Patents

Literature

42results about How to "Reduce bubbling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

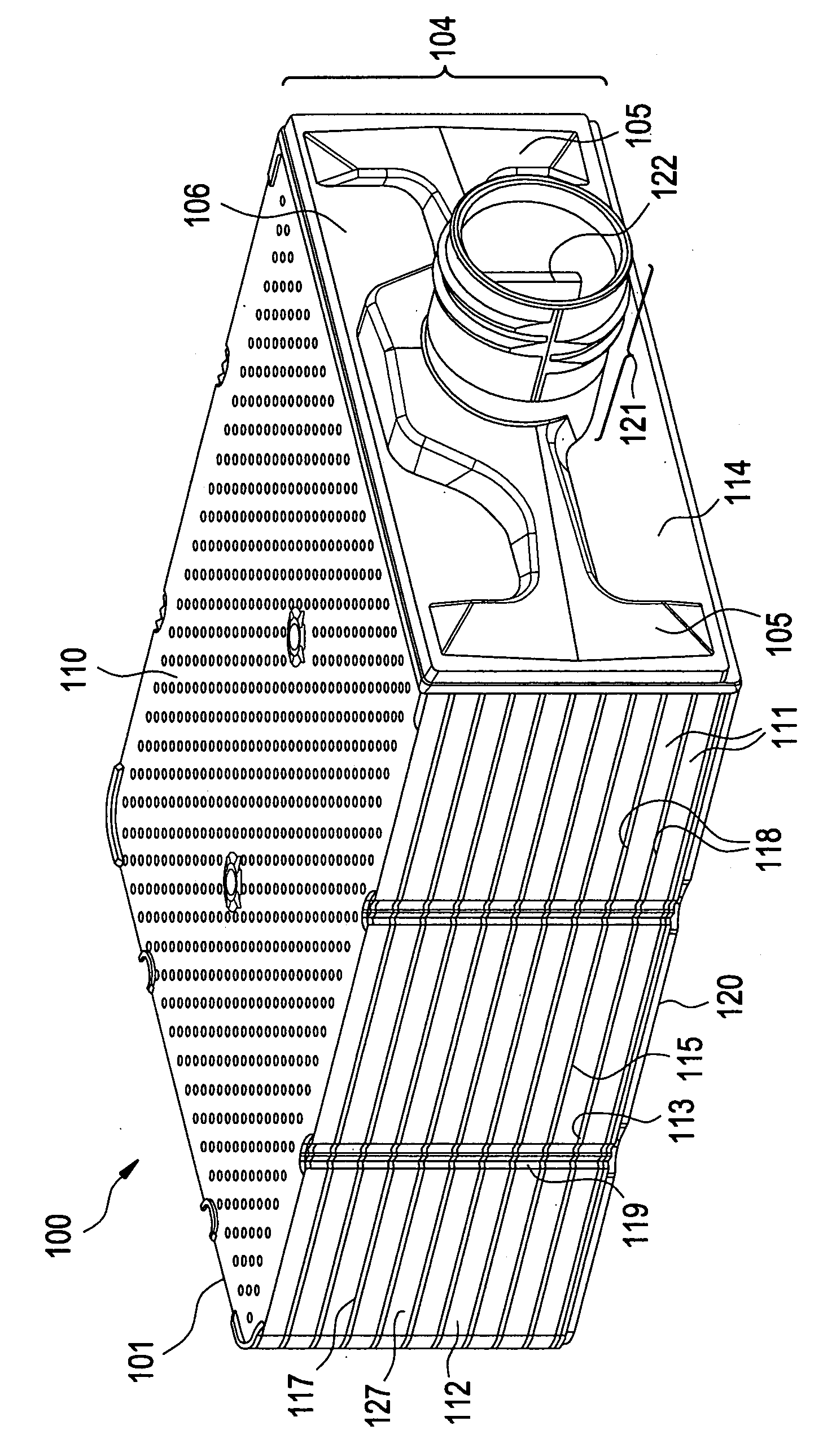

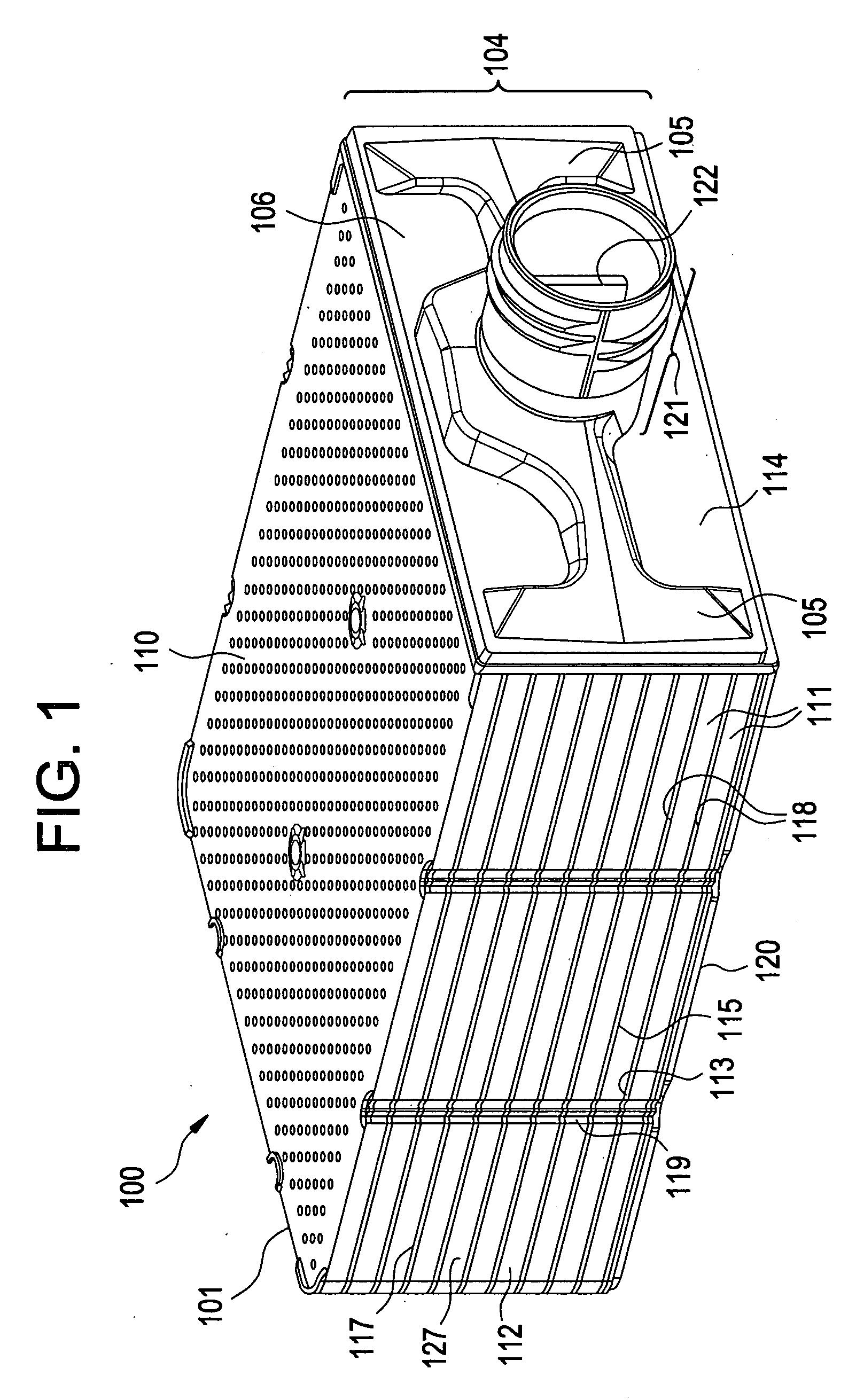

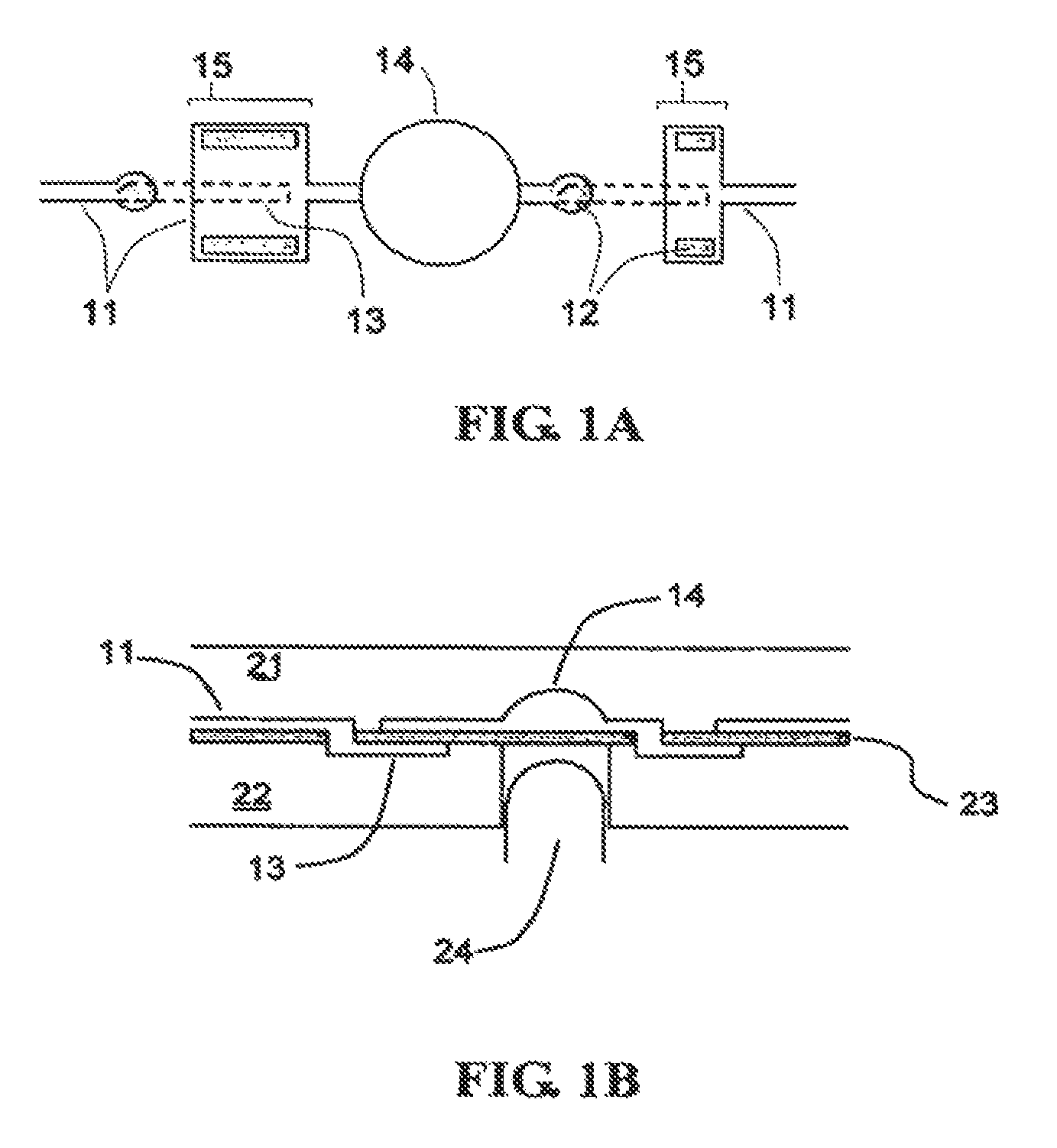

Device and method for reducing bubble formation in cell culture

ActiveUS20080206857A1Reduce bubblingReduce foamingBioreactor/fermenter combinationsBiological substance pretreatments3D cell cultureCell culture media

A device for minimizing the formation of bubbles or foam in cell culture is disclosed. The device has a manifold which directs the inflow of cells and cell culture media into a cell culture vessel so as to allow for displaced air or gas to vent from the cell culture vessel without mixing with the incoming cell culture media, thereby preventing the mixing of air and cell culture media and minimizing the formation of bubbles or foam inside the cell culture vessel.

Owner:CORNING INC

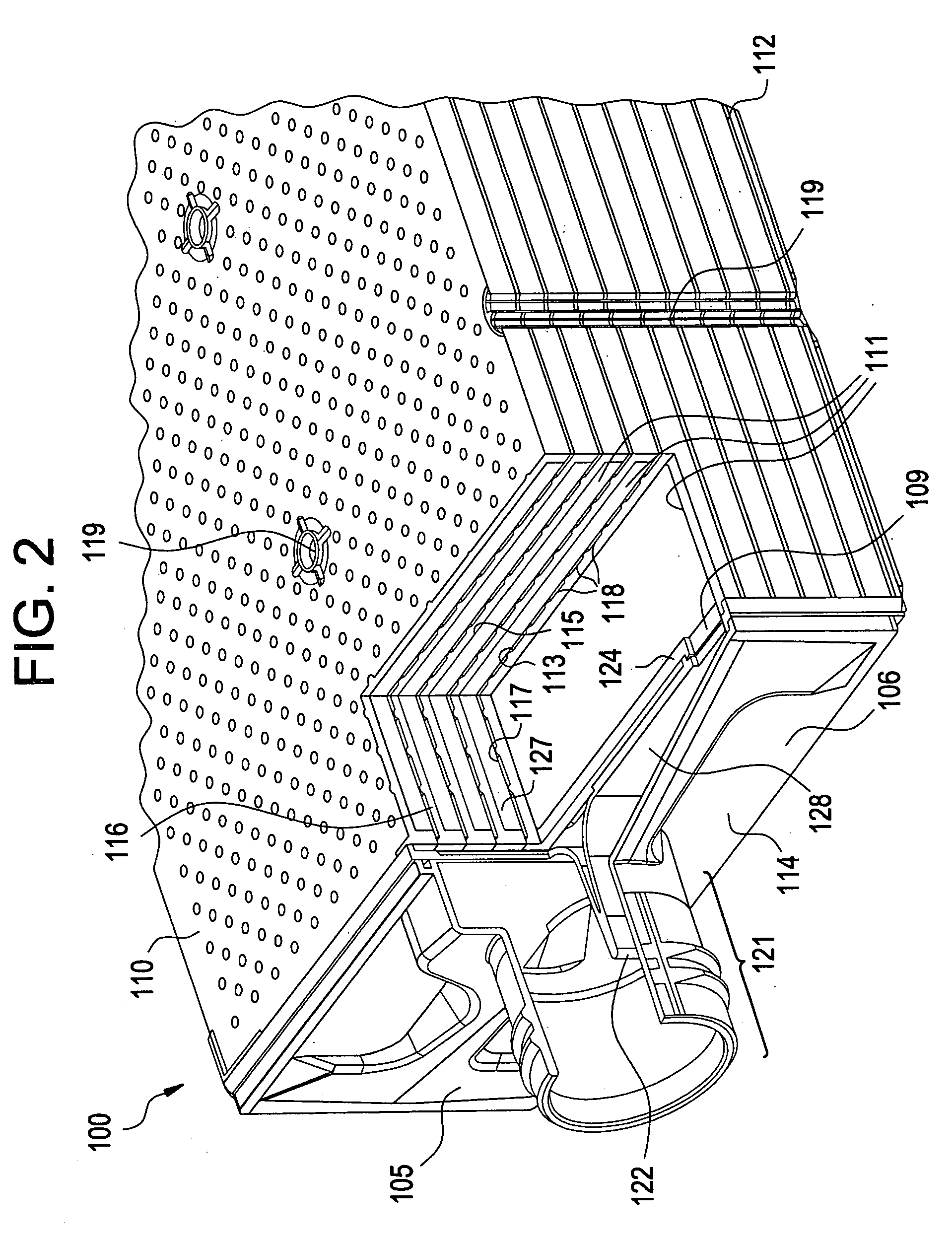

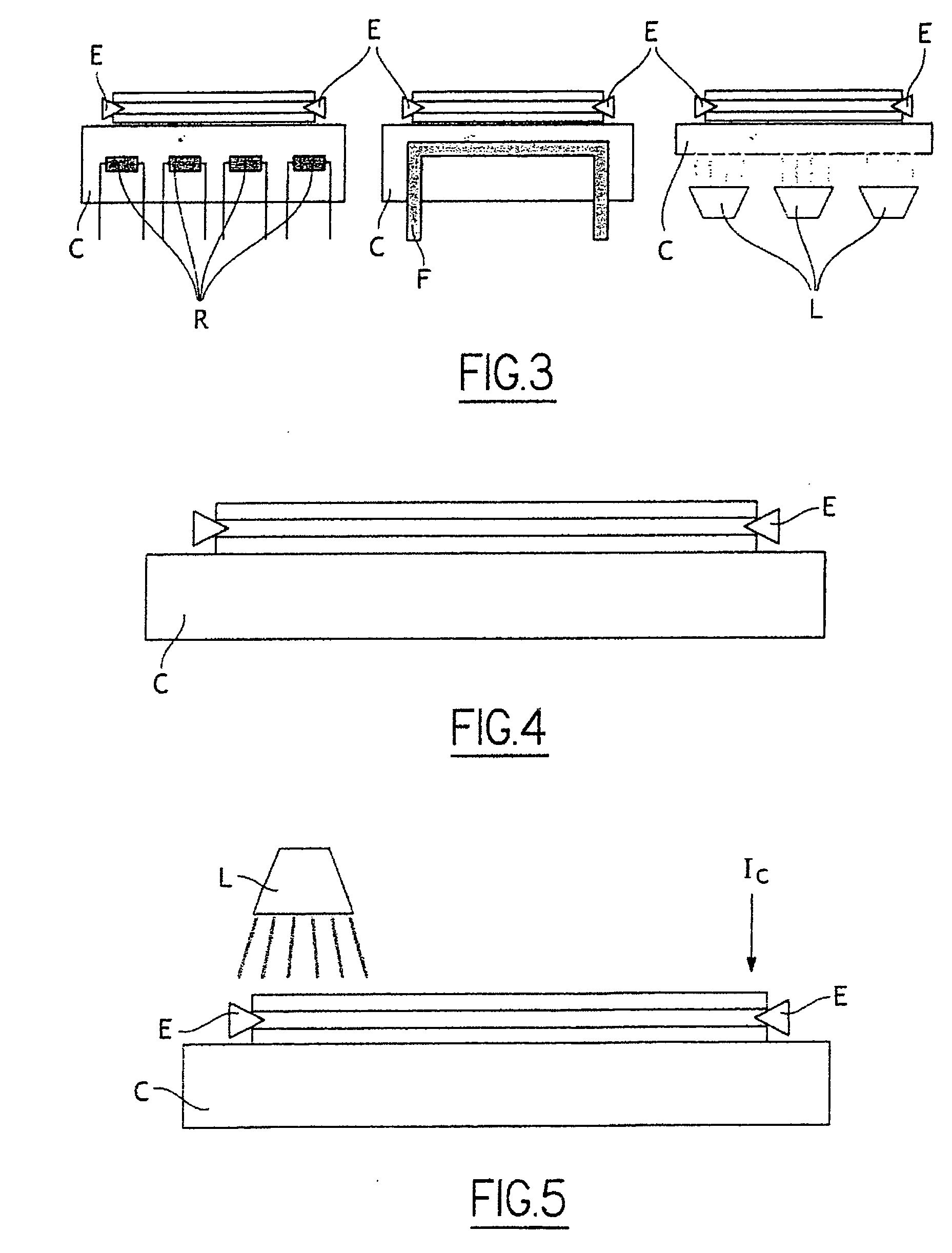

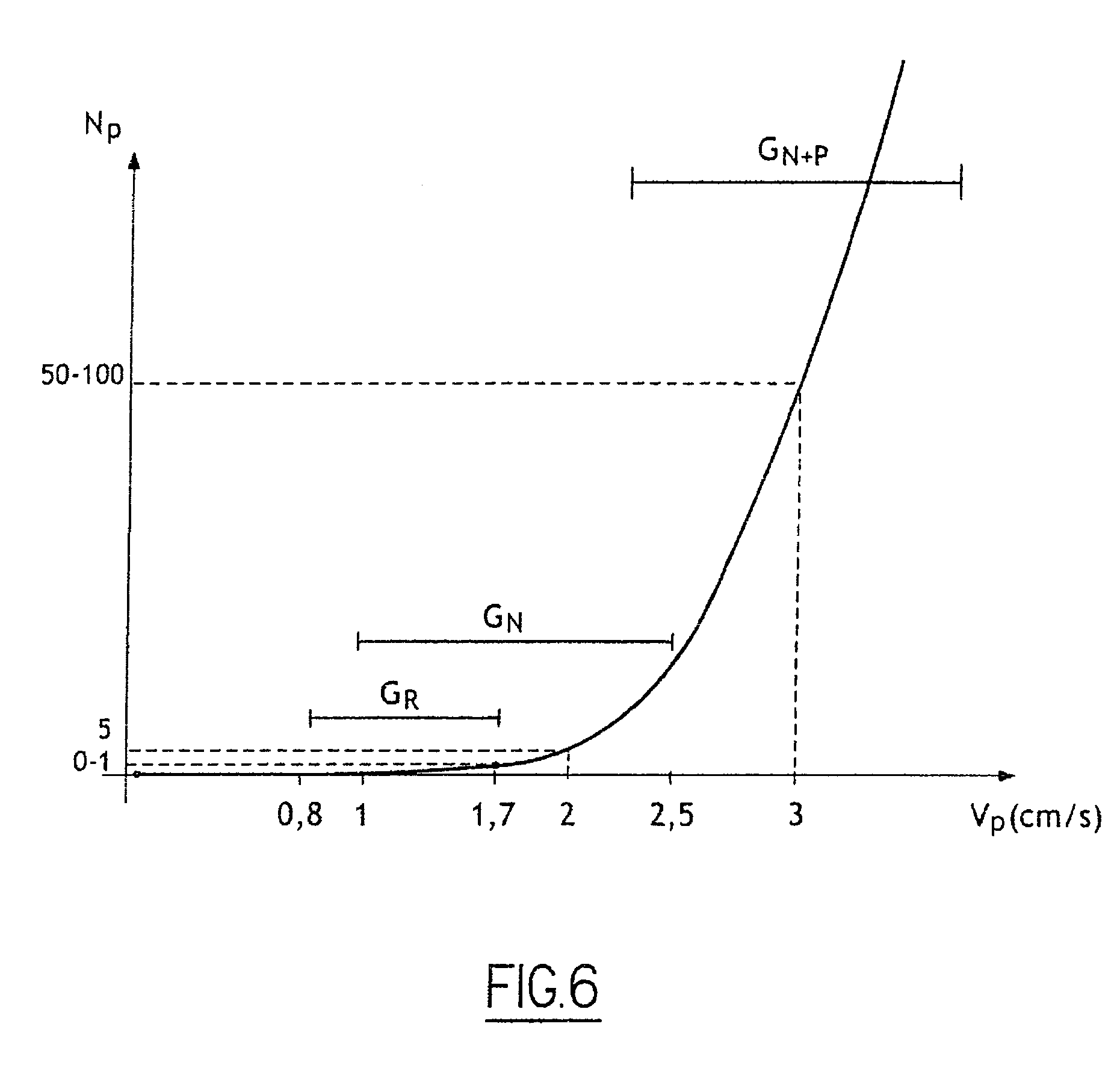

Process and equipment for bonding by molecular adhesion

ActiveUS20070119812A1Rectify disadvantageImprove bindingDecorative surface effectsSolid-state devicesSurface statesClose contact

The invention relates to a process for bonding by molecular adhesion of two substrates to one another during which the surfaces of the substrates are placed in close contact and bonding occurs by propagation of a bonding front between the substrates. The invention includes, prior to bonding, a step of modifying the surface state of one or both of the surfaces of the substrates so as to regulate the propagation speed of the bonding front. The surface can be modified by locally or uniformly heating or roughening the surface(s) of the substrate(s).

