Slow-release flavor filter stick and preparation method thereof

A slow-release and aroma technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of short aroma retention time, uneven aroma release, and low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

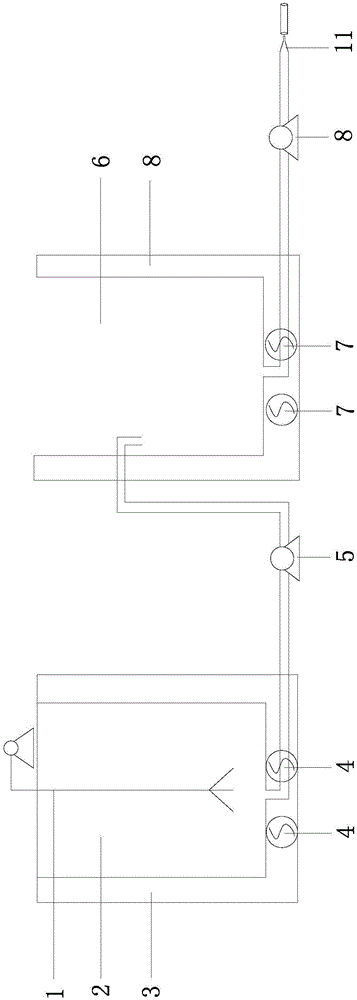

Image

Examples

Embodiment 1

[0070] Example 1: Preparation of slow-release fragrance filter sticks with different patterns

[0071] The implementation steps of this embodiment are as follows:

[0072] A. Preparation of Polyethylene Glycol Mixture

[0073] Polyethylene glycol 400, polyethylene glycol 4000, polyethylene glycol 10,000, polyethylene glycol 40,000, polyethylene glycol 200,000 and polyethylene glycol 500,000 according to the mass ratio of 10:34:20:12: 8:0 mixing to obtain the polyethylene glycol mixture;

[0074] The polyethylene glycol mixture contains 24% by weight of polyethylene glycol 10,000 and polyethylene glycol 40,000, and the weight ratio of polyethylene glycol 10,000 to polyethylene glycol 40,000 is 1.5:1.

[0075] B, prepare the pasty material that contains fragrance substance

[0076] The aroma substance of maple maple extract, the polyethylene glycol mixture obtained in step A, and sodium polyacrylate are mixed according to the mass ratio of 25:28:1, and then mixed in a water b...

Embodiment 2

[0079] Example 2: Preparation of slow-release fragrance filter sticks with different patterns

[0080] The implementation steps of this embodiment are as follows:

[0081] A. Preparation of Polyethylene Glycol Mixture

[0082] Polyethylene glycol 400, polyethylene glycol 4000, polyethylene glycol 10,000, polyethylene glycol 40,000, polyethylene glycol 200,000 and polyethylene glycol 500,000 according to the mass ratio of 28:28:20:10: 0:5 mixing to obtain the polyethylene glycol mixture;

[0083] The polyethylene glycol mixture contains 62% by weight of polyethylene glycol 400 and polyethylene glycol 4000, and the weight ratio of polyethylene glycol 400 and polyethylene glycol 4000 is 1:1;

[0084] B, prepare the pasty material that contains fragrance substance

[0085] National wine fragrance, flavor and fragrance substances, the polyethylene glycol mixture obtained in step A and sodium polyacrylate are mixed according to the mass ratio of 5:28:4, and then mixed in a water ...

Embodiment 3

[0088] Example 3: Preparation of slow-release fragrance filter sticks with different patterns

[0089] The implementation steps of this embodiment are as follows:

[0090] A. Preparation of Polyethylene Glycol Mixture

[0091] Polyethylene glycol 400, polyethylene glycol 4000, polyethylene glycol 10,000, polyethylene glycol 40,000, polyethylene glycol 200,000 and polyethylene glycol 500,000 according to the mass ratio of 38:16:25:3: 2:2 mixing to obtain the polyethylene glycol mixture;

[0092] The polyethylene glycol mixture contains 4.6% by weight of polyethylene glycol 200,000 and polyethylene glycol 500,000, and the weight ratio of polyethylene glycol 200,000 to polyethylene glycol 500,000 is 1:1.

[0093] B, prepare the pasty material that contains fragrance substance

[0094] Jujube flavor and aroma substances, the polyethylene glycol mixture obtained in step A and sodium polyacrylate are mixed according to the mass ratio of 68:12:5, and then stirred in a water bath w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com