Patents

Literature

139results about How to "Artistic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for printed matter anti-counterfeit mark of combination splicing of grating and image carrier

The invention belongs to the technical field of printing anti-counterfeit technical and discloses a manufacturing method for printed matter anti-counterfeit mark of combination splicing of grating and image carrier. The manufacturing method comprises the following steps that S1, background color blocks are built, specifically, four channels of the cyan channel, the fuchsine channel, the yellow channel and the back channel are separated to form four color plates of the cyan color plate, the fuchsine color plate, the yellow color plate and the black color plate, and the four color plates are screened; S2, graphic and text information needing to be hidden is manufactured; S3, the graphic and text information needing to be hidden is partitioned to form a part A and a part B; S4, the graphic and text information A is placed into the cyan plate, and the four color plates of the yellow color plate, the fuchsine color plate, the cyan color plate and the black color plate are combined to form a digital image with the hidden graphic and text information; S5, the grating is manufactured according to the background color blocks, specifically, the grating is processed, the graphic and text information B is placed in the explicit-implicit grating, and the explicit-implicit grating with the graphic and text information is formed; and S6, the graphic and text information on the grating and the graphic and text information placed in the digital image are spliced, and the anti-counterfeit mark with the complete hidden information is obtained.

Owner:SHENZHEN KECAI PRINTING

Wax color dying product and production process thereof

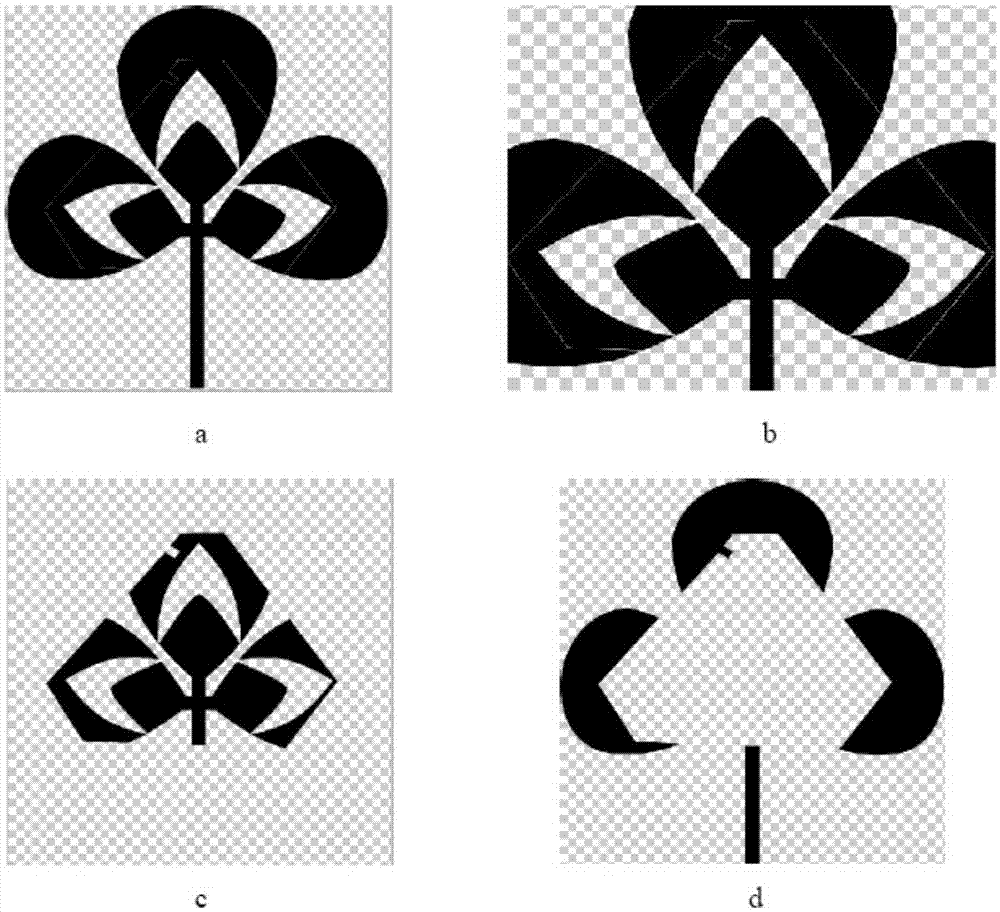

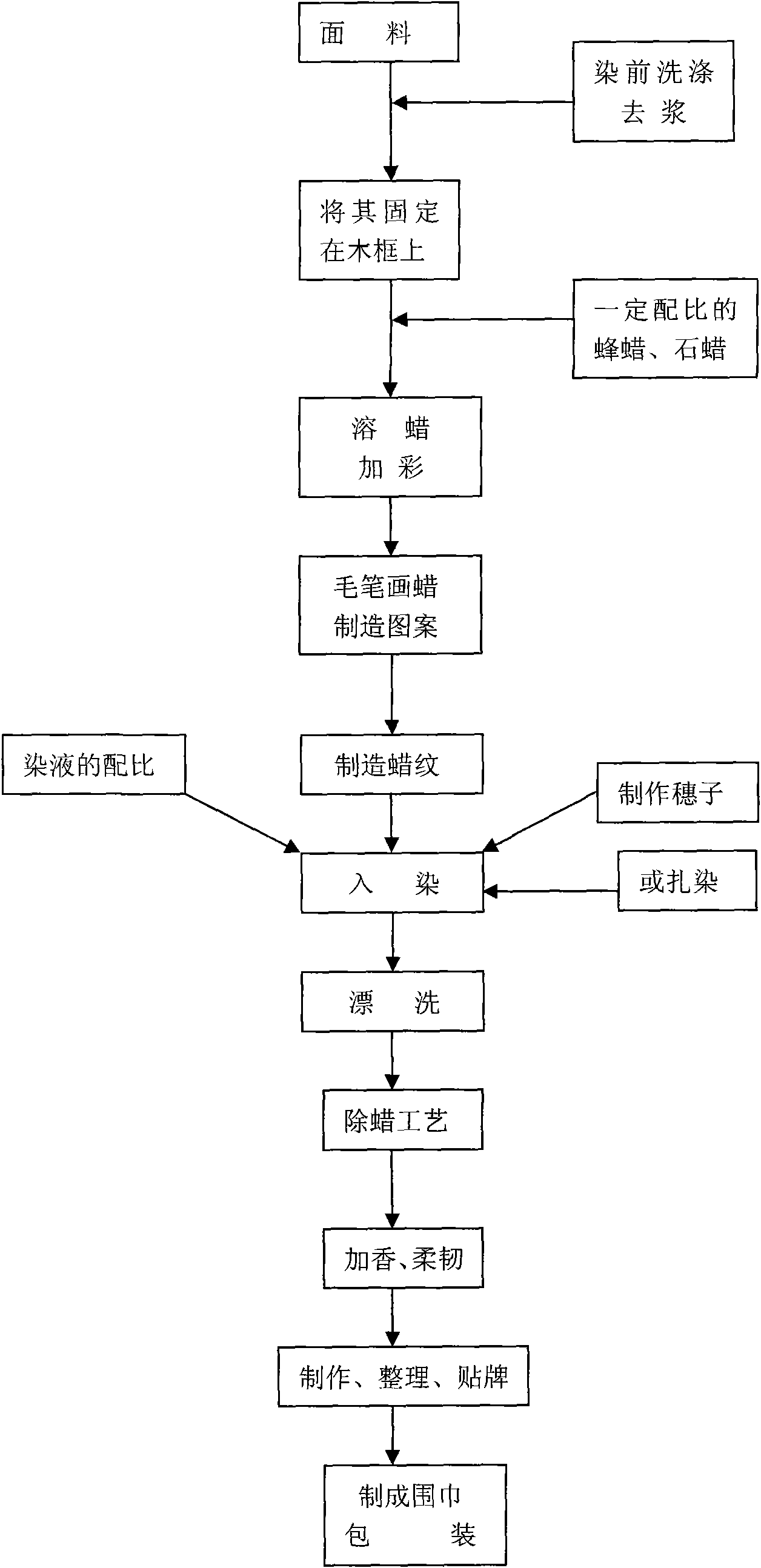

InactiveCN101608409AArtisticMeet aesthetic needsSpecial artistic techniquesDyeing processWaxL&D process

The invention discloses a wax color dying product and a production process thereof, and belongs to the printing and dyeing technology field of artworks. The production process comprises the following steps: taking a wax as a vector, applying different dyes, drawing by adopting Chinese painting technique, organically converging Chinese painting color ink and batik ice pattern through the environment-friendly technical process of stacked dyeing (tie dyeing and dip dyeing) and stacked painting, and finally forming an artwork with various tonal ice grain texture and tie dyeing colorful texture effects. The artwork includes hanging walls, bed articles, capes, scarves, various adornments and the like. Therefore, the invention has good market prospect.