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Thickener for excavating slurry, excavating slurry using the the thickener, and cast-in-place underground pile work method and underground continuius wall work method using the excavating slurry

InactiveUS20040121916A1Reduce the presence of air bubblesConstruction works can be stably conductedEmbankmentsExcavationsSlurry wallEmulsion

Subjects for the present invention are to provide a thickening agent for excavation stabilizing slurries which has excellent cement contamination resistance, is difficult to putrefy, and is prevented from bubbling, which may be problematic in construction works, and to provide an excavation stabilizing slurry containing the thickening agent and a cast-in-place underground pile method and an diaphragm wall construction method each using the slurry. The present invention provides a thickening agent for excavation stabilizing slurries which contains an emulsion thickening with an alkali, wherein in a strong agitation bubbling test of a mixture prepared by adding an alkaline substance to the thickening agent, the resulting mixture has an apparent specific gravity of 1.05 g / ml or higher as measured immediately after the strong agitation and has an apparent specific gravity of 1.10 g / ml or higher as measured at 10 minutes after the strong agitation. This thickening agent is used to prepare an excavation stabilizing slurry.

Owner:NIPPON SHOKUBAI CO LTD

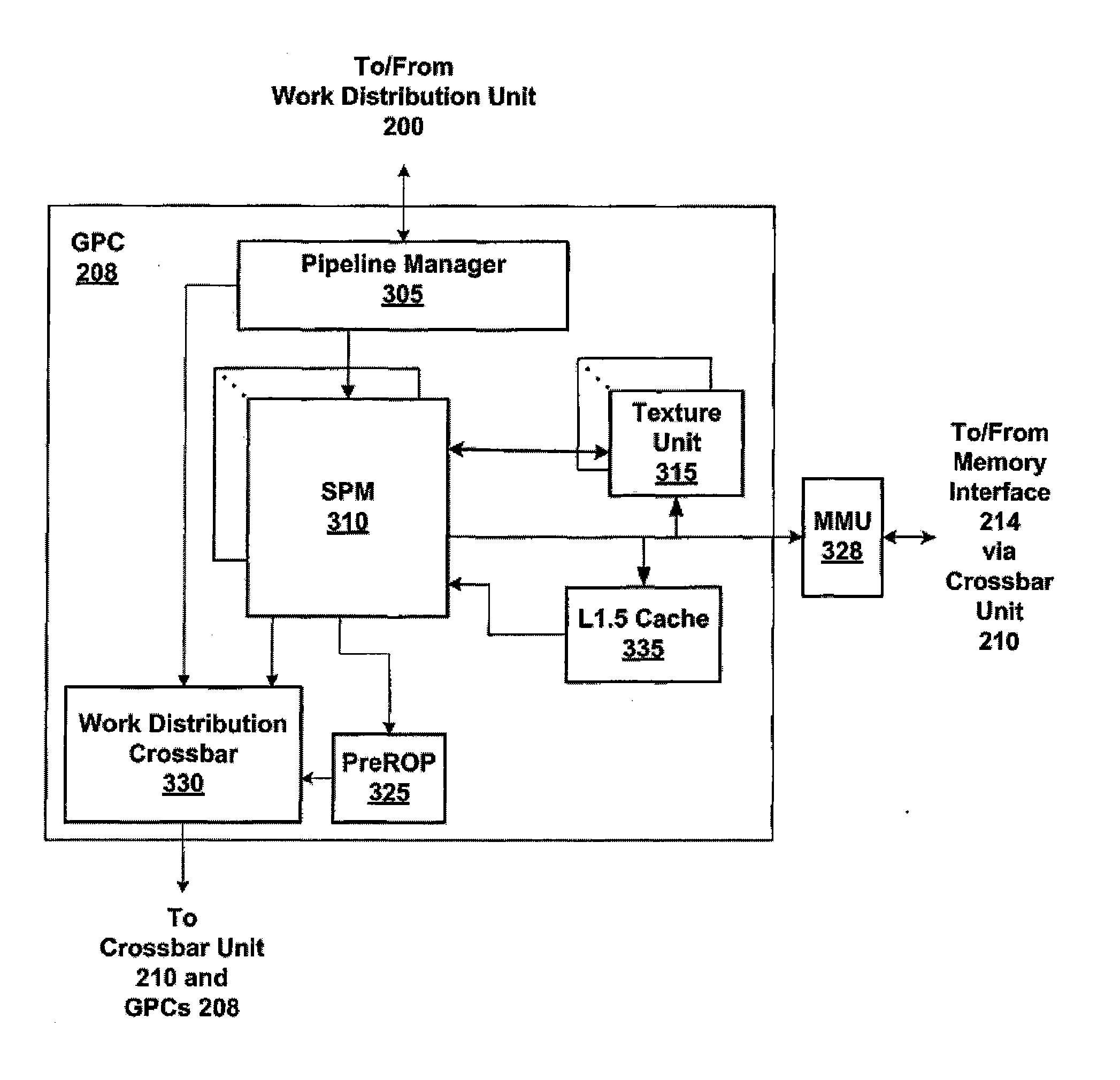

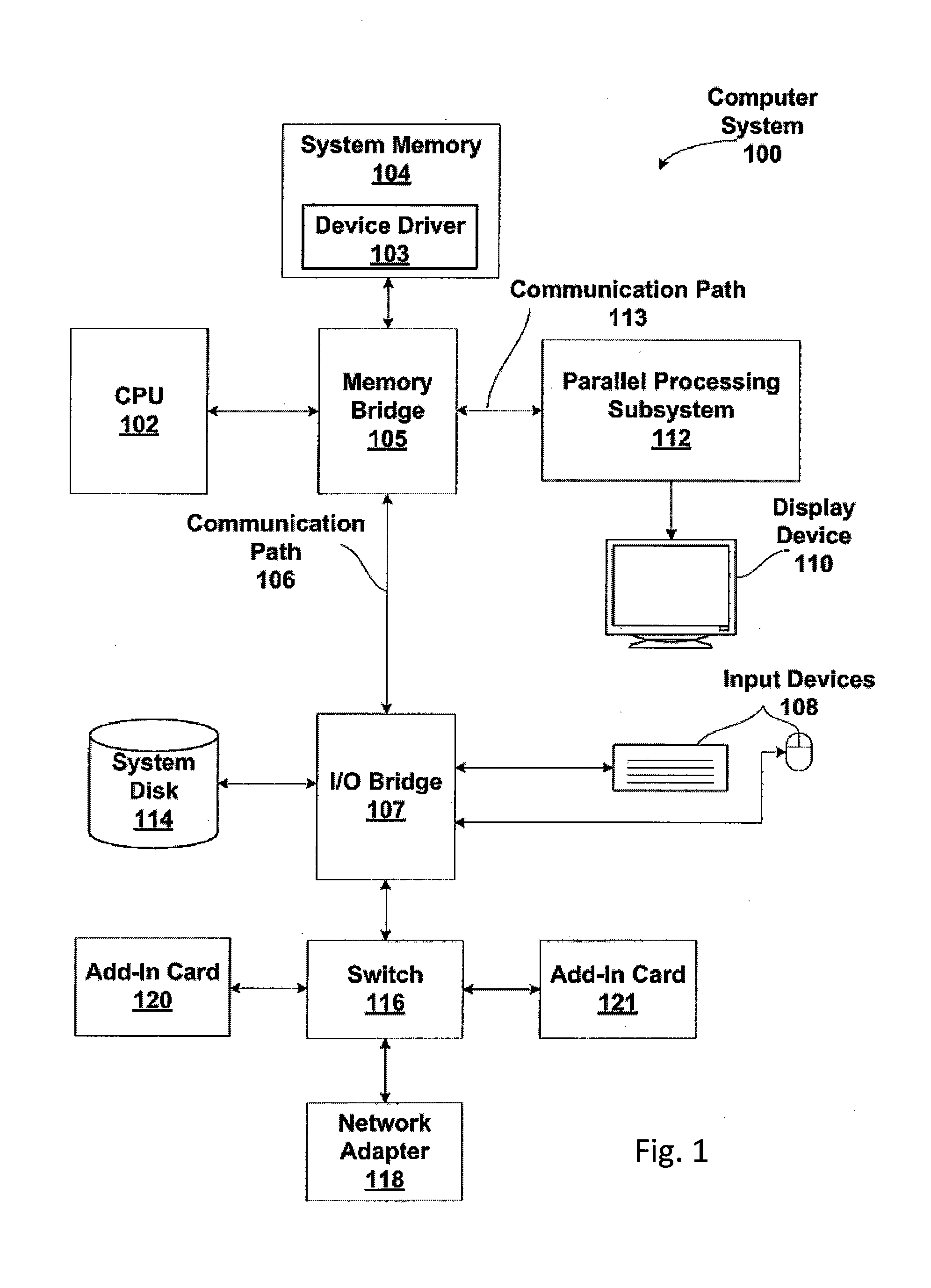

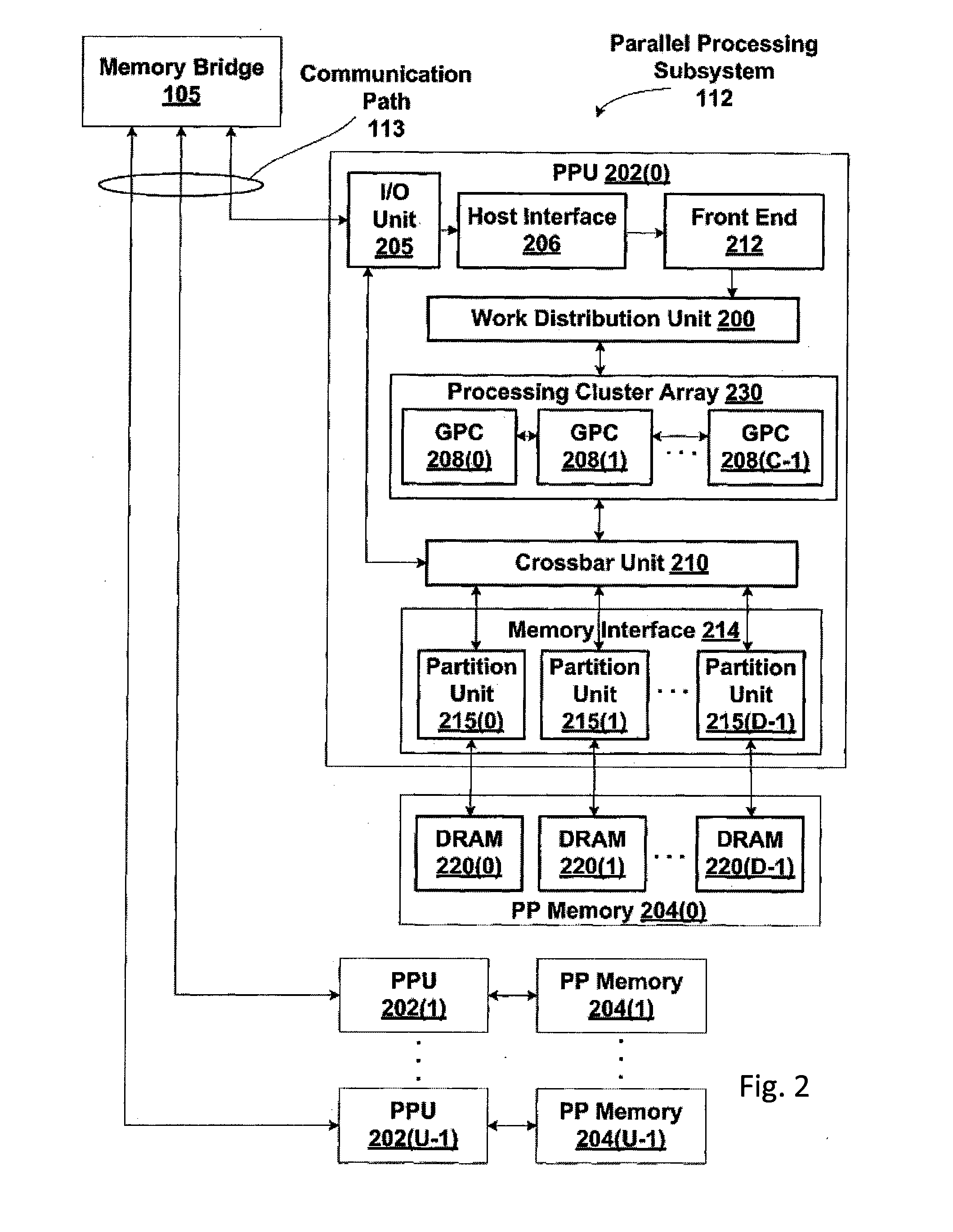

Method and sytem for predicate-controlled multi-function instructions

InactiveUS20120084539A1Reduce bubblingReduces idle stateRegister arrangementsDigital computer detailsTruth valueParallel computing

Techniques are disclosed for executing conditional computer instructions in an efficient manner that reduces bubbles and idle states. In one embodiment, dual-function instruction execution is disclosed where the dual-function instruction has two possible functions (or operations), the choice of which is controlled by a predicate value with a true or false value. Among other things, the disclosed techniques provide dynamic control for choosing which operation to execute leading to more efficiently executed code.

Owner:NVIDIA CORP

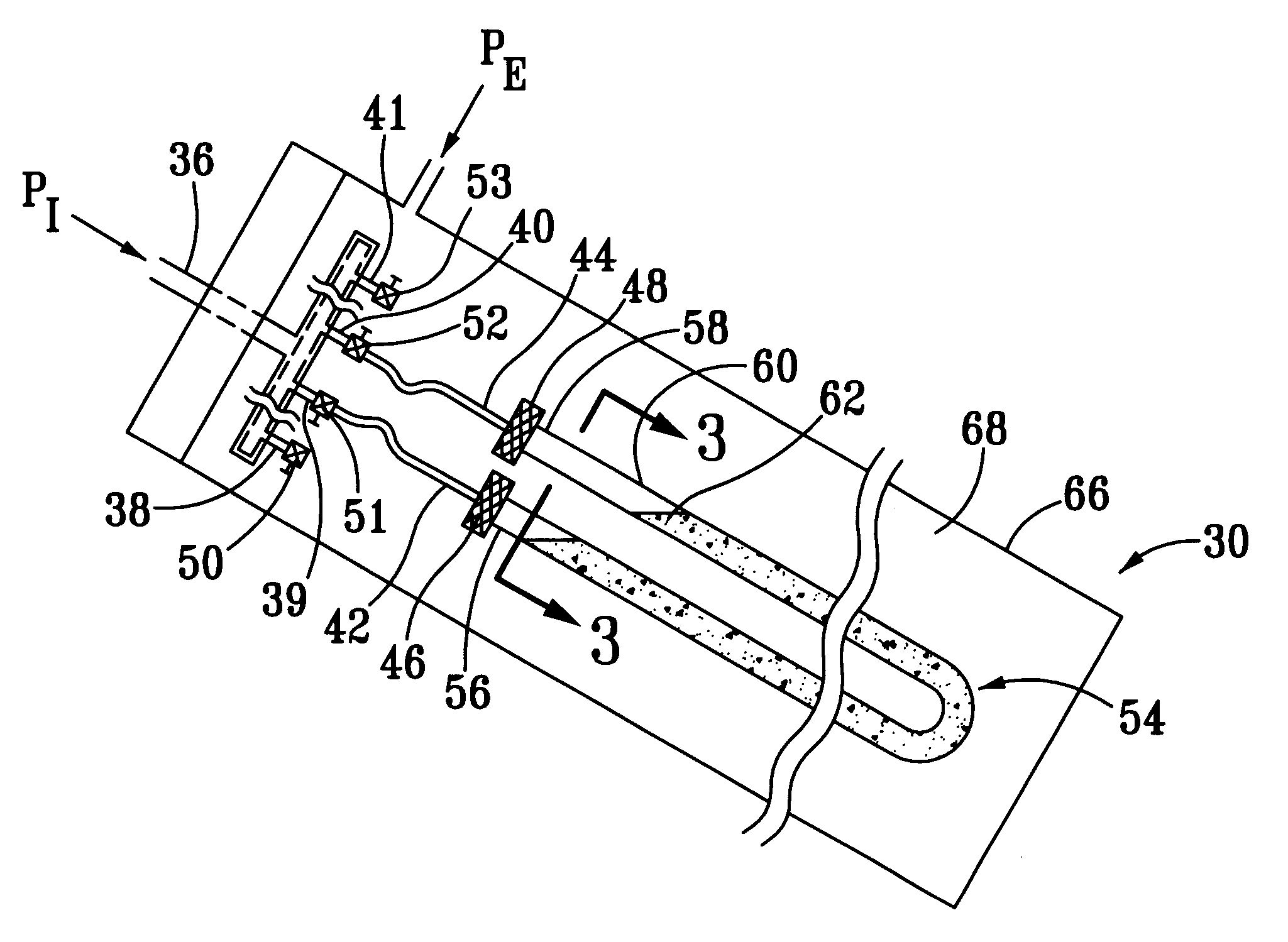

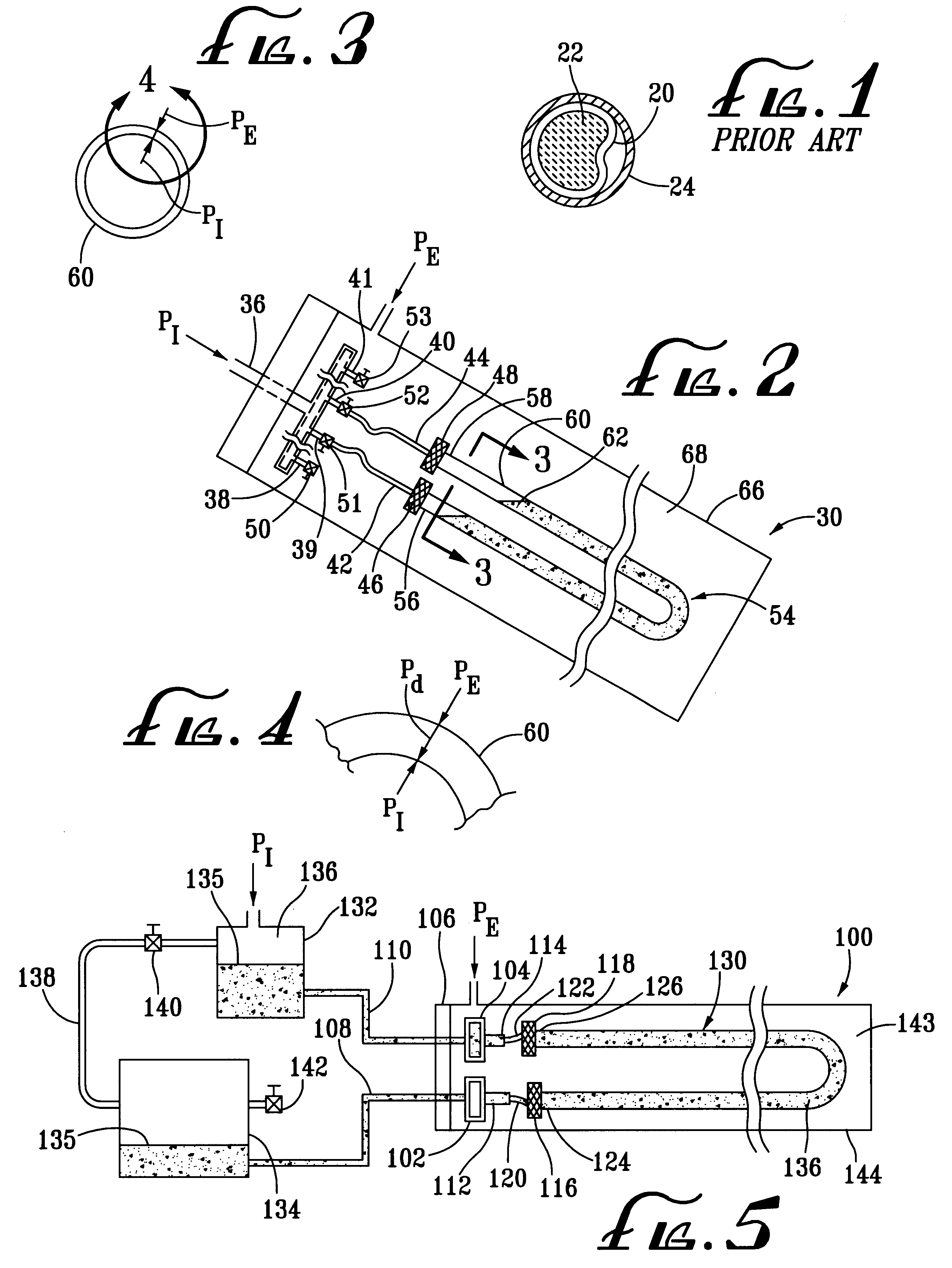

Optical fibers and processes and apparatus for making the same

InactiveUS6251311B1Increase absolute pressureReduce numberOptical articlesAuxillary shaping apparatusEngineeringOptical fiber cable

A large core polymeric optical fiber having improved light transmitting characteristics includes a cladding filled with a light transmitting core. The core is formed during a polymerization reaction within the cladding in which the pressure internal to the cladding is greater than the pressure external to the cladding to form a pressure differential supported by the cladding.

