Single-component epoxy resin caulking material

A technology of epoxy resin and caulking material, applied in the direction of epoxy resin glue, non-polymer adhesive additive, adhesive type, etc., can solve low-strength extensibility, poor extensibility, high epoxy resin strength, etc. problem, to achieve the effect of reducing tensile strength, reducing modulus, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the weight ratio of the raw materials in Table 1, the epoxy resin, curing agent, inorganic filler, chain extender and diluent are sheared evenly under the stirring of a high-speed shearer, and then the magnetic ionic liquid, coupling agent, Anti-aging agent, leveling agent, stir evenly, and react for 1 hour to obtain 4 kinds of epoxy resin caulking materials with different compositions. Then, according to GB / T 13477-2002, performance tests were performed on the epoxy resin caulking materials of Comparative Examples 1-3 and Example 1, and the results are shown in Table 2.

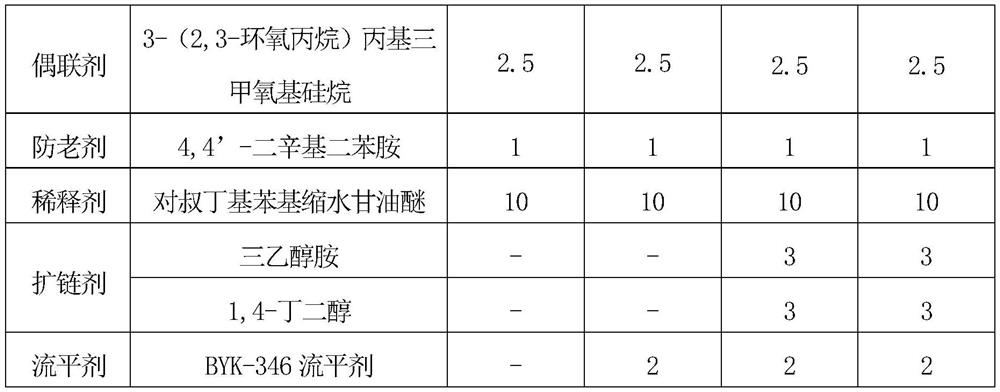

[0023] Formulation composition of table 1

[0024]

[0025]

[0026] Table 2 Test results

[0027] Test items Comparative example 1 Comparative example 2 Comparative example 3 Example 1 Leveling Lots of holes on the surface smooth surface smooth surface smooth surface Surface dry time / min 25 28 53 65 Shore Hardness / HD 56 63 45 31 ...

Embodiment 2

[0030] According to the weight ratio of the raw materials in Table 3, the epoxy resin, curing agent, inorganic filler, chain extender and diluent are sheared evenly under the stirring of a high-speed shearer, and then the magnetic ionic liquid, coupling agent, The anti-aging agent and the leveling agent were stirred evenly and reacted for 1 hour to obtain the one-component epoxy resin caulking materials of Examples 2-7. Then, according to GB / T 13477-2002, performance tests were performed on the epoxy resin caulking materials of Examples 2-7, and the results are shown in Table 4.

[0031] Formulation composition of table 3

[0032]

[0033]

[0034] Table 4 test results

[0035]

[0036] It can be seen from Table 4 that the one-component epoxy resin caulking materials of the present invention have relatively low strength, good extensibility, and good adhesion to concrete or asphalt substrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com