Hot rolling method for improving surface quality of steel plate

A surface quality and steel plate technology, applied in the field of hot rolling of steel plates, can solve problems such as strip steel defects, achieve good formability, increase r value, and improve roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

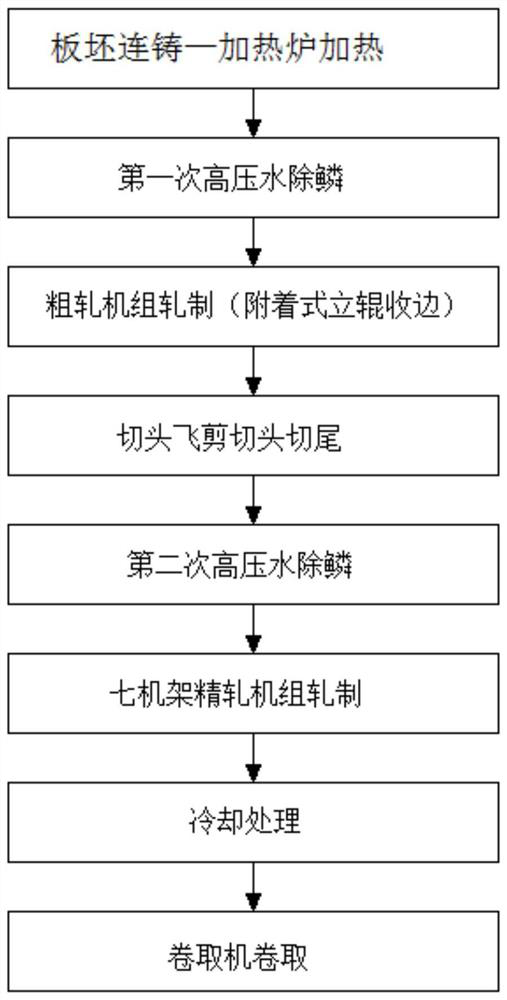

[0028] figure 1 A schematic flow chart of a hot rolling method for improving the surface quality of a steel plate according to an embodiment of the present invention is shown.

[0029] Present embodiment proposes a kind of hot-rolling method that improves steel plate surface quality, and hot-rolling method comprises the following steps:

[0030] Slab continuous casting—heating furnace heating—the first high-pressure water descaling—rolling by the roughing mill (attached vertical rolls)—head cutting, flying shearing, head and tail cutting—the second high-pressure water descaling—seventh machine Rack finishing mill rolling - cooling treatment - coiler coiling;

[0031] Wherein, the lateral pressure of the vertical roll is 15mm to 35mm, and the cooling treatment is strip laminar cooling.

[0032] In the normal process, there is a step of fixed-width press, but it is only used when the side pressure is large. When the side pressure reaches 35mm or more, it is put into the fixed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com