Owner:ROGER K HUGHES AS SUCCESSOR & TRUSTEE

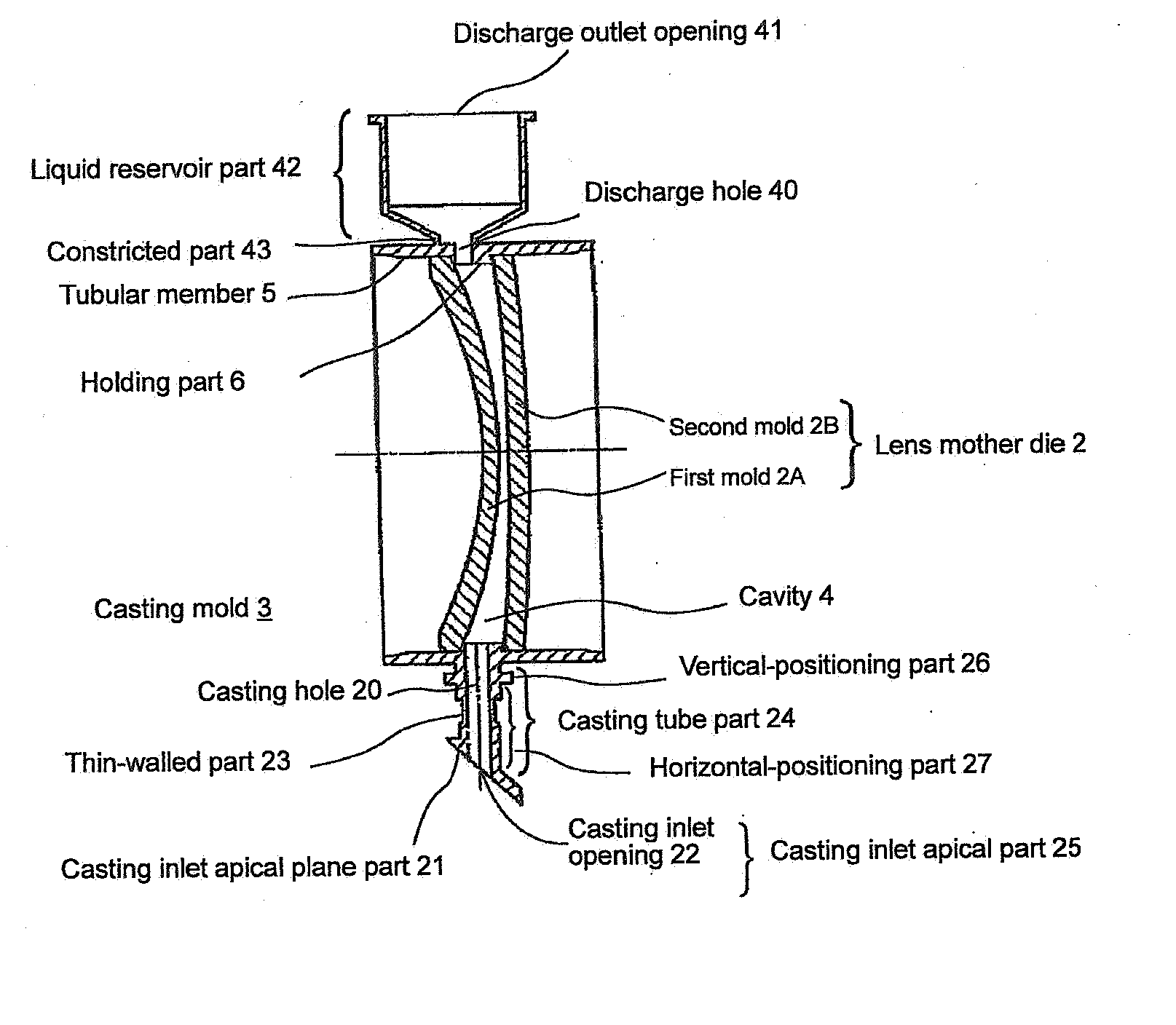

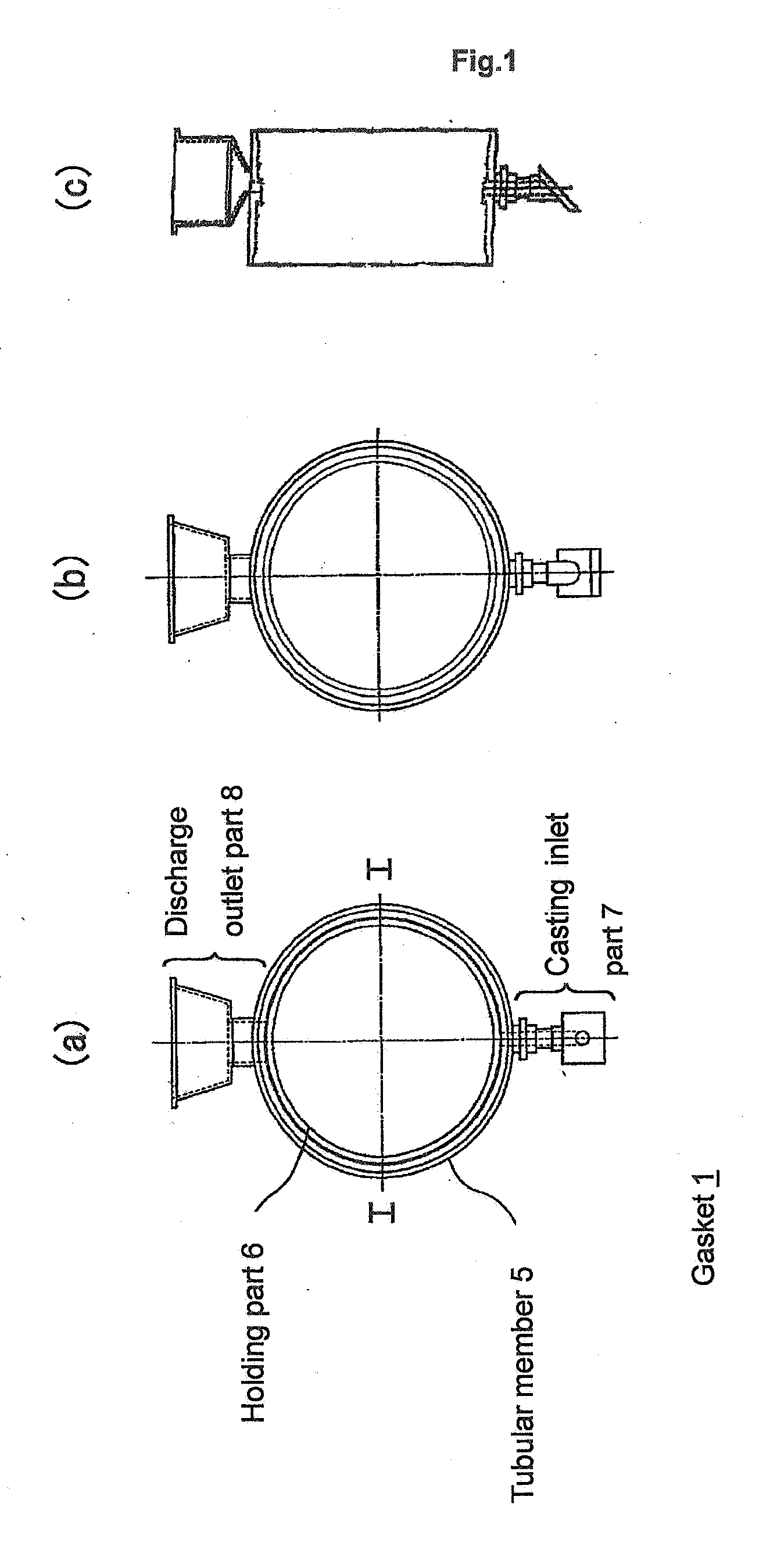

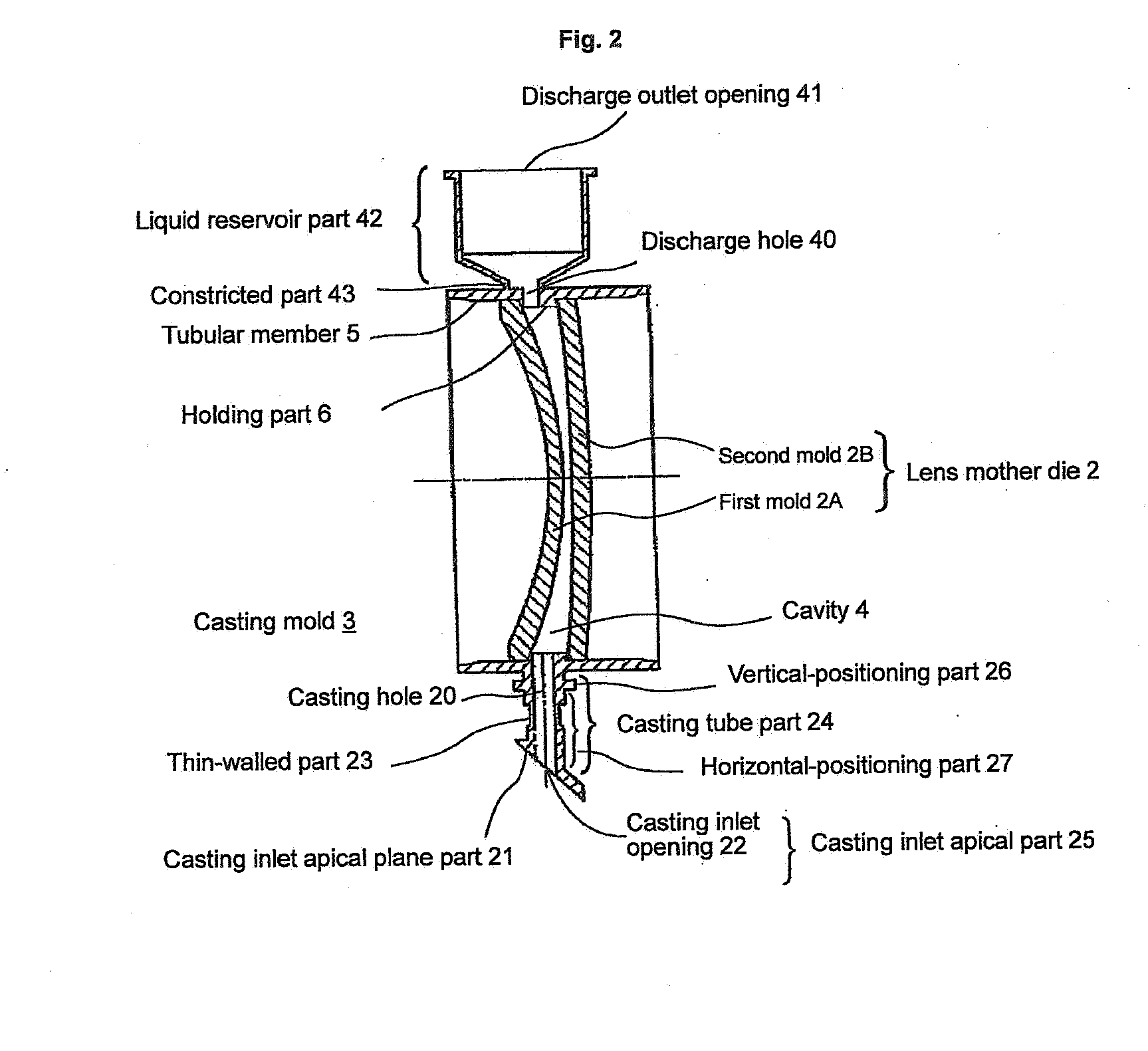

Method Of Manufacturing Plastic Lens, Gasket For Molding Plastic Lens, Casting Mold For Molding Plastic Lens, Casting Jig For Plastic Lens Starting Material Liquid, Holding Member For Plastic Lens Casting Mold, And Plastic Lens Manufacturing Apparatus

InactiveUS20080018005A1Reduce bubblingReduced optical defectOptical articlesCasting moldPolymerization

A method of manufacturing a plastic lens by mixing plural polymerizable components, and immediately after mixing, casting a mixture into a casting mold and conducting polymerization to obtain a molded article. A method of manufacturing a plastic lens by casting a plastic lens starting material liquid flowing out of a casting jig opening into a casting mold and curing the above starting material liquid to form a molded article. A gasket for molding plastic lens comprised of a cylindrical member comprising openings for fitting by insertion two molds. A casting mold for molding plastic lens, wherein the above molds are detachably held in the above openings of the above gasket so that molding surfaces of the two molds are positioned opposite at a prescribed interval to form a cavity corresponding to a lens shape within the above cylindrical member. A casting jig for plastic lens starting material liquid equipped with a nozzle for casting a plastic lens starting material liquid into the casting mold. A method of manufacturing a plastic lens comprising casting of a plastic lens starting material liquid into a casting mold held by a holding member and curing the above starting material liquid to form a molded article. A holding member for plastic lens casting mold for holding a casting mold for molding a plastic lens.

Owner:HOYA CORP

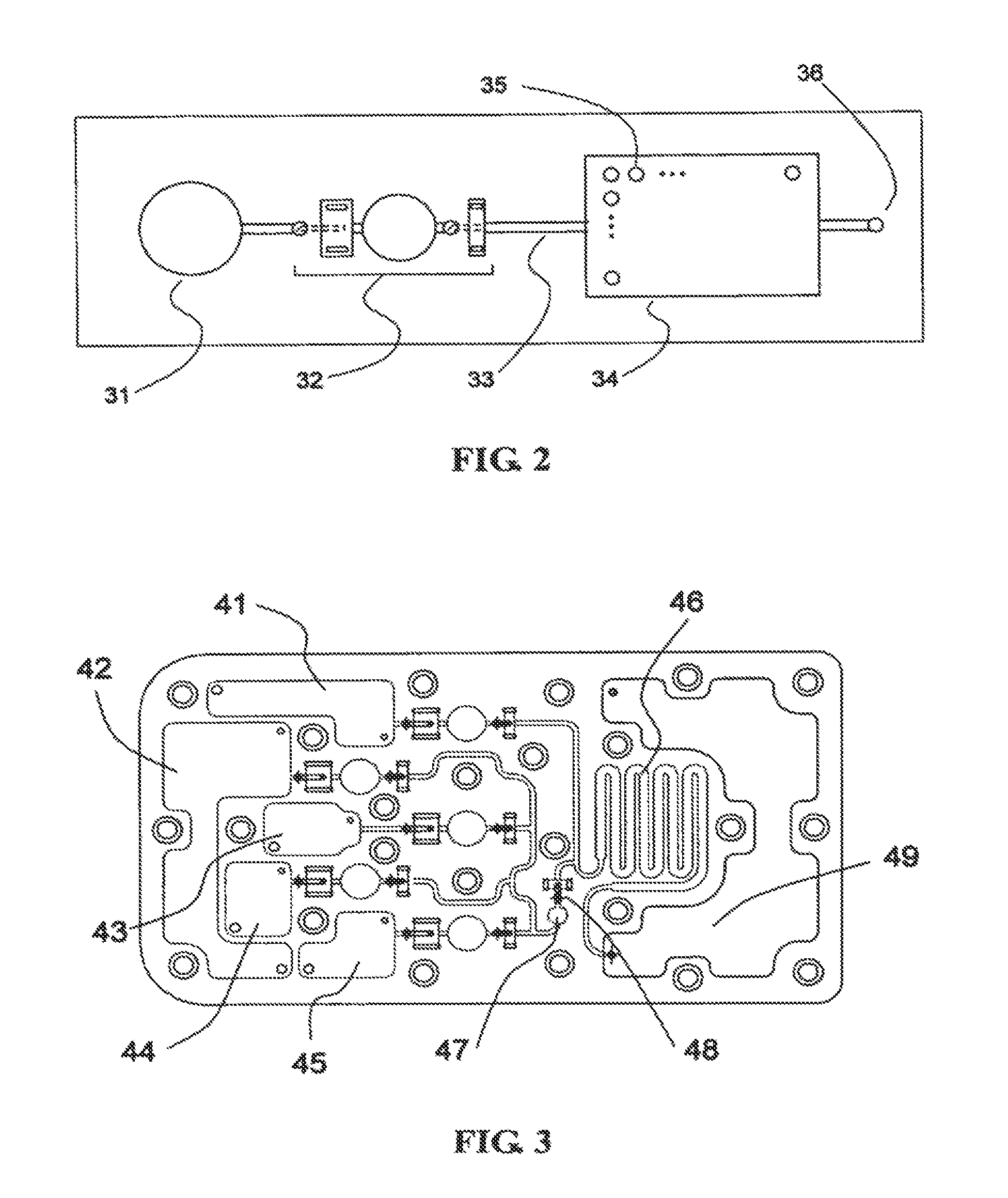

Valve structure for consistent valve operation of a miniaturized fluid delivery and analysis system

InactiveUS8309039B2Improve consistencyImprove reliabilityBioreactor/fermenter combinationsBiological substance pretreatmentsOpen cavityVALVE PORT

A valve structure of a fluid delivery and analysis system having an upper substrate, a lower substrate and an intermediate layer with at least one opening and at least one open cavity having a first touch point between the upper substrate and the intermediate layer and a second touch point between the lower substrate and the intermediate layer where the first touch point and the second touch point are offset to create a torque so that when intermediate layer is compressed between the upper substrate and the lower substrate that the torque deforms the intermediate rubber layer in the direction of the opening for better sealing.

Owner:WEBSTER JAMES RUSSELL +2

Piezoelectric devices and methods for manufacturing same

InactiveUS20090085431A1Improve conductivityImprove surface roughnessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringMetal

Devices are disclosed that include a piezoelectric vibrating piece; a glass base and lid form a package enclosing the piezoelectric vibrating piece. The piece has first and second electrodes. The base has first and second opposing surfaces. The base mounts the piezoelectric vibrating piece, and the lid seals the piezoelectric vibrating piece in the package. The base includes first and second metal wires, extending therethrough, whose ends are denuded to the first and second surfaces and connected to the first and second electrodes, respectively. In disclosed methods for making the packaged devices, such as piezoelectric oscillators, multiple packaged devices are made simultaneously by stacking and simultaneously bonding respective wafers on which glass bases, piezoelectric vibrating pieces, and lids have been formed.

Owner:NIHON DEMPA KOGYO CO LTD

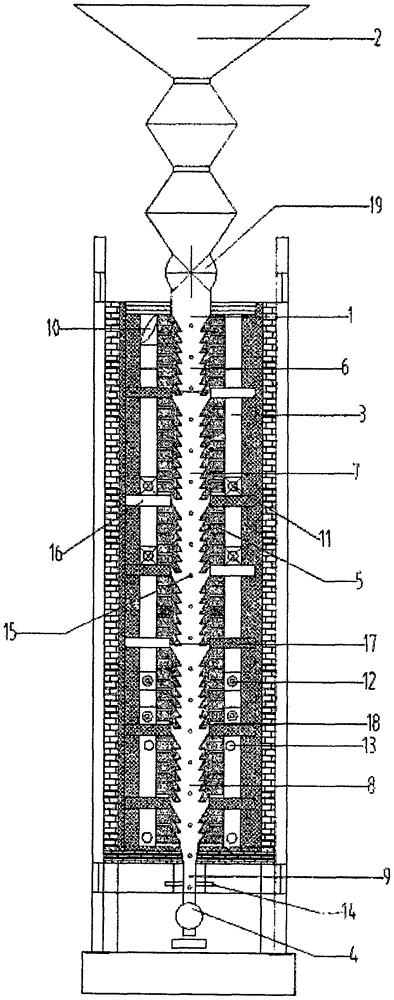

Carbonization and activation device for active coke production

The invention belongs to the field of chemical engineering devices and relates to a carbonization and activation device for active coke production. The device comprises a material channel and flues at two sides of the material channel. The device also comprises a preheating section, a carbonization section, an activation section and a cooling section and the sections are orderly arranged from top to bottom along a vertical direction. The flues in the carbonization and activation sections are respectively provided with gas burners. The flue in the activation section is provided with an activator inlet. The device realizes combination of carbonization and activation, has less processes, uniform and continuous reaction processes, a fast activation rate, a high raw material utilization rate and high production power, greatly reduces power and energy consumption and has a low cost and a high product yield.

Owner:赵英杰

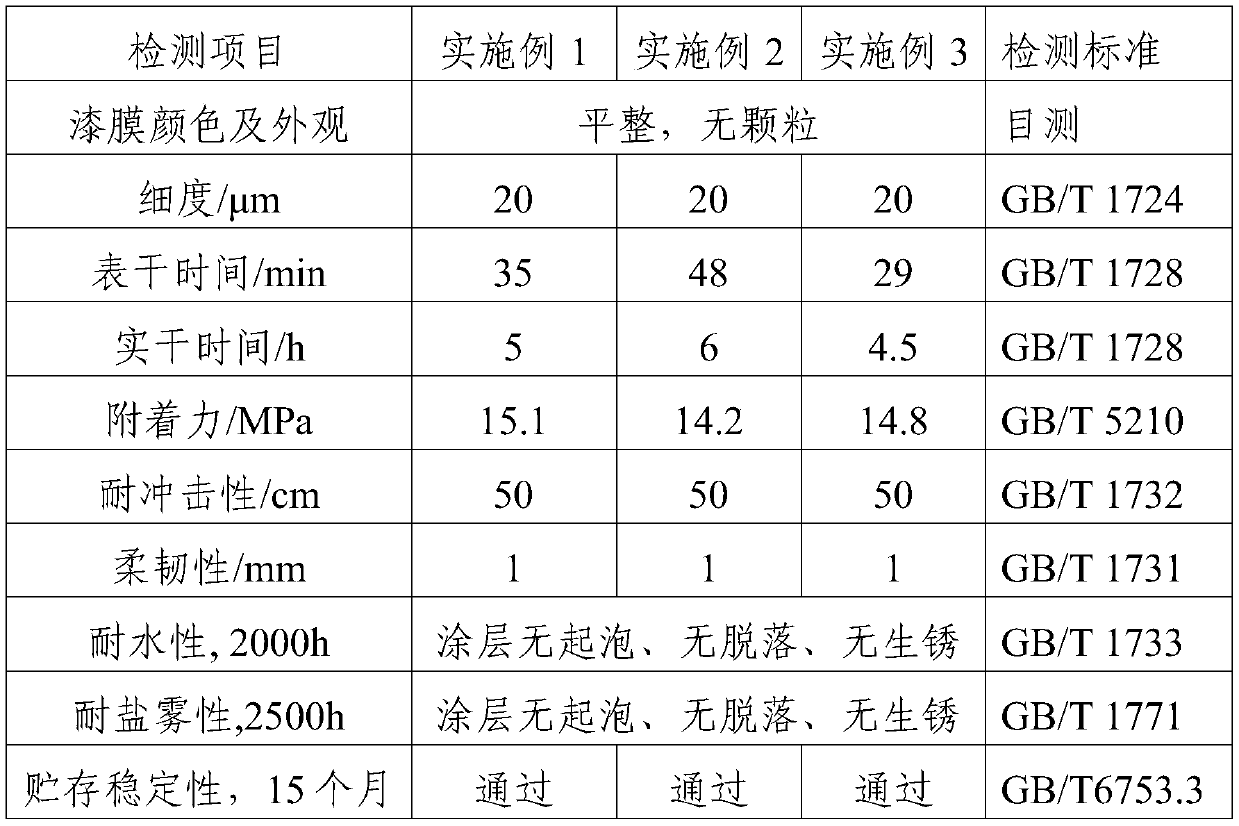

Aqueous epoxy zinc-enriched antirust priming paint for railway steel bridges and preparation method thereof

InactiveCN110922857AGood electrical conductivityStrong electron mobilityAntifouling/underwater paintsPaints with biocidesCardanolWeather resistance

The invention provides an aqueous epoxy zinc-enriched antirust priming paint for railway steel bridges and a preparation method thereof, and relates to the technical field of paints. The priming paintcomprises a component (a) and a component (b) according to a mass ratio of 1:4. The component (a) is prepared from following raw materials: aqueous epoxy resin emulsion, graphene coated glass fibers,nano antimony doped tin dioxide, nano titanium dioxide, an epoxy silane coupling agent, n-butyl alcohol, propylene glycol mono-methyl ether, an antifoaming agent (A), and deionized water; and the component (b) is prepared from following raw materials: a cardanol modified polyamide curing agent, zinc powder, a filling material, a thixotropic agent, an antifoaming agent (B), a dispersant, a flush-rust resistant agent, and a mixed solvent. By adding graphene coated glass fibers and nano antimony doped tin dioxide into the paint, the prepared epoxy zinc-enriched antirust priming paint has an excellent corrosion resistant performance, a strong adhesion force, and good weatherability even if the zinc powder content is low.