Owner:吴国梁

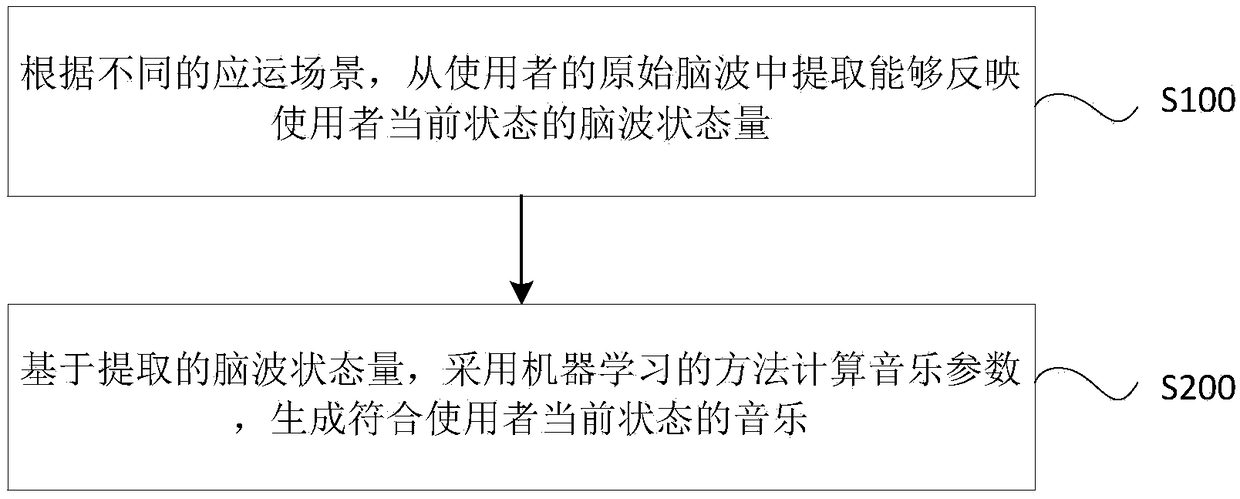

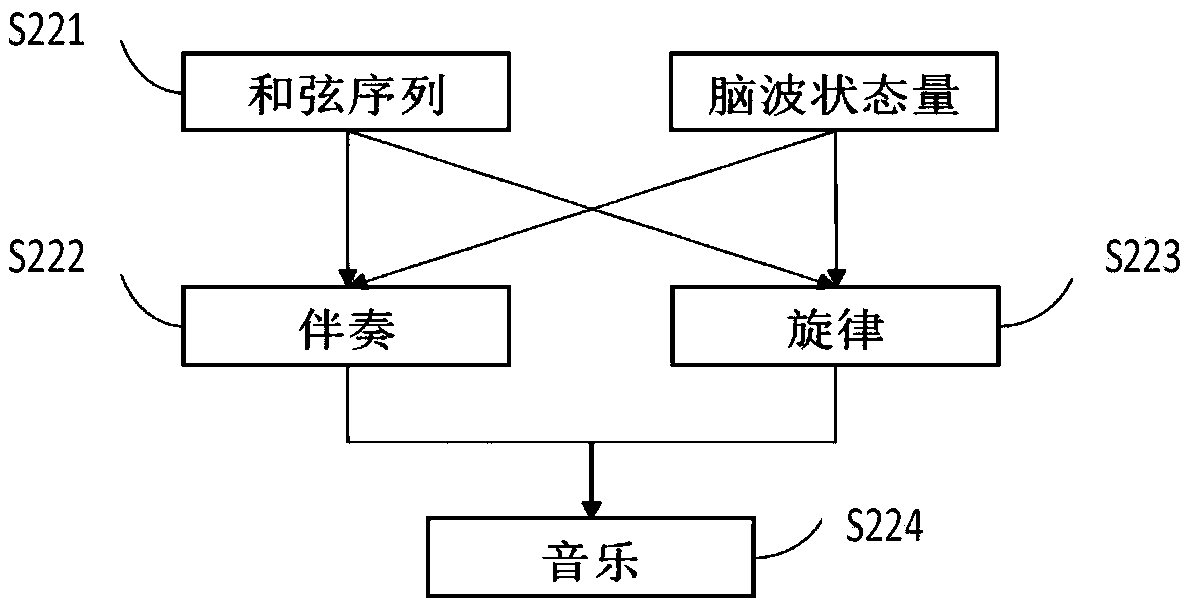

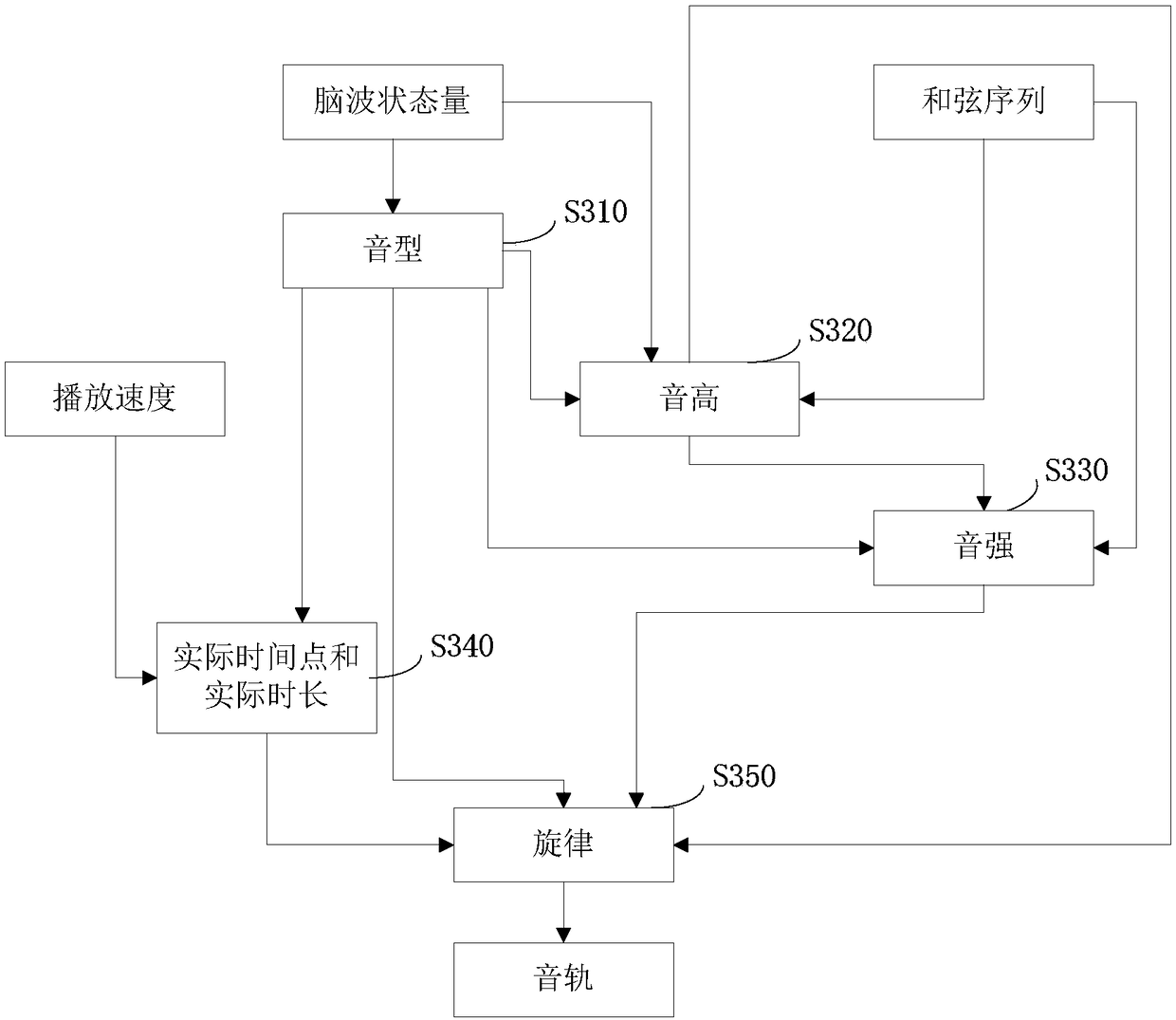

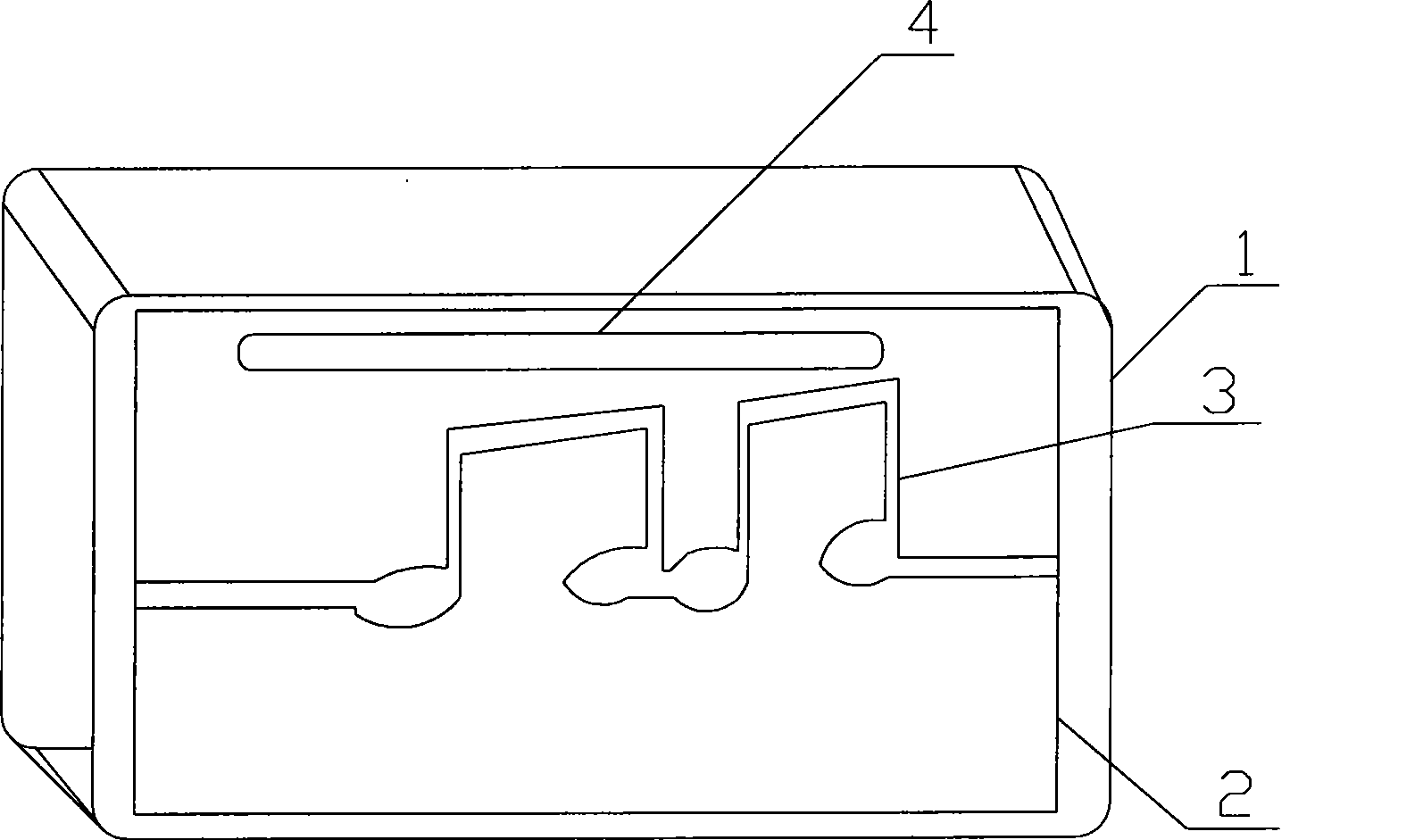

Brain wave AI music generation method and system

ActiveCN108877749AReal-time controlArtisticElectrophonic musical instrumentsSensorsStudy methodsTime control

The invention discloses a brain wave AI music generation method and system. The method comprises the following steps: extracting the brain wave state quantity which can reflect the current state of the user from the original brain waves of the user according to different application scenes; and then calculating music parameters based on the extracted brain wave state quantity by using the machinelearning method so as to generate the music meeting the current state of the user. The brain wave state quantity which can reflect the current state of the user is extracted from the brain waves according to different application scenes through combination of the machine learning method, and the brain wave AI music meeting the current state can be generated in real time. The shortcomings of the present AI music in real-time controllability and artistry can be compensated, real-time control of the brain waves of the AI music can be realized and the music generated by the brain waves is ensuredto have good artistry.

Owner:杭州回车电子科技有限公司

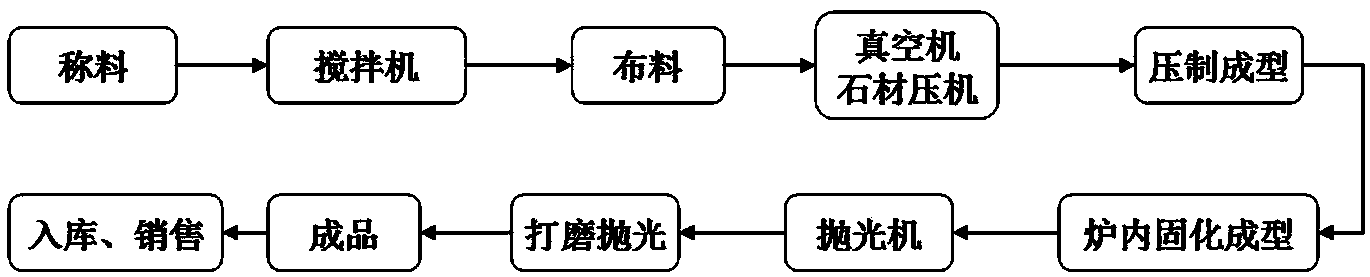

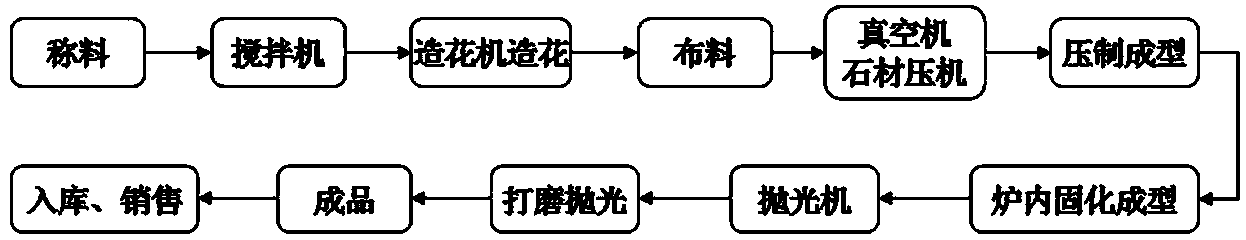

Artificial stone and preparation method thereof

