Prying-off type bottle cap and prying-off type bottle

A pry-off, bottle cap technology, applied in bottle filling, bottle/container caps, closure with stoppers, etc., can solve the problems of poor anti-counterfeiting effect of bottle caps, and achieve the effect of improving the anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

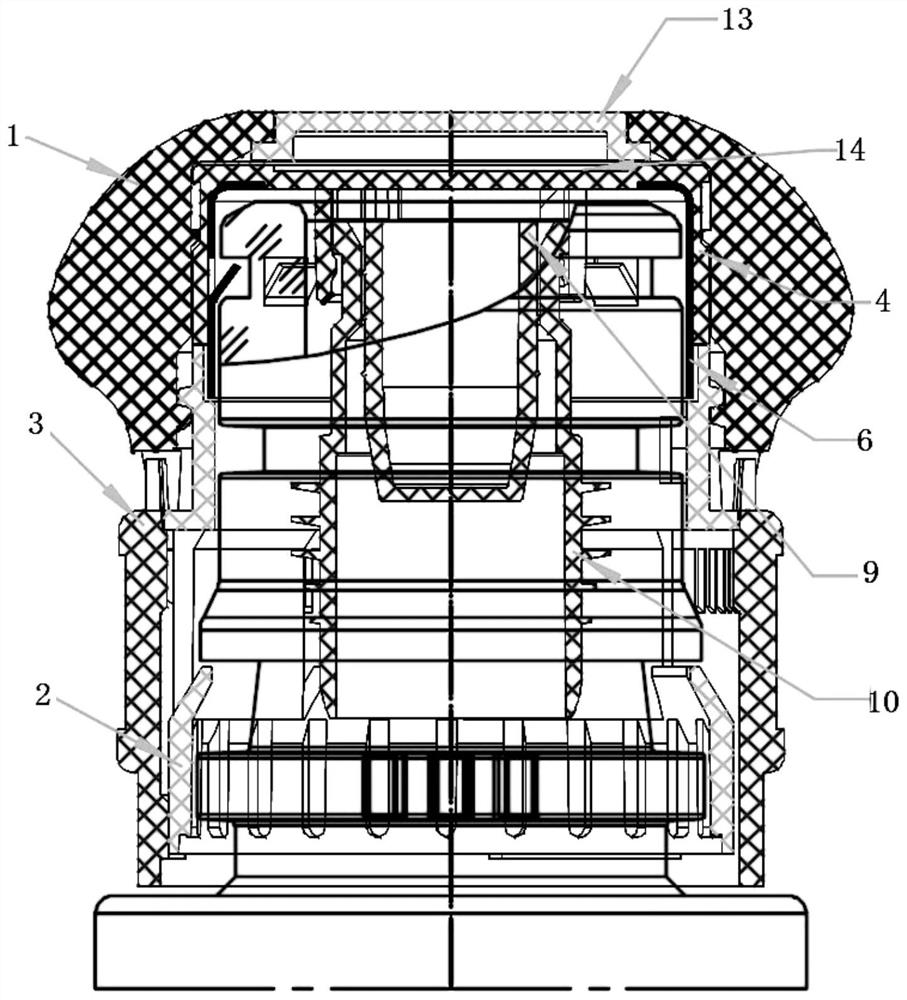

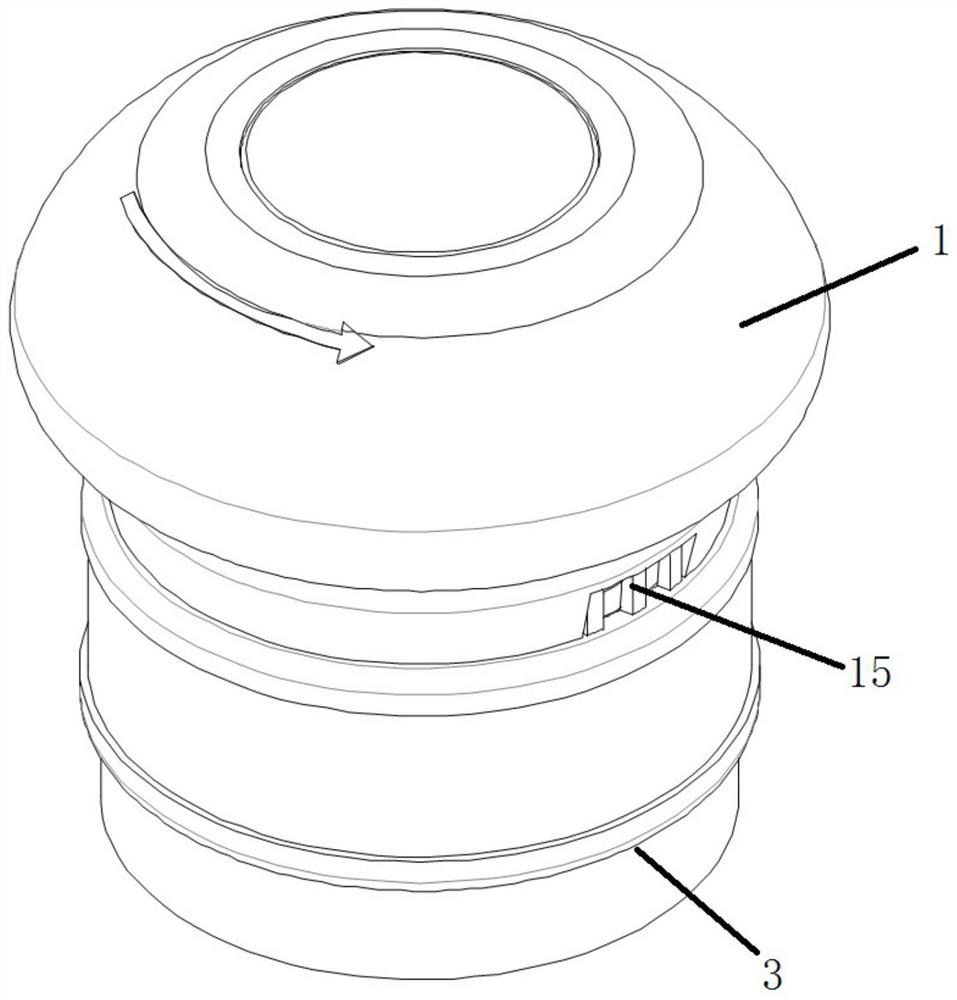

[0042] see Figure 1-5 , the present embodiment provides a pry off type bottle cap, the bottle cap is covered on the bottle mouth of a bottle. Wherein, the mouth of the bottle has a mouth that is easily broken, that is, the mouth of the bottle is provided with a recess that is easy to break, and the mouth of the bottle can be partially detached under the action of an external force. For example, the mouth of the bottle can be pried by an external prying member, so that the mouth of the bottle is broken from the frangible depression, thereby permanently damaging the bottle. In this embodiment, the pry-off bottle cap includes an outer cap 1 , an inner sleeve 2 , an outer sleeve 3 , an inner cap assembly 4 and an inner plug assembly, and may also include a transparent insert 13 and a two-dimensional code gasket 14 .

[0043] The outer cap 1 can be a ball cap, or a cap of other shapes, which is the topmost part of the bottle cap. The outer cover 1 is generally a plastic structur...

Embodiment 2

[0055] This embodiment provides a pry-off bottle cap, which is similar to the bottle cap of Embodiment 1, the difference is that there is a gap on the bottom end of the lower connecting sleeve 6 in this embodiment. There is at least one notch, and at least one notch corresponds to at least one pry hole respectively, and each notch and the corresponding pry hole are located on the same radial direction of the inner sleeve 2 . The protruding end of the prying part can pass through the prying hole and the notch to abut against the easy-to-break recess. The notch extends directly to the bottom of the inner sleeve 2, so that the prying member can be vertically disengaged from the notch after being inserted into the notch.

[0056] Therefore, because there is a gap on the lower connection sleeve 6 of the pry-off type bottle cap, the prying part passes through the pry hole and the gap when the bottle cap is opened, so that the insertion depth of the lower connection sleeve 6 can be i...

