Oil drilling pump convenient to fix

A technology of oil drilling and pump body, which is applied in the field of oil drilling, which can solve the problems affecting the normal and stable operation of the pump body, affecting the operation stability of the pump body, and the limited length of the hook and hoe, so as to increase the stability and fixing effect and increase the efficiency of installation and placement , the effect of reducing the effect of humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

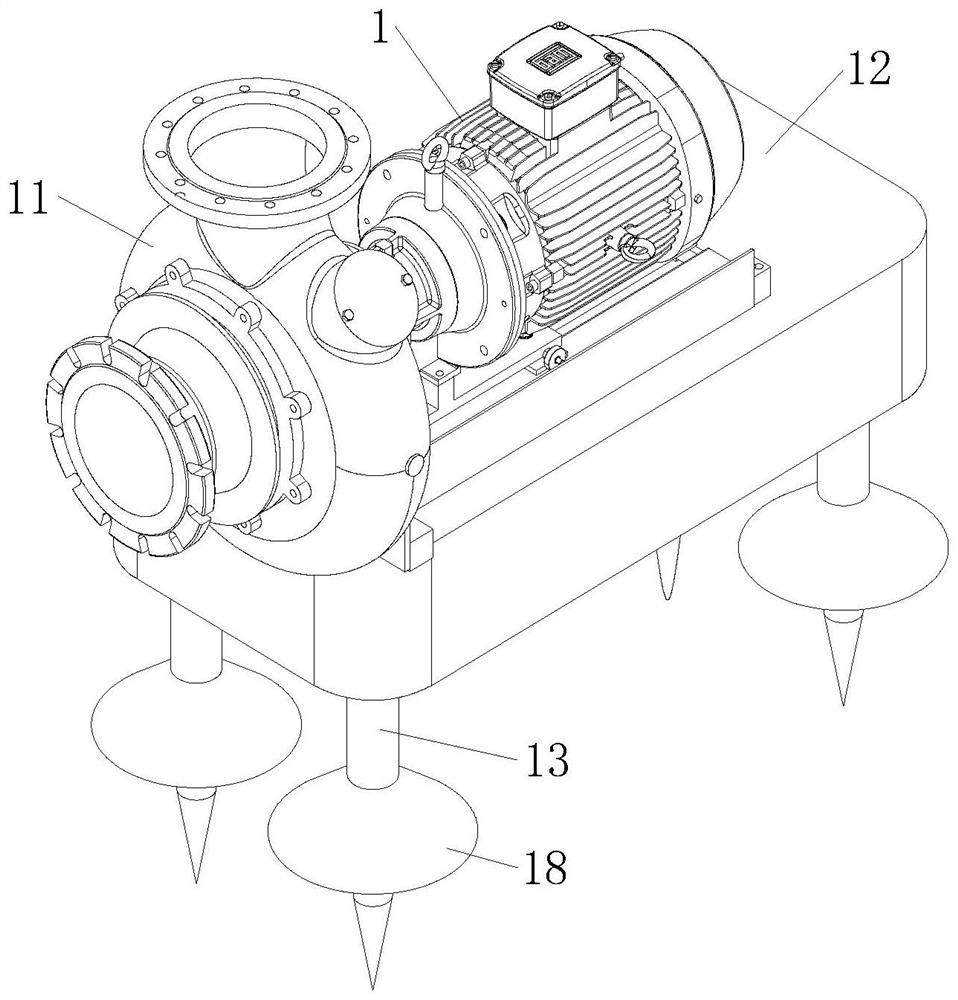

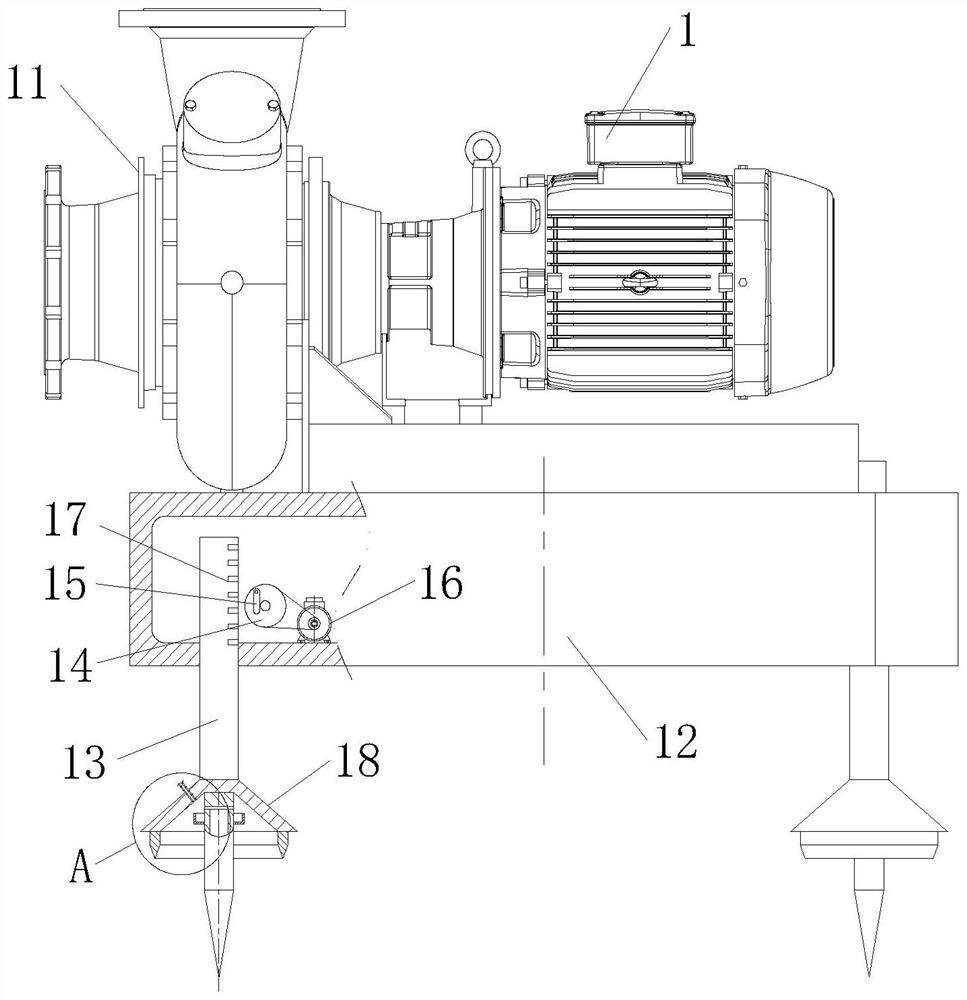

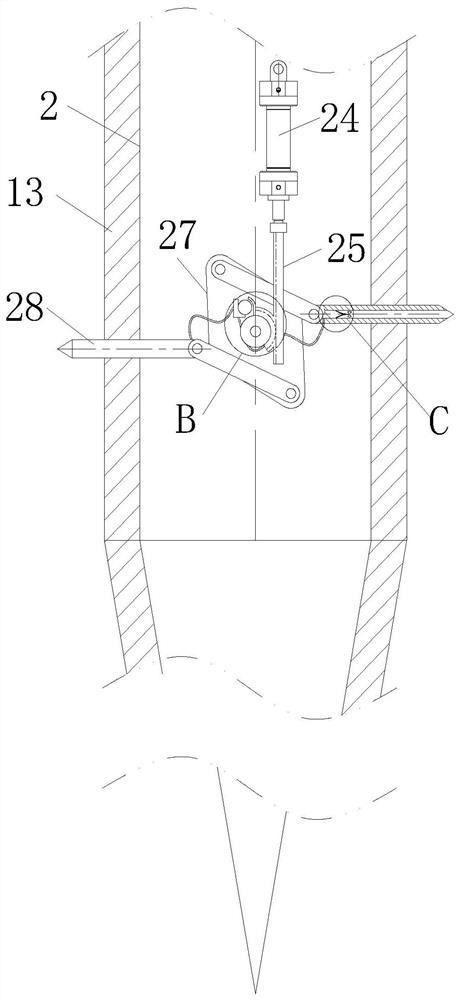

[0032] As an embodiment of the present invention, a conical inverted funnel 18 is fixedly connected to the lower part of the throwing rod 15, and the bottom of the funnel 18 is fixedly connected with a cut-in cylinder 19, and a knife edge is provided at the bottom of the cut-in cylinder 19; The contact area between the insertion rod 13 and the ground increases the bearing capacity of the ground to the pump body 11. At the same time, it cooperates with the cut-in cylinder 19 to insert downward into the ground to further reduce the lateral displacement between the installation frame 12 and the pump body 11 and ensure the stable operation of the pump body 11. The conical funnel 18 forms the protection of the ground soil at the bottom of the funnel 18, reduces the impact of the leakage of the pump body 11 on the ground soil layer, further increases the bearing capacity of the soil layer near the insertion rod 13, and ensures the levelness of the pump body 11.

[0033] As an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com