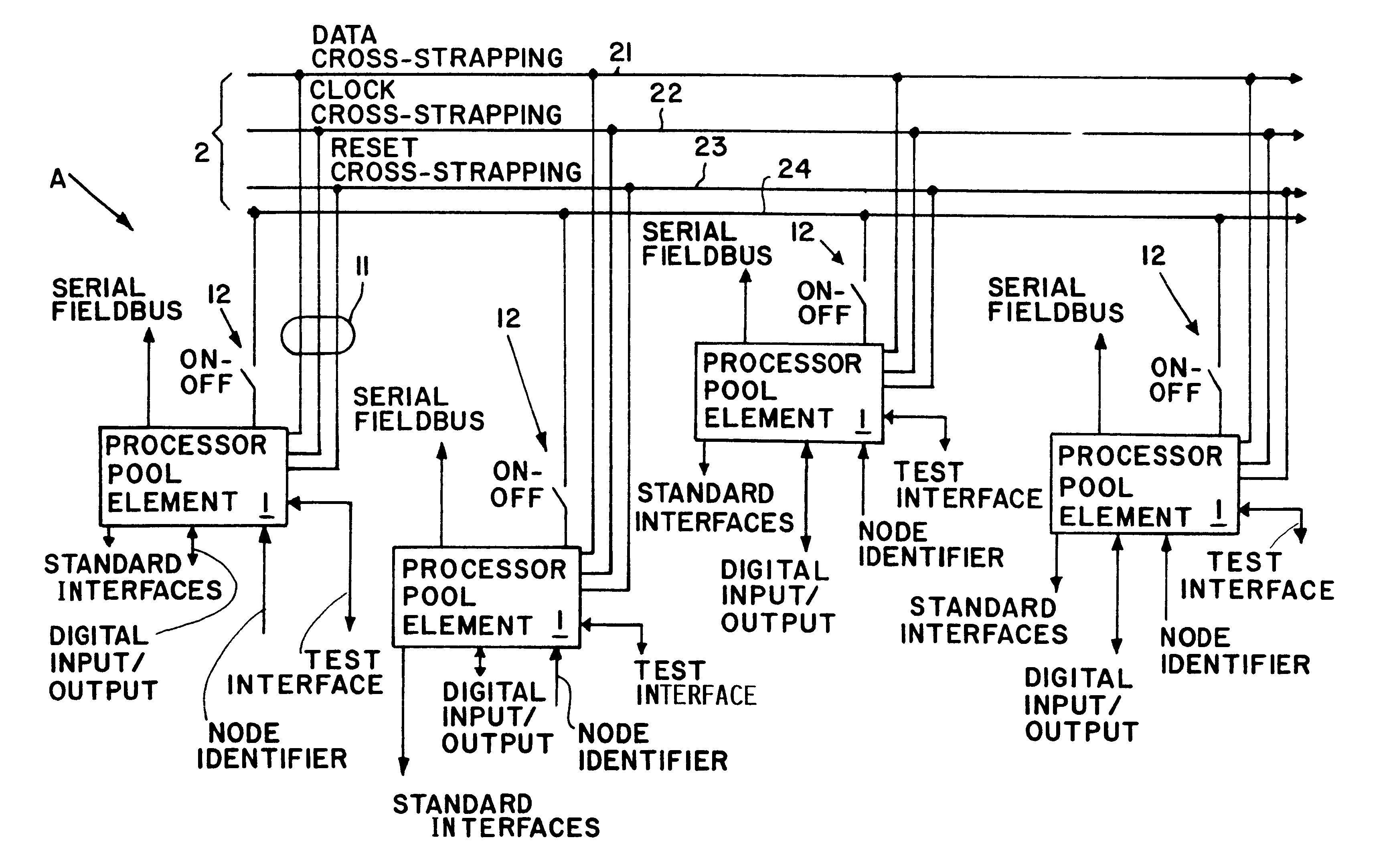

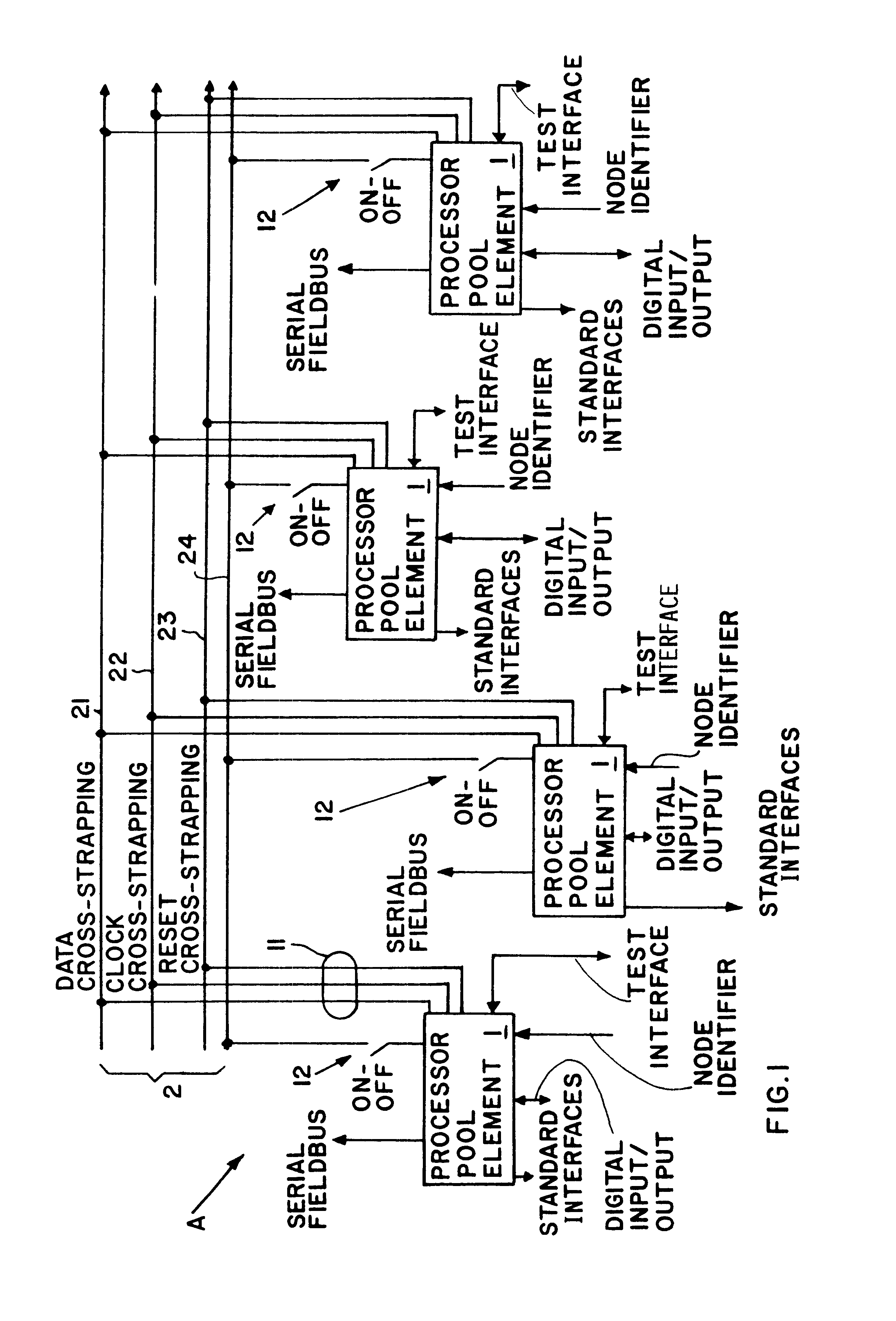

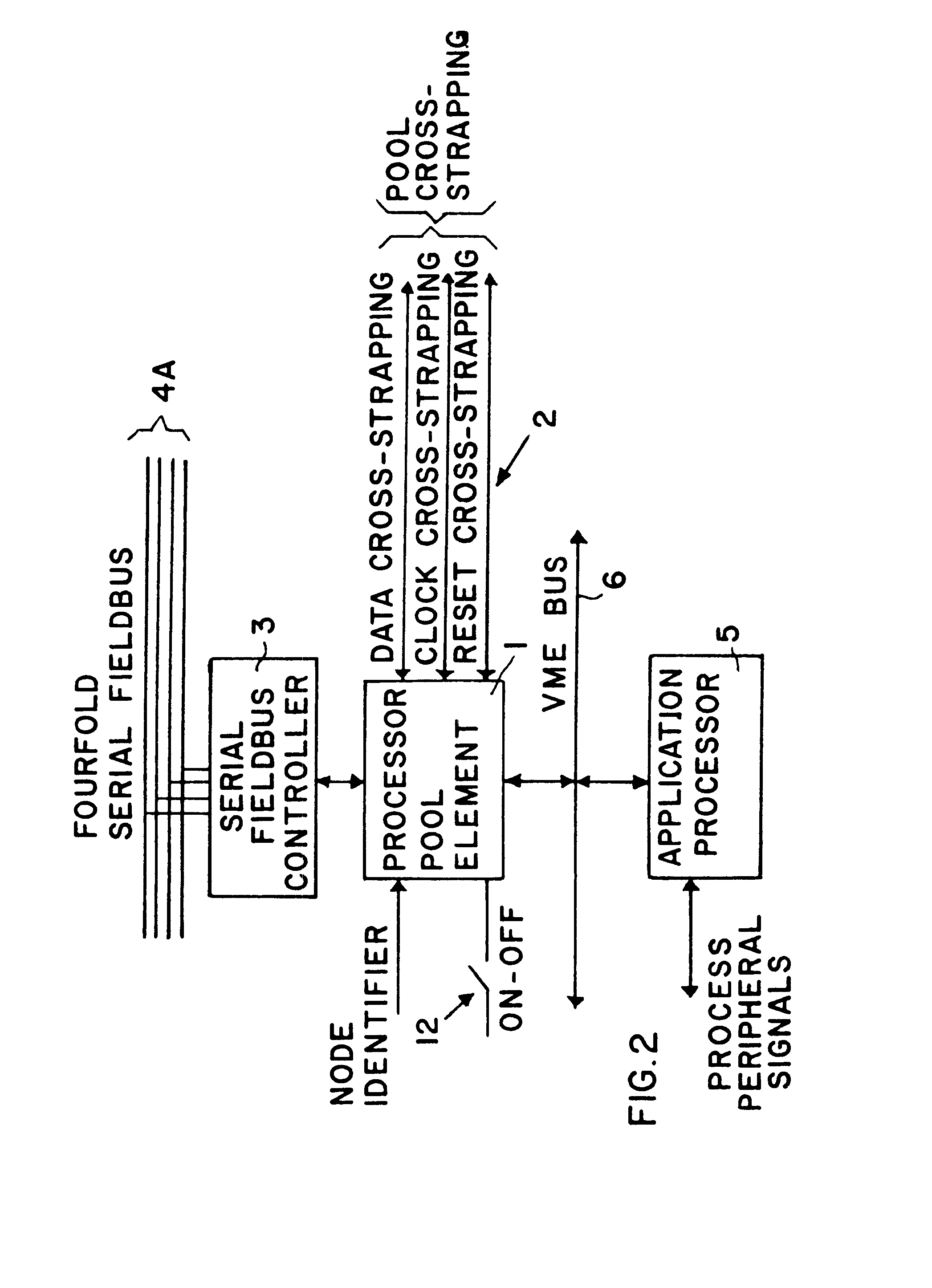

Method and apparatus for fault tolerant execution of computer programs

InactiveUS6434712B1Maximum countEconomically manufacturedRedundant hardware error correctionArithmetic logic unitProcessor element

A circuit arrangement for the fault tolerant execution of digital computer programs includes a plurality of arithmetic logic units embodied as processor pool elements connected together so that they can each execute the program in parallel. The processor elements are connected to each other through respective data, clock and reset cross-strapping interconnect lines, and are each connected to one or more serial field buses. Each processor element includes at least one microprocessor controller for controlling the functions of the processor element in such a manner that any selected number of the processor elements can be automatically actuated at any time to simultaneously execute the program in parallel and thereby achieve a prescribed degree of redundancy in the circuit arrangement. The data cross-strapping line transmits data among the several processor elements, the clock signal cross-strapping line achieves a compelled synchronization of all of the processor elements, and the reset cross-strapping line carries out the deactivation of any processor element that is recognized as carrying out a faulty execution of the program or that is not necessary for achieving the required degree of redundancy. A deactivated processor element may later be reactivated to again participate in the parallel execution of the program.