Owner:安徽壹信通讯科技有限公司

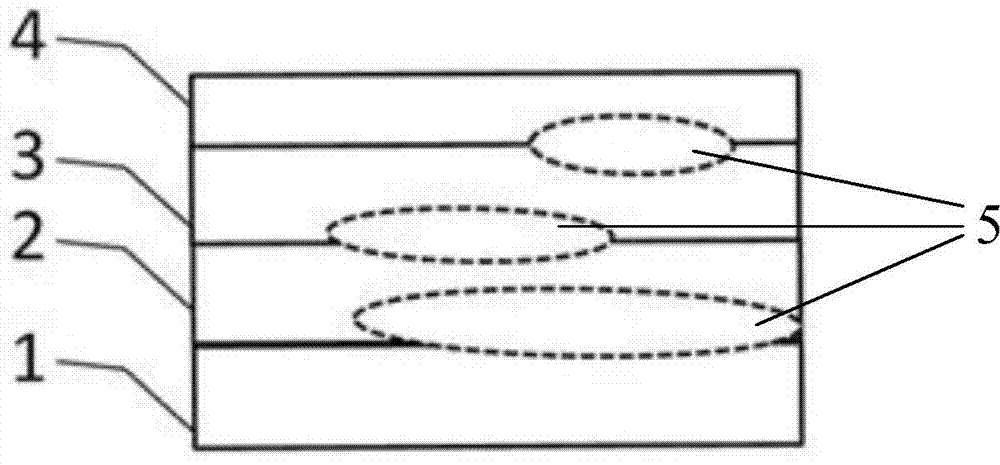

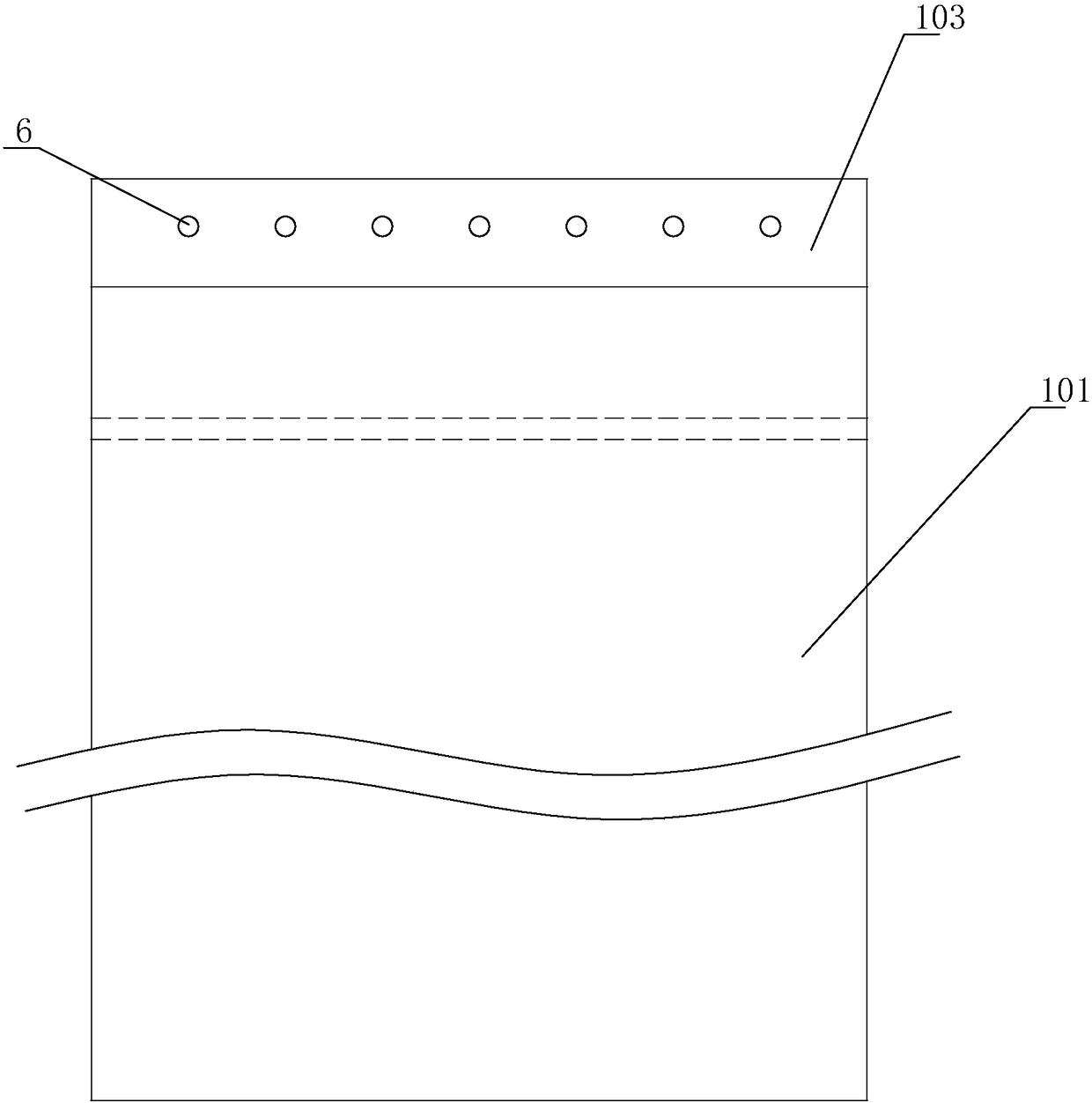

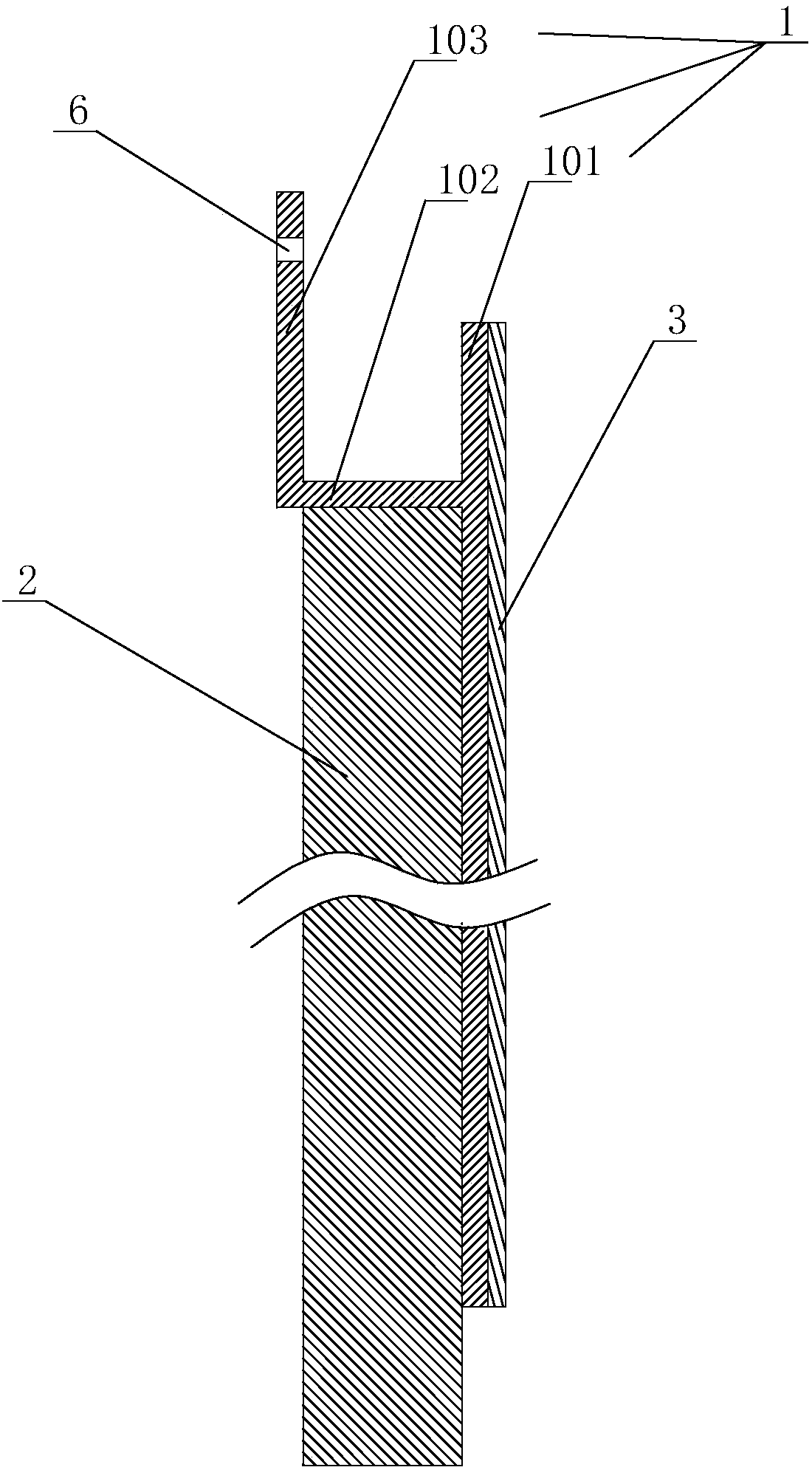

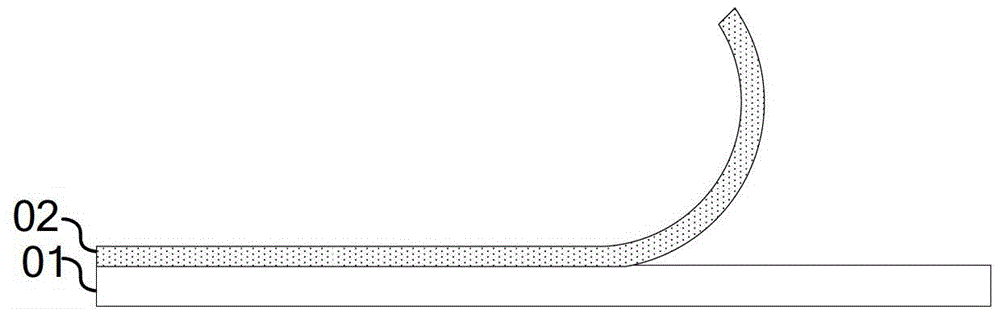

Immobilized breeding method of microalgae

ActiveCN104726339AGas dissolved concentration decreasedImproving the production of immobilized farmingUnicellular algaeMicroorganism based processesCell layerGas release

The invention relates to the field of microalgae breeding, and particularly relates to an immobilized breeding method of microalgae. A bubbling phenomenon in the process of immobilized breeding can be reduced, so that the immobilized breeding yield of microalgae is improved. The defect that in the prior art, the gas dissolved concentration or gas release of microalgae culture liquid in the process of immobilized breeding is large, so that a bubbling phenomenon easily occurs between a baseplate and a liquid conveying layer, between the liquid conveying layer and a carrier and between the carrier and a microalgae cell layer, thereby causing that the supply of the microalgae culture liquid is obstructed and the immobilized breeding yield of microalgae is low is overcome. An embodiment of the invention provides an immobilized breeding method of microalgae, which is used for carrying out immobilized breeding on microalgae by using pretreated microalgae culture liquid, wherein the gas dissolved quantity or gas release of the pretreated microalgae culture liquid in comparison with microalgae culture liquid before being pretreated is reduced.

Owner:ENN SCI & TECH DEV

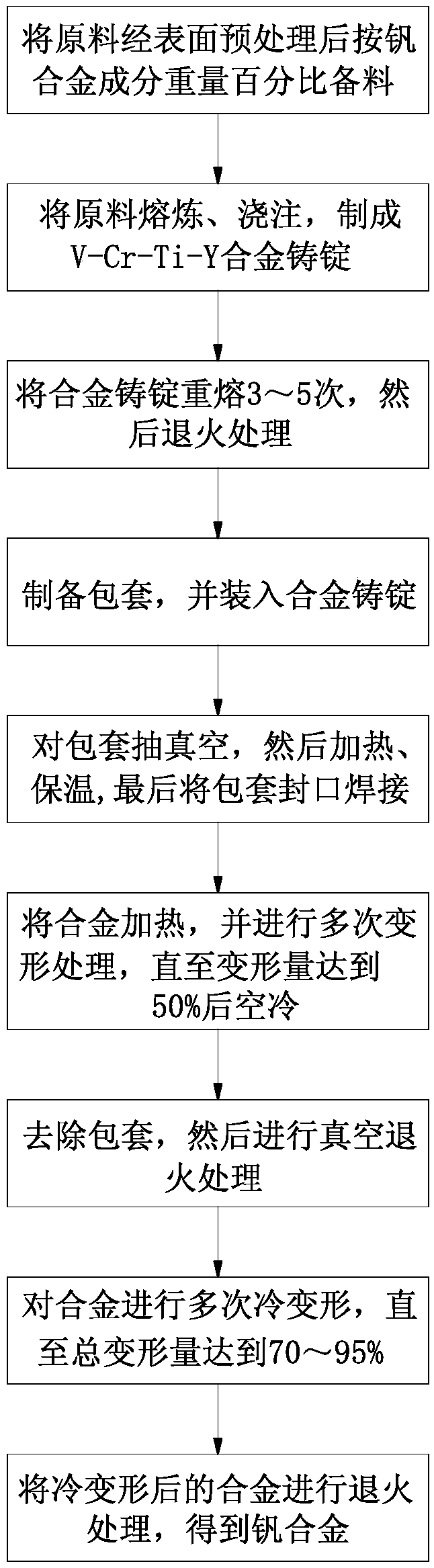

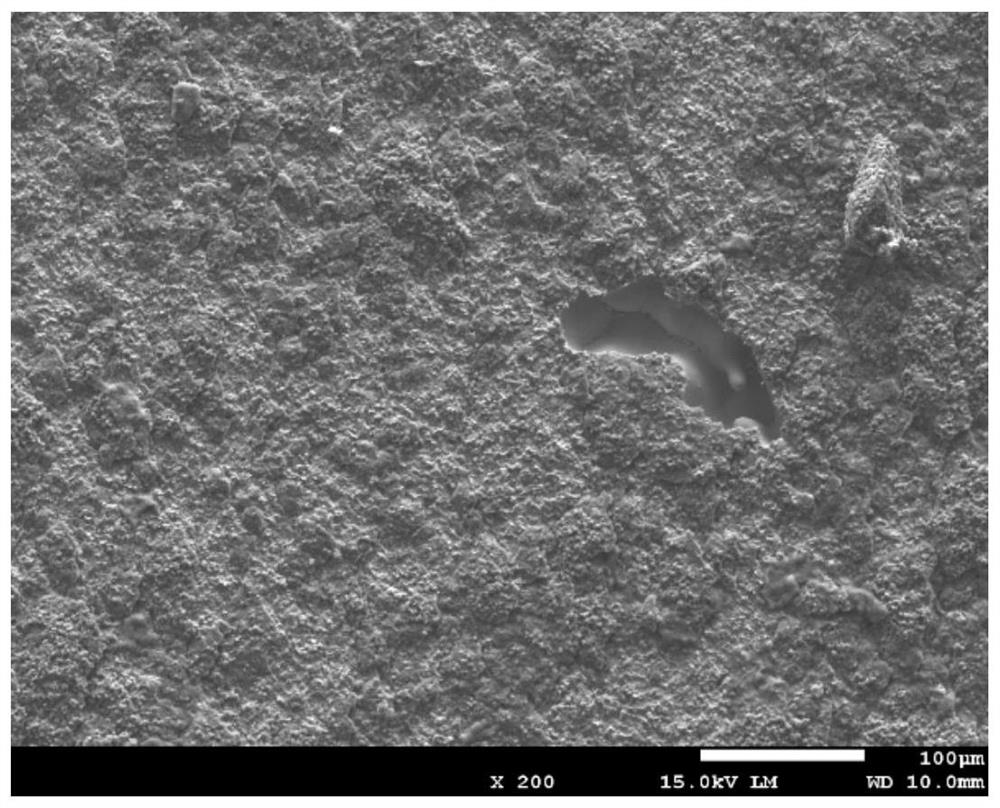

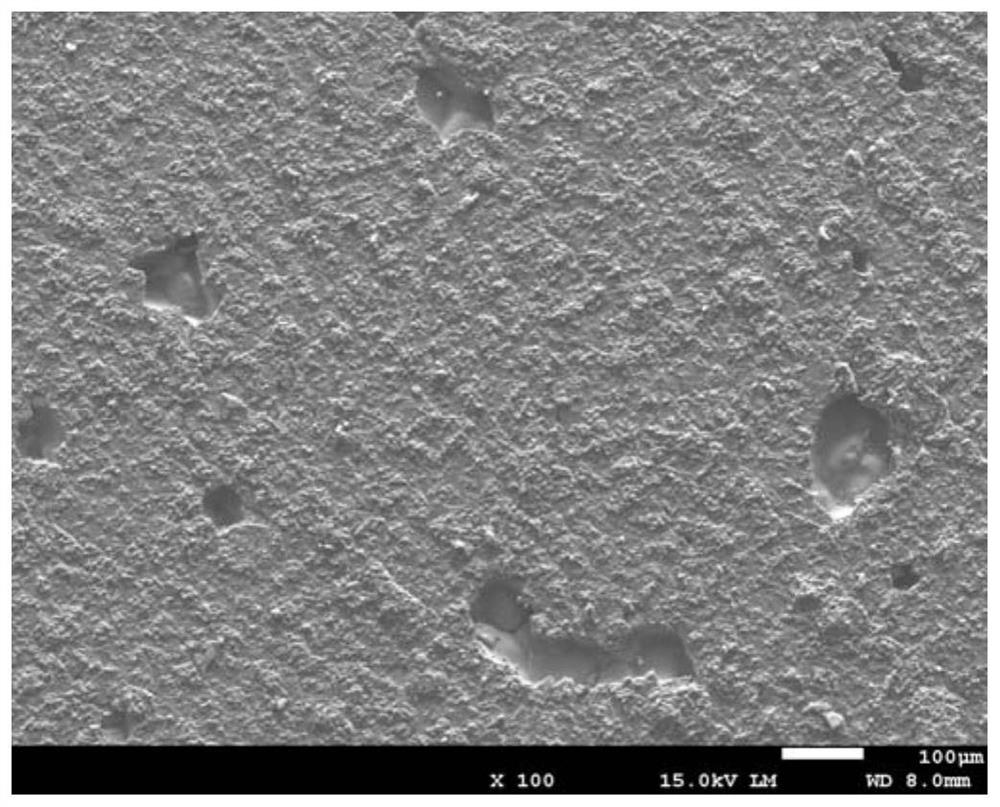

Novel helium ion sputtering-resistant vanadium alloy and preparation method thereof

InactiveCN105506428AReduce the dissolved oxygen contentRefine as-cast grain sizeRare-earth elementAlloy element

The invention discloses a novel helium ion sputtering-resistant vanadium alloy. The problem of low helium ion sputtering resistance of the prior art is solved. The alloy comprises the following components in percentage by weight: 3.0 to 6.5 percent of Cr, 3.0 to 6.5 percent of Ti, 0.1 to 2.0 percent of Y and the balance of V. In addition, the invention further provides a method for preparing the alloy. According to the vanadium alloy, on the basis of a V-Cr-Ti ternary alloy system, Cr and Ti are employed as main alloy elements, the rare earth element Y is added to reduce the content of solid solution oxygen in the vanadium alloy and reduce the dimensions of ingot crystals by virtue of a simple alloying means, and a plastic deformation machining means is combined to disperse and distribute yttrium oxide with stable high-temperature performance on a substrate and remarkably reduce and uniformize the dimensions of the annealed alloy crystals, thereby improving the toughness of the alloy and greatly enhancing the helium ion sputtering resistance of the alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

