Patents

Literature

83results about How to "Thoroughly deodorized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Innocent comprehensive approach method for human feces by biotechnology

InactiveCN101307332AThoroughly deodorizedElectricity for own useBio-organic fraction processingSolid waste disposalElectricityFiltration

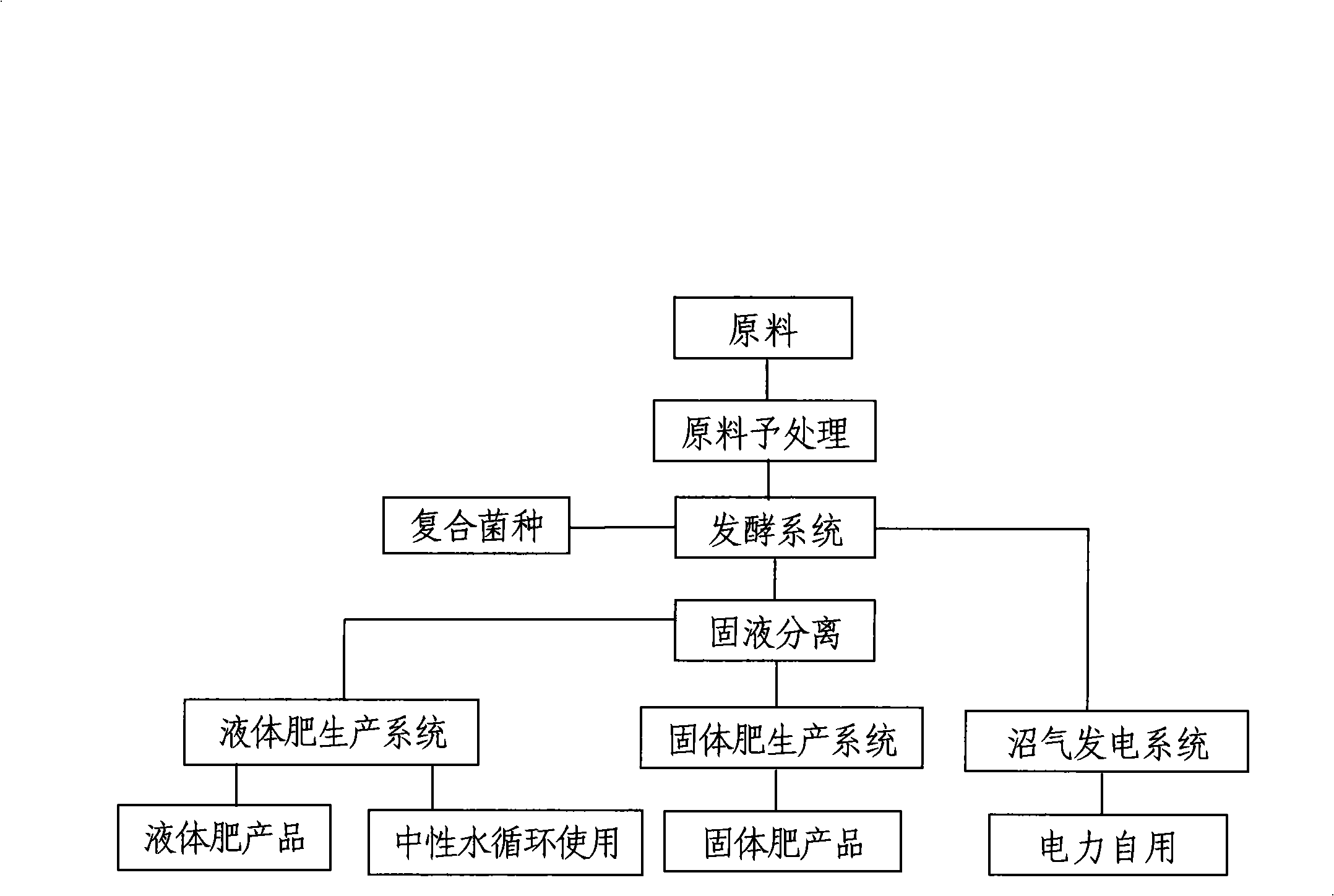

The invention relates to a method for realizing harmless comprehensive treatment of human excrements through adopting biotechnology, in particular to a comprehensive technology used for the harmless centralized treatment of human excrements in urban areas. The method comprises the following steps that: (1) human excrements, aquatic plants and terrestrial plants are added in a fermenter, and then a composite strain mixed solution of microzyme, bacillus and lactobacillus is fed into the fermenter so as to carry out aerobic fermentation and anaerobic fermentation in turn; (2) the biogas generated during fermentation is fed into a biogas generating set so as to generate electricity; (3) the products after fermentation undergoes solid-liquid separation, and the solid fermentation products are made into solid organic fertilizer through dewatering, drying, preparation and regranulation; (4) the liquid fermentation products is obtained after solid-liquid separation undergo decoloring, filtration and settlement layering, in the liquid, the sublayer liquid in the solution is made into liquid organic fertilizer through coarse filtration, secondary filtration, sterilization and preparation and the supernatant is made into rinsing meeting effluent standard through aeration and settlement filtration. The method can realize clean, environment-friendly and energy-saving ecological production.

Owner:昆明伽得科贸有限公司

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

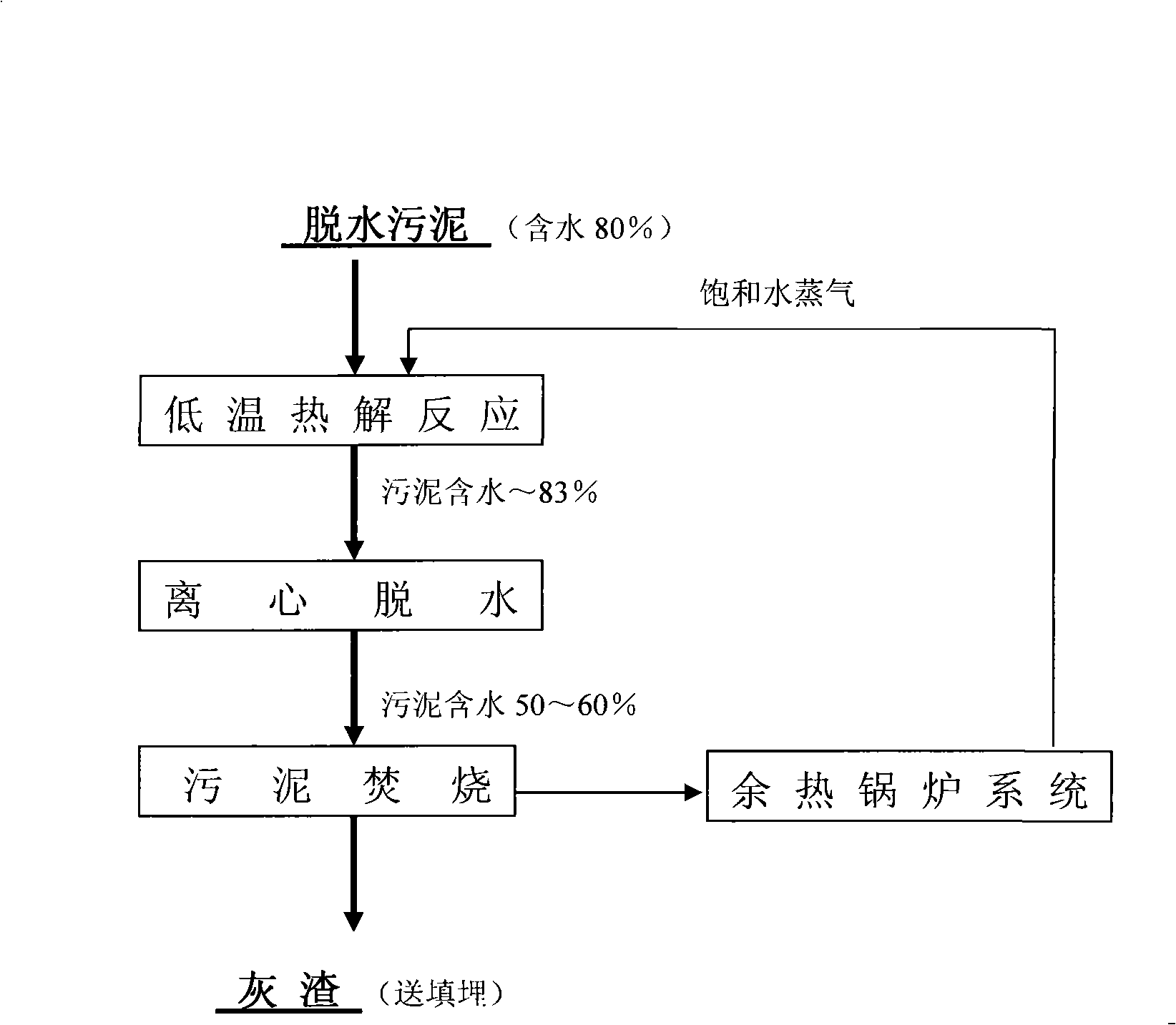

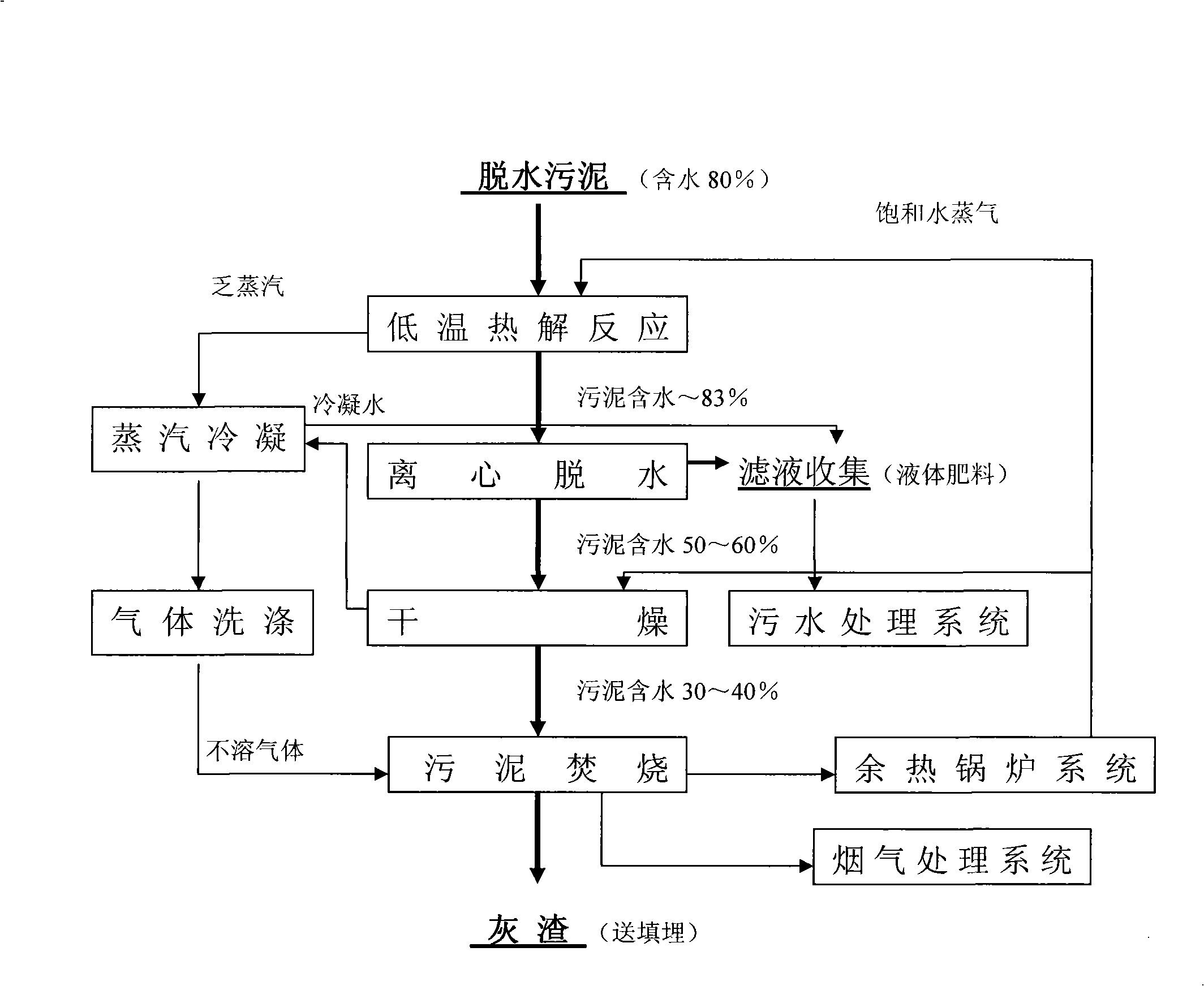

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Manure composting deodorization treating compositions

InactiveCN101284737AImprove performanceDeodorize quicklyClimate change adaptationExcrement fertilisersPlant stalkAnimal feces

The invention belongs to the field of environmental sanitation controlling products and particularly relates to a compound used for deodorizing night soil compost. The compound is formed by mixing materials by the weight parts as follows: 5 to 9 parts of ferrous chloride, 1.5 to 3 parts of ferrous sulfate, 0.2 to 0.4 parts of magnesium sulfate, 0.4 to 0.8 parts of boric acid or borax, 5 to 30 parts of natural zeolite powder, 25 to 45 parts of one optionally selected from peanut residue or wood sawdust, straw powder and plant-stalk powder or the optional mixture thereof and 3 to 8 parts of deodorizing microorganism. The compound has the advantages of stable product performance and fast and thorough deodorization. The compound can be used for deodorizing the night soil of various permanent or movable toilets, and for deodorizing the compost, the processed night soil or the processed compost can be adopted as the organic fertilizer, and the growth of various plants can be facilitated.