Owner:DAMELERKLESLER AVIATION

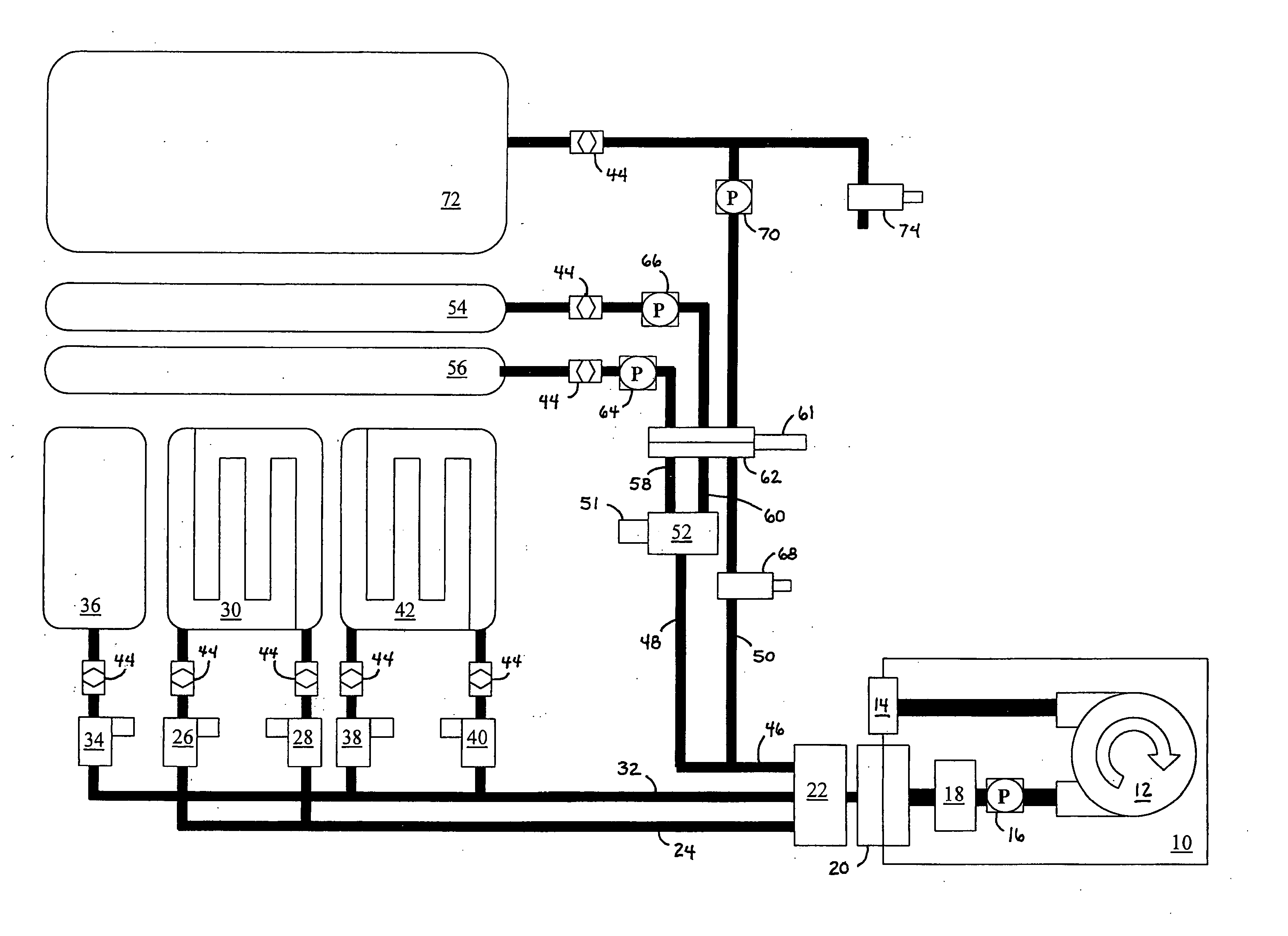

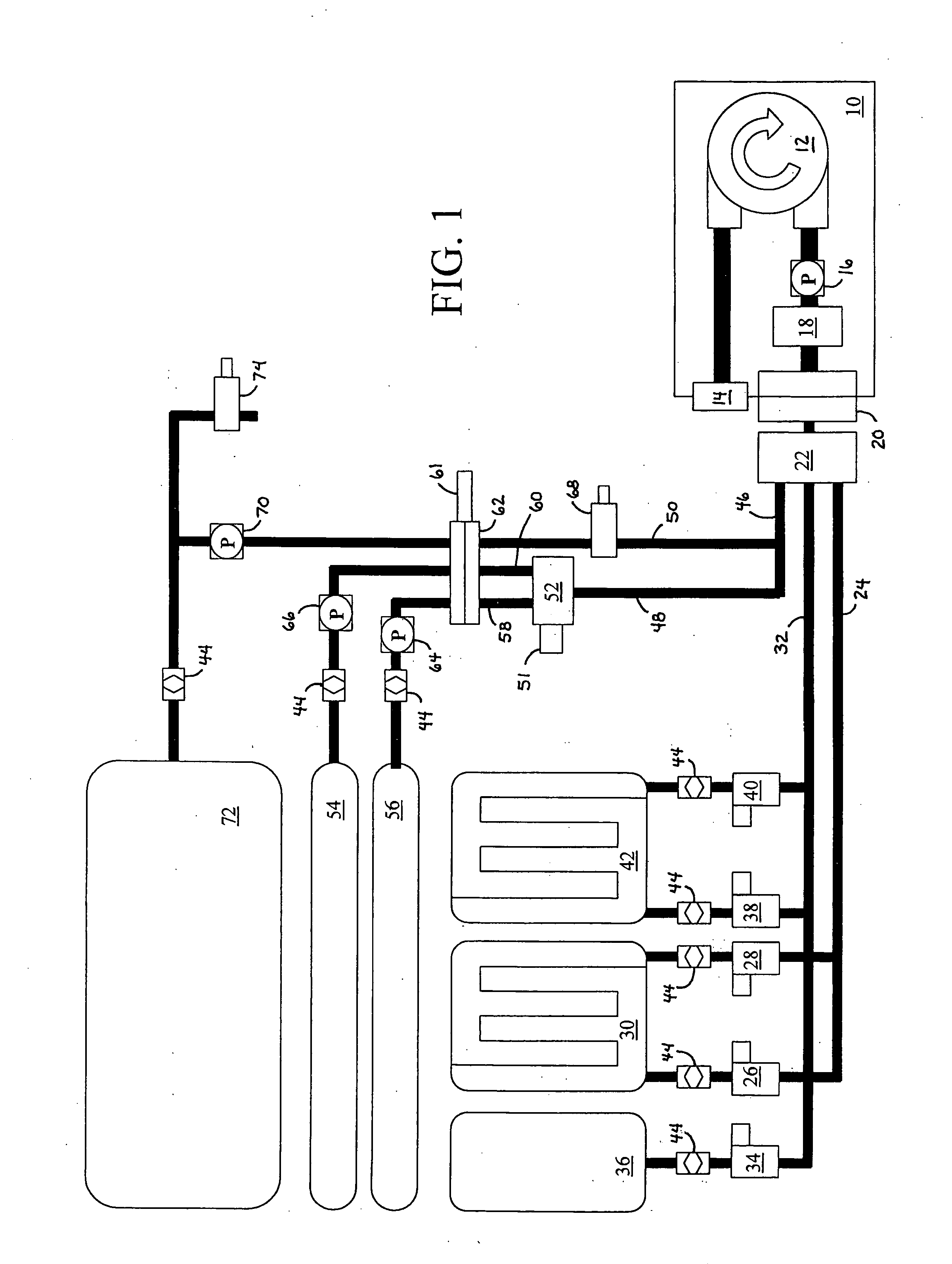

System and method for maintaining air inflatable mattress configuration

ActiveUS20060179579A1Easy maintenanceReduce crosstalkStuffed mattressesSpring mattressesFoot cushionControl system

A system and method for maintaining an air inflation mattress configuration sufficient for patient support and comfort. Infrared illumination levels are measured within individual or groups of inflated mattress chambers. A staggered approach to illumination monitoring of chambers or sections to eliminate crosstalk between the infrared sensors is carried out. Distributed microprocessor controllers established in a network configuration utilizing controller network protocols reduces the wiring and connections necessary for the assembled system. Various mattress cushion construction techniques, such as sewing and or RF welding methods, are used for the creation of individual chambers utilizing specific types of IR translucent, transparent or reflective materials. The construction of the cushions and bladders in the system includes the use of various types of fabrics with low to high air loss qualities as required. The overall mattress assembly, including the control systems and the methodologies associated with such control systems, provide a unique approach to the maintenance of a consistently comfortable patient support surface. The use of a handheld unit for both programming the system and downloading information about the operation of the system is also anticipated. The specific cushion construction designs associated with the head, body, and foot cushion components of the mattress are tailored to operate specifically with the control capabilities (sensors and air flow regulators) of the invention.

