Wet sludge anhydration burning processing system and process

A treatment system, sludge incineration technology, applied in sludge treatment, water/sludge/sewage treatment, sludge drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

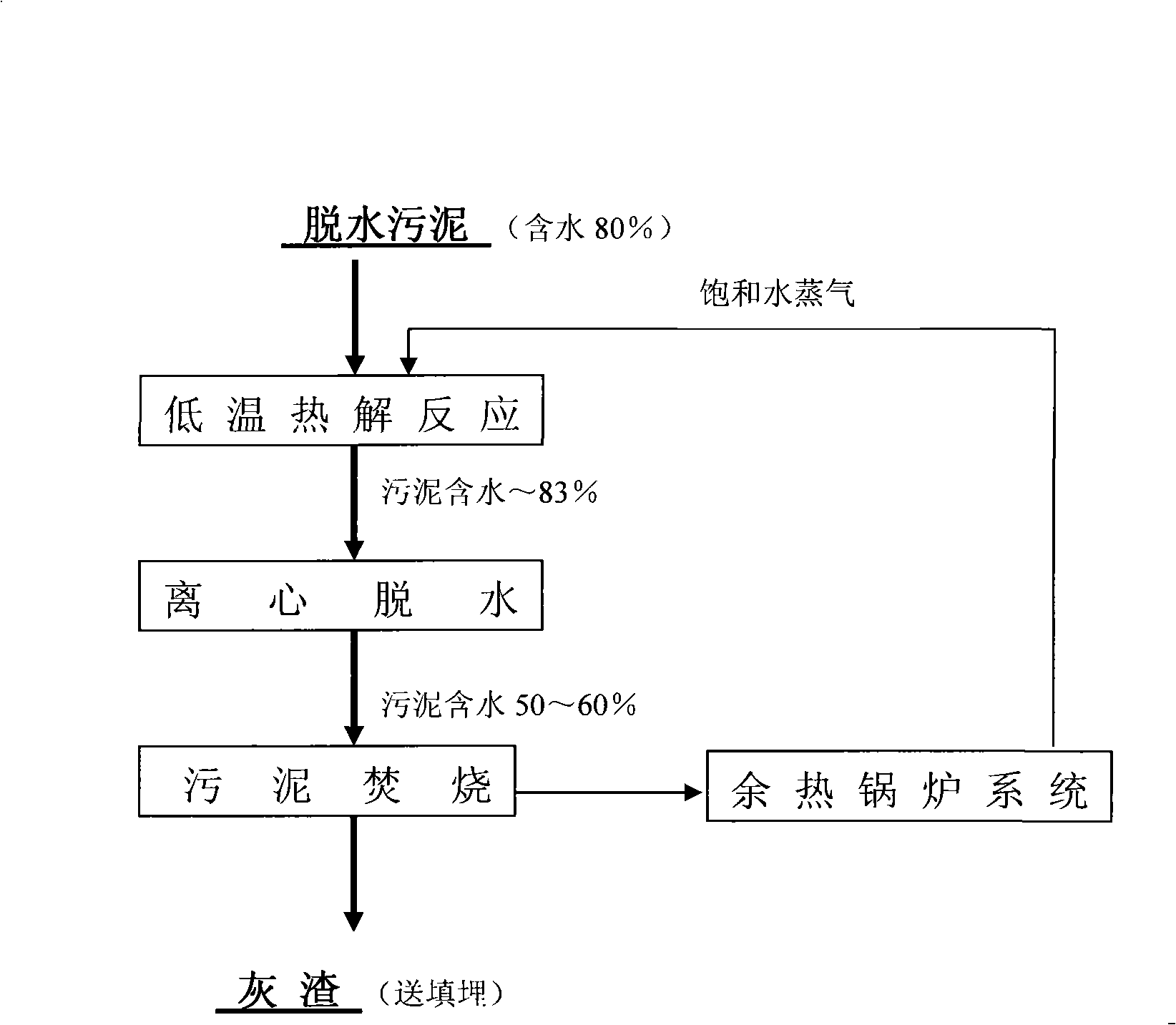

[0034] Such as figure 1 Shown is a process flow diagram of an embodiment of the wet sludge drying treatment system and process of the present invention. In this process, wet sludge (water content about 80%) is put into a low-temperature pyrolysis reactor, and saturated water vapor with a pressure of 1.5-3.0MPa and a temperature of 150-300°C is introduced into the reactor; the reactor is a closed horizontal The pressure vessel is equipped with a stirring device; the wet sludge and steam are stirred and mixed evenly in the kettle, and under the action of heat and pressure, the water-holding structure of solid-phase substances such as organic polymer structures and colloidal flocs in the sludge is destroyed. The physical and chemical bound water in the sludge is fully released, thereby greatly improving the dehydration and drying performance of the sludge, so that most of the water in the dewatered sludge can be released in the form of liquid water through subsequent mechanical s...

