Downhole same-well injection-production gas-liquid separator

A gas-liquid separator, gas-liquid separation technology, applied in wellbore/well components, production fluid, earth-moving drilling and other directions, to achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

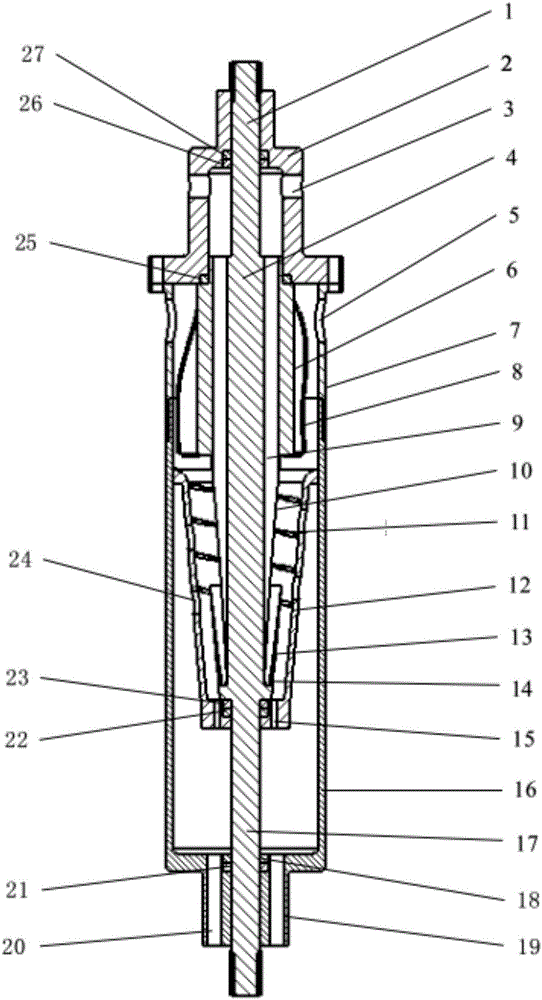

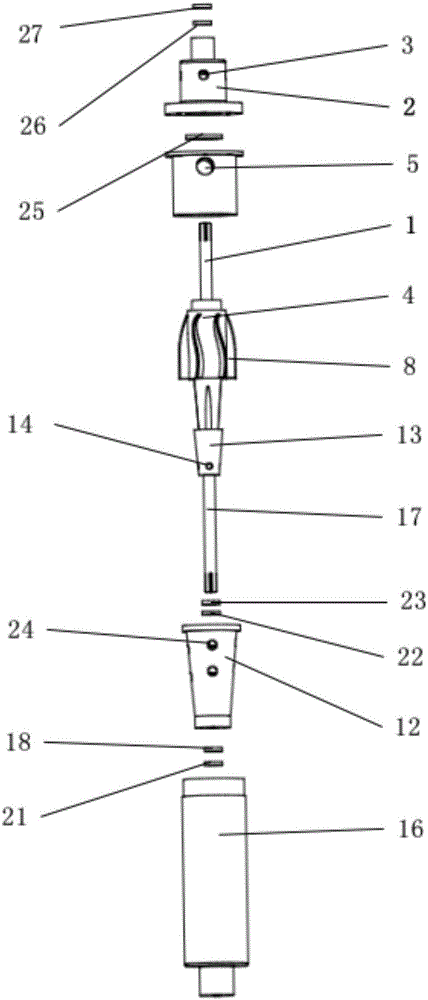

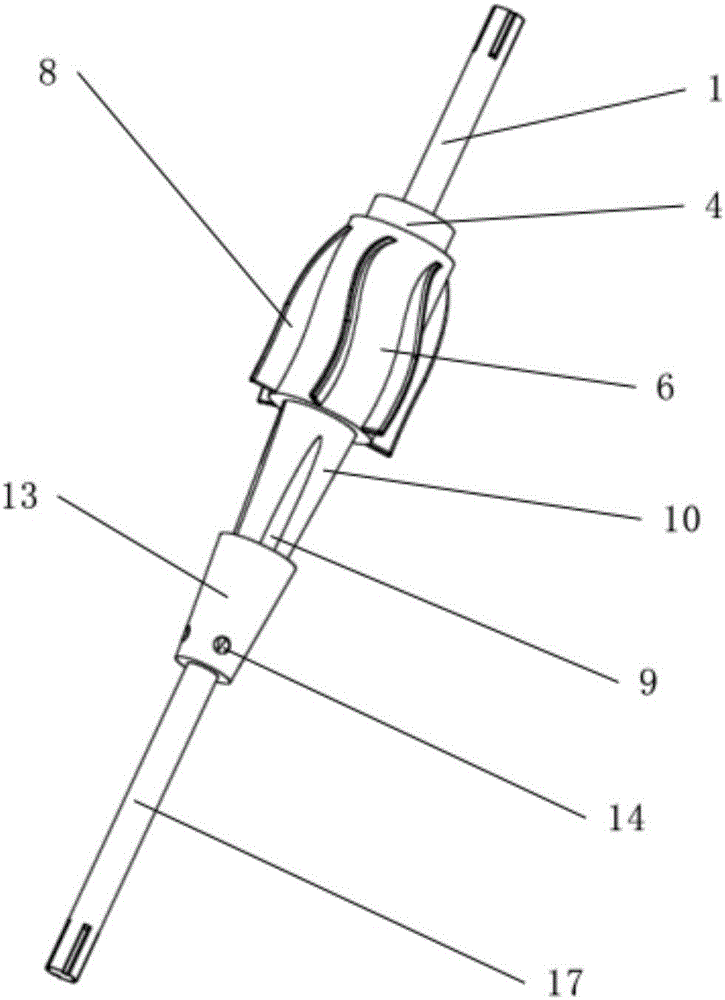

[0029] Depend on Figure 1 to Figure 12 As shown, this kind of gas-liquid separator for downhole production and injection in the same well includes an upper casing 2, a liquid inlet casing 7 and a lower casing 16. Its unique feature is that the gas-liquid separator also has a gas-liquid separation main body 4, a gas Liquid separation cover 13 and gas-liquid outer spiral body 12 .

[0030] Wherein, the upper shell 2 has a connecting flange and an inner cavity, and a central through hole is opened vertically for the upper transmission shaft to pass through, and an exhaust hole 3 is opened on the upper part of the inner cavity;

[0031] The upper part of the liquid inlet casing 7 is provided with a liquid inlet hole 5, and the liquid inlet casing 7 and the upper casing 2 are connected by a flange; the lower end of the liquid inlet casing 7 and the top end of the lower casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com