Owner:HUNTLEIGH TECH LTD

Laser projection system

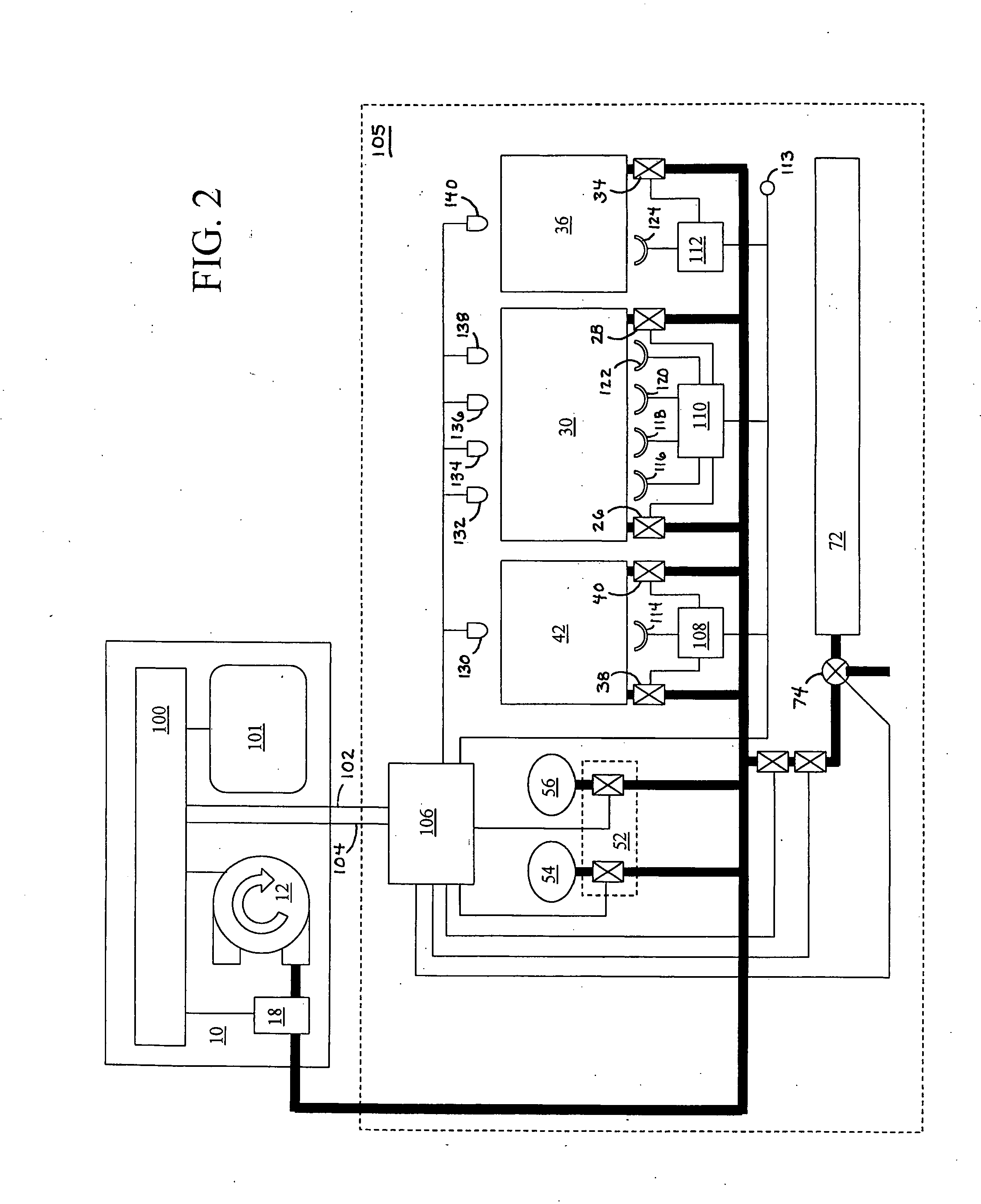

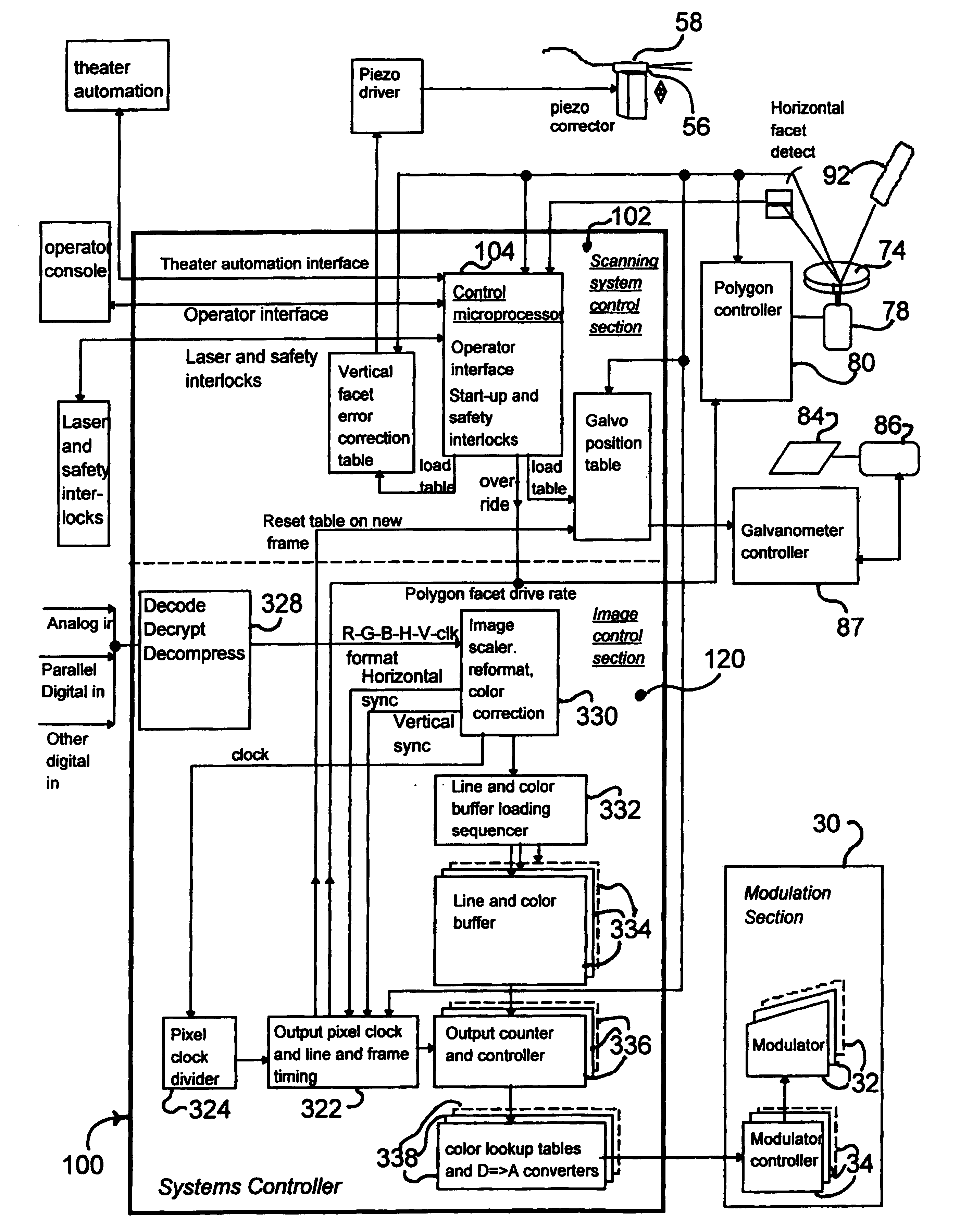

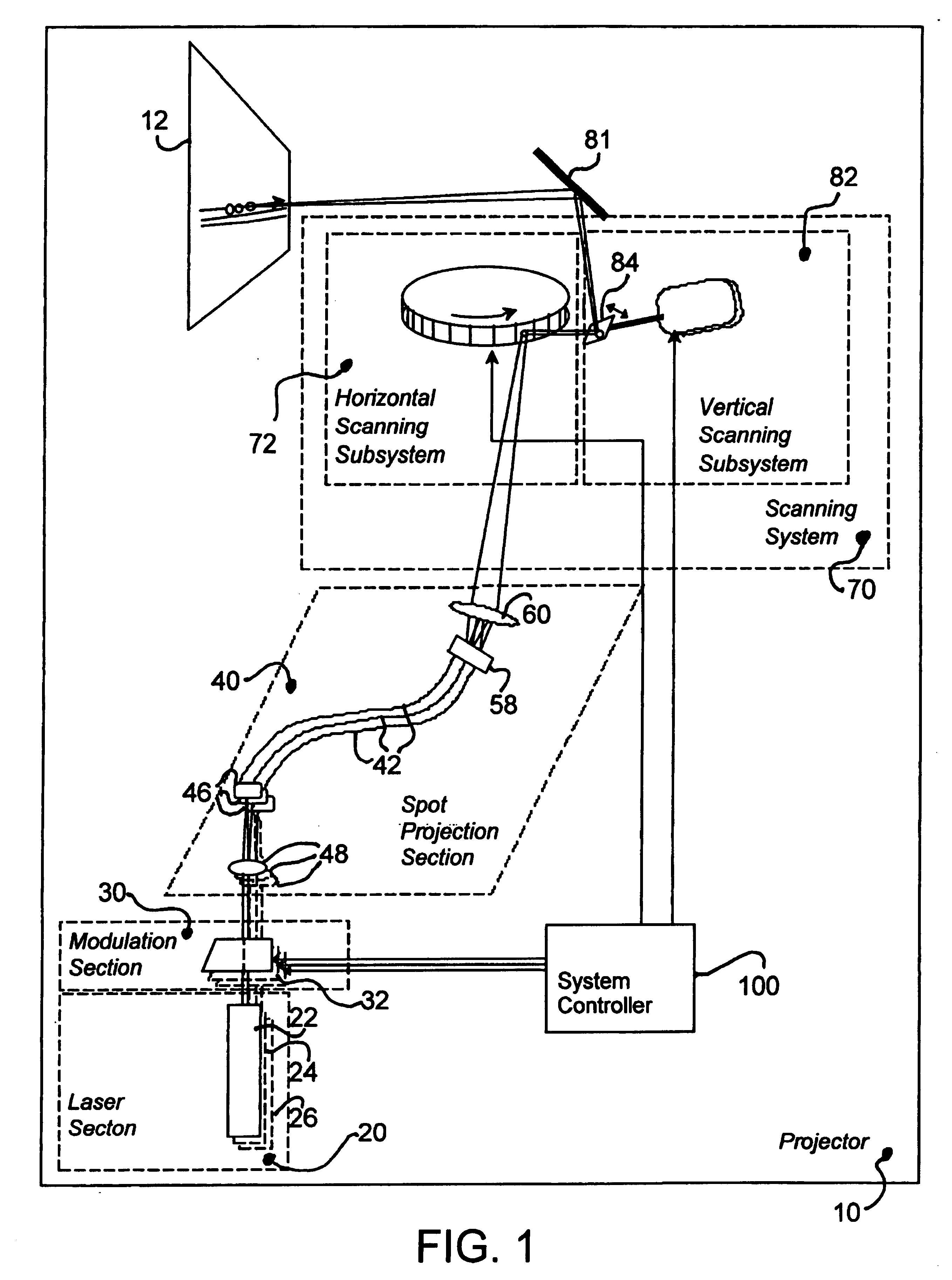

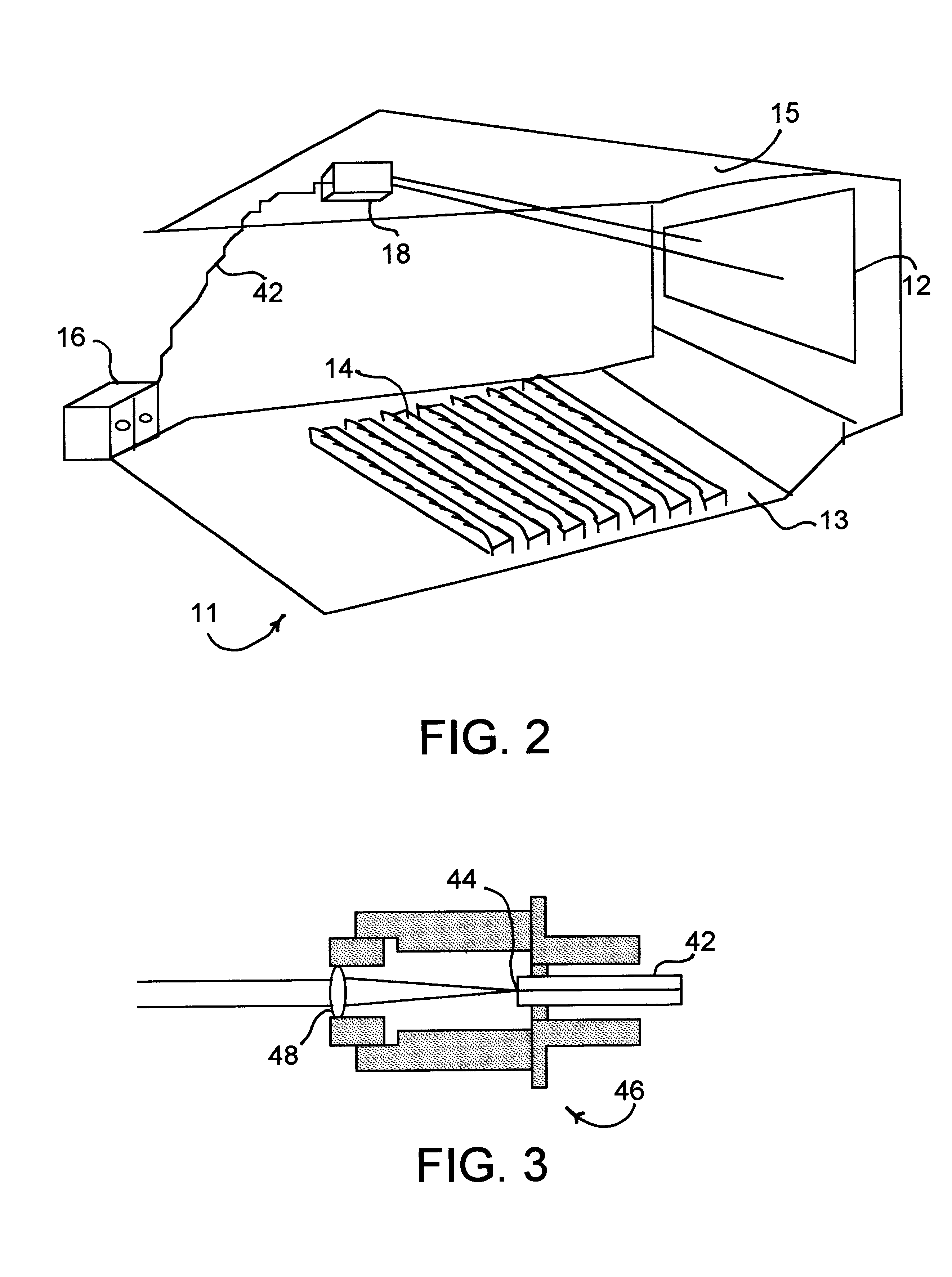

InactiveUS7102700B1Easy to useLow costTelevision system detailsPicture reproducers using projection devicesGratingScan line

A laser projection system preferably for use in commercial motion picture theaters and other large screen venues, including home theater, uses optical fibers to project modulated laser beams for raster scanning on the screen. The emitting ends of the optical fibers are arranged in an array such that red, green and blue spots are simultaneously scanned onto the screen in multiple lines spaced one or more than one scan line apart. The use of optical fibers for laser beam projection eliminates the need to use complex optics, and enables the scanning of small, high resolution spots on the screen. The use of optical fiber also permits convenient packaging and permits replacement, upgrading or modification of the system components. The scanning of multiple lines simultaneously is accomplished by reordering the video signal with a microprocessor controller component to write lines in a sequence after repeated vertical sweeps to form a complete picture. In a preferred embodiment, the video signal is reordered to scan different color beams at different times to render the desired composite of the red, green and blue spots at each dot location on the screen. Alternate embodiments are disclosed to illustrate the flexibility of the system for different optical fiber output head spacings, and for different types of laser, modulation, and scanning components.

