Patents

Literature

72results about How to "Reduce or even eliminate the impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

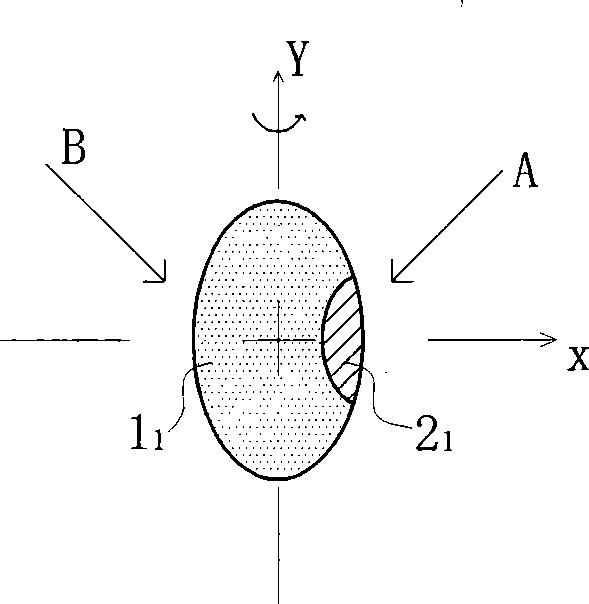

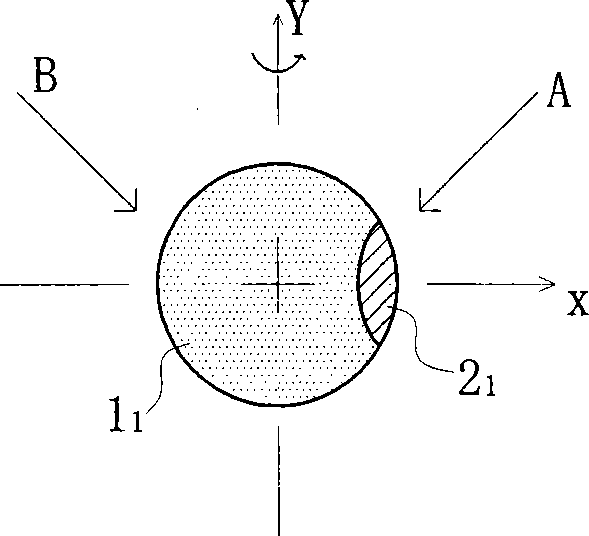

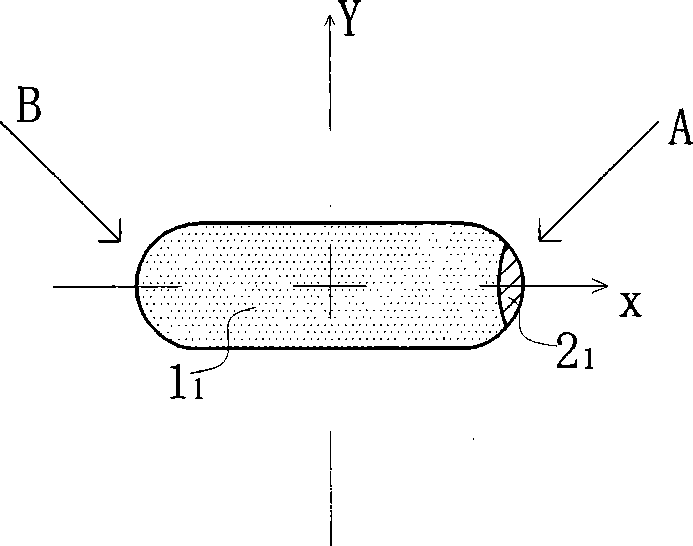

Anti-counterfeiting fiber with fluorescence fiber color changing with the change of optic angle of exciting light and anti-counterfeiting material

ActiveCN101519857AProcesses to Solve Directional BendingEasy to produceNon-fibrous pulp additionPaper/cardboardFiberFine line

The invention provides an anti-counterfeiting fiber with fluorescence fiber color changing with the change of an optic angle of exciting light and an anti-counterfeiting material, which relates to fluorescence fiber with illuminant color changing with the change of the illumination angle of exciting light and an anti-counterfeiting material. The anti-counterfeiting fiber is combined by at least two material components extending parallelly without twisting along the length direction of the fiber, at least one component contains luminescent material and the anti-counterfeiting fiber is characterized in that: the distribution of at least two components of the fiber at the cross section causes the fiber to construct an exciting light shielding structure which can shield the exciting light and an oriented structure with oriented direction, thus ensuring that at least two illumination angles A and B of the exciting light exist at the upper space of the plane when the fiber falls down to a plane parallel to the horizontal plane due to free-fall gravity; and the illuminant color has obvious visual differences when the two angles illuminate to the fiber. The method solves the difficult problem that the visual characteristic of fluorescence anti-counterfeiting material is easy to be imitated by printing fine line for the first time in the world.

Owner:SHANGHAI KOS SECURITY PAPER TECH CO LTD

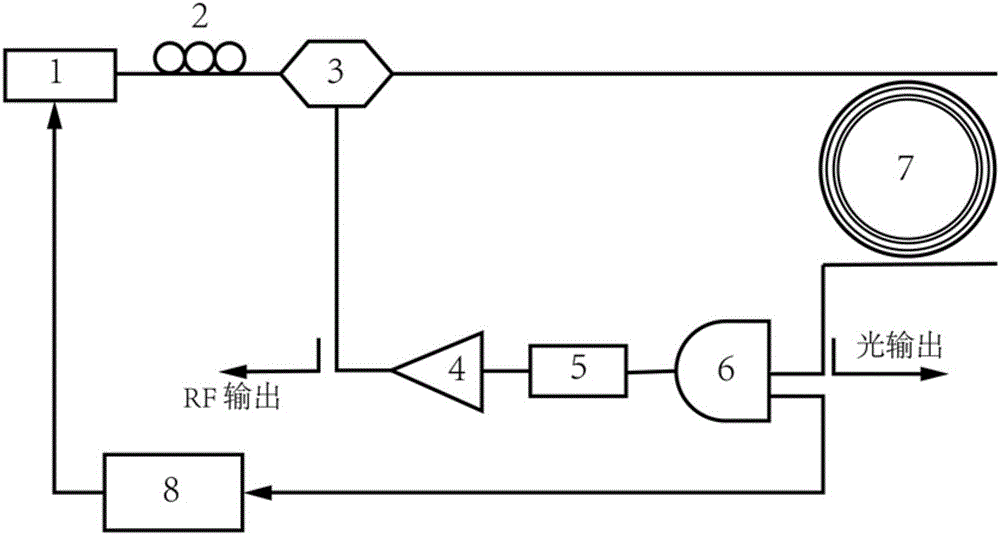

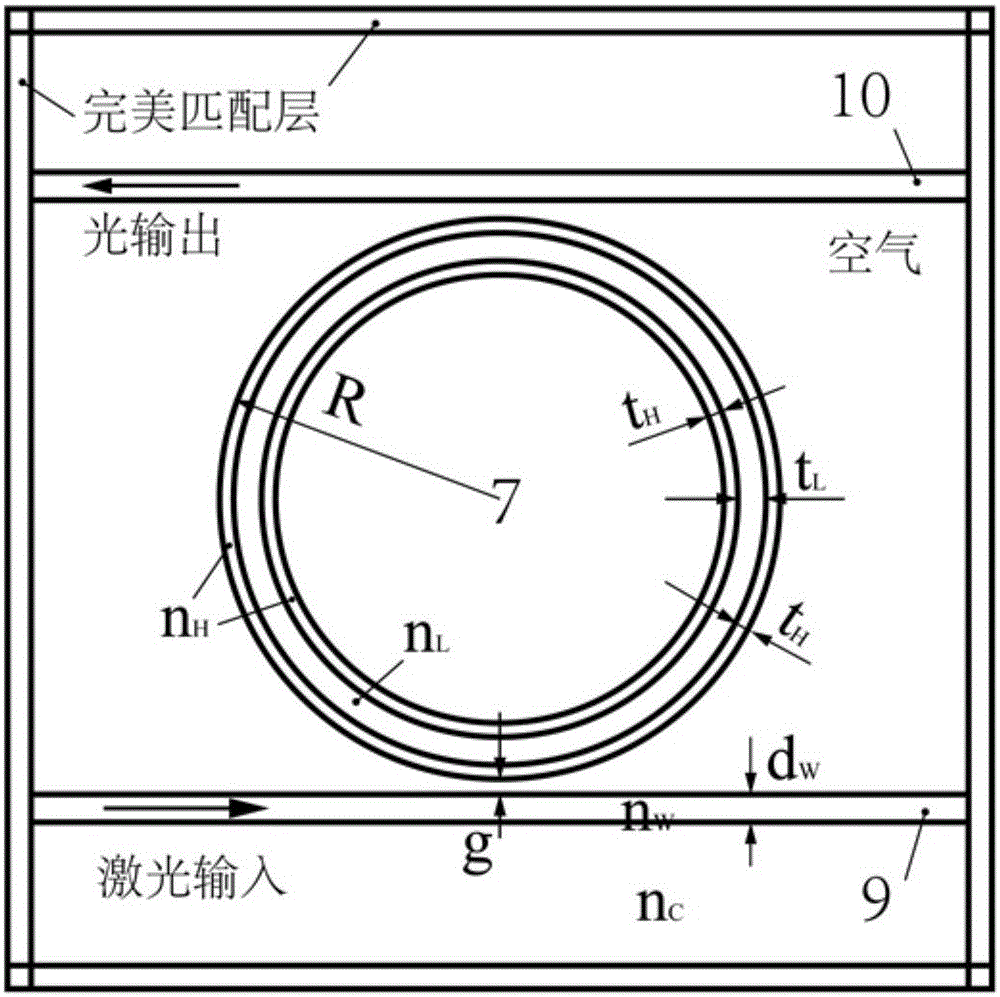

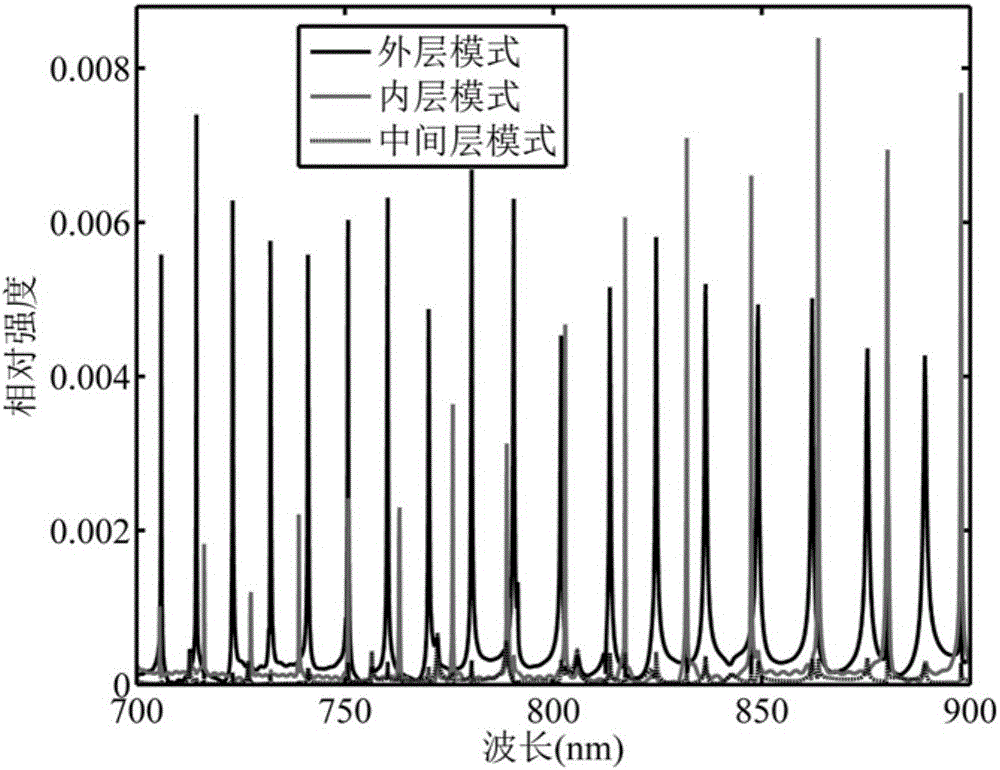

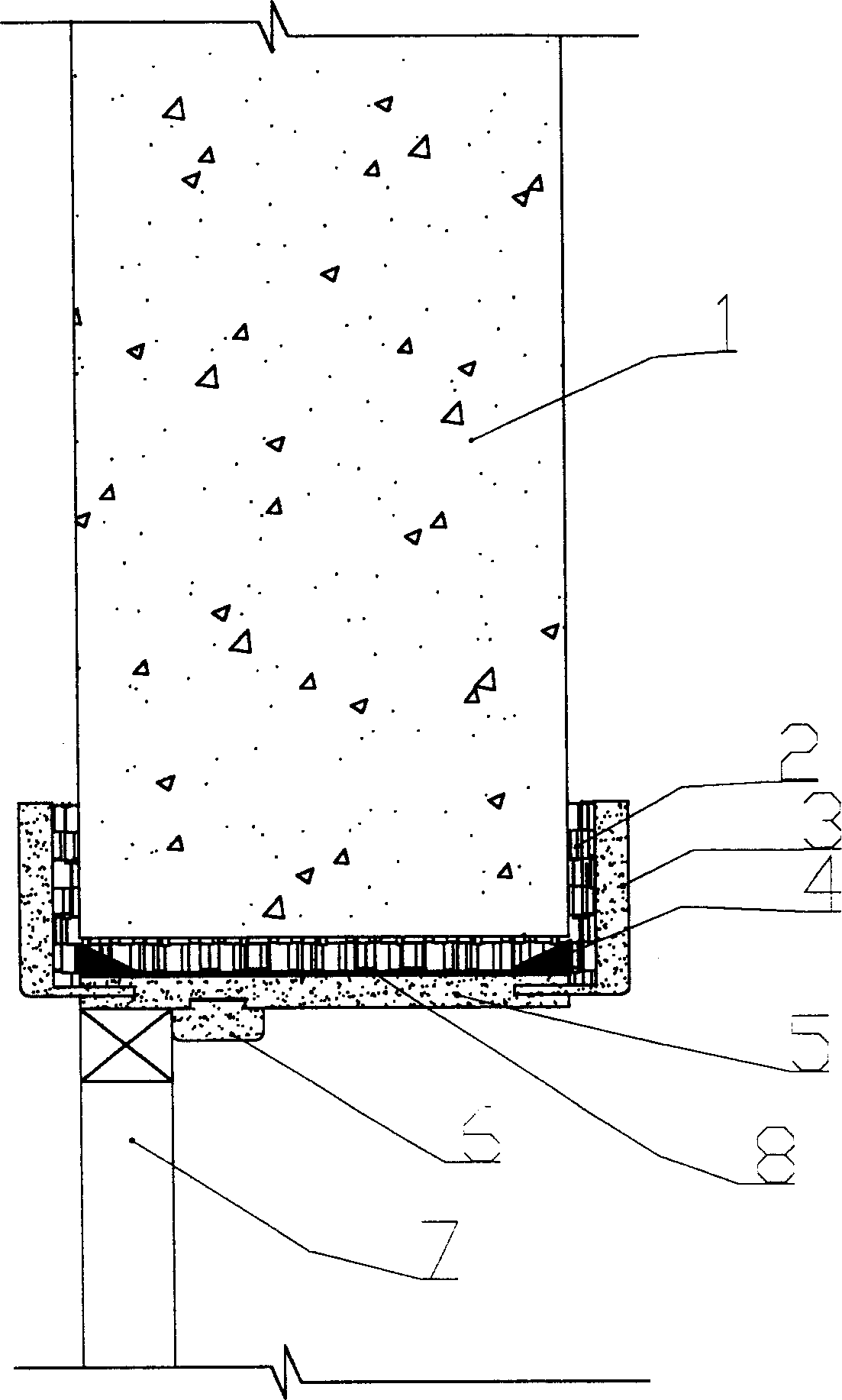

Optoelectronic oscillator based on multilayer film echo wall mode optical microcavity

ActiveCN105896235ASuppress spurious modesReduce phase noiseSolid masersMicrowave frequencyOpto-electronic oscillator

The invention discloses an optoelectronic oscillator based on a multilayer film echo wall mode optical microcavity. A closed optoelectronic feedback loop consists of a laser (1), a polarization controller (2), a Mach-Zehnder intensity modulator (3), an RF amplifier (4), a filter (5), an optoelectronic detector (6), a multilayer film echo wall mode optical microcavity (7) and a laser frequency-locking module (8); and the closed optoelectronic feedback loop is the main structure of the optoelectronic oscillator. The optoelectronic oscillator provided by the invention can effectively reduce influence on the generated microwave frequency from temperature fluctuations and other external environment factors, and high-quality and steady microwave signals can be obtained; meanwhile, the signal noise can be weakened; and furthermore, the optoelectronic oscillator is small in size, light in weight, and easy to package and integrate.

Owner:UNIV OF SCI & TECH OF CHINA

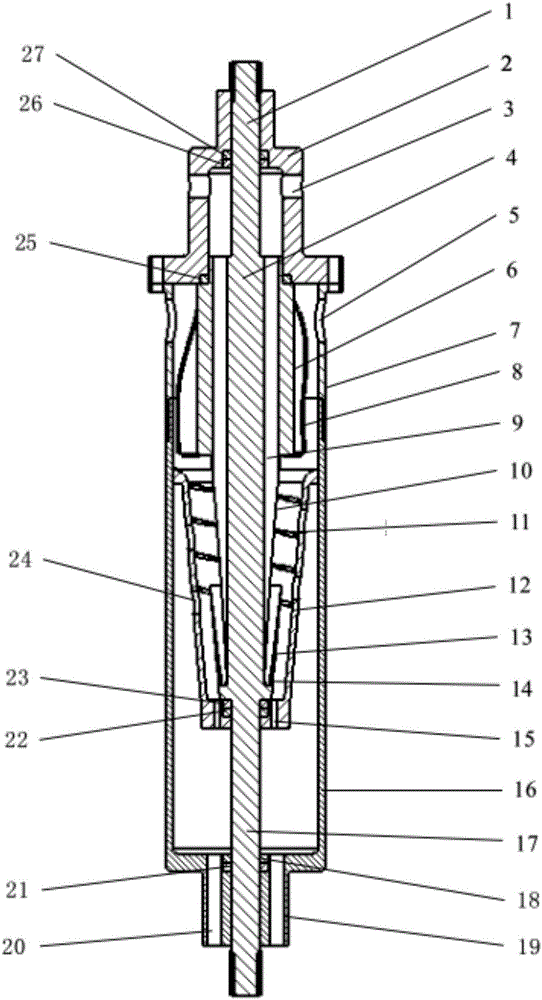

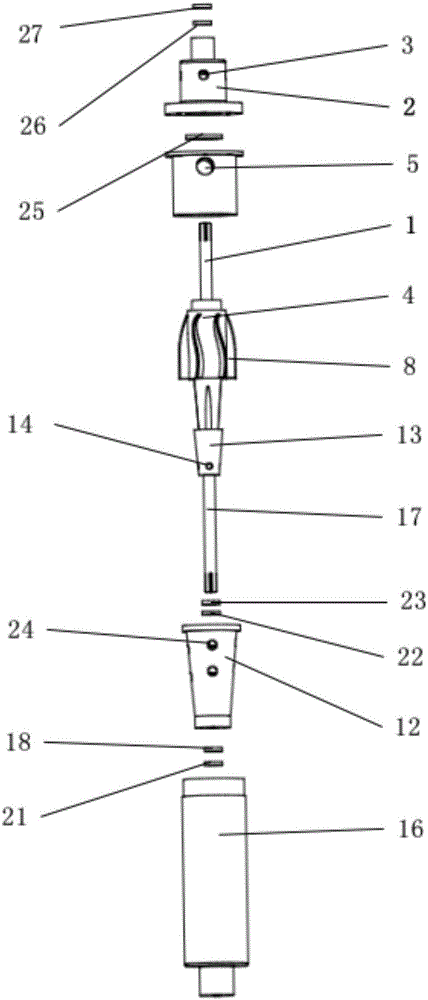

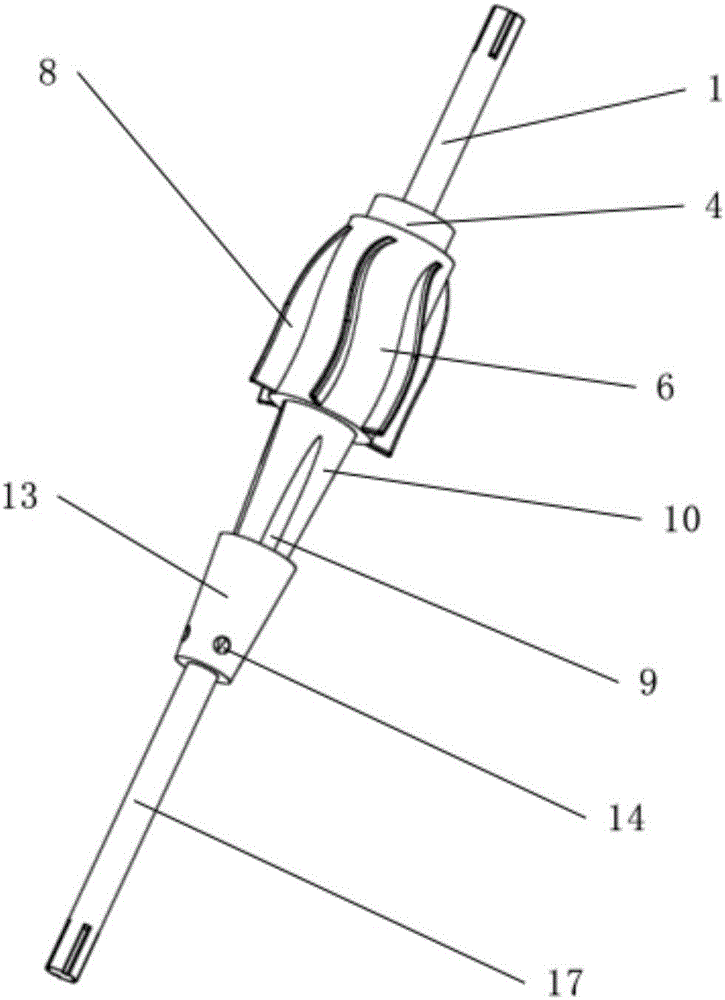

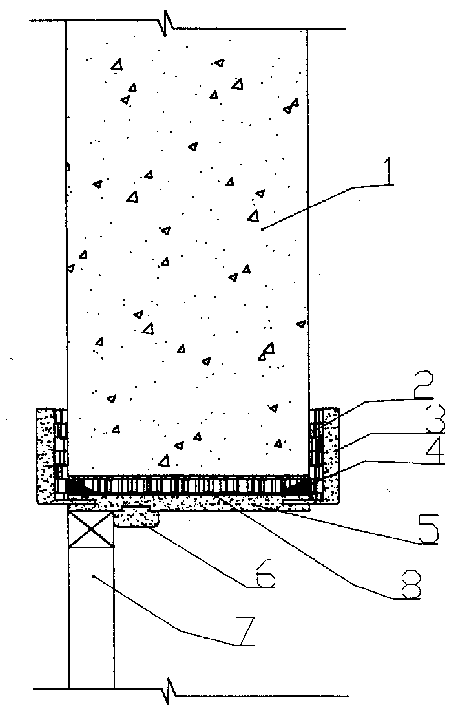

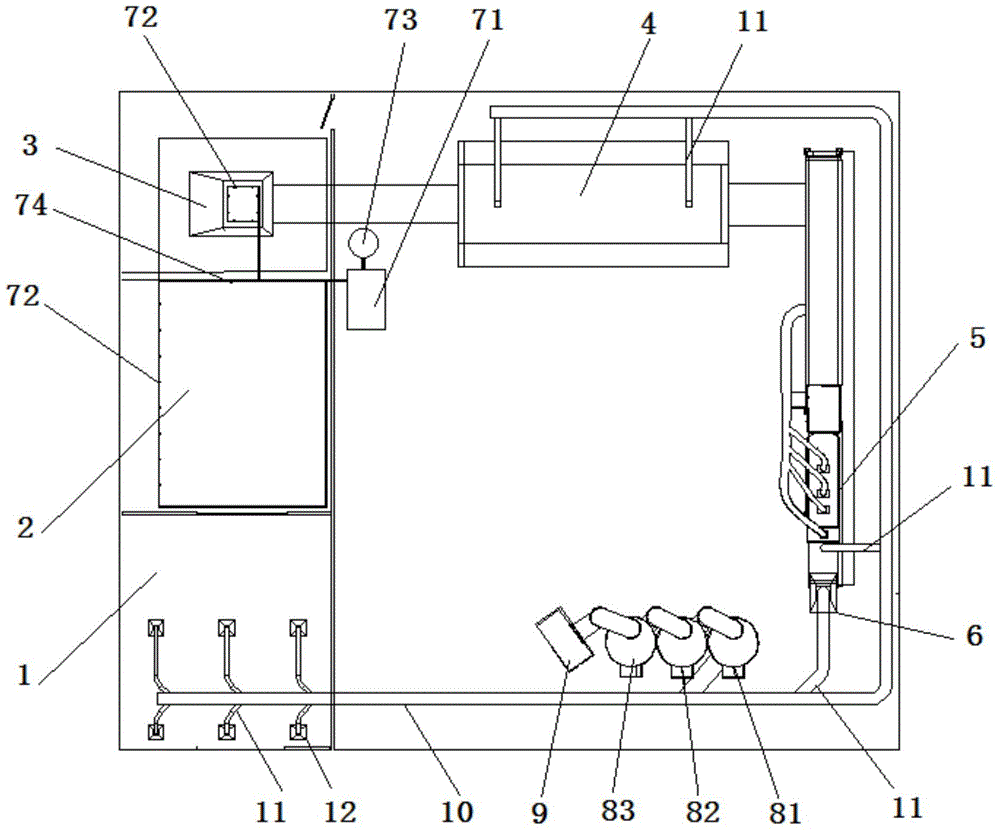

Downhole same-well injection-production gas-liquid separator

ActiveCN106640031AEliminate the effects ofReduce or even eliminate the impactFluid removalElectricityEngineering

The invention provides a downhole same-well injection-production gas-liquid separator. The gas-liquid separator is combined with an electric submersible pump, an overhead type electric submersible pump drainage gas production lifting system is adopted, and downhole separation of gas-liquid mixed flow can be achieved. The downhole same-well injection-production gas-liquid separator is characterized in that the gas-liquid separator is further provided with a gas-liquid separator body, a gas-liquid separating cover and a gas-liquid outer spiral body; the gas-liquid separator body is located in a cavity body surrounded by an upper housing, a liquid inlet housing and a lower housing, and formed in the mode that a gas-liquid separating body upper transmission shaft, a gas-liquid separating guide section, a gas-liquid separating body reverse cone section and a gas-liquid separating body lower transmission shaft are connected in sequence from top to bottom; a guide vane is welded outside the gas-liquid separating guide section; a gas inlet is formed in the gas-liquid separating body reverse cone section, and the outlet of a gas hole channel is located in the inner cavity of the upper housing; the gas-liquid separating cover is a hollow inverted frustum, and the gas-liquid outer spiral body is also the hollow inverted frustum.

