Door and window frame installing method

An installation method and technology of door and window covers, applied in the direction of window/door frame, etc., can solve the problems of uneven thickness of wooden keels, large harmful gases, etc., and achieve the effects of ensuring health, good airtight performance, and controlling emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

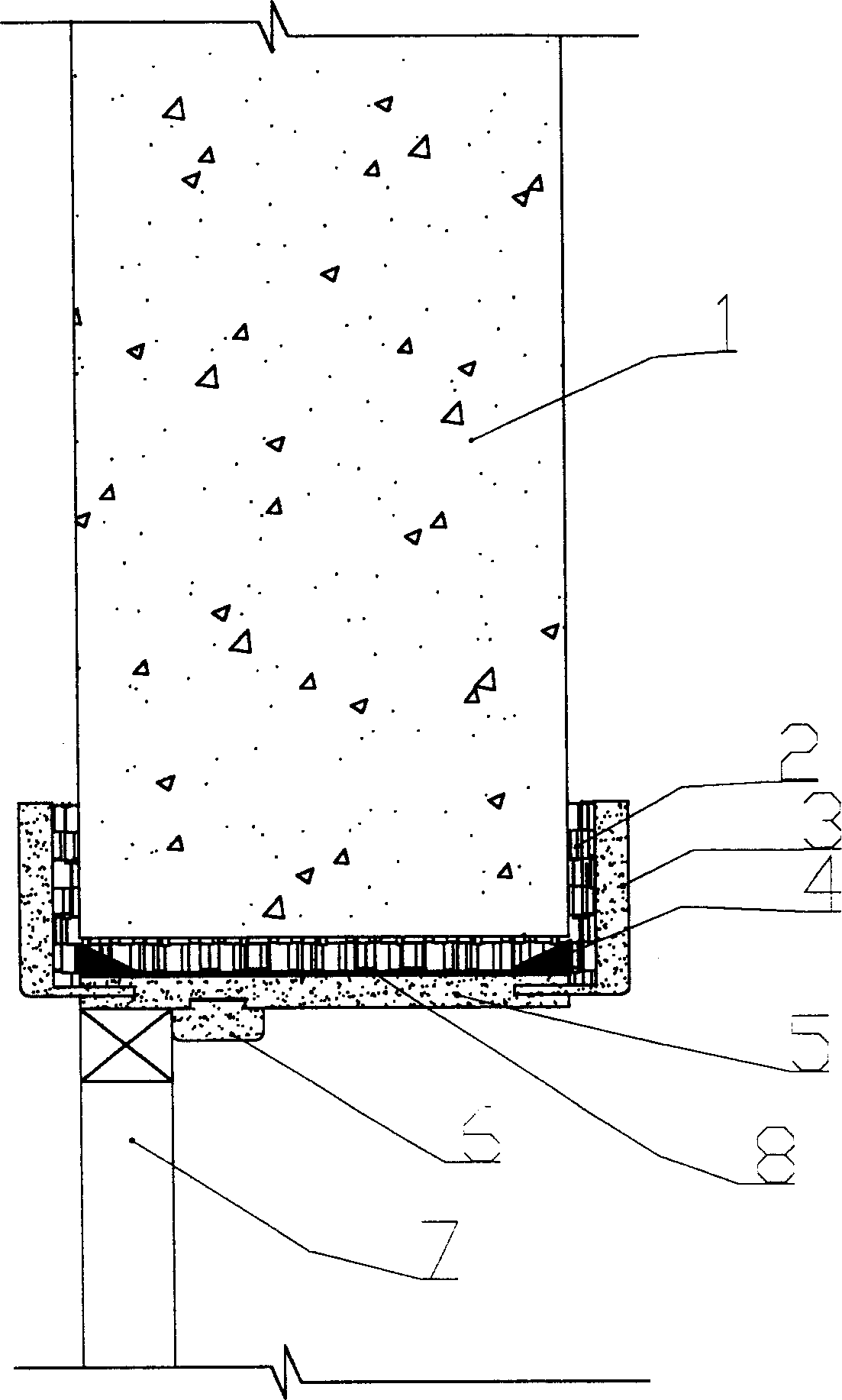

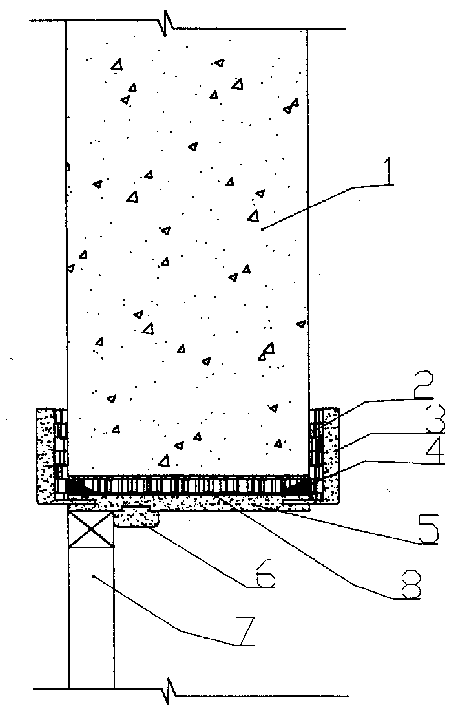

[0012] The installation steps of this embodiment are as follows: (1) process components such as uprights, decorative lines, and slits, (2) assemble and fix the uprights in the door and window openings, (3) punch the uprights between the two sides of the uprights and the wall. Insert the wooden wedge, (4) inject expansion glue into the gap between the uprights, the wall and the wooden wedge, (5) decorate the line, (6) support the positioning until the glue is dry, (7) veneer paint.

Embodiment 2

[0014] The installation steps of this embodiment are as follows: (1) process components such as uprights, decorative lines, and slits, (2) assemble and fix the uprights outside the door and window holes, (3) push the assembled door and window covers into the holes, (4) Drive wooden wedges between the two sides of the stand and the wall, (5) Drive expansion glue into the gap between the stand and the wall and the wooden wedge, (6) Decorative line, (7) Position the support to Glue dries, (8) paints.

Embodiment 3

[0016] The installation steps of this embodiment are as follows: (1) process parts such as uprights, decorative lines, spigots, and veneer and paint them, and the inner surface of the uprights is shaped with a moisture-proof balance layer, (2) assemble in the door and window holes And fix the stand, install the spigot, (3) drive wooden wedges between the two sides of the stand and the wall, (4) inject expansion glue between the stand and the wall, and the gap between the wooden wedges, (5) Trim wire, (6) support positioned until glue dries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com