Owner:MAGIC LANTERN

Ferromagnetic detection enhancer

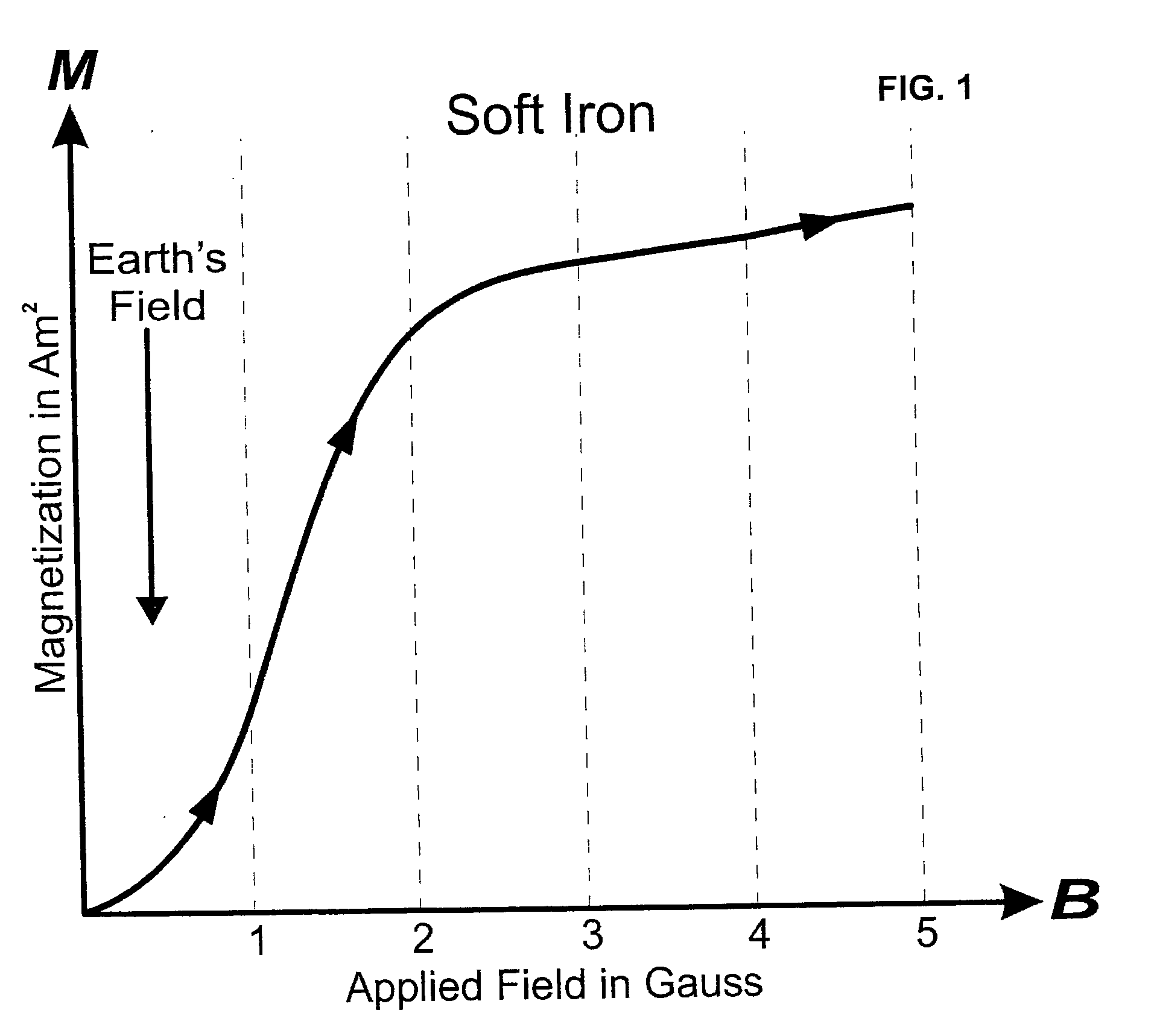

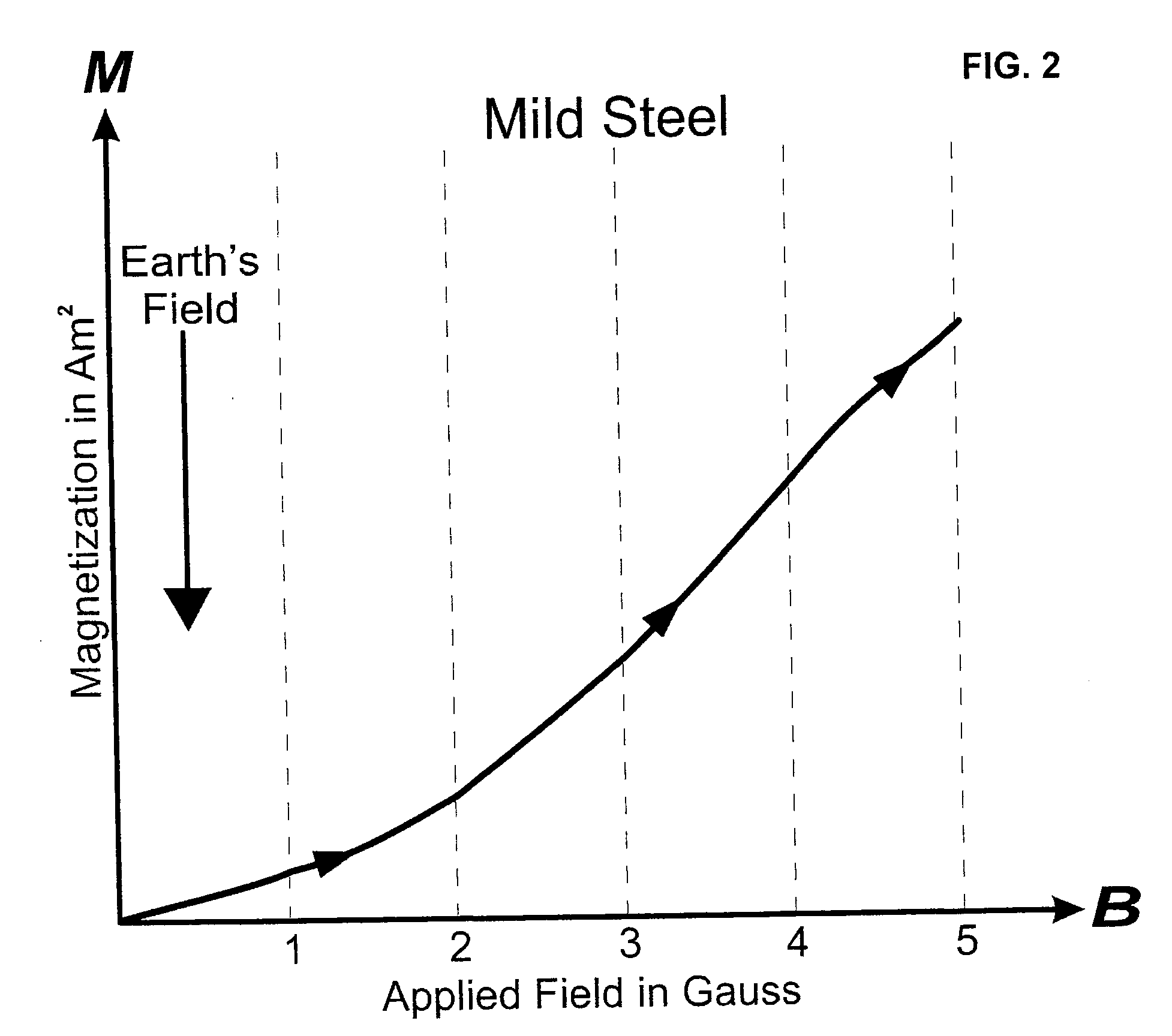

ActiveUS20090167307A1Massive supply requirementAbility to detectElectric/magnetic detectionMeasurements using magnetic resonanceElectronic switchMagnetization

An apparatus for increasing the ability to detect ferromagnetic objects by increasing the magnetization of the objects. The apparatus includes at least one coil to generate a magnetic field positioned in the area of the object to be detected. The apparatus includes an electrical energy storage capacitor bank capable of quickly releasing stored energy. The apparatus includes a high speed, high current electronic switch capable of quickly transferring the stored energy from the capacitor bank to the coil thereby producing in the coil a short duration, single polarity magnetic field pulse. The apparatus includes a sample and hold circuit capable of acquiring magnetic field sensor data during periods when the pulsed magnetic field is not present. The apparatus includes a microprocessor controller to control timing and sequence of the magnetic pulse generation and the sensor data sample and hold process. The apparatus may be for portal handheld or head mounted applications.

Owner:KOPP KEITH

Patient compliance monitor

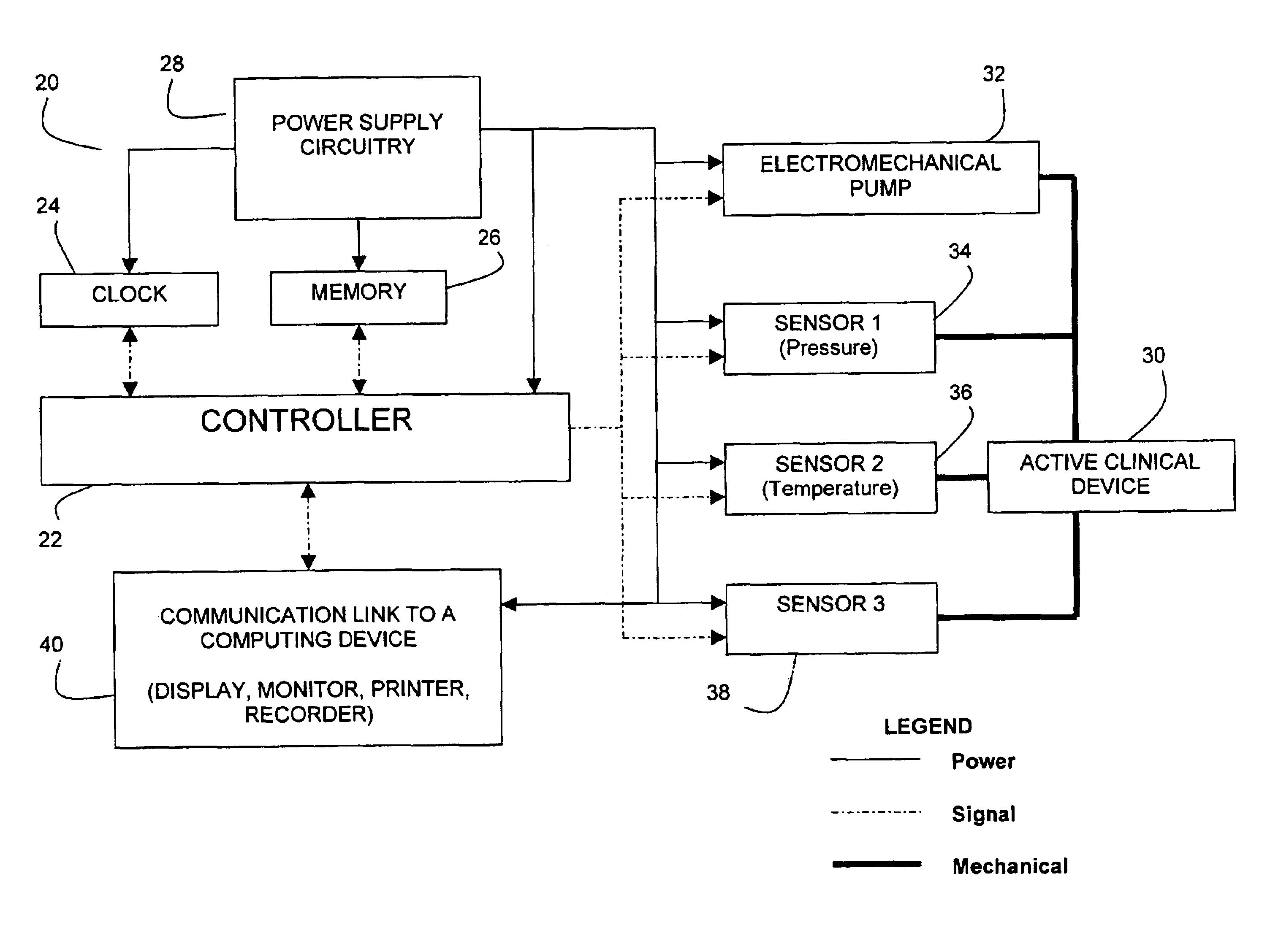

InactiveUS6926667B2Physical therapies and activitiesPneumatic massagePatient complianceMicroprocessor controller

A patient monitoring device includes a microprocessor controller having a clock circuit and memory coupled to one or more sensors physically carried by a medical appliance such that as the medical appliance is properly fitted to and worn by the patient, the sensors provide an electrical signal confirming that which may be then timed to provide data which confirms a patient's compliance with a recommended protocol. By combining and correlating the sensor data with the clock or timer provided as part of the controller, a time chart of data may be created indicating when and for how long the patient actually wears the device. Additionally, other sensors may be used to collect data relating to various operational parameters of the device including the amount of negative pressure presented under a vacuum dome or other parameters related to the operation of the medical appliance itself, as desired.

Owner:BRAVA

Burn-in testing apparatus and method

ActiveUS20050206368A1Quick releaseThermometer detailsFault location by increasing destruction at faultTelecommunications linkPackage testing

An integrated circuit (IC) package testing apparatus integrates a temperature sensor, heater (or cooler), and controller within a single modular unit. The controller is a microprocessor embedded within the modular unit and in communication with the sensor and heater. The controller allows a selected testing temperature to be input by a user via a communications link to the controller. Each IC package has its testing temperature individually controlled by a controller. The module is easily attached and removed from an open-top socket through the use of latches on the testing socket. Many IC packages can be quickly placed and removed from testing sockets when a matrix of sensors and heaters (or coolers) are located on a single top attach plate with the sensors and heaters (or coolers) individually spring-loaded on the single top attach plate.

Owner:LTI HLDG INC

Method and system for hot wire welding

InactiveUS20020117488A1Welding/cutting media/materialsWelding electrode featuresWelding power supplyEngineering

A hot wire welding method and system includes a welding torch with a non-melting electrode, a melting metal filler wire fed into the weld puddle created by the welding arc, a microprocessor controller for controlling the current of the main welding arc, filler wire feed speed, and hot wire current control for the heating of the hot wire. The method and system also includes a main welding power supply for supplying the main welding arc and a secondary DC supply for supplying the hot wire current. The hot wire current is automatically controlled by the microprocessor to supply the correct amount of hot wire current to the filler wire with changes in wire feed speed.

