Anti-counterfeiting fiber with fluorescence fiber color changing with the change of optic angle of exciting light and anti-counterfeiting material

An anti-counterfeiting fiber and photoluminescent material technology, which is applied in fiber raw material processing, fiber chemical characteristics, non-fiber pulp addition, etc., can solve the problems of fiber luminous color change, unknown effect of excitation light angular discoloration, inability to overcome influence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

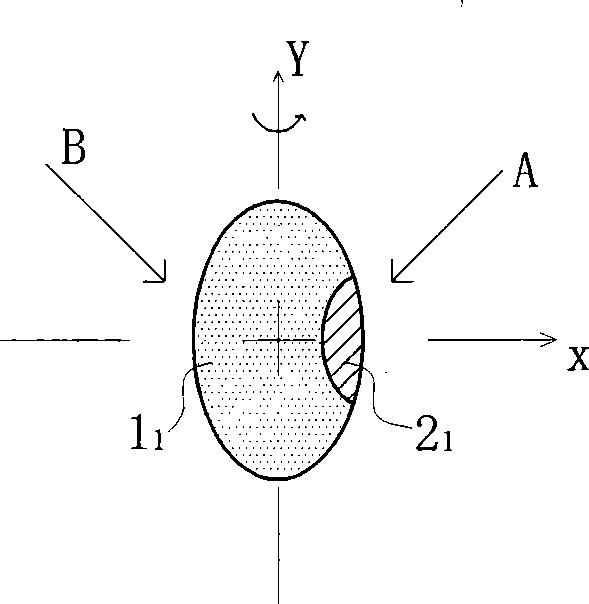

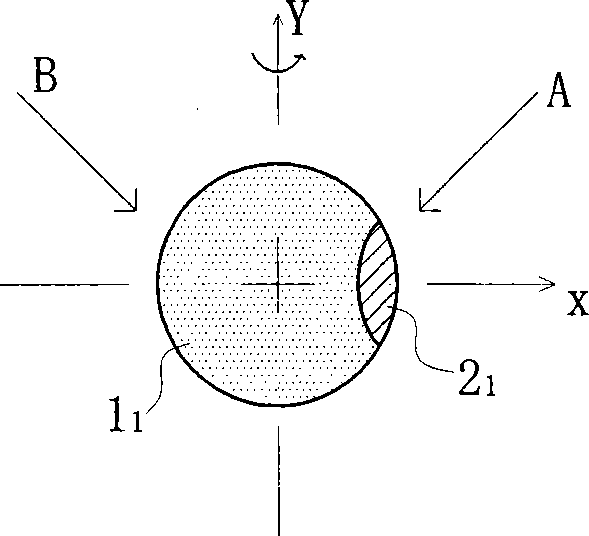

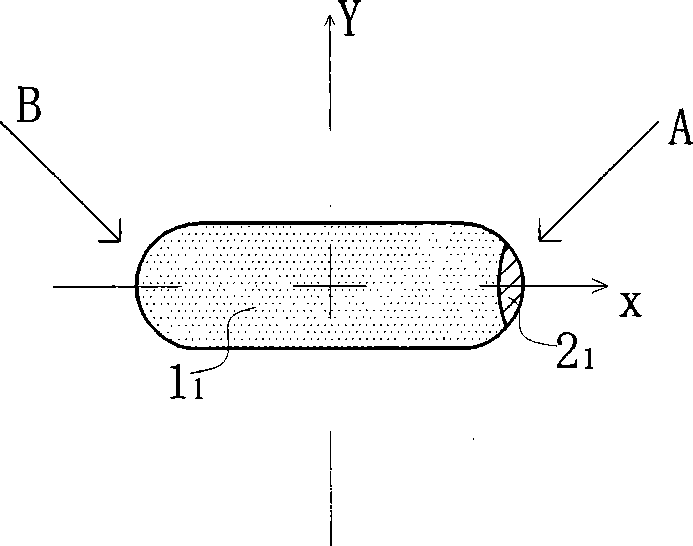

[0097] Example 1: Figure 1a , Figure 1b , Figure 1c , Figure 1d , Figure 1e , Figure 1f is a cross-sectional view of a two-component fiber with one component containing luminescent material.

[0098] The cross-section of the fiber consists of the barrier component 1 1 and luminescent component 2 1 Composite composition of two components, the two components are distributed side by side on the cross section, and extend in parallel without twisting in the fiber length direction. Barrier component 1 1 It is an absorbing material that does not contain photoluminescent material, can transmit visible light and block excitation light, and the absorption spectrum in the absorbing material includes at least the excitation wavelength of the luminescent material; luminescent component 2 1 The photoluminescent material M is contained in the cross-section, which is located on one side of the vertical axis Y-axis, and the horizontal axis X-axis of the cross-section bisects the p...

Embodiment 2

[0105] Example 2: with Figure 2a , Figure 2b The cross-section of the fiber consists of the first luminescent component 2 2 and the second luminescent component 3 2 The two components are side by side and compounded. The two components are distributed side by side on the cross section, and extend in parallel without twisting in the fiber length direction. Since the flatness of the fiber cross section is ≤ 1, the expressed fiber is a two-component bend. Fiber, first luminescent component 2 2 Contains photoluminescent material M, the second luminescent component 3 2 contains photoluminescent material N, the luminescent color of photoluminescent material M and photoluminescent material N have the same excitation light wavelength, but the luminescent color M and luminescent color N have obvious visual differences; the two components are respectively Located on one side of the vertical axis Y-axis, the horizontal axis X-axis of the cross-section bisects the two components in ...

Embodiment 3

[0110] Example 3: Figure 3a , Figure 3b , Figure 3c , Figure 3d , Figure 3e , Figure 3f is a cross-sectional view of a three-component fiber in which two components contain luminescent material,

[0111] The above-mentioned is an absorbing material that does not contain photoluminescent material, can pass through visible light and can block excitation light. The absorption spectrum in the absorbing material includes the excitation wavelength of the luminescent material. The first luminescent component 2 3 Contains photoluminescent material M, the second luminescent component 3 3 contains photoluminescent material N, and the luminescent color of photoluminescent material M has the same excitation light wavelength as photoluminescent material N, but the luminescent color has obvious visual difference. In the cross section, the first luminescent component 2 3 and the second luminescent component 3 3 Located on both sides of the Y-axis, each figure of Example 3 shows th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com