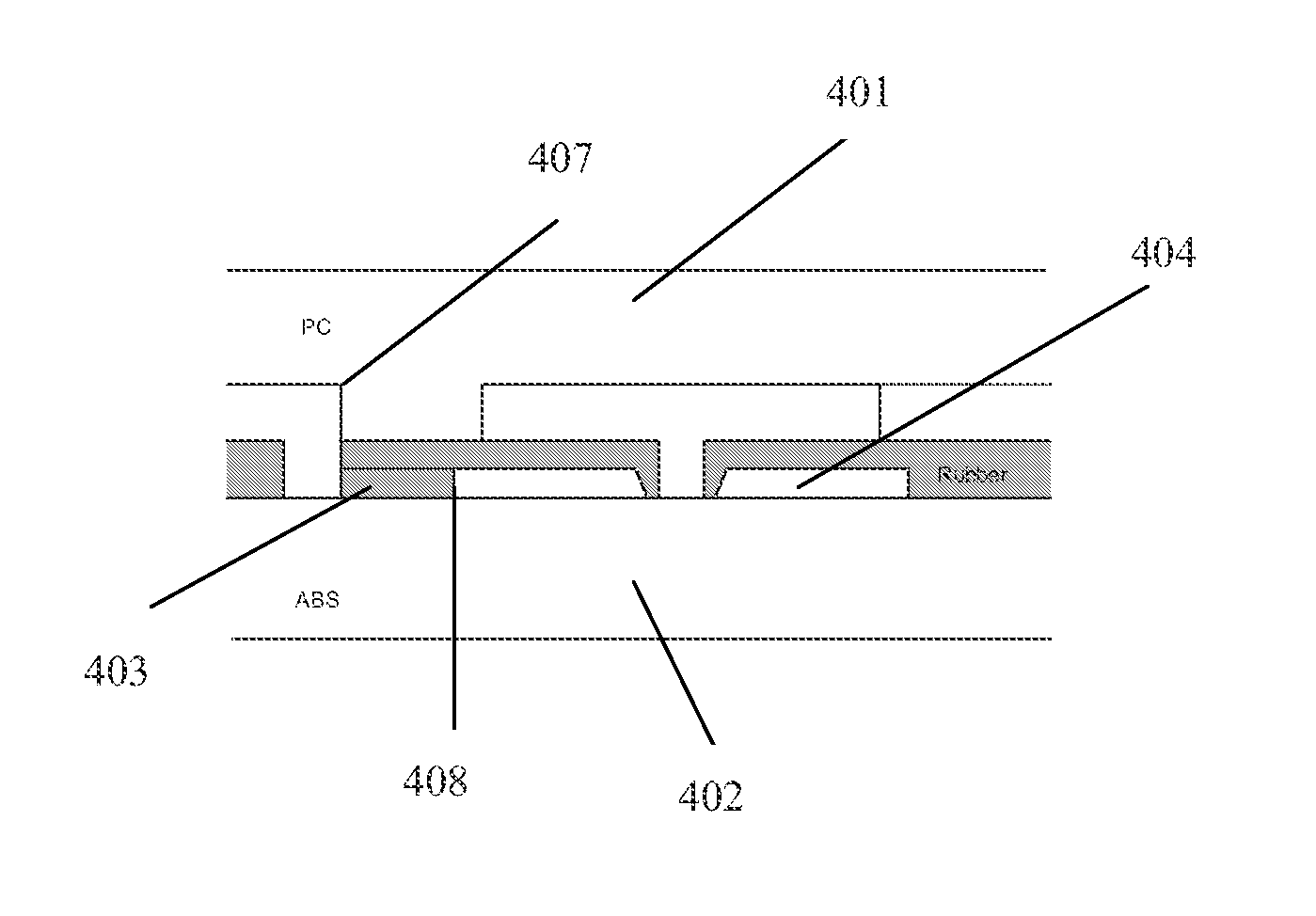

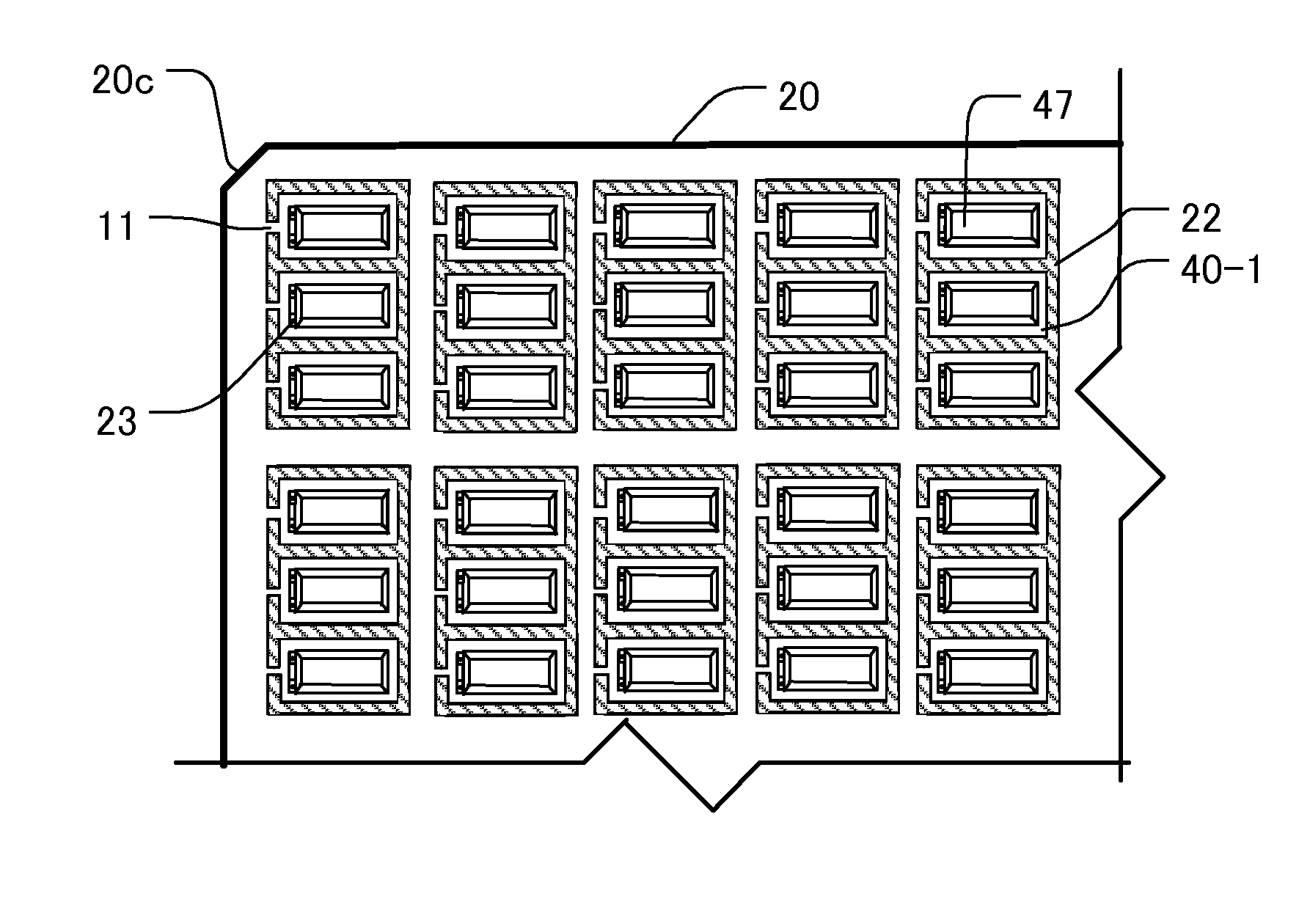

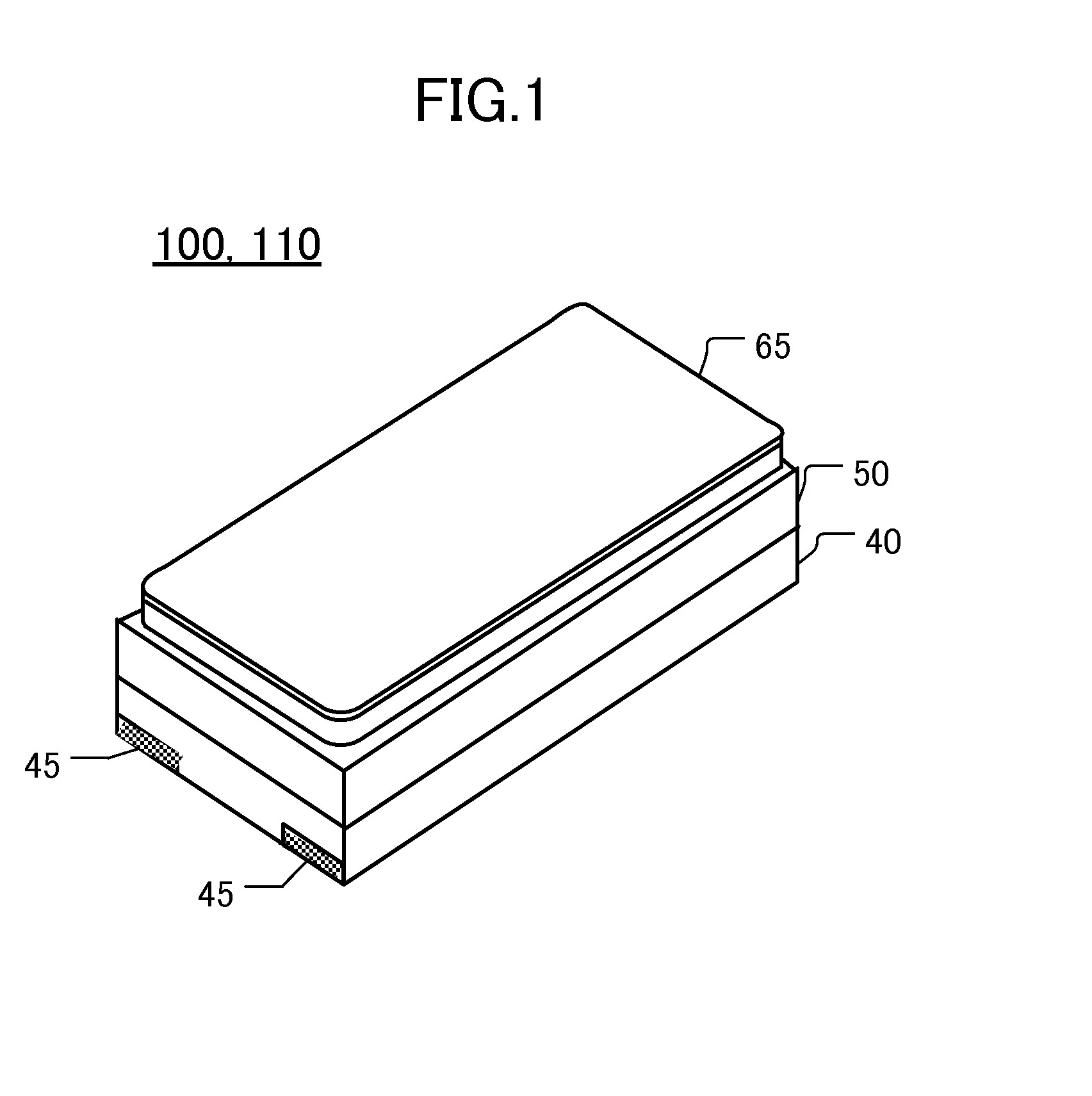

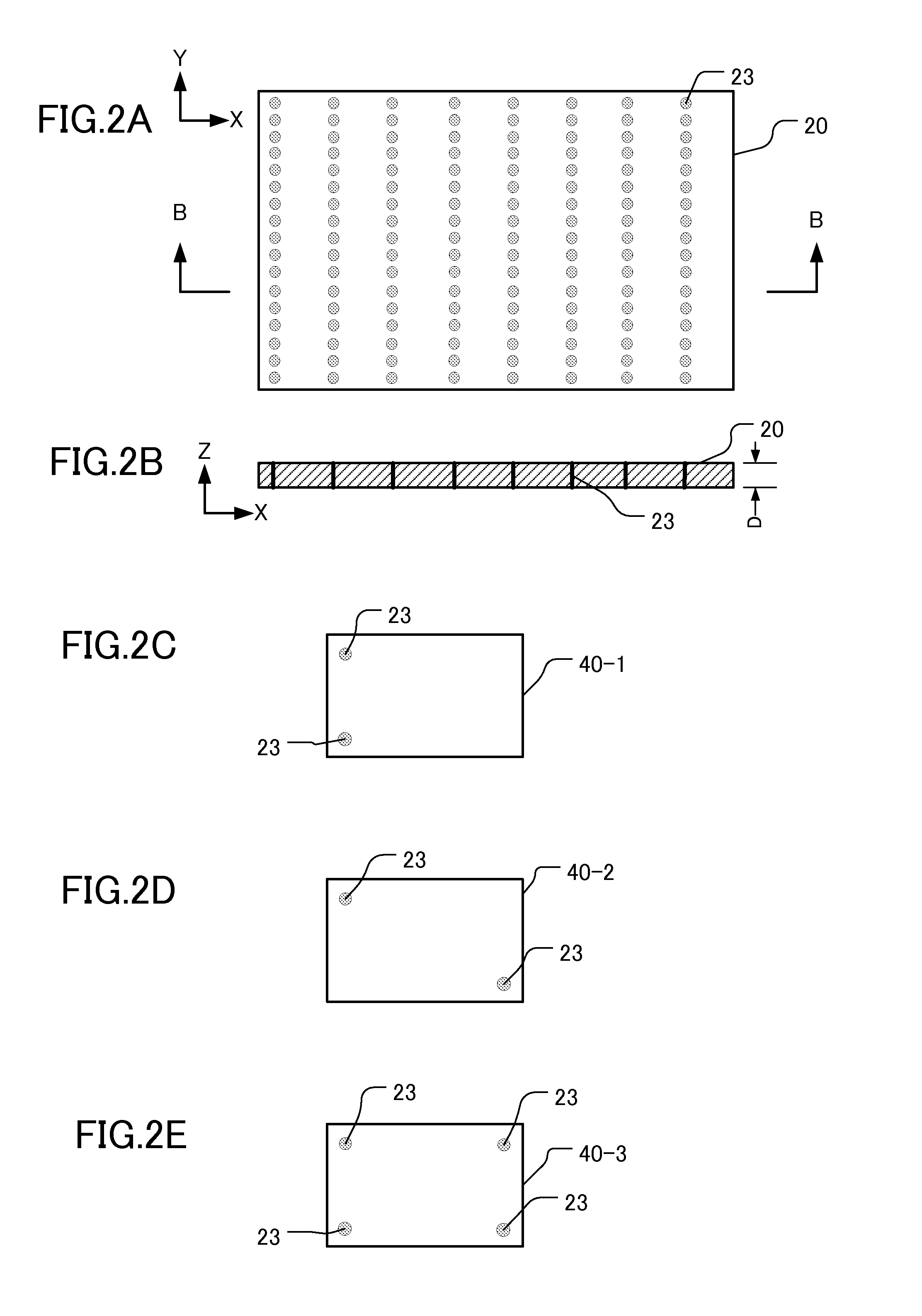

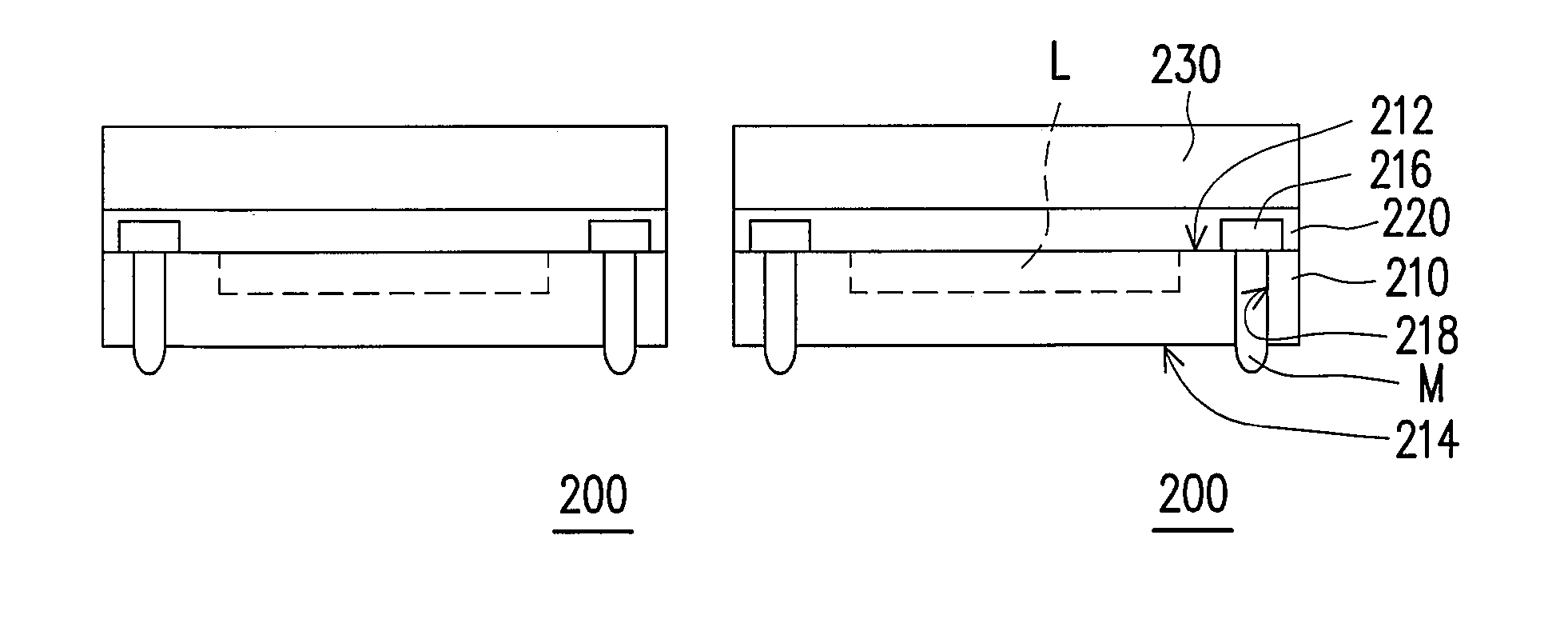

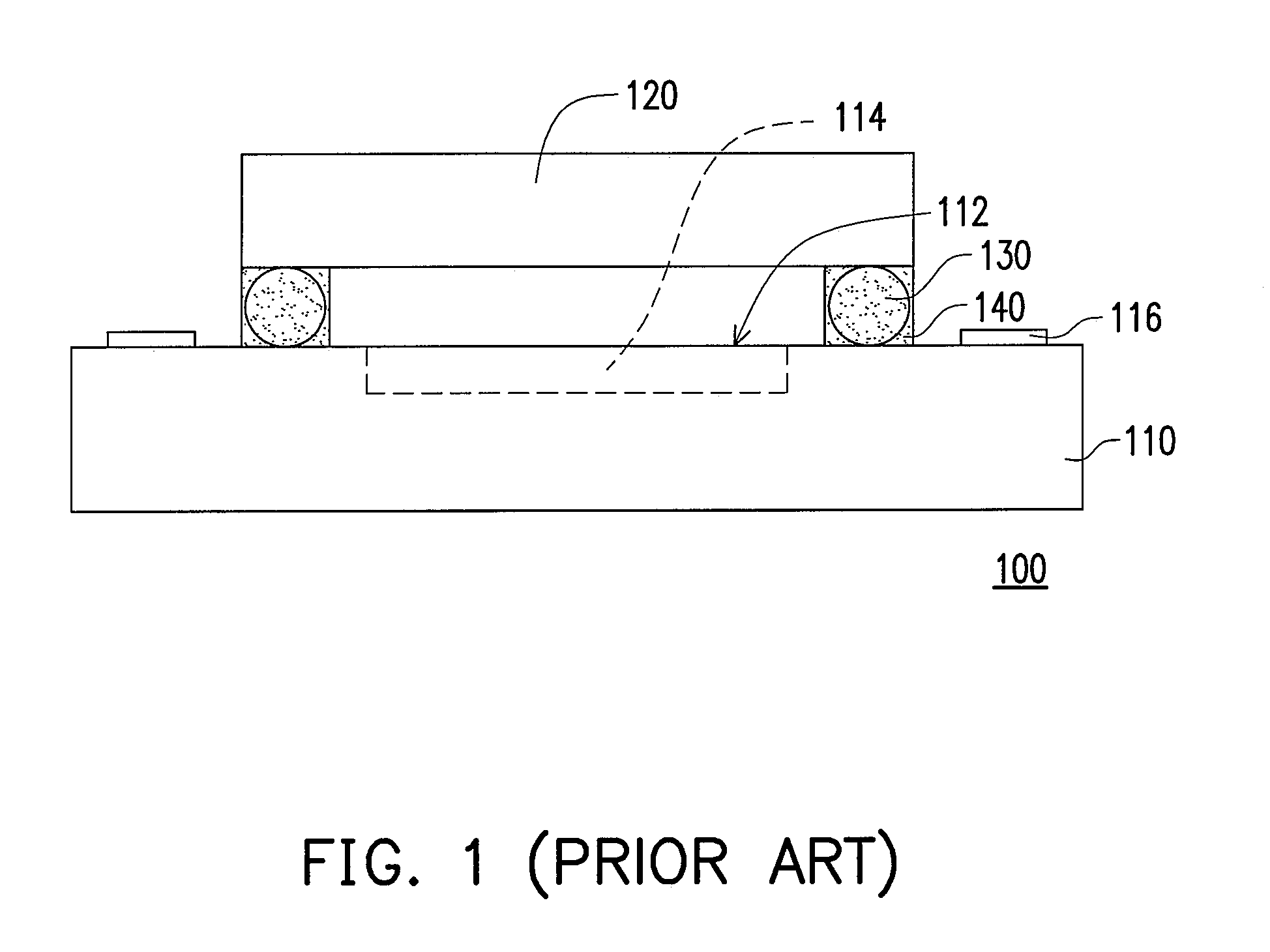

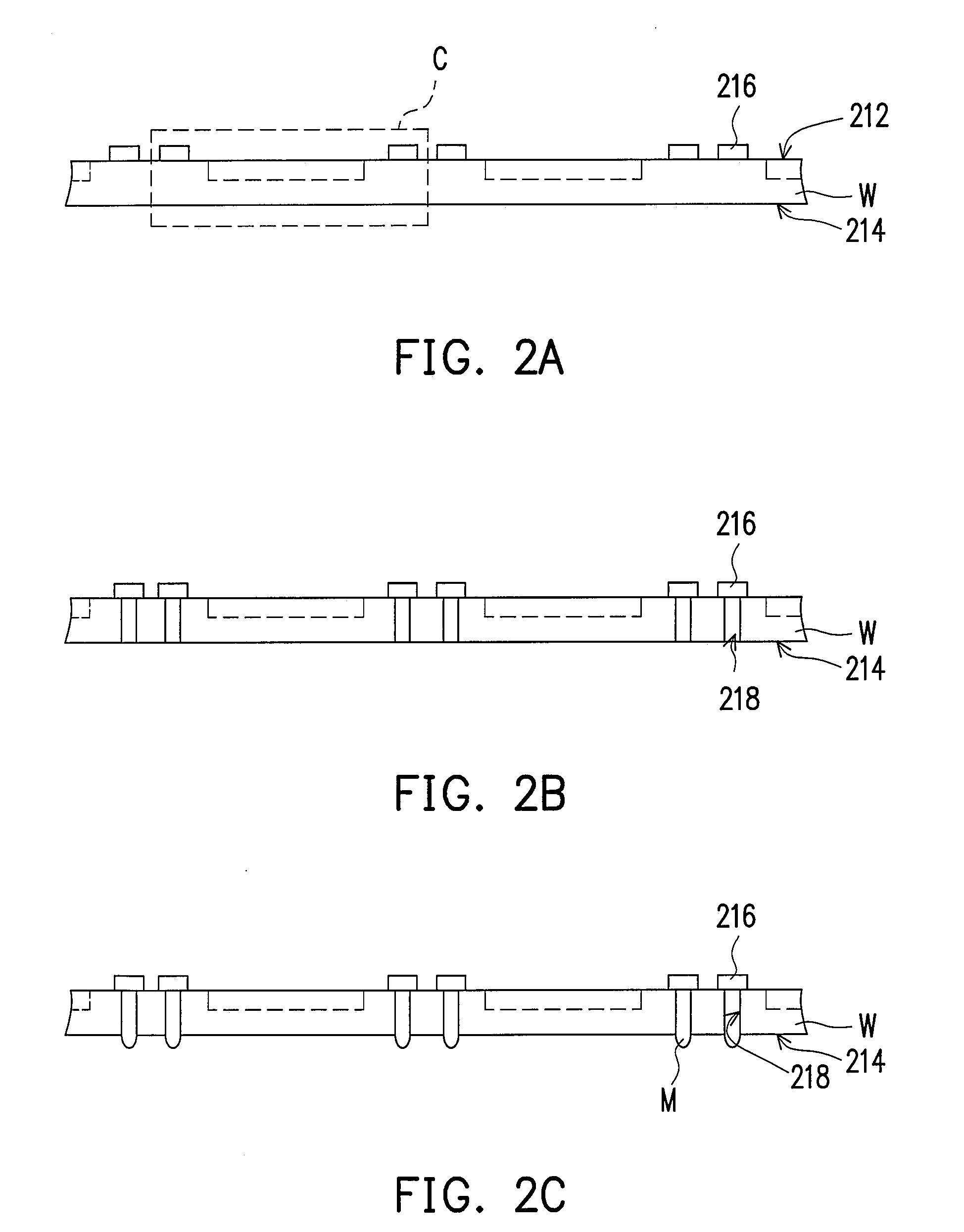

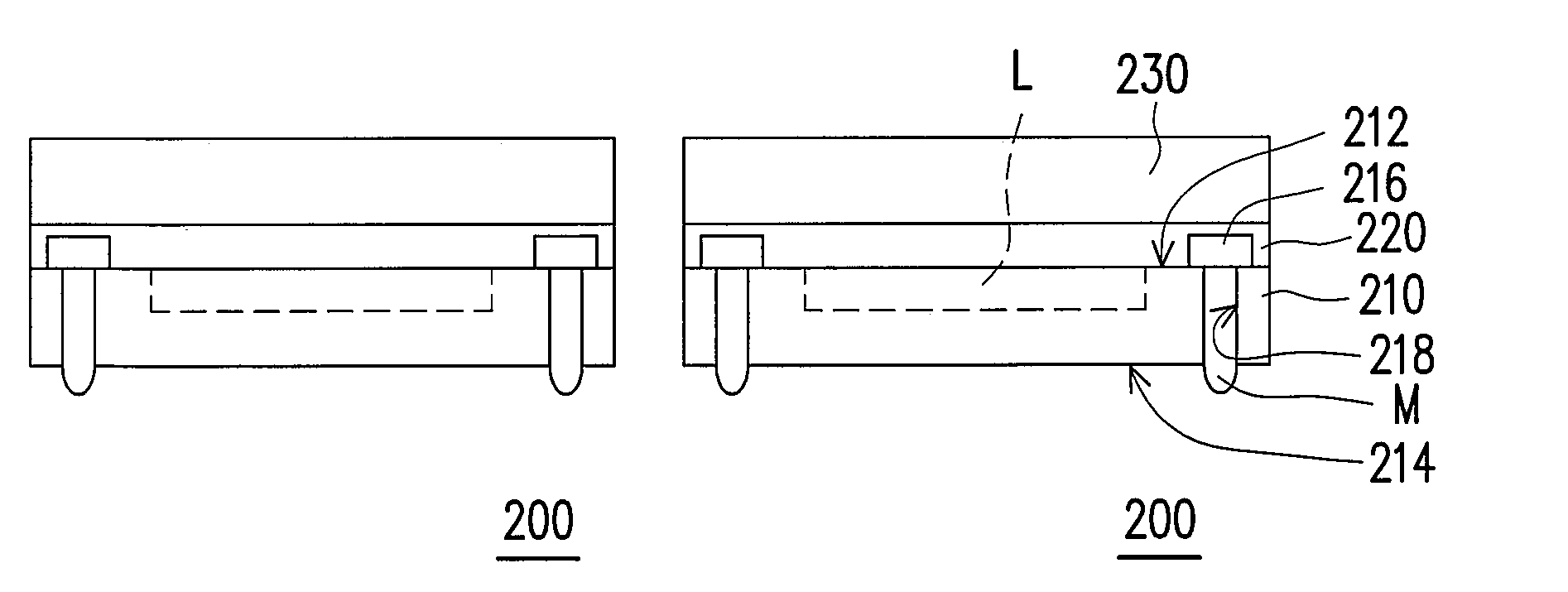

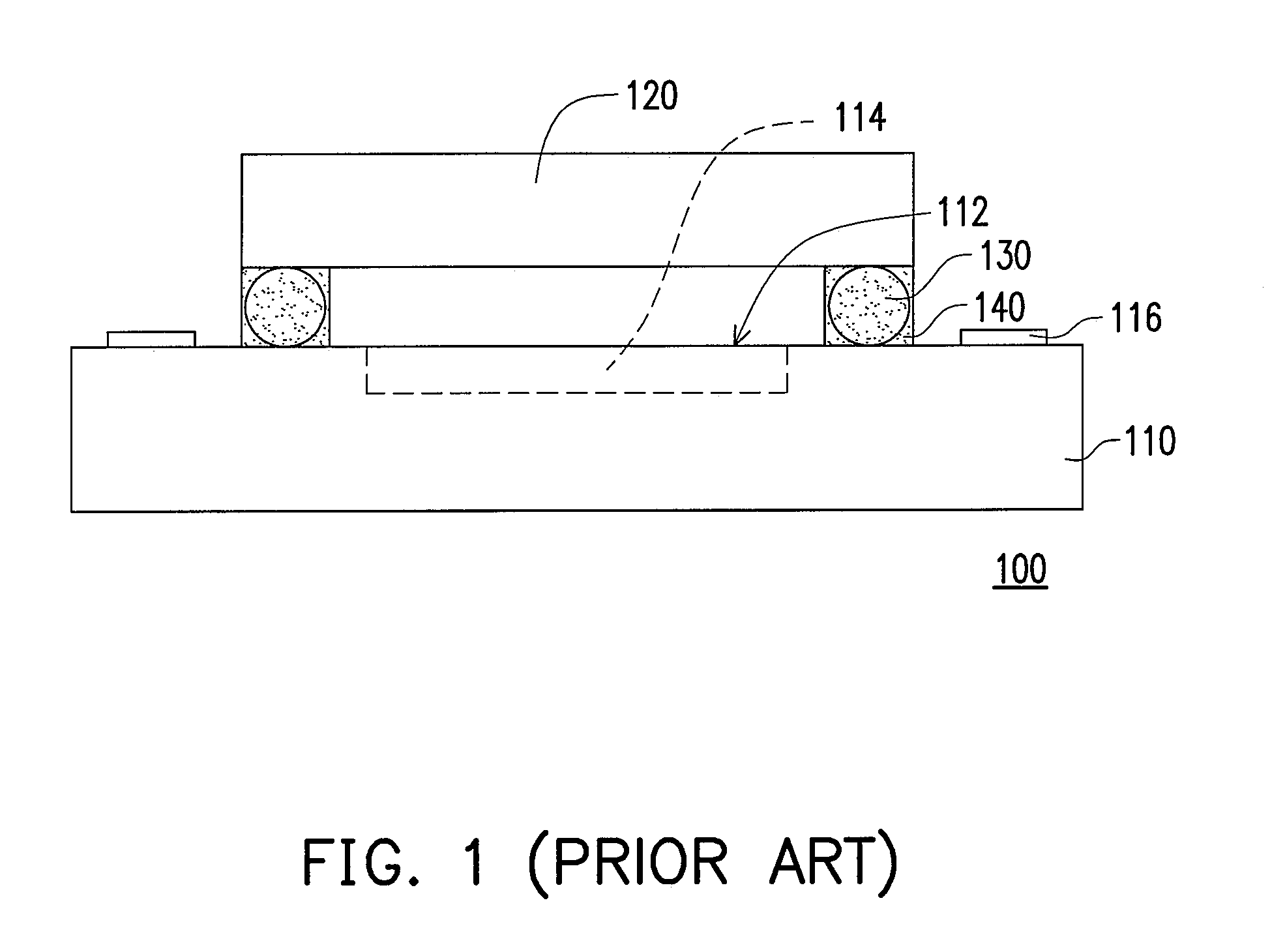

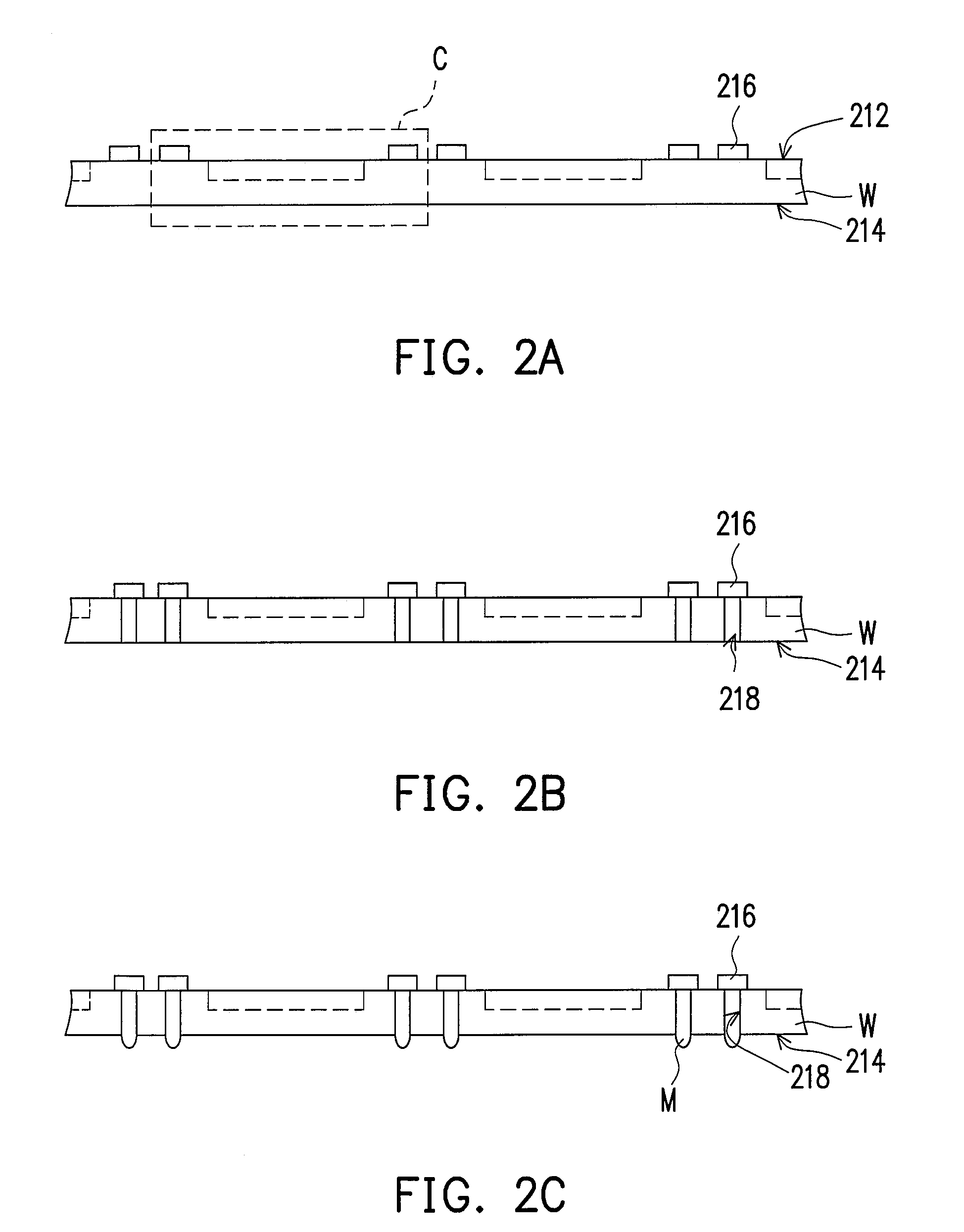

Wafer-level chip packaging process and chip package structure

ActiveUS20070158673A1Reduce bubblingReduce voidsSemiconductor/solid-state device detailsSolid-state devicesEffective surfaceConductive materials

A wafer-level chip packaging process includes the following steps. First, a wafer having a plurality of chip units, an active surface, and a corresponding back surface is provided. Each chip unit has a plurality of pads on the active surface. Next, a plurality of through holes is formed under the pads. The through holes are filled with a conductive material such that the conductive material within each through hole is electrically connected to corresponding one of the pads and a portion of the conductive material is exposed and protrudes from the back surface of the wafer. Thereafter, a transparent adhesive layer is formed on the active surface. Next, a transparent cover panel is disposed on the transparent adhesive layer such that the transparent cover panel is connected to the wafer through the transparent adhesive layer. Afterwards, a singulation step is performed to form a plurality of independent chip package structures.

Owner:ADVANCED SEMICON ENG INC

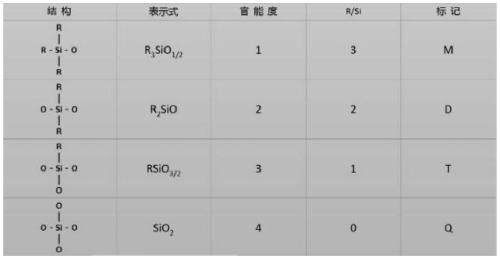

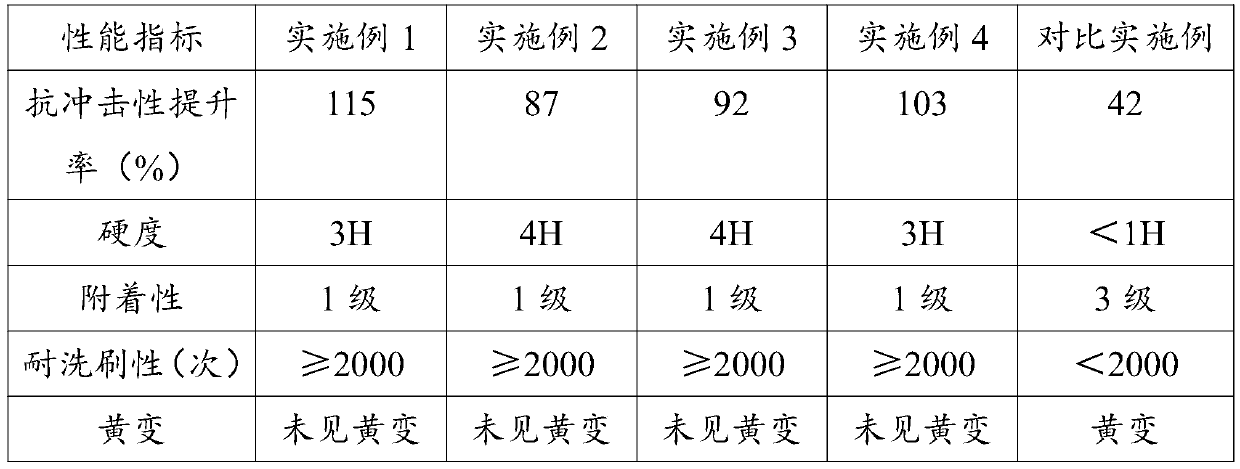

Preparation method of impact-resistant glass with coating

ActiveCN111533464AImprove toughnessImprove elasticity and toughnessInksCoatingsSilicone resinWeather resistance

The invention discloses a preparation method of impact-resistant glass with a coating. The coating comprises the following components in parts by weight: 20-30 parts of condensed silicon resin, 2-10 parts of vinyl silicon resin, 1-5 parts of a curing agent, 1-5 parts of an adhesion promoter, 0.1-1 part of a leveling agent and 55-65 parts of a solvent. A step-by-step spraying mode is adopted, an anti-impact coating is sprayed on a preheated glass base material, after ultraviolet curing and thermal curing, the coating is cooled to room temperature step by step, according to the impact-resistantglass with the coating prepared by the method, the impact resistance can be improved by 85% or more, and the coating is high in hardness, free of yellowing, strong in adhesiveness and scrub resistance, not easy to fall off, and good in weather resistance and durability.

Owner:索菲立(福建)新材料科技有限公司

Wafer-level chip packaging process and chip package structure

ActiveUS7696008B2Reduce bubblingReduce voidsSemiconductor/solid-state device detailsSolid-state devicesEffective surfaceConductive materials

A wafer-level chip packaging process includes the following steps. First, a wafer having a plurality of chip units, an active surface, and a corresponding back surface is provided. Each chip unit has a plurality of pads on the active surface. Next, a plurality of through holes is formed under the pads. The through holes are filled with a conductive material such that the conductive material within each through hole is electrically connected to corresponding one of the pads and a portion of the conductive material is exposed and protrudes from the back surface of the wafer. Thereafter, a transparent adhesive layer is formed on the active surface. Next, a transparent cover panel is disposed on the transparent adhesive layer such that the transparent cover panel is connected to the wafer through the transparent adhesive layer. Afterwards, a singulation step is performed to form a plurality of independent chip package structures.

Owner:ADVANCED SEMICON ENG INC

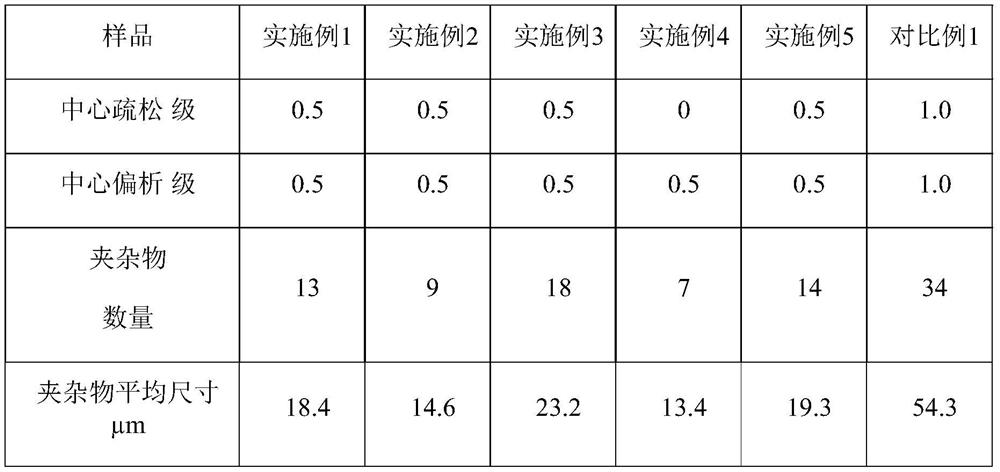

Preparation process of H08A steel

The invention provides a preparation process of H08A steel. The preparation process comprises the following specific steps of first, smelting in a converter, wherein magnesium alloy is added in the tapping process to carry out pre-deoxidation and argon blowing, and the free oxygen content of molten steel is controlled to range from 80 ppm to 100 ppm; second, LF refining, wherein calcium is added in the process to remove oxygen again, and the free oxygen content is controlled to range from 10 ppm to 20 ppm after LF refining heating of the molten steel is finished; and third, continuous casting;wherein according to the feeding manner of adding the magnesium alloy in the first step, powdery magnesium alloy is blown into the bottom of a steel ladle by using carrier gas. According to the preparation process of the H08A steel, the section of a produced casting blank (8 hours of continuous casting) sample produced is free of any obvious bubbles, the central porosity grade is less than or equal to 0.5 grade, the central segregation grade is less than or equal to 0.5 grade, other obvious defects do not exist, and the percent of pass is 99%; and meanwhile, in the cross section of a steel body with the area of 100 * 100 millimeters, the number of inclusions is no larger than 30, and the maximum diameter of the inclusions is no larger than 20 micrometers.

Owner:福建三宝钢铁有限公司

Efficient, solid, high-temperature-resistant and high-pressure-resistant corrosion and scale inhibitor

InactiveCN106927583AFunctionalAvoid corrosionSpecific water treatment objectivesScale removal and water softeningCarboxylic acidKetone