Owner:LIBURDI ENG

Removing biases in dual frequency GNSS receivers using SBAS

ActiveUS8085196B2Improve performanceImprove navigation accuracySatellite radio beaconingDual frequencyIonosphere

A method for removing biases in dual frequency GNSS receivers circumvents the need for ionosphere corrections by using L2(P) in combination with either L1(P) or L1(C / A) to form ionosphere-free ranges. A table of biases is stored in microprocessor controller memory and utilized for computing a location using corrected ionosphere-free pseudo ranges. A system for removing biases in dual frequency GNSS receivers includes a dual frequency GNSS receiver and a controller microprocessor adapted to store a table of bias values for correcting pseudo ranges determined using L2(P) in combination with either L1(P) or L1(C / A).

Owner:HEMISPHERE GNSS

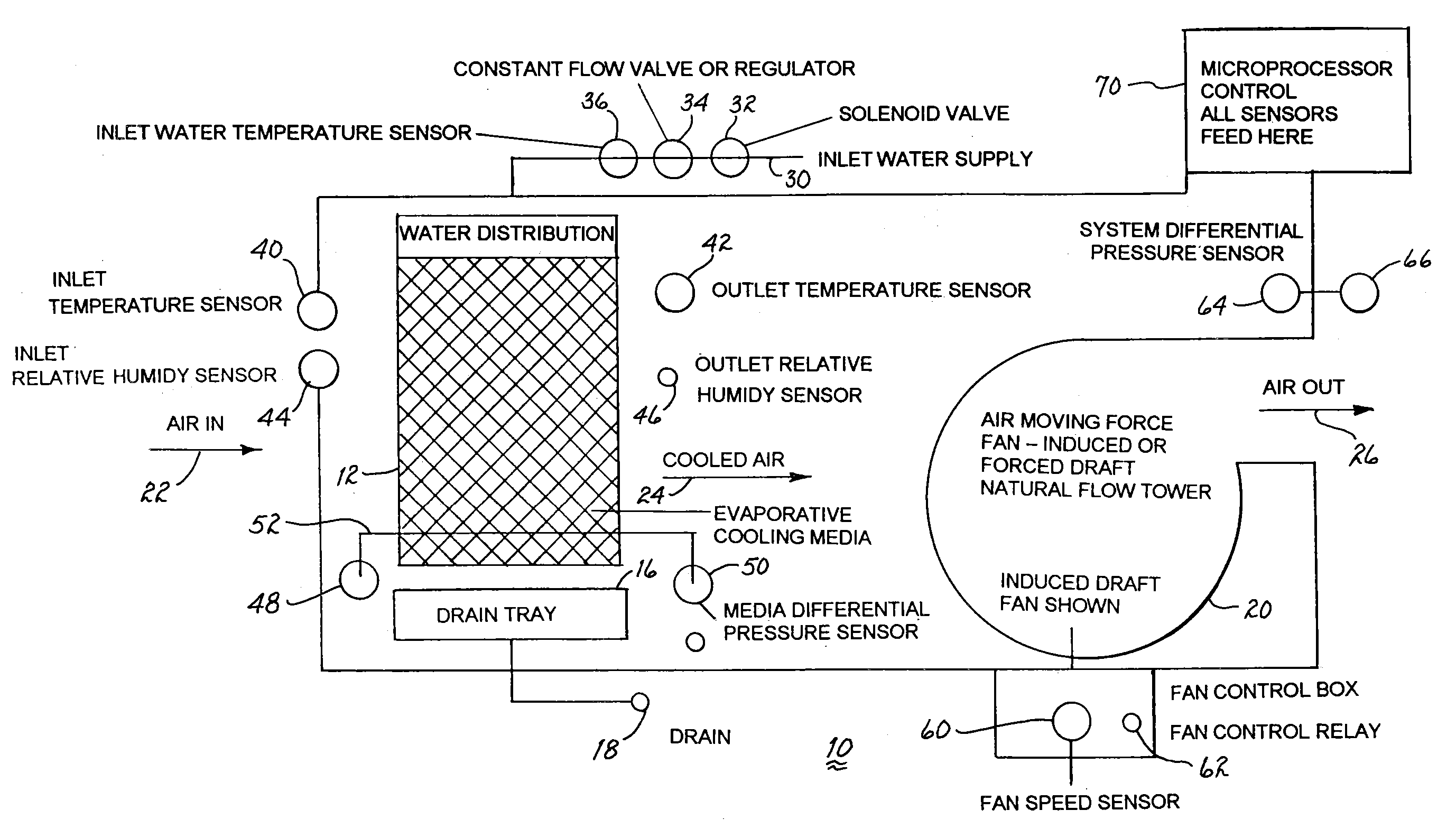

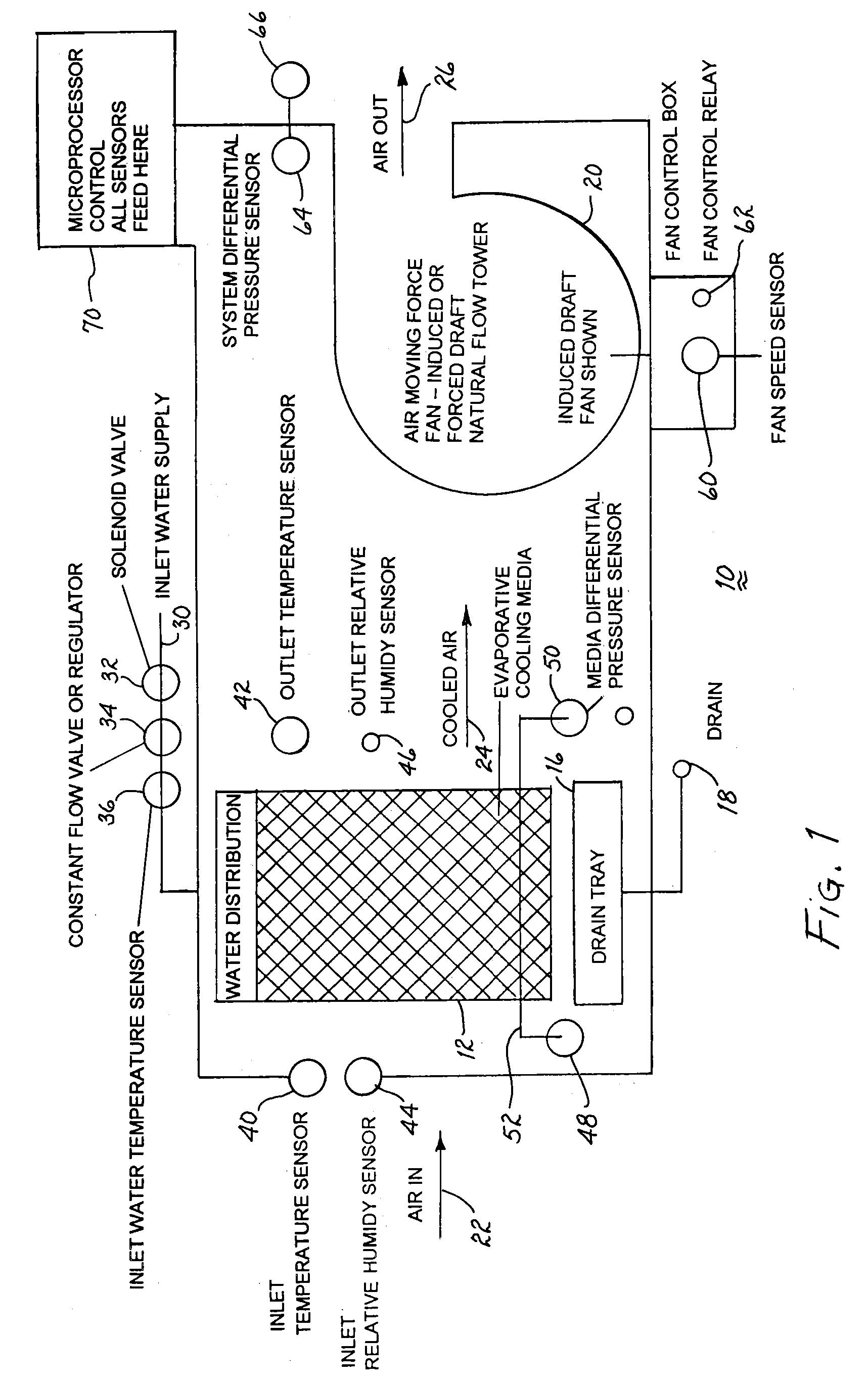

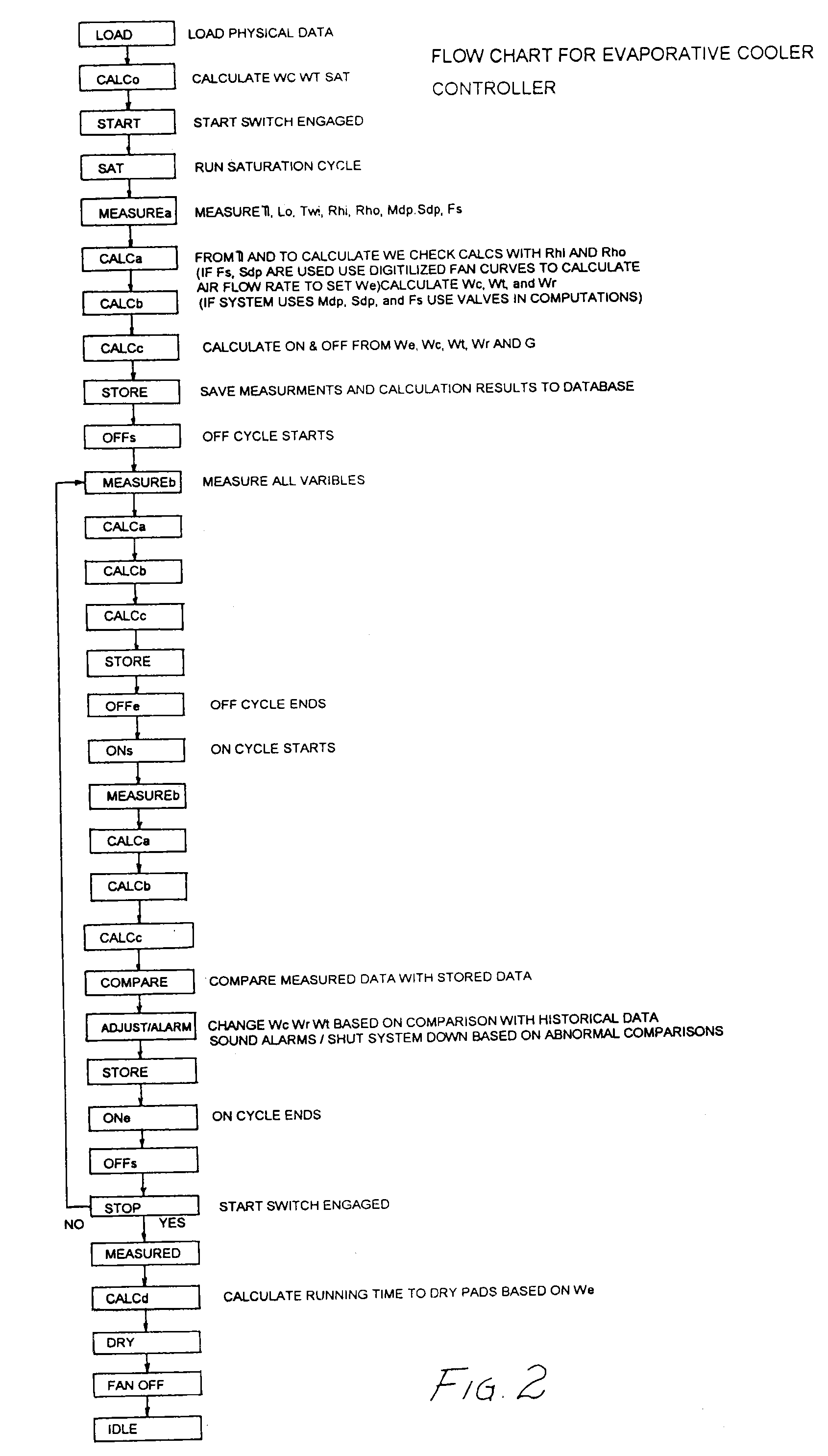

Non Uniform Water Distribution System for an Evaporative Cooler

InactiveUS20080018001A1Increase concentrationHigh cooling effectiveness levelMixing methodsUsing liquid separation agentEvaporative coolerDifferential pressure

An evaporative cooler, including one or more media, distributes water from a source of water to each media through a constant flow valve. A distribution unit at each media includes a pair of spray bars for spraying water through two rows of uniformly spaced apertures disposed in each spray bar. A spray bar channel associated with each spray bar distributes the streams of water impinging thereupon from one row of apertures to the underlying media in specific locations. A distribution cap associated with each spray bar distributes streams of water impinging thereupon to the front and back edges of the underlying media. The water dripping from the media is drained. A fan or other air moving device draws air through the media to obtain cooled air resulting from evaporation of water flowing downwardly along the media. A microprocessor controller, responsive to any of one or more sensors for sensing the temperature of the air flowing into and out of the media, the relative humidity of the air flowing into and out of the media, the pressure differential between the upstream and downstream sides of the media, the temperature of the water flowing to the spray bars, the fan speed, and the pressure differential between the downstream side of the media and the downstream side of the fan, controls the flow of water and the fan speed.