The invention discloses an artificial stone and a preparation method thereof. The artificial stone comprises the following raw materials in percentage by weight: 30-60% of quartz, 30-60% of crushed glass, 5-10% of alloy resin, 0.01-3% of alloy powder, 0.01-0.5% of pigment, 0.01-0.5% of a coupling agent and 0.01-0.5% of a curing agent. The artificial stone has the characteristics of art attractiveness, health and environment-friendliness. Due to addition of the alloy powder and the alloy resin in the formula, the artificial stone has an outstanding antibacterial function, is relatively high in anti-permeability and moisture resistance, long in service life and relatively good in glossiness, fullness and moisturizing property, the waste glass and the waste gel can be utilized again, thus being energy-saving and environmentally friendly; flowers can be also made according to demands, and thus artificial stone with patterns can be manufactured.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

Seat cushion weaving method

The invention discloses a seat cushion weaving method and relates to a weaving method, which adopts a bulge hollow-out net knitting method, a magic gourd hollow-out net knitting method, a rhombus hollow-out knitting method, a hexagon round flat sennit combined hollow-out net knitting method, and the product manufactured by the method has graven artistic aesthetic perception and strong stereoscopic effect, and brings artisitc beauty for people, and simultaneously the people can enjoy the refreshed and transparent satisfactoriness which common similar products do not have.