Owner:袁双喜

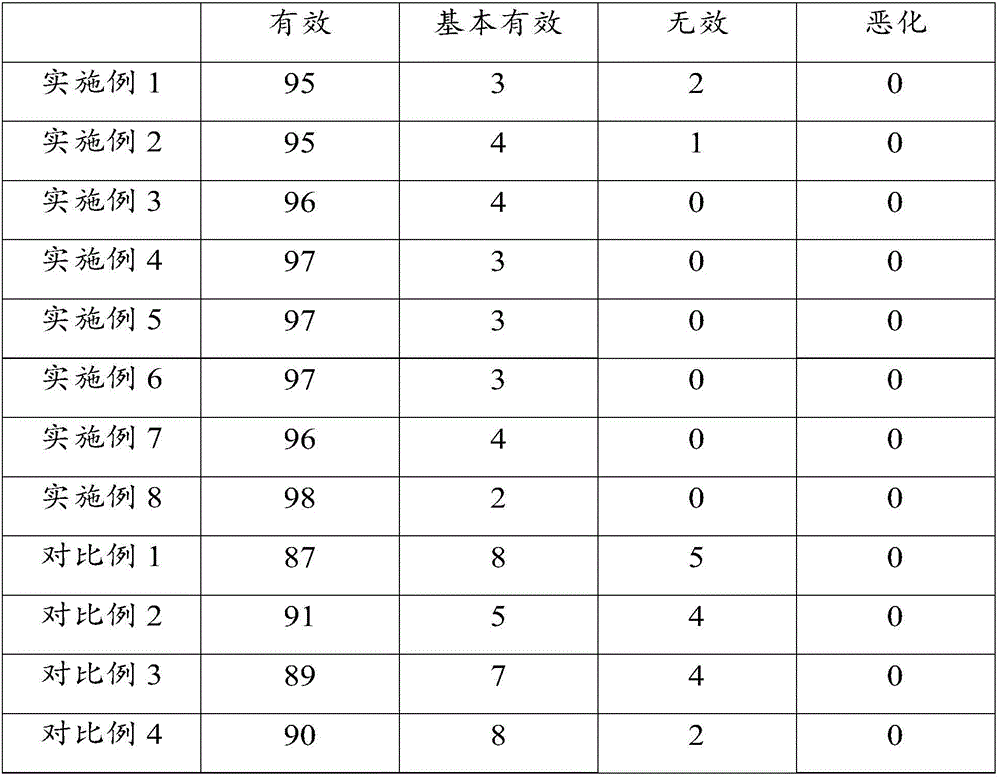

Device and method for purification treatment of gas of medical waste non-incineration treatment

InactiveCN103585866AThoroughly deodorizedDeodorization stableDispersed particle separationAir quality improvementPhotocatalytic reactionMedical treatment

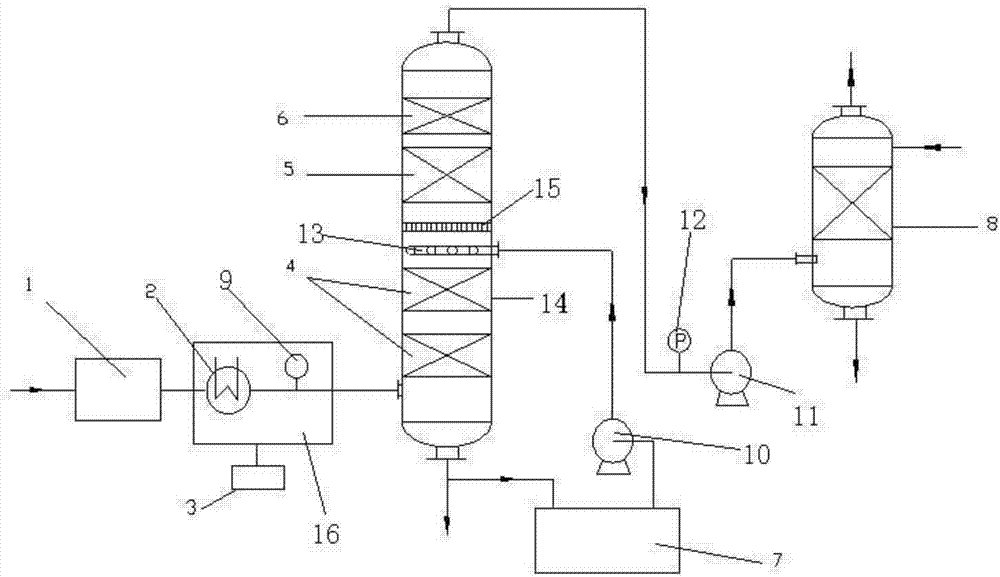

The invention discloses a device and a method for purification treatment of gas of medical waste non-incineration treatment. The device and the method comprise the following structure and the following treatment process: exhaust gas goes into a gas buffer tank, and online detection of the exhaust gas composition is carried out; then the exhaust gas goes into a gas pretreatment device and is subjected to heat exchange with a heat exchanger; next, the exhaust gas goes into the interior of a reaction tower through a pipeline and an inlet at the lower end of the reaction tower, then flows from bottom to top, and successively passes through microorganism filler layers, an activated carbon filler layer and a photocatalytic reaction layer; after being subjected to three-time purification in the tower, the exhaust gas is discharged from the top of the reaction tower, then goes into the bottom of a water washing device through a pipeline, and at the same time, goes into the top of the water washing device for elution with water; sewage is discharged from the bottom of the water washing device, sewage treatment is carried out, and the water-washed air is exhausted from the top of the water washing device. Three treatment means are reasonably combined to control VOC and odor components in the exhaust gas; and compared with a single method, the combined three treatment means have more thorough exhaust gas treatment, basically eliminate odors, and have the VOCs removal rate which reaches more than 95%.

Owner:TIANJIN UNIV

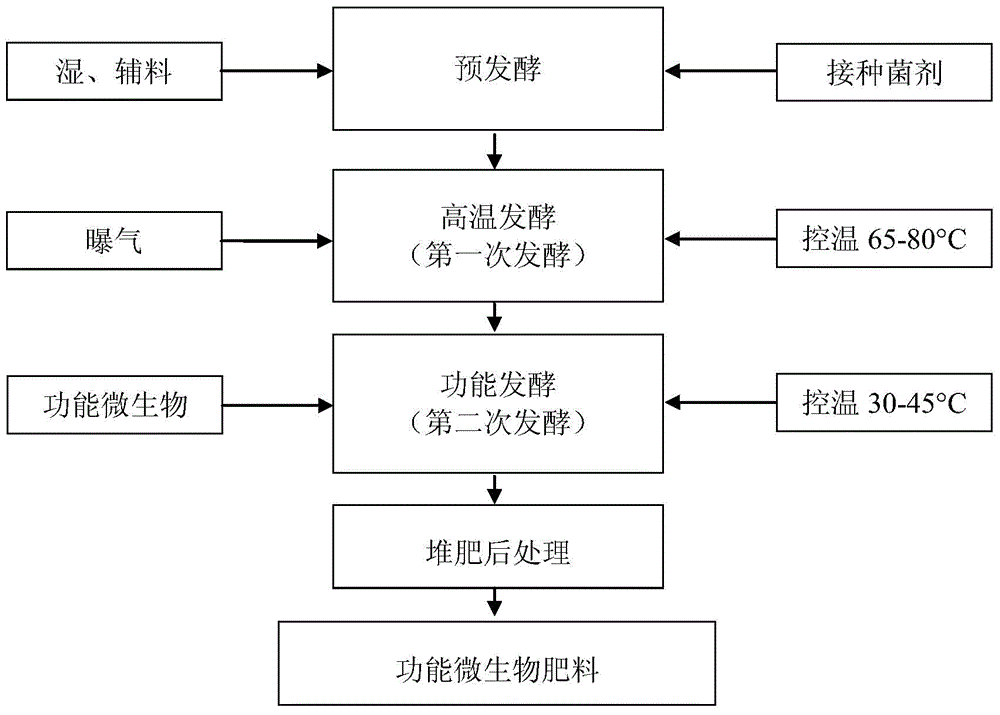

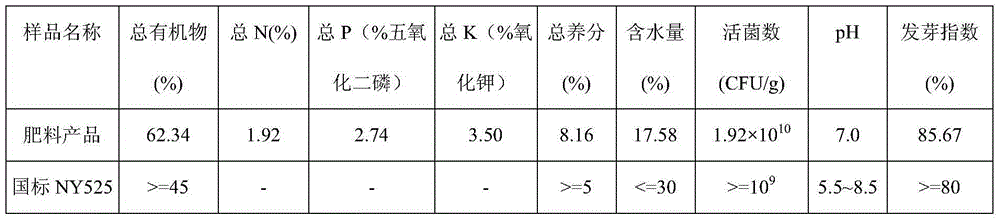

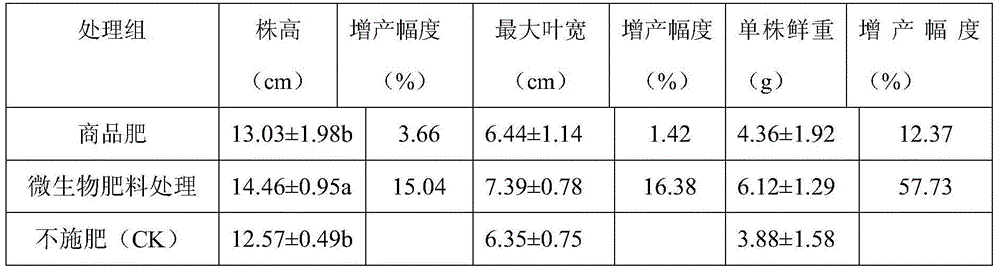

Method for producing functional microbial fertilizer by two-step fermentation and application of functional microbial fertilizer

ActiveCN104961585AReduce heating energy consumptionShort production cycleBio-organic fraction processingOrganic fertiliser preparationNutrientWater content

The invention discloses a method for producing a functional microbial fertilizer by two-step fermentation and the application of the functional microbial fertilizer. By the method, the functional microbial fertilizer is obtained by pre-fermentation, primary high-temperature fermentation and secondary functional fermentation. According to the method, efficient aerobic fermentation is adopted for the whole process, the method is short in production cycle, high in yield and flexibility, stable in product quality and wide in application range, and can be used for producing functional biological fertilizers from various organic waste, production lines in different scales can be established according to needs, the influence of regions, seasons and climates is little, and the obtained product has 50 to 68 percent of total organic matters, total nutrients of 5.5 to 8.8 percent, water content of 15 to 30 percent, viable count of 5.8*10<8> to 4.5*10<10>CFU / g and germination index of over 85 percent.

Owner:HUAZHONG AGRI UNIV

Dirt decomposition deodorant for portable toilet

InactiveCN103613204APromote reproductionDecompose thoroughlyBiological water/sewage treatmentAmylasePortable toilet

The invention discloses a dirt decomposition deodorant for a portable toilet. The decomposition deodorant contains the following raw materials in percentage by weight: 6-30% of cellulase, 1-15% of protease, 1-15% of amylase, 1-15% of lipase, 1-15% of complex bacteria, 10-50% of morus alba tortuosa leaf extract, 10-20% of dextrin, 29-69% of starch and 1-3% of ascorbic acid. The invention further discloses a method for preparing the decomposition deodorant, wherein the method comprises the steps of mixing the raw materials in a dark, sterile and dry environment and then directly carrying out vacuum and dark preservation. The decomposition deodorant has the advantages that dirty organic substances in the portable toilet can be rapidly and thoroughly decomposed into non-toxic and harmless micromolecular substances, and meanwhile, odors are removed from the portable toilet.

Owner:QINGDAO UNIV

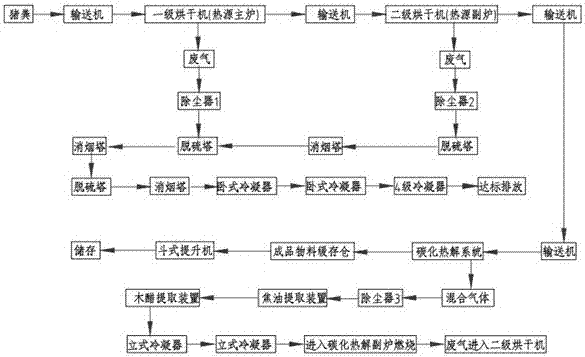

Comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology

InactiveCN107162373ARealize "three modernizations" processingImprove thermal efficiencySludge treatment by pyrolysisByproduct vaporizationHazardous substanceRetention time

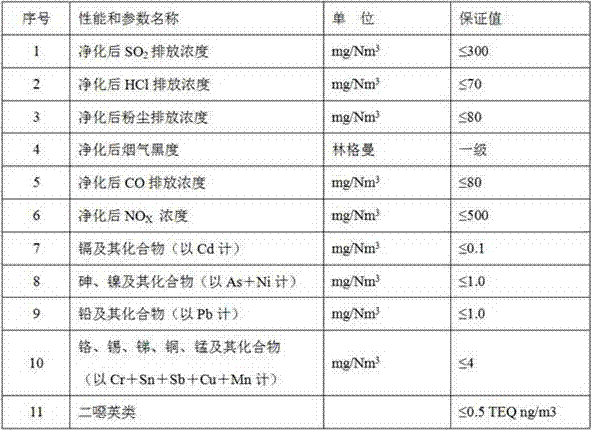

The invention provides a comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology. Through steps including multi-stage drying to the pig manure, carbonization pyrolysis to the pig manure, flue gas treatment and the like, the pig manure is subjected to dry pyrolysis in a furnace, high-temperature pyrolysis gasification, and re-pyrolysis gasification to flue gas (outlet flue gas temperature is higher than 850 DEG C), wherein retention time of flue gas in the furnace is prolonged to more than 2 sec. In the whole pyrolysis process, generation of PCDDs / PCDFs harmful substances is effectively inhibited. Through quenching cooling to high-temperature flue gas, re-synthesis of dioxin is effectively avoided. Main measurements, such as a desulfurization column, adsorption in a smoke removal column, liquefaction in a condenser and the like, are all employed in the technology, so that national smoke and dust discharge standard at present can be satisfied.

Owner:FUJIAN YUYI ENVIRONMENT TECH CO LTD

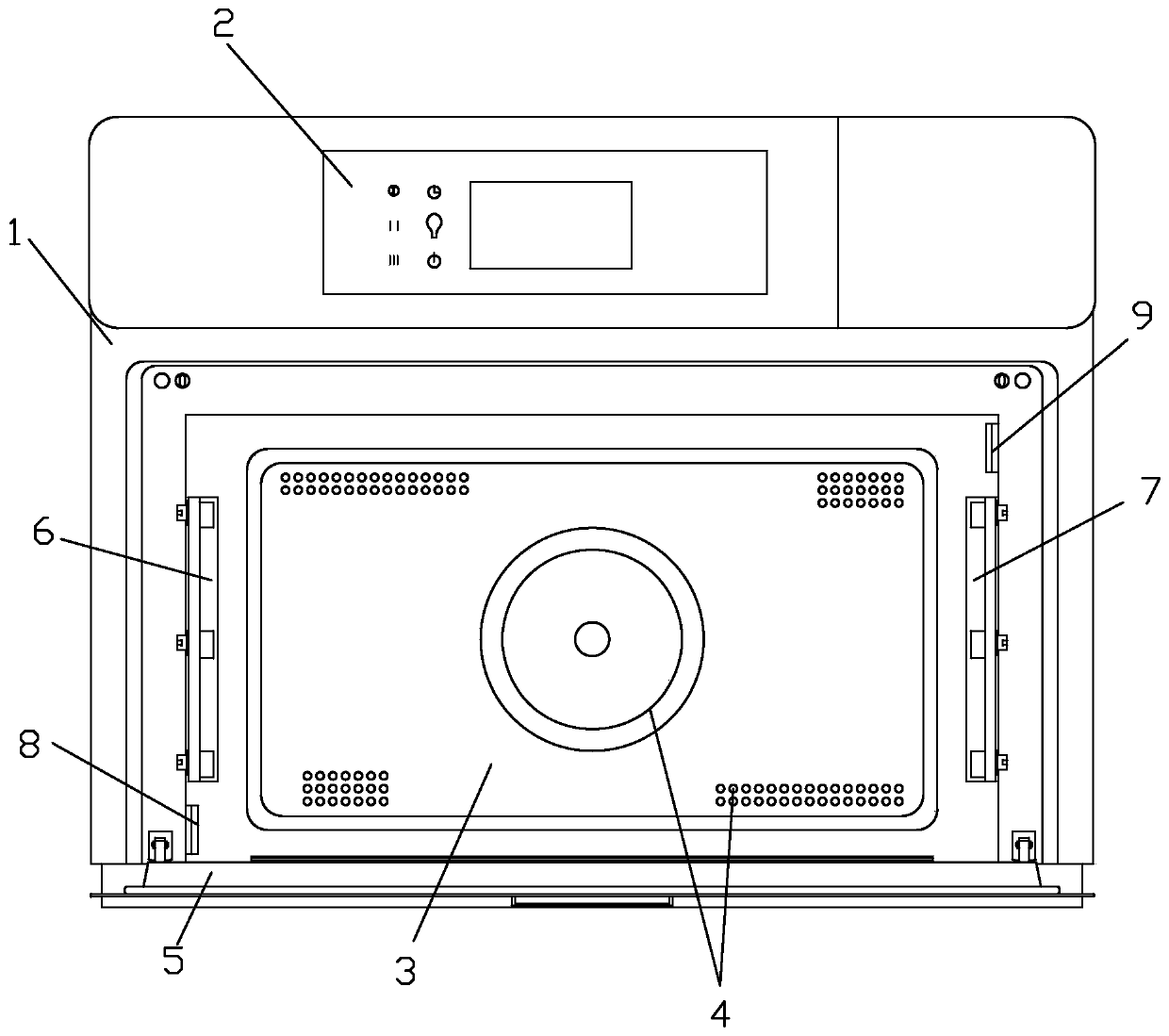

Combined type steam oven and self-odor removal method thereof

PendingCN110236410AClever layoutEasy to carrySteam cooking vesselsRoasters/grillsAir changeEngineering