Owner:NORTHEAST GASOLINEEUM UNIV

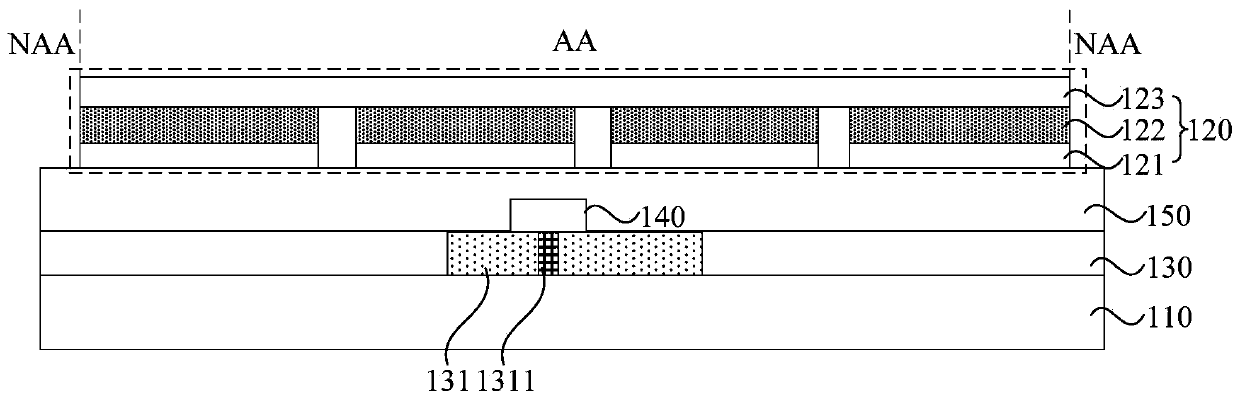

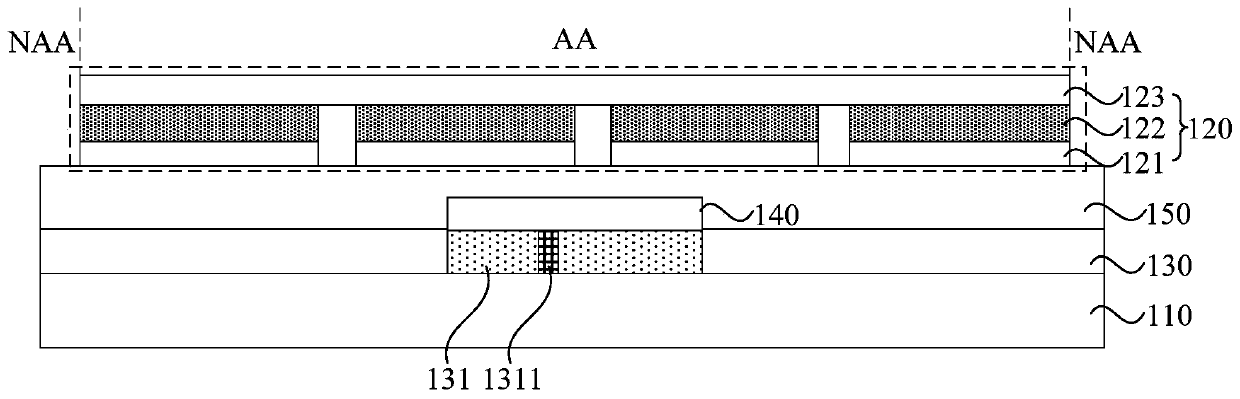

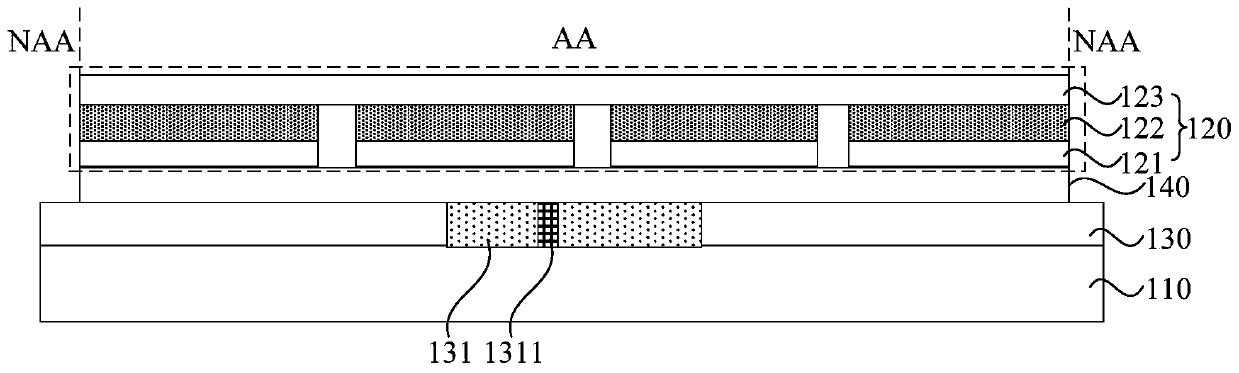

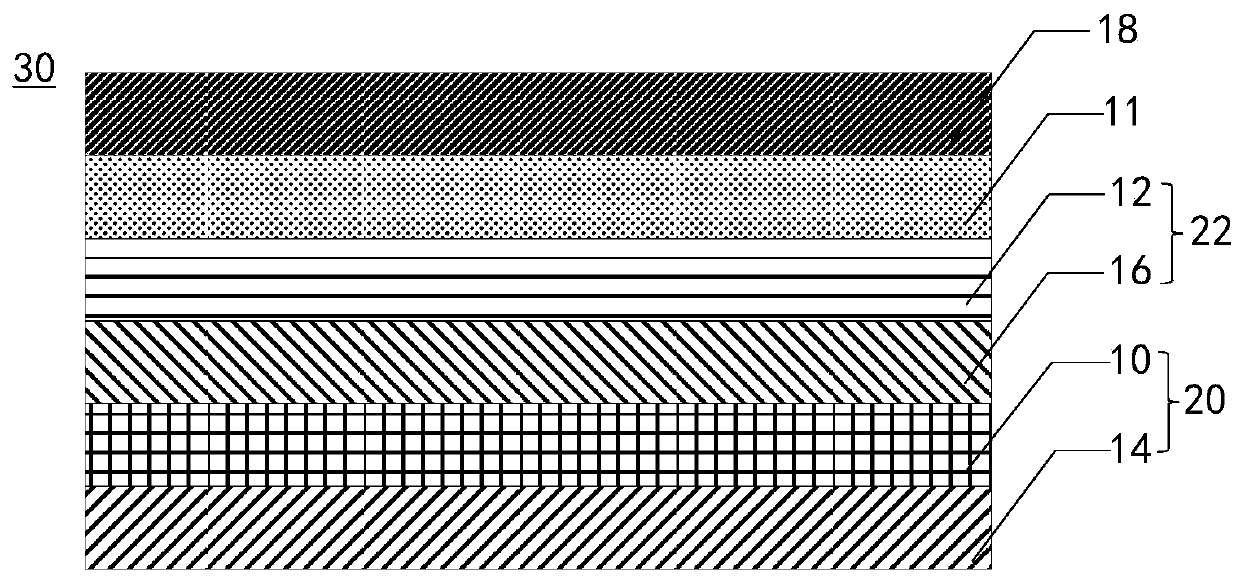

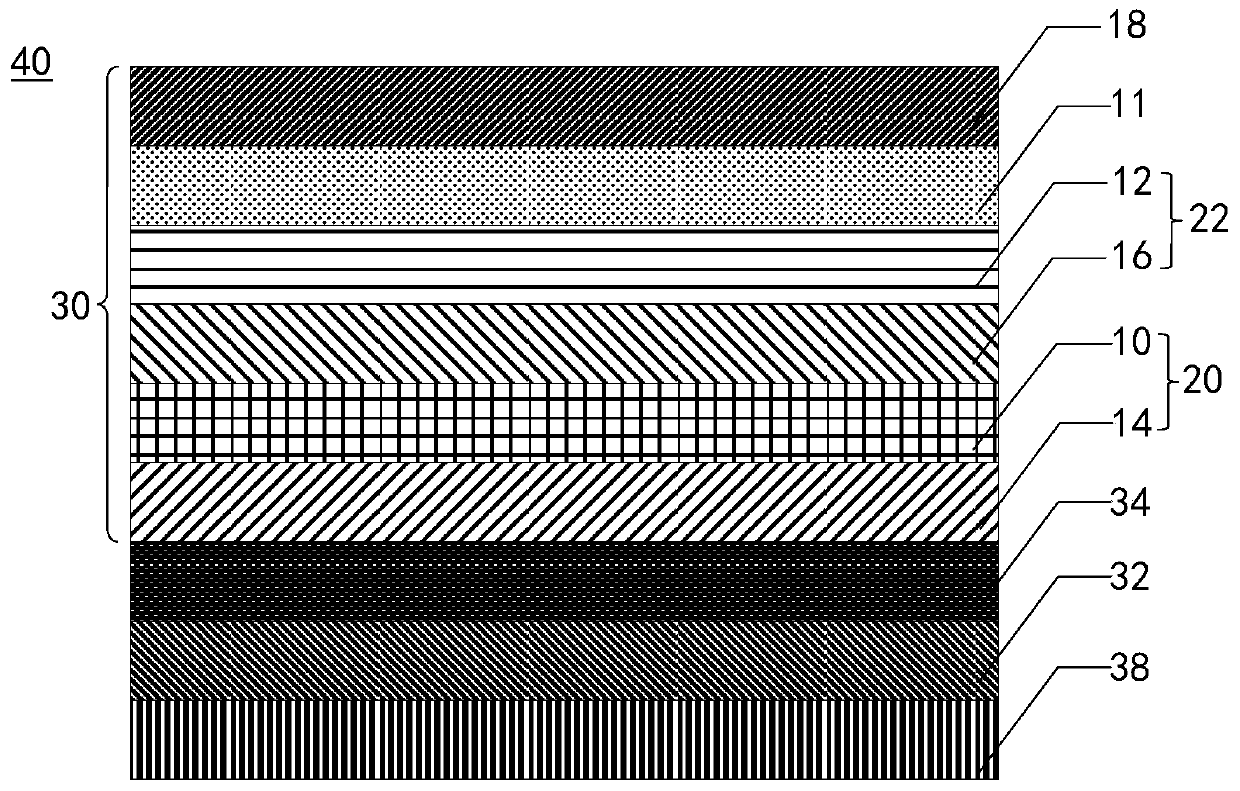

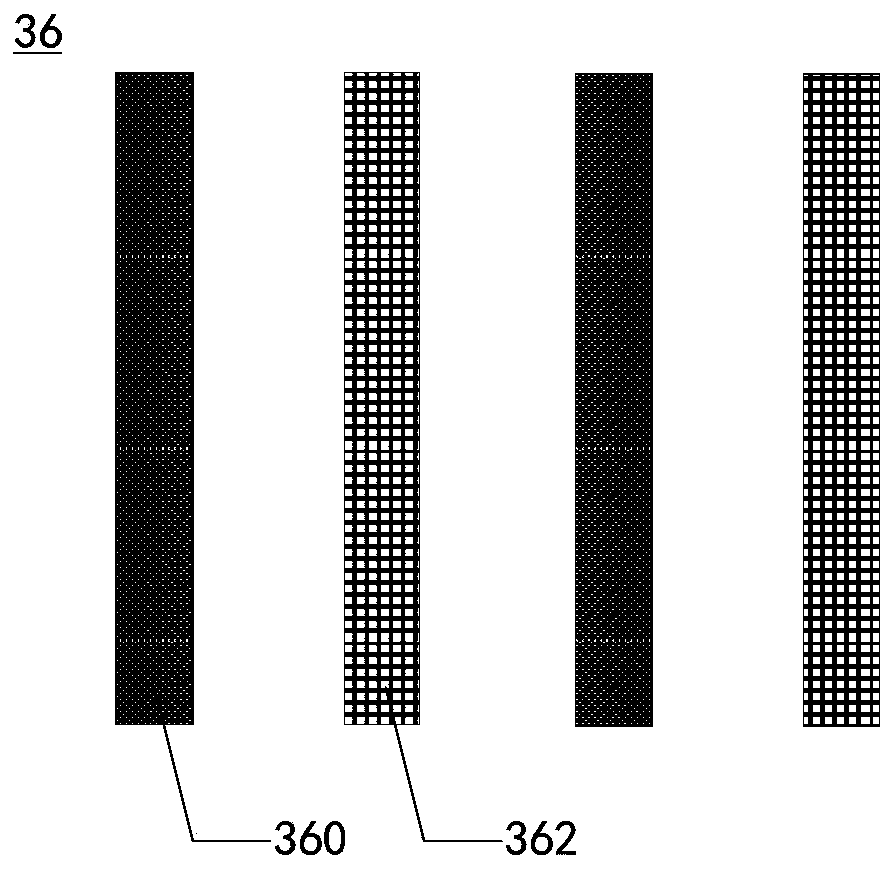

Display panel and manufacturing method thereof and display device

ActiveCN110416226AImprove display uniformityReduce couplingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the present invention discloses a display panel and a manufacturing method thereof and a display device. The display panel is divided into a display area and a non-display area. Thedisplay panel comprises a substrate; a light emitting device layer which comprises a first electrode layer, a light emitting layer and a second electrode layer which are laminated in turn from the substrate; an array circuit layer which is arranged between the first electrode layer and the substrate, wherein the array circuit layer comprises a gate driving circuit which is arranged in the displayarea; and a shielding layer which is arranged between the array circuit layer and the first electrode layer. The gate driving circuit comprises a clock signal line. The shielding layer at least coversthe clock signal line of the gate driving circuit in a direction perpendicular to the substrate so that the luminance of the light emitting device overlapping with the clock signal line and the luminance of the light emitting device not overlapping with the clock signal line tend to be the same in the direction perpendicular to the substrate, thereby improving the display uniformity of the display panel and the display effect.

Owner:YUNGU GUAN TECH CO LTD

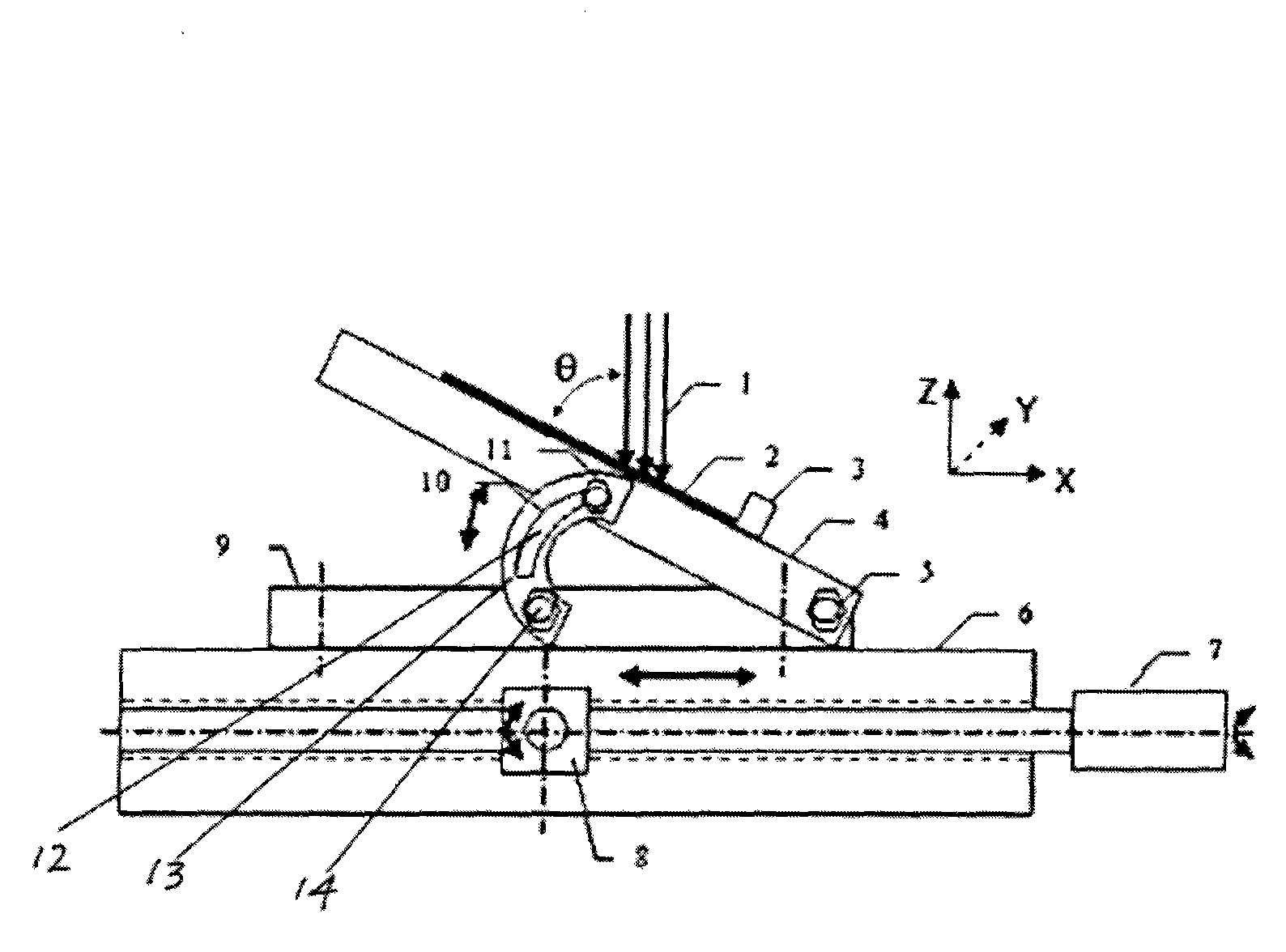

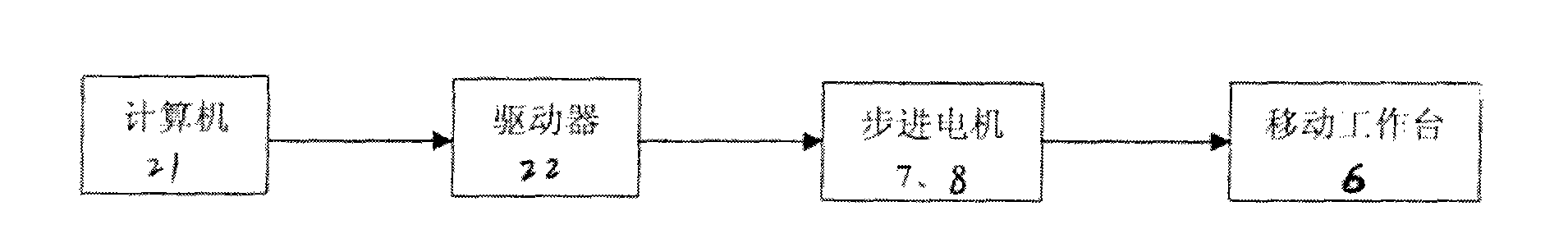

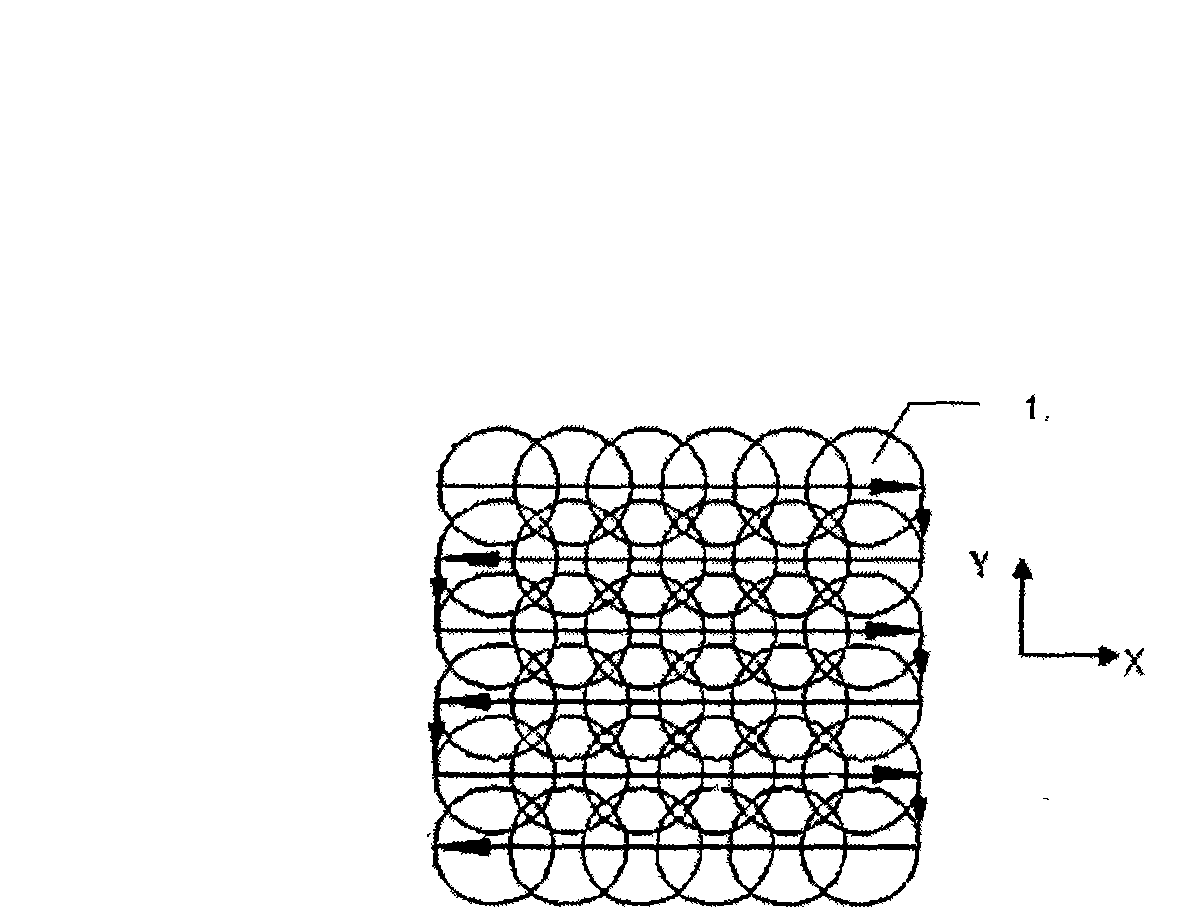

Polishing device and method of sapphire

InactiveCN101664894ALittle thermal impactEliminate the effects ofEdge grinding machinesEngineeringLaser beams

The invention relates to polishing device and method of sapphire. The polishing device comprises a laser beam, a shoe plate, a worktable and a connecting piece, wherein the worktable is provided witha stepper motor driving the worktable to make X-direction movement and a stepper motor driving the worktable to make Y-direction movement, the connecting piece is fixed on the worktable, the shoe plate is arranged on the connecting piece, and a sapphire wafer to be polished is fixed on the shoe plate; the laser beam radiates to the sapphire wafer from the upward side of the sapphire wafer to be polished, and the stepper motor driving the worktable to make the X-direction movement and the stepper motor driving the worktable to make the Y-direction movement are respectively connected with a control device. The invention controls the X-direction movement and the Y-direction movement of a workpiece and the movement track of the workpiece relative to the laser beam by regulating the incident angle of the laser beam and controlling the worktable, thereby realizing the comprehensive scanning and polishing on the surface of the sapphire wafer. The invention can remove very little material, reduce and even eliminate the influence of heat on the sapphire material, thereby obtaining a polished surface with low surface roughness and low subsurface injury degree.

Owner:GUANGDONG UNIV OF TECH

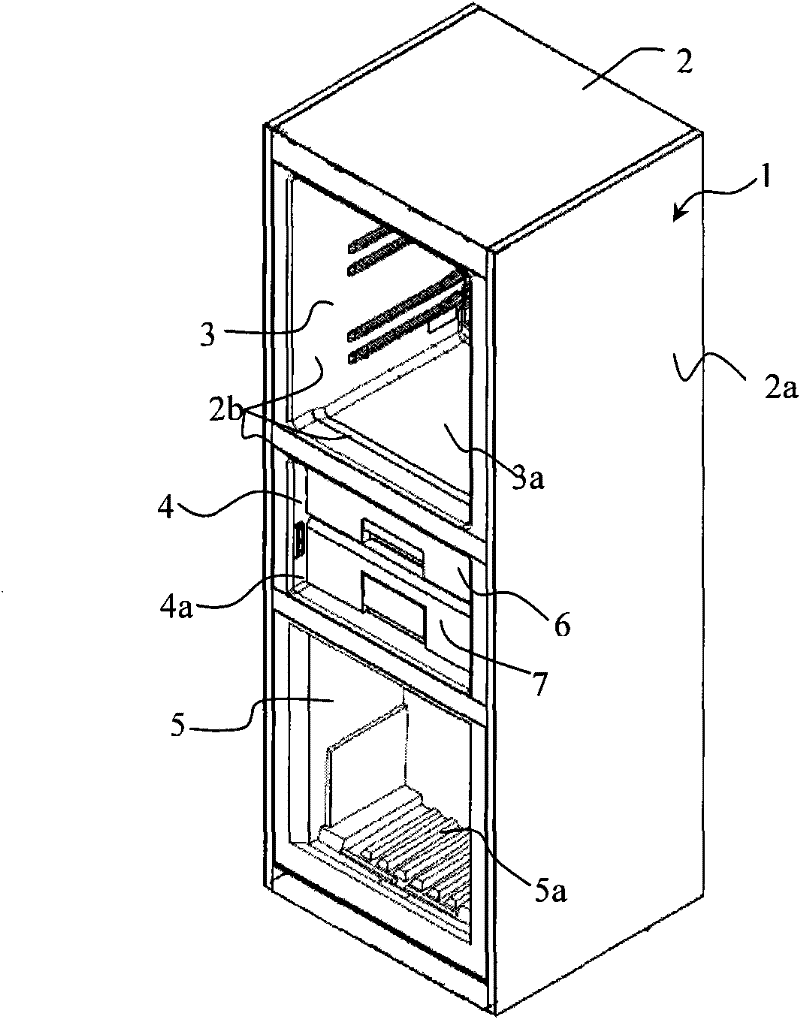

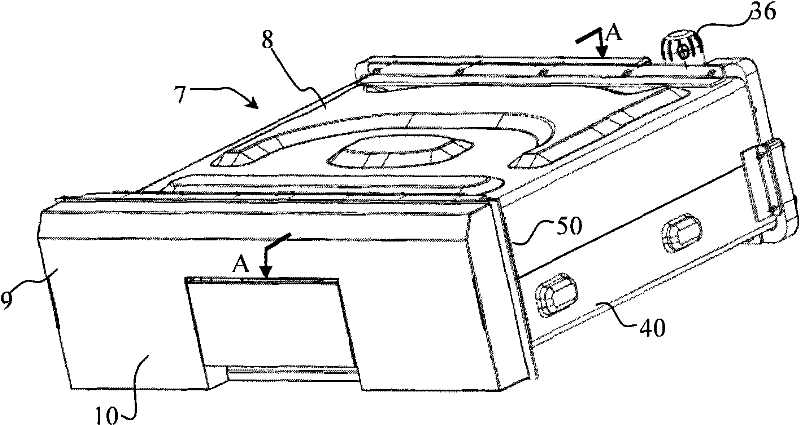

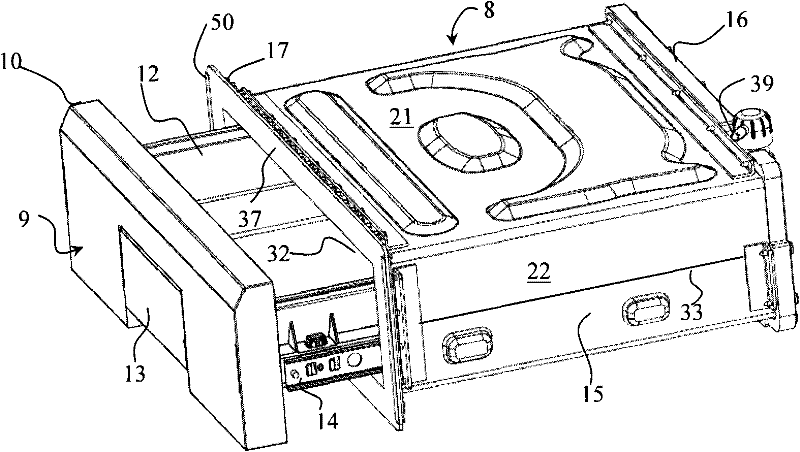

household appliances

ActiveCN102261794AInsert smoothlyTake it out smoothlyLighting and heating apparatusCooling fluid circulationBiomedical engineeringHome appliance

The present invention relates to a household appliance, in particular a refrigeration appliance. The household appliance comprises: a cabinet (2) defining a compartment (4), wherein the compartment (4) has a front opening (4a); and a storage unit (7) which is constructed independently from the cabinet (2) and is received within the compartment (4), wherein a gap (G) is formed between at least one side of the storage unit (7) and a corresponding side wall (2b) of the compartment (4). According to suggestions of the present invention, the household appliance further comprises a gap shielding member (50), which is located adjacent the front opening (4a) to cover at least a part of the gap (G).