Embodiment 2

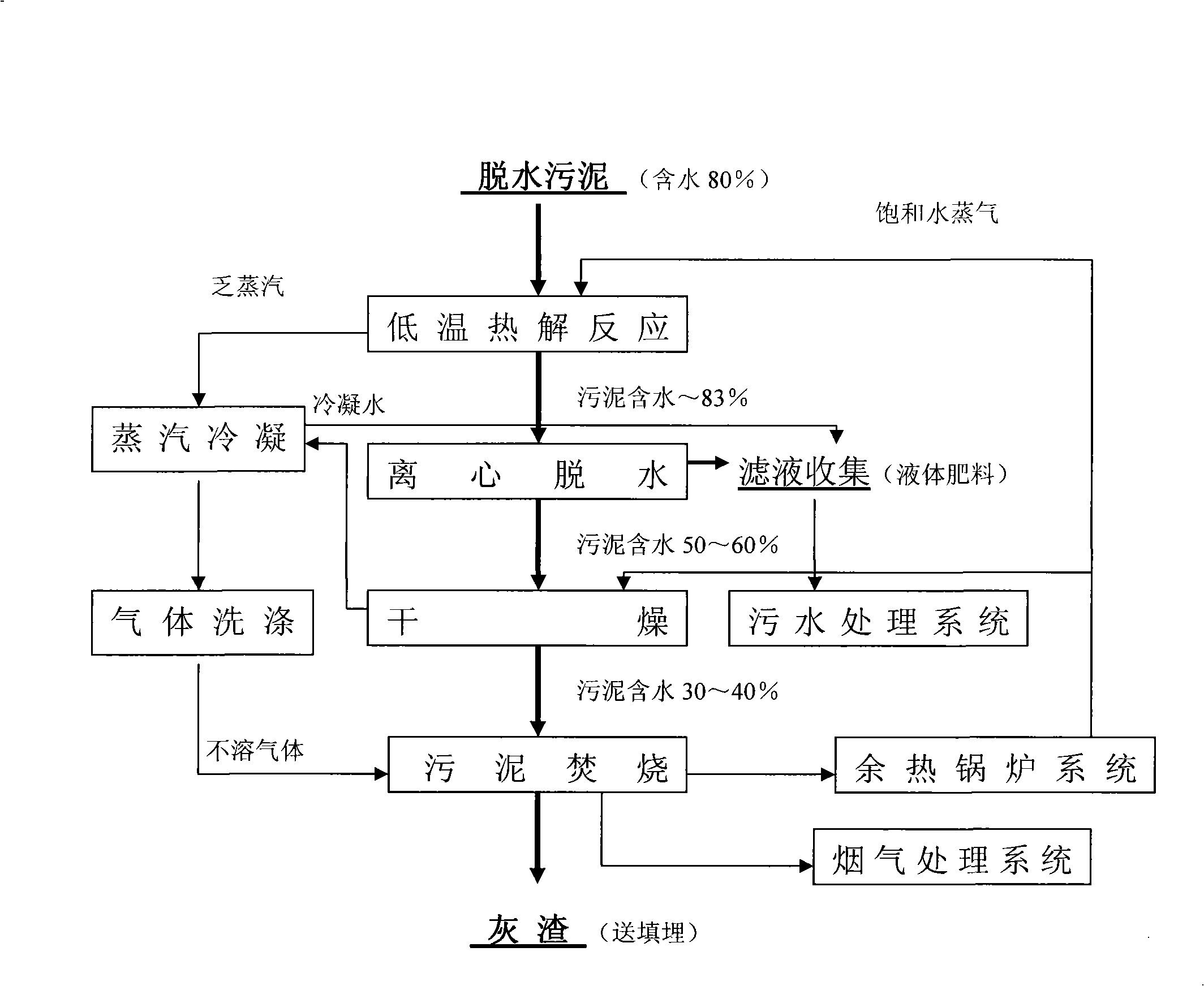

[0040] Such as figure 2 Shown is a process flow diagram of another embodiment of the wet sludge drying treatment system and process of the present invention. In this process, on the basis of the process flow of embodiment 1, the following devices and process steps have been added:

[0041] A hollow paddle dryer (fluidized bed drying equipment or airflow drying equipment, etc. can also be selected) is installed between the centrifugal dehydrator and the sludge incinerator for drying, which is used to dry and remove the semi-dry sludge after centrifugal filtration After obtaining the dried sludge-type solid fuel with a moisture content of 10-40%, it is supplied to the sludge incinerator.

[0042] In this embodiment, the saturated steam generated by the waste heat boiler is not only supplied to the low-temperature cracking reactor, but also optionally provides heat to the drying equipment for sludge drying.

[0043] At the same time, the filtrate removed by the centrifugal deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com