The invention discloses a combined type steam oven and a self-odor removal method thereof. The combined type steam oven comprises a box body and an inner cavity, and a box door is installed at an end opening of the inner cavity. The combined type steam oven is characterized in that a left odor removal pipe and a right odor removal pipe are separately arranged on two sides of the inner cavity, the left odor removal pipe and the right odor removal pipe communicate with the inner cavity, an exhaust pipe and a fresh air machine are arranged on the back surface of the box body, the exhaust pipe is connected with the right odor removal pipe, and the fresh air machine is connected with the left odor removal pipe. An air changing odor removal system is additionally arranged in the box body, the purpose of thorough odor removal is achieved by changing air in the steam oven, so that the steam oven continuously steam and bake different food, and mouthfeel and odor of the food cannot be affected. A reversing air bellow is further arranged to reach the purpose of automatically changing wind direction of the left odor removal pipe and the right odor removal pipe, so that two kinds of wind flow directions are separately formed in the inner cavity, complete extrusion and changing the air in the steam oven are realized by virtue of the two kinds of wind flow blowing, and thorough odor removal is achieved.

Owner:浙江蓝炬星电器有限公司

Rapid footgear deodorant agent and preparation method thereof

ActiveCN102973966ABroad-spectrum bactericidalImprove the bactericidal effectDeodrantsDeodorantSolvent

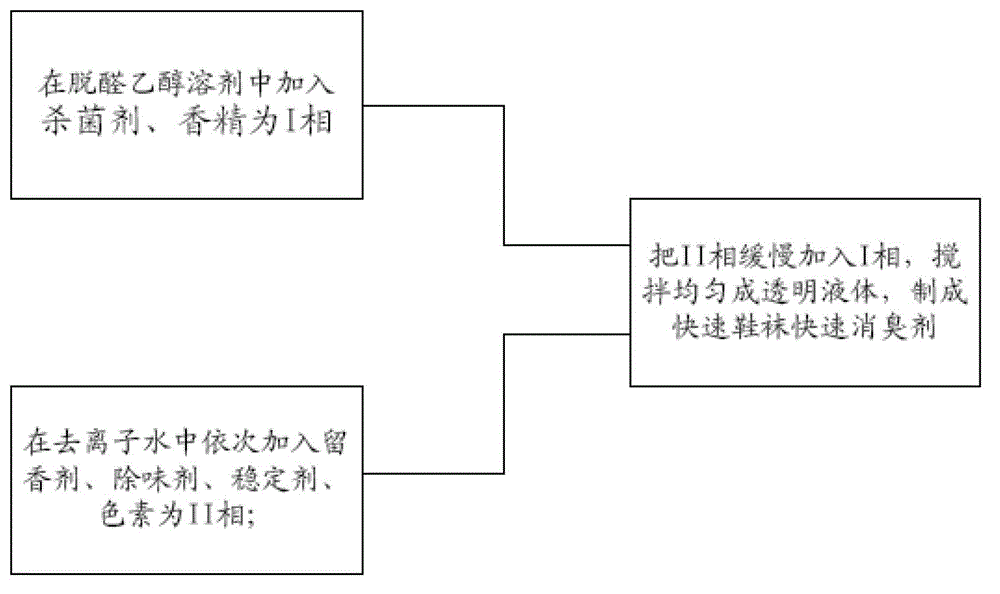

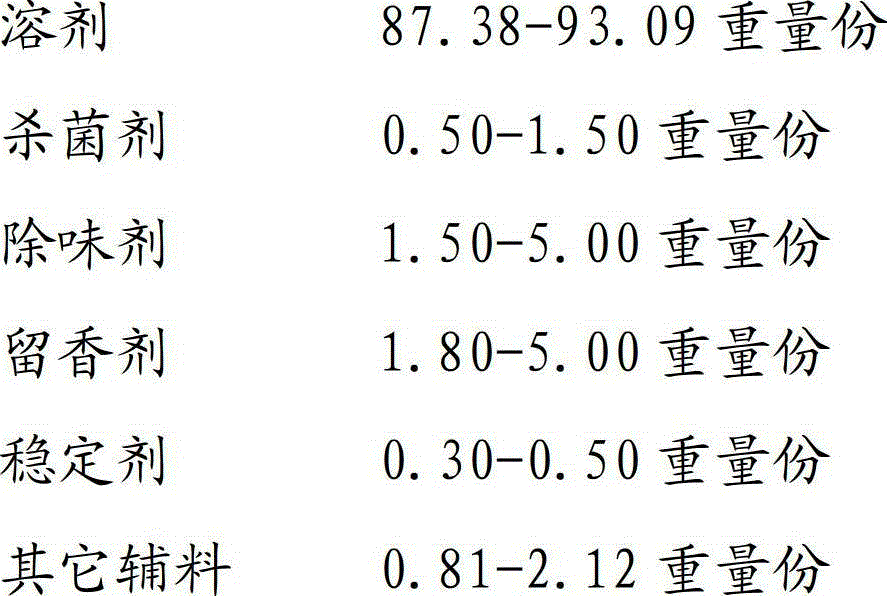

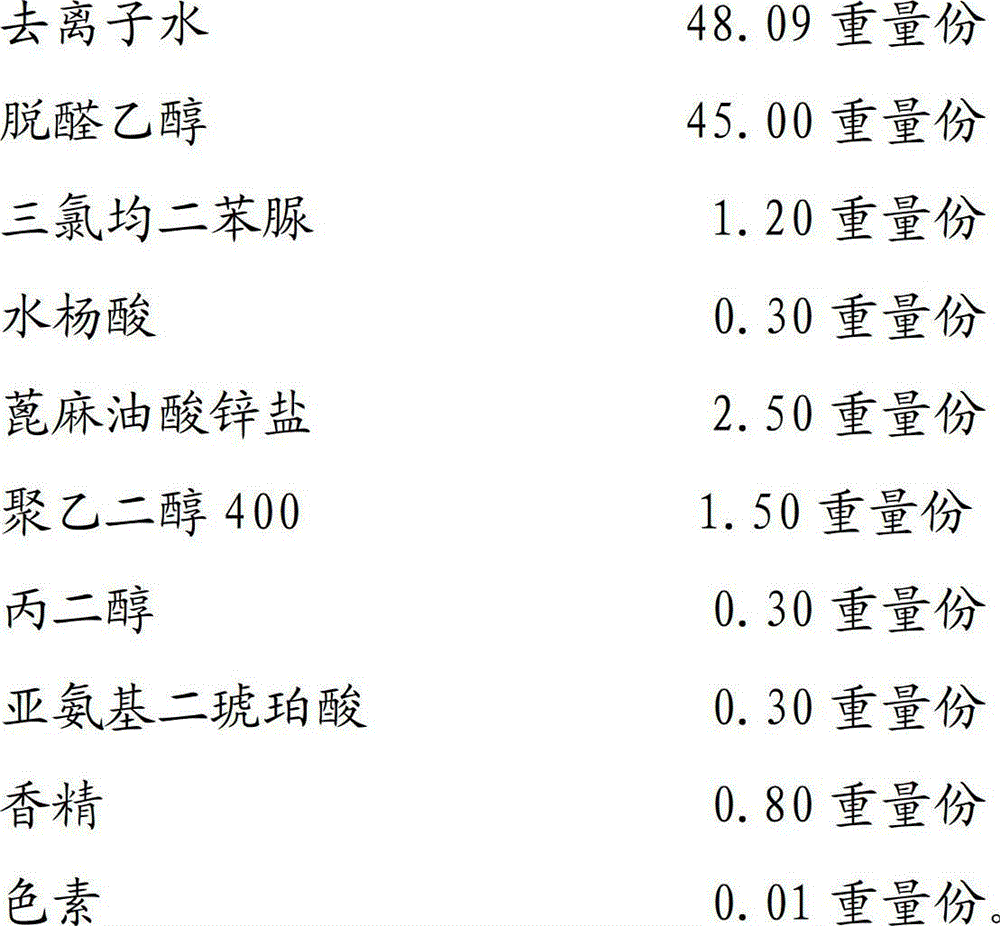

The invention discloses a rapid footgear deodorant agent, which is prepared from the following components in parts by weight: 87.38-93.09 parts of solvent, 0.50-1.50 parts of sterilizing agent, 1.50-5.00 parts of deodorant, 1.80-5.00 parts of fragrant agent, 0.30-0.50 part of stabilizing agent and 0.81-2.12 parts of other auxiliary materials. The rapid footgear deodorant agent is good in comprehensive deodorant performance and convenient to use, the deodorant agent is sprayed inside shoes or socks with odors, so that the odors of the footgear can be rapidly taken away, and a fresh and pleasant effect is achieved. Meanwhile, the invention also discloses a scientific and reasonable preparation method, which comprises the following steps of: adding the sterilizing agent and essence into a dealdehyding ethanol solvent to form a phase I; sequentially adding the fragrant agent, deodorant, sterilizing agent and pigment into deionized water to form a phase II; and slowly adding the phase II into the phase I, and uniformly stirring to form transparent liquid, thus manufacturing the rapid footgear deodorant agent.

Owner:HUANGBAO TECH SHANGHAI

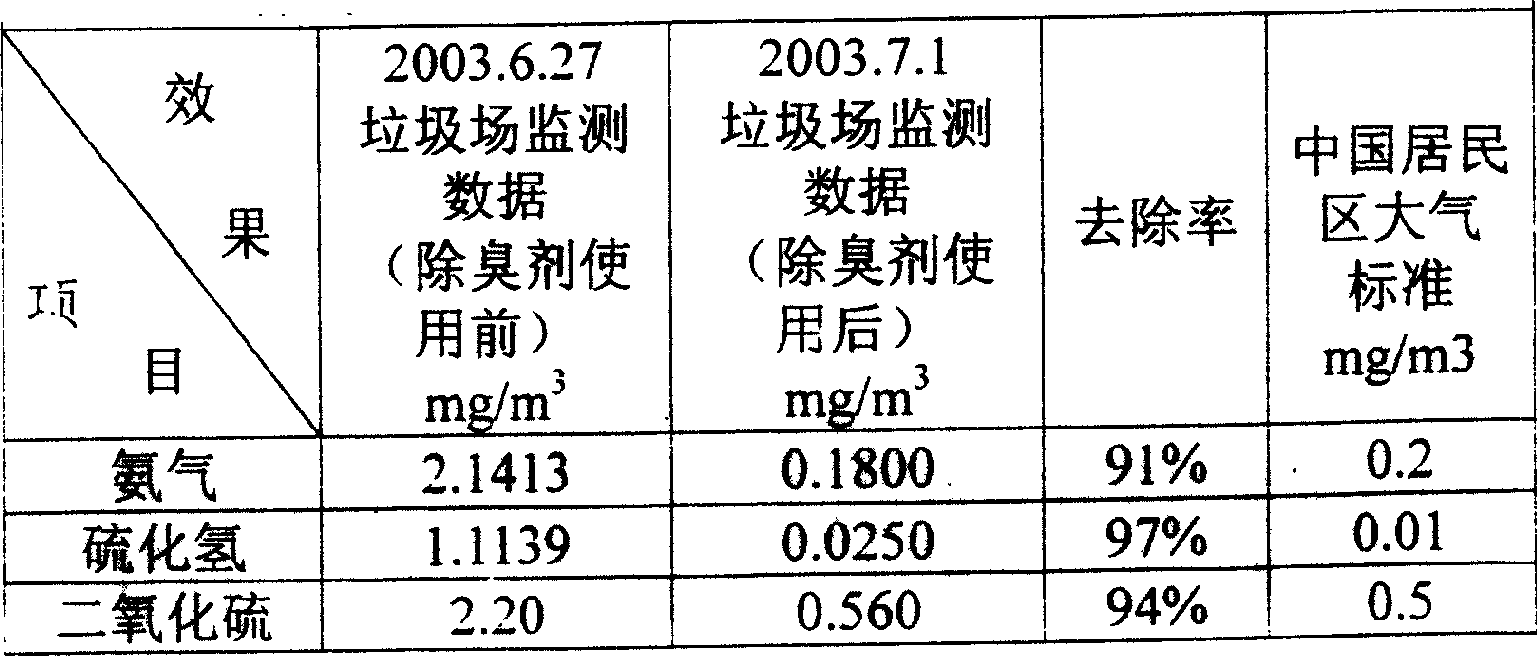

Use of humic acid sodium/potassium for deodorizing rubbish as biochemical deodorizer, its preparation method and deodorizing method

InactiveCN1607009ADeodorize quicklyThoroughly deodorizedMedical waste disposalDeodrantsSucrosePotassium

Said invention relates to an application of biochemical refuse deodorant used in refuse disposal plant, which uses sodium / potassium humecant, and preparation and deodorizing method thereof. The any one kind of peat, brown coal and weathered coal is used as raw material and reacted according to coal, alkali and water proportion of 100:8.5-9.5:400-500,,then deposited to obtain said deodorant. Or further more, drying the colloid solution to make the powder or granular sodium / potassium humecant deodorant. Said invention can be used by directly spraying or used in dilution form by adding cane sugar or fructose and biological fermentation, which not only can deodorize but also kill fly pupa, maggot and clarify refuse percolate.

