High-activity stone powder-based concrete admixture

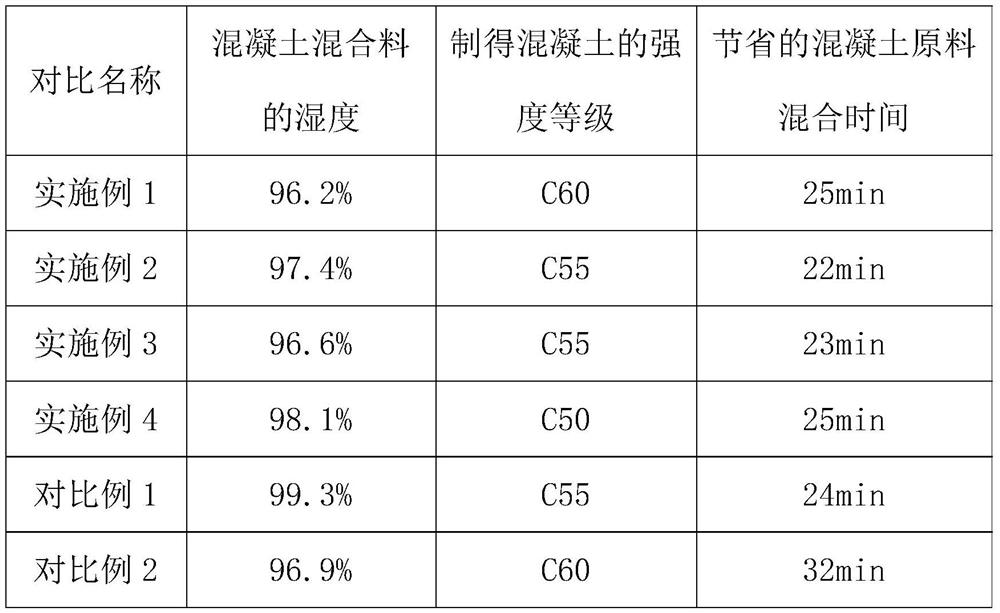

A concrete admixture and high-activity technology, which is applied in the field of concrete preparation, can solve the problems of longer concrete preparation time, low concrete preparation efficiency, and lower concrete strength, and achieve the effects of saving preparation time, good mixing effect, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A highly active stone powder-based concrete admixture includes mixture A, mixture B and mixture C. In parts by mass, mixture A includes 70 parts of water reducer, 6 parts of activated clay powder, and 6 parts of surfactant; mixture B includes 4 parts of early strength agent and 5 parts of thickener; mixture C includes 7 parts of cosolvent and 1.9 Parts of defoamer.

[0050] Among them, the water reducing agent is composed of natural stone powder ore base powder, naphthalene sulfonate formaldehyde condensate powder and carbonyl pyraldehyde liquid with a mass ratio of 5:0.5:1; the main component of activated clay is attapulgite clay; the surfactant is mass The mixture of calcium metal soap and organic amine soap with a ratio of 3:1; the thickener is a mixture of polyacrylamide and epoxy resin with a mass ratio of 1.5:1; the early strength agent is a triethanolamine liquid with a mass ratio of 2:1 It is a mixture of calcium formate and crystal powder; the co-solvent is ce...

Embodiment 2

[0054] A highly active stone powder-based concrete admixture includes mixture A, mixture B and mixture C. In terms of parts by mass, mixture A includes 75 parts of water reducer, 4 parts of activated clay powder, and 4 parts of surfactant; mixture B includes 7 parts of early strength agent and 6 parts of thickener; mixture C includes 2 parts of cosolvent and 1.5 parts of Parts of defoamer.

[0055] Among them, the water reducer is composed of natural stone powder ore base powder, naphthalene sulfonate formaldehyde condensate powder and carbonyl pyraldehyde liquid with a mass ratio of 4:0.8:1; the main component of activated clay is attapulgite clay; the surfactant is mass The mixture of calcium metal soap and organic amine soap with a ratio of 4:1; the thickener is a mixture of polyacrylamide and epoxy resin with a mass ratio of 1.2:1; the early strength agent is a triethanolamine liquid with a mass ratio of 1.5:1 A mixture of calcium formate and crystalline powder; the cosol...

Embodiment 3

[0059] A highly active stone powder-based concrete admixture includes mixture A, mixture B and mixture C. In terms of parts by mass, mixture A includes 80 parts of water reducer, 2 parts of montmorillonite powder, and 2 parts of surfactant; mixture B includes 3 parts of early strength agent and 4 parts of thickener; mixture C includes 8 parts of cosolvent and 0.8 parts of defoamer.

[0060] Among them, the water reducing agent is composed of natural stone powder ore base powder, naphthalenesulfonate formaldehyde condensate powder and carbonyl pyraldehyde liquid with a mass ratio of 3:1:1; the chemical formula of montmorillonite is Al 2 o 3 4SiO2 2 ·nH 2 O; the surfactant is a mixture of calcium metal soap and organic amine soap with a mass ratio of 5:1; the thickener is a mixture of polyacrylamide and epoxy resin with a mass ratio of 1.1:1; the early strength agent is a mass ratio of 1.1:1 mixture of triethanolamine liquid and crystalline powdered calcium formate; cosolven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com