Owner:博西华家用电器有限公司

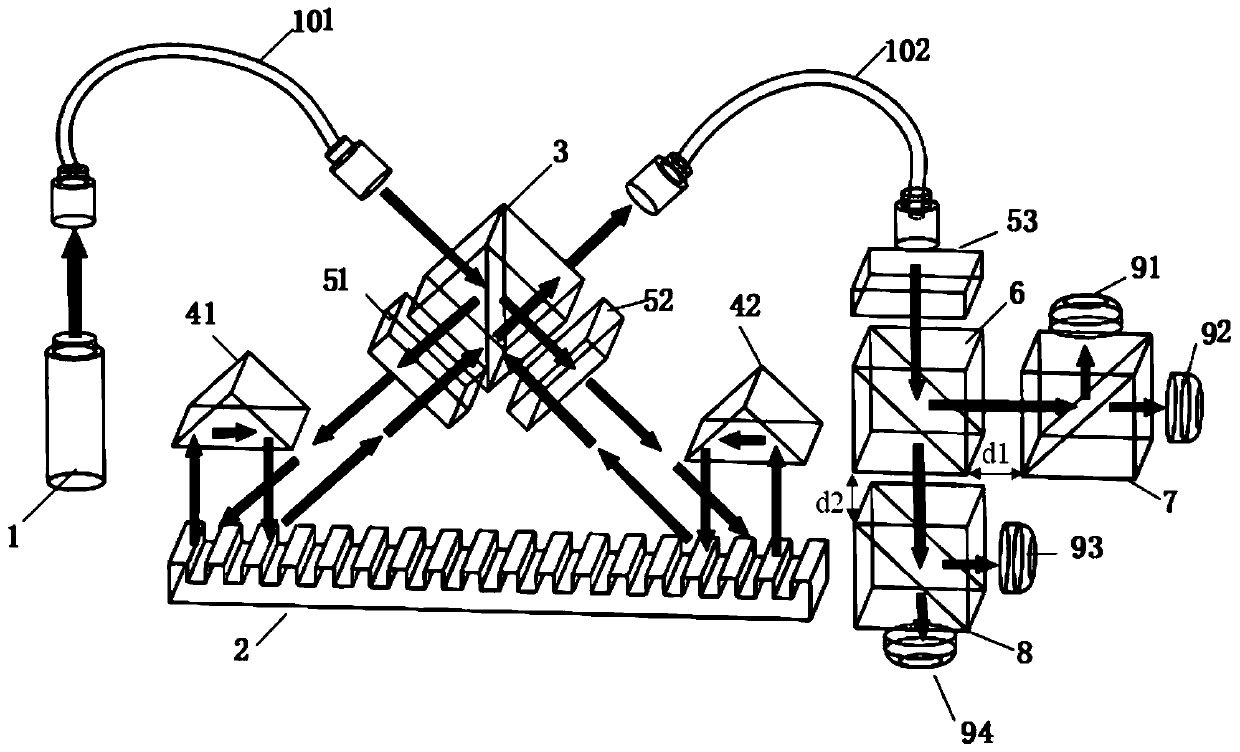

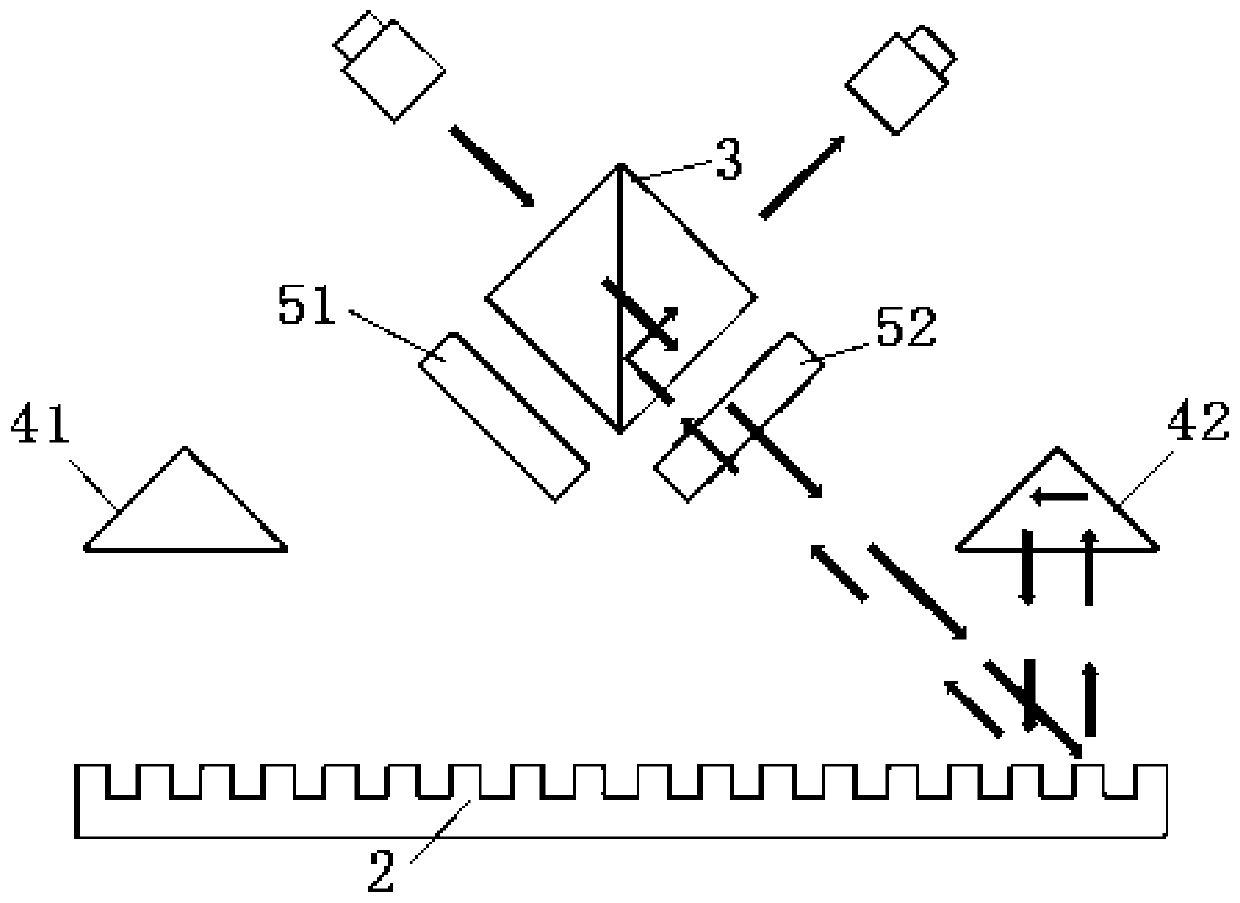

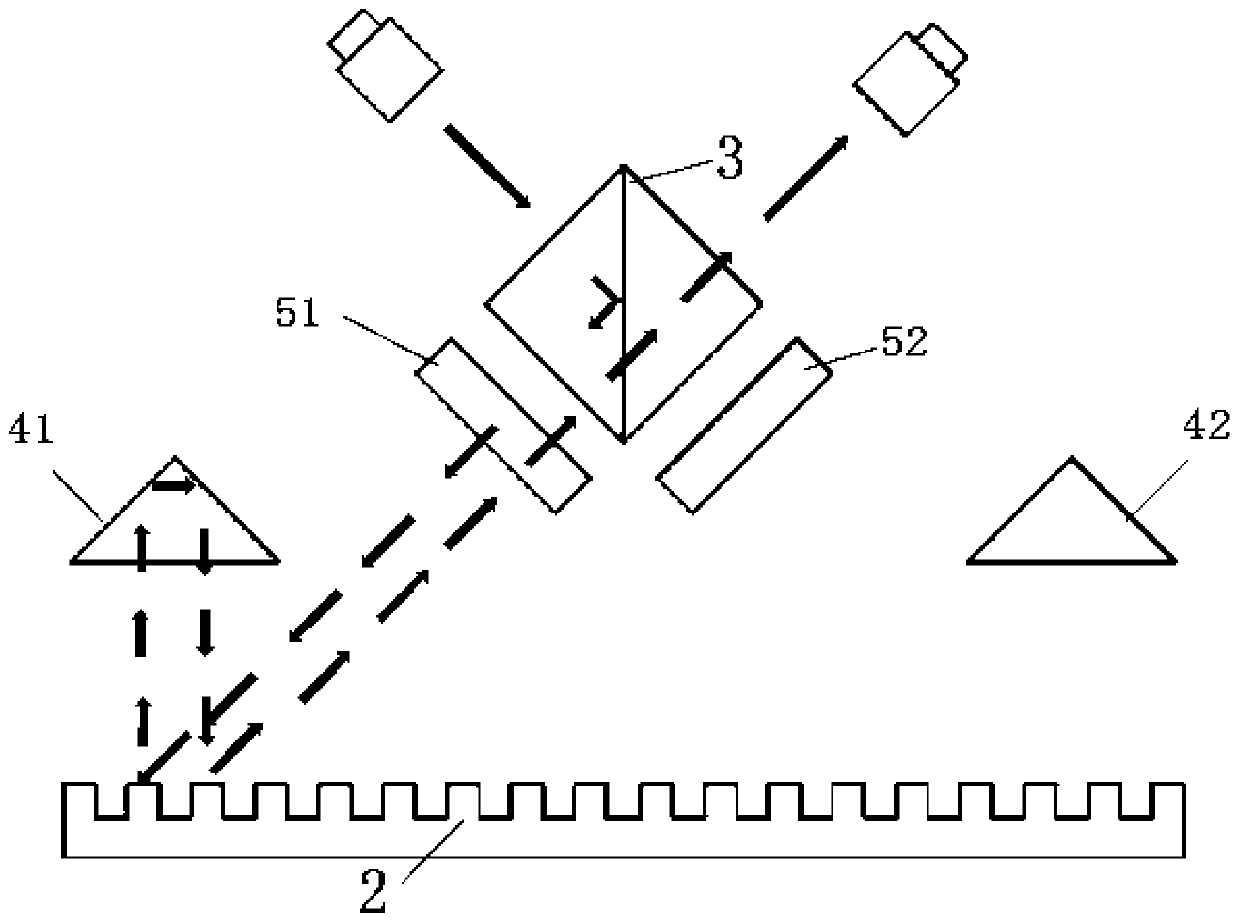

Grating displacement sensor based on second diffraction light interference

ActiveCN109916313AOptimizing the Light Path StructureHigh resolutionUsing optical meansOptical pathOpto electronic

The present invention discloses a grating displacement sensor based on second diffraction light interference. The sensor comprises a laser, a grating, a polarizing beam splitter, a quarter-wave plate,a backward reflector, a beam splitter, a photoelectric detector and an optical fiber. The method of second diffraction polarized light interference is employ to improve the resolution ratio of the system twice and improve the measurement precision; and an optical structure with symmetrical common paths is employed so that the optical path difference of two coherent lights is zero and the influence of an external environment on the system is reduced; and moreover the polarization optics features are utilized to improve the light application efficiency and improve the system reliability. The grating displacement sensor based on second diffraction light interference has important values for improvement of the measurement resolving power and the actual use precision of the grating displacement sensor.

Owner:XI AN JIAOTONG UNIV

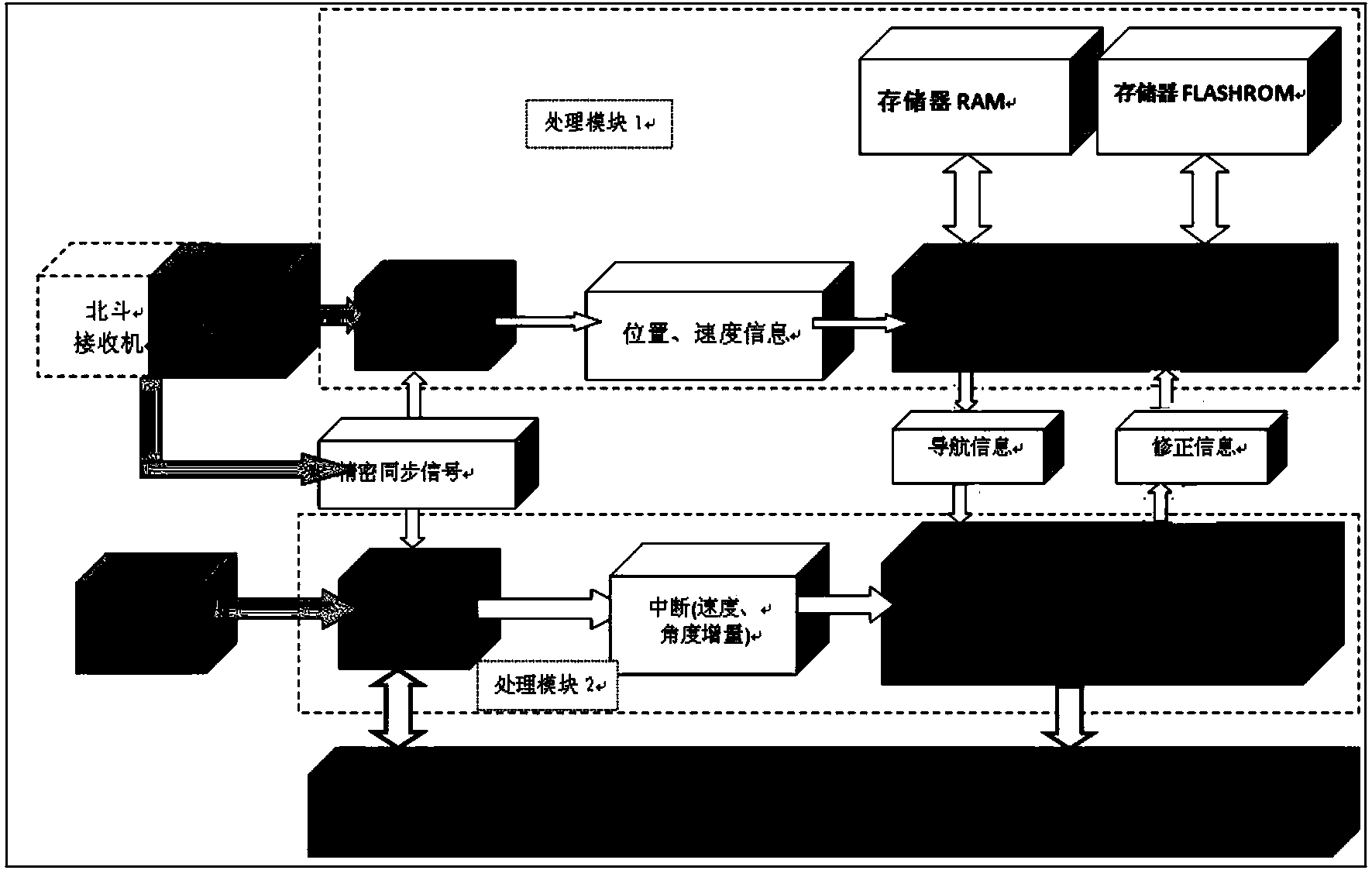

Double-DSP (Digital Signal Processor) step-by-step type POS (Point Of Sale) real-time navigation resolving system

ActiveCN103900575AReduce or even eliminate the impactEliminate the effects ofNavigational calculation instrumentsReal time navigationUniversal asynchronous receiver/transmitter

The invention discloses a double-DSP (Digital Signal Processor) step-by-step type POS (Point Of Sale) real-time navigation resolving system which comprises a first processing device and a second processing device, wherein the first processing device comprises a first DSP processor, a first FPGA (Field Programmable Gate Array) circuit and a UART (Universal Asynchronous Receiver / Transmitter) serial circuit; the first FPGA circuit is connected with the first DSP processor; the second processing device comprises a second DSP processor and a second FPGA circuit connected with the second DSP processor. Due to the adopted double-DSP structure, labor division of algorithm and product function development is achieved, the influence of a user function code on the algorithm is reduced or even eliminated, the working efficiency of developers is improved, and the research and development period of a product is shortened.

Owner:LEADOR SPATIAL INFORMATION TECH CORP

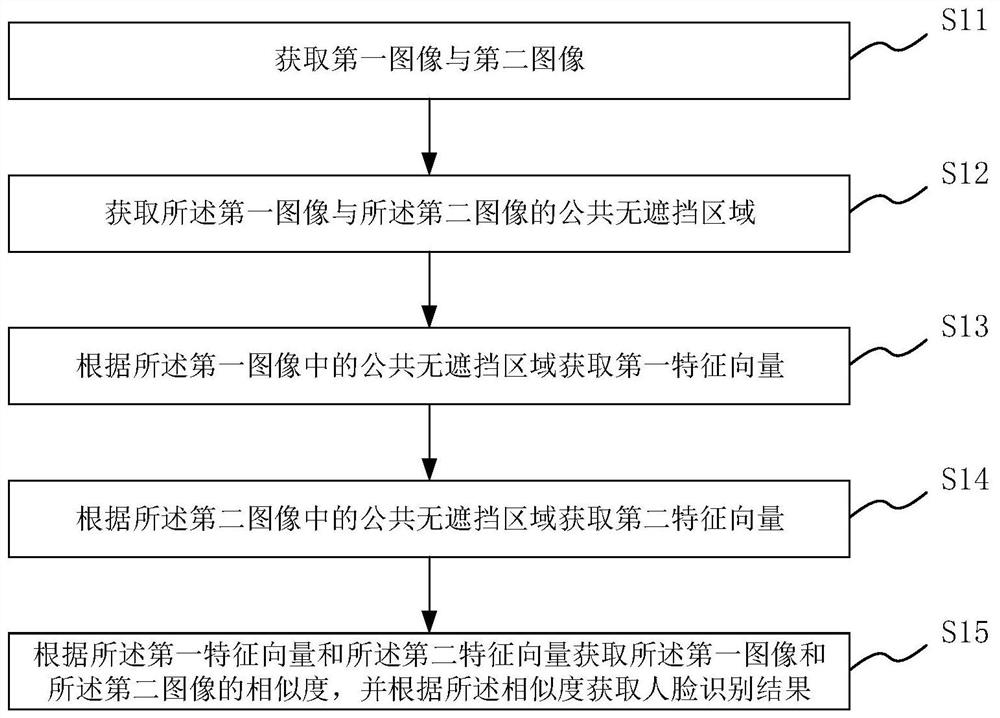

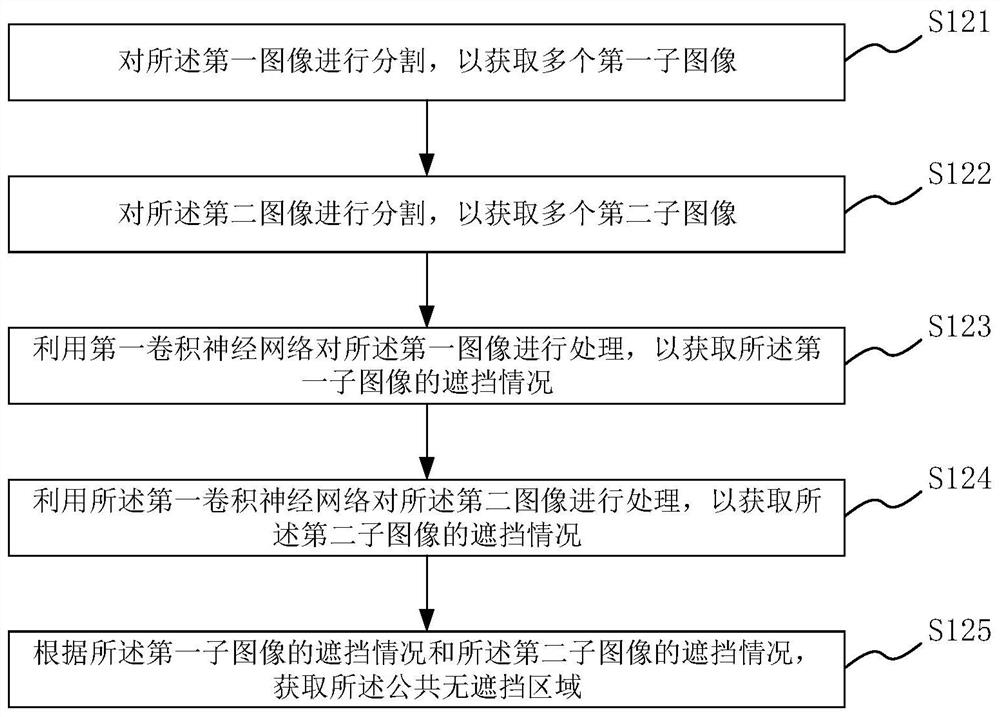

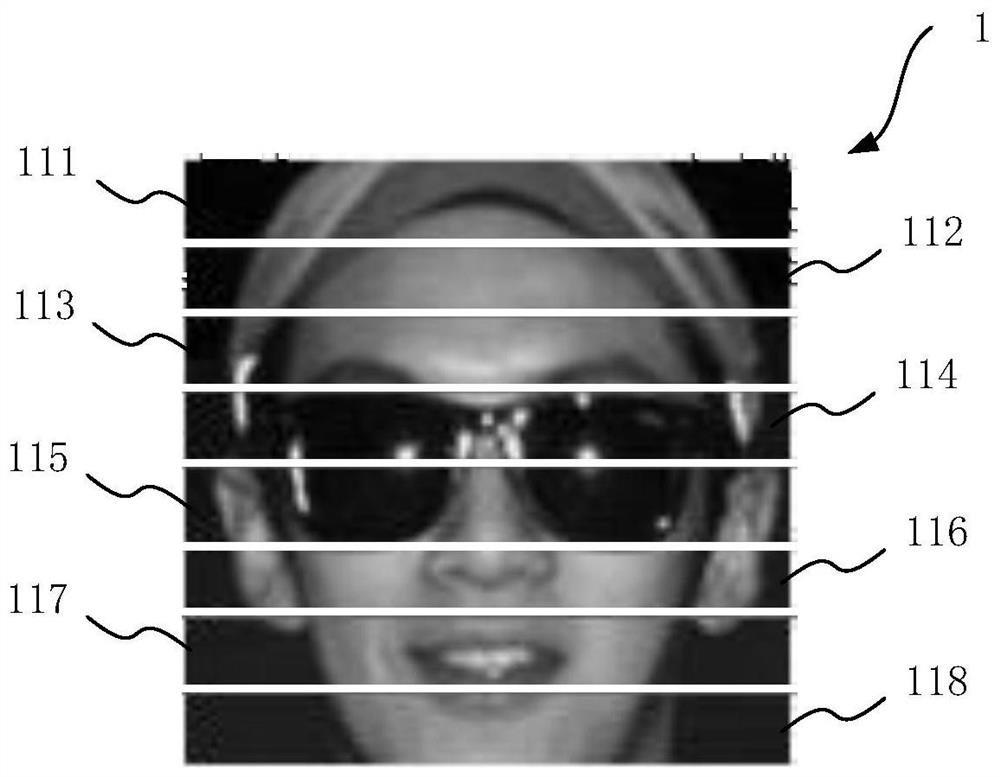

Face recognition method, medium and electronic equipment

PendingCN111814603AReduce or even eliminate the impactImprove accuracyCharacter and pattern recognitionNeural architecturesFeature vectorRadiology

The invention provides a face recognition method, a medium and electronic equipment. The face recognition method comprises the steps: acquiring a first image and a second image; obtaining a public non-occlusion area of the first image and the second image; obtaining a first feature vector according to a public non-occlusion area in the first image; obtaining a second feature vector according to apublic non-occlusion area in the second image; and obtaining the similarity between the first image and the second image according to the first feature vector and the second feature vector, and obtaining a face recognition result according to the similarity. According to the face recognition method, the accuracy of face recognition can be improved.