Owner:张振和

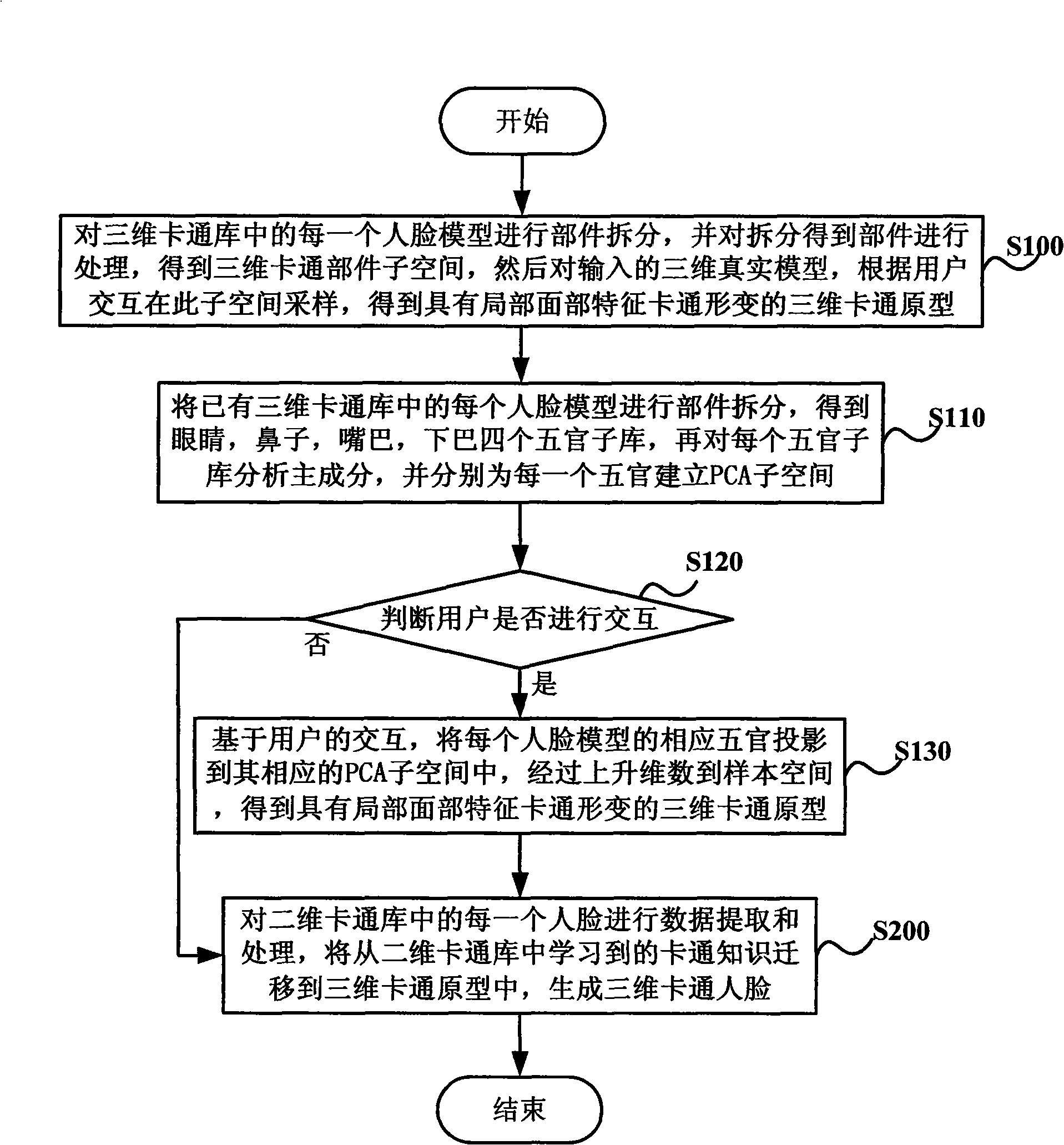

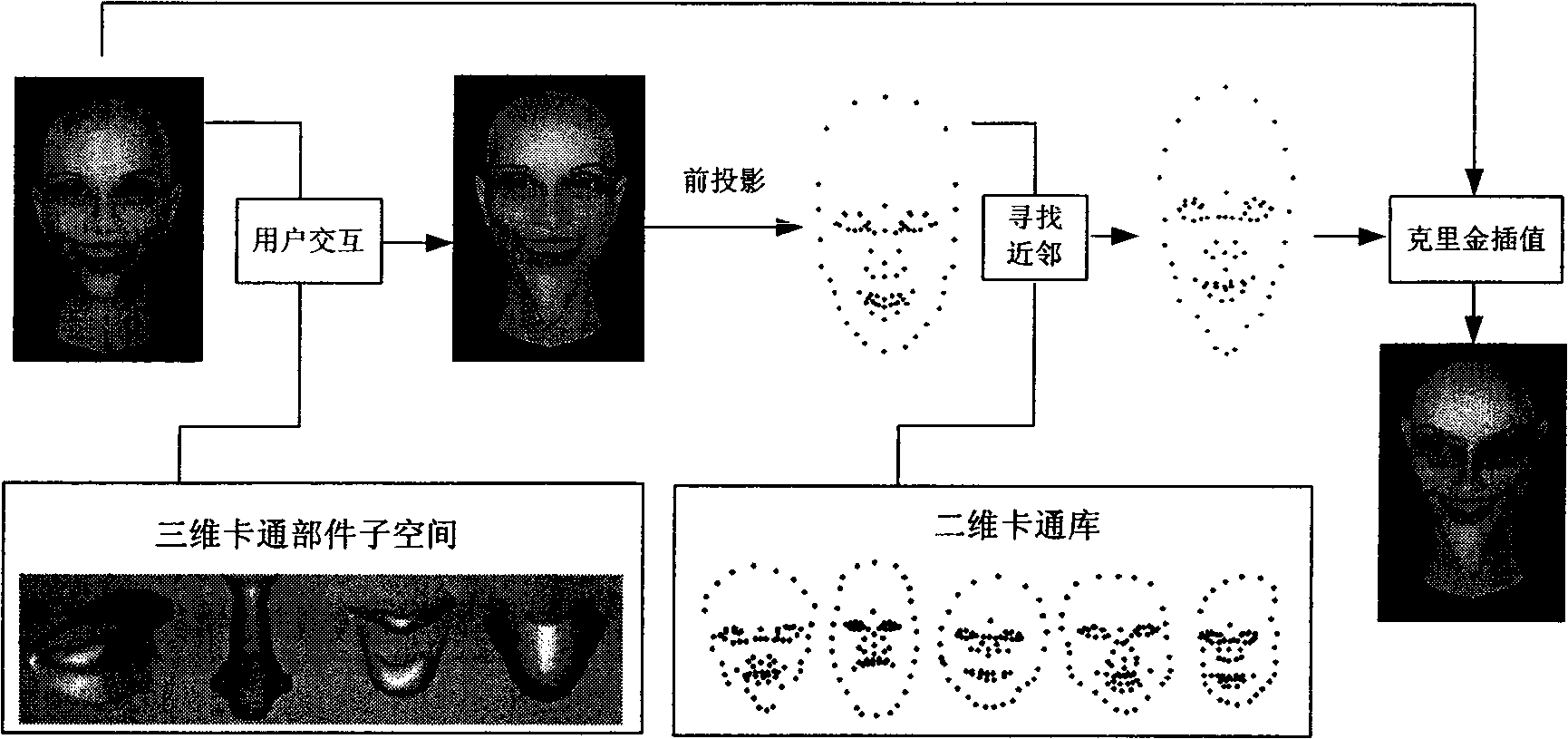

Interactive three-dimensional cartoon human face generating method and device

InactiveCN101493953AReduce art background knowledgeGuaranteed artistryAnimation3D-image renderingFace modelComputer graphics (images)

The invention discloses an interactive three-dimensional cartoon face generation method and a device thereof. The method comprises the following steps: component disassembly is conducted over each face model in a three-dimensional cartoon library; the obtained components are processed to obtain a three-dimensional cartoon component subspace and then the inputted three-dimensional true model is sampled in the three-dimensional cartoon component subspace in accordance with user interaction so as to obtain a three-dimensional cartoon prototype provided with partial facial feature cartoon deformation; data fetch and processing are conducted over each face in a two-dimensional cartoon library; and the cartoon knowledge learned from the two-dimensional cartoon library is transferred to the three-dimensional cartoon prototype so as to generate a three-dimensional cartoon face. The method can overcome the shortcoming of the traditional method that only a single cartoon style can be generated, thereby rendering the finally generated three-dimensional cartoon face to have a plurality of styles and be vivid and providing an interactive three-dimensional cartoon generation method based on knowledge transfer.

