Spiral self-preheating deodorization furnace and waste gas deodorization process using same

A self-preheating and spiral technology, applied in the field of waste gas treatment devices, can solve the problems of heat loss, high heat energy consumption and high exhaust gas temperature, and achieve the effect of small equipment footprint, easy operation and maintenance, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

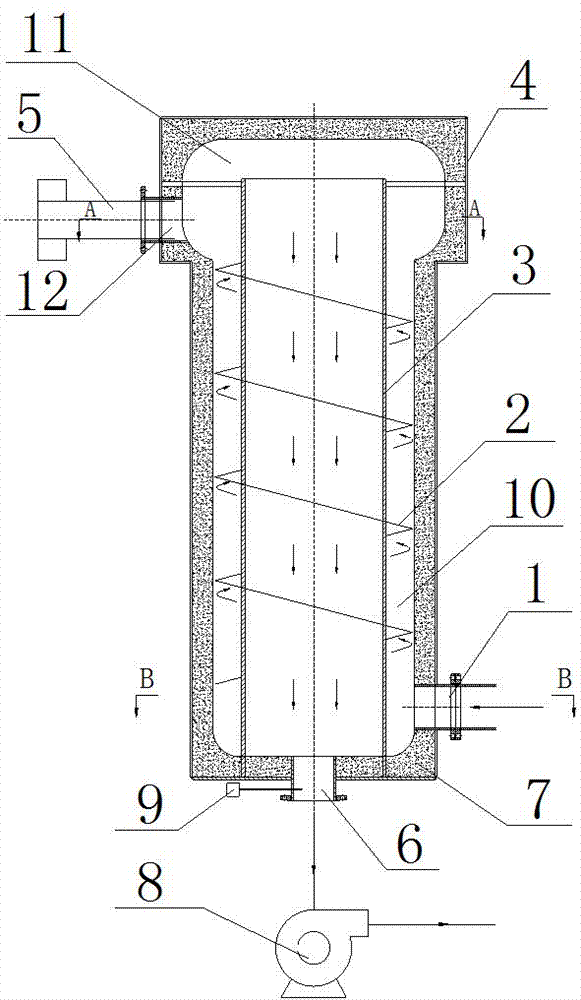

[0028] like Figure 1 to Figure 4 As shown, it is a spiral self-preheating deodorization furnace provided in Embodiment 1 of the present invention, which includes an inner cylinder 3 , an outer cylinder 4 , a spiral guide 2 , an insulation layer 7 , a fan 8 , and a gas analyzer 9 .

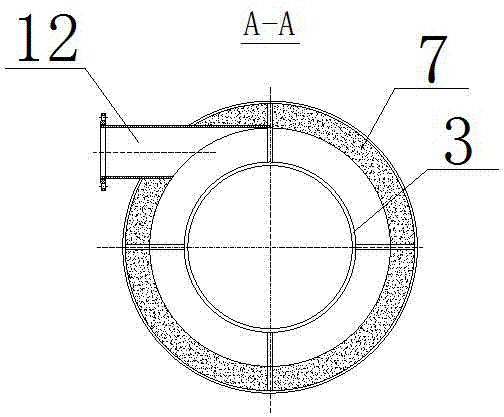

[0029] The outer cylinder 4 includes a preheating chamber 10 and a combustion chamber 11 . The bottom side of the outer cylinder 4 is provided with an exhaust gas inlet 1 . The exhaust gas inlet 1 communicates with the preheating chamber 10 . A gas inlet 12 is provided on the top side of the outer cylinder 4 . The gas inlet 12 communicates with the combustion chamber 11 . In this embodiment, the gas inlet 12 is tangent to the outer wall of the combustion chamber 11 .

[0030] The top of the inner cylinder 3 communicates with the combustion chamber 11 of the outer cylinder 4 . A waste gas outlet 6 communicates with the bottom of the inner cylinder 3 . In this embodiment, the outer cylinder 4 ...

Embodiment 2

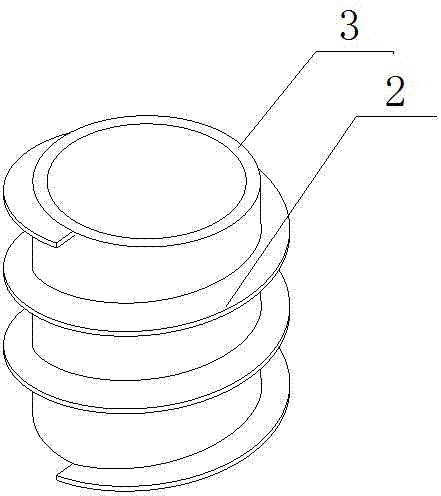

[0042] This embodiment is roughly the same as Embodiment 1, except that the helical guide piece in this embodiment is set in a form of variable pitch (such as Figure 5 As shown), the pitch of the helical guide piece gradually decreases from bottom to top, so that the gas can be compressed step by step during the rising process, and the temperature of the exhaust gas to be treated can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com