Owner:WINNER TECH CO INC

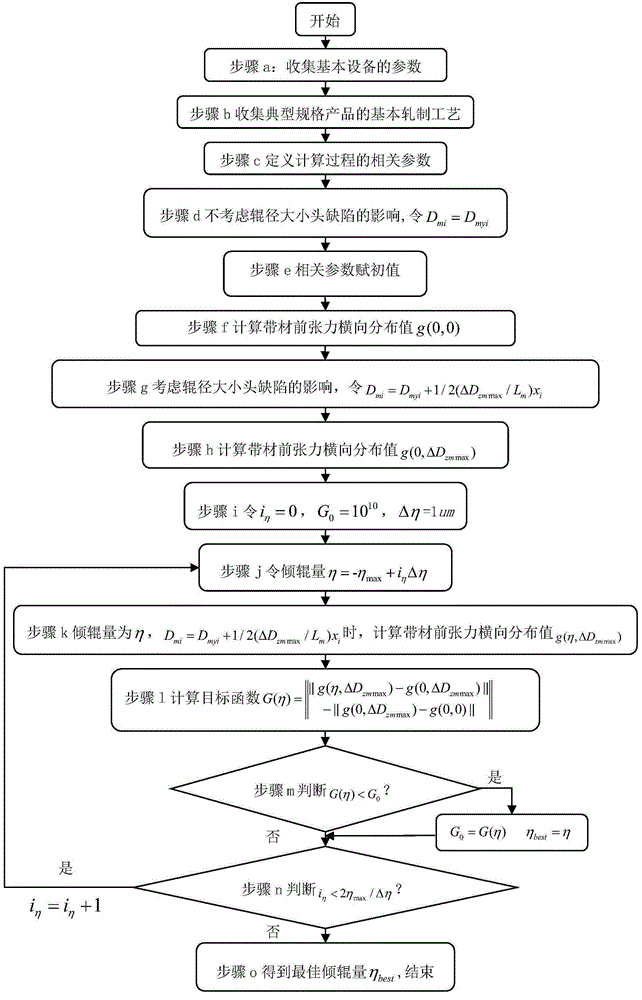

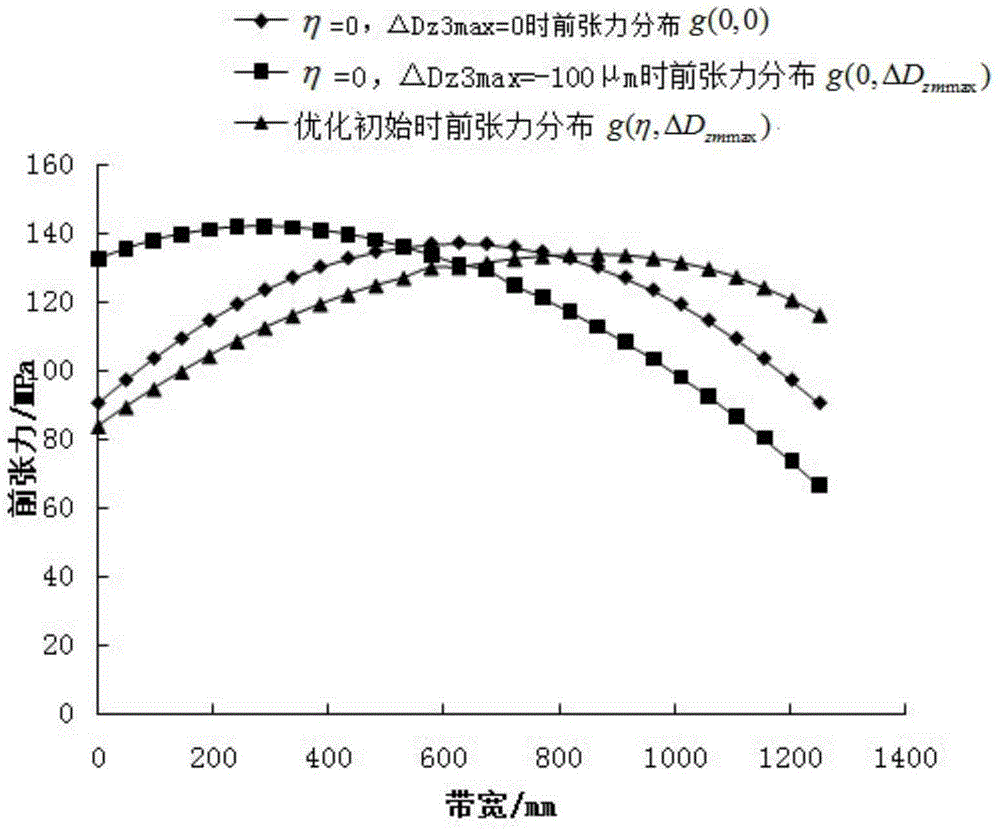

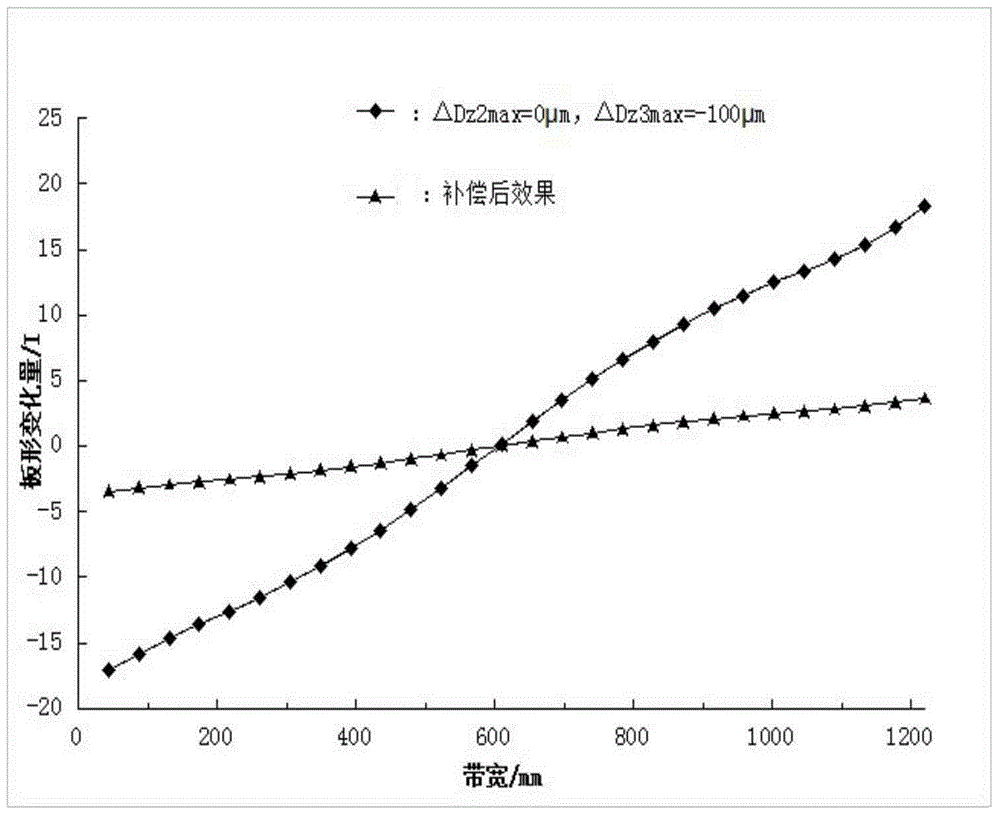

Roller taper defect treatment method for four-high rolling mill

InactiveCN104525579AAchieving Quantitative CompensationReduce or even eliminate the impactMetal rolling stand detailsProfile control deviceBending forceObject function

A roller taper defect treatment method for a four-high rolling mill mainly includes the following steps executed by a computer of 1 collecting basic device parameters; 2 collecting basic rolling process parameters of products of typical specifications; 3 defining an optimal roller inclining calculation process variable, a roller inclining amount, a roller inclining optimal step size, an objective function, an initial value of the objective function, a working roller channeling amount, a working roller bending force and an optimal roller inclining amount; 4 calculating the working roller channeling amount, the working roller bending force, the roller inclining amount and lateral distribution values of front tension of strips at an outlet of the rolling mill; 5 calculating the objective function; 6 completing the calculation after obtaining the roller inclining amount. The roller taper defect treatment method for the four-high rolling mill can achieve quantitative compensation for roller taper defects, minimizes or even eliminates the impact of the roller taper defects on the shape of the strips, solves the problem that the treatment of strip shape defects caused by roller taper is almost entirely dependent on experience of field operators and improves the accuracy quality of rolled strips.

Owner:山东冠洲股份有限公司

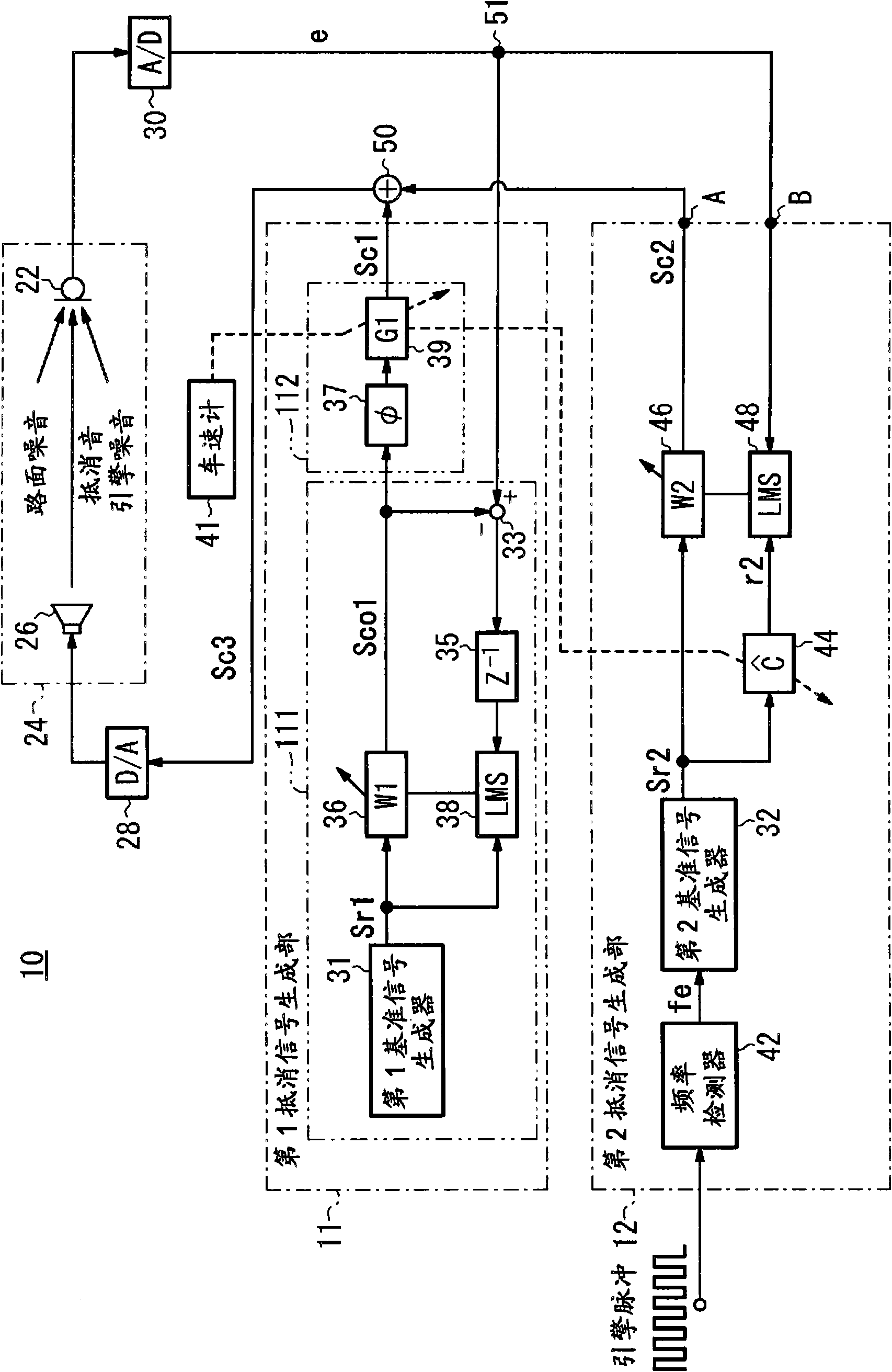

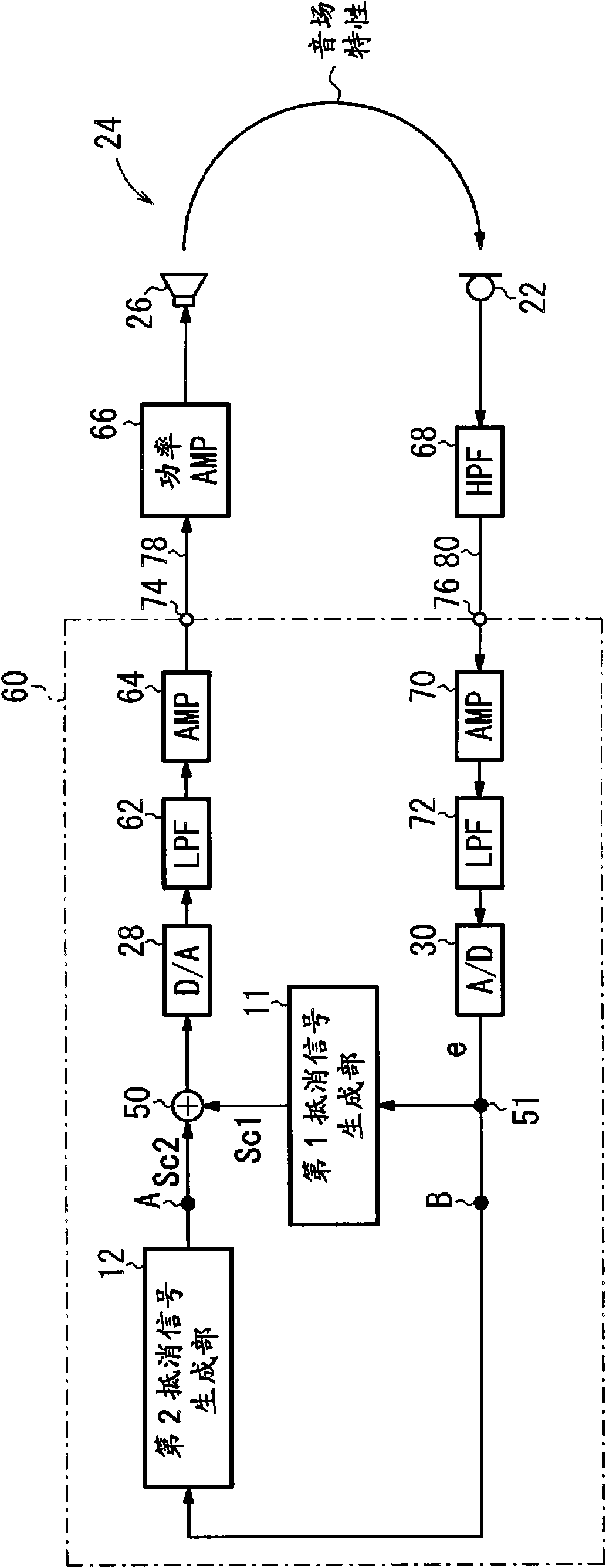

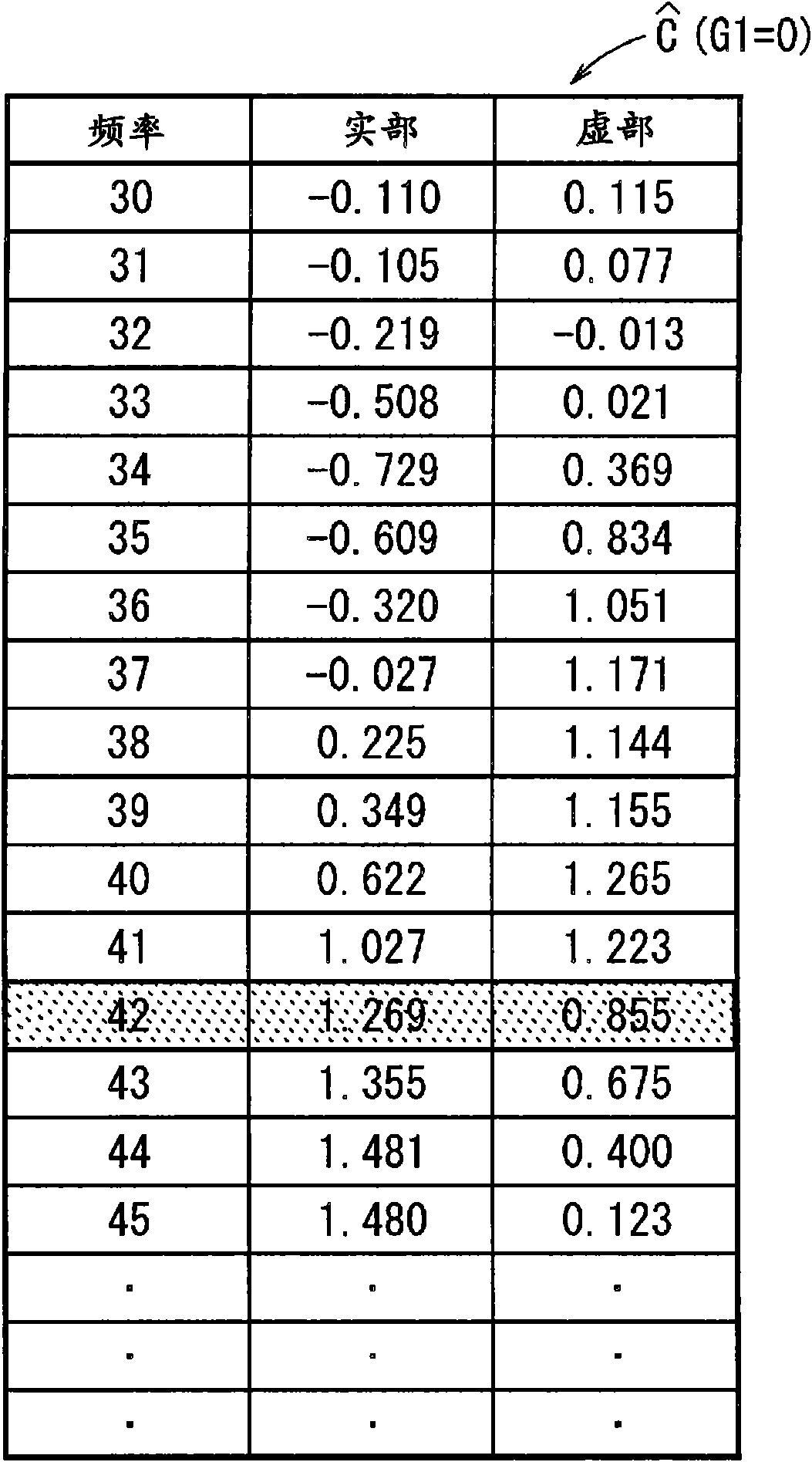

Active vibration/noise control device

ActiveCN102046426AReduce or even eliminate the impactEliminate the effects ofVehicle componentsSound producing devicesNoise generationNoise control

An active vibration / noise control device which is provided with a plurality of cancel signal generation parts for generating output signals for respectively cancelling noises generated at a plurality of vibration / noise generation sources. The effect of the suspension of either of first and second cancel signal generation parts (11, 12) on the other is reduced. According to the operating state (a gain G1 is 0 or 1) of the first cancel signal generation part (11), the simulated transmission properties (C^) of the second cancel signal generation part (12) are adjusted. Consequently, without regard to the operating state of the first cancel signal generation part (11), the noise control performance of the second cancel signal generation part (12) can be maintained.