Embodiment 3

[0058] This embodiment provides a method for assembling the pry-off bottle cap, which is used for assembling the pry-off bottle cap in Embodiment 1 or 2. Wherein, the assembly method includes the following steps.

[0059] (1) The lower inner plug 10 is installed on the bottleneck of the bottle, and the outer cover 3 and the inner sleeve 2 are assembled and installed on the bottleneck of the bottle.

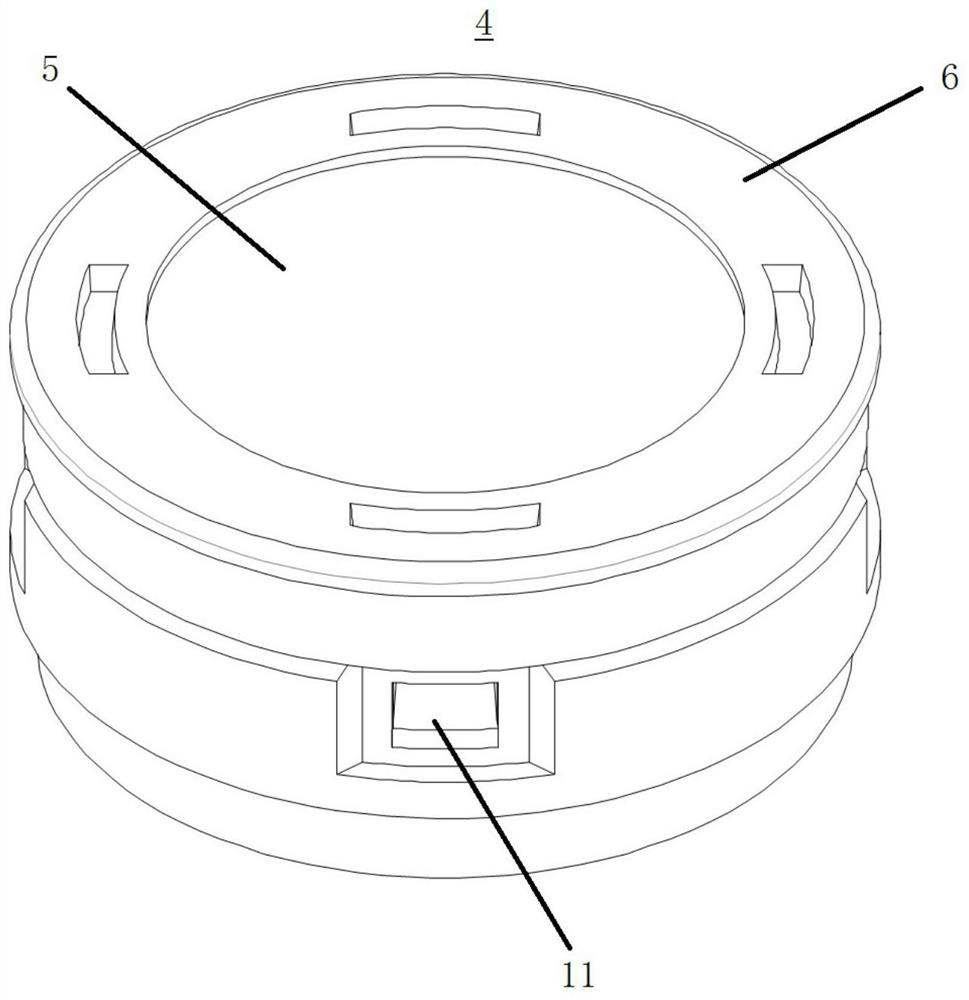

[0060] (2) Fix the upper inner plug 9 on the limiting structure 7 , and at the same time assemble the upper cover body 5 , the lower connecting sleeve 6 and the limiting structure 7 into the inner cover assembly 4 .

[0061] (3) Connect the inner cover assembly 4 with the inner sleeve 2, and at the same time make the lower inner plug 10 plugged in the bottle mouth, and form the sealing structure of the bottle mouth with the upper inner plug 9.

[0062] (4) Install the outer cover 1 on the inner sleeve 2 so that the top end of the outer cover 3 touches the bottom end of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com