Owner:薛明

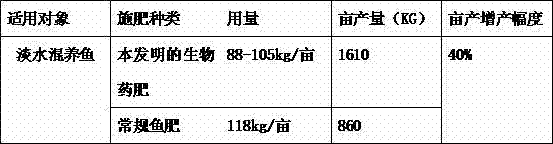

Fresh water polyculture fish compound biological pesticide fertilizer and preparation method thereof

InactiveCN104119152AThoroughly deodorizedImprove disease resistanceFertilizer mixturesMonkshoodsSolubility

The invention discloses a fresh water polyculture fish compound biological pesticide fertilizer and a preparation method thereof. A formula of the fresh waterpolyculture fish compound biological pesticide fertilizer consists of the following components in parts by weight: 50-60 parts of chicken manure, 20-25 parts of acidolysis residues, 10-15 parts of straw powder, 8-10 parts of egg shell powder, 0.1-0.2 part of bacillus subtilis, 0.1-0.2 part of aspergillus oryzae, 0.1-0.2 part of brewer's yeast, 8-10 parts of celastrus orbiculatus, 3-4 parts of azadirachta indica, 4-6 parts of monkshood, 3-5 parts of coptidis rhizome, 2-4 parts of copper sulfate, 12-14 parts of potassium sulfate, 12-14 parts of ammonium bicarbonate, 10-15 parts of calcium superphosphate and 12-14 parts of urea. According to the fresh water polyculture fish compound biological pesticide fertilizer, fermented organic substances and inorganic fertilizer are mixed, and Chinese herbal medicine juice with an insect killing function is added, so that the fresh water polyculture fish compound biological pesticide fertilizer is good in water solubility, can quickly cultivate planktons in a pond to provide baits for the polyculture fish, can improve water quality, can increase dissolved oxygen, can restrain and reduce diseases, and can regulate a micro-ecological environment in offspring seed organisms of the polyculture fish to improve the immunity of the polyculture fish.

Owner:旌德县鸿雁养殖有限公司

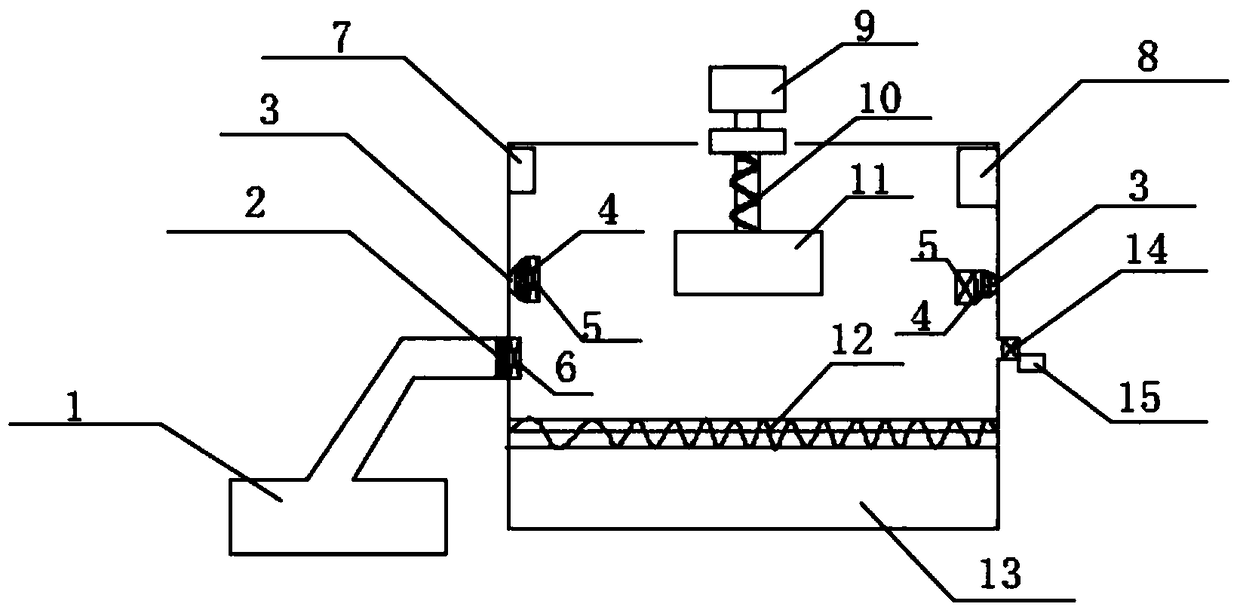

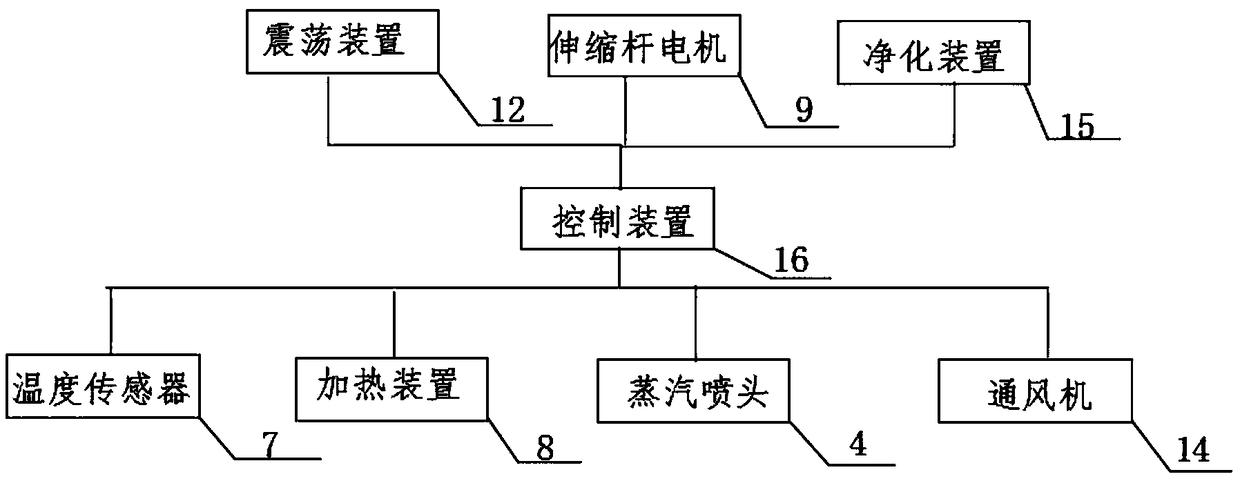

Intelligent garbage collecting system

InactiveCN108792354AMonitor temperature in real timeImprove efficiencyRefuse receptaclesRefuse cleaningLiquid wasteRefuse collection

The invention discloses an intelligent garbage collecting system. The intelligent garbage collecting system comprises a garbage conveying device and a garbage collecting device, wherein the garbage collecting device comprises a plurality of steam nozzles, a temperature sensor, a heating device, an extruding device, an oscillating device and a control device; the garbage extruding device is arranged at the upper part of the garbage collecting device, the plurality of steam nozzles are arranged on the side wall of the garbage collecting device, and the steam nozzles communicate with the garbagecollecting device through gas guide pipes; and the temperature sensor is arranged at the upper part of the left side wall inside the garbage collecting device, the heating device is arranged at the upper part of the right side wall inside the garbage collecting device, the oscillating device is arranged at the bottom of the garbage collecting device, and a waste liquid collecting tank is arrangedbelow the oscillating device. According to the intelligent garbage collecting system, garbage which is of a large object can be extruded through the intelligent garbage collecting device, the space issaved, meanwhile, the garbage is disinfected and deodorized, and the system is reasonable in structural design and simple to operate.

Owner:张嵩

Deodorant, preparation method and application thereof

InactiveCN106362183ARealize the function of deodorizing and degreasingAchieve deodorizationGaseous substancesDeodrantsDeodorantPolyethylene glycol

The invention relates to the field of purification and smell removal, and concretely provides a deodorant, a preparation method and application thereof. The deodorant is prepared from the following raw materials in parts by weight: 3 to 12 parts of citric acid, 1 to 4 parts of polyethylene glycol, 4 to 10 parts of cyclodextrine, and 800 to 1,200 parts of water. The deodorant has the advantages that the smell can be removed thoroughly and quickly, can be used for quickly removing the smell within three minutes, has hot pot smell and fuel fume smell removal rate achieving 95 percent or above, and is safe without damaging clothes.

Owner:孙永跃

Green and environment-friendly organic fertilizer capable of effectively improving soil components

InactiveCN105985187AReduce compactionImprove fertilityExcrement fertilisersBioloigcal waste fertilisersBiotechnologyAlcohol

The invention discloses green and environment-friendly organic fertilizer capable of effectively improving soil components. The green and environment-friendly organic fertilizer is prepared by, by weight, 16.5 parts of human feces, 18-20 parts of chicken manure, 14.5-16 parts of pig manure, 11.5-13 parts of sheep manure, 10-12 parts of wheat straw, 8.5-10 parts of corn straw, 3.5-5 parts of biogas residue, 2-4 parts of alcohol residue, 1-2 parts of humic acid, 1-2 parts of azotobacteria inoculant, 1.5-2 parts of phosphobacteria inoculant, 2-3 parts of silicate bacteria inoculant, 1.5-2 parts of actinomycetes inoculant, 1-2 parts of bone meal, 1-2 parts of bentonite and 2-4 parts of deodorizing agent.

Owner:许明天

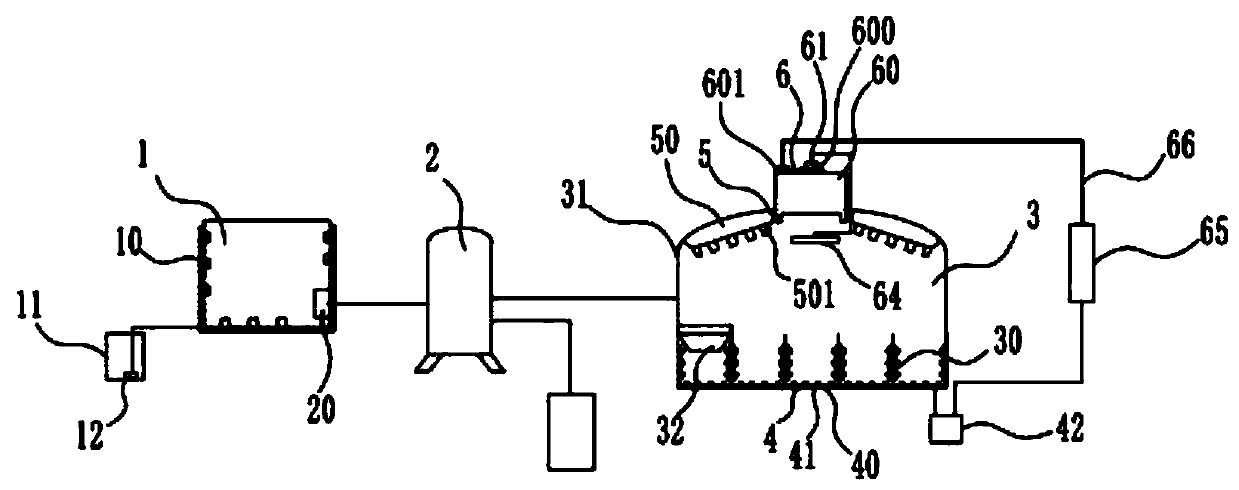

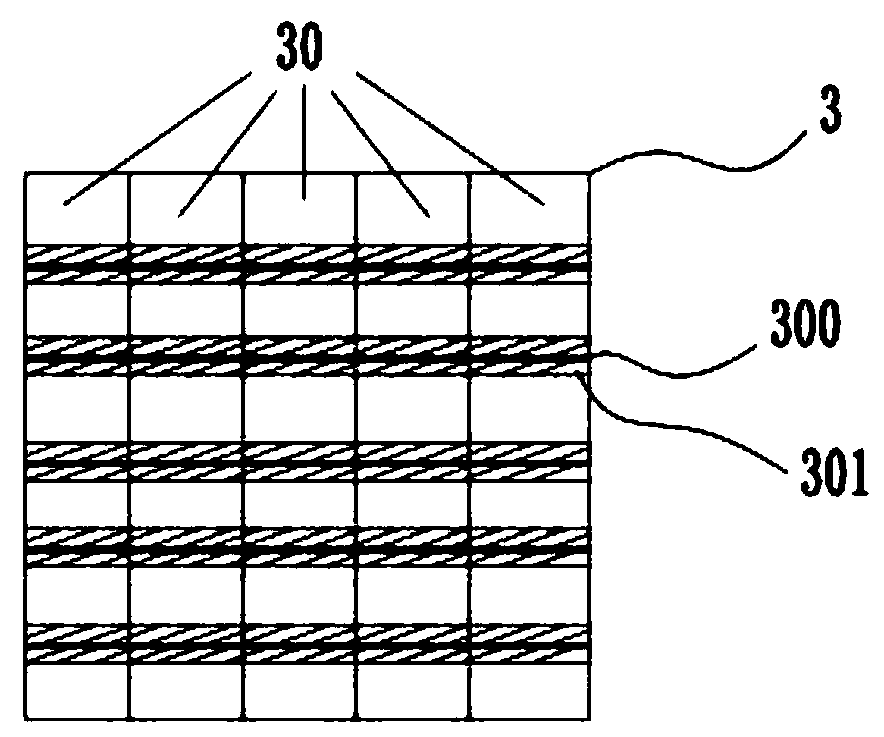

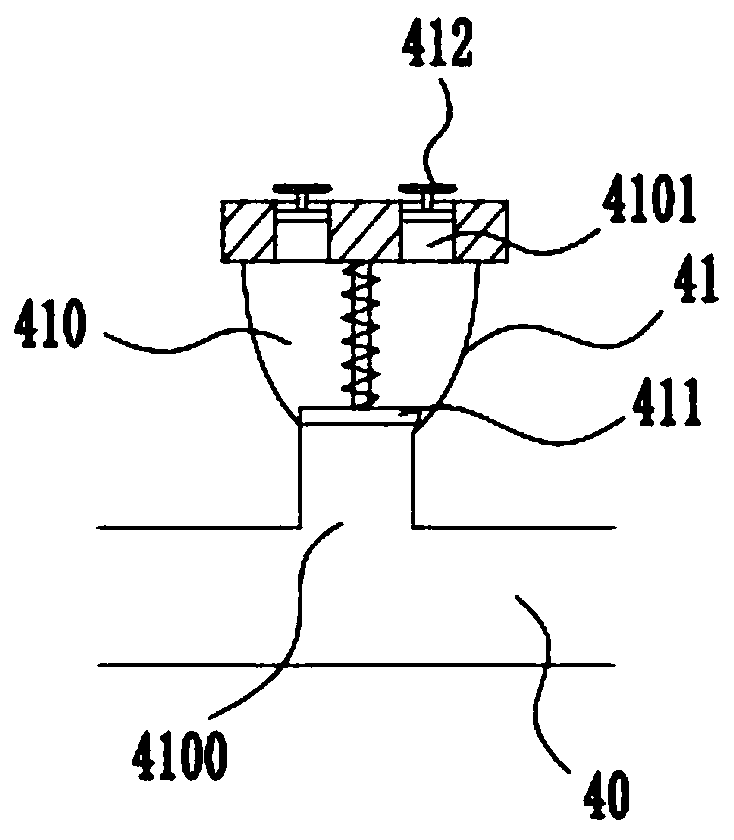

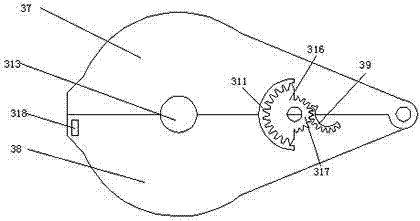

Chemical co-production device of preparing organic fertilizer from livestock and poultry manures

InactiveCN110803946AImprove filtration efficiencyWith energy saving and emission reductionClimate change adaptationExcrement fertilisersAgricultural engineeringPoultry manure