Owner:HONDA MOTOR CO LTD

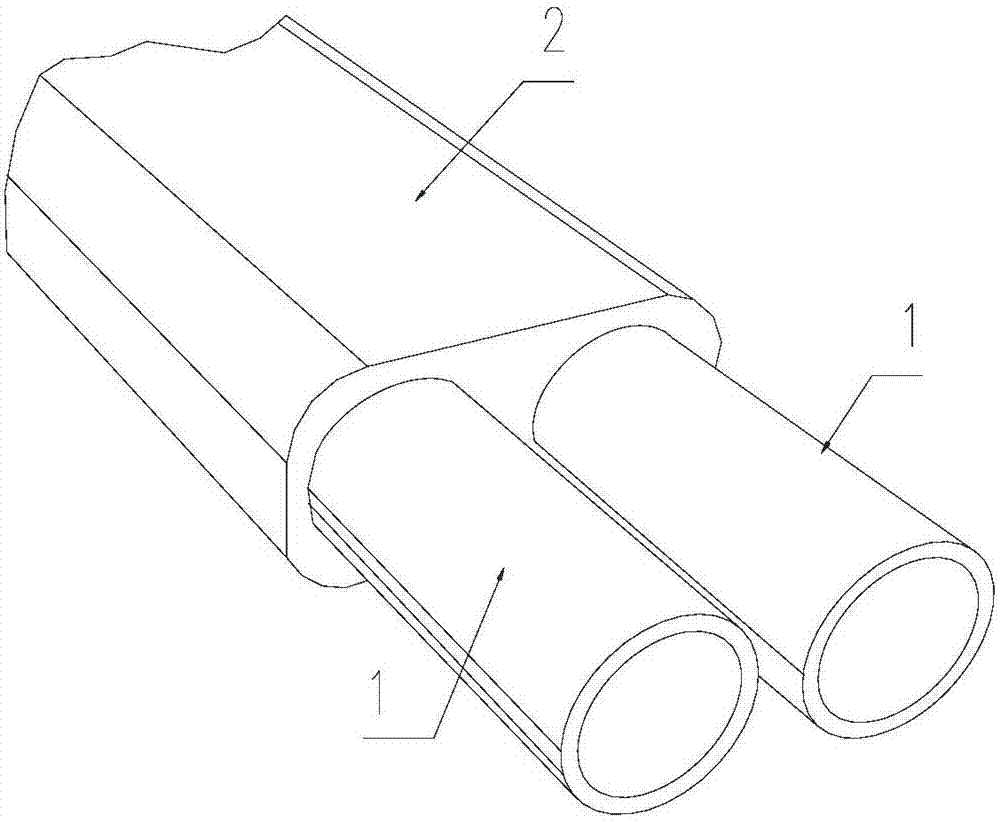

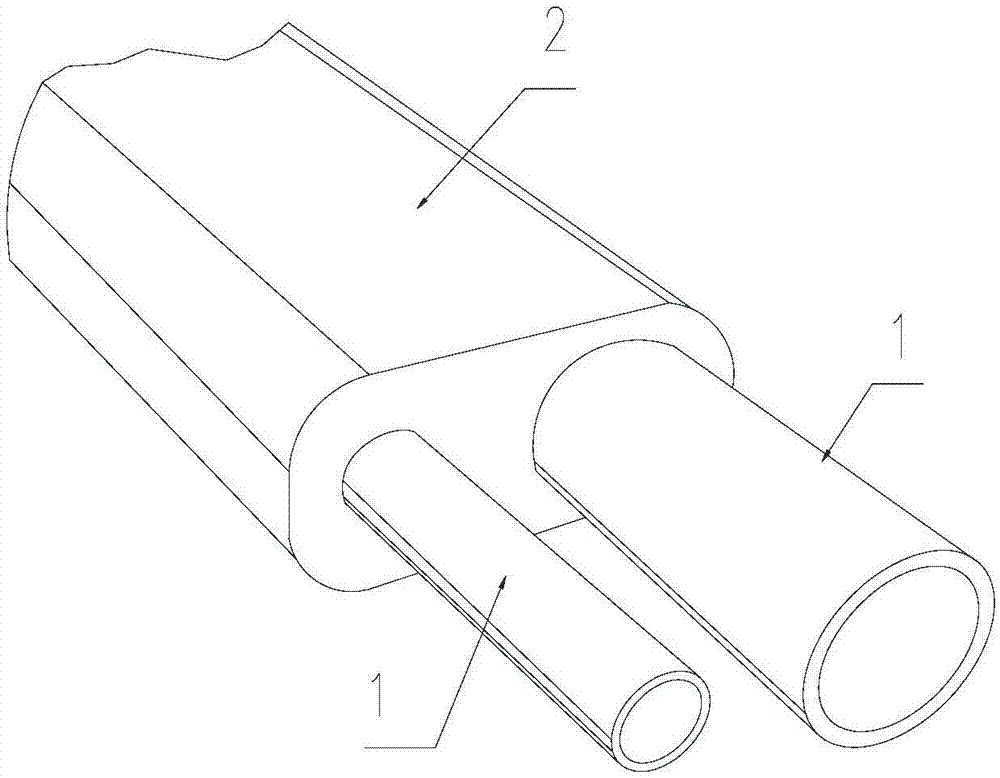

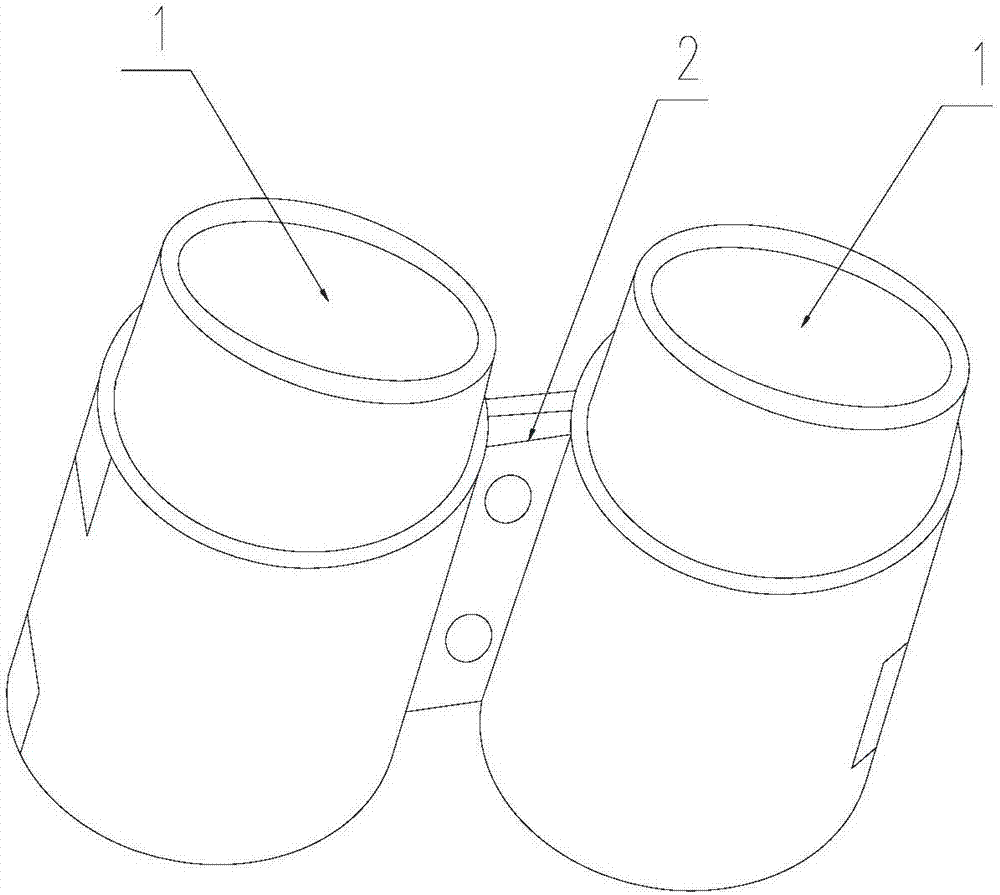

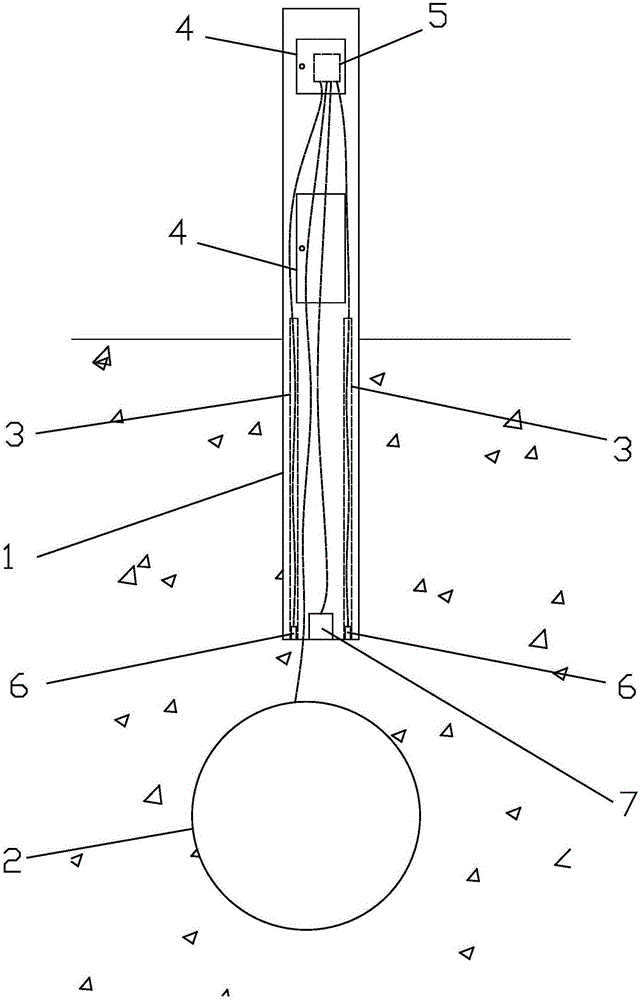

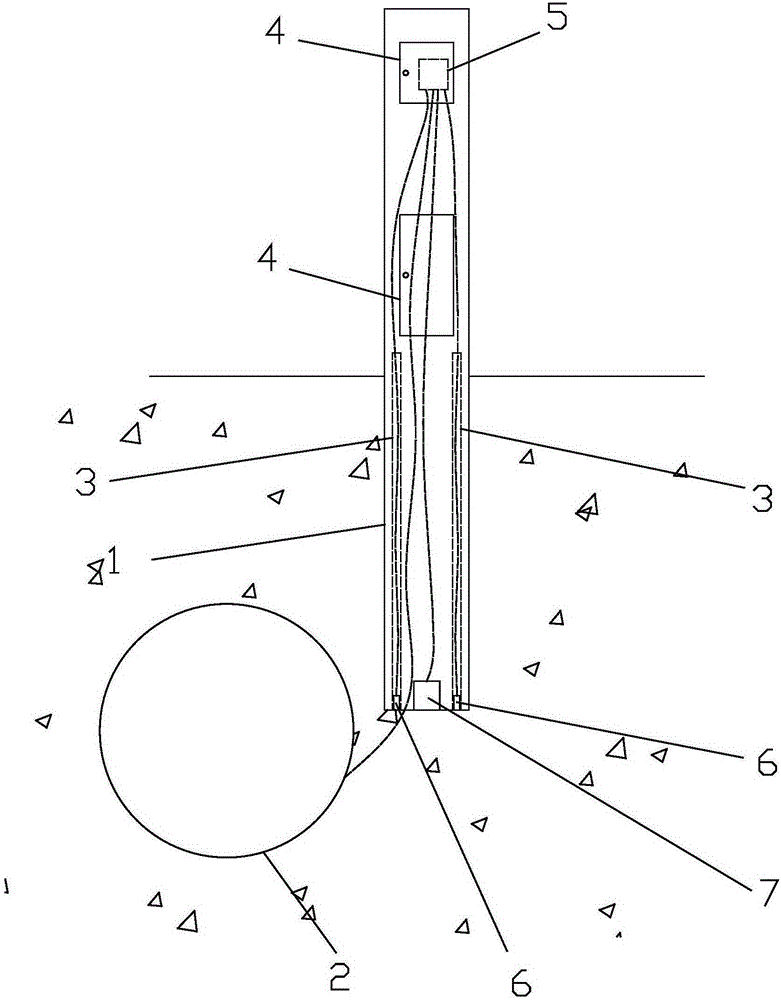

Flux tube device and flux tube conveying device for underground coal gasification

PendingCN107956464AReduce negative impactReduce or even eliminate the impactConstructionsCoal gasificationThermodynamicsCoiled tubing

The invention discloses a flux tube device and flux tube conveying device for underground coal gasification. The flux tube device comprises at least two coiled tubings and further comprises a fixing member. A number of coiled tubings are connected in parallel to the fixing member, the axes of the coiled tubings are arranged in parallel, and a predetermined gap is reserved between the outer walls of any two adjacent coiled tubings. According to the flux tube device and flux tube conveying device for the underground coal gasification, the coiled tubings are arranged in parallel, and the predetermined gap is reserved between the adjacent coiled tubings, so that influences on other coiled tubings are reduced or even eliminated when different coiled tubings are deformed in different amplitudes,thereby reducing or even eliminating negative effects of normal operations.

Owner:XINJIANG GUOLIHENG CLEAN ENERGY TECH CO LTD

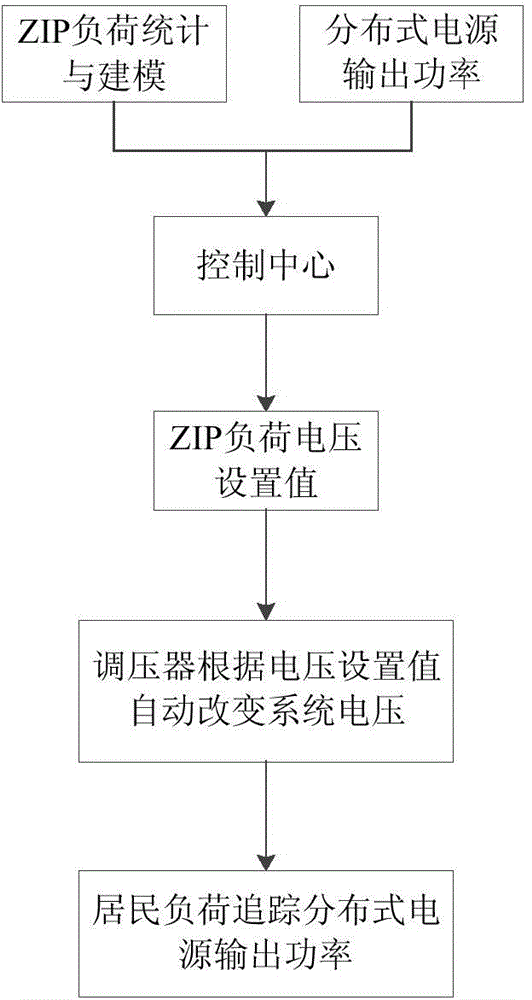

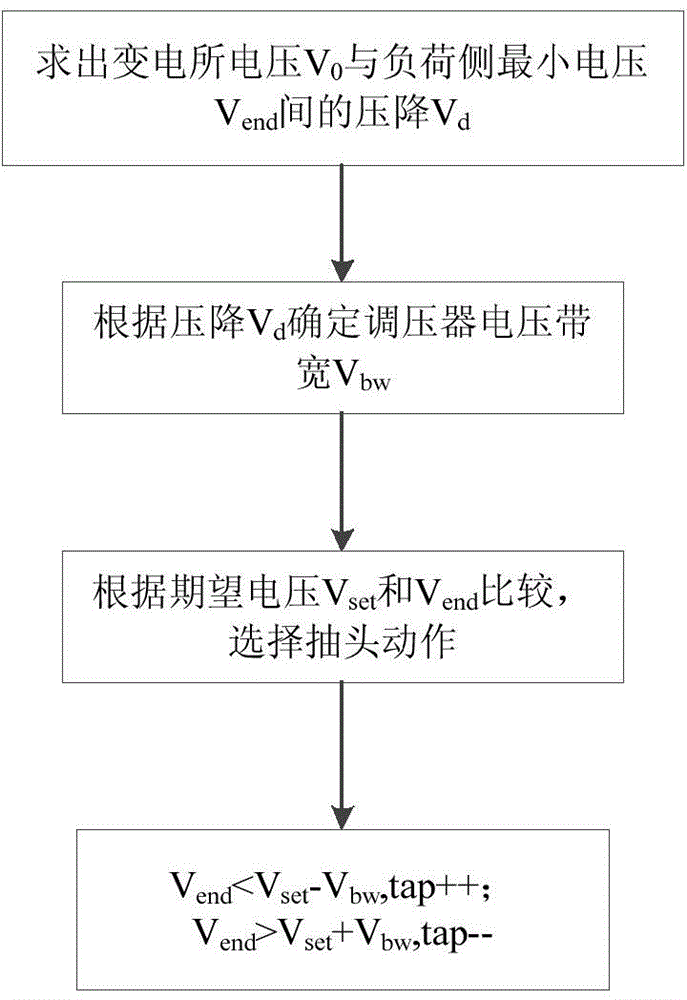

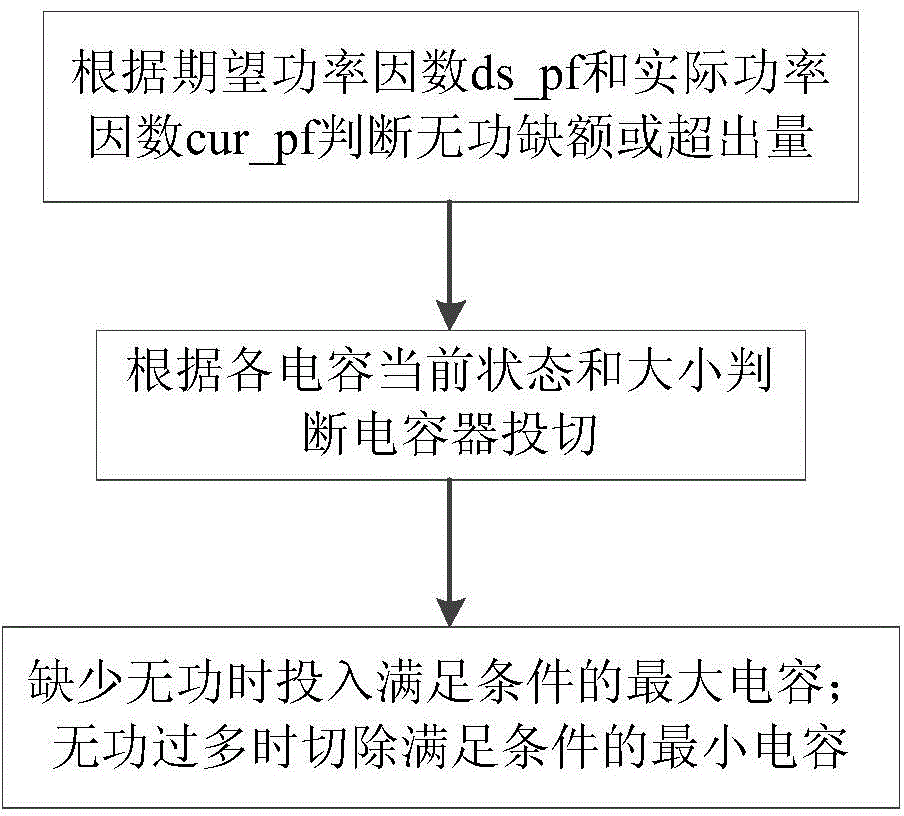

Load control method for stabilizing fluctuation of distributed power supply

ActiveCN104882903AGood effectRealize coordinated controlSingle network parallel feeding arrangementsPower oscillations reduction/preventionLoad modelPower grid

The invention relates to a load control method for stabilizing fluctuations of a distributed power supply. The load control method comprises the steps of: determining static load information, and establishing a static load model; determining output power of the distributed power supply; determining static load voltage set value; and tracing the output power of the distributed power supply. The load control method traces output of the distributed power supply through changing load magnitude by adjusting voltage, so as to reduce even eliminate adverse effects of output power fluctuations of the distributed power supply on a power grid. The load control method focuses on active and reactive joint optimization of the power system, has broad application prospect, and has a certain guiding significance to the intelligent development of the power grid.

Owner:STATE GRID CORP OF CHINA +2

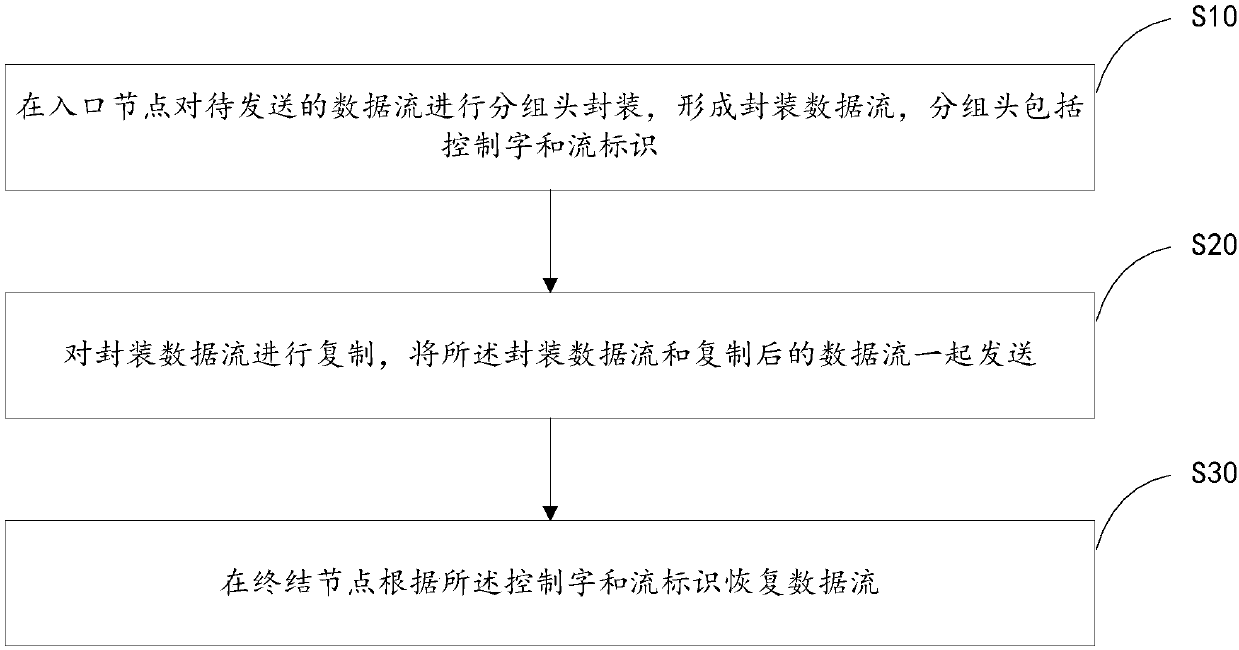

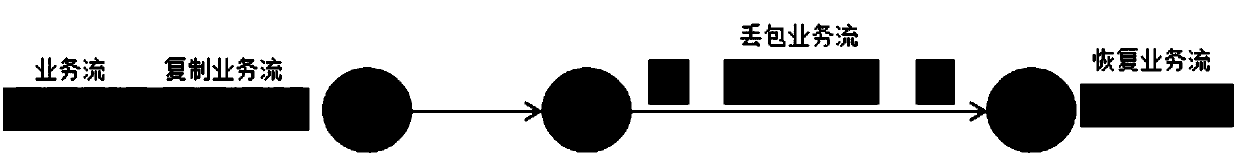

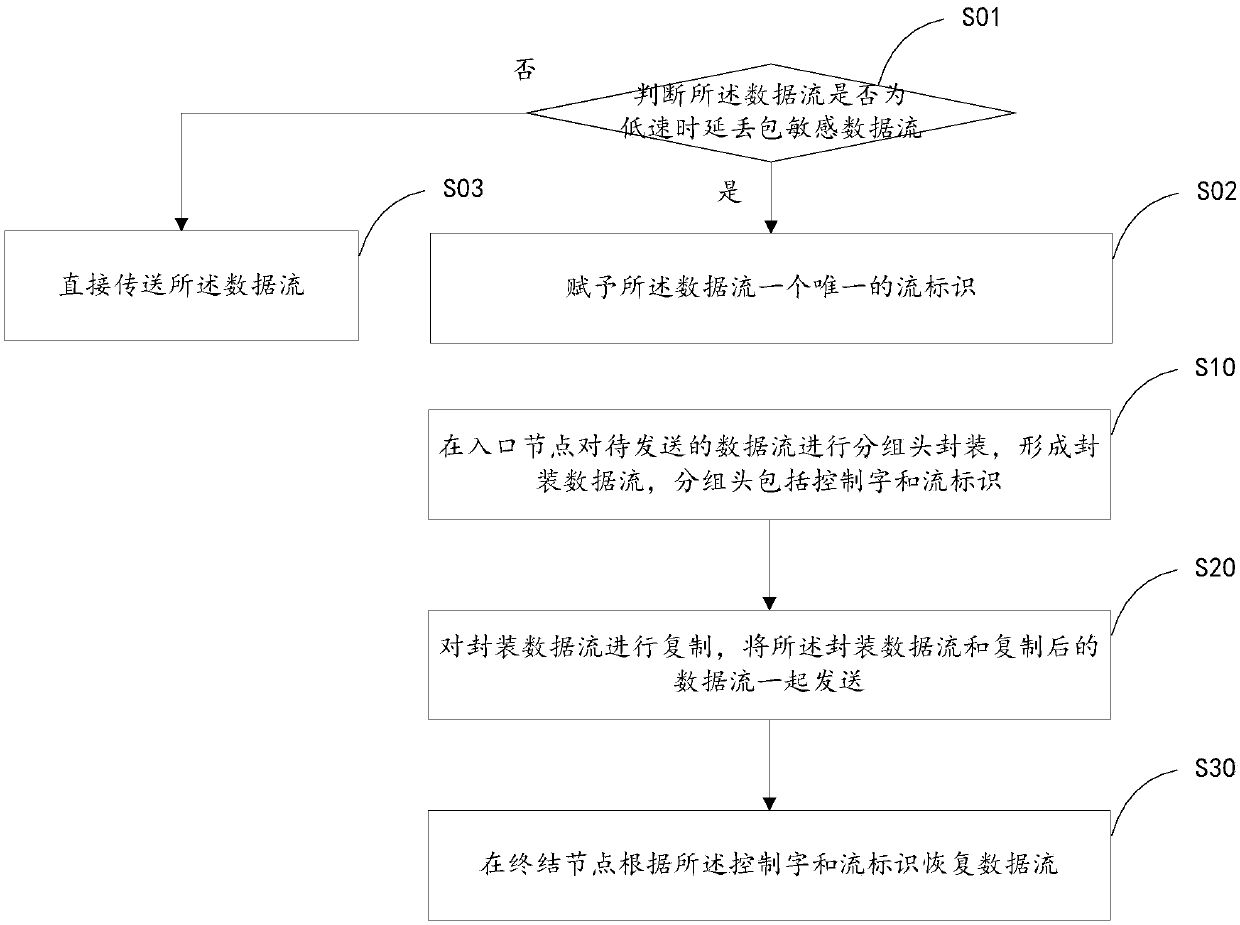

Data sending protection method, device and system and computer readable storage medium

ActiveCN110417707AReduce or even eliminate the impact of packet loss eventsReduce or even eliminate the impactChannel coding adaptationTransmitted data organisation to avoid errorsLow speedData stream

The invention discloses a data sending protection method, device and system and a computer readable storage medium, and belongs to the technical field of communication, the method comprises the following steps: performing packet header encapsulation on a to-be-sent data stream at an entry node to form an encapsulated data stream, wherein a packet header comprises a control word and a stream identifier; copying the packaged data stream, and sending the packaged data stream and the copied data stream together; recovering the data flow at the end node according to the control word and the flow identifier. The data flow of the low-speed deterministic network service is subjected to same-path redundant replication, so that the influence of a packet loss event is reduced or even eliminated, andthe service delay is reduced.

Owner:ZTE CORP

Polarizer, display panel and preparation method of display panel

ActiveCN110275239AReduce forceReduce or even eliminate the impactStatic indicating devicesPolarising elementsCrystallographyLiquid-crystal display

The invention discloses a polaroid, a display panel and a preparation method of the display panel. The polaroid comprises a first liquid crystal layer and a second liquid crystal layer which are stacked, wherein the first liquid crystal layer is formed in front of the second liquid crystal layer, and the polarity of first liquid crystal molecules in the first liquid crystal layer is less than that of the first liquid crystal molecules in a natural state. In this way, the influence of the first liquid crystal layer on the second liquid crystal layer in the polaroid can be reduced.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Door and window frame installing method

The door and window frame installing method includes the steps of: machining vertical stile, decorating bar, rim and other parts; assembling and fixing vertical stile; driving wooden wedges into wall, jetting expanding glue between the vertical stile and the wooden wedges; installing decorating bar; and supporting and positioning until the glue becomes dry. The said construction process uses factory fabricated parts, and has the features of simple construction process, no noise, etc.

Owner:任建国

Multi-node cooperative interference and secure spectrum sensing method in spectrum sensing

ActiveCN106254004APerceived performance is goodImprove reliabilityTransmission monitoringCognitive networkComputer science

The invention discloses a multi-node cooperative interference and secure spectrum sensing method in spectrum sensing. In the multi-node cooperative interference method, a current sensing environment and an interference target are learnt by nodes, an optimal interference strategy is selected, the execution of the interference strategy is monitored in real time and is adjusted in real time, and the cooperative interference of PUEA and SSDF is fully used to increase the interference success probability. Meanwhile, the invention further discloses a secure spectrum sensing method used in a PUEA and SSDF cooperative interference environment. Trusted SU and untrusted SU are distinguished by identity identification values, and based on a sensing result of the trusted SU to a previous sensing time slot of a PU signal, the identity identification value of the SU of the next sensing time slot is modulated in real time to determine the SU that can enter a merging state of FC. By adopting the secure spectrum sensing method disclosed by the invention, in a comprehensive and complex sensing environment where PUEA and SSDF coexist, the influence of the PUEA and SSDF can be reduced and even eliminated at the same time, so that the entire sensing network keeps better sensing performance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

