Tunnel supporting structure

A technology for supporting structures and tunnels, which is applied in tunnels, tunnel linings, shaft linings, etc. It can solve problems such as hindering later rescue, difficulty adapting to combined deformation of tension, compression, bending, shearing, and torsion, and large excavation volume, so as to ensure normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

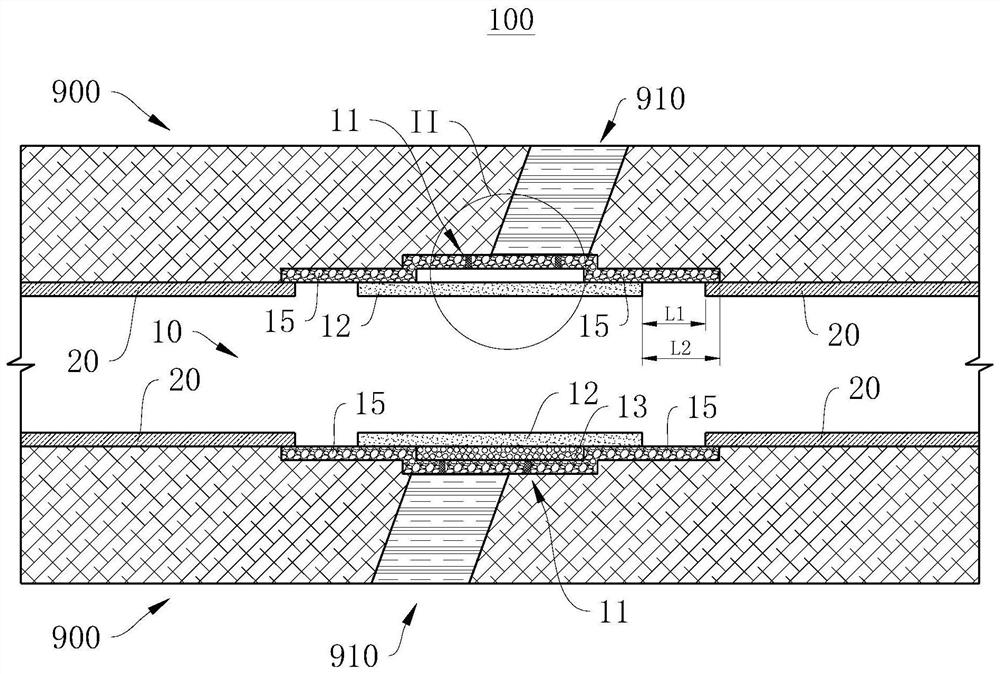

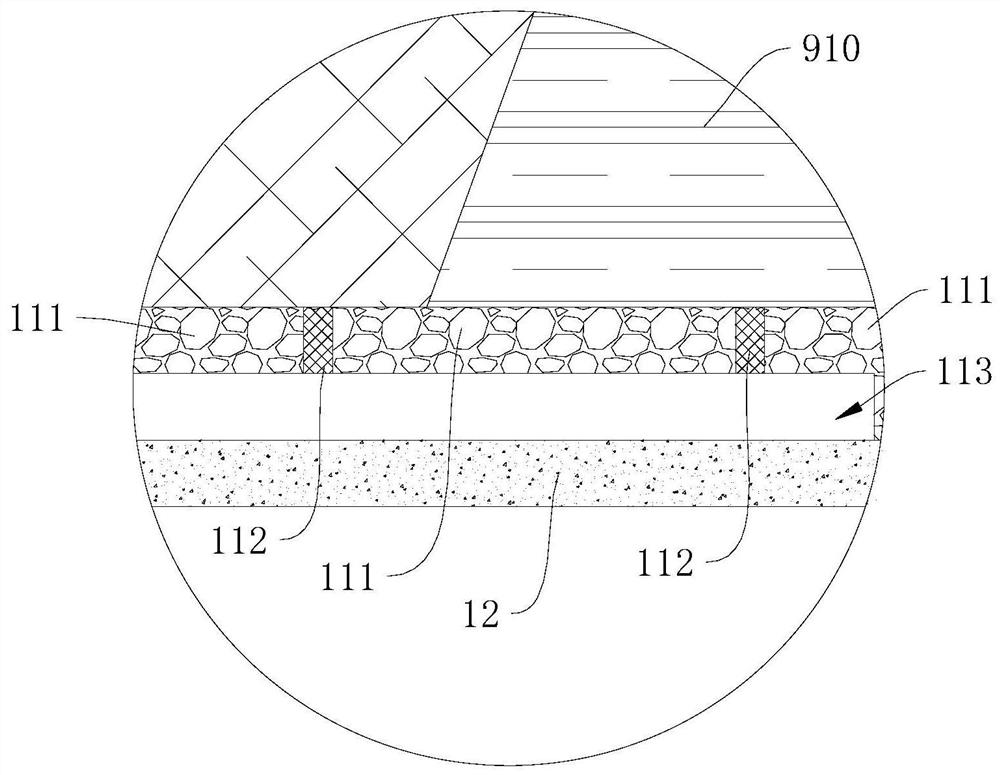

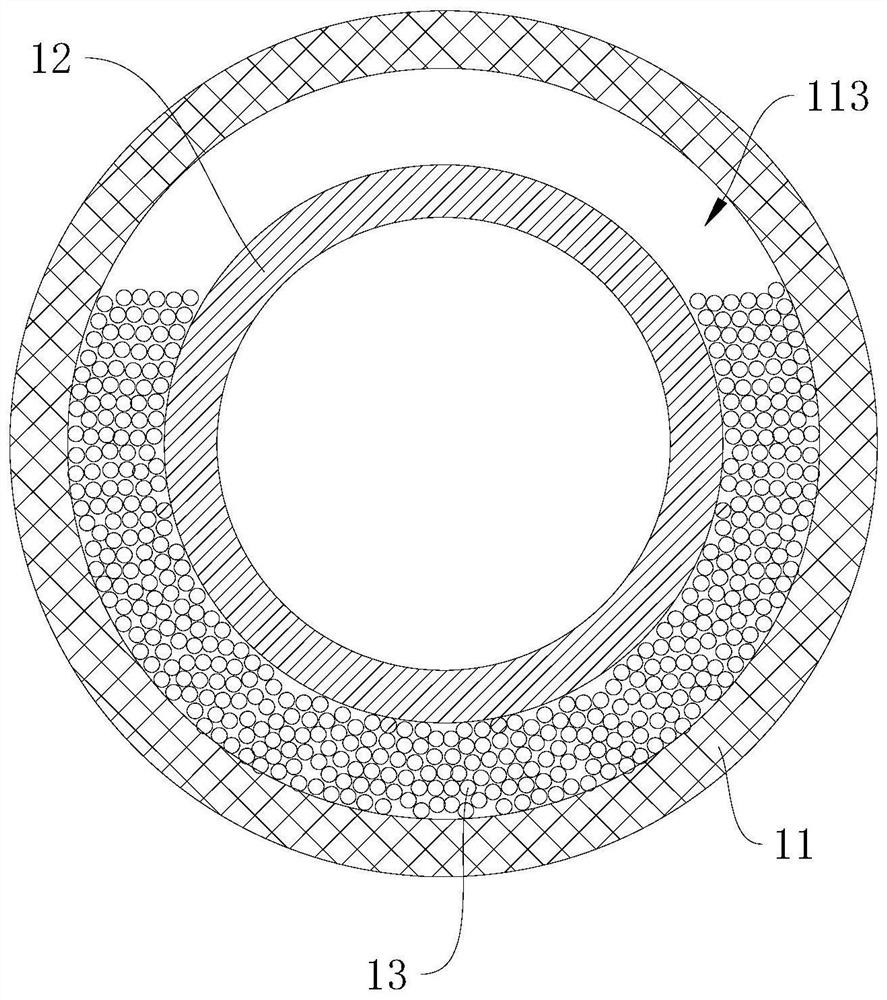

[0038] see figure 1 , figure 1 It is a structural schematic diagram of the tunnel support structure 10 provided in the embodiment of the present invention when it is applied to the tunnel structure 100 . At this time, the outer peripheral surface of the tunnel support structure 10 corresponds to the active fault zone 910 of the surrounding rock 900 .

[0039]An embodiment of the present invention provides a tunnel support structure 10 for supporting an active fault zone 910. The tunnel support structure 10 can not only adapt to large-scale shear deformation and combined deformation of tension, compression, bending, shear, and torsion, but also enable After the earthquake, the inner lining 12 of the tunnel structure 100 will not be damaged due to misalignment, so as to ensure the normal use of the tunnel structure 100, ensure the smooth lifeline, and provide guarantee for later rescue. The tunnel support structure 10 can be applied to a scene where an active fault zone 910 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com