The invention discloses a chemical co-production device of preparing an organic fertilizer from livestock and poultry manures, and belongs to the technical field of organic fertilizer production equipment. The chemical co-production device comprises a homogenization storage tank, a solid-liquid separator, a groove type fermentation tank, a ventilation aeration element, a heat collection element, and a power supply. Through the ventilation aeration element, manures will not enter an aeration pipeline, the aeration pipeline will not be obstructed, the aeration process is guaranteed, and enough oxygen is supplied to the organic fertilizer to ensure the quality of the produced organic fertilizer. By utilizing the ventilation aeration element, air flows out in a spiral form, the wind power is increased, the air ejected in a spiral form is broken into a plurality of air bubbles, and the aeration efficiency is improved therefore. Through a deodorizing element, the odor generated by the fermentation in the groove type fermentation tank is processed centrally; the manures are recycled and reused, the energy consumption and discharge are reduced, and the provided device has the advantages ofuniform aeration, high production efficiency, energy saving, and reduced emission, and is suitable for popularization.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

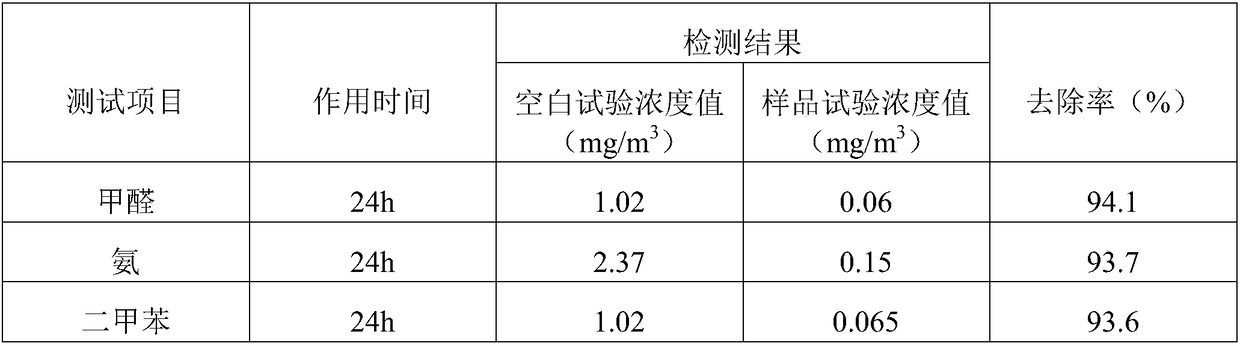

Deodorant antibacterial agent with high stability

The invention discloses a deodorant antibacterial agent with high stability, and belongs to the deodorization and antibacterial field. The invention aims to provide the deodorant antibacterial agent with high stability, wherein the deodorant antibacterial agent cannot cause fiber discoloration or deterioration also cannot cause metal corrosion, allows an amino acid to play the safest effect, has obvious antibacterial effect and can be effectively antibacterial for a long time. The deodorant antibacterial agent with high stability is prepared from the following components: 1-10% of a cereal extract, 1-10% of an amino acid mixture, 5-15% alkyl dimethyl-ammonium benzodiazepine-chloride, 1-5% of lauryl ester-amido-dipropionic acid, 1-9% of polyoxypropylene glycol, and the balance water.