Owner:AZ EVAP

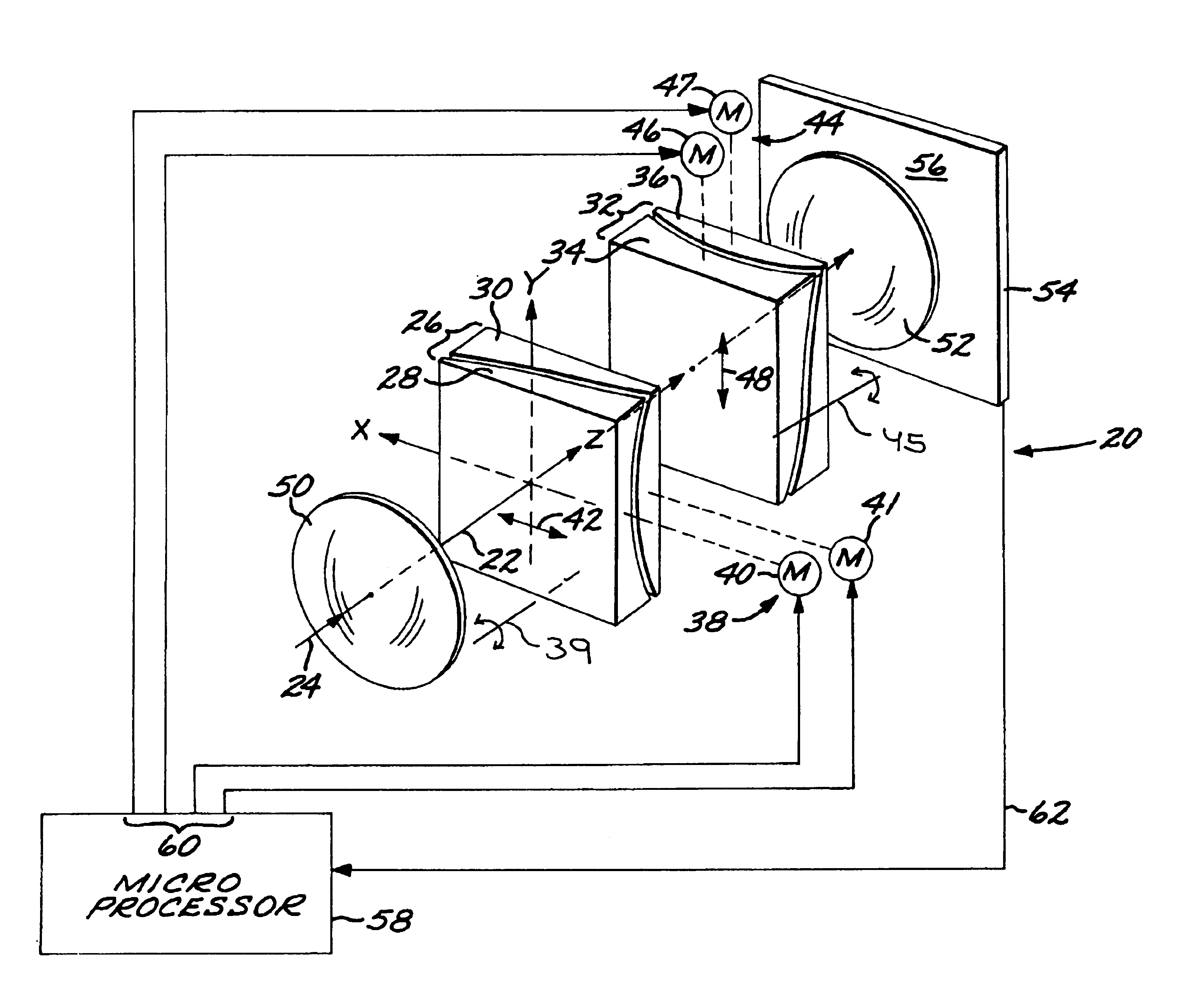

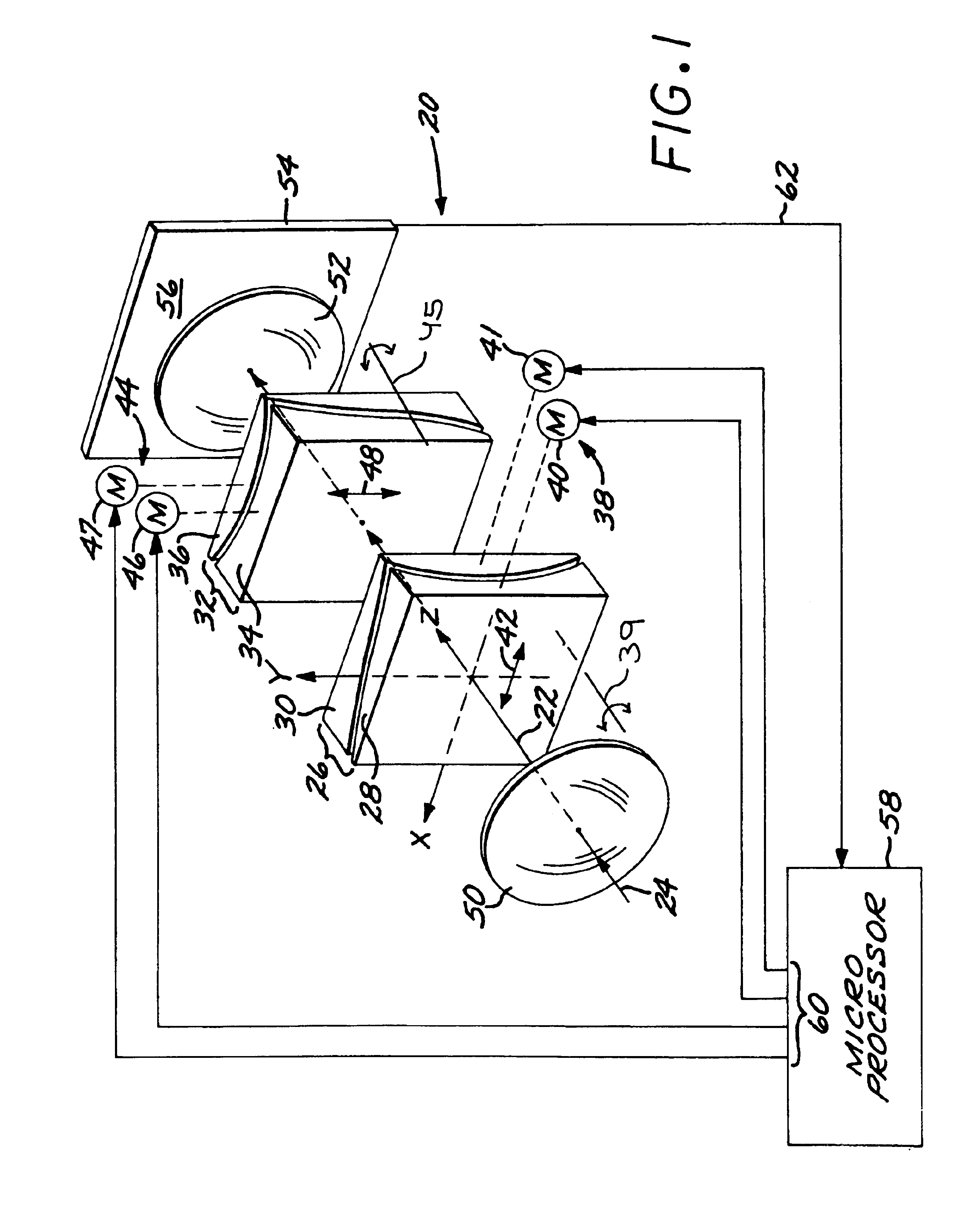

Orthogonal movement lateral shift zoom lens

An optical zoom lens mechanism is arranged along an optical axis and produces a zooming effect by a transverse movement of transparent elements perpendicular to the optical axis. A first lens group has two adjacent, rotationally nonsymmetric transparent first optical lens plates that are each rotationally nonsymmetric relative to the optical axis, and a first-group drive is operable to move the first optical lens plates together and relative to each other in a first-movement radial direction relative to the optical axis. A second lens group has two adjacent, rotationally nonsymmetric transparent second optical lens plates that are each rotationally nonsymmetric relative to the optical axis, and a second-group drive is operable to move the second optical lens plates together and relative to each other in a second-movement radial direction relative to the optical axis. The second-movement radial direction is angularly rotated from the first-movement radial direction by a nonzero, preferably about 90 degrees, rotational angle about the optical axis. The first optical lens plates and the second optical lens plates are shaped so that the relative movement of the first optical lens plates and second optical lens plates produces an optical zoom relative to a focal surface. The drives may be driven by a controller, such as a feedback controller having an imaging sensor located at the focal surface, and a microprocessor controller receiving an output of the imaging sensor and having a control output signal set operably connected to the drives.