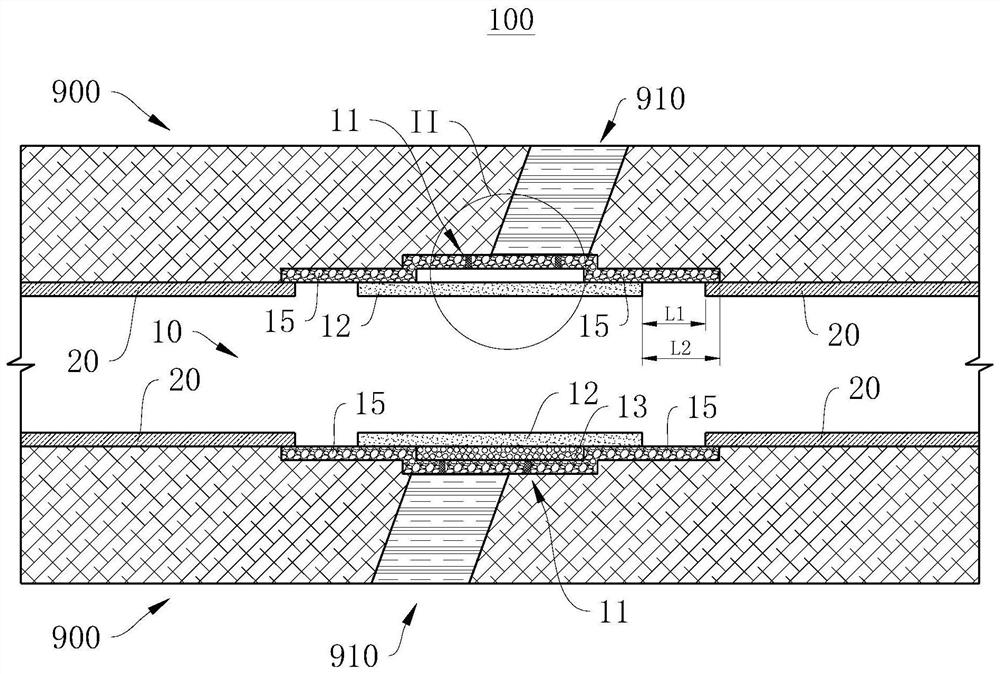

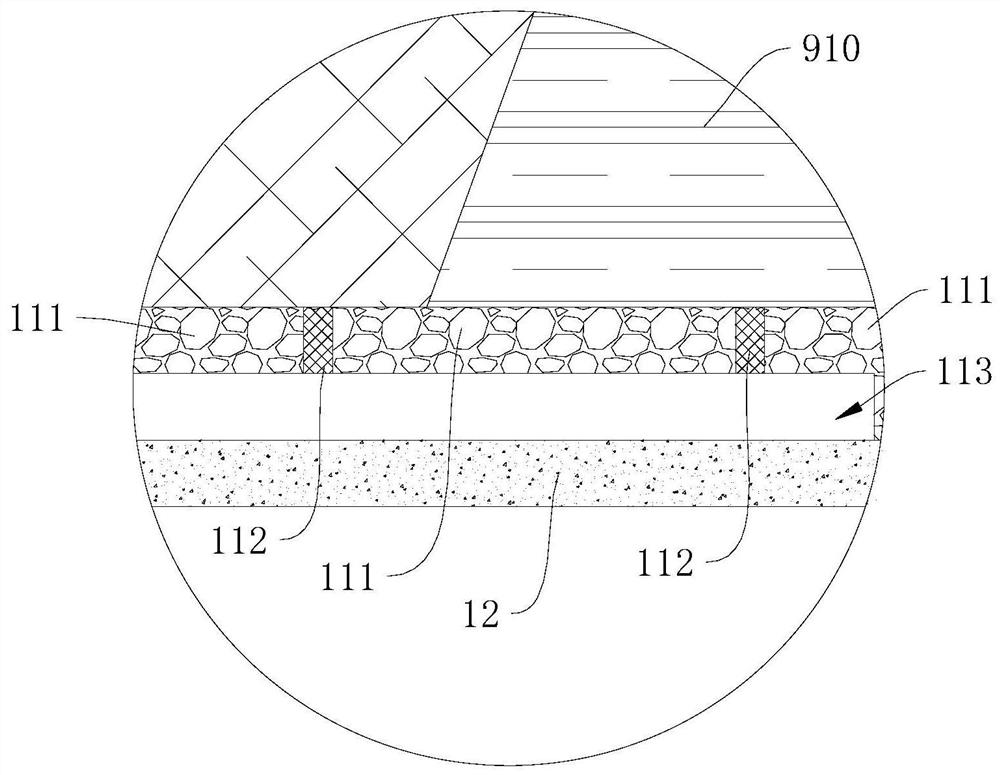

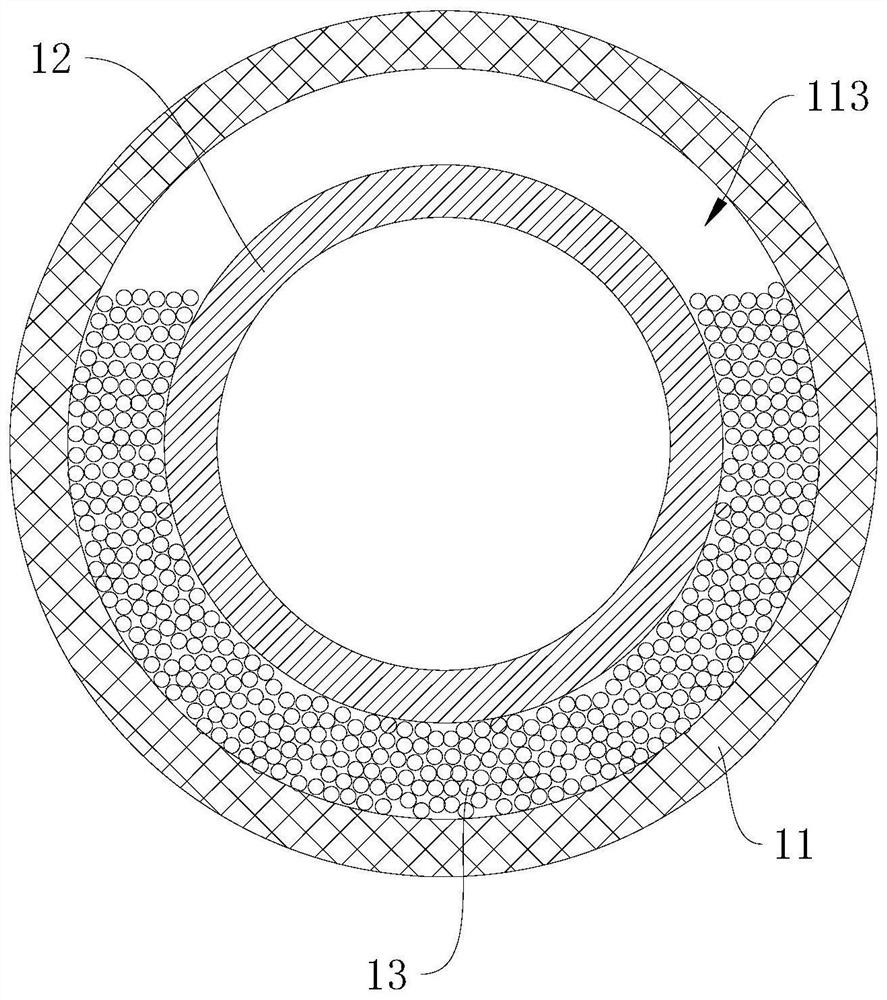

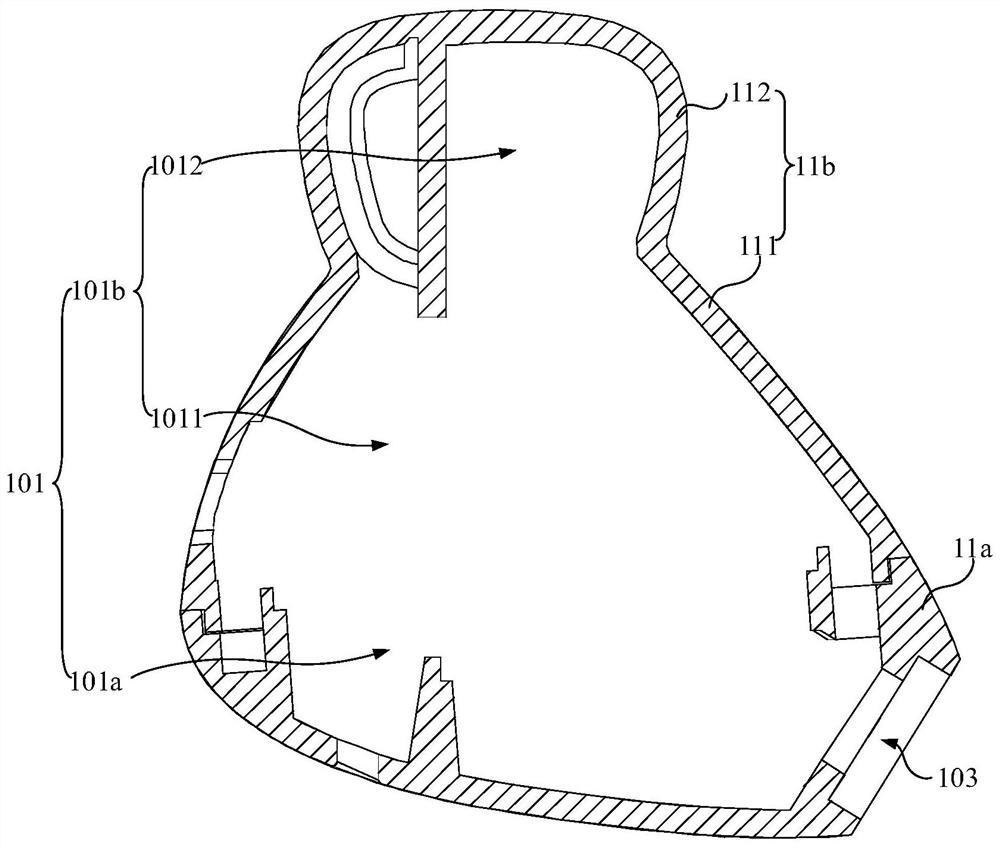

Tunnel supporting structure

PendingCN113338999AGuarantee normal useEasy to useUnderground chambersTunnel liningActive fault zoneShearing deformation

The invention discloses a tunnel supporting structure, and relates to the technical field of tunnel supporting. The tunnel supporting structure comprises an outer-layer lining, an inner-layer lining and a filling material, wherein, The outer side face of the outer layer lining is used for corresponding to an active fault zone of surrounding rock and is arranged on the inner layer lining in a sleeving mode, and the filling material is steel beads and is arranged between the outer layer lining and the inner layer lining. The tunnel supporting structure can adapt to large-scale shear deformation and tension, compression, bending, shear and torsion combined deformation, and the inner layer lining of the tunnel structure cannot be damaged by slab faulting after an earthquake.

Owner:SOUTHWEST JIAOTONG UNIV

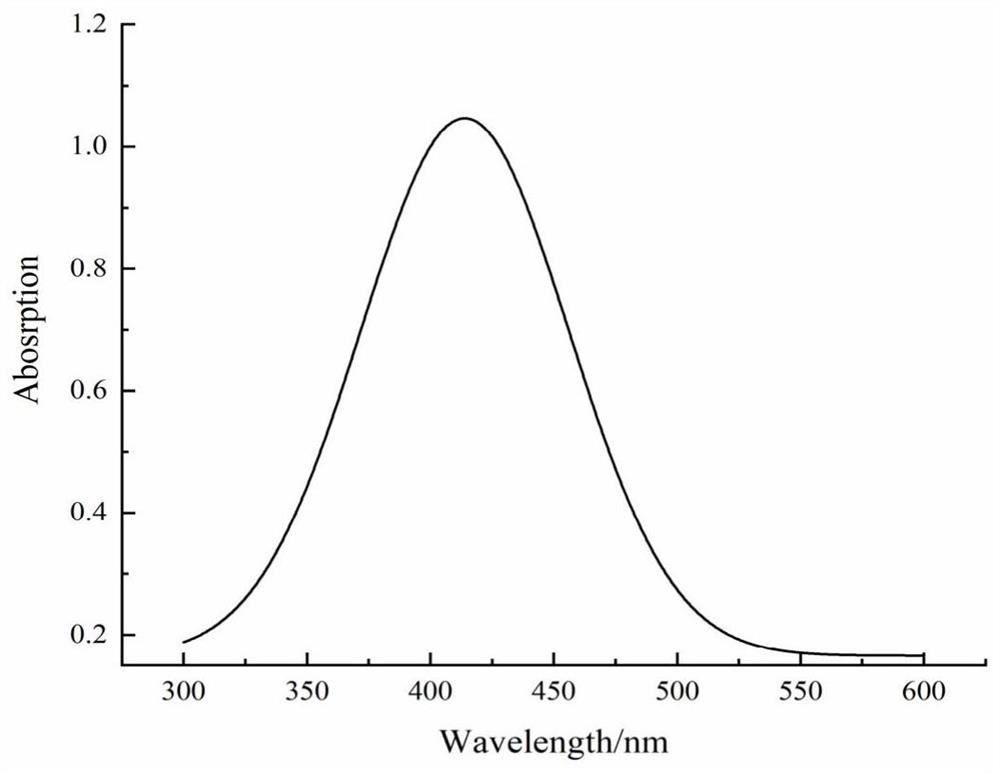

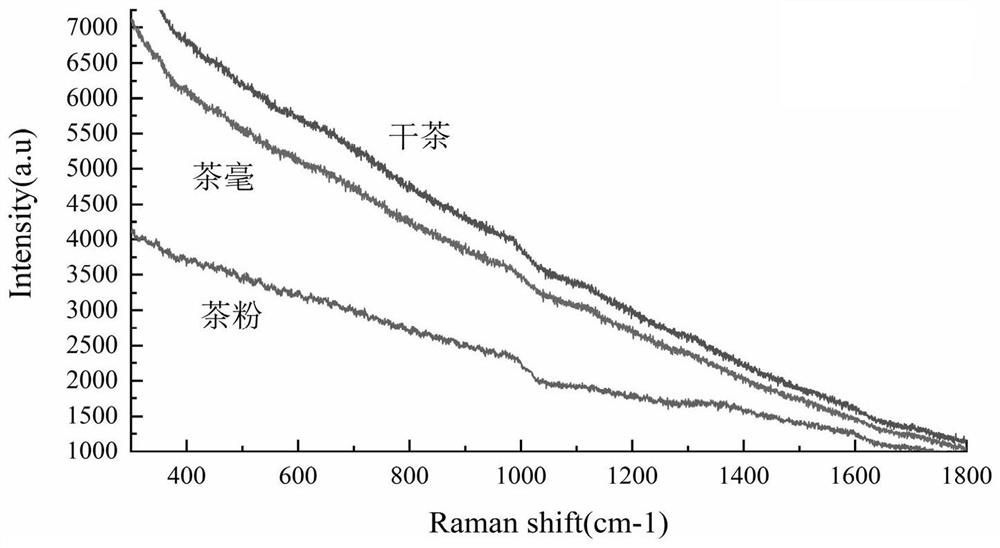

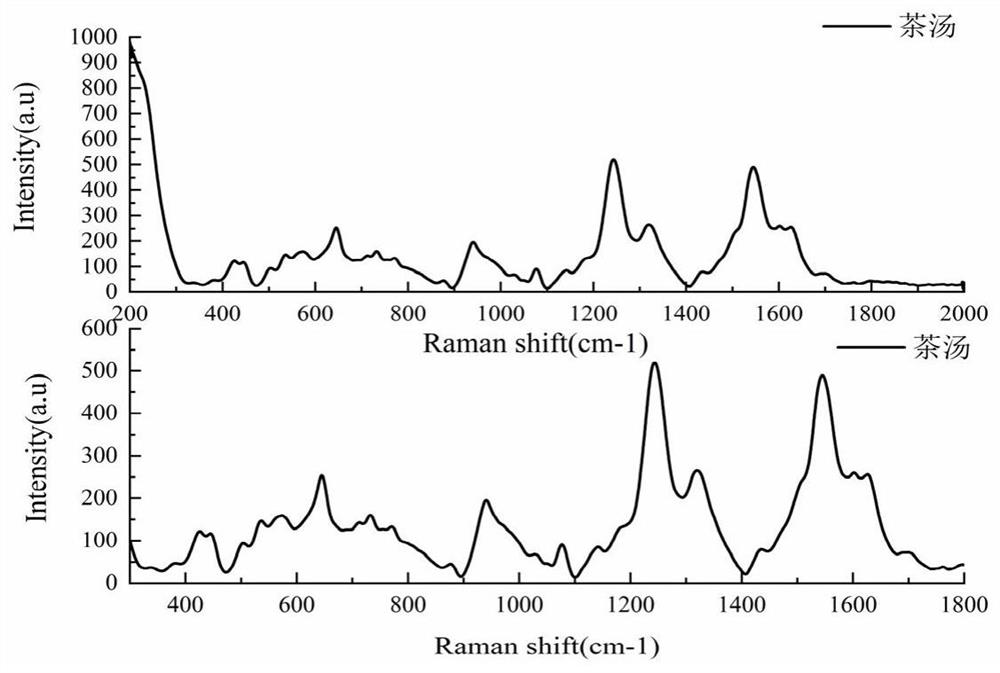

Method for judging freshness of green tea based on Raman spectrum

PendingCN113049571AThe pretreatment method is simpleKeep styleRaman scatteringPretreatment methodGreen teas

The invention discloses a method for discriminating the freshness of green tea based on Raman spectroscopy and relates to the field of tea quality discriminating. The method comprises the following steps of 1, the boiling water being added into the green tea, and the green tea being covered and placed in a water bath kettle at the temperature of 70-100 DEG C for water bath; the ratio of the mass of the green tea to the volume of the boiling water being (1-3): (50-100); (2) preparing nano-silver colloid; (3) mixing the tea soup with nano-silver colloid in an equal amount, dripping the mixture on a glass slide, air-drying the mixture, and performing Raman detection in a collection range of 300-1800cm<-1>; and (4) carrying out baseline removal and smoothing pretreatment on the Raman spectrum, then carrying out OPLS-DA analysis on data, and carrying out discrimination according to spectral difference. Compared with the prior art, the method is advantaged in that the tea soup is simply brewed and used for Raman detection, then freshness of the green tea is judged, the sample pretreatment method is simple, the most original style of the tea soup is reserved, and the method can be widely applied to the fields of tea quality identification and the like.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Deodorizing method and deodorizing device used for municipal household refuse-derived fuel production

InactiveCN105107003AReduce or even eliminate the impactThoroughly deodorizedSolid waste disposalAtomized substancesRefuse-derived fuelEnvironmental engineering

The invention relates to designing of refuse treatment equipment, in particular to a deodorizing method and deodorizing device used for municipal household refuse-derived fuel production, and aims to solve the problem of influence on surrounding environment caused by stink generated in the process of RDF production. The deodorizing method includes: deodorizing stink generated by municipal household refuse in a refuse discharging area, a refuse storing pit, a primary refuse smashing area, a refuse screening area, a refuse winnowing area and a secondary smashing area by which the municipal household refuse passes. By the deodorizing method and the deodorizing device, deodorizing is realized more thoroughly, and influence, on the surrounding environment, of stink is reduced and even eliminated.

Owner:HUNAN VARY TECH

P-N junction manufacturing technology of solar cell

InactiveCN110265293AAdd depthReduce peakFinal product manufactureSemiconductor/solid-state device manufacturingManufacturing technologySilicon solar cell

The invention belongs to the manufacturing field of crystalline silicon solar cells, and particularly relates to a P-N junction manufacturing technology of a solar cell. By using P-N junctions manufactured by a tubular high temperature diffusion annealing furnace, oxygen precipitations close to a surface are flown over under the effect of oxygen at low temperature by using a certain temperature variation. According to the manufacturing technology, the probability of hole electron recombination can be reduced under the light condition of the P-N junctions, then redistributed processing of P atoms is carried out under the condition of oxygen, the peak value of P atoms distributed at a maximum concentration is reduced, and the influence of a counter potential field on Voc is reduced or even eliminated, so that the purpose of improving the efficiency is reached, and an optimal P-N junction depth applicable for a current production line is obtained through the matching of temperature and time.

Owner:江苏润阳悦达光伏科技有限公司

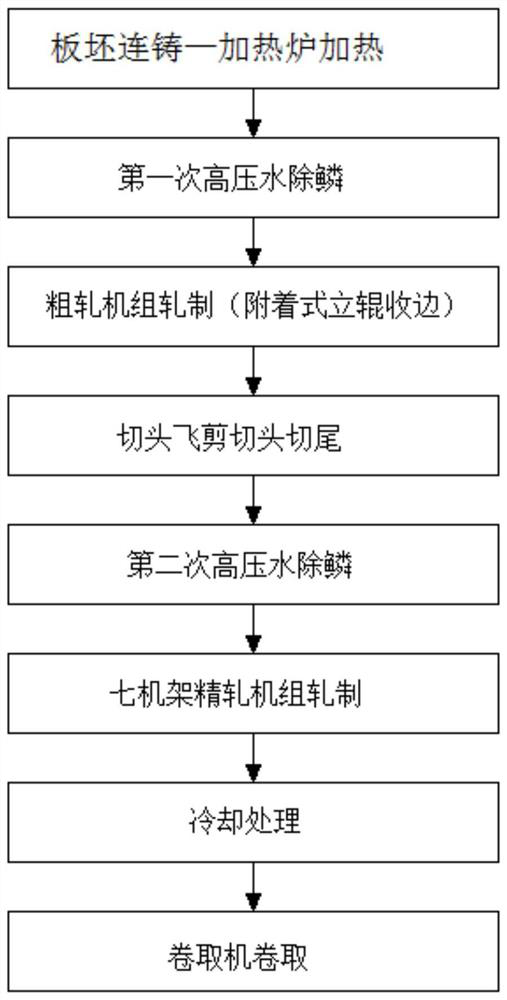

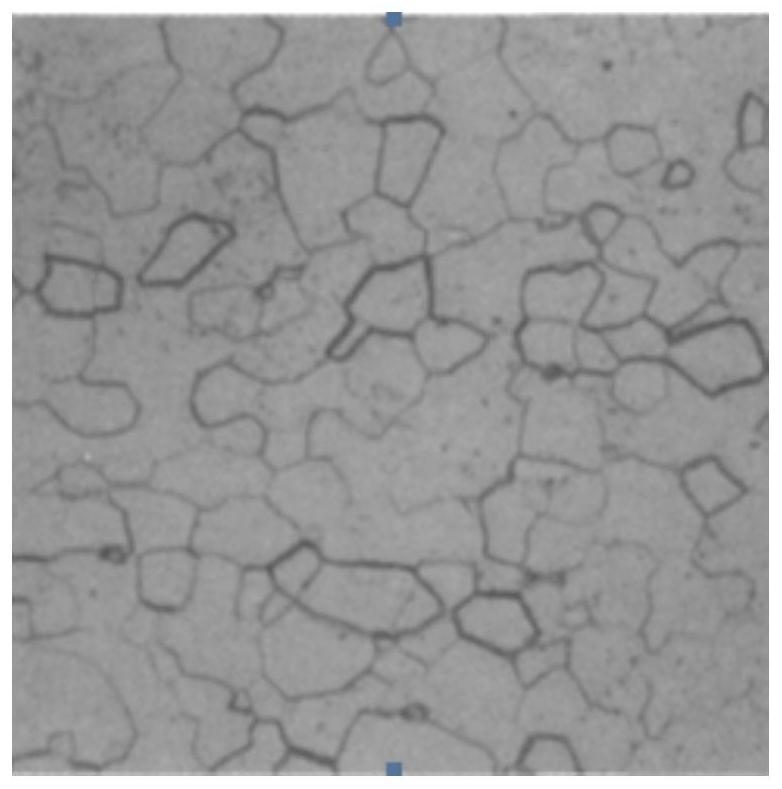

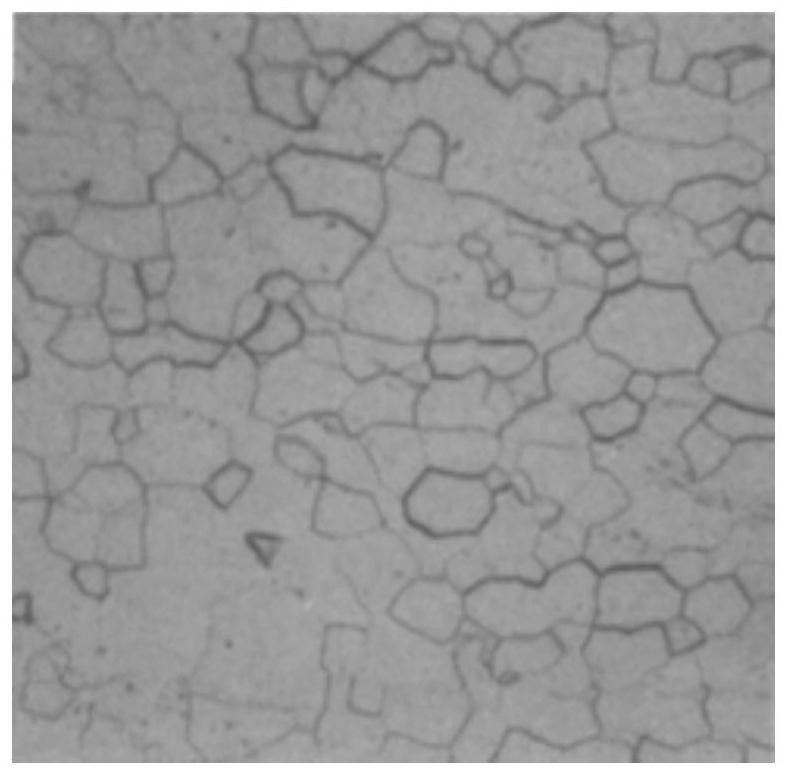

Hot rolling method for improving surface quality of steel plate

InactiveCN112692061AReduce or even eliminate the impactEliminate the effects ofTemperature control deviceRollsLaminar coolingEngineering

The invention relates to a hot rolling method for improving the surface quality of a steel plate. The hot rolling method comprises the following steps of slab continuous casting, heating furnace heating, first-time high-pressure water descaling, roughing rolling unit rolling (attached type vertical roll edge closing), head cutting flying shear head cutting and tail cutting, second-time high-pressure water descaling, seven-rack finishing rolling unit rolling, cooling treatment and coiling machine coiling, the vertical roll side pressure amount of vertical roll edge closing ranges from 15 mm to 35 mm, and cooling treatment adopts strip steel laminar cooling. Edge defects can be effectively reduced and even eliminated through vertical roll edge closing; the r value is increased, so that the formability of a strip steel is better; the roughness of a working roll of a F7 rack is improved, and the influence of grinding knife patterns on the surface of the strip steel is eliminated; working rollers from a F1 rack to a F4 rack are high-speed steel rollers, and rolling oil input is controlled, so that the surface quality of strip steel is improved, and the pressing-in defect of oxide scales is avoided; and rapid cooling can reduce the cooling difference between the edge and the core of the strip steel, and the uniformity of the structure and crystal grains of the strip steel is improved.

Owner:BENGANG STEEL PLATES

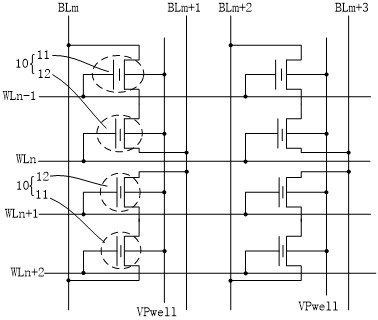

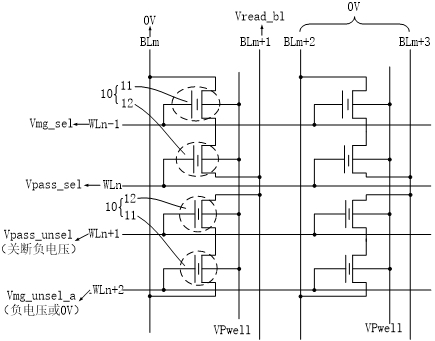

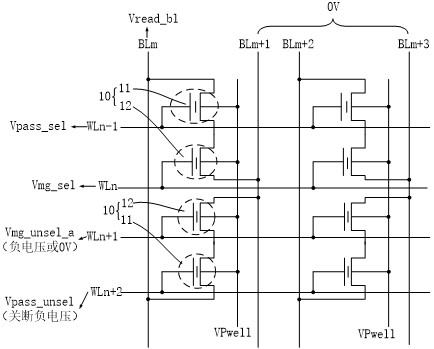

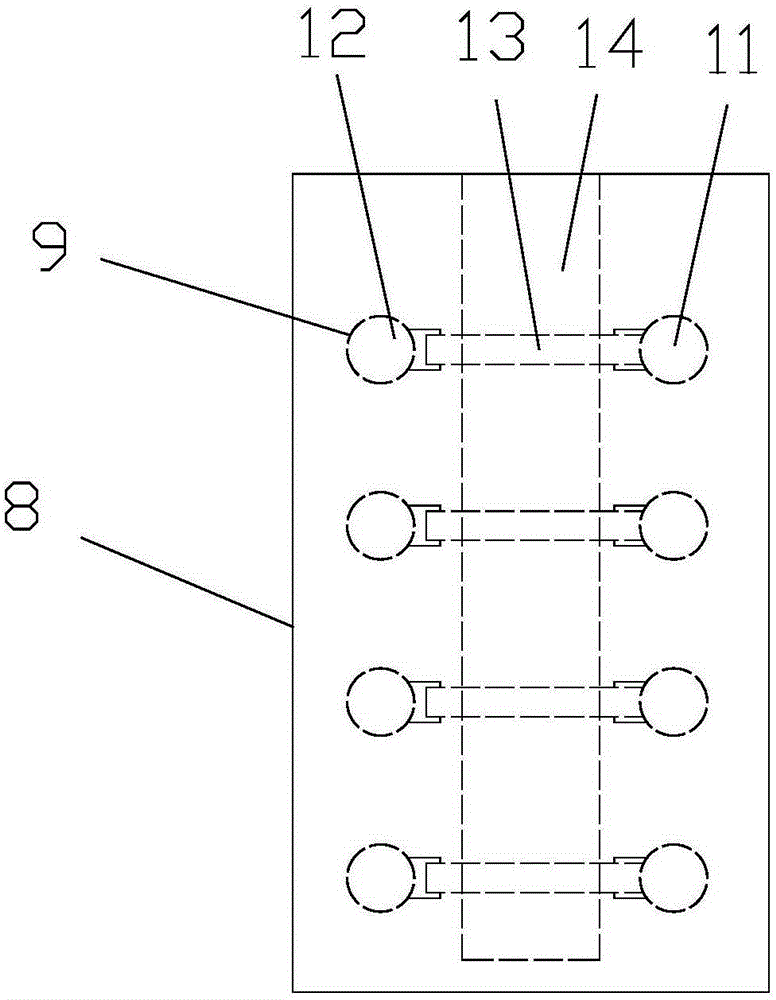

Data reading method of non-volatile memory array with pairing structure

ActiveCN114171091AReduce or even eliminate the impactShorten the timeRead-only memoriesEngineeringComputer science

According to the data reading method of the non-volatile storage array with the pairing structure, in a first data reading period, zero-volt voltage is applied to a word line of a first storage tube of a selected storage unit, and starting voltage is applied to a word line of a second storage tube of the selected storage unit; a compensation positive voltage is applied to a word line of a first storage tube of a non-selected storage unit different from the selected storage unit, and a turn-off negative voltage is applied to a word line of a second storage tube of the non-selected storage unit; in a second data reading period, zero-volt voltage is applied to the word line of the second storage tube of the selected storage unit, turn-on voltage is applied to the word line of the first storage tube of the selected storage unit, compensation positive voltage is applied to the word line of the second storage tube of the non-selected storage unit, and turn-off negative voltage is applied to the word line of the first storage tube of the non-selected storage unit. Through the cooperation of the two data reading cycles, the soft erasure effect generated by turning off the negative voltage can be compensated by compensating the soft programming effect generated by the positive voltage, so that the probability of reading interference is reduced under the condition of not increasing additional circuits and reading cycle time.

