Ethylene prepared by catalytic dehydration of ethylene

An ethylene and catalyst technology, applied in the field of ethanol dehydration to ethylene reaction and corresponding catalysts, can solve the problems of high reaction temperature, use of inert diluent gas, etc., achieve high ethylene selectivity, increase single-pass production, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1H

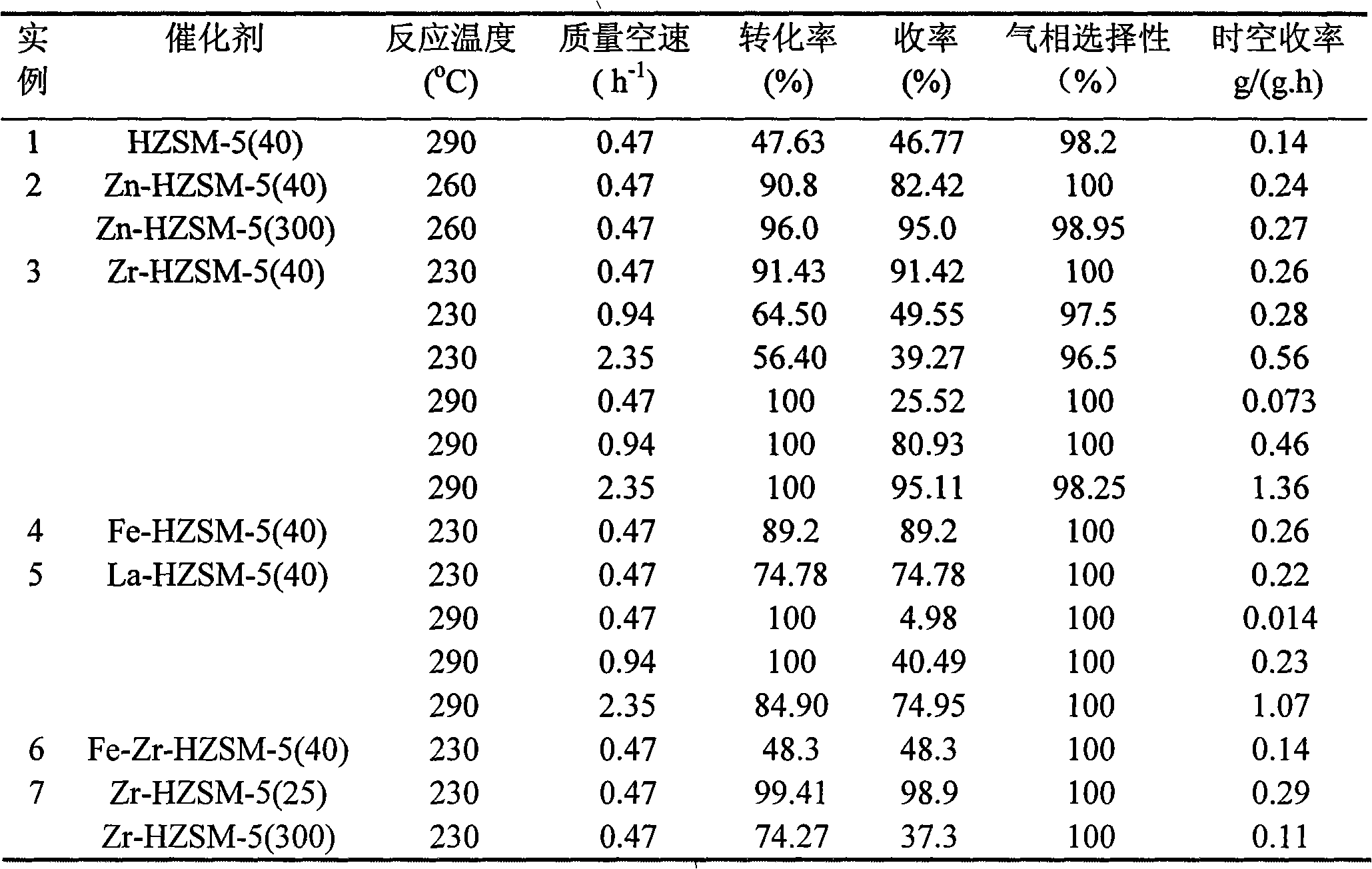

[0024] Example 1HZSM-5(40)

[0025] Weigh 10g of HZSM-5 raw powder with Si / Al=40, wash it with deionized water, dry it at 110°C, and put it into a muffle furnace at 500-700°C for 2-5 hours to prepare HZSM-5(40) catalyst.