Owner:INST OF COMPUTING TECHNOLOGY - CHINESE ACAD OF SCI

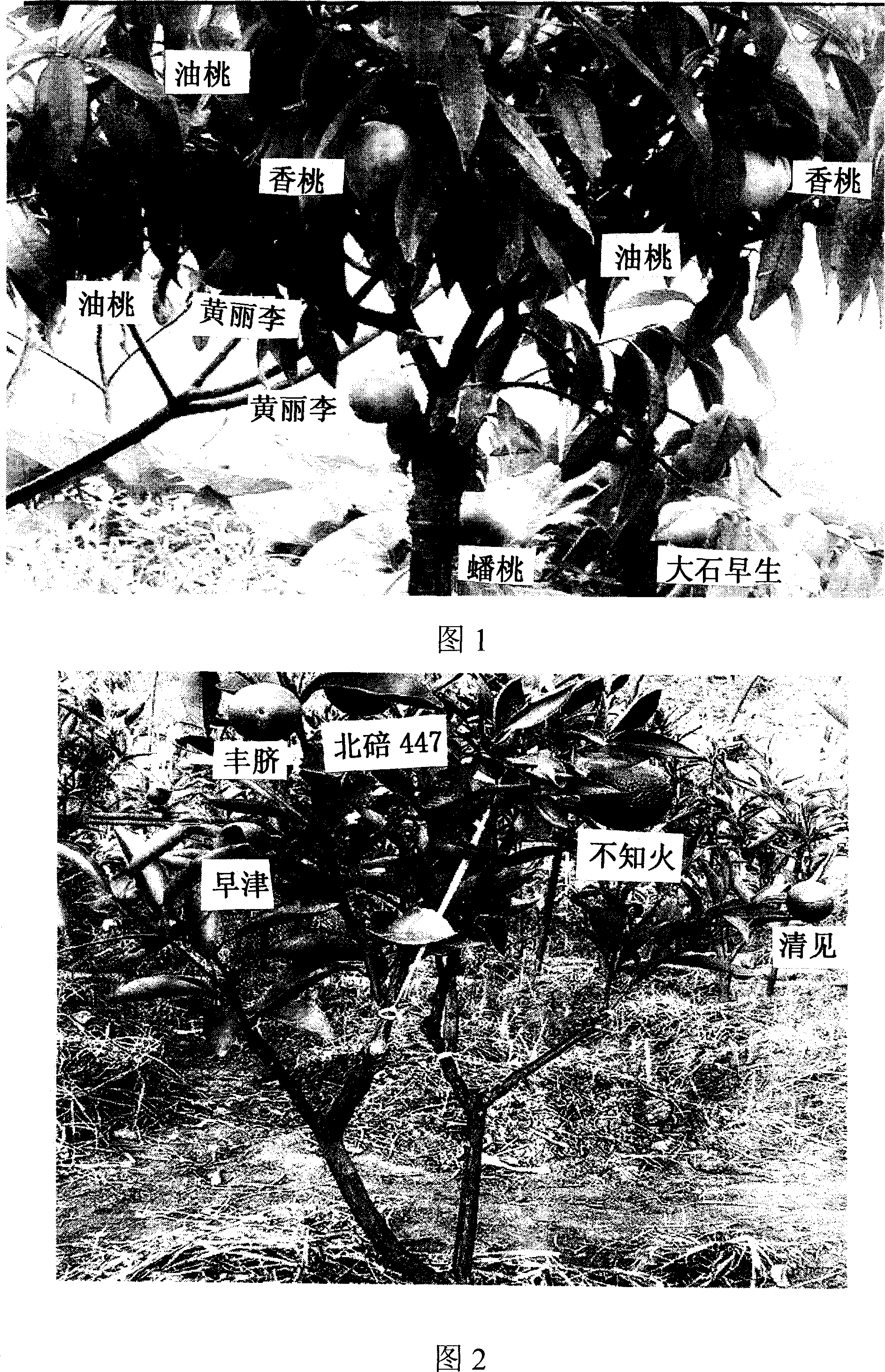

Multiple strain tender sprout grafting sprying method for the same fruit plant

InactiveCN1985562AImprove efficiencyImprove viewing valueCultivating equipmentsHorticultureFruit treeRootstock

The multiple strain tender sprout spraying and grafting method for the same fruit plant includes the following steps: selecting tree stock, collecting scion, grafting and management. The method features that compounded nutritious solution sprayed to the scion timely to replenish the nutrients. The method of grafting tender sprout and spraying nutritious solution can save scion, raise the survival rate, save planting area, prolong grafting season, reduce grafting labor and raise economic benefit.

Owner:刘备

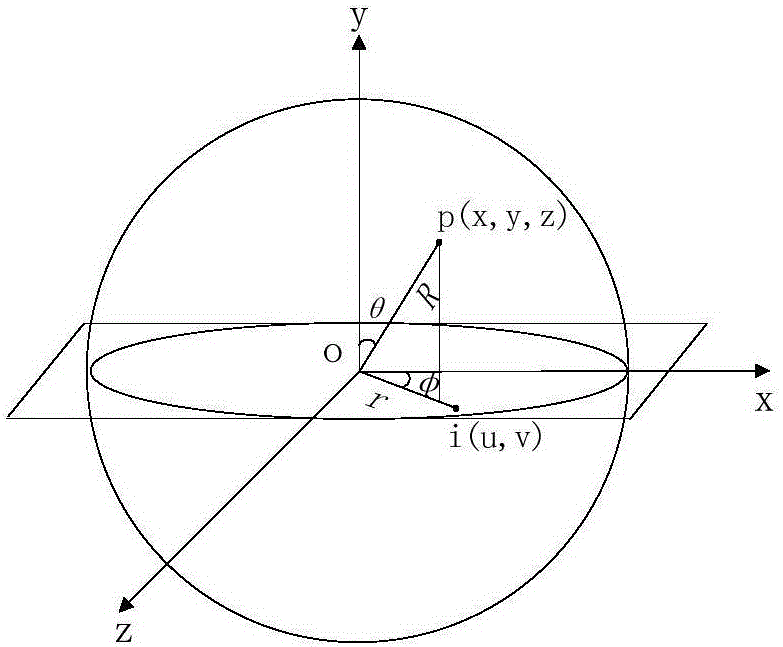

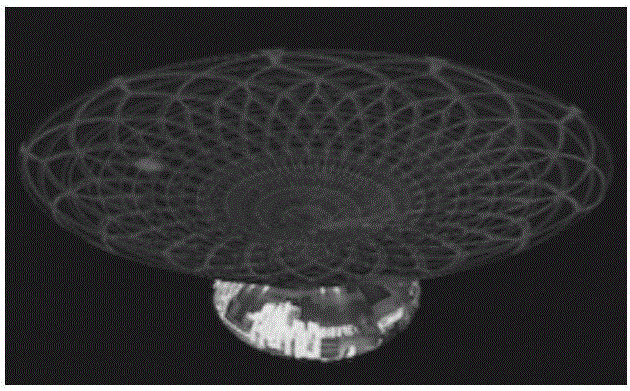

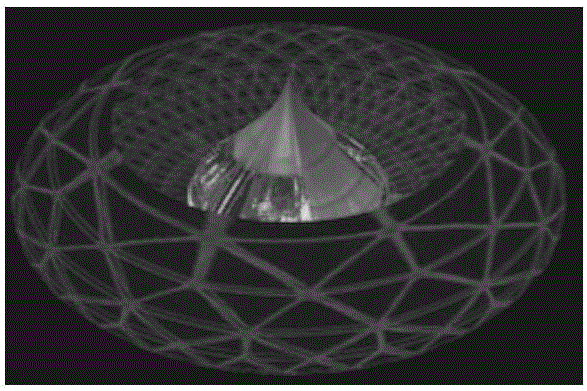

3D special-effect panoramic display method and system for image photographed by fisheye lens

ActiveCN105787951AImprove participationPanoramic display richImage enhancementImage analysisCamera lensFisheye lens

The invention discloses a 3D special-effect panoramic display method and a system for an image photographed by a fisheye lens. According to the method of the invention, when 3D model is built or a mapping relationship between a model vertex and fisheye image coordinates is built, a function system with adjustable parameters is adopted, and the parameter values are dynamically adjusted. The thinking set of the existing 3D panoramic display model is broken, the panoramic display can be more beautiful and cooler and has artistic temperament, and individuality is shown in network sharing.

Owner:凯眸(中山)电子科技有限公司

Method for making digital photos on pure cotton cloths and application

InactiveCN101629389AImprove the artistic effectGood adhesionDyeing processPulp and paper industryCotton cloth

A method for making digital photos on pure cotton cloths comprises the following steps: first selecting the pure cotton cloths of required specifications to undergo alkalifying, bleaching, whitening and sizing; pouring printing paste into a container, soaking the sized white cloths in the paste and then exerting pressure on the white cloths, drying the white cloths at a temperature of 100-130 DEG C and rolling the white cloths for later use; injecting reactive dye ink into an ink channel of an inkjet printer and placing the cloths to be used on a paper winder for following printing on the inkjet printer; loading the files on which pictures are to be made into a computer to be subjected to type setting, zooming the files according to the requirements and then printing the files, taking out the files after printing is completed; revolving the pure cotton cloths on which the digital photos are printed in a steamer or a steam box under the pressure of 0.1-0.2MPa and temperature of 90-110 DEG C for 10-40min; washing the pure cotton cloths with hot water at a temperature of 90-100 DEG C to remove loose colors and the paste, then drying and ironing the pure cotton cloths to ensure the cloth surfaces to be dry, smooth and neat. The made pure cotton cloths are used in the home textiles and indoor decoration products. The photos have the advantages that the picture effects are ideal, the photos are not easy to deform, can be washed by water and conform to the environmental protection requirements, and the specifications are not restricted.

Owner:刘锦山

Material and preparation method for granular filler paper pulp molded product

InactiveCN110331624AImprove physical strengthReduce dosageDefoamers additionWater-repelling agents additionFiberPrill

The present invention relates to the field of paper pulp molded packaging products, and especially relates to a method for preparing a novel pulp molded product from a granular filler. The method comprises the following steps: uniform mixing of proper amounts of plant fibers, biomass particles, a sizing agent, a reinforcing agent, a dispersant, a retention and drainage aid, a plasticizer, a defoaming agent and water, mold adsorption, vacuum suction filtration, compression molding, drying or natural drying, hot pressing shaping, and cutting for producing the molded product having a moisture content of 8-12%. The pulp molded product prepared in the invention can reduce the dosage of the plant fibers by up to 60%, has a higher physical strength than conventional pulp molded products, can reduce the use of forest resources, is economical and environmentally friendly, and can be reused or naturally degraded and returns to soil after being used.