Owner:ZHUHAI SAINTLONGINUS ENVIRONMENTAL SYST CO LTD

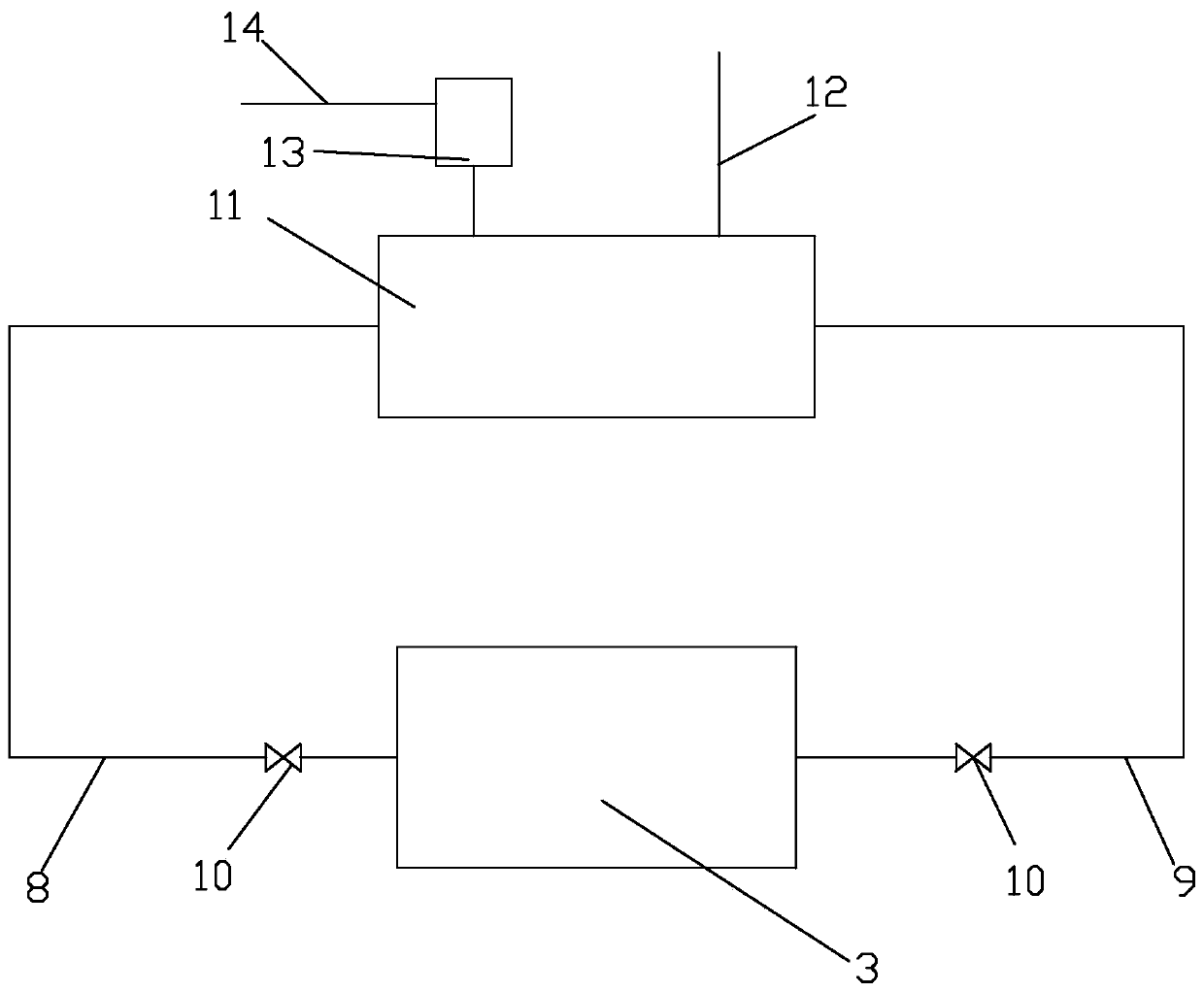

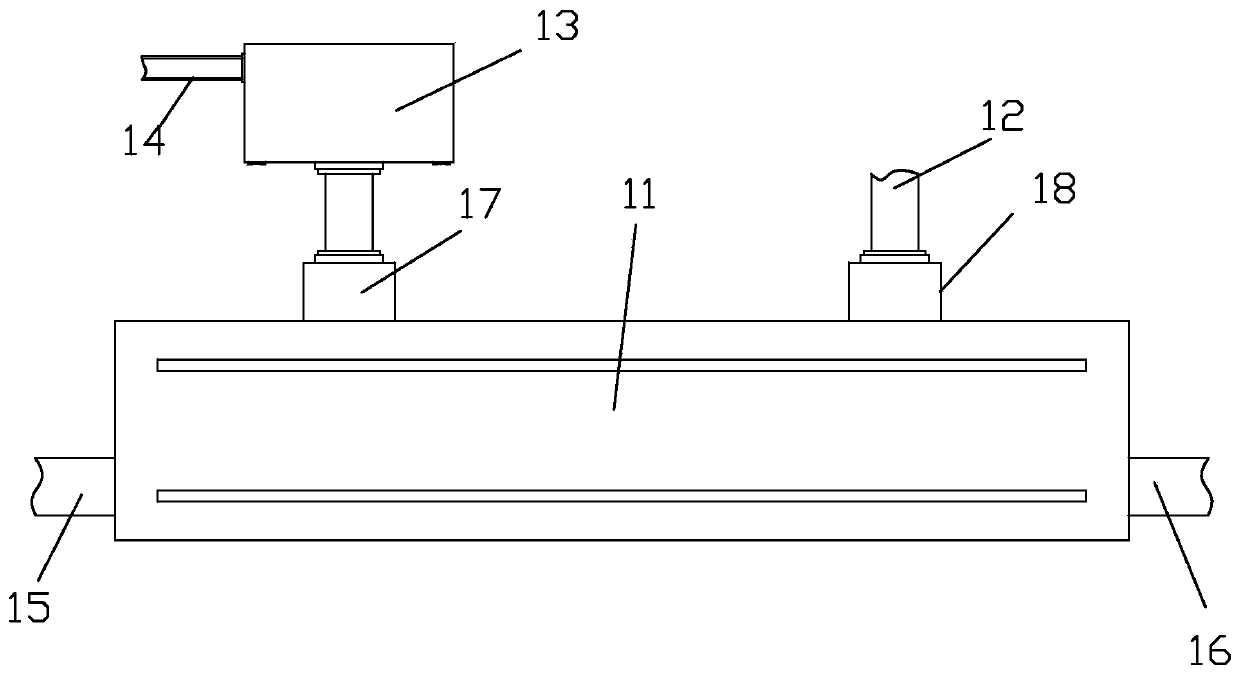

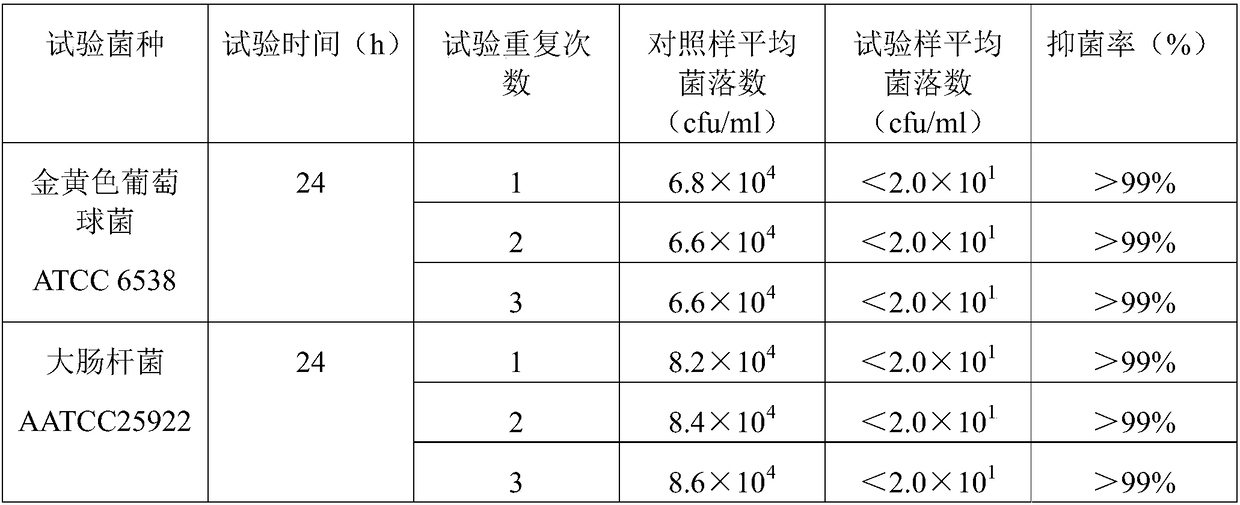

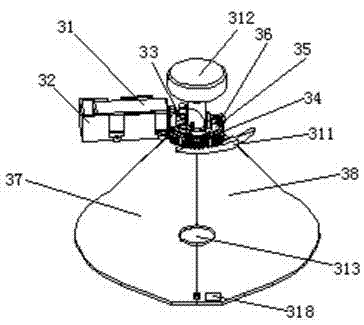

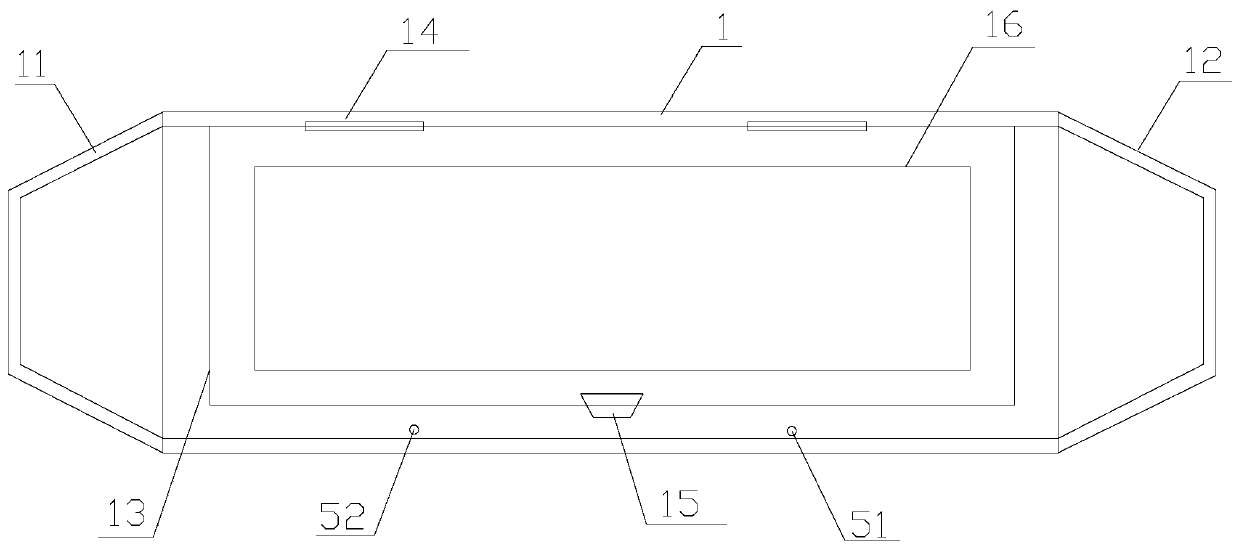

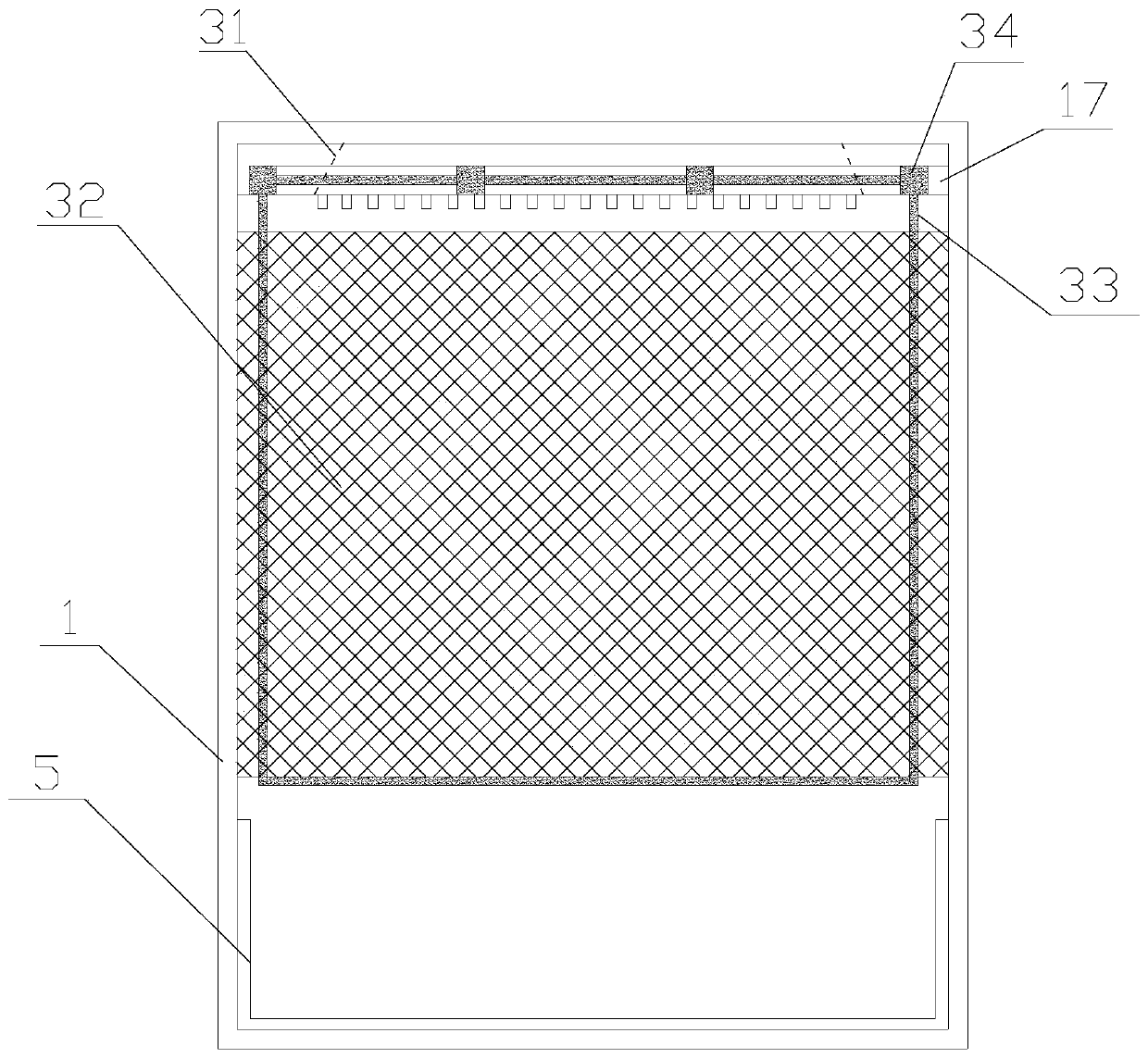

Automatic washing machine for mop and special mop thereof

InactiveCN104840162AGuaranteed pick and placeReduce manufacturing costCarpet cleanersFloor cleanersFixed frameEngineering

The invention discloses an automatic washing machine for a mop and a special mop thereof, and relates to the field of daily necessaries. The automatic washing machine for the mop comprises a shell (11), a washing barrel body (1), a disinfecting system (12), a mop fixing frame (2), a two-way door opening and closing system (3), a driving mechanism, a water inlet and drain system, a cleaning solution feeding device (14) and a control panel, and is characterized in that the washing barrel body is arranged in the middle of the shell, a disinfecting system which is arranged on the shell and the two-way door opening and closing system (3) are arranged above the washing barrel body, the driving mechanism is arranged below the washing barrel body, and the water inlet and drain system and a water level detection system are arranged at the side wall of the washing barrel body; the shell is provided with the mop fixing frame, and a control panel is arranged at the top of the mop fixing frame. The automatic washing machine provided by the invention has the active effects of being stronger in detergency, safe to use, simple in structure, easy to produce, automatic to operate and convenient to operate, and the sterilization and deodorization can be realized.

Owner:日照海智电器有限公司

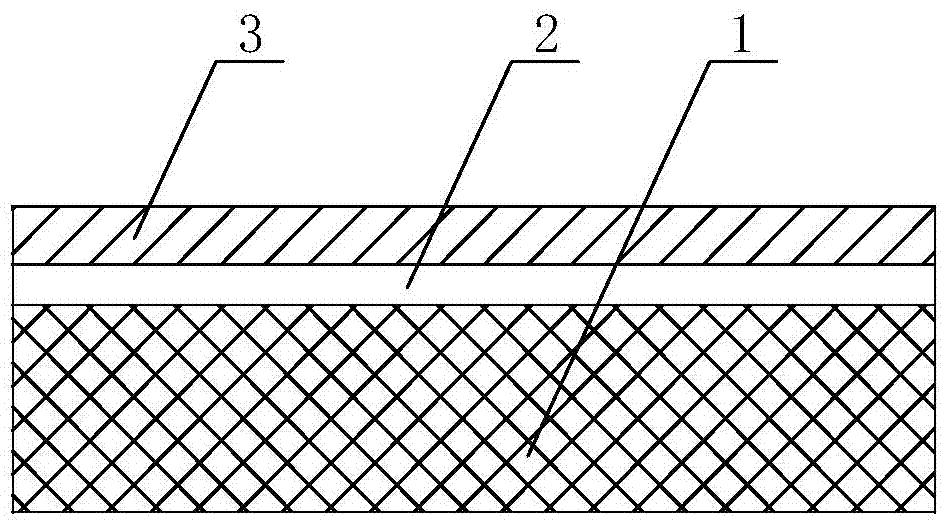

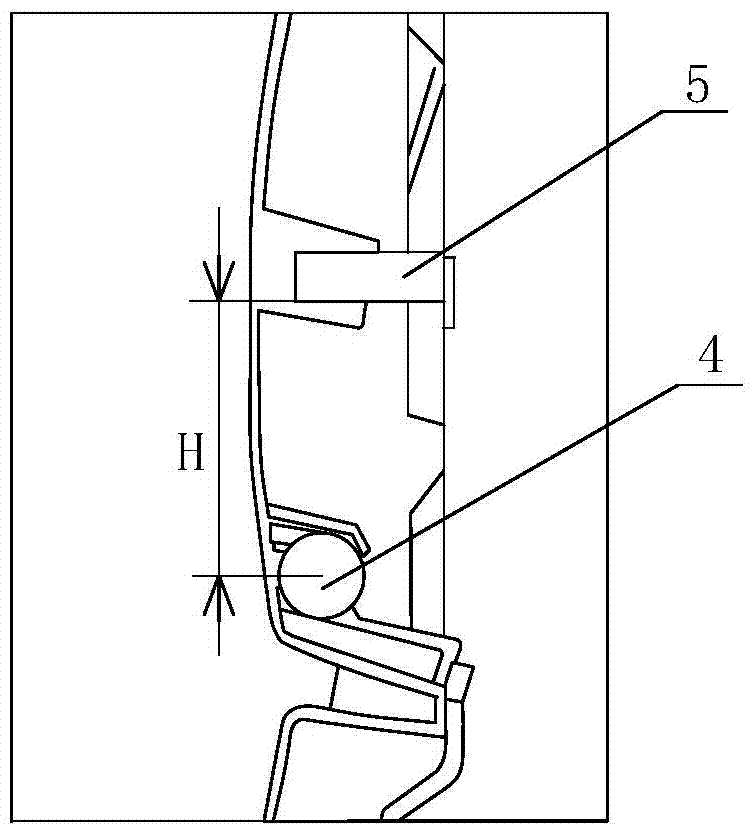

Refrigerator deodorizer and refrigerator

ActiveCN104258437AEffectively balance moistureBalance moistureDomestic cooling apparatusLighting and heating apparatusDeodorantStore food

The invention discloses a refrigerator deodorizer and a refrigerator, belongs to the technical field of refrigerators and is designed to solve the problems that a conventional refrigerator cannot efficiently, permanently and radically sterilize and deodorize, cannot keep food fresh and is low in safety. The refrigerator deodorizer comprises a deodorizer main body provided with a porous reticulate structure and coated with a deodorant layer. The invention also provides a refrigerator including the refrigerator deodorizer and a light source. According to the invention, the porous reticulate structure of the deodorizer main body not only can filter solid impurities in air, but also can absorb water in air so as to effectively balance the food moisture content to keep food fresh, and accordingly, the stored food has low probability of breeding bacteria and fungi; and the deodorant layer coating the deodorizer main body can efficiently, permanently and radically sterilize and deodorize, so that the deodorization rate reaches more than 95%, the fresh-keeping effect is good, no harm is caused to human bodies and the safety is high.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

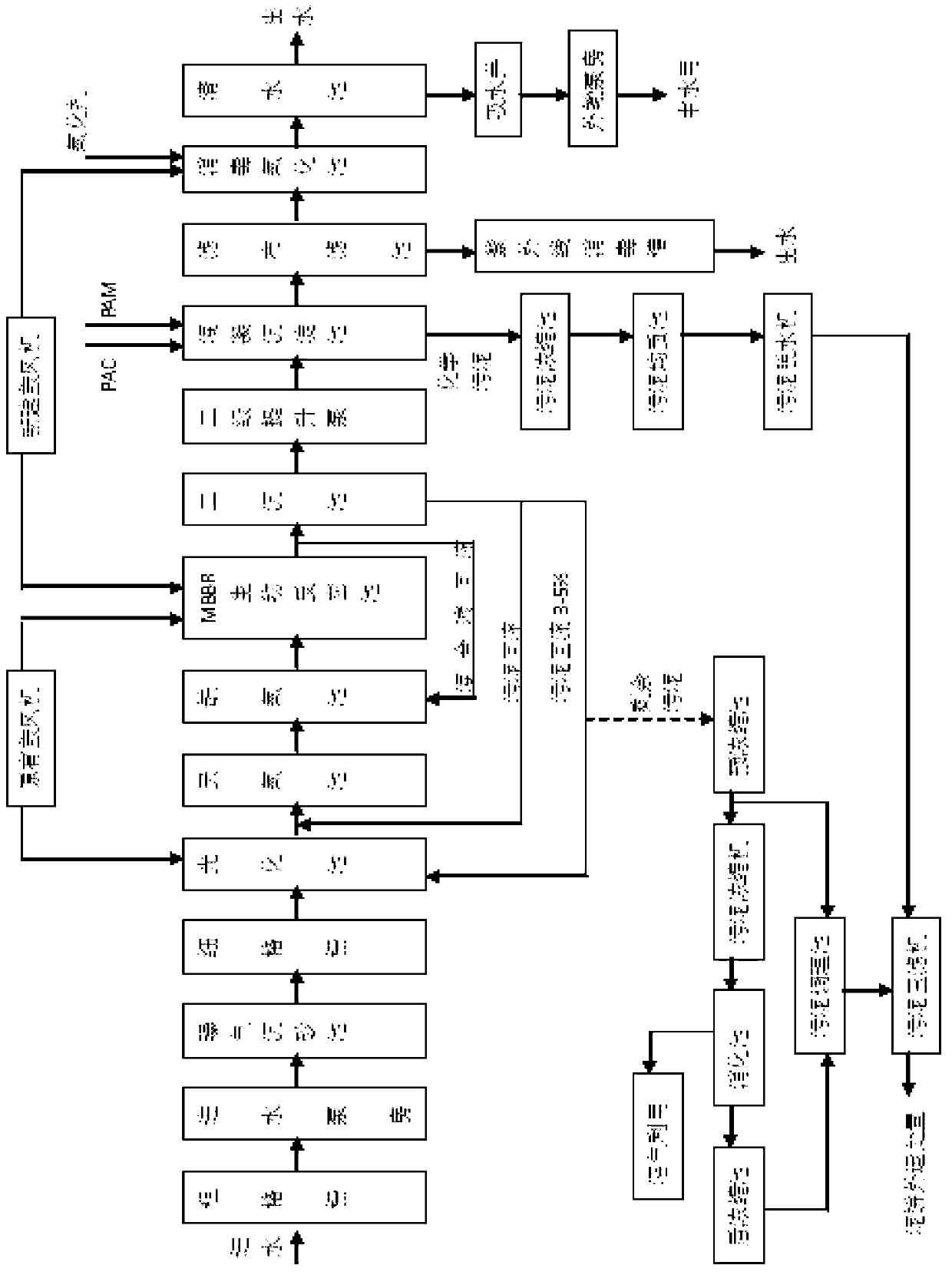

Sewage and sludge processing system

ActiveCN103342438AReduce odorThoroughly deodorizedSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentPost concentrationUv disinfection

The invention discloses a sewage and sludge processing system. A cloth filter is connected with an ultraviolet disinfection tank; a coarse screen, an influent pump station, an aerated grit chamber, a fine screen, a photochemical pool, an anaerobic tank, a anoxic tank, an MBBR biological reaction tank, a secondary sedimentation tank, a two-stage pumping station, a coagulative sedimentation tank, the cloth filter, a disinfection oxidation pond and a clear-water reservoir are connected successively; the clear-water reservoir is connected with a suction well and an efflux pump station successively; the photochemical pool is connected with the MBBR biological reaction tank; the secondary sedimentation tank is connected with the photochemical pool and then connected with pipelines behind the photochemical pool; the MBBR biological reaction tank is connected with the disinfection oxidation pond; the coagulative sedimentation tank is connected with a sludge concentration tank, a sludge homogeneous tank, a sludge dewatering machine and a sludge filter press in order; the secondary sedimentation tank is connected with a pre-concentration tank; the pre-concentration tank is connected with a sludge concentration machine, a digestion tank and a post-concentration tank in order; and at the same time, the pre-concentration tank and the post-concentration tank are connected with a sludge conditioning tank. With the sewage and sludge processing system, the sewage processing quality is improved; and regression of an ecological system is achieved.

Owner:SHANDONG PACIFIC ENVIRONMENTAL PROTECTION

Mumia protein and its production process

ActiveCN1763091ATake advantage ofLow costAnimals/human peptidesBulk chemical productionBioavailabilityNutrient

The silkworm chrysalis protein preparing process includes the following steps: crushing silkworm chrysalis; supercritical CO2 extraction at 30-40 deg.c temperature and 20-35 MPa pressure inside a 400 L container; separation at 25-34 deg.c temperature, 4-8 MPa pressure and 1-2 cu m / hr CO2 flow rate for 80-150 min to obtain coarse protein; grinding, sieving, and airflow crushing to obtain the silkworm chrysalis protein product. The preparation process has advanced supercritical extraction and low temperature airflow crushing, and the prepared silkworm chrysalis protein has no bad smell, high safety, high nutrient value, high bioavailability and obvious effect of remitting fatigue.