Owner:RAYTHEON CANADA LTD

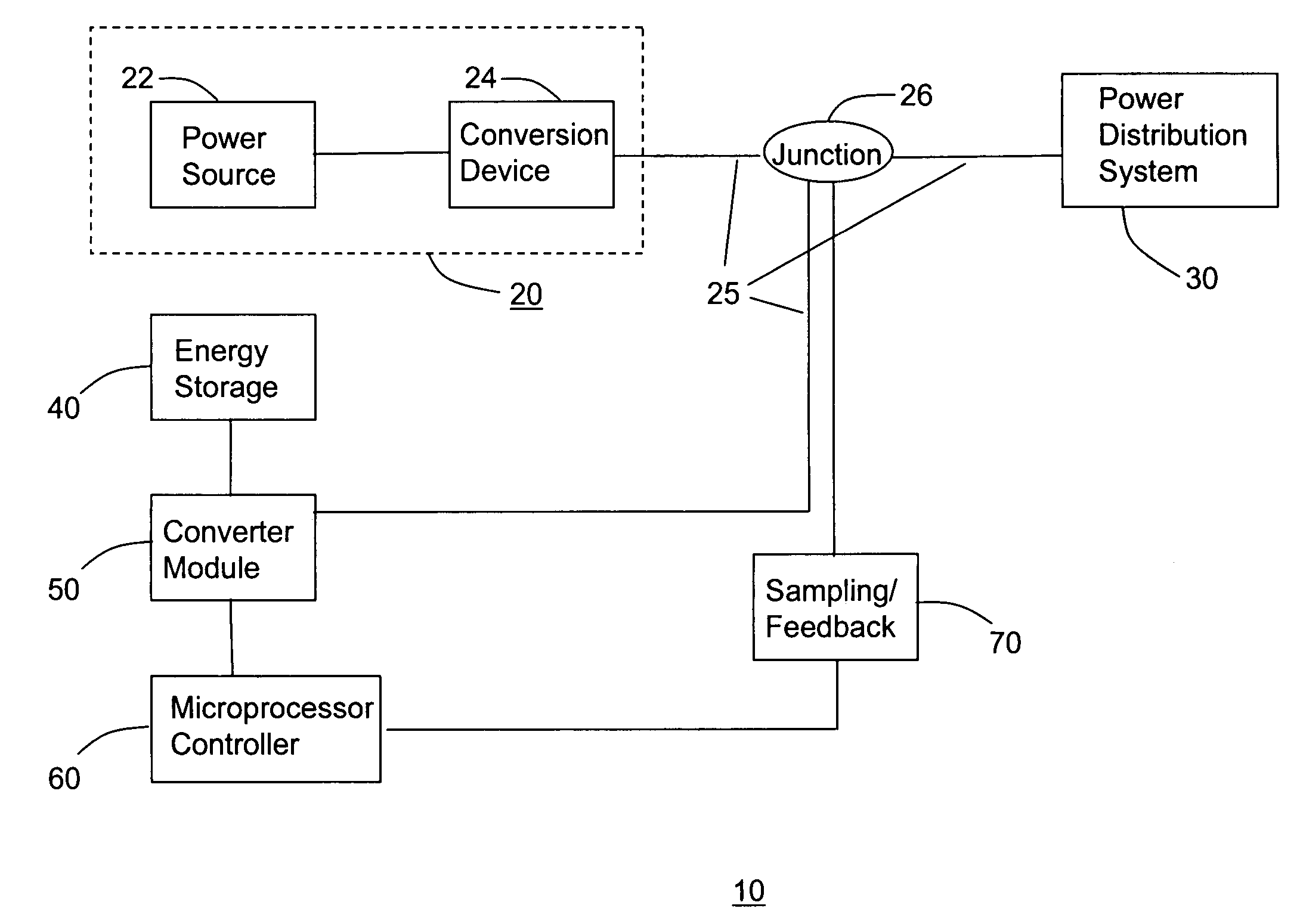

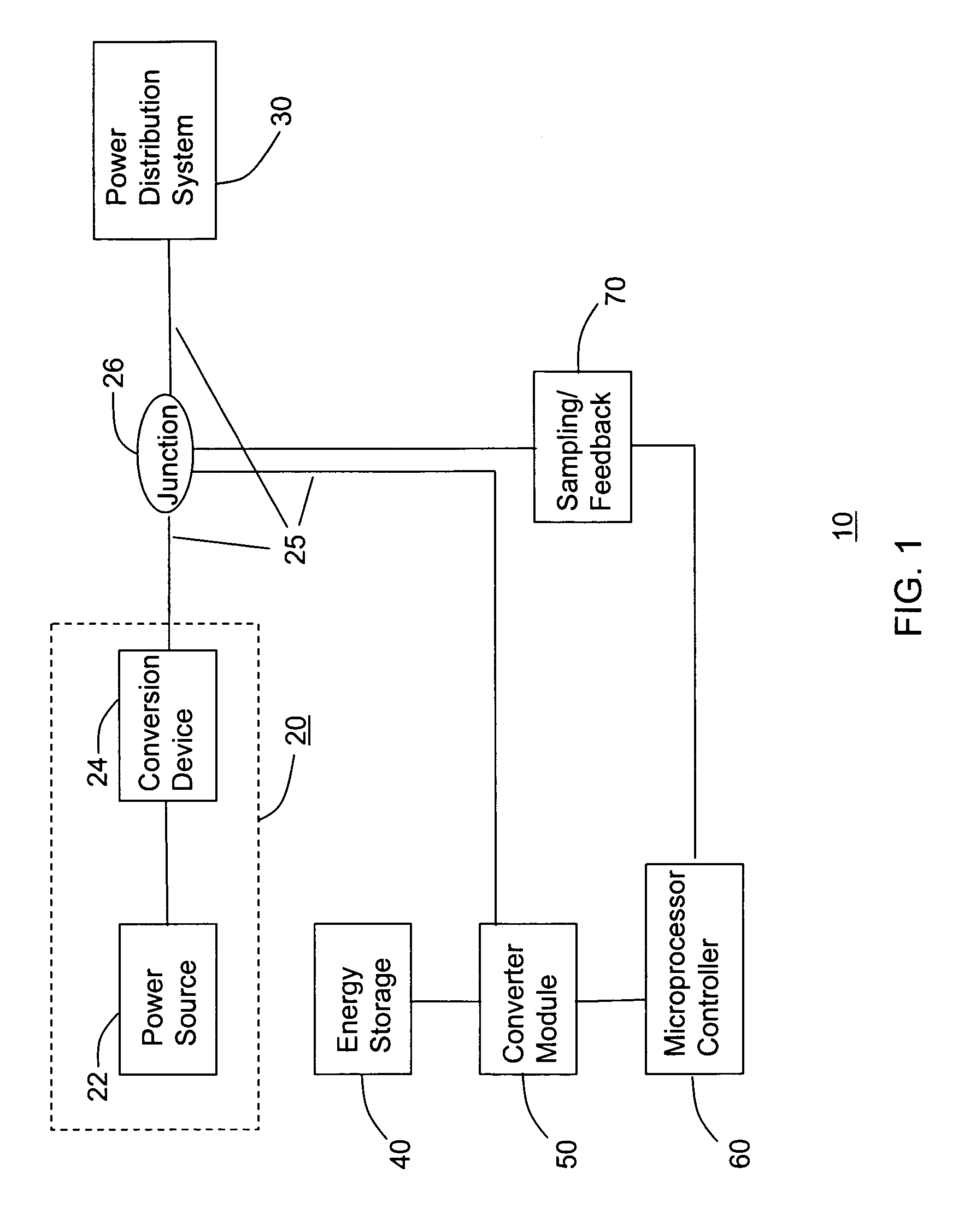

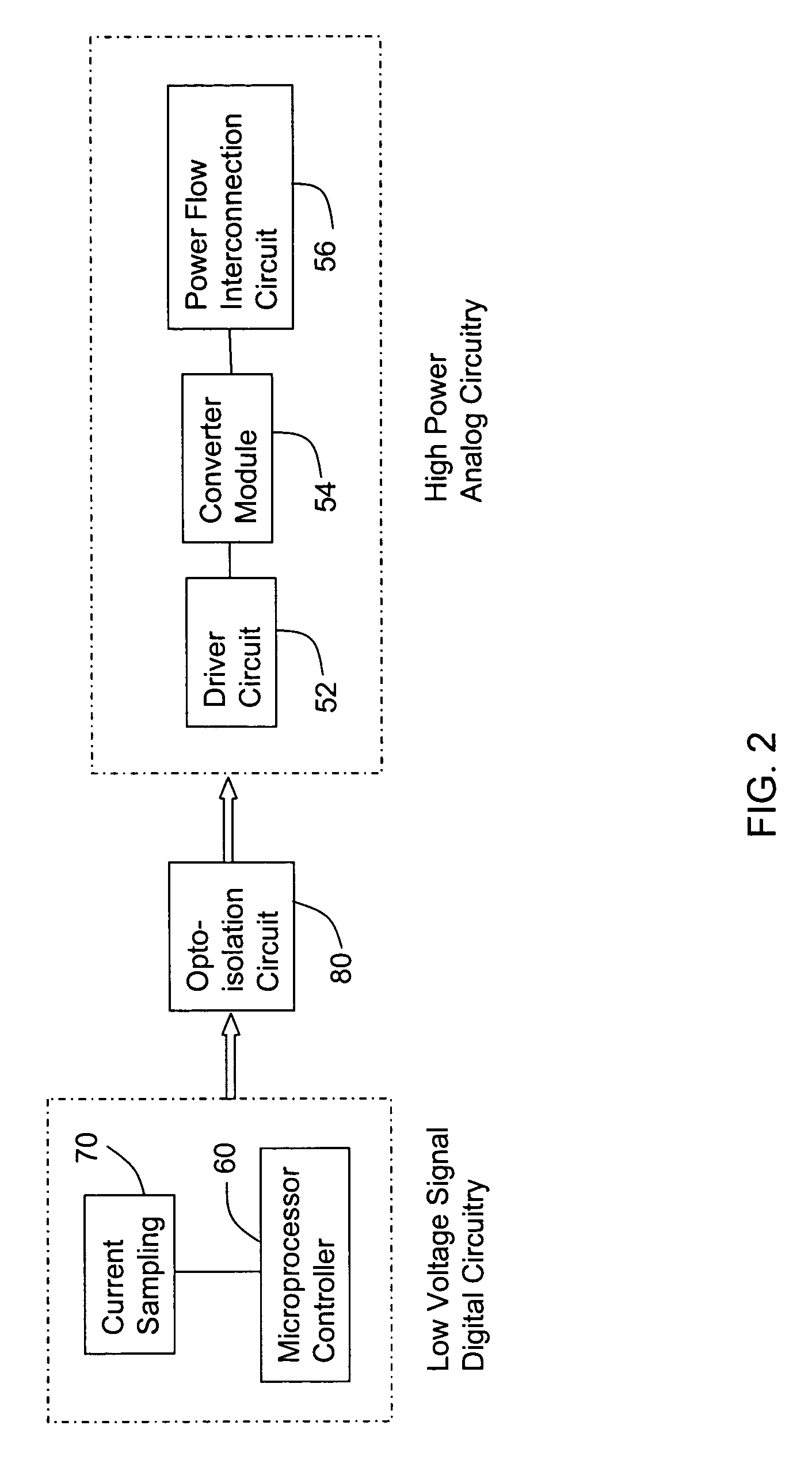

Enhanced distributed energy resource system

ActiveUS7239044B1Electrical storage systemBatteries circuit arrangementsElectric power transmissionMicroprocessor controller

A power transmission system including a direct current power source electrically connected to a conversion device for converting direct current into alternating current, a conversion device connected to a power distribution system through a junction, an energy storage device capable of producing direct current connected to a converter, where the converter, such as an insulated gate bipolar transistor, converts direct current from an energy storage device into alternating current and supplies the current to the junction and subsequently to the power distribution system. A microprocessor controller, connected to a sampling and feedback module and the converter, determines when the current load is higher than a set threshold value, requiring triggering of the converter to supply supplemental current to the power transmission system.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

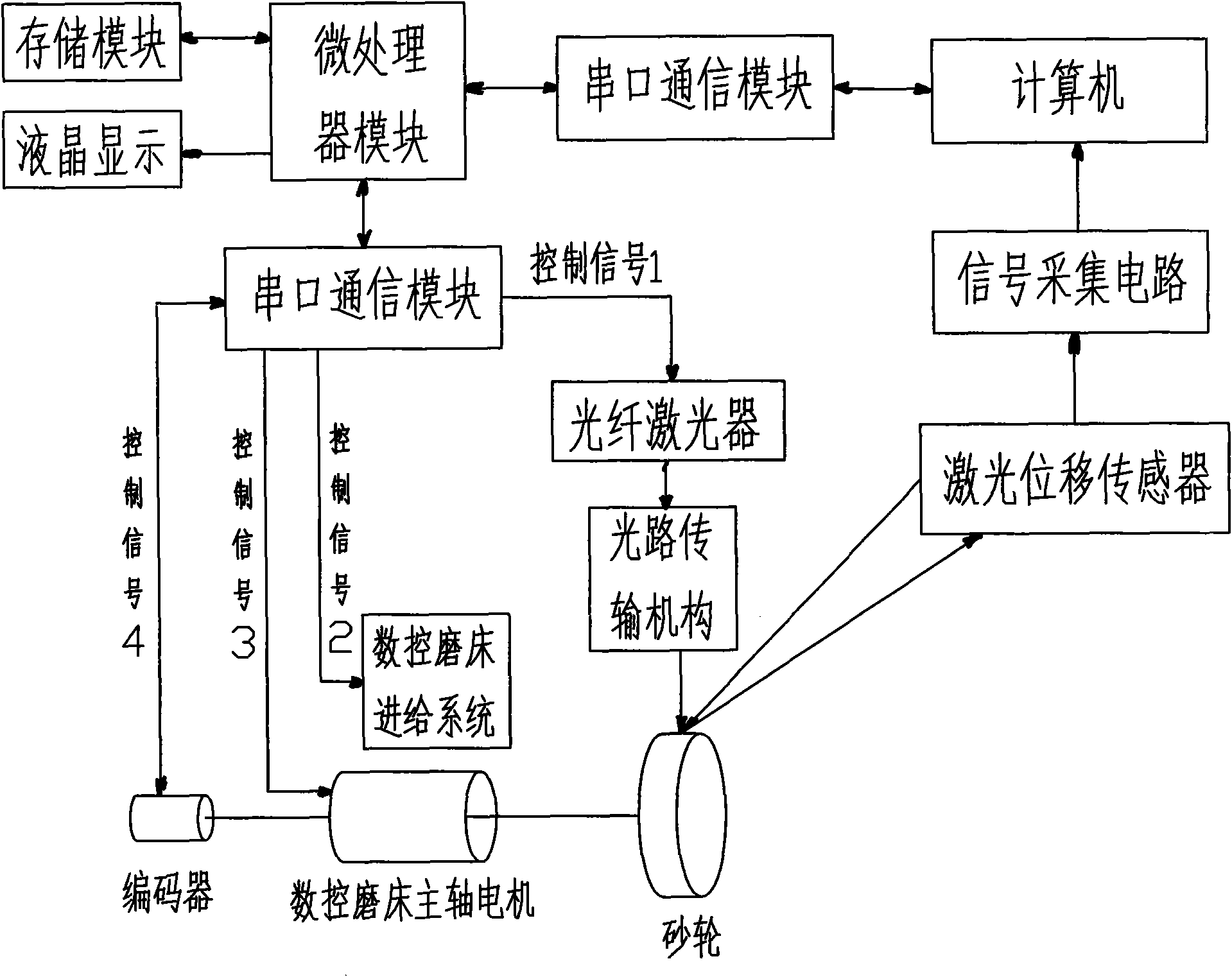

Laser trimming method for super-abrasive grinding wheel

InactiveCN101642895ANo lossImprove power densityAbrasive surface conditioning devicesNumerical controlControl signal

The invention discloses a laser trimming method for a super-abrasive grinding wheel, comprising the following steps: a, a grinding wheel is mounted on a numerical control grinding machine and is driven to rotate; b, a laser displacement sensor is aligned to the surface of the grinding wheel, does axial feeding movement relative to the grinding wheel and scans the surface of the grinding wheel, scanning data is input into a computer storing an ideal profile of the grinding wheel to form an actual profile of the grinding wheel on the surface, the actual profile is compared with the ideal profileof the grinding wheel to obtain a distribution condition of allowance removal; c. the computer sends trimming control signals to the numerical grinding machine and a laser through a microprocessor controller, so that the laser emits an appropriate laser pulse to burn a point to be trimmed on the grinding wheel according to the control signals, the laser displacement sensor detects present remained allowance of the point, and the allowance of the point in the computer is updated timely; and d, the step c is carried out repeatedly till the trimming precision as required is achieved.

