High-density cast film forming device

A molding device and casting film technology, which are applied to flat products, household appliances, other household appliances, etc., can solve the problems of surface adhesion of casting rolls, uneven film surface, uneven thickness, etc., and improve the surface smoothness, Simple structure and the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

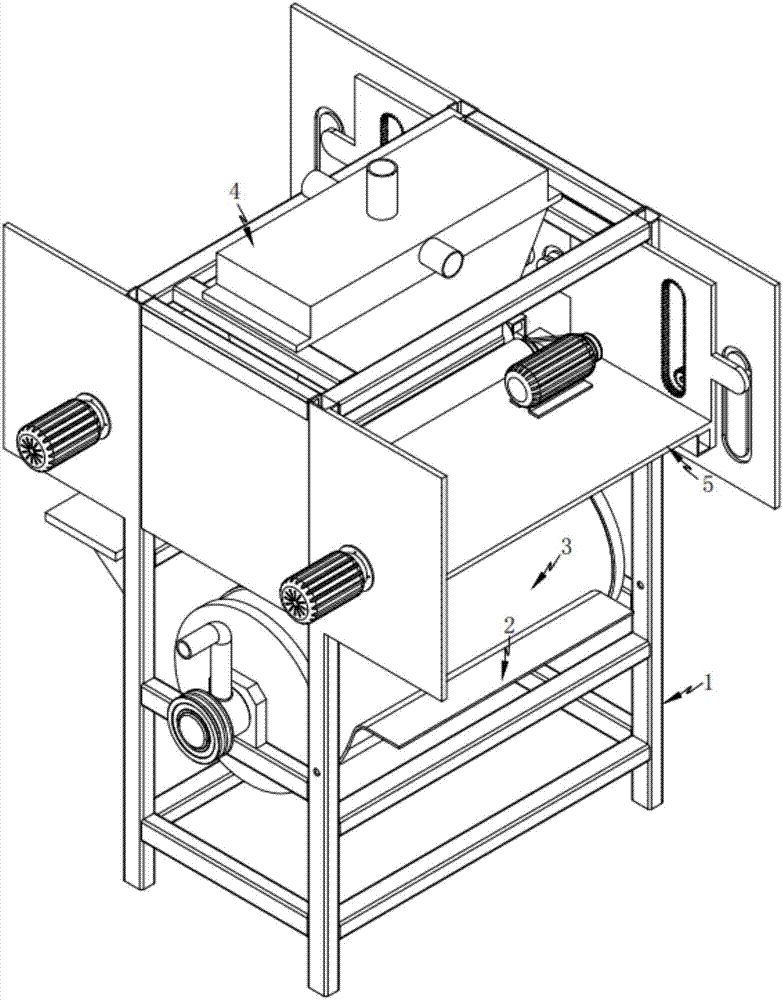

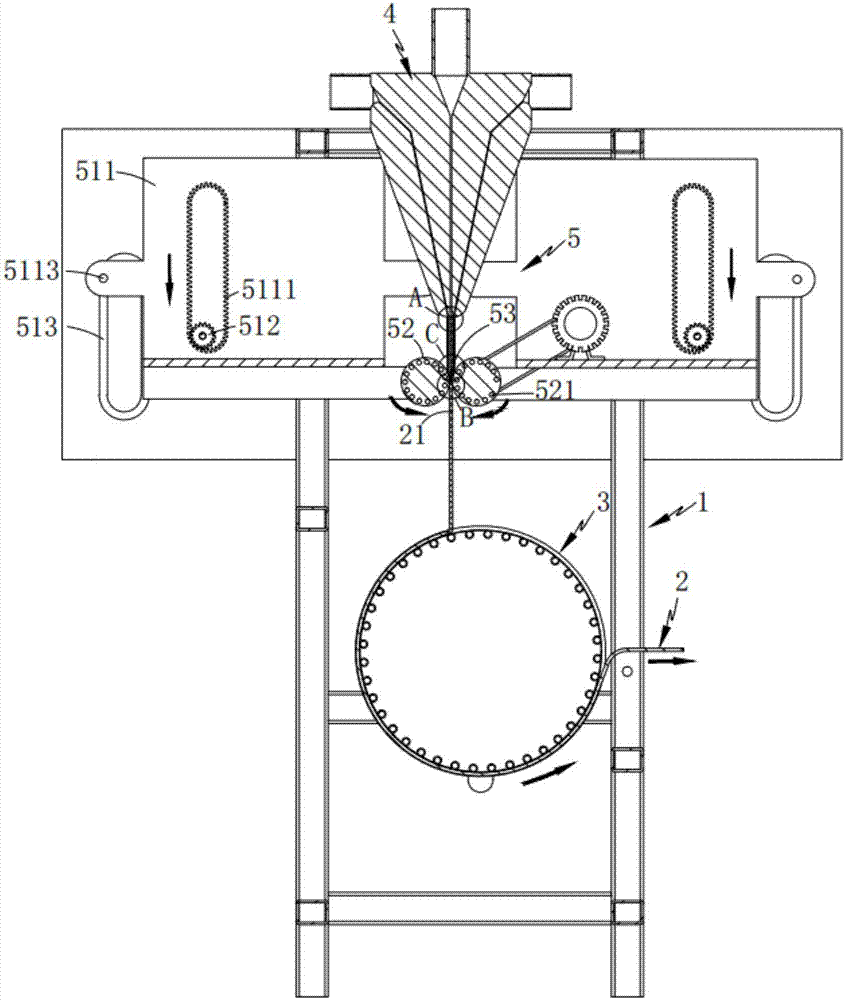

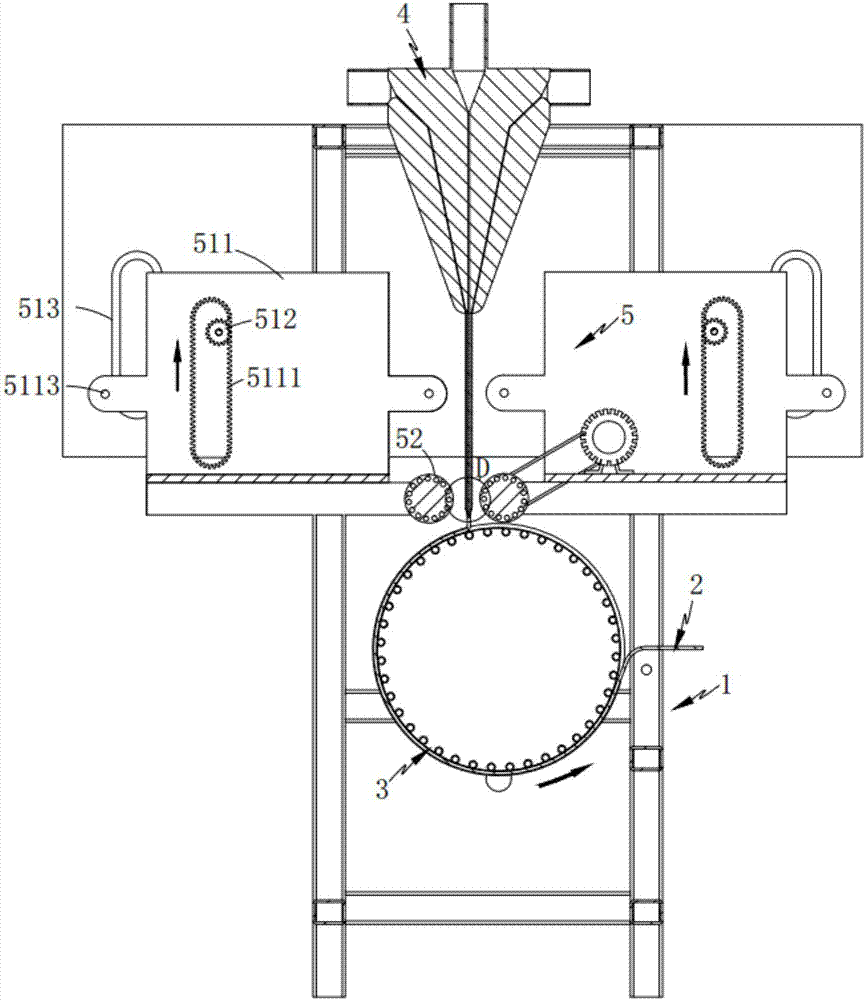

[0037] Such as figure 1 , 2 As shown in and 3, a coating-type casting film forming mechanism includes a frame 1, a casting roll 3 that is rotatably mounted on the frame 1 to form a casting film 2, and also includes a feeding assembly 4 and a sizing assembly 5. The feeding assembly 4 is fixedly arranged on the frame 1, and solutions with different viscosities pass through the feeding assembly 4, forming a first liquid curtain 411 and a second liquid curtain 412 independent of each other in sequence below it. and the third liquid curtain 413; the sizing assembly 5 is located below the feeding assembly 4, which includes two horizontally arranged rotatably mounted on the frame 1 and set in contact with the liquid curtain group 41 A sizing roller 52, a solution channel 52 is formed between the sizing rollers 52, and the first liquid curtain 41, the second liquid curtain 42 and the third liquid curtain 43 pass through the solution channel 52 and the surface formed therebelow is in ...

Embodiment 2

[0039]The inventor believes that in order to better implement the technical solution, further specific implementation methods are necessary, so the inventor describes the second embodiment on the basis of the first embodiment.

[0040] Such as figure 1 , 2 As shown in and 3, a high-density casting film forming device includes a frame 1, a casting roll 3 that is rotatably mounted on the frame 1 to form a casting film 2, and also includes:

[0041] The feeding assembly 4, the feeding assembly 4 is fixedly arranged on the frame 1, the solutions with different viscosities pass through the feeding assembly 4, and form mutually independent liquid curtain groups 41 sequentially below it; and

[0042] The sizing assembly 5, the sizing assembly 5 is located below the feeding assembly 4, it includes the sizing rollers 52 installed on the frame 1 and symmetrically arranged on both sides of the liquid curtain group 41, between the two A flow channel 53 is formed between them. During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com