Owner:CHENGDU YUYI SILK

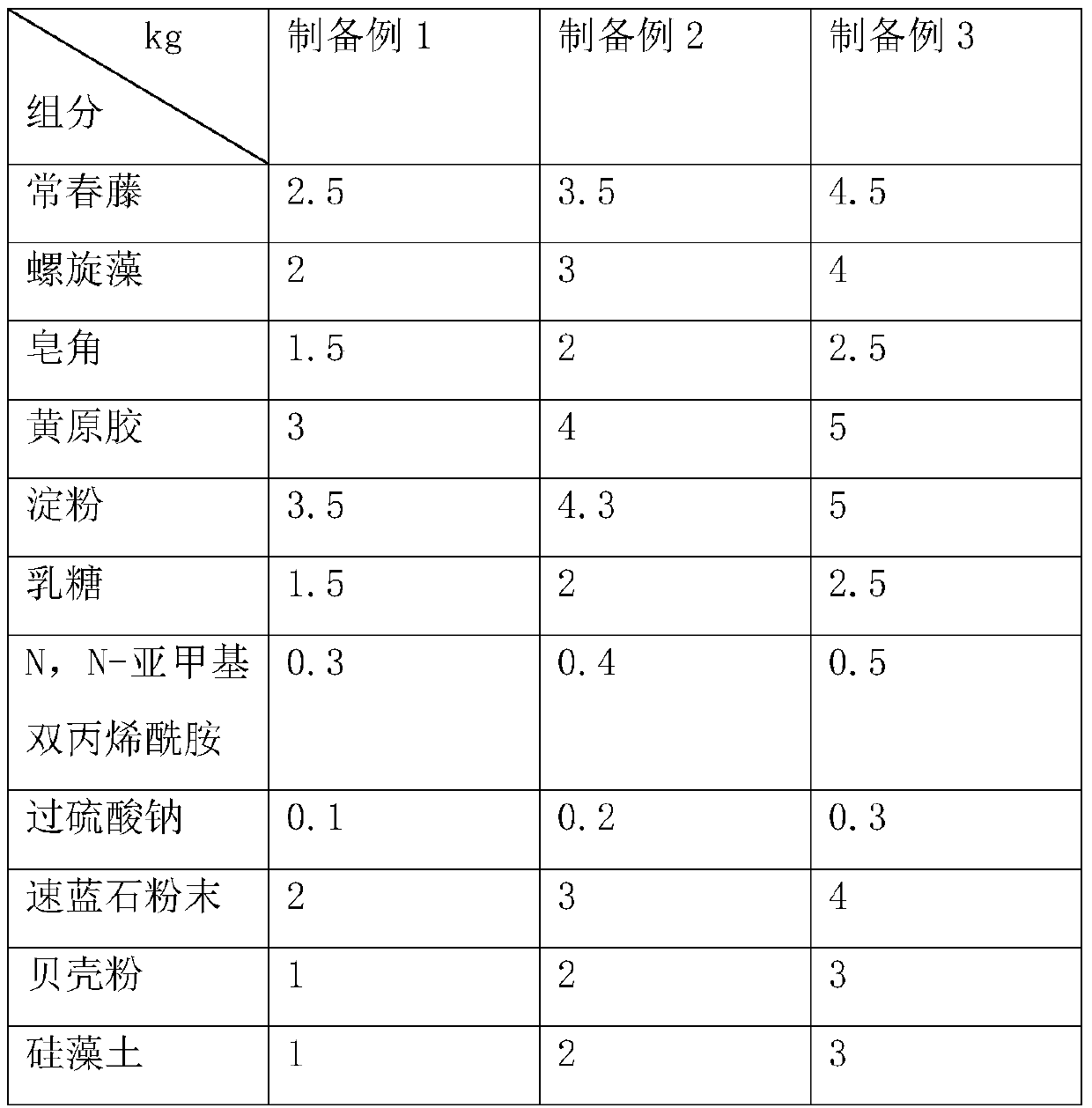

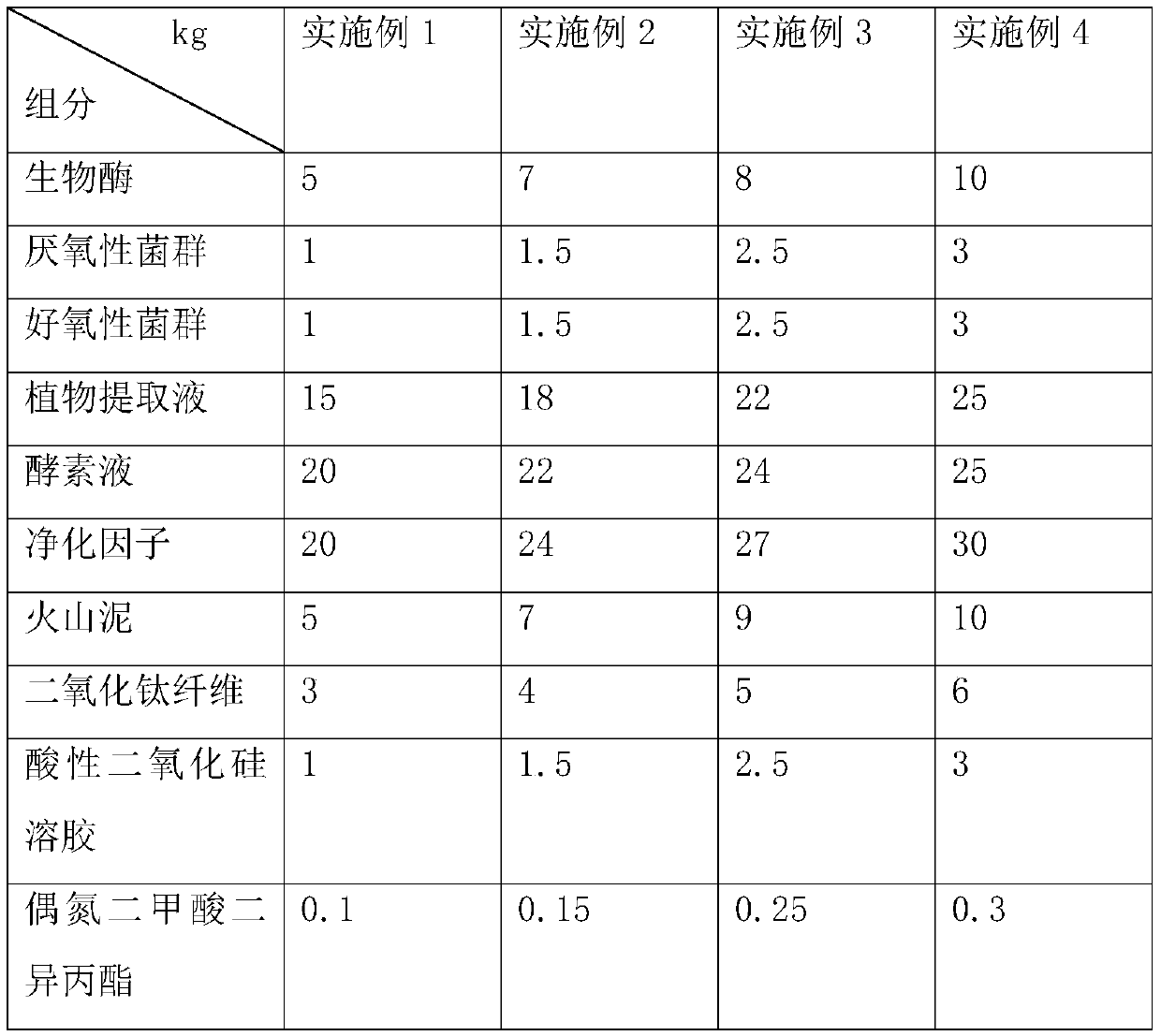

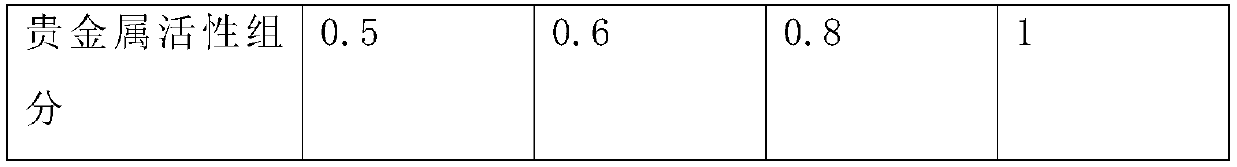

Biological deodorant and preparation method thereof

ActiveCN111514740AGood removal effectFast onset timeGas treatmentDispersed particle separationDiisopropyl azodicarboxylateOrganic synthesis

The invention discloses a biological deodorant and a preparation method thereof. The biological deodorant is prepared from the following raw materials: biological enzyme, anaerobic flora, aerobic flora, a plant extracting solution, an enzyme solution, a purification factor, volcanic mud, titanium dioxide fiber, acidic silicon dioxide sol, diisopropyl azodicarboxylate and a noble metal active component. The biological deodorant has the advantages that the deodorizing time is long for foul smells of livestock and poultry farms, sewage around the farms, municipal sewage, wasteyards, sludge and the like, the removal efficiency is high, the effect returns quickly, the removal effect is comprehensive and thorough, various odor-causing substances can be purified and absorbed, mosquitoes and fliescan be repelled to resist and inhibit bacteria; meanwhile, formaldehyde, methylbenzene and TVOC emitted by wastewater discharged from places such as organic synthesis, synthetic fibers, dyes and woodprocessing can be removed and purified to a certain extent, and harm to human bodies can be reduced.

Owner:BEIJING SHUANGLONG AMMS TECH +1

Chestnut liver-nourishing and spleen-tonifying garlic juice drink and preparation method thereof

InactiveCN105248643AFull of nutritionHas health benefitsMilk preparationTreatment effectPhysical health

The invention discloses chestnut liver-nourishing and spleen-tonifying garlic juice drink. The chestnut liver-nourishing and spleen-tonifying garlic juice drink is prepared from the following raw materials in parts by weight: 270-280 parts of garlics, 180-200 parts of pure milk, 30-34 parts of peanut kernels, 60-65 parts of chestnuts, 30-32 parts of eggplants, 30-32 parts of silverfishes, 20-24 parts of fructus lycii, 8-10 parts of chrysanthemum flowers, 90-110 parts of white sugar and a proper amount of water. The chestnut liver-nourishing and spleen-tonifying garlic juice drink has the advantages that garlic deodourization treatment effect in a processing process is good, so that nutrients of the garlics are maintained; multiple auxiliary materials, such as chestnuts, silverfishes and fructus lycii, are also contained in raw materials, and multiple raw materials are reasonably mixed and processed, so that the chestnut liver-nourishing and spleen-tonifying garlic juice drink is more rich in nutrients, also has a certain health care effect, can be used for nourishing the liver and tonifying spleen and is beneficial to physical health after being drunk.

Owner:金张

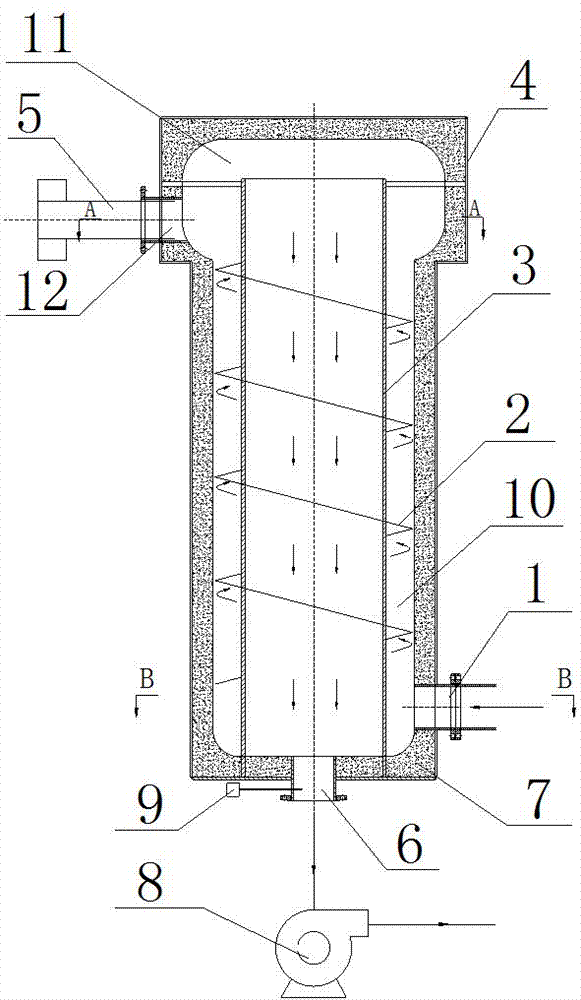

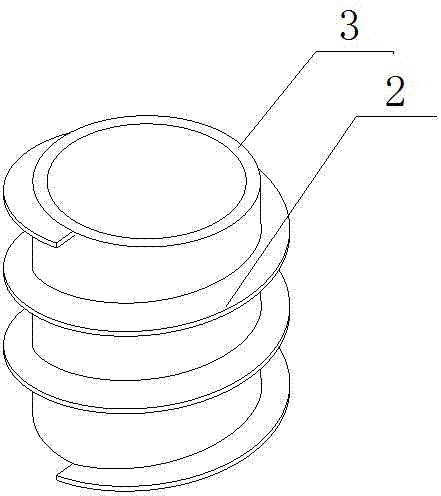

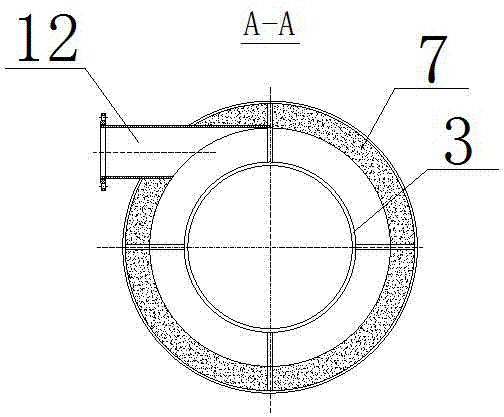

Spiral self-preheating deodorization furnace and waste gas deodorization process using same

InactiveCN103196148AGuaranteed uptimeLow running costIncinerator apparatusHigh concentrationCombustion chamber

The invention provides a spiral self-preheating deodorization furnace and waste gas deodorization process using the same. The spiral self-preheating deodorization furnace comprises an inner cylinder, an outer cylinder and a spiral guiding plate. The outer cylinder comprises a preheating chamber and a combustion chamber. The top portion of the inner cylinder is communicated with the combustion chamber of the outer cylinder. The spiral guiding plate is arranged on an outer wall of the inner cylinder in spiral mode from the bottom to the top. A waste gas inlet is arranged at the bottom side of the outer cylinder. The waste gas inlet is communicated with the preheating chamber. A gas inlet is arranged on the top side of the outer cylinder. The gas inlet is communicated with the combustion chamber. The gas inlet is tangential with an outer wall of the combustion chamber. A waste gas outlet is communicated with the bottom of the inner cylinder. The spiral self-preheating deodorization furnace can adapt to deodorization processing of different foul gas substances with high concentration and large gas quantity, is stable and reliable in operation and does not require special pre-processing, such as heating, humidifying, on the foul gas. Operation cost is low, covered area of equipment is small, operation and maintaining are simple, and the spiral self-preheating deodorization furnace can provide heat for other systems.

Owner:CECEP BOTH HUBEI ENVIRONMENT ENG & TECH

Toilet deodorizer

The invention provides a preparation method of a toilet deodorizer. The toilet deodorizer comprises the following components: sodium C11-C14 alkyl benzene sulfonate, hydrochloric acid, ferrous chloride, zinc chloride, aluminium trichloride, sodium chloride, magnesium nitride, lignin, diatomite and water. The toilet deodorizer has the characteristics that the deodorization is thorough, the effect is durable, the air is odorless and sterile after deodorization, materials which are bad for human body are not generated after using the deodorizer, the source of raw materials is wide, the cost is low, etc.

