Chemical co-production device of preparing organic fertilizer from livestock and poultry manures

A technology of organic fertilizer and livestock and poultry manure, which is applied in the direction of organic fertilizer, fertilization device, excretion fertilizer, etc. It can solve the problems of inability to treat odor, reduce the service life of the device, and cannot be removed, so as to achieve convenient operation, increase fermentation efficiency, and improve The effect of aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

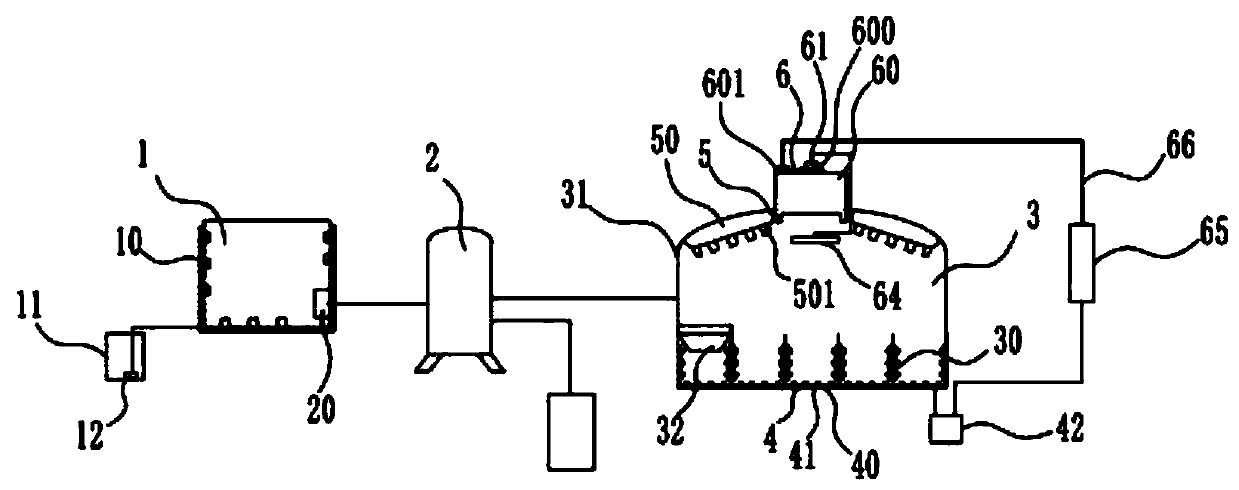

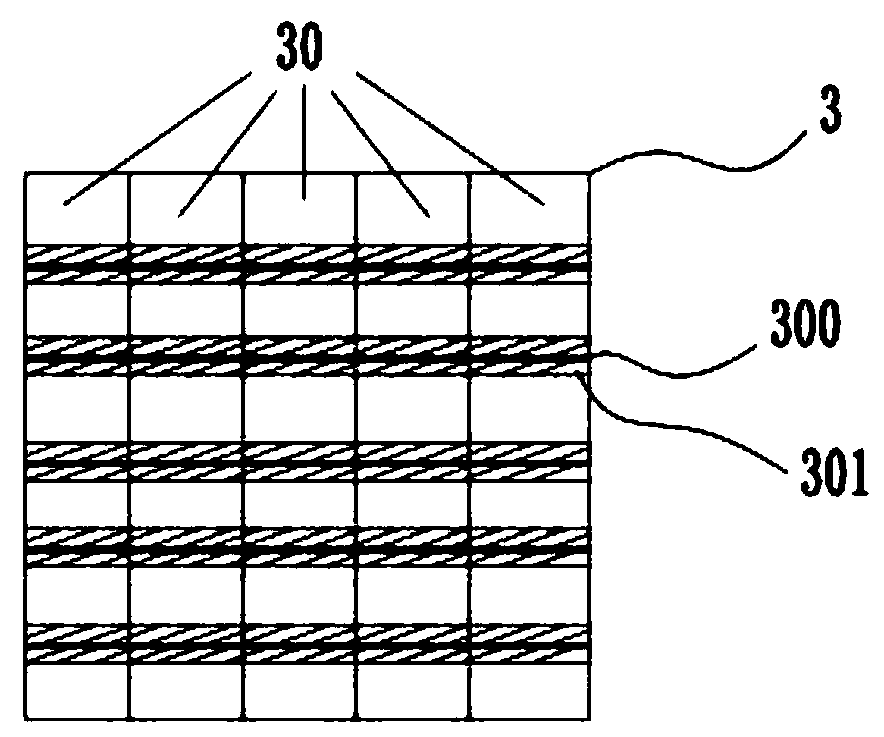

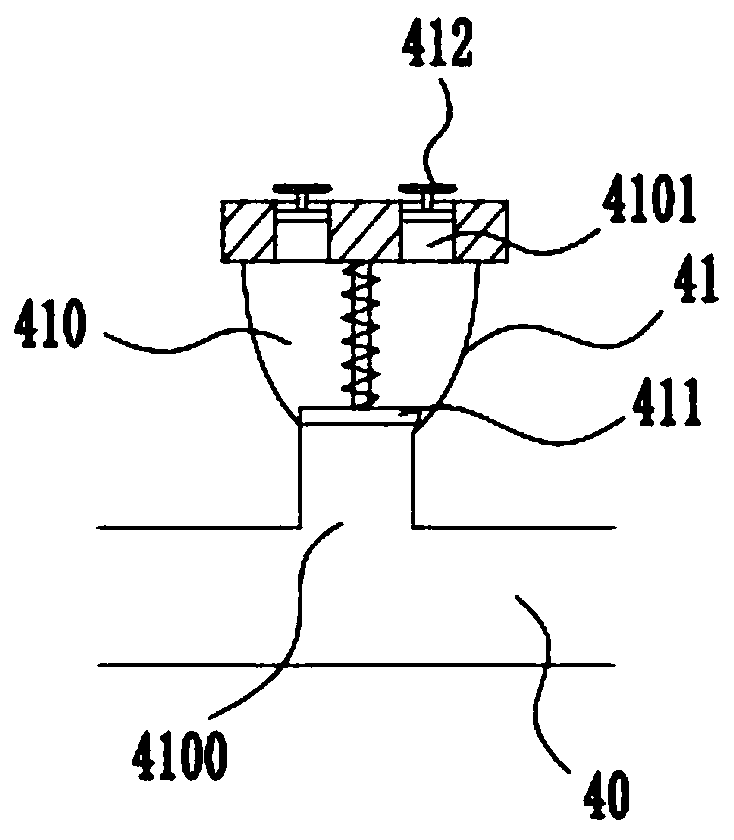

[0033] Example: as figure 1 A chemical co-production device for converting livestock and poultry manure to organic fertilizer is shown, which mainly includes a homogeneous storage tank 1 connected to the livestock and poultry pens through sewage pipes, and a sewage pump connected to the homogeneous storage tank 1 The solid-liquid separator 2 of 20 is connected with the solid-liquid separator 2 and is provided with five fermentation tanks 30 parallel to each other inside and a tank-type fermentation tank 3 with an arc-shaped sealing cover 31 at the upper end, and is located in the tank-type fermentation tank 3 The ventilation and aeration element 4 inside, the heat collection element 5 located at the upper end of the trough fermentation tank 3, the deodorizing element 6, and the power supply;

[0034] The side wall of the homogeneous storage tank 1 is provided with 25 shower outlets 10, and the shower outlets 10 are connected with a fungicide box 11 through a connecting pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com