Method for producing functional microbial fertilizer by two-step fermentation and application of functional microbial fertilizer

A technology of functional microorganisms and fertilizers, applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve the problems of long production cycle, high labor cost, secondary pollution, etc., achieve reduced heating energy consumption, stable product quality, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

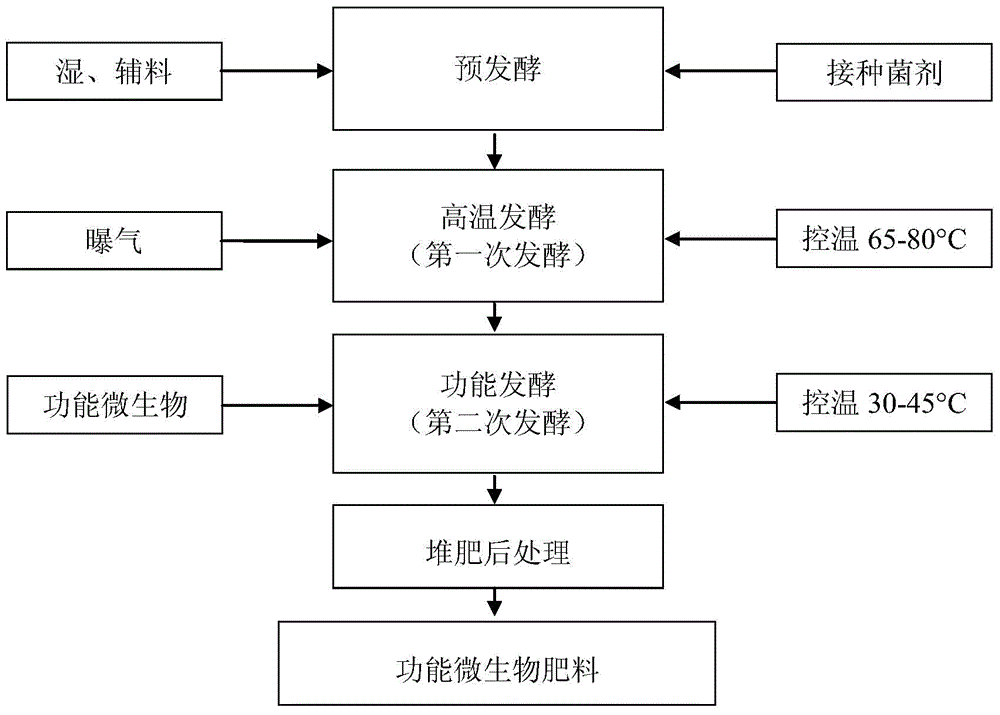

[0035] A method for producing functional microbial fertilizer by two-step fermentation, the steps are:

[0036] 1) Material pretreatment and pre-fermentation

[0037] Mix pig manure (moisture content 72%) with crushed rice bran (30 mesh) in proportion (pig manure: rice bran = 5:1, weight ratio), adjust the final water content of the material at 60%, and adjust the water content according to 0.5% of the material weight is inoculated with high-temperature decomposing bacteria, and the material is stacked after mixing. The height of the material stack is controlled at 1.2m, and the stack is long and 2m wide, and the constant temperature is maintained at 60°C for 4 days.

[0038] The high-temperature decomposing bacteria is an organic material decomposing agent (Chengdu Tianxing Agricultural Technology Co., Ltd.).

[0039] During pre-fermentation, PC sunshine panels are installed on the indoor ceiling to increase the material temperature.

[0040] 2) High temperature fermentatio...

Embodiment 2

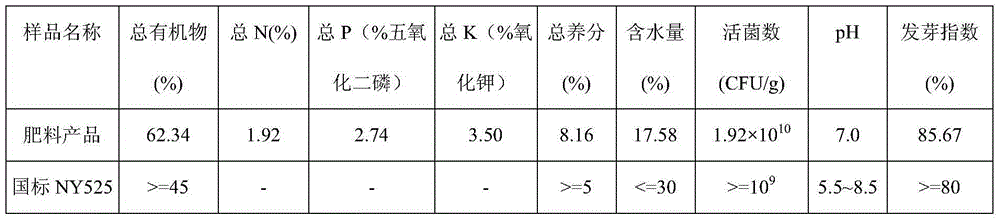

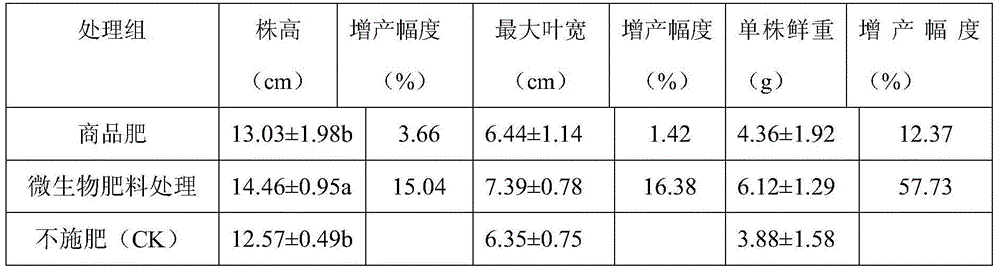

[0054] The microbial fertilizer prepared in Example 1 was used as a base fertilizer, mixed with soil and applied to potted planting of capsicum and Chinese cabbage seedlings, and the commercial fertilizer was used as a control to compare its growth-promoting and disease-resistant effects.

[0055] See Table 2 and Table 3 for the application effect of the microbial fertilizer prepared by the present invention on capsicum; see Table 4 for the application effect on Chinese cabbage.

[0056] Table 2 The growth-promoting results of the microbial fertilizer prepared in Example 1 on pepper seedlings

[0057] treatment group root length (cm) stem length(cm) Plant fresh weight (g) Plant dry weight (g) Commodity fertilizer 8.00±2.80a 9.70±3.41a 1.35±1.09a 0.21±0.17a Microbial Fertilizer Treatment 14.60±5.20b 14.80±2.00b 2.69±0.85b 0.37±0.13b

[0058] Note: The values in the table are the average of two repeated experiments. Different lowercase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com