Test pile and working method thereof

A technology of test piles and test strips, which is applied in the field of test piles for detecting the state of cathodic protection of pipelines. It can solve problems affecting the working efficiency of cathodic protection potential of pipelines, difficulties for operators to reach the site, and influence on the measurement accuracy of polarization potentials, etc., so as to increase the calibration Accuracy, simple installation and layout, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

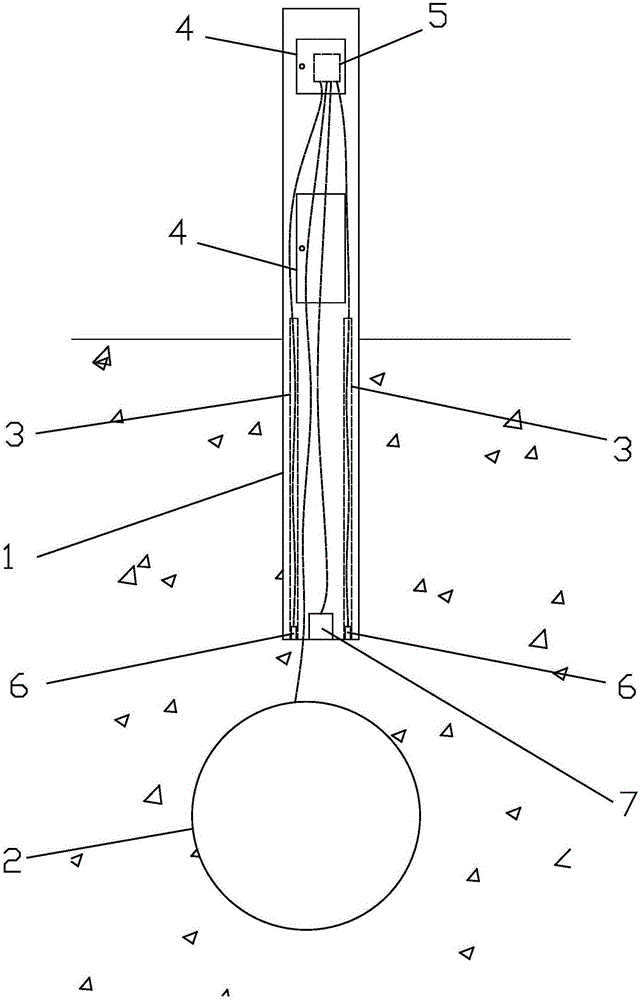

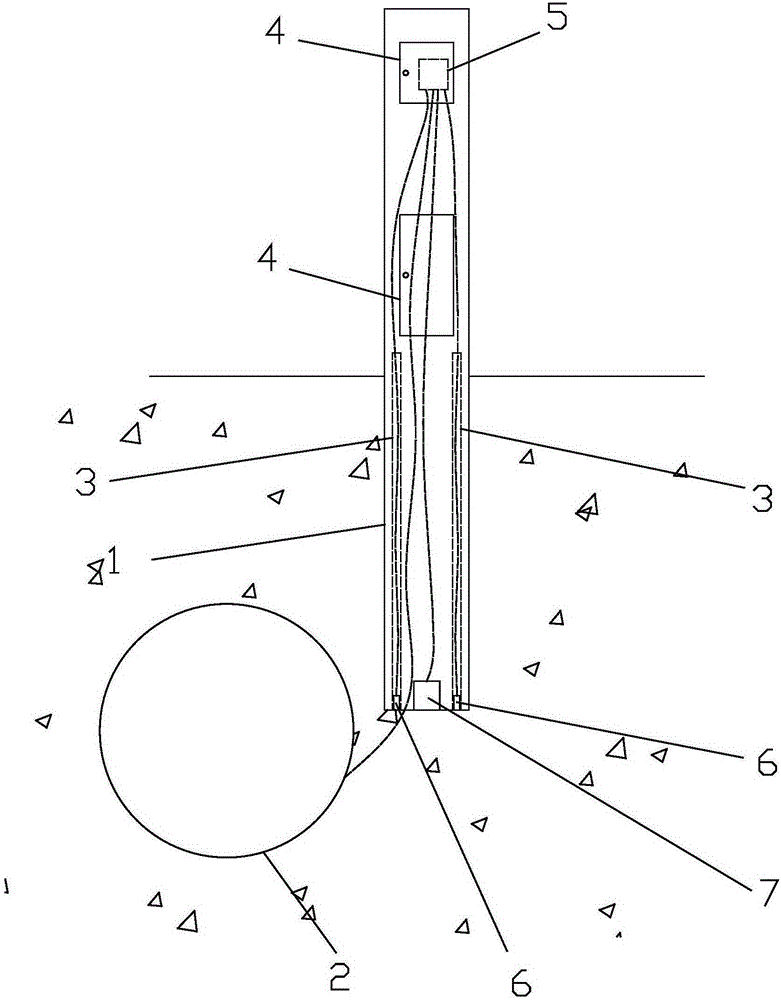

[0043] Such as figure 1 and figure 2 As shown, the test pile includes a hollow pile body 1, the pile body 1 is made of insulating material or other materials that have been insulated, the lower part of the pile body 1 is located underground, and the pile body 1 is located above or on the side of the underground pipeline 2 .