Owner:JIANGNAN UNIV

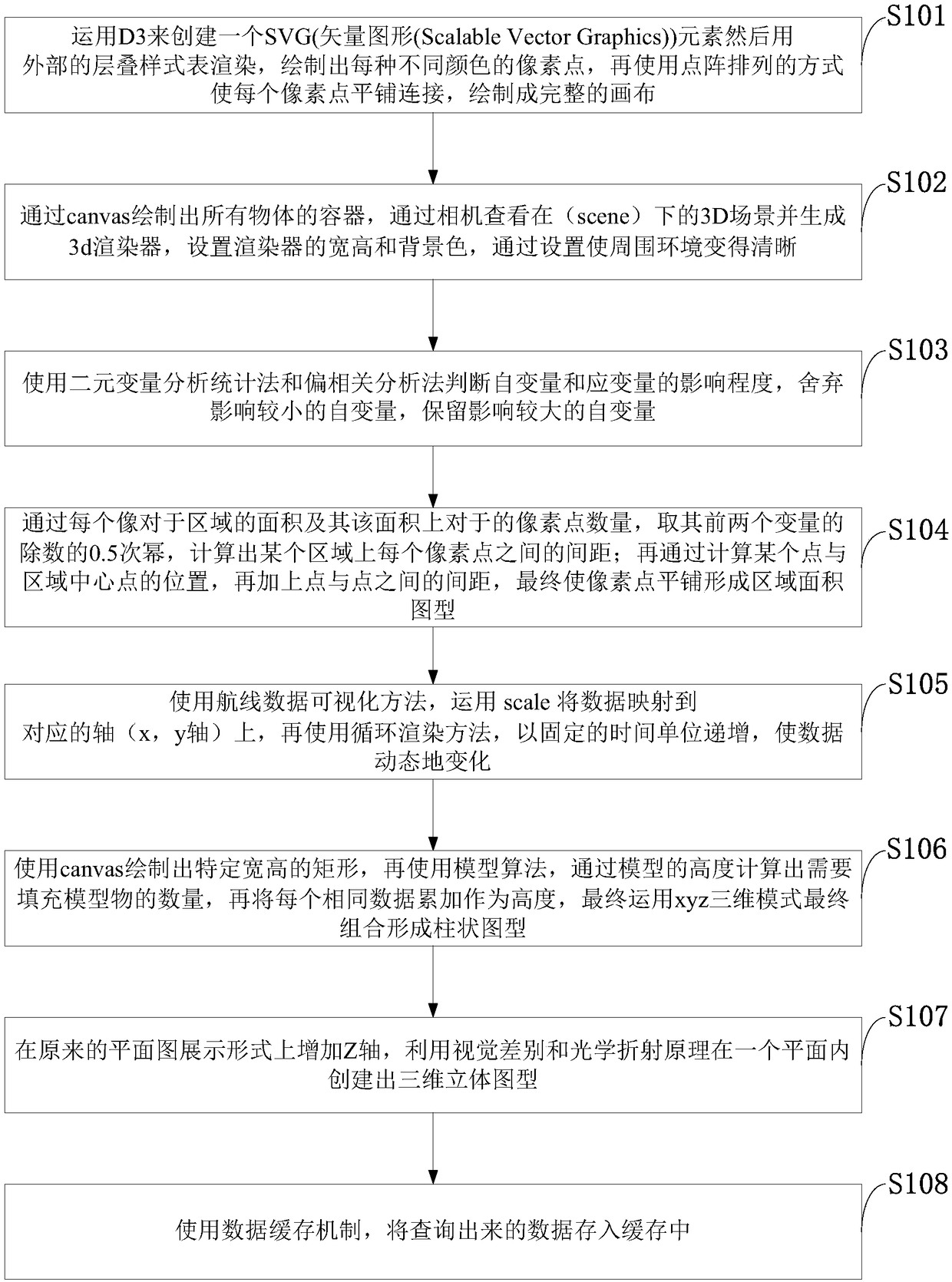

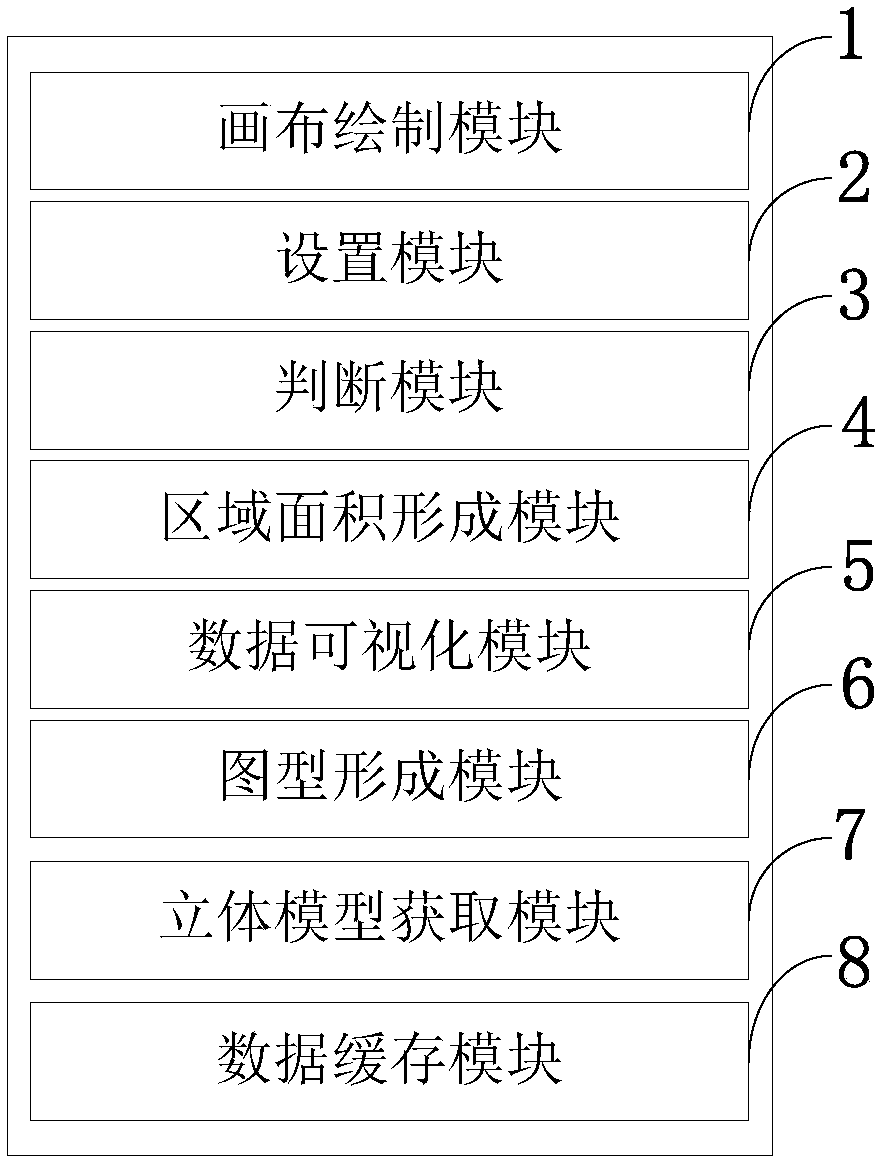

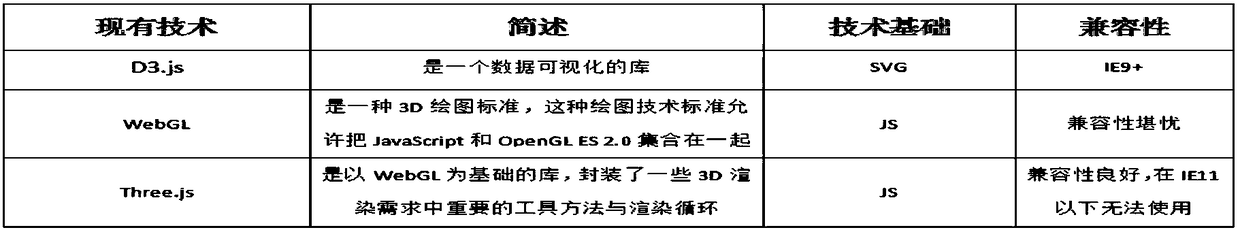

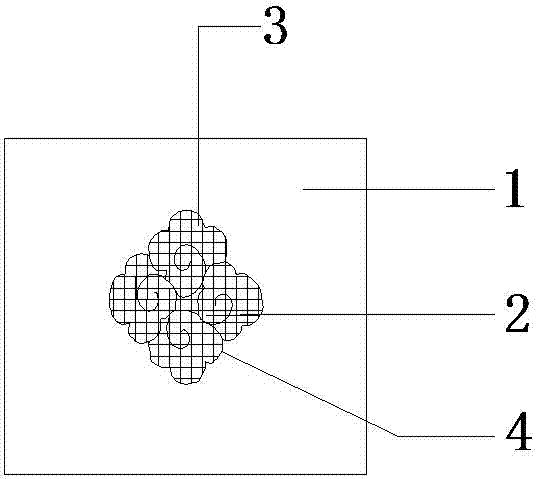

3D map scatter data display method and system as well as information data processing terminal