Owner:杭州领开半导体技术有限公司

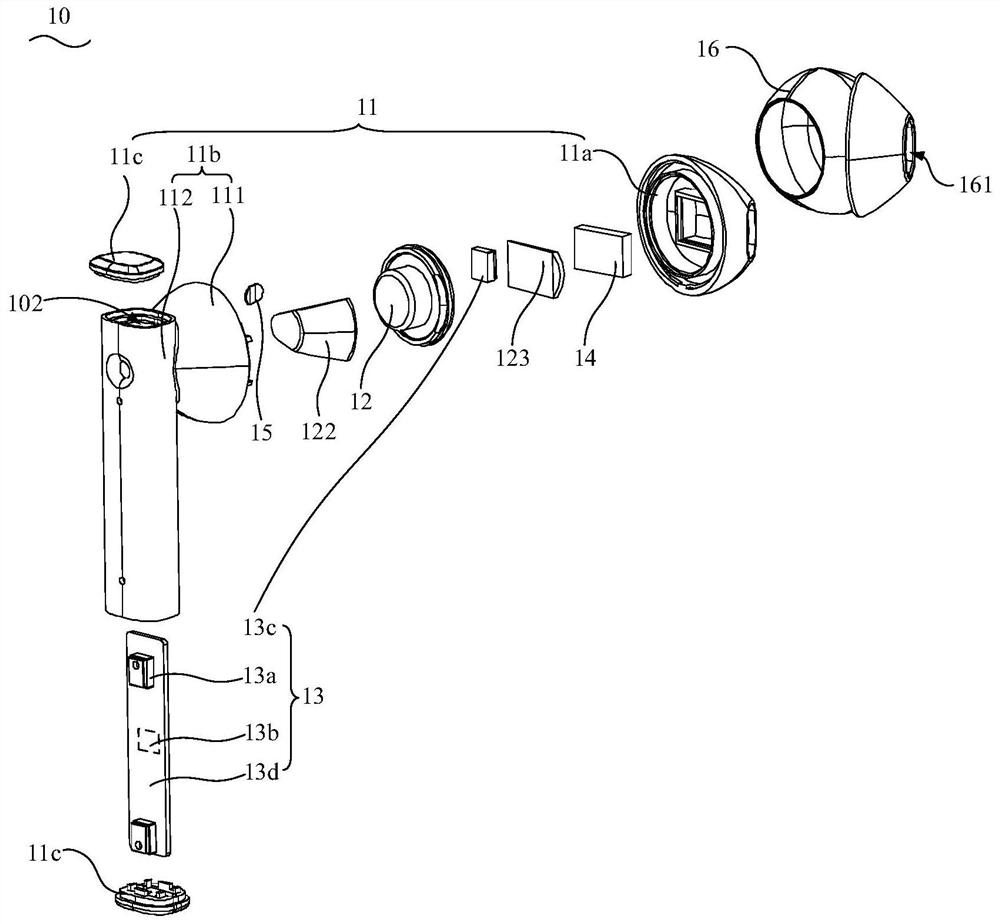

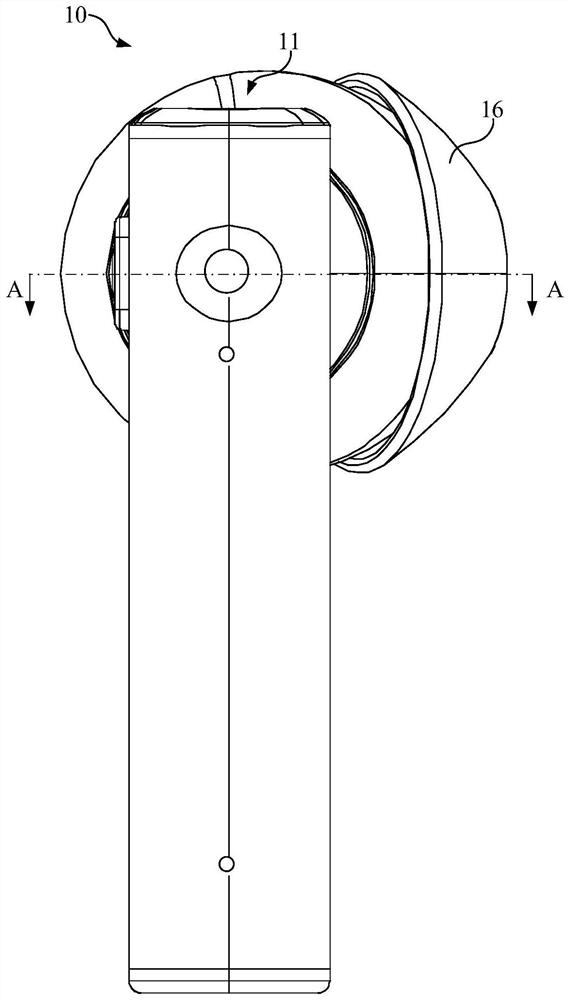

Earphone

ActiveCN112104936AImprove soundReduce or even eliminate the impactMicrophonesLoudspeakersHeadphonesNoise reduction

The invention provides an earphone which comprises a shell, a first loudspeaker and a noise reduction assembly, and is characterized in that the shell is provided with an accommodating space and a sound outlet hole communicated with the accommodating space; the first loudspeaker is arranged in the accommodating space and is used for making a sound to the sound outlet hole; the noise reduction assembly is arranged in the containing space and comprises a first microphone, a noise reduction chip and a second microphone, the first microphone and the second microphone are used for receiving external sound of the shell, and the noise reduction chip is electrically connected with the first microphone and the second microphone; therefore, noise reduction processing is carried out on the external sound to reduce or even eliminate the influence of the external sound on the pronunciation of the first loudspeaker, thereby improving the sound effect of the earphone.

Owner:SHENZHEN 3NOD ACOUSTICLINK CO LTD

Test pile and working method thereof

A test pile comprises a hollow pile body. The lower portion of the pile body is located underground, and the pile body is located above or beside an underground pipeline. A test block pipe is installed in the pile body. A cabin door is arranged on the pile body. A wiring board is installed in the pile body. A test block is installed in the test block pipe. A reference electrode is installed in the pile body. The test block, the reference electrode and the pipeline are connected with the wiring board. The lower portion of the test pile is inserted underground, the test block is installed in the test block pipe, the reference electrode is installed in the lower end of the test pile, and therefore the lower portion of the test pile can be used as a reference pipe, and it is unnecessary to additionally install a reference pipe; installation and layout are simple, and the cost of whole pipeline cathode protection engineering is also reduced. When the reference electrode is calibrated, a working electrode for calibration can be conveyed to an underground position through the test pile, the working electrode is made to be close to the reference electrode to be calibrated as much as possible, and calibration is more accurate; the reference electrode to be calibrated can also be taken out to an overground position from the underground position along an inner cavity of the test pile, the reference electrode directly gets close to the working electrode on the ground, calibration is conducted, and therefore calibration accuracy is improved; moreover, the reference electrode and the test block can be taken out from the underground position and are convenient to replace and maintain.

Owner:QINGDAO YAHE SCI & TECH DEV

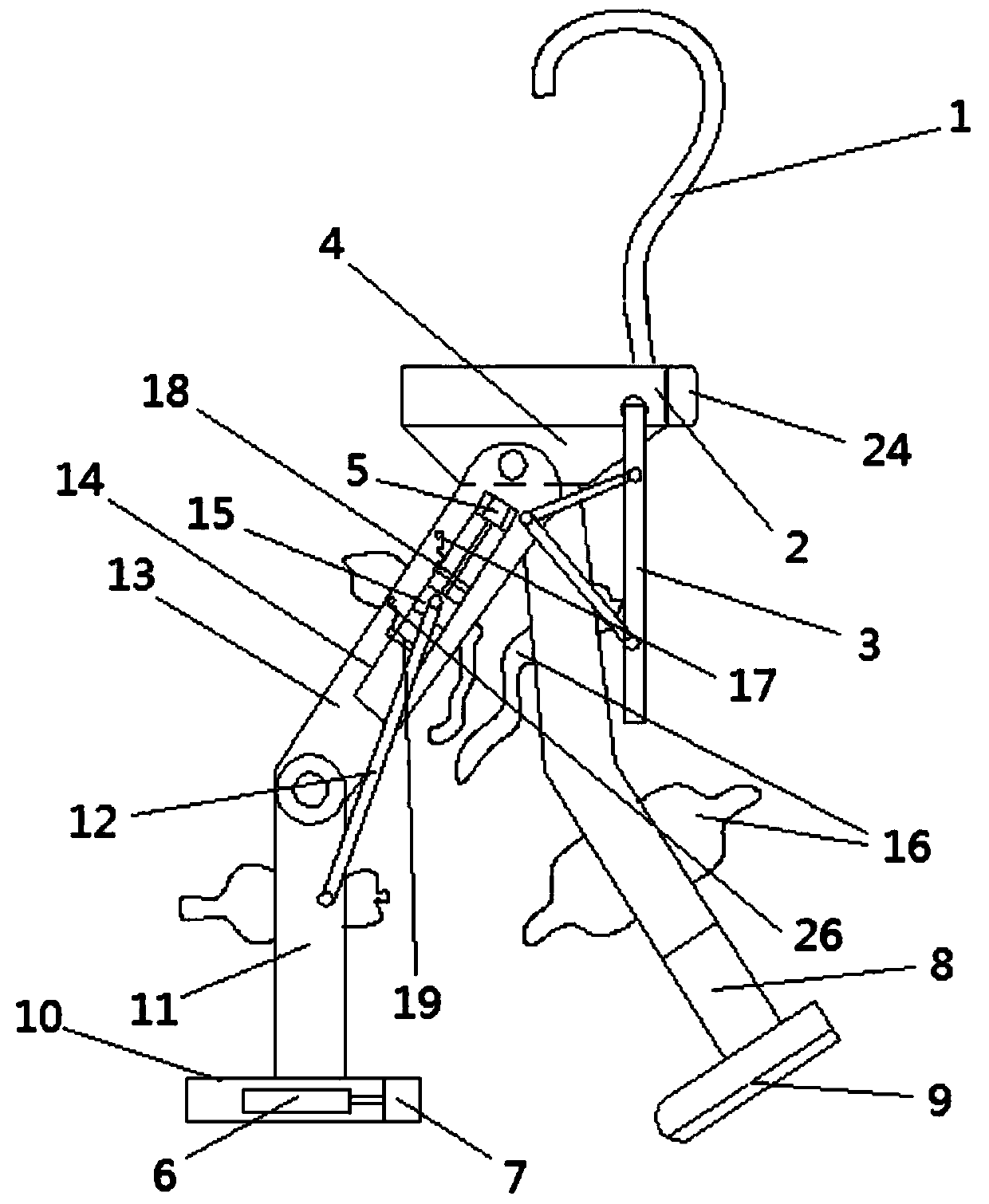

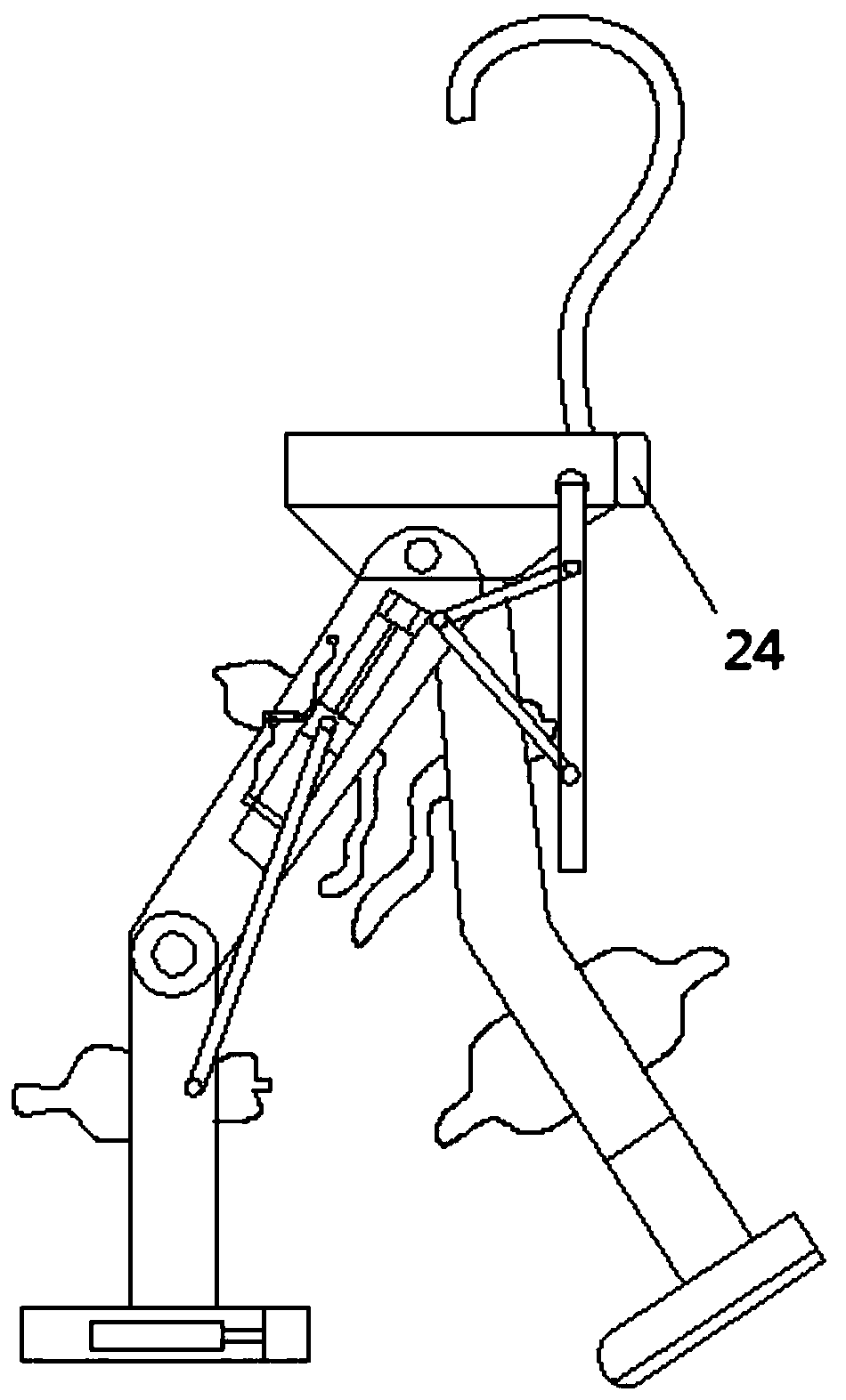

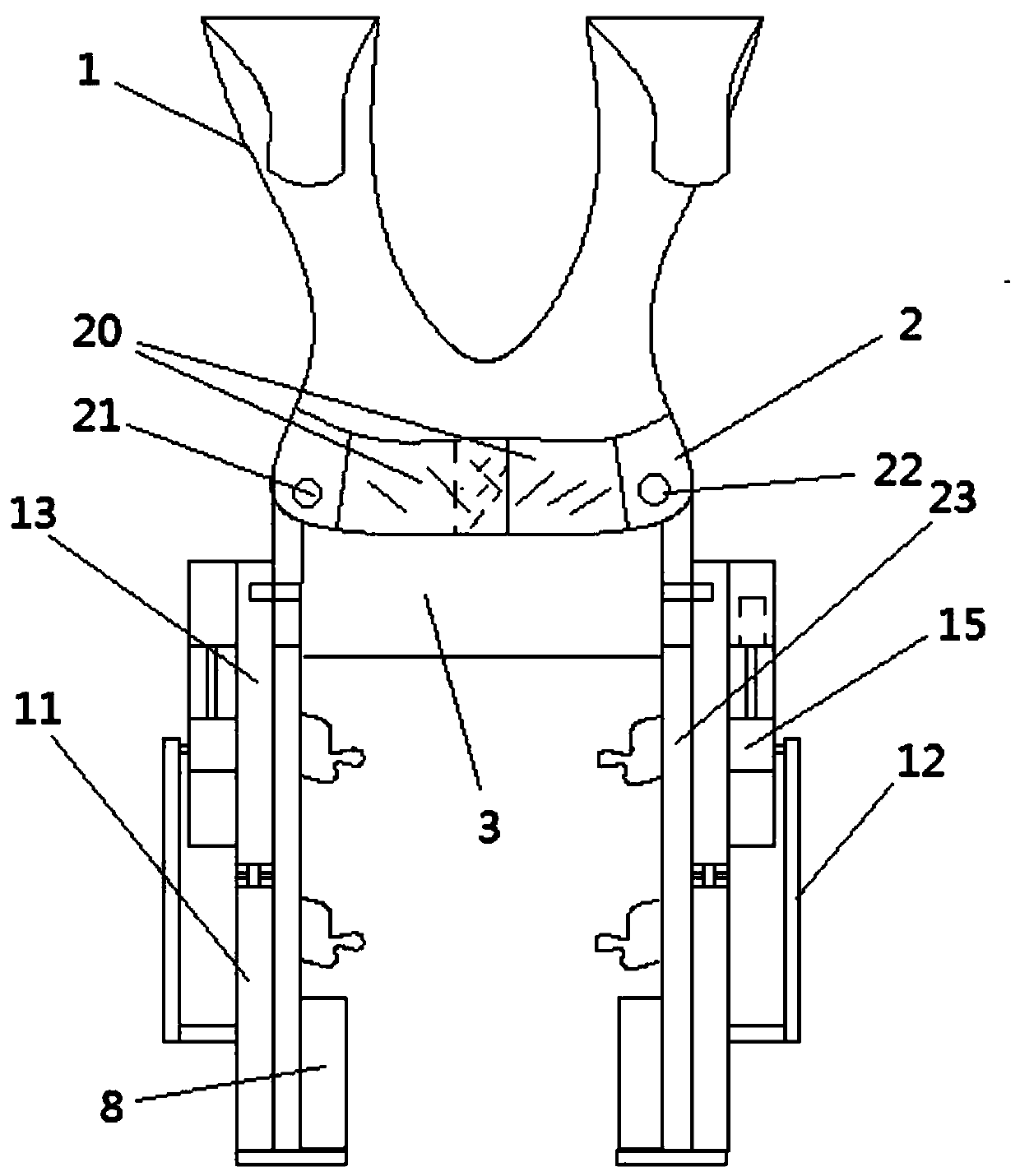

Lead clothes wearing walking device and using methods

ActiveCN110584700AReduce or even eliminate the impactFreedom of movementRadiation safety meansShieldingMultiple useEngineering

The invention discloses a lead clothes wearing walking device and using methods, and belongs to the technical field of medical instruments. The lead clothes wearing walking device comprises shoulder supporting parts, a waist and hip connecting part and walking parts, and conversion of a following walking mode, a self-service walking mode and a sitting posture mode can be achieved through electricpush rods and sliding connecting pieces. The using methods of the lead clothes wearing walking device comprise the using method of the following walking mode, the using method of the self-service walking mode and the using method of the sitting posture mode. The influence of the load of lead clothes on medical personnel can be effectively reduced or even eliminated, and the medical personnel can keep a better working state during interventional therapy due to the conversion of the multiple use modes.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

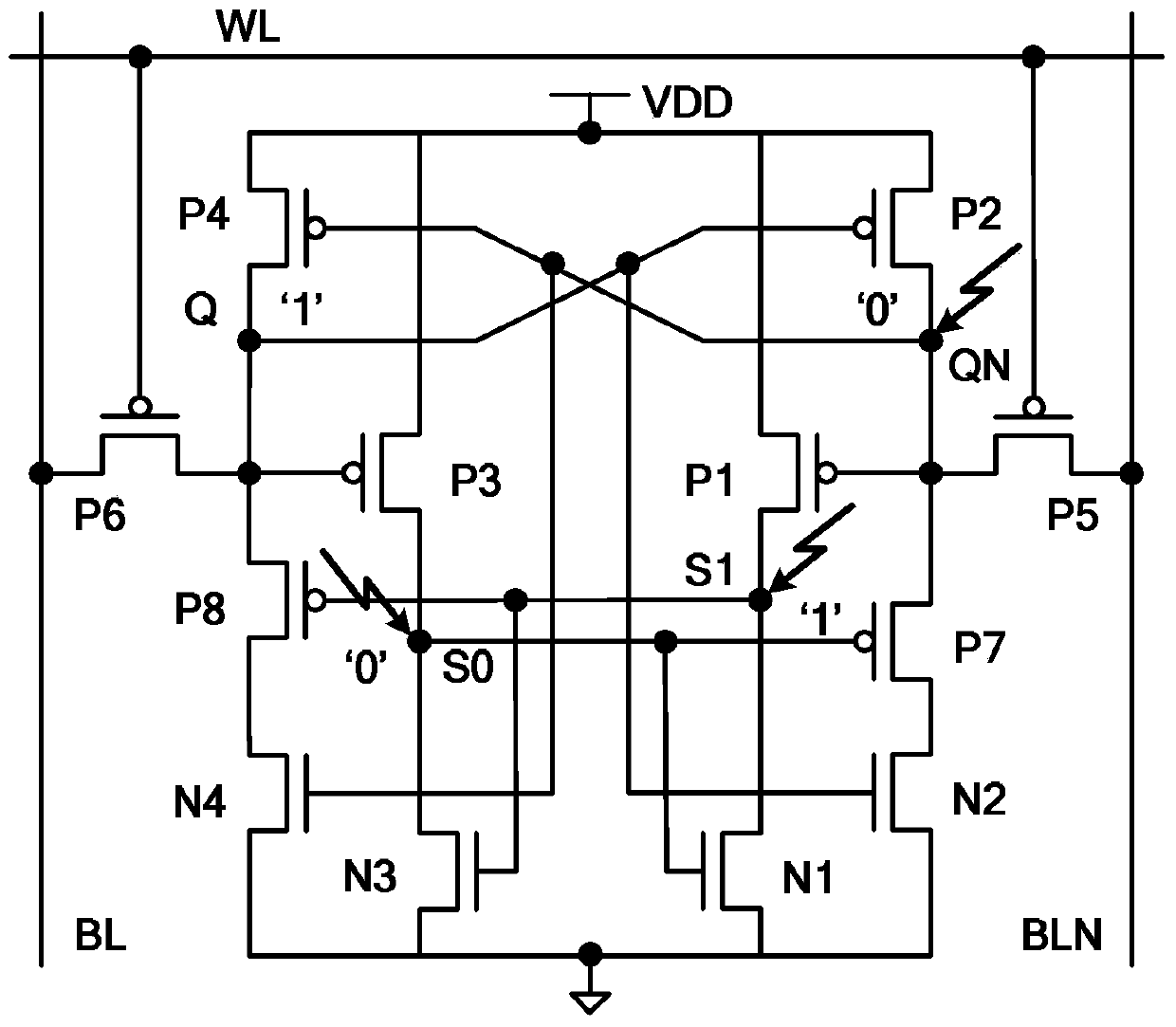

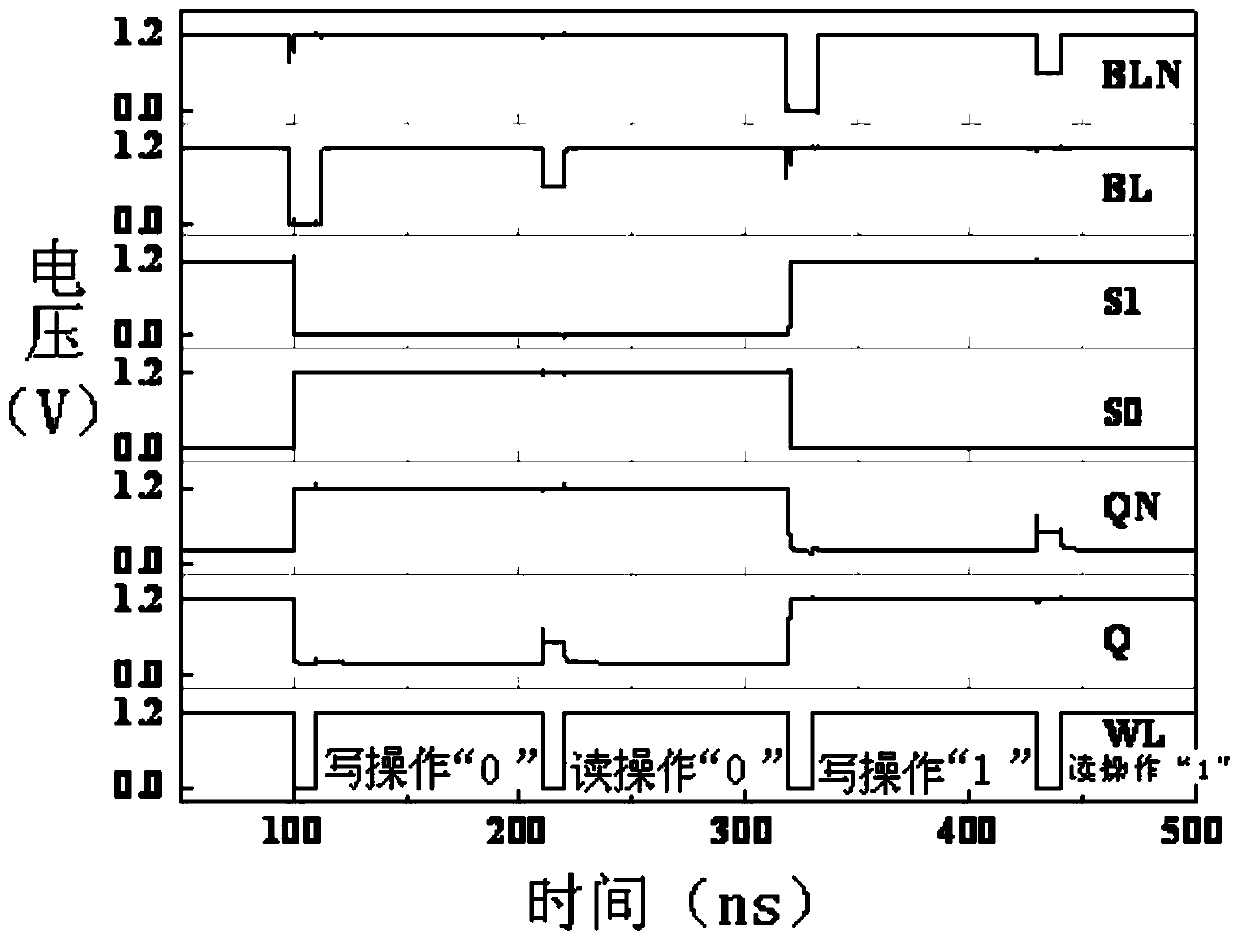

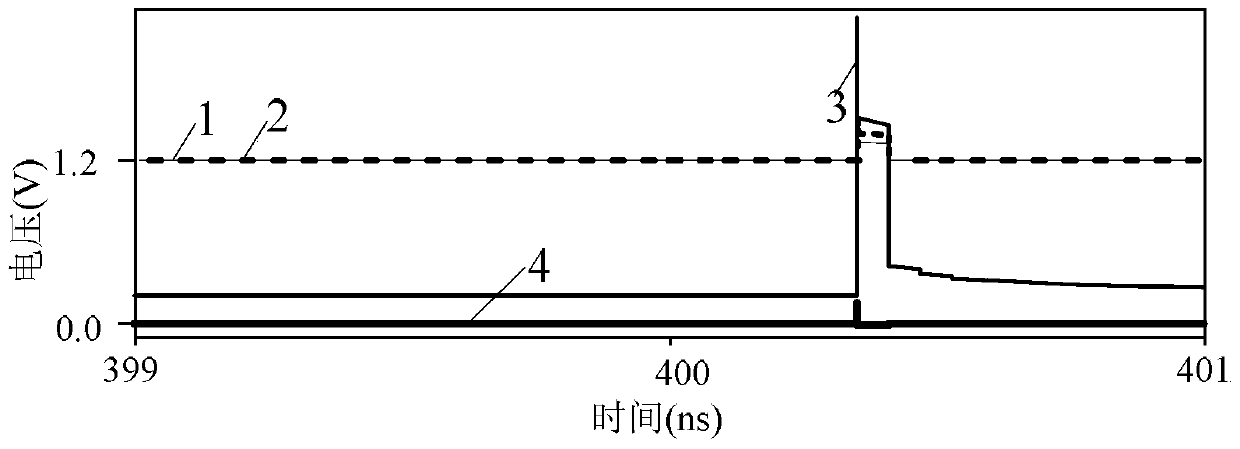

Rad Hardened Static Random Access Memory

InactiveCN105336362BReduce or even eliminate the impactEliminate the effects ofDigital storageStatic random-access memoryRandom access memory

The invention relates to a anti-radiation hardened static random access memory, which relates to the field of anti-radiation hardened circuits. The invention aims to solve the problem that the existing static random access memory is sensitive to radiation particles in space and natural radiation environment, resulting in poor reliability. The present invention consists of 12 MOS transistors, which are respectively PMOS transistors P1, P2, P3, P4, P5, P6, P7 and P8 and NMOS transistors N1, N2, N3 and N4. The invention can strengthen the flipping of any single node in the SRAM unit, and can also implement anti-multi-node flipping and fault tolerance for two fixed nodes without depending on the stored value. It is used in integrated circuit design.