Owner:戚冬梅

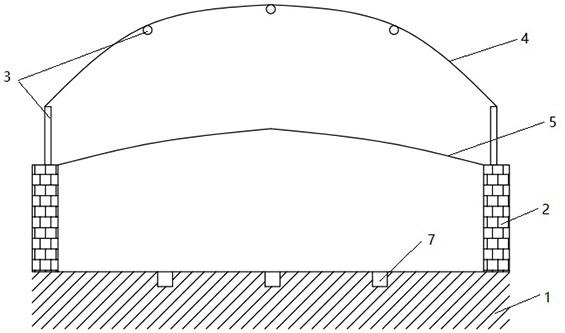

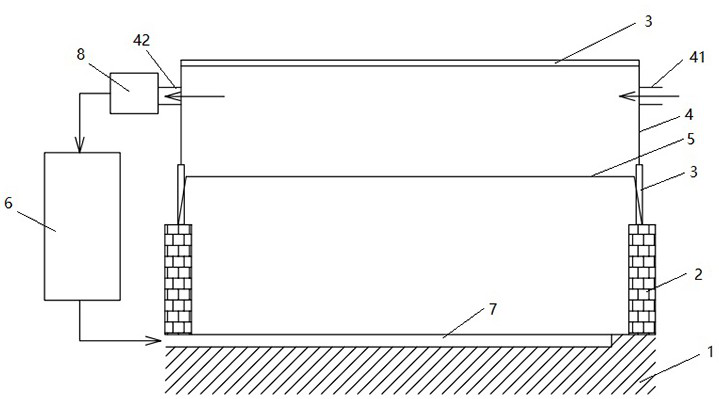

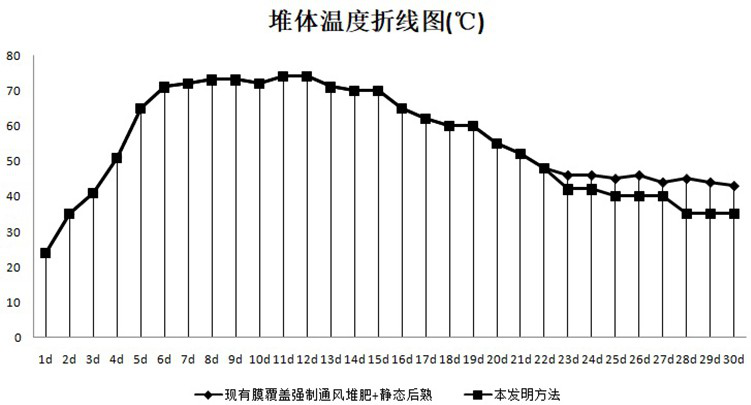

Greenhouse film covering forced ventilation aerobic composting method

PendingCN112266286AStabilize and improve tasteGreat tasteBio-organic fraction processingExcrement fertilisersGreenhouseEnvironmental engineering

The invention discloses a greenhouse film covering forced ventilation aerobic composting method which comprises the following steps of mixing rice and wheat straws, vines, livestock and poultry excrement and urine, perishable garbage and garden wastes in proportion, and putting the mixture into a composting body space of a greenhouse film covering forced ventilation aerobic composting system for composting. According to the system, a composting body space is defined by an expanded polytetrafluoroethylene film, a composting body side wall and a composting body ground, a ventilation groove is formed in the composting body ground, a greenhouse framework is arranged above the expanded polytetrafluoroethylene film and covers a plastic greenhouse film, and the plastic greenhouse film is providedwith an air inlet; the forced ventilation device extracts air from the space between the plastic greenhouse film and the expanded polytetrafluoroethylene film and leads the air into the ventilation groove, and after 20 days of composting and when the temperature of the compost is reduced to 50 DEG C or below, the expanded polytetrafluoroethylene film is removed to enable the compost to be exposedto the lower portion of the plastic greenhouse film. According to the method, turning and turning treatment is not needed during composting, odor escaping in the whole composting process is circularly fed into the composting body through the forced ventilation system, the deodorization and ventilation effects are achieved, and the overall operation cost is low.

Owner:常熟市小强农业发展有限公司

Health-preserving health-care buckwheat and garlic juice beverage and preparation method thereof

InactiveCN105285113APreliminary deodorizationKeep active ingredientsMilk preparationPolygonum fagopyrumPine pollen

The invention discloses a health-preserving health-care buckwheat and garlic juice beverage. The health-preserving health-care buckwheat and garlic juice beverage is prepared from the following raw materials in parts by weight: 270-280 parts of garlic bulbs, 180-200 parts of pure milk, 30-34 parts of peanut kernels, 50-56 parts of buckwheat, 34-37 parts of coconut milk, 19-21 parts of pine pollen disruption powder, 24-27 parts of bean curds, 10-13 parts of Chinese waxgourd peel, 90-110 parts of white sugar and an appropriate amount of water. The health-care garlic juice beverage disclosed by the invention is prepared through reasonably matching and processing the main materials of the garlic bulbs and the auxiliary materials of the buckwheat, the coconut milk, the pine pollen disruption powder and the like, and in the processing course of the health-care garlic juice beverage, the deodorizing treatment effects on garlic are good, so that the health-care garlic juice beverage disclosed by the invention is rich in nutrition; besides, the garlic bulbs, the buckwheat and the coconut milk also have definite nutrient and health-care efficacies, so that the health-care garlic juice beverage is beneficial to the health of bodies after being drunk.

Owner:金张

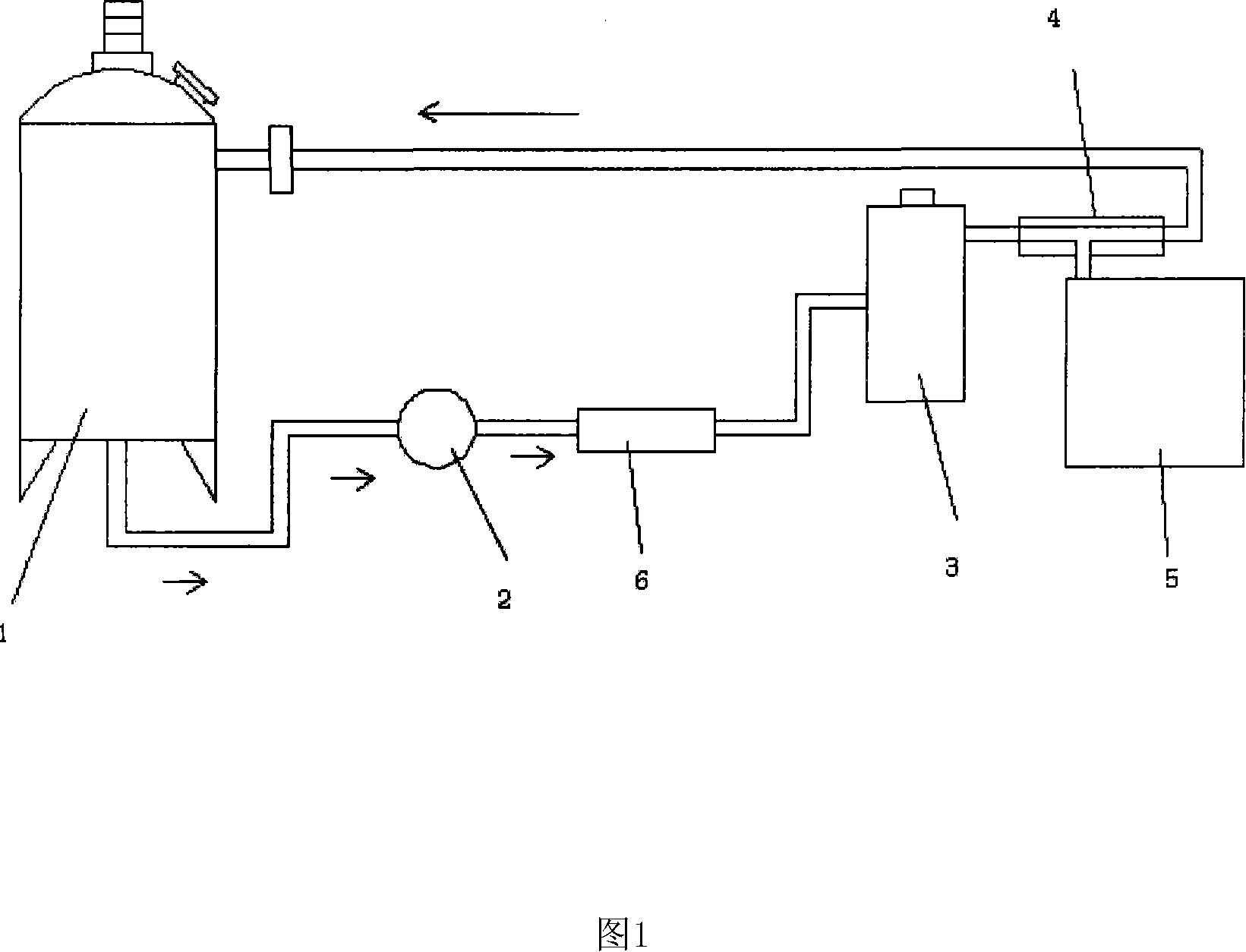

Fresh-keeping and Deodorization device for pickled vegetables

InactiveCN101081071AImprove the bactericidal effectGood killing effectFruits/vegetable preservation using acidsFood preparationOzone generatorEnvironmental engineering

The present invention provides one kind of pickle preserving and deodorizing apparatus, which includes a fermenting tank, a conveying pump, a solid-liquid separator, a mixer and an ozone generator connected successively through pipeline, with the outlet of the mixer being connected through pipeline to the fermenting tank. The apparatus has the ozone generator and the fermenting tank well combined, so that it can sterilize pickle and water simultaneously after fermentation in the fermentation system and before packing, reduce microbial contamination and prolong the preservation period while maintaining the flavor of pickle. The apparatus of the present invention has simple structure, and is suitable for scale development of pickle industry.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Health-care cheese and garlic juice beverage capable of strengthening bodies and preparation method of cheese and garlic juice beverage

The invention discloses a health-care cheese and garlic juice beverage capable of strengthening bodies. The health-care cheese and garlic juice beverage is prepared from the following raw materials in parts by weight: 270-280 parts of garlic bulbs, 180-200 parts of pure milk, 30-34 parts of peanut kernels, 17-20 parts of pork rind, 30-34 parts of dried marine algae powder, 20-23 parts of lily bulbs, 26-29 parts of purslane herbs, 56-60 parts of sour cream, 90-110 parts of white sugar and an appropriate amount of water. The health-care garlic juice beverage disclosed by the invention is prepared through reasonably matching and processing the main materials of the garlic bulbs and the auxiliary materials of the dried marine algae powder, the lily bulbs, the sour cream and the like, and in the processing course of the health-care garlic juice beverage, the deodorizing treatment effects on garlic are good, so that the health-care garlic juice beverage disclosed by the invention is good in drinking mouth feel and rich in nutrition; besides, varied raw materials also have definite nutrient and health-care efficacies, so that the health-care garlic juice beverage can strengthen bodies after being drunk.

Owner:金张

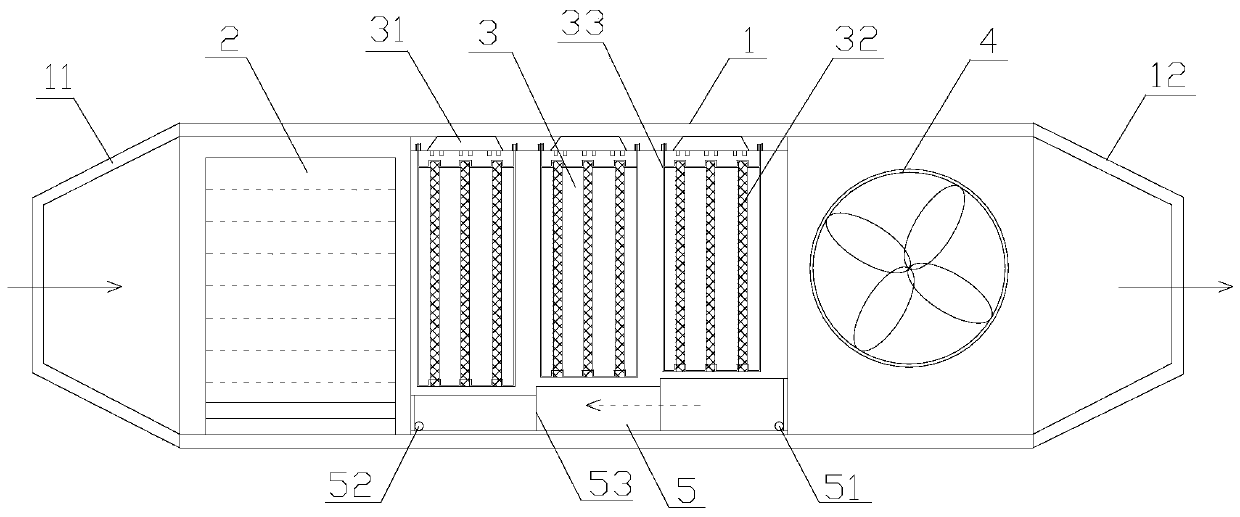

Odor purification integrated device

PendingCN110756031AReduce construction costsReduce use costGas treatmentDispersed particle separationHoneycombProcess engineering

The invention relates to the technical field of waste gas treatment. The invention discloses an odor purification integrated device. The odor purification integrated device comprises a box-type shell,and a plasma purification unit, multiple stages of spraying assemblies, and a fan which are arranged in the box-type shell, wherein an air inlet and an air outlet are respectively formed in two endsof the box-type shell; the plasma purification unit is located at the end, close to the air inlet, of the box-type shell. The fan is positioned at one end, close to the air outlet, of the box-type shell; the multiple stages of spraying assemblies are positioned between the plasma purification unit and the fan; each stage of the multi-stage spraying assembly comprises a spraying head and a water tank located below the spraying head, a fluff-shaped honeycomb reaction layer is further arranged between the spraying head and the water tank of at least one stage of spraying assemblies, and the fluff-shaped honeycomb reaction layer is installed in the box-type shell through a hanging frame. The device is small in size, good in occupied area effect and suitable for small-air-volume waste gas treatment projects, low-temperature plasma and multi-stage washing, adsorption and reaction combined purification is adopted, and a better deodorization effect can be achieved.

Owner:重庆明道环保科技有限公司

Deodorization foam and foam deodorization system

InactiveCN107441918AFast workThoroughly deodorizedDispersed particle separationDeodrantsChemistryDecomposition

The invention discloses deodorization foam and a foam deodorization system. The deodorization foam contains the following components in percentage by weight: 95%-98% of a deodorization agent, 1%-2% of lauryl dimethyl amine oxide, 1%-2% of lauryl sodium sulfate and 0.1%-1% of a silicon resin polyether emulsion. The foam deodorization system comprises deodorization foam, a foam generation device, a pressurizing device and a liquid spraying device, wherein the foam generation device is connected with the pressurizing device and the liquid spraying device, respectively, and the deodorization foam enters the foam generation device through the pressurizing device and is sprayed out by virtue of the liquid spraying device. The deodorization foam is sprayed to the surface of landfill works, has a thorough deodorization effect through multiple ways of decomposition, coverage, inhibition and the like and is long in effective time.

Owner:福州艾美林环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com