ActiveCN108230433ALarge independent variableLarge strain3D-image rendering3D modellingData displayRelative motion

The invention belongs to the technical field of computer software and discloses a 3D map scatter data display method and system as well as an information data processing terminal. A 3D stereoscopic graph is created in a plane in a 2D graphic mode and a 3D space mode by use of visual difference and optical diffraction; an object is made to be rendered to a webpage, and the object is enabled to looksmall in the distance and big on the contrary in a 3D projection manner; in the photographing principles, an included angle in the view point of a camera is set, so that the displayed object moves relatively; the influence degree of independent variables and dependent variables is judged with a binary variable analysis and statistic method and a partial correlation analysis method, and the independent variable with higher influence is reserved; data are mapped to a corresponding axis by use of scale with an airline data visualization method, progressive increase is performed at a regular timeunit with a circular rendering method, so that data dynamically change. Three 3D scenes can be created, and the cool 3D effect is sufficiently shown.

Owner:GLOBAL TONE COMM TECH

Vein carving and preparation method

ActiveCN1727211AEasy to prepareEasy to operateDecorative surface effectsWood treatment detailsVeinMedicine

Owner:郑泰均

Antique-looking jade mosaic pasted vitrolite picture

The invention relates to an antique-looking jade mosaic pasted vitrolite picture. Ancient flower and plant as well as bird and fish texture line drawings are drawn on a vitrolite with a fixed shape, then various colors of jades are cut into small jade slices which are identical in the shape and are pasted onto the drawn texture patterns according to the color gradient sequence until the whole texture pattern is gradually pasted with the jade slices, and side pressing is carried out on the drawn texture patterns, thus forming the vitrolite picture for decoration.

Owner:王旭东

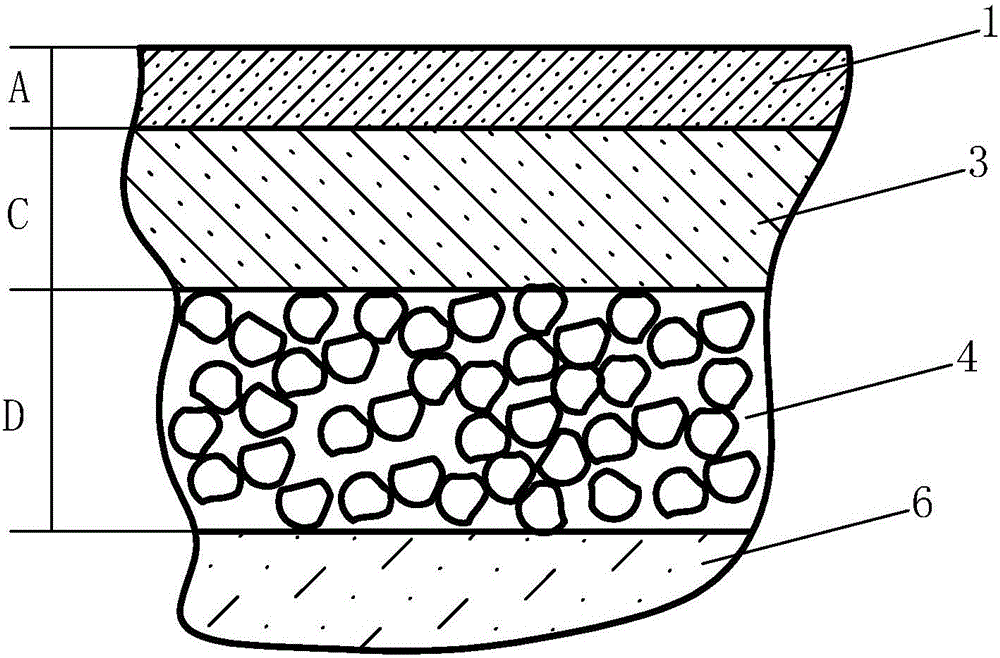

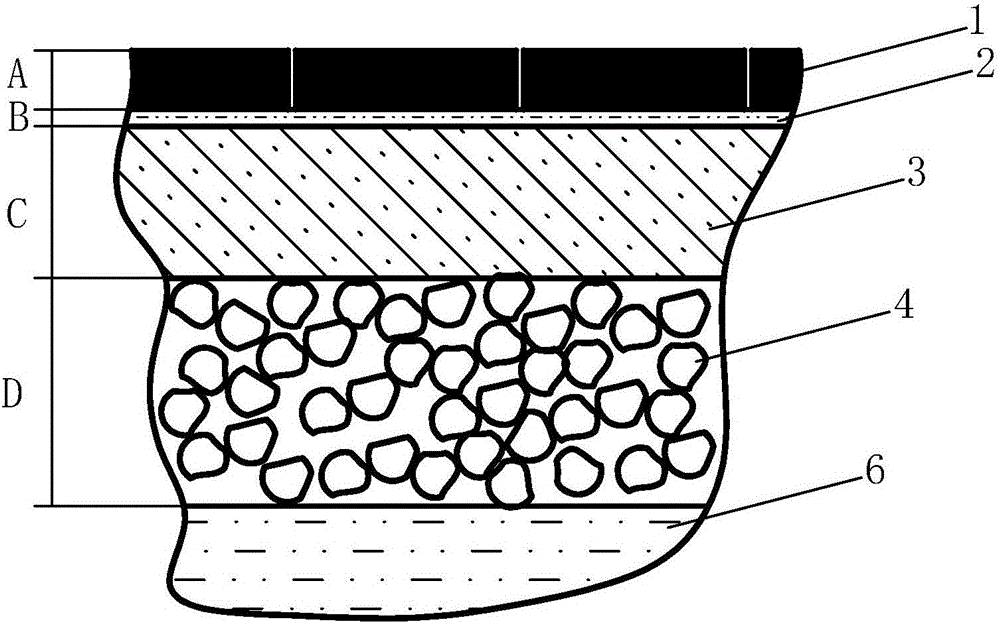

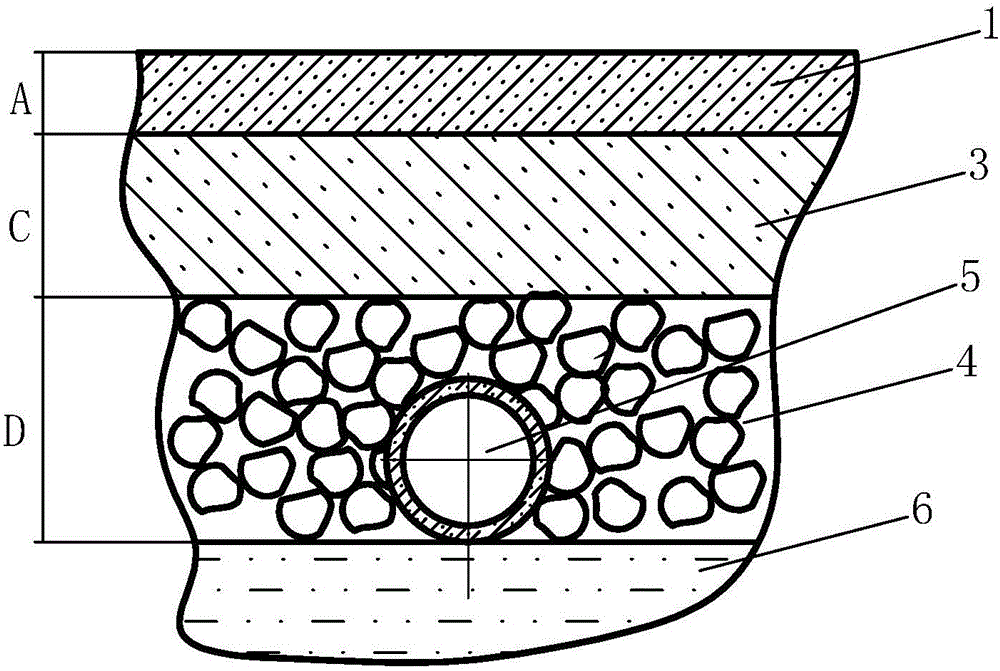

Water-retention water-water-permeable concrete utilizing construction waste and preparation method of water-retention water-permeable concrete

ActiveCN106431124AEfficient use ofReduce wasteSolid waste managementExpanded clay aggregateConstruction aggregate

The invention discloses water-retention water-permeable concrete utilizing construction waste and a preparation method of the water-retention water-permeable concrete. The water-retention water-permeable concrete is prepared from, by weight, 1-30 parts of cement, 1-3 parts of a mineral additive, 50-90 parts of aggregates, 0-3 parts of a coloring agent, 0.1-3 parts of a special additive SZ-BS-02 and 4-9 parts of water, wherein the mineral additive is ultrafine powder which is generated in the construction waste treatment process and has the specific surface area larger than or equal to 550 m<2> / kg, and the aggregates are prepared from, by weight, 25-35 parts of waste concrete particles with the particle size ranging from 2 mm to 30 mm, 45-55 parts of waste clay brick particles with the particle size ranging from 2 mm to 30 mm and 15-25 parts of light ceramisite with the particle size not larger than 15 mm. The water-retention water-permeable concrete prepared through the method has the good water retention, water permeability and gas permeability and is suitable for being used by a sponge city.

