Device and method for purification treatment of gas of medical waste non-incineration treatment

A technology for purification and treatment of gases, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as odor emissions, achieve stable deodorization, and ensure effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

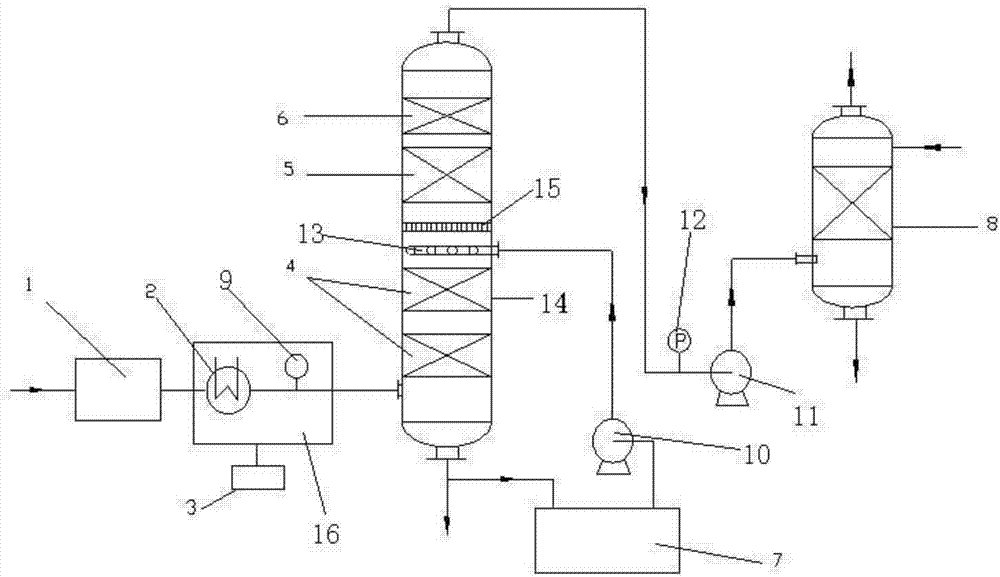

Method used

Image

Examples

Embodiment 1

[0043] Early driving

[0044] 1) The composition of the waste gas from the medical waste high-temperature steam treatment device is quite different. Before entering the next step treatment device, the VOCs content is sampled and analyzed every 10 minutes, and the total VOCs content is 300-1100mg / m3 3 The analysis results of 4 of them are as follows:

[0045] First time: total VOCs content 538mg / m 3 Roughly: Benzene 210mg / m 3 , toluene 115mg / m 3 , ethylbenzene 53mg / m 3 , Xylene 105mg / m 3 , other aromatic compounds 18mg / m 3 , Chloroform 22mg / m 3 , other low carbon halogenated alkanes 15mg / m 3 .

[0046] The second time: the total content of VOCs is 1156mg / m 3 Roughly: Benzene 562mg / m 3 , toluene 267mg / m 3 , ethylbenzene 131mg / m 3 , Xylene 85mg / m 3 , other aromatic compounds 55mg / m 3 , Chloroform 28mg / m 3 , other low carbon halogenated alkanes 28mg / m 3 .

[0047] The third time: the total content of VOCs is 840mg / m 3 Roughly: Benzene 425mg / m 3 , toluene 145mg / m...

Embodiment 2

[0059] After driving stably

[0060] 1) The composition of the waste gas from the medical waste high-temperature steam treatment device is quite different. Before entering the next step treatment device, the VOCs content is sampled and analyzed every 10 minutes, and the total VOCs content is 300-1100mg / m3 3 , and its composition is the same as the example one step (1).

[0061] Pass the exhaust gas into the gas buffer tank.

[0062] 2) The pressure-stabilized exhaust gas from the buffer tank is passed into the automatic temperature control device, which is composed of a heat exchanger and a thermometer, and can freely control the temperature of the outlet gas. Adjust the device to maintain the outlet exhaust gas temperature at 25-35°C.

[0063] 3) Let the temperature-controlled exhaust gas flow into the air inlet at the lower end of the deodorization tower. The interior of the deodorization tower is divided into three sections. An exhaust fan is connected to the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com