Greenhouse film covering forced ventilation aerobic composting method

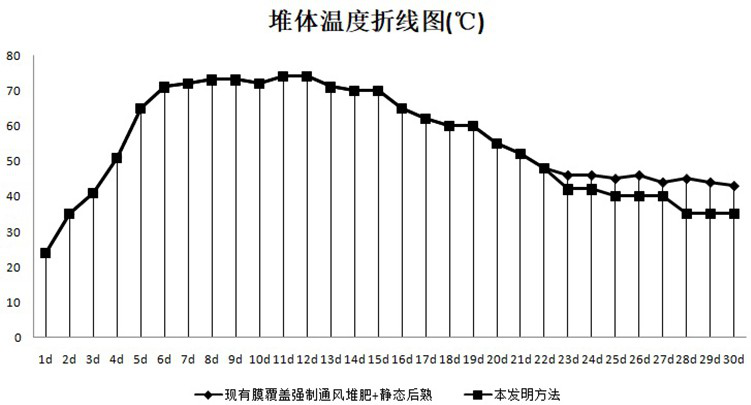

A technology of forced ventilation and aerobic composting, which is applied in the direction of organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of aeration and deodorization in the post-ripening stage, the slow rate of water drop in the heap, and the inability to solve the odor Escape and other problems, to reduce the overall investment and operating costs, low cost, improve the effect of raw material taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

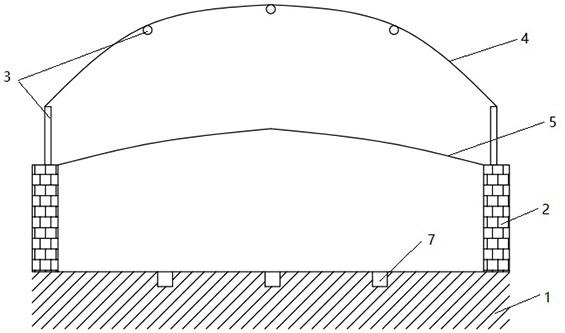

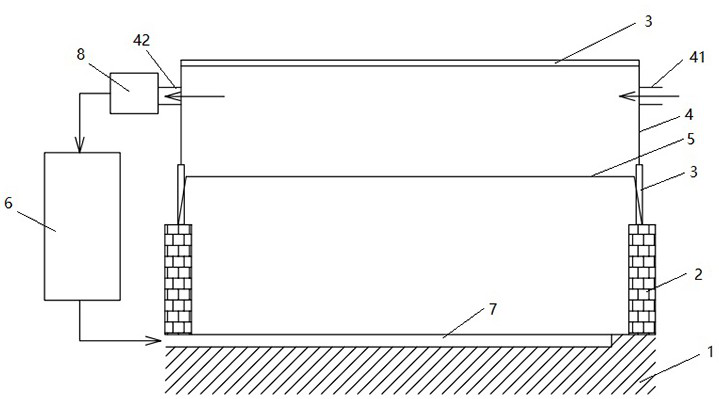

[0019] Please combine figure 1 and figure 2 As shown, the greenhouse film-covered forced-air aerobic composting system used in the greenhouse film-covered forced-air aerobic composting method involved in this embodiment includes a pile ground 1, a pile side wall 2, a greenhouse skeleton 3, a plastic greenhouse film 4, an expanded Body polytetrafluoroethylene film 5 and forced ventilation device 6. The ground 1 of the pile body is poured with cement, and the horizontal span is 6-10m. In this embodiment, the ground with a horizontal span of 8 meters and a vertical length of 30 meters is used, and three ventilation grooves 7 extending in the longitudinal direction are set on the ground for conveying the pile body. Air. Brick walls with a height of 1.2 to 1.5 m are built around the ground 1 of the pile to form the side wall 2 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com