Carbonization and activation device for active coke production

A technology of activated coke and carbonization, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems not mentioned, and achieve the effects of low material wear, timely precipitation, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

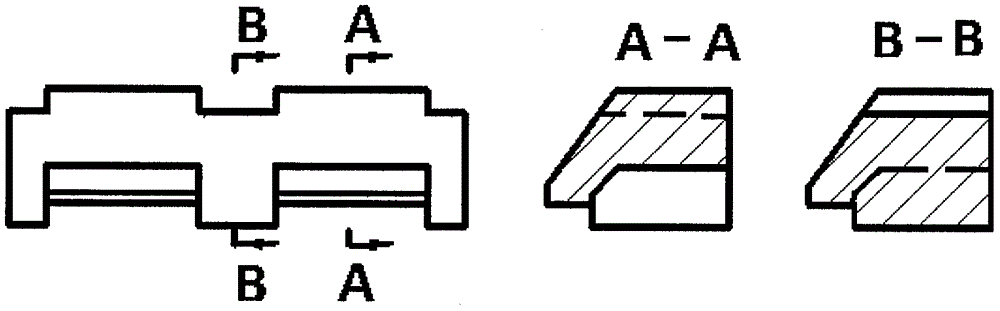

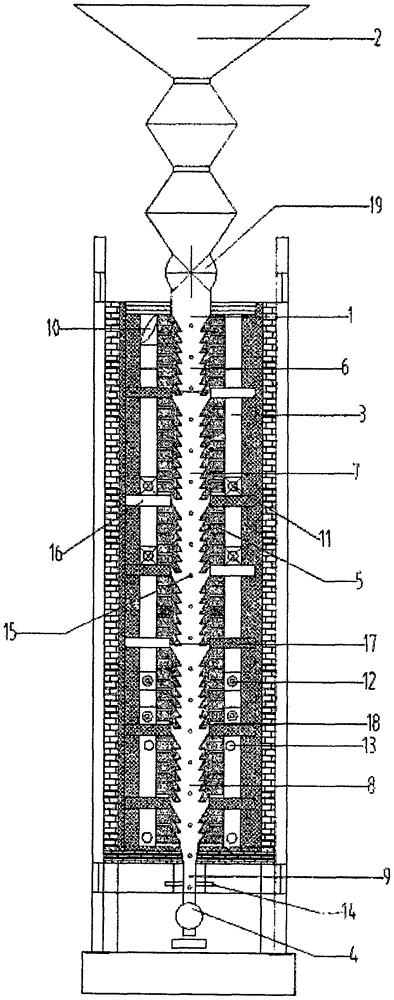

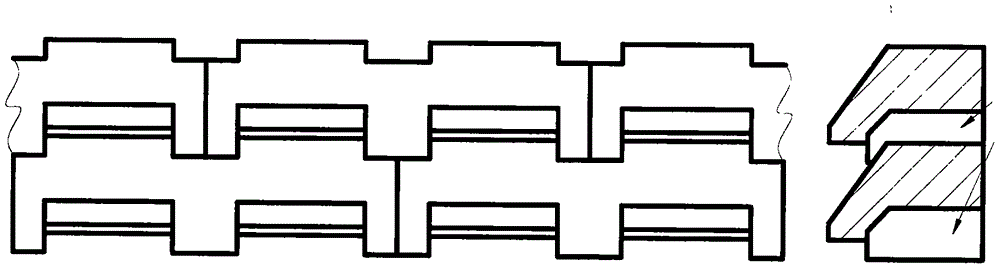

[0026] The carbonization activation device used for the production of active coke includes a forehearth 1, a silo 2 above the forehearth 1, a flue 3 on both sides of the forehearth 1, and a discharge device 4 below the forehearth 1; the forehearth 1 It is made of interlaced wing-shaped special-shaped bricks 5, one side of the wing-shaped special-shaped bricks 5 is a slope, and the slope part of the wing-shaped special-shaped bricks 5 forms the inner wall of the material channel 1, and the internal section of the material channel 1 is in the shape of a multi-section inverted Christmas tree; the material channel 1 Vertically and downwards, there are preheating section 6, carbonization section 7, activation section 8, and cooling section 9; preheating section 6 provides heat to the pressed semi-finished activated coke and drives out moisture; carbonization section 7 forms activated coke Dry distillation under anaerobic conditions to precipitate tar vapor; activation section 8 pass...

Embodiment 2

[0035] The carbonization activation device used for the production of active coke includes a forehearth 1, a silo 2 above the forehearth 1, a flue 3 on both sides of the forehearth 1, and a discharge device 4 below the forehearth 1; the forehearth 1 It is made of interlaced wing-shaped special-shaped bricks 5, one side of the wing-shaped special-shaped bricks 5 is a slope, and the slope part of the wing-shaped special-shaped bricks 5 forms the inner wall of the material channel 1, and the internal section of the material channel 1 is in the shape of a multi-section inverted Christmas tree; the material channel 1 Vertically and downwards, there are preheating section 6, carbonization section 7, activation section 8, and cooling section 9; preheating section 6 provides heat to the pressed semi-finished activated coke and drives out moisture; carbonization section 7 forms activated coke Dry distillation under anaerobic conditions to precipitate tar vapor; activation section 8 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com