Owner:HUNAN UNIV

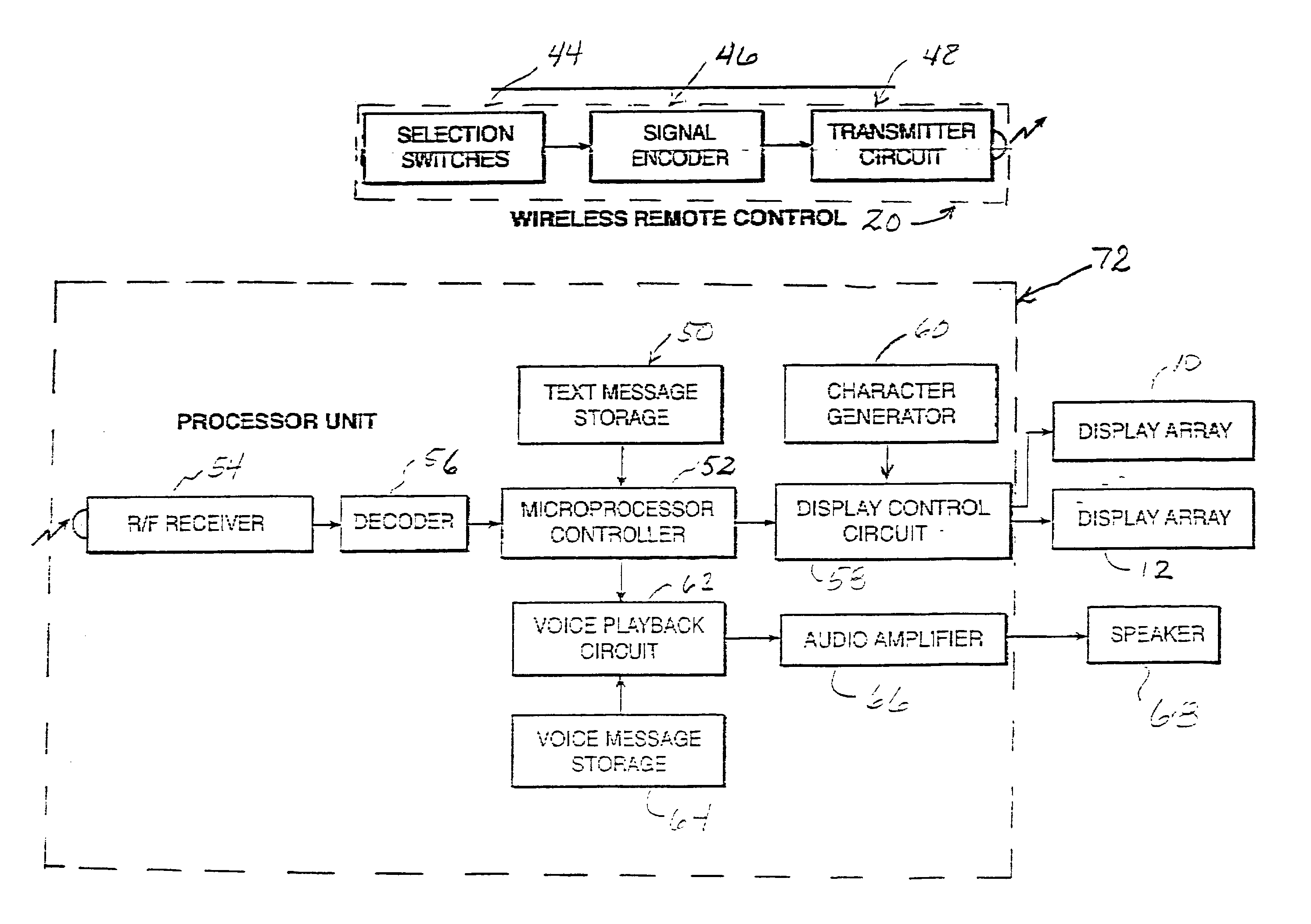

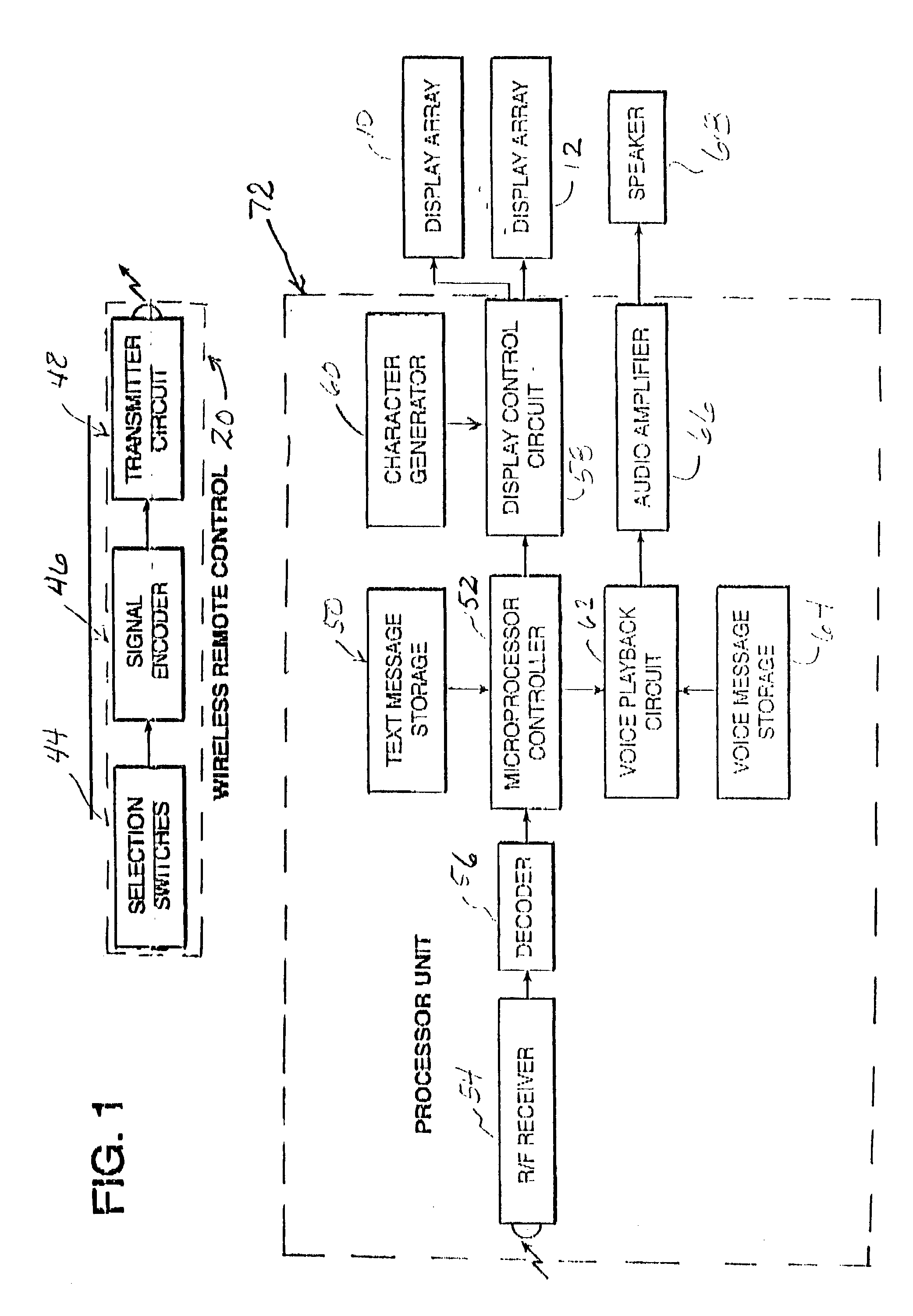

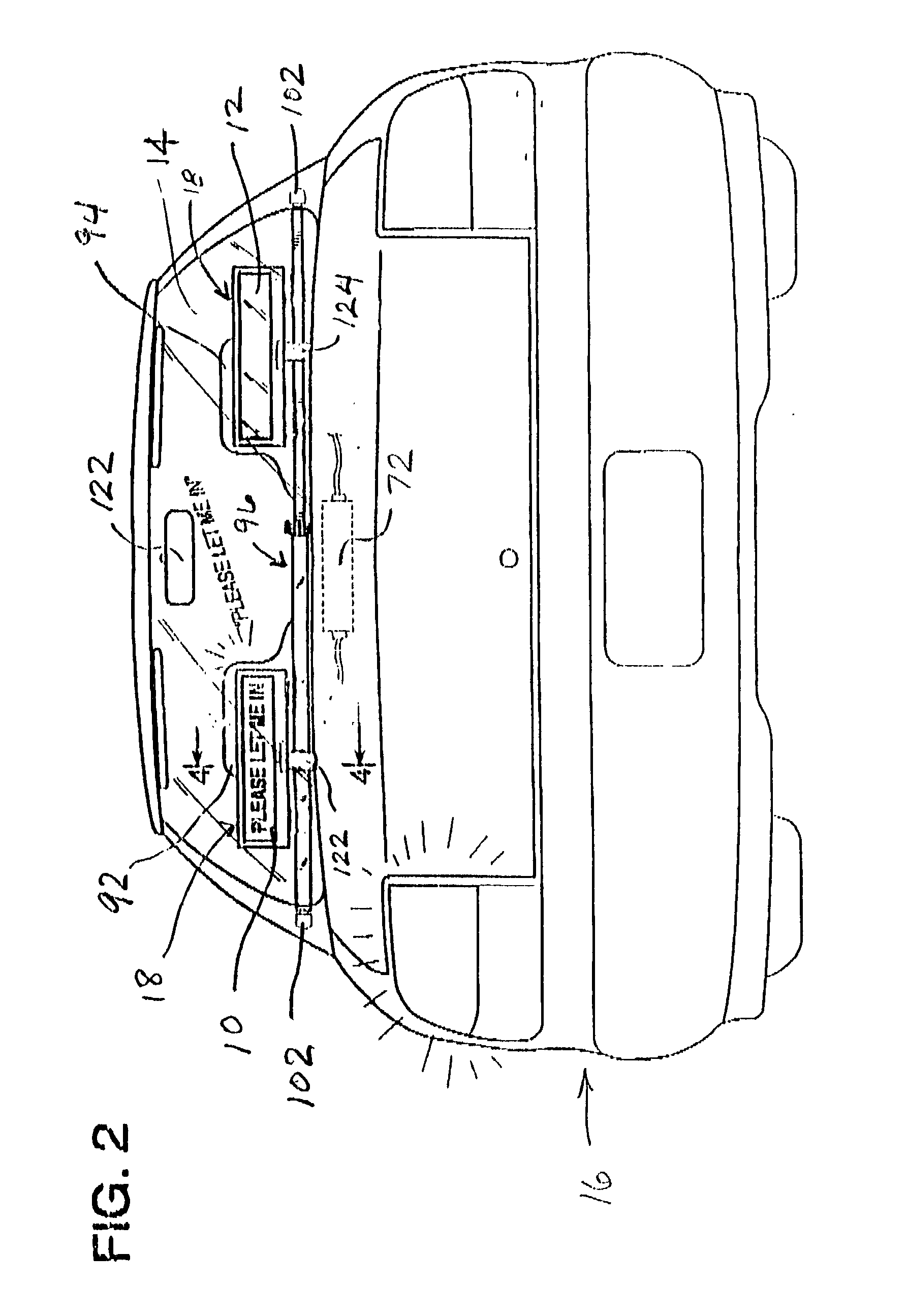

Automotive courtesy display

InactiveUS20030227375A1Reduce road rage among driversLower insurance premiumsOptical signallingWireless controlDriver/operator

An automotive vehicle courtesy message display system allows the driver of a automotive vehicle to visually display courtesy messages to the drivers of vehicles located to the rear. Such messages may be for an occasional urgent request to "cut in" for safe passage. The message display system provides the driver of the vehicle in which the visual display is installed with an audible feedback so that the vehicle driver can verify that the correct message has been selected, without visually distracting the driver's attention. The system includes three main components, namely a wireless control unit located on the vehicle operator's steering wheel, a processor unit containing most of the electronics of the system positioned in an unobtrusive location so as to avoid impairing the drivers view, and one or a pair of display screens which are typically located behind the rear seat headrests of an automotive passenger vehicle. A microprocessor controller withing the microprocessor unit selects a text message corresponding to the particular touch sensor depressed, and transmits it to an appropriate one the display screens. The audible announcement of the message selected by the touch sensor provides the operator with a positive feedback indicating selection of the correct message.

Owner:YONG PETER

Extendable frame work vehicle having lift member movable in a true vertical fashion

ActiveUS8103418B2Improve effectivenessImprove securitySafety devices for lifting equipmentsVehicle body stabilisationVehicle frameHydraulic pump

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor and at least one valve network.

Owner:EXTENDQUIP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com