The invention relates to an efficient, solid, high-temperature-resistant and high-pressure-resistant corrosion and scale inhibitor. The efficient, solid, high-temperature-resistant and high-pressure-resistant corrosion and scale inhibitor is prepared from, by mass, 20-40% of macromolecule multibase polymers, 5-20% of amino carboxylic acid, 40-60% of sodium carbonate and 0.1-5% of sodium hydroxide; the macromolecule multibase polymers (HA and FA) extracted from papermaking waste, coal mining waste and other waste are adopted, the basic structure is aromatic rings and alicyclic rings, the rings are connected with carboxyl groups, hydroxyl groups, hydroxyl groups, quinonyl groups, phenol groups, ketone methoxy groups and other functional groups, the macromolecule multibase polymers have exchange, adsorption, complexation and chelation effects on metal ions, serve as polyelectrolyte in a dispersion body and have the effects of condensation, peptisation, dispersion and the like, the macromolecule multibase polymers and the amino carboxylic acid such as sodium ethylene diamine tetracetate have complexing properties and are alkaline, and the macromolecule multibase polymers are formed by compounding according to the weight ratio. According to the efficient, solid, high-temperature-resistant and high-pressure-resistant corrosion and scale inhibitor, the anti-corrosion scale inhibition rate is 95% or above, the quality guarantee period is up to 8-10 years, the corrosion and scale inhibitor can be directly thrown into a medium so that the use amount is low, and expensive boiler supporting facilities are replaced.

Owner:滕文良

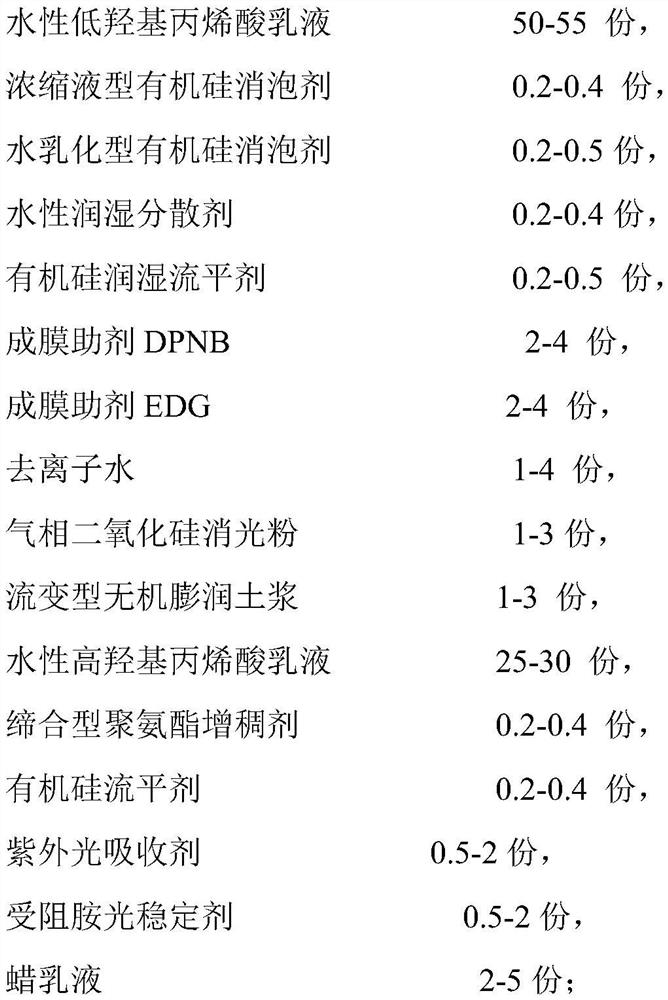

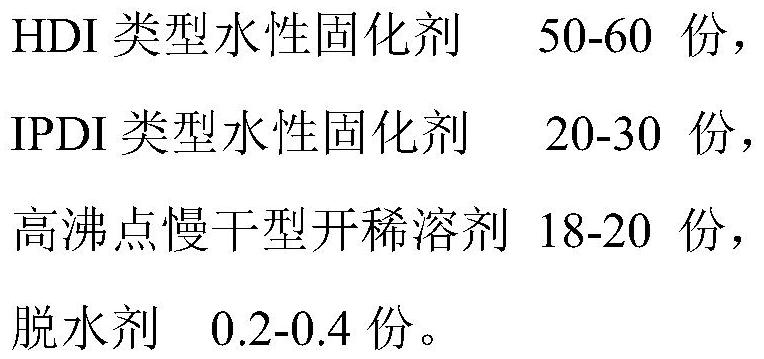

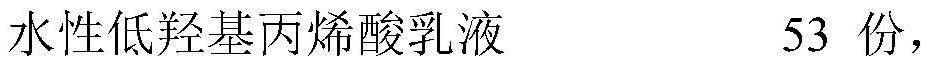

Water-based two-component matte varnish and preparation method thereof

InactiveCN111690314AIncrease contentImprove water resistancePolyurea/polyurethane coatingsRadiation-absorbing paintsPolymer scienceEmulsion

The invention provides a special yellowing-resistant high-performance water-based two-component matte varnish for dyed veneers. By selecting an emulsion, a curing agent, a light stabilizer, a cosolvent and other auxiliary agents, and by optimizing the ratio of the raw materials, the varnish is suitable for coating of dyed veneer substrate with characteristics of easy discoloration in the presenceof light, provides the protection effect for the substrate, and provides the dyed veneer with characteristics of strong light discoloration resistance; meanwhile, a paint film has strong chemical resistance, outstanding moisture resistance, outstanding water resistance, no bubbling, no delaminating, high adhesion and long activation period.

Owner:HUIZHOU CHANGRUNFA PAINT

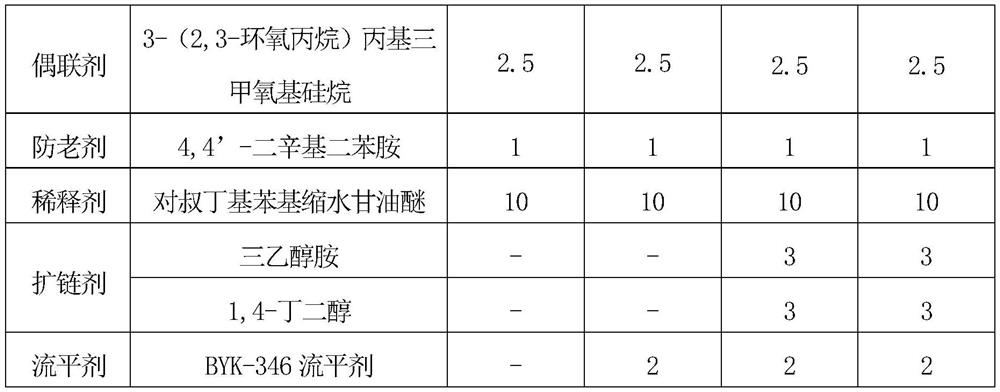

Single-component epoxy resin caulking material

InactiveCN112760072AIncrease the lengthLow tensile strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceDimer acid

The invention discloses a single-component epoxy resin caulking material which comprises the following components in parts by mass: 100 parts of flexible epoxy resin, 20-25 parts of a curing agent, 5-10 parts of magnetic ionic liquid, 50-80 parts of inorganic filler, 2-5 parts of a coupling agent, 1-3 parts of an anti-aging agent, 5-10 parts of a diluent, 5-8 parts of a chain extender and 1-3 parts of a flatting agent, wherein the flexible epoxy resin is polyurethane modified epoxy resin, dimer acid modified epoxy resin, nitrile rubber modified epoxy resin or cardanol modified epoxy resin, and the chain extender is 1, 4-butanediol, 1, 6-hexanediol, triethanolamine or diethylaminoethanol. By adopting the flexible epoxy resin, the tensile strength of the epoxy resin is greatly reduced, the elongation at break is improved, and the elastic property is improved; meanwhile, the chain extender is added to further increase the chain length of the polymer and improve the flexibility; the coupling agent is added so that an interface layer for transmitting stress is formed between the base material and the epoxy resin, and the adhesive force and the compatibility between the epoxy resin and the concrete or asphalt base material are enhanced.

Owner:河南新路航交通科技有限公司

Waterproof coating and production method thereof

InactiveCN114163916AQuality improvementReduce shockLiquid degasificationRotary stirring mixersPolymer sciencePtru catalyst

The invention belongs to the field of coating preparation, and particularly relates to a waterproof coating and a production method thereof.The waterproof coating is prepared from 40-60 parts of epoxy modified polyether polyol, 20-30 parts of polyisocyanate monomers, 20-30 parts of plasticizer, 1-5 parts of latent curing agent, 0.3-3 parts of catalyst, 0.1-2 parts of defoaming agent, 1-5 parts of anti-sagging agent, 10-20 parts of graphene oxide and 5-10 parts of silane coupling agent. According to the scheme, the graphene oxide is added, and the graphene oxide is tiled in a coating film to form a multi-layer compact structure, so that the waterproof performance of the coating is improved, and meanwhile, the extensibility of a waterproof film formed by the coating is improved; hydroxyl groups on the surface of the graphene oxide respectively react with the silane coupling agent, so that the extensibility of a waterproof film formed by the coating is improved.

Owner:重庆品涂新材料科技有限公司

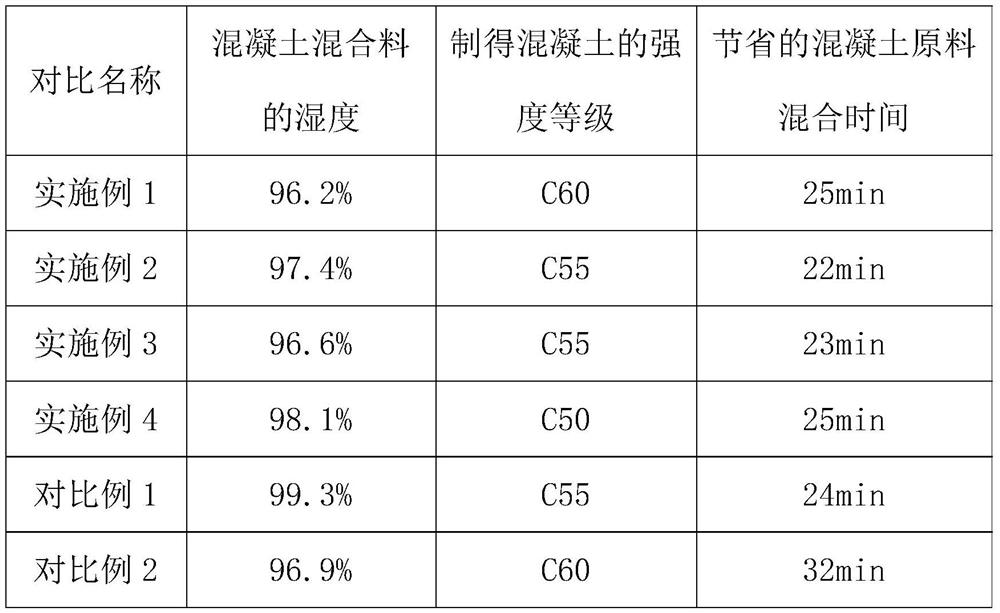

High-activity stone powder-based concrete admixture

PendingCN114031327AReduce the effect of humidityLow preparation efficiencyActive agentMontmorillonite

The invention discloses a high-activity stone powder-based concrete admixture which comprises a mixture A, a mixture B and a mixture C. The mixture A comprises a water reducing agent, activated clay powder or montmorillonite powder and a surfactant, the mixture B comprises an early strength agent and a thickening agent, and the mixture C comprises a cosolvent and a defoaming agent. Free water is reduced by utilizing the moisture absorption effect of the activated clay powder or montmorillonite powder, so that the influence of a humid environment on the humidity of the concrete mixture is reduced. The strength of the concrete is improved by adding the water reducing agent, the early strength agent and the defoaming agent, and meanwhile, by adding the components such as the surfactant, the thickening agent and the cosolvent, the fusion effect of all the components of the admixture is improved, the stirring and mixing time is shortened, the concrete is more viscous and easy to form, bubbles are reduced, and the strength is further improved.