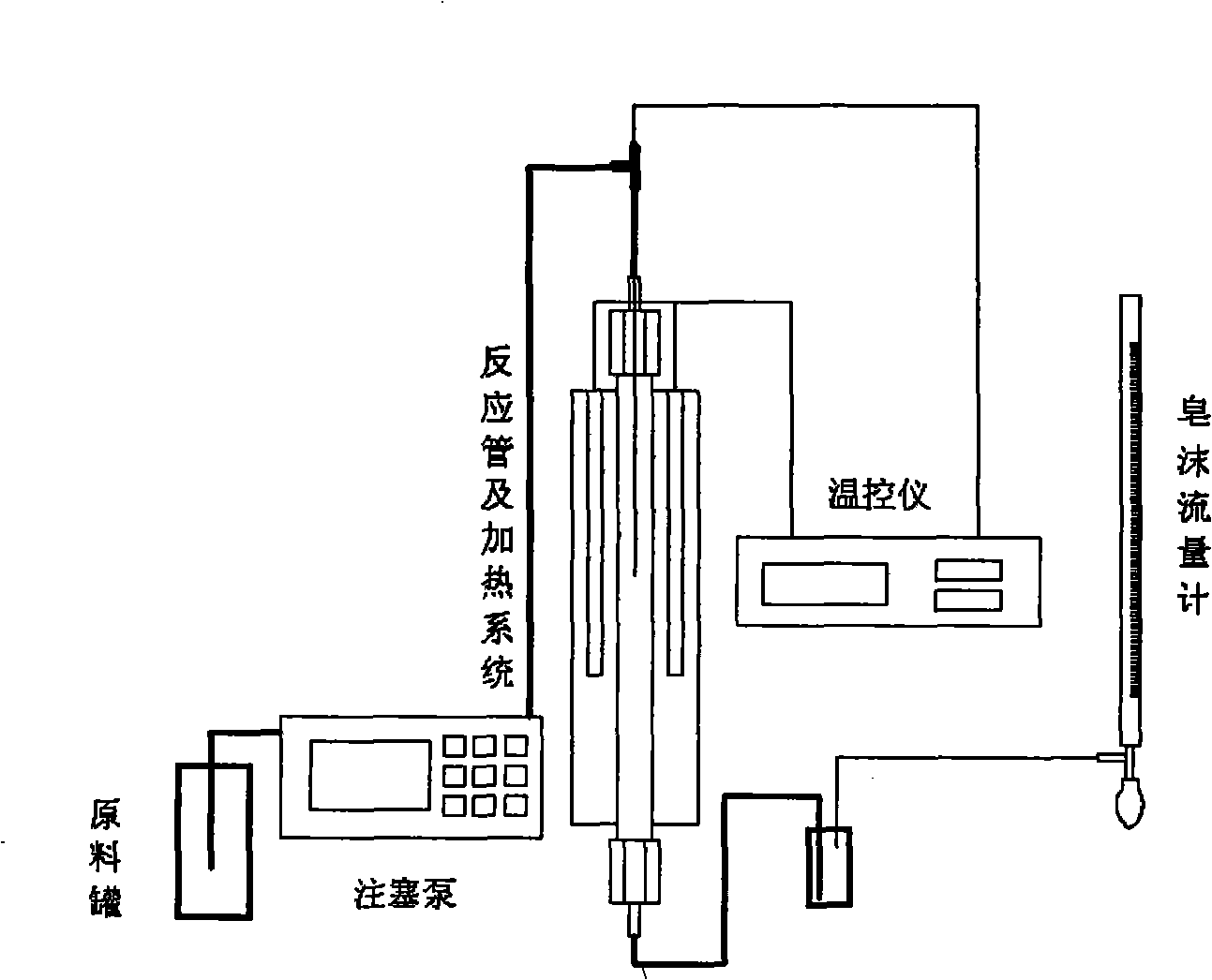

[0026] The prepared catalyst was put into an atmospheric fixed-bed reactor (see Figure 1) for investigation, and the dehydration performance of the catalyst is shown in Table 1. Example 2Zn-HZSM-5(40) and Zn-HZSM-5(300)

example 2

[0026] The prepared catalyst was put into an atmospheric fixed-bed reactor (see Figure 1) for investigation, and the dehydration performance of the catalyst is shown in Table 1. Example 2Zn-HZSM-5(40) and Zn-HZSM-5(300)

[0027] Weigh 10g of HZSM-5 raw powder with Si / Al=40, add 0.2M Zn 2+ The solution is refluxed and exchanged 2 to 4 times under boiling conditions, each time is 4 hours, and the amount of solution added each time is 50-100mL. After the exchange, wash with deionized water, dry at 110°C, and then put it into a muffle furnace at 500-700°C The Zn-HZSM-5(40) catalyst can be prepared by medium calcination for 2-5 hours. The content of the active metal component in the prepared catalyst is 1.5-3.0 wt%.

[0028] Weigh 10g of HZSM-5 raw powder with Si / Al=300, add 0.2M Zn 2+ The solution is refluxed and exchanged 2 to 4 times under boiling conditions, each time is 4 hours, and the amount of solution added each time is 50-100mL. After the exchange, wash with deionized ...

example 3

[0030] Example 3 Zr-HZSM-5(40)

[0031] Weigh 10g of HZSM-5 raw powder with Si / Al=40, and use 0.2MZr 4+ The solution is refluxed and exchanged 2 to 4 times under boiling conditions, each time is 4 hours, and the amount of solution added each time is 50-100mL. After the exchange, wash with deionized water, dry at 110°C, and then put it into a muffle furnace at 500-700°C The Zr-HZSM-5(40) catalyst can be prepared by medium calcination for 2-5 hours. The content of the active metal component in the prepared catalyst is 1.5-3.0wt%

[0032] The prepared catalyst was put into an atmospheric pressure fixed-bed reactor for investigation, and the dehydration performance of the catalyst is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com