Owner:ZHONGBEI UNIV +1

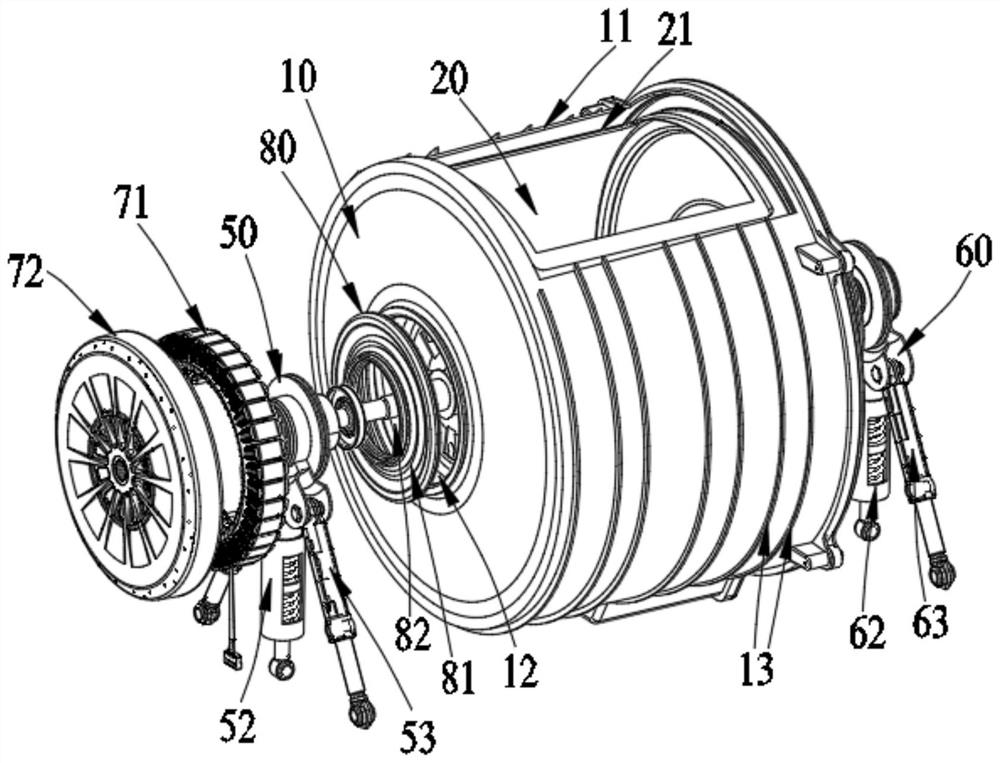

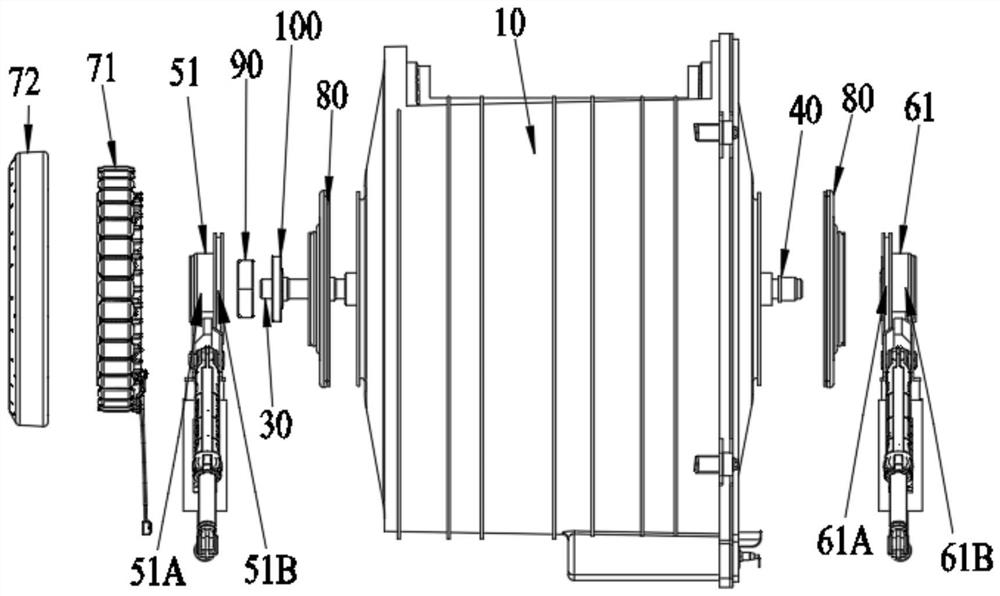

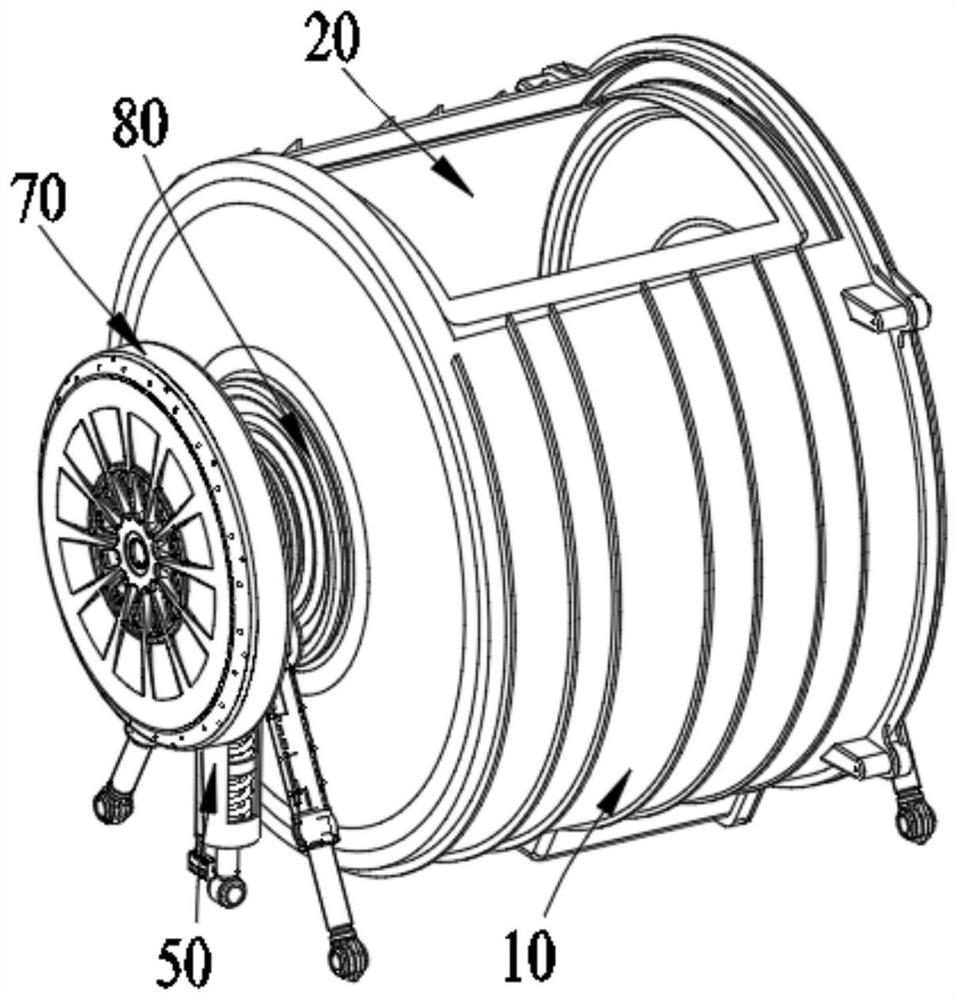

Washing drum assembly of drum washing machine and drum washing machine

InactiveCN112899998AReduce or even eliminate the impactReduce volumeOther washing machinesTextiles and paperLaundry washing machineIndustrial engineering

The invention belongs to the technical field of washing machines, and particularly discloses a washing drum assembly of a drum washing machine and the drum washing machine. The washing drum assembly of the drum washing machine includes an outer drum, wherein end walls are arranged at two ends of the outer drum in an axial direction, through holes are formed in the two end walls, and an outer opening is further formed in the side circumferential wall of the outer drum; an inner drum rotationally arranged in the outer drum, wherein rotating shafts are arranged at two ends of the inner drum in the axial direction, the rotating shafts penetrate through the through holes in the two end walls of the outer drum, an inner opening is formed in the side circumferential wall of the inner drum, and the inner drum can rotate to enable the inner opening to be aligned with the outer opening; and two vibration reduction assemblies arranged on two sides of the outer drum correspondingly and rotationally connected with the rotating shafts, wherein each vibration reduction assembly includes a vibration damper, a damper and a bearing block, the vibration dampers and the dampers are both connected with the bearing blocks, and the bearing blocks are used for supporting the rotating shafts. According to the washing drum assembly of the drum washing machine, vibration generated during operation of the inner drum and transmitted to the outer drum can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

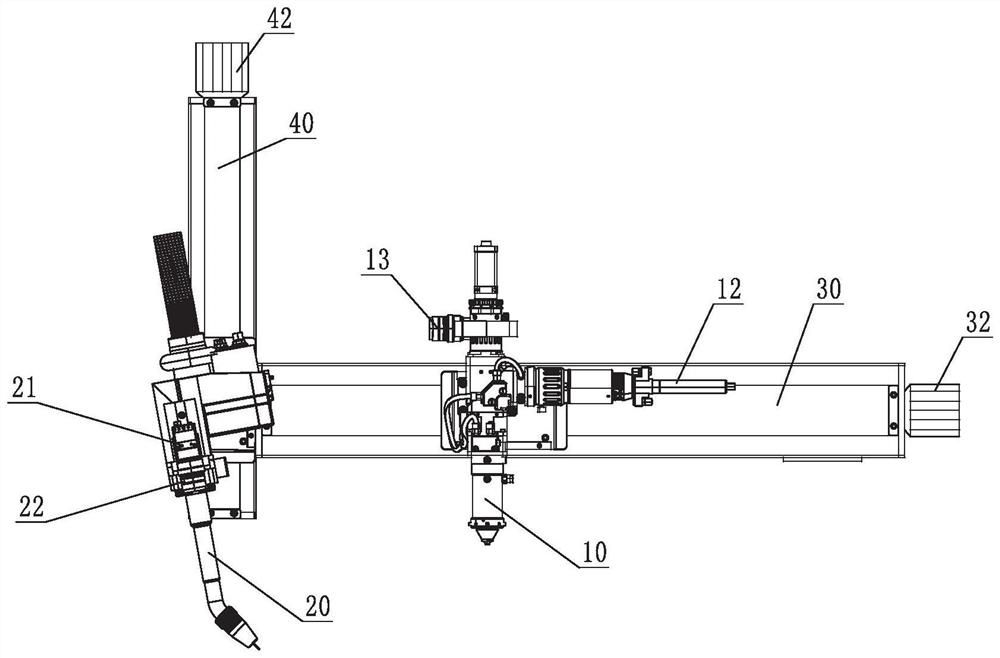

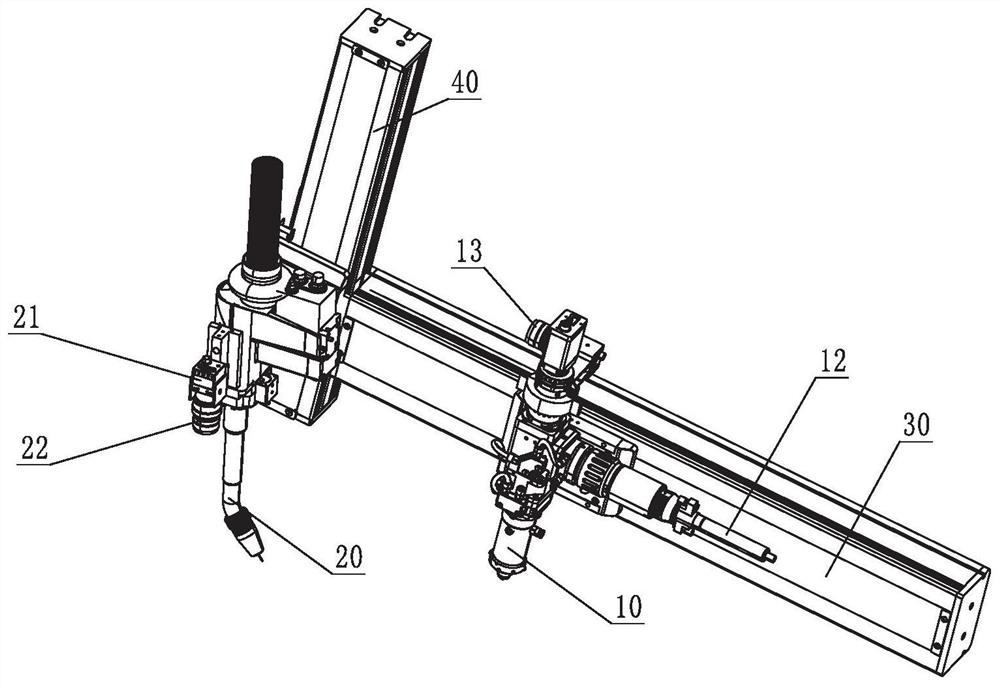

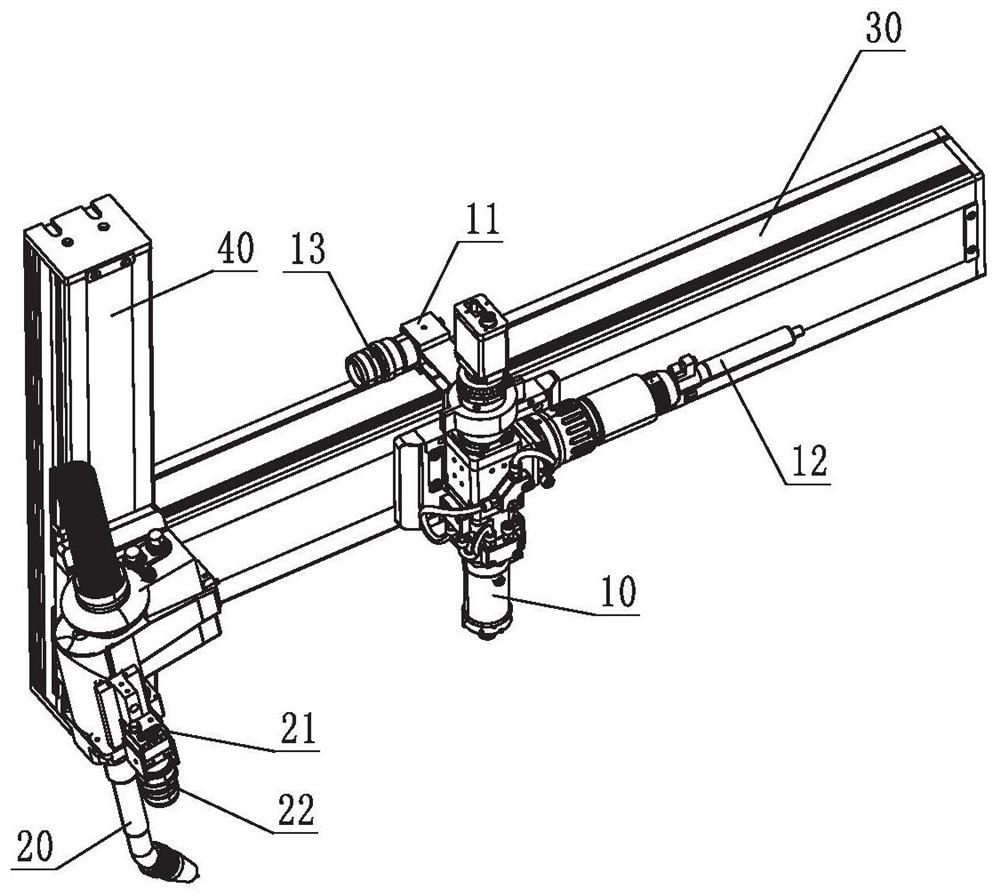

A real-time self-adaptive adjustment system and adjustment method for laser-arc hybrid welding

ActiveCN108581207BGuaranteed real-time adaptive adjustmentReduce or even eliminate the impactLaser beam welding apparatusComputer control systemEngineering

Owner:HARBIN INST OF TECH AT WEIHAI +1

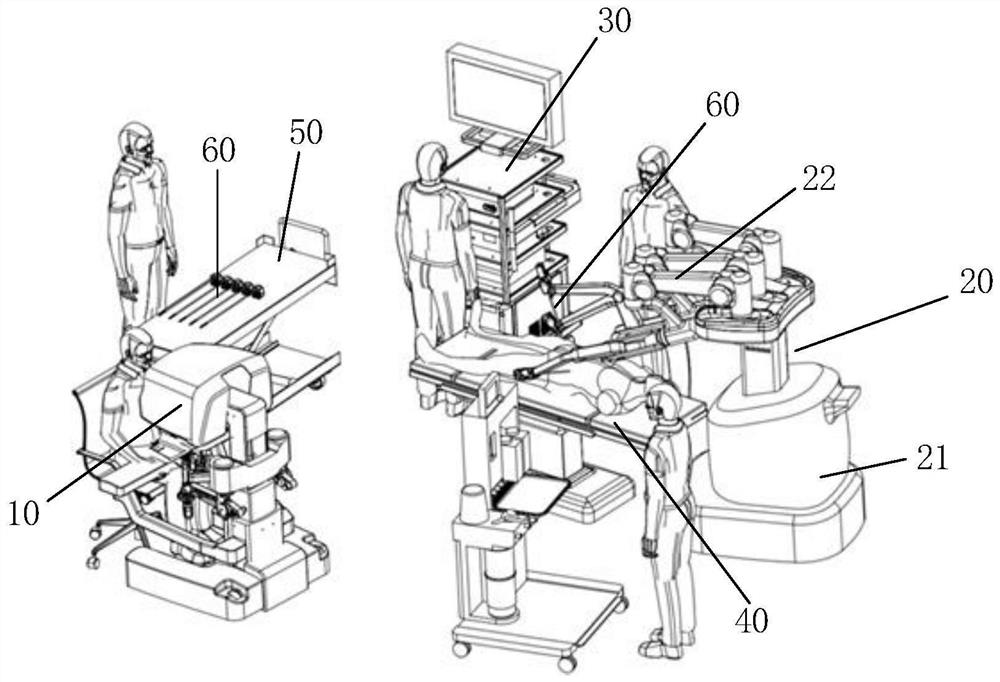

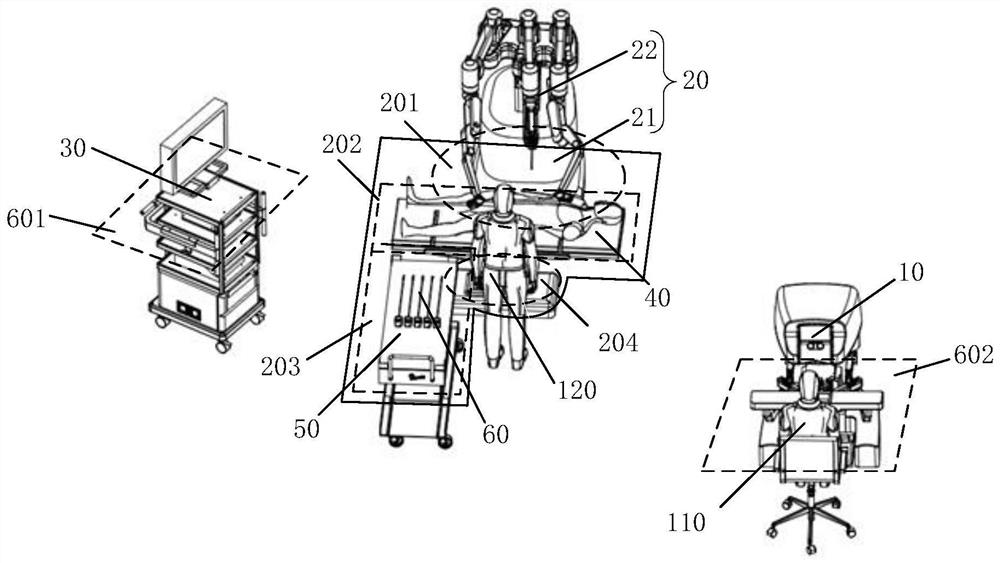

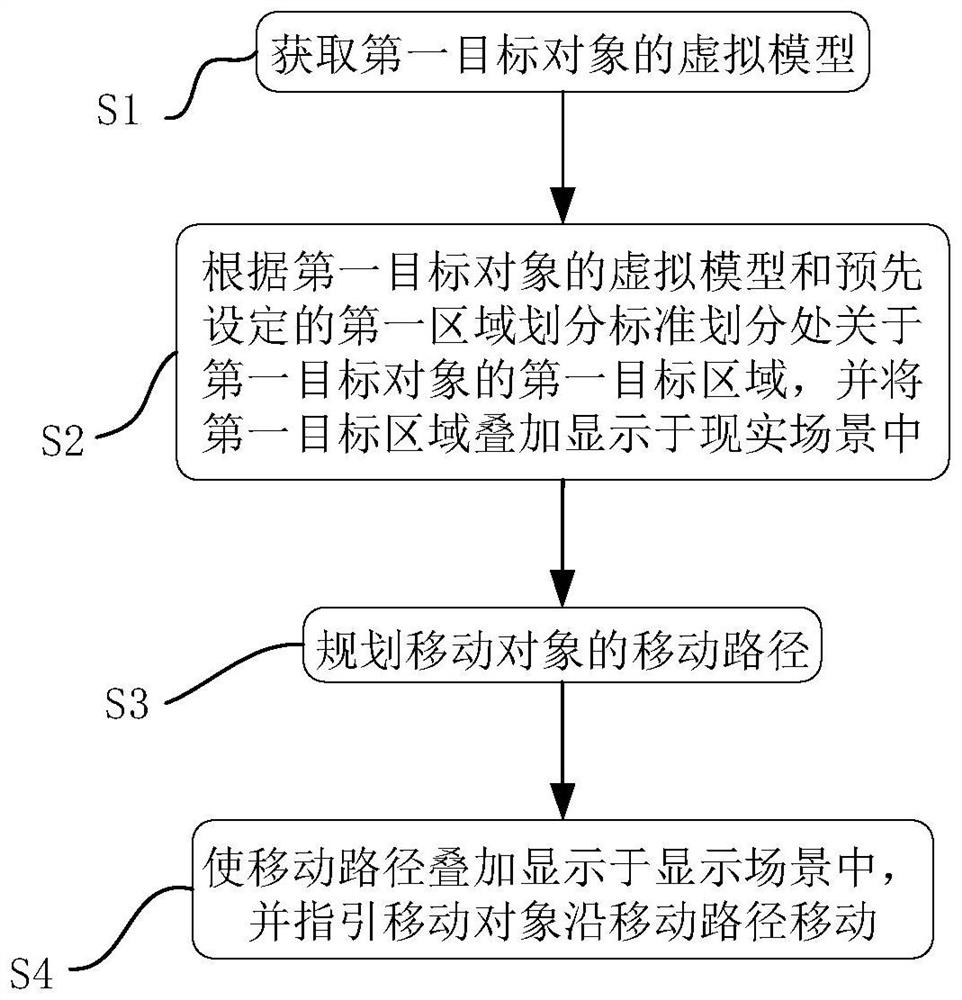

Movement guiding method and system, readable storage medium, and surgical robot system

PendingCN114305695AReduce or even eliminate the impactEliminate the effects ofComputer-aided planning/modellingSurgical robotsOperating theatresMobile object

The invention provides a movement guiding method and system, a readable storage medium and a surgical robot system. The movement guiding method comprises the following steps: acquiring a virtual model of a first target object; according to the virtual model of the first target object and a preset first area division standard, a first target area related to the first target object is divided, and the first target area is displayed in a real scene in an overlapping mode so as to guide a moving object to move outside the boundary of the first target area. The movement guiding method can be applied to an operation executed by a surgical robot system and is used for guiding a moving object to move in an operating room, and the situation that the moving object mistakenly enters a first target area to interfere with the operation is avoided.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com