Owner:武安市浩泽环保科技有限公司

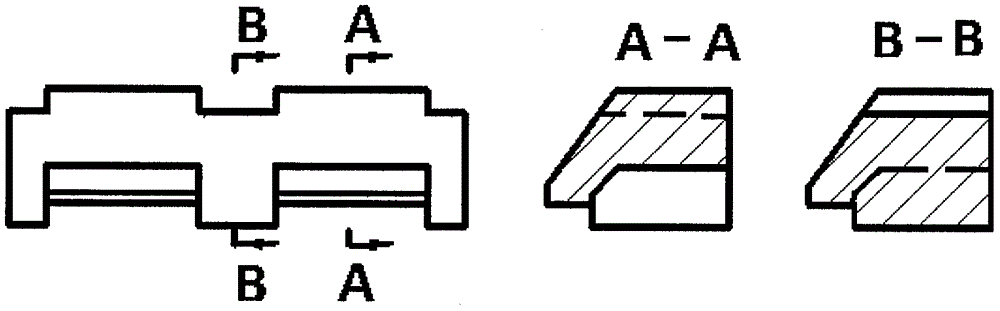

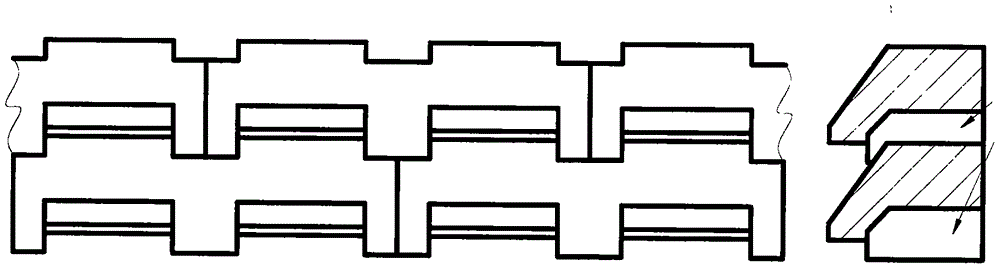

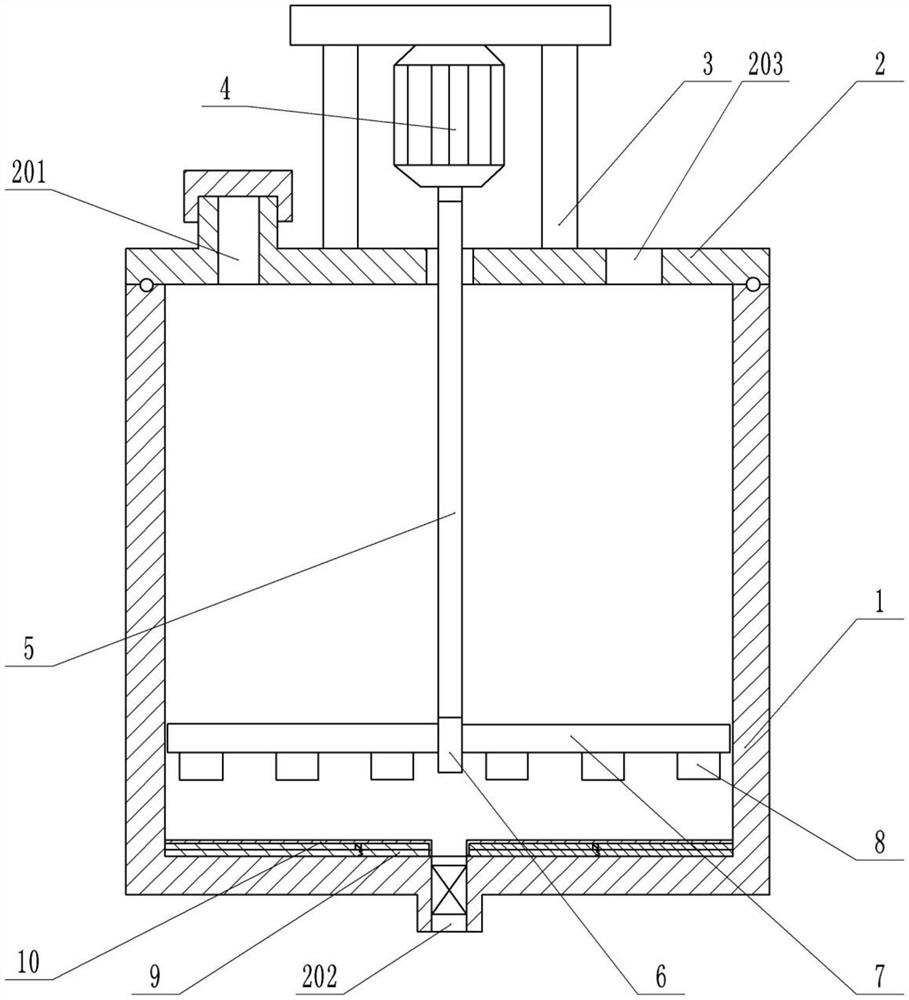

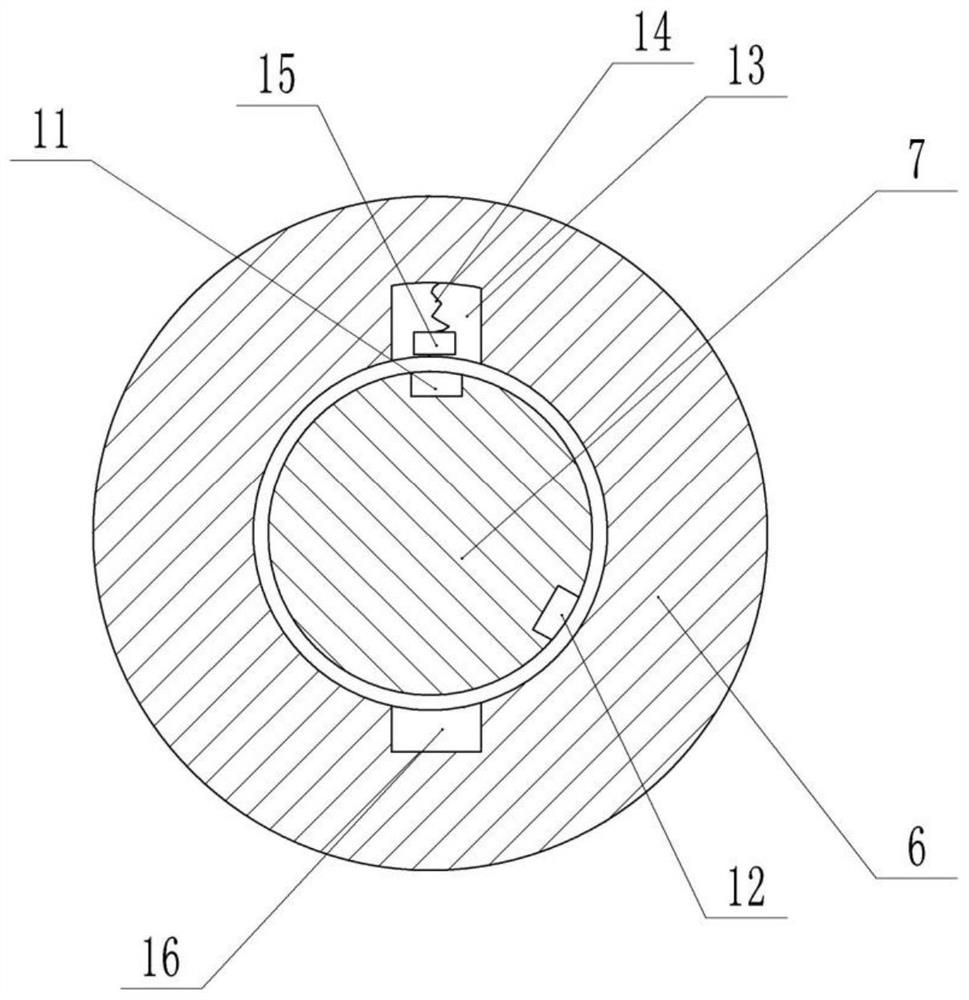

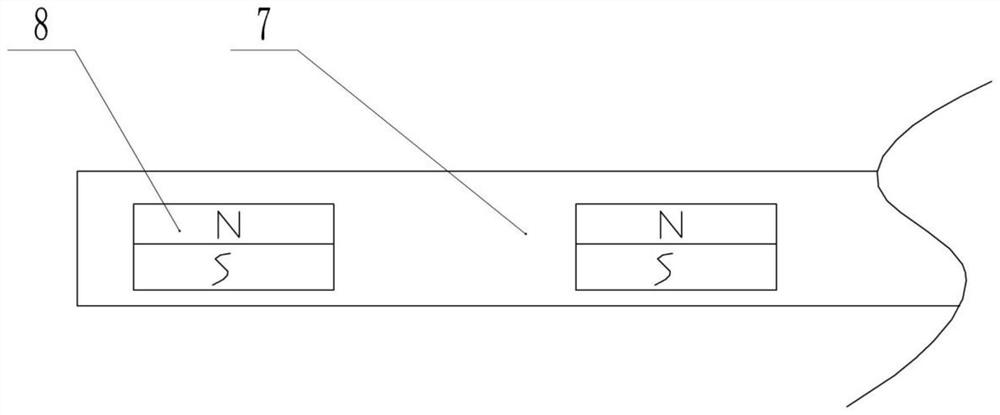

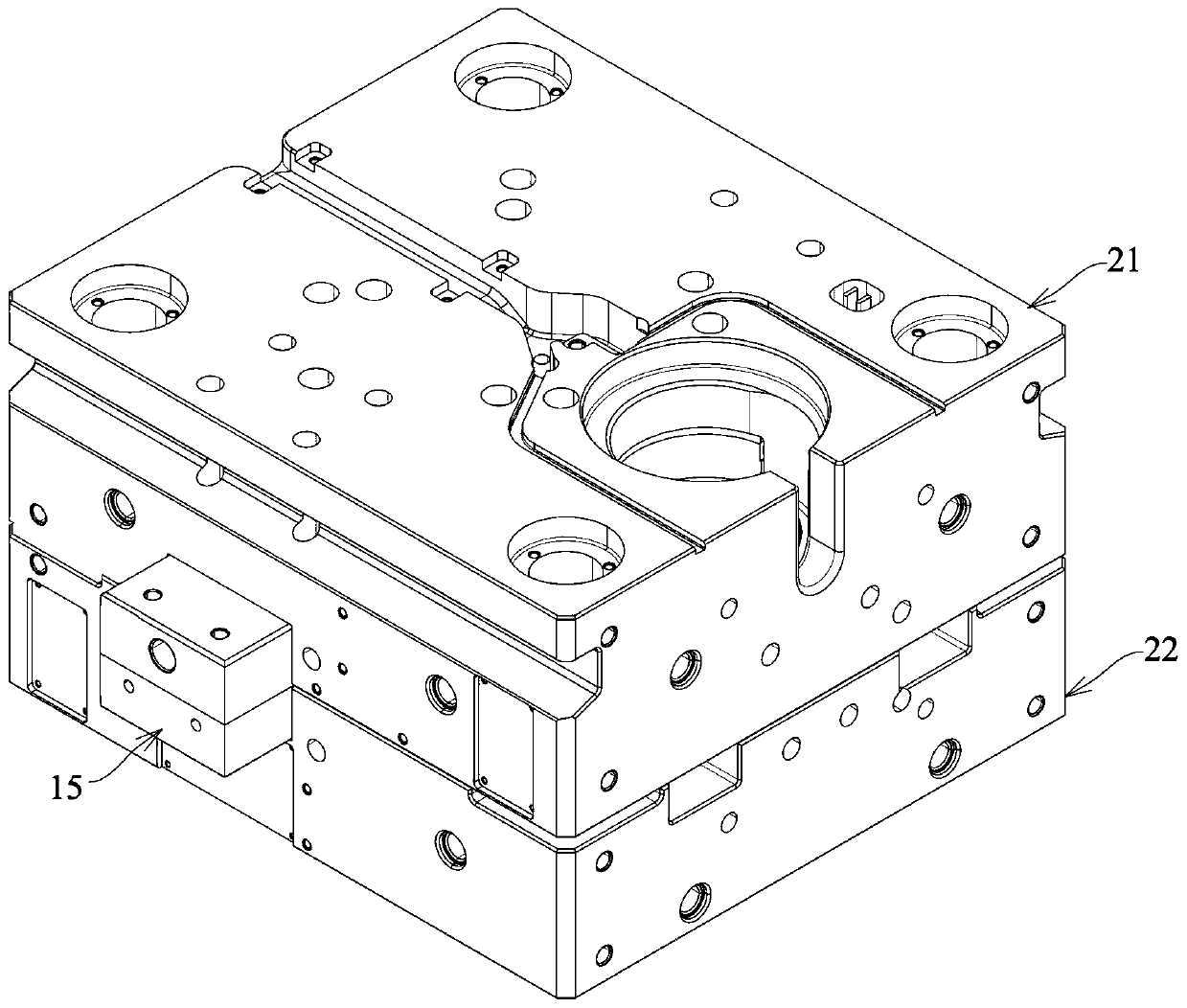

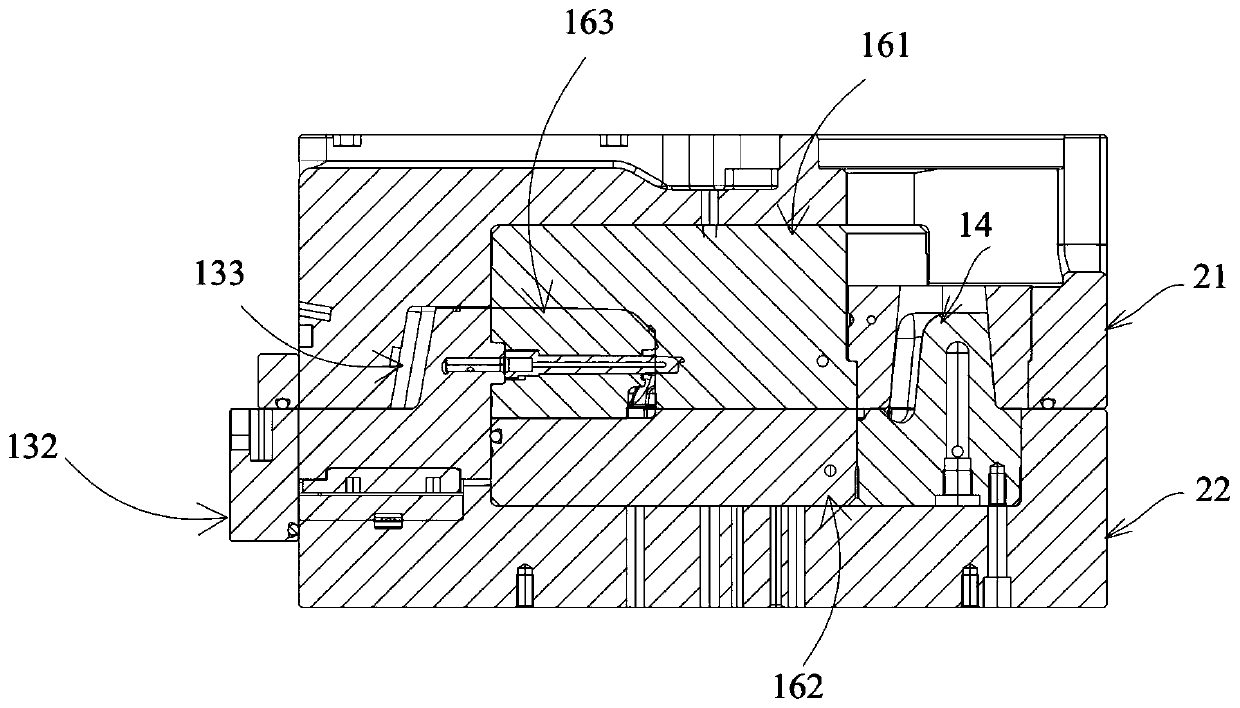

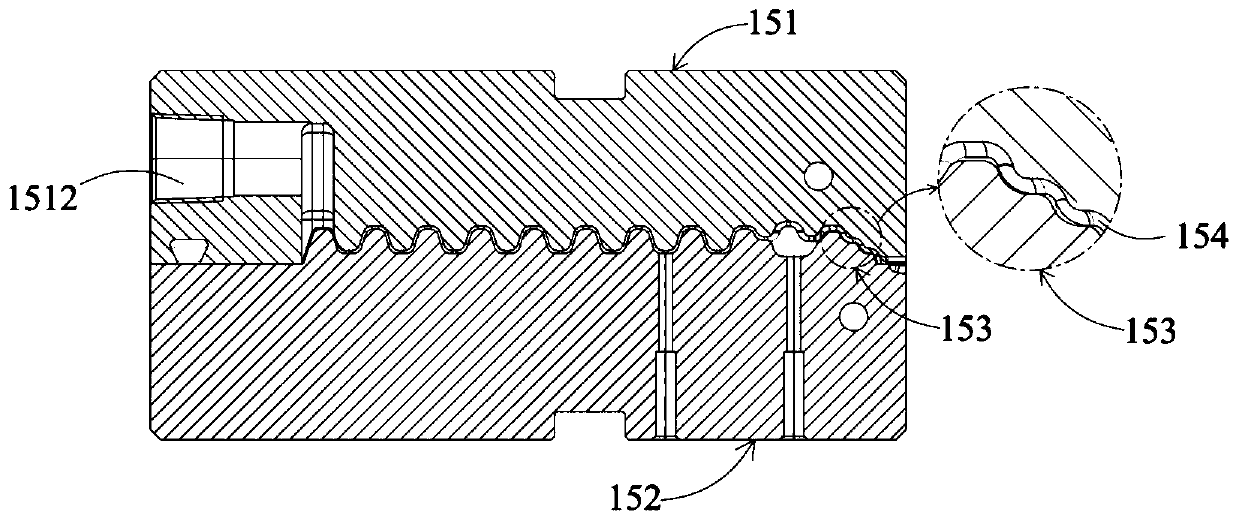

Mold vacuum suction device

The invention discloses a mold vacuum suction device, which comprises a movable mold plate provided with a movable mold core; a fixed mold plate provided with a fixed mold core, and the movable mold core and the fixed mold core are matched to form a cavity; and vacuum suction pieces comprising a first vacuum suction piece embedded in the fixed mold plate and a second vacuum suction piece embeddedin the movable mold plate. When the movable mold plate and the fixed mold plate are matched, the first vacuum suction piece and the second vacuum suction piece are matched to form an air flow channel,and the air flow channel is communicated with the cavity to discharge air in the cavity to form a vacuum state. The mold vacuum suction device disclosed by the invention is capable of sucking a largeamount of air out of the mold cavity to form a vacuum state by arranging the vacuum suction pieces, so that the bubbling phenomenon is reduced in the product manufacturing process, and the service life of products is prolonged.

Owner:SUZHOU GUANGXING MOLD

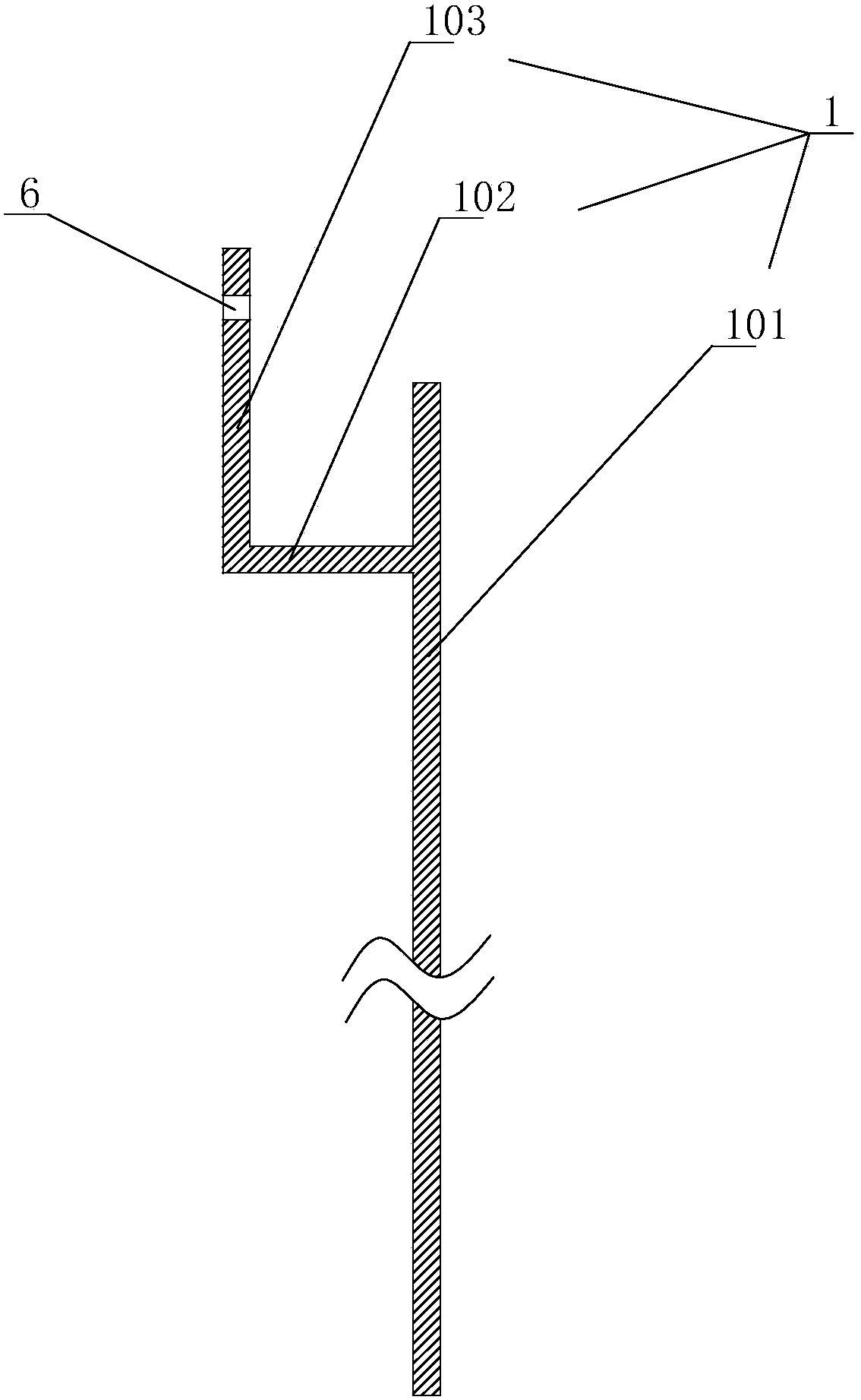

Construction method of an external wall thermal insulation system

InactiveCN105756203BSimple structureFast processingCovering/liningsHeat proofingThermal insulationEngineering

The invention discloses a waterproof supporting piece which comprises a first vertical platy part, a first horizontal platy part and a second vertical platy part.By means of the waterproof supporting piece, an external wall external heat preservation system can be simpler in structure, lower in production and construction cost, higher in connection strength with a wall foundation, convenient and rapid to install and construct, few in internal and external cold and heat bridge phenomenon, and good in waterproof effect.The invention further discloses a heat preservation and decoration integrated plate with the waterproof supporting piece, the external wall external heat preservation system with the waterproof supporting piece, and a construction method of the external wall external heat preservation system.