[0044] A test piece tube 3 is installed on the pile body 1 inner wall, and the test piece tube 3 is also made of insulating material or other materials through insulating treatment, and the bottom end of the test piece tube 3 is flush with the opening provided at the bottom end of the pile body 1 .

[0045] The pile body 1 is provided with a hatch 4, at least one hatch 4 is provided, and the lower edge of the hatch 4 is higher than the top of the test piece tube 3 and also higher than the ground, meeting the industry requirements for cathodic protection calibration operations.

[0046]A wiring board 5 is installed in the pile body 1, and the wiring boa...

Embodiment 2

[0051] The structure of embodiment two is basically the same as that of embodiment one, the difference is:

[0052] Such as figure 1 As shown, two cabin doors 4 are provided, including a measuring door arranged above and an inspection door arranged below. The measuring door is aligned with the wiring board 3 so that the detection equipment can be connected with the wiring board 3 through the measuring door. The access door is used to send the calibrated working electrode into the pile body 1, and at the same time, the test piece 6 and the reference electrode 7 can be taken out from the ground through the access door.

Embodiment 3

[0054] The structure of embodiment three is basically the same as that of embodiment one, the difference is:

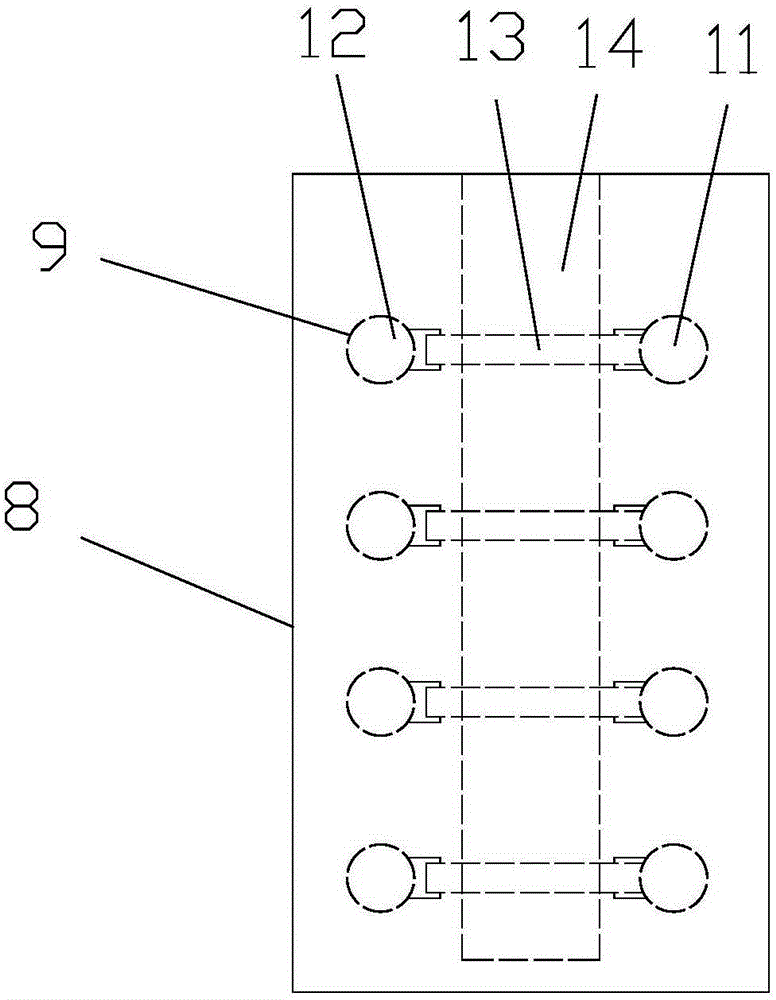

[0055] Such as image 3 As shown, the wiring board 5 includes a housing 8 in which a wiring switch 9 is installed.

[0056] The wiring switch 9 includes a main connector 11 and a secondary connector 12. The primary connector 11 and the secondary connector 12 are connected by an elastic metal sheet 13.

[0057] The housing 8 is provided with a socket 14 , the elastic metal sheet 13 of the wiring switch 9 is aligned with the socket 14 , and the wiring board 5 is connected with a detection plug that can be inserted into the socket 14 .

[0058] The test piece 6 includes a polarized test piece, and a plurality of connection switches 9 are provided, including a pipeline connection switch, a reference electrode connection switch and a polarization test piece connection switch.

[0059] The main joint 11 of the pipeline wiring switch is electrically connected to the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com