Horizontal forging technology for middle-sized spline shaft yoke

A spline shaft fork, flat forging technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of difficult installation, increased forging costs, lack of material in the final forging of pre-forgings, etc., to achieve mold processing And the effect of convenient positioning, reducing heating energy consumption, and reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

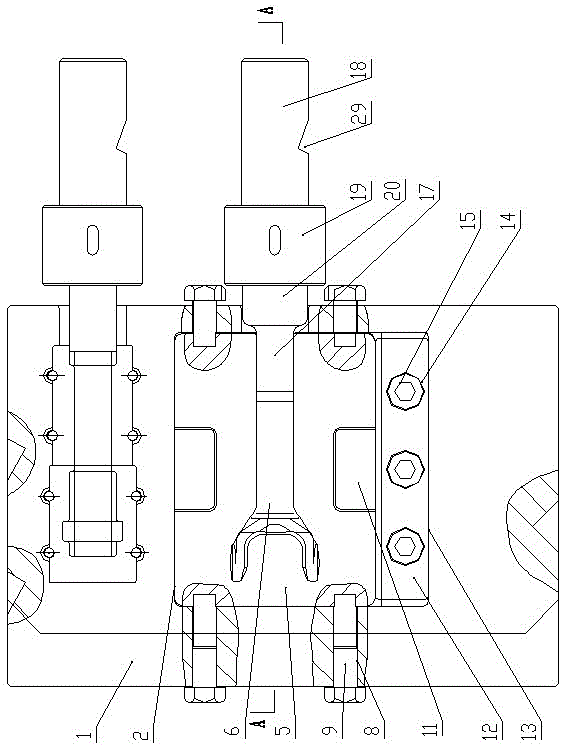

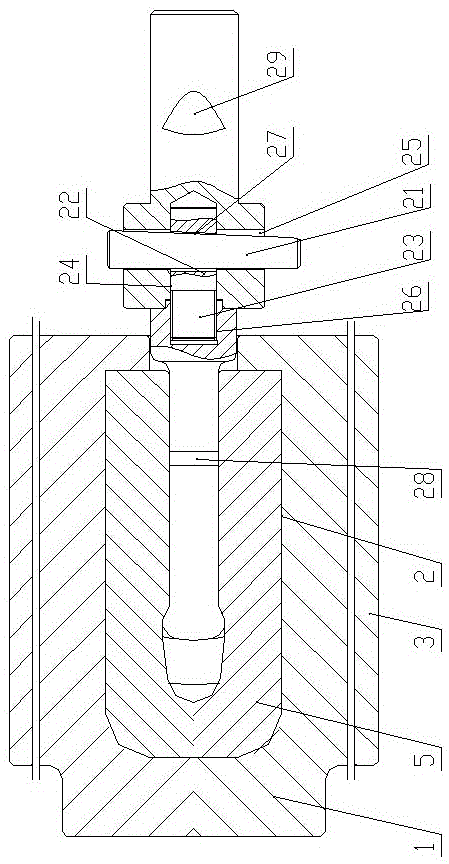

[0022] like Figure 1-2 As shown, the forging process of the spline shaft fork includes the following steps:

[0023] (1) Cutting: the diameter of the blank is 55mm, the material is 40Cr, and the length is 295mm;

[0024] (2) Upsetting: heating the end of the blank, the heating temperature is 1150°C, the heated blank is the blank to be upset, and then the blank to be upset is placed on the flat forging machine for the pre-forging of the spline shaft fork flat forging die In the spline shaft fork cavity of the die, the power drive end drives the pre-forging punch to upset the blank to be upset, and the pre-forging blank is formed after the upsetting is completed;

[0025] (3) Final forging: Take out the pre-forging blank and place it in the spline shaft fork cavity of the final forging die of the spline shaft fork flat forging mold on the flat forging machine, control the flat forging machine, and the power drive end drives the final forging punch to upset Extrude the pre-for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com