Comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology

A pig manure and pyrolysis technology, which is applied in the field of comprehensive utilization of pig manure based on carbonization and pyrolysis technology, can solve the problems of technical bottlenecks, secondary pollution, and low treatment efficiency, and achieve perfect environmental protection technology, high thermal efficiency, and full utilization of waste heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

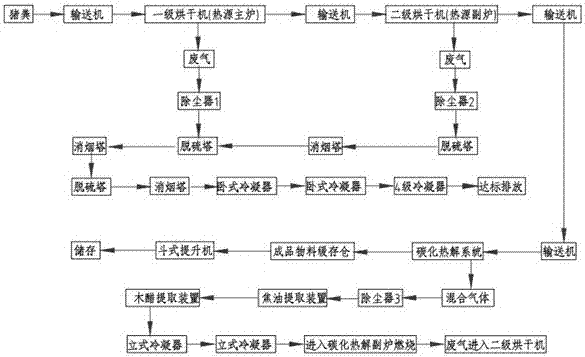

[0029] The process is mainly composed of three parts: multi-stage drying of pig manure, carbonization and pyrolysis of pig manure and flue gas treatment, such as figure 1 .

[0030] (1) Multi-stage drying of pig manure

[0031] The pig manure is transported by the transport vehicle to the pig manure storage pit, firstly measured, and then sent to the pyrolysis furnace of the pig manure dryer by the conveyor belt, and then enters the pyrolysis furnace through the double-roller feeder, and is evenly and loosely distributed. On the pyrolysis furnace grate. In the pyrolysis furnace, the pig manure is dried by the first-level dryer and the second-level dryer from top to bottom. The pig manure is dried in the primary dryer at 90°C for 50 minutes to remove most of the moisture. The temperature of the secondary dryer is 110°C and the drying time is 40 minutes. The moisture content of pig manure is reduced to below 1%. .

[0032] (2) Pig manure carbonization pyrolysis

[0033] Aft...

Embodiment 2

[0040] The process is mainly composed of three parts: multi-stage drying of pig manure, carbonization and pyrolysis of pig manure and flue gas treatment, such as figure 1 .

[0041] (1) Multi-stage drying of pig manure

[0042] The pig manure is transported by the transport vehicle to the pig manure storage pit, firstly measured, and then sent to the pyrolysis furnace of the pig manure dryer by the conveyor belt, and then enters the pyrolysis furnace through the double-roller feeder, and is evenly and loosely distributed. On the pyrolysis furnace grate. In the pyrolysis furnace, the pig manure is dried by the first-level dryer and the second-level dryer from top to bottom. The pig manure is dried in the primary dryer at 80°C for 45 minutes to remove most of the moisture, and the temperature of the secondary dryer is 105°C, and the drying time is 30 minutes, and the moisture content of the pig manure is reduced to below 1%. .

[0043] (2) Pig manure carbonization pyrolysis

...

Embodiment 3

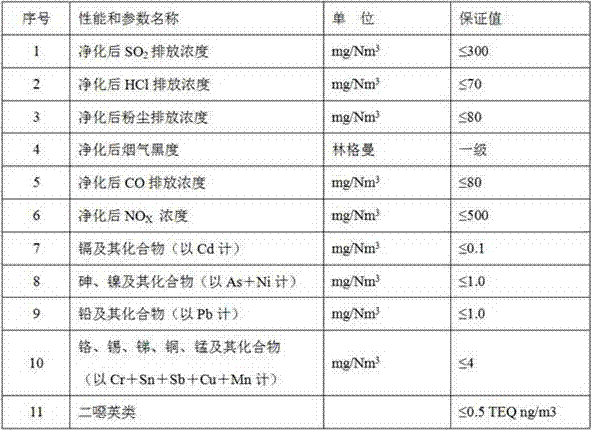

[0051] Pig manure was provided by a pig farm in the suburbs of Fuzhou. After natural air-drying until the moisture content is about 45%, it is transported to the pig manure storage pit by a transport vehicle, and about 1,000 tons of pig manure is weighed, and it is transferred to the pyrolysis furnace of the pig manure dryer by the conveyor belt in batches, and fed by double rollers. feeder into the pyrolysis furnace, evenly and loosely spread on the grate of the pyrolysis furnace. In the pyrolysis furnace, the pig manure is dried from top to bottom by primary drying and secondary drying. The generated high-temperature flue gas (845°C) is discharged through the exhaust port, passes through the dust collector, desulfurization tower and smoke elimination tower, and enters the condenser, so that the temperature of the flue gas is rapidly reduced to 200°C, and can be discharged into the atmosphere up to the standard. The dried manure enters the carbonization pyrolysis system, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com