Sewage and sludge processing system

A treatment system and technology for sewage sludge, applied in biological sludge treatment, water/sewage multi-stage treatment, dehydration/drying/concentrated sludge treatment, etc. , to achieve the effect of reducing spoilage and odor, reducing operating costs, and inhibiting spoilage flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

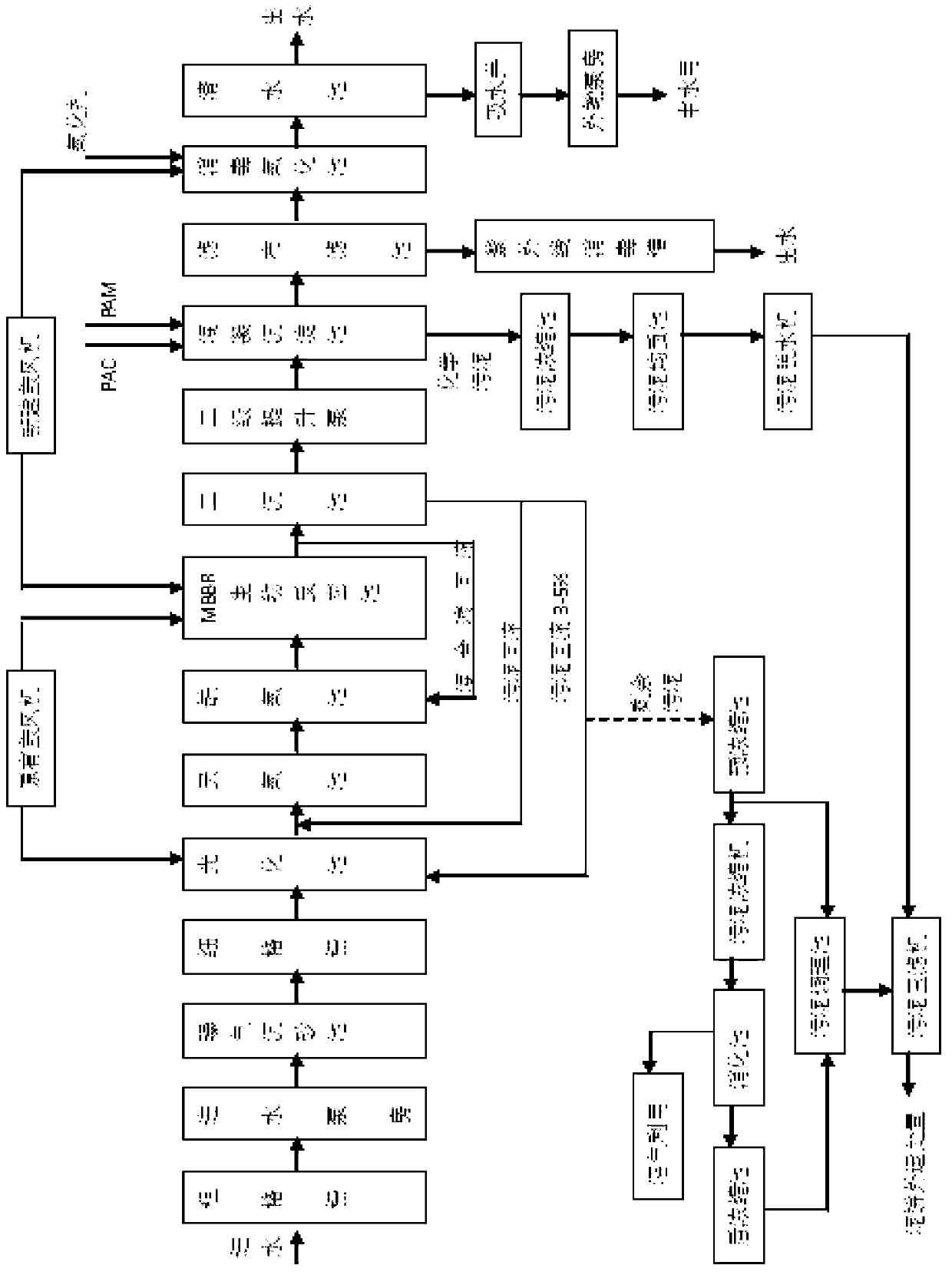

[0023] A sewage sludge treatment system that combines figure 1 , including coarse screen, water inlet pump room, aeration grit chamber, fine screen, photochemical tank, anaerobic tank, anoxic tank, MBBR biological reaction tank, secondary settling tank, secondary lifting pump room, coagulation sedimentation Pond, filter cloth filter, disinfection and oxidation pool, clear water pool, water absorption well, export pump room, the filter cloth filter is connected with ultraviolet disinfection tank, among them, coarse grid, water inlet pump room, aeration grit chamber, The fine grid, photochemical pool, anaerobic pool, anoxic pool, MBBR biological reaction pool, secondary sedimentation tank, secondary lifting pump room, coagulation sedimentation tank, filter cloth filter tank, disinfection and oxidation tank, and clear water tank are connected in sequence, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com