Owner:宁夏中京晟榕节能开发有限公司

A method of using a release agent for copper anode plate casting

The invention discloses a method for using a release agent for copper anode plate casting, comprising the following steps: preparing a release agent emulsion; spraying the release agent emulsion; and forming a release agent protective layer by the release agent emulsion ; The protective layer of the release agent is sintered to form a sintered layer of the release agent; the sintered layer of the release agent is separated from the anode plate. Through this method, the release agent can form a sintered layer of release agent on the surface of the copper mold, reduce the occurrence of adhesion between the copper mold and the anode plate, reduce the bubbling of pores on the surface of the anode plate, improve the quality of the anode plate, and protect the copper mold. Extend its service life.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT +2

A kind of aluminum nitride ceramic copper-clad substrate and preparation method thereof

The present disclosure relates to an aluminum nitride ceramic copper-clad substrate and a preparation method thereof. The aluminum nitride ceramic copper-clad substrate includes an aluminum nitride ceramic substrate and a copper foil covered on at least one surface of the aluminum nitride ceramic substrate. An interfacial bonding layer is formed between the aluminum nitride ceramic substrate and the copper foil; the interfacial bonding layer contains CuAlO 2 , the interface bonding layer also contains Al 2 Zr 3 o 9 、Al 2 Si 3 o 9 , AlCrO 3 、Cu 2 ZrO 3 、Cu 2 SiO 3 and CuCrO 2 one or more of. The aluminum nitride ceramic copper-clad substrate of the present disclosure reduces the gas and bubbling between the ceramic substrate and the copper foil, and the bonding strength between the ceramic substrate and the copper foil is further significantly improved.

Owner:BYD CO LTD

Composite paper strength enhancer and preparation method thereof

ActiveCN114481692AImprove internal bond strengthGuaranteed qualityReinforcing agents additionPaper/cardboardCompound aPolymer science

The invention discloses a composite paper strength enhancer and a preparation method thereof. The composite paper strength enhancer is specifically obtained by compounding a starch-polyethyleneimine graft polymer and polyamide epichlorohydrin resin. The paper strength enhancer can enhance the internal bonding strength of paper, ensure the quality of the paper, reduce the occurrence of bubbling and layering phenomena, is small in dosage, does not influence the dehydration performance of the paper, reduces the cost and improves the production efficiency.

Owner:SHANDONG BOHUI PAPER INDUSTRY CO LTD

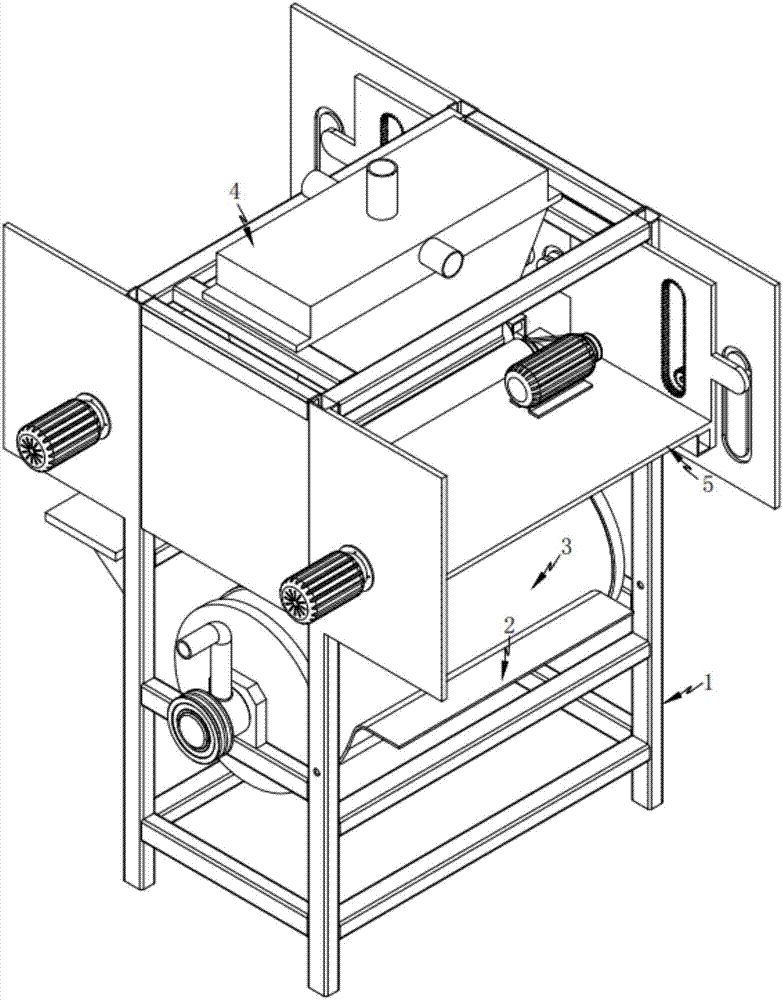

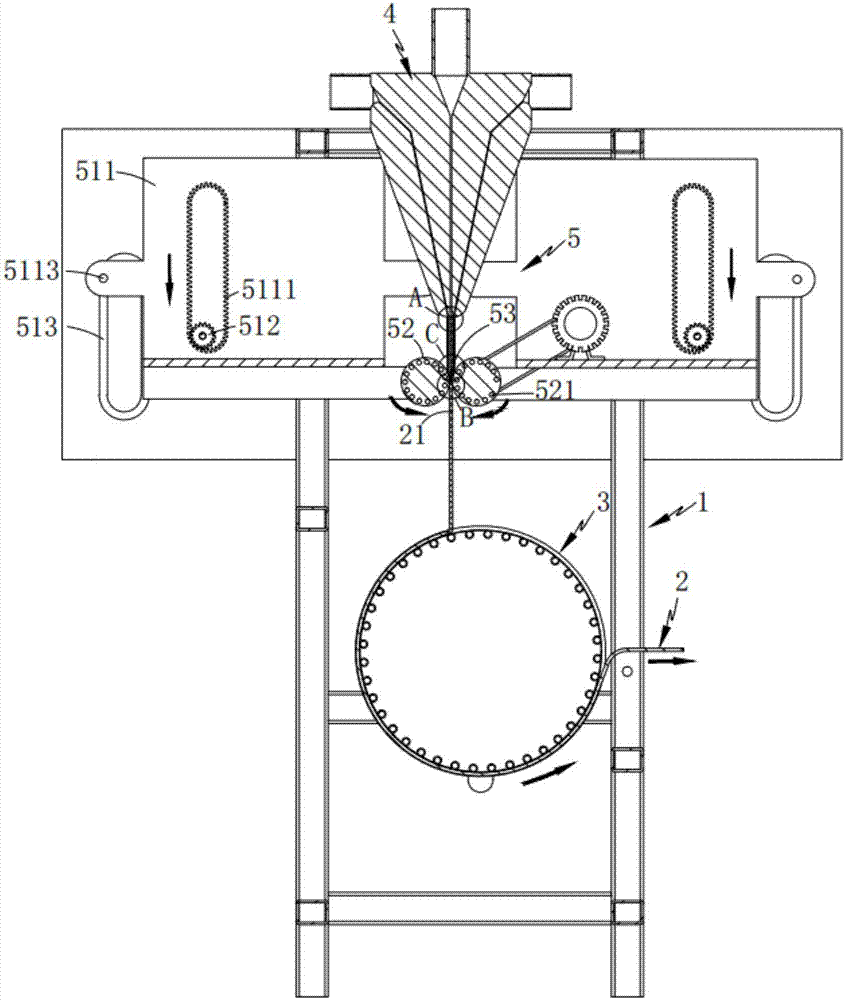

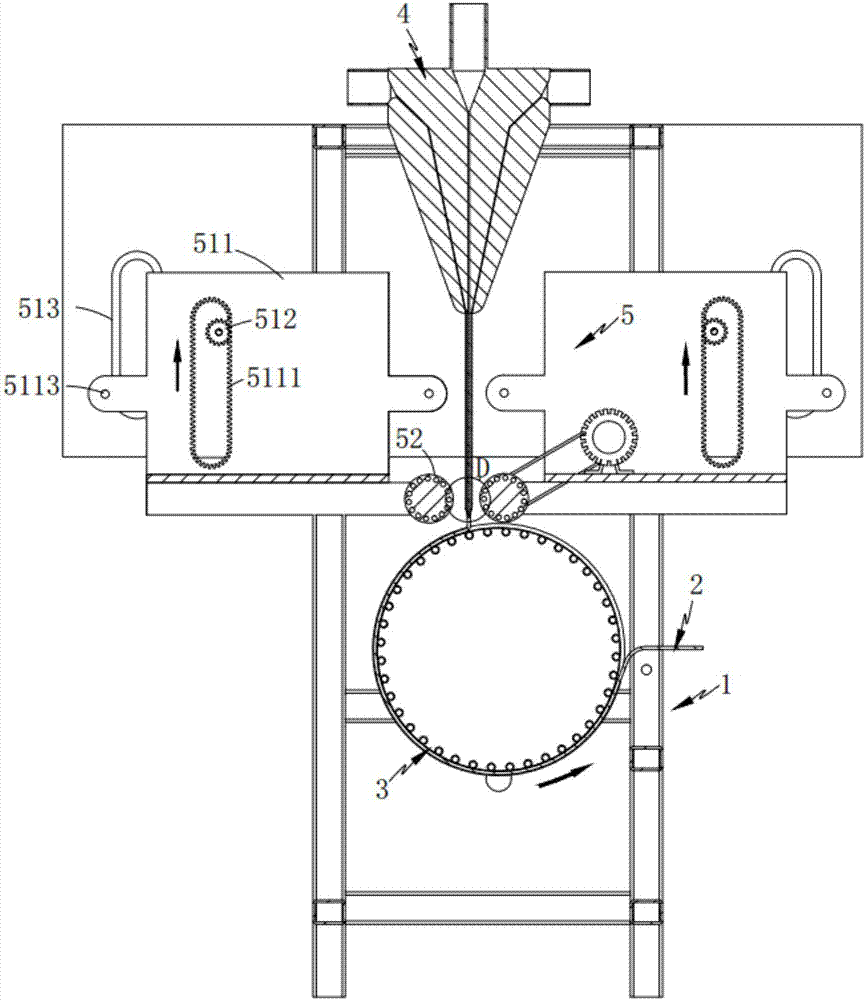

High-density cast film forming device

InactiveCN107379369ATroubleshoot technical problems with stickiesPlay a guiding roleFlat articlesCoatingsSurface coolingHigh density

The invention relates to a high-density casting film forming device, comprising a frame, a casting roll, a feeding component and a setting component. The feeding component is fixedly arranged on the frame, and solutions with different viscosities pass through the feeding component , forming mutually independent liquid curtain groups in sequence below it, the shaping component is located below the feeding component, which includes a moving part and a shaping roller rotatably installed on the moving part to guide the liquid curtain group, the The setting roller is in intermittent contact with the liquid curtain group. During the contact between the two, the setting roller conducts guiding and forming treatment on the liquid curtain group; The cast film, which is the initial shape of the film structure, is formed by the casting roll, which solves the problems in the prior art that the surface of the casting roll is bonded, the surface of the film is uneven, and the precision of the produced film is not high during the peeling process of the cast film. question.

Owner:浙江聚彩精密设备有限公司

Pretreatment method of chemical nickel-phosphorus plating of aluminum and aluminum alloy and application

PendingCN114032530ASimple processSave operating timeLiquid/solution decomposition chemical coatingPretreatment methodElectrolysis

The invention belongs to the field of chemical technology and metal material surface protection treatment methods, and relates to a pretreatment method of chemical nickel-phosphorus plating of aluminum and aluminum alloy and application of the pretreatment method in the field of metal material surface protection treatment. The method comprises the steps of: organic solvent oil removal, stress relief annealing treatment, chemical oil removal, electrolytic passivation treatment and activating treatment. A production test proves that an aluminum and aluminum alloy surface passivation film layer prepared by the pretreatment method is very uniform, the binding force of a plating layer is obviously increased, and the plating layer has certain porosity, so that a good metal surface condition is provided for a later chemical nickel-phosphorus plating process, and the occurrence rate of product quality problems such as nickel-phosphorus layer falling and bubbling can be greatly reduced; and the pretreatment method is simple in technological process, stable in product quality and low in production cost, and obviously reduces pollution compared with that of a traditional zinc immersion process.

Owner:云南昆船机械制造有限公司

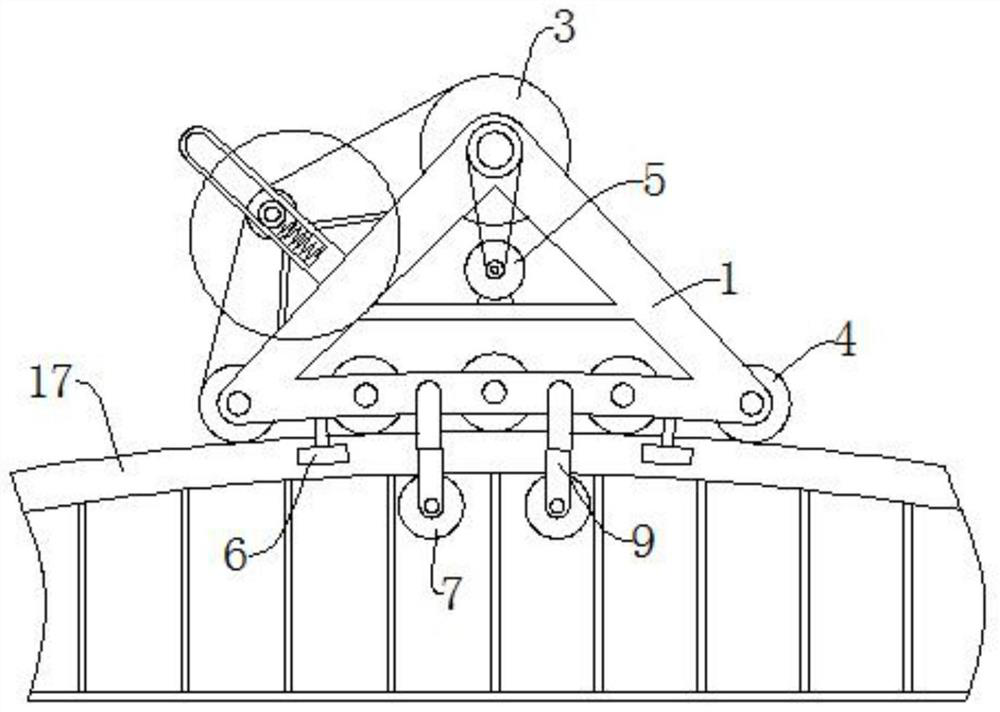

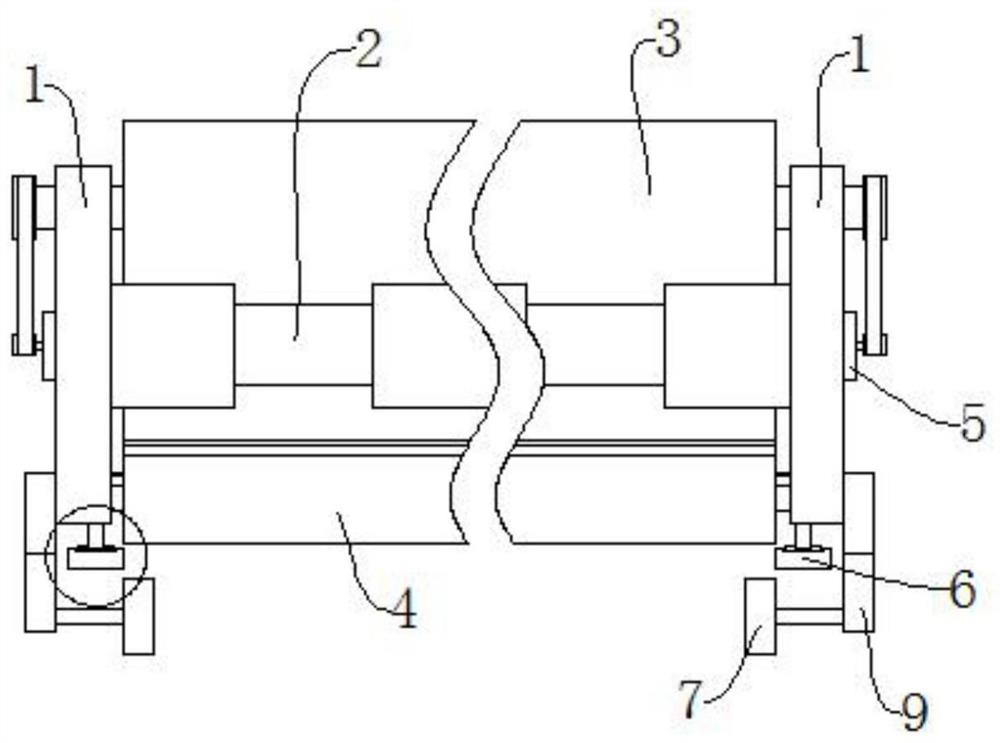

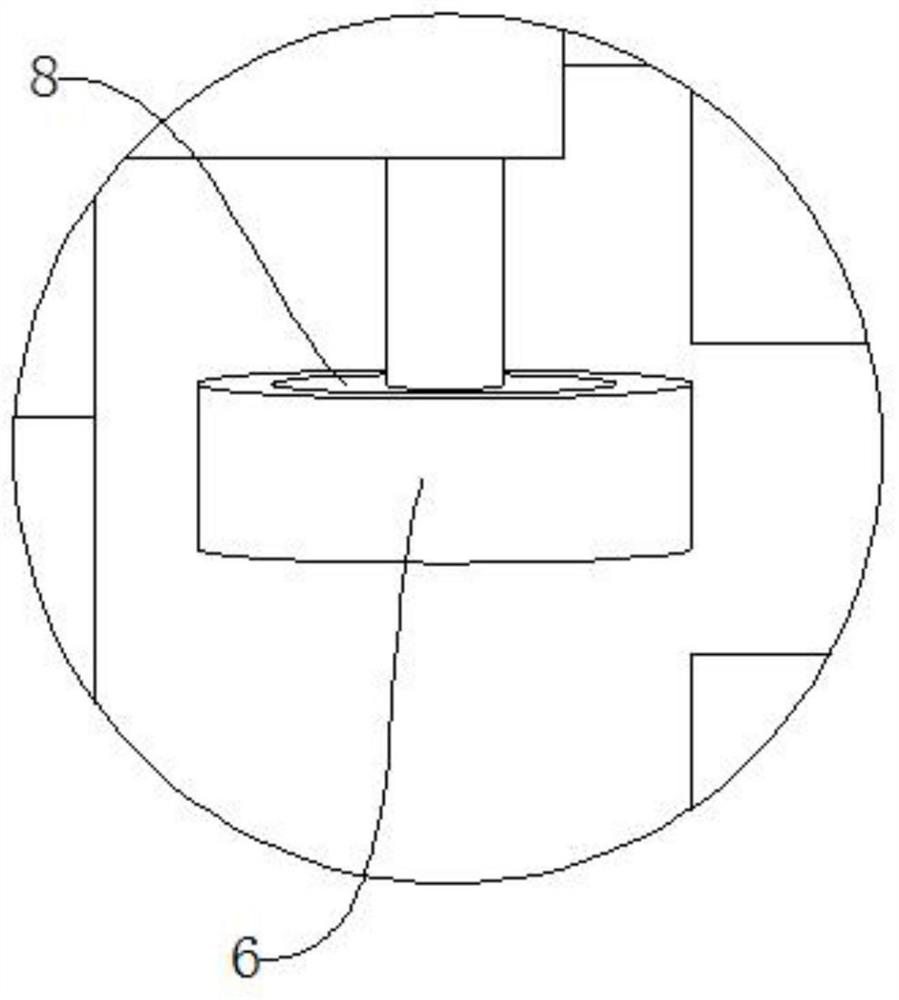

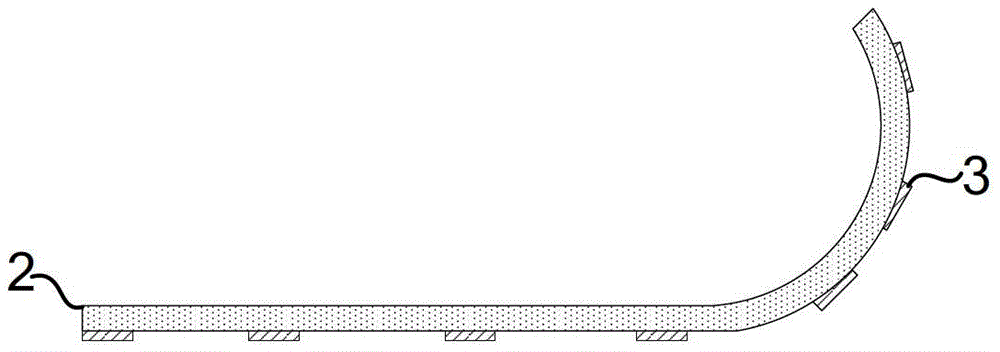

A fully automatic plastic film covering equipment for arch slab concrete pouring construction

ActiveCN109208909BReduce labor intensityPracticalBuilding material handlingArchitectural engineeringThin membrane

The invention discloses a full-automatic plastic film covering device for arch slab concrete pouring construction. The full-automatic plastic film covering device includes a plurality of connecting rods and two parallel mounting frames fixedly arranged at the two ends of the connecting rods, the upper ends and the lower ends between the two mounting frames are provided with a film roller and a flattening roller used for flattening the film on the upper surface of an arch plate, the film on the film roller is compressed on the upper surface of the arch plate through the flattening roller afterbeing unfolded, and a film unfolding motor used for driving the film roller to rotate and unfold the film is further installed on the mounting frames. The full-automatic plastic film covering device for the arch plate concrete pouring construction can cover the film automatically on the upper surface of the arch plate, is free of manual coverage, saves time and labor, greatly eliminates the laborintensity of workers, reduces the labor cost, and is high in covering speed, high in efficiency, good in coverage effect (small in bubbling) and high in practicability.

Owner:青岛绿谷知识产权有限公司

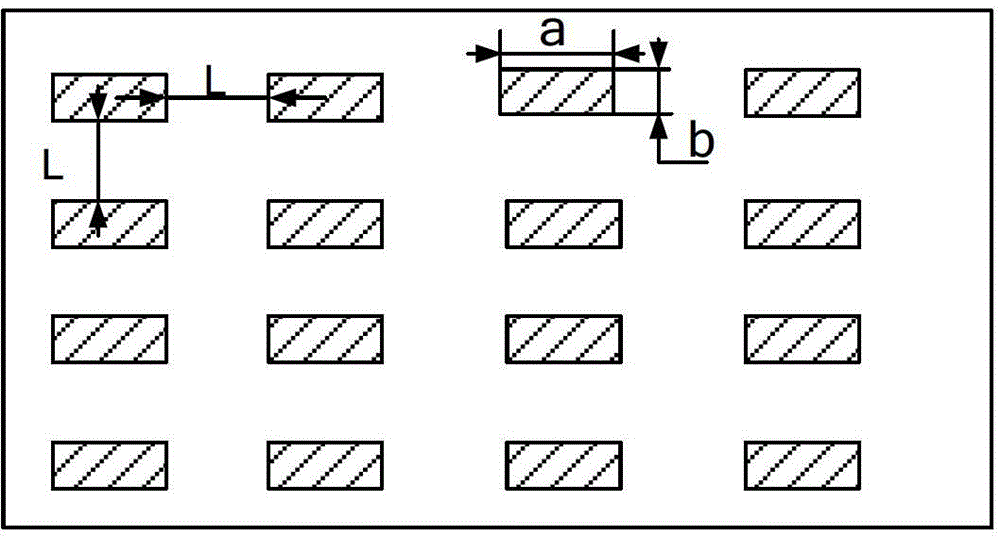

Flexible substrate, carrier platform, flexible display and preparation method thereof

ActiveCN102902093BImprove flatnessQuality improvementPrinted circuit manufactureThin material handlingDisplay deviceEngineering

The invention relates to manufacturing of displays. A flexible substrate is disclosed, which has a plurality of spacers arranged at intervals on one side thereof. The invention also discloses a support platform with spacers arranged at intervals, a flexible display formed from the flexible substrate with the spacers arranged at intervals and a method for manufacturing the flexible display. it

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com