Owner:厦门宏鹭升建筑新材料有限责任公司

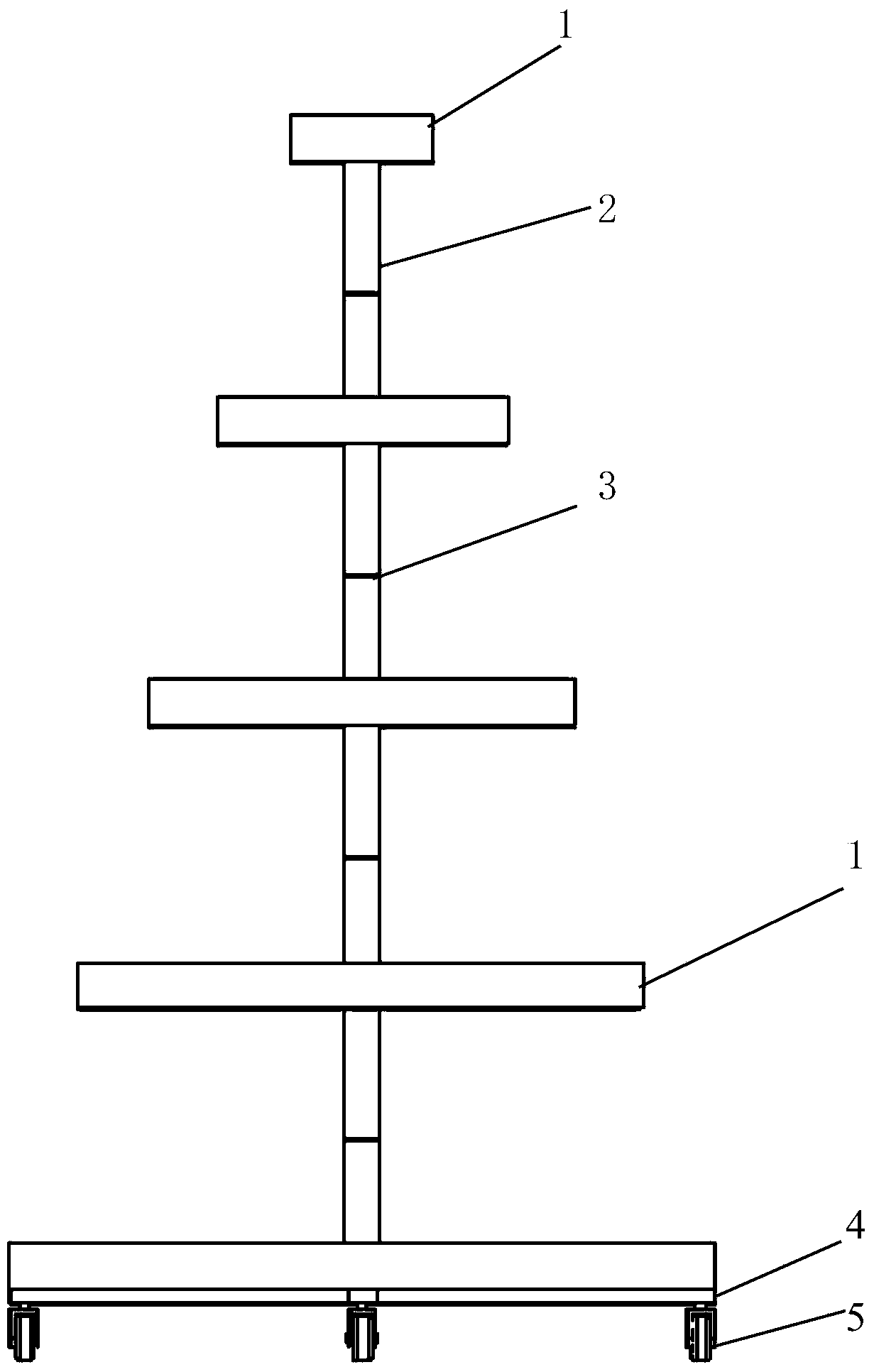

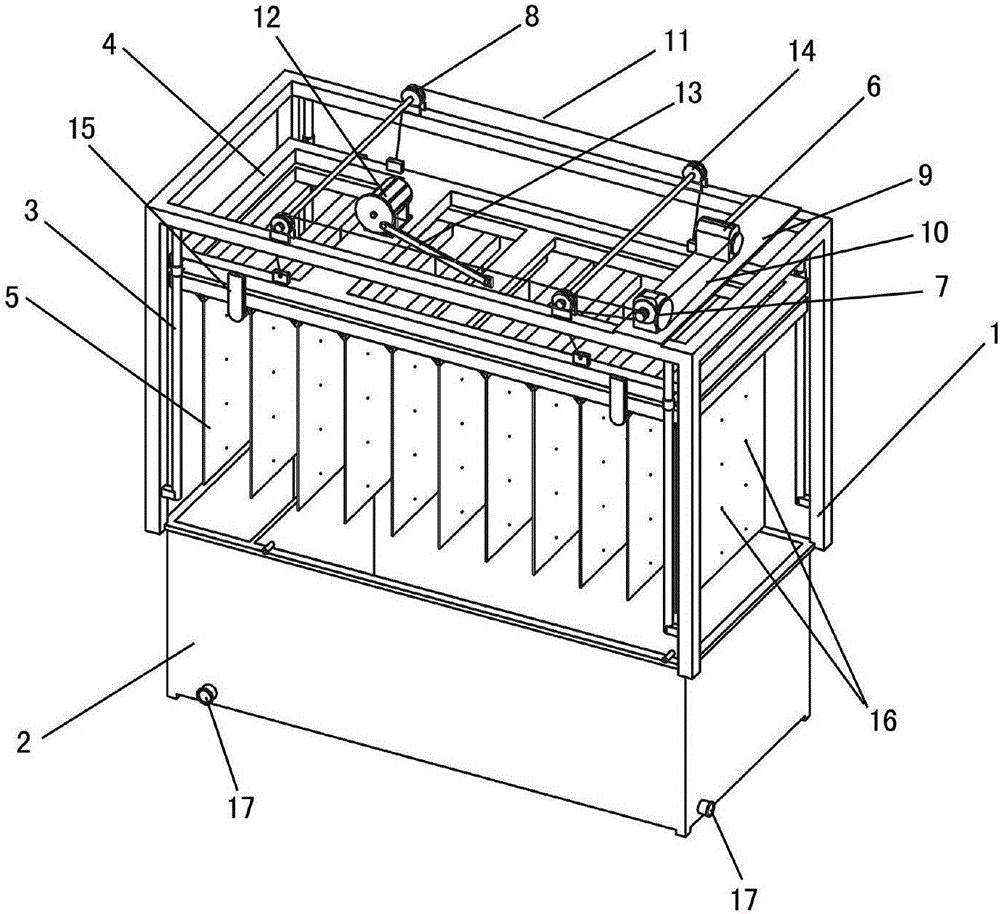

Flower and grass planting rack and manufacturing method thereof

ActiveCN103461027AReasonable useSmall footprintFlower holdersReceptacle cultivationPublic placeEngineering

The invention relates to a flower and grass planting rack, which comprises planting discs, a pillar and an underframe, and is characterized in that the pillar is longitudinally arranged on the underframe, and a plurality of planting discs are arranged on the pillar. The planting rack is in a tower shape. Nutrient soil is put in the planting discs, so that flowers and grasses are planted; and flowerpots can also be directly put in the planting discs for planting the flowers and grasses. The flower and grass planting rack is widely used in houses and indoor and outdoor public places for planting the flowers and grasses, has the advantages of saving the building area and expanding the green space, has the functions of beatifying the environment, purifying air, and cultivating the taste, is convenient to move, and has artisticity and scientificity.

Owner:广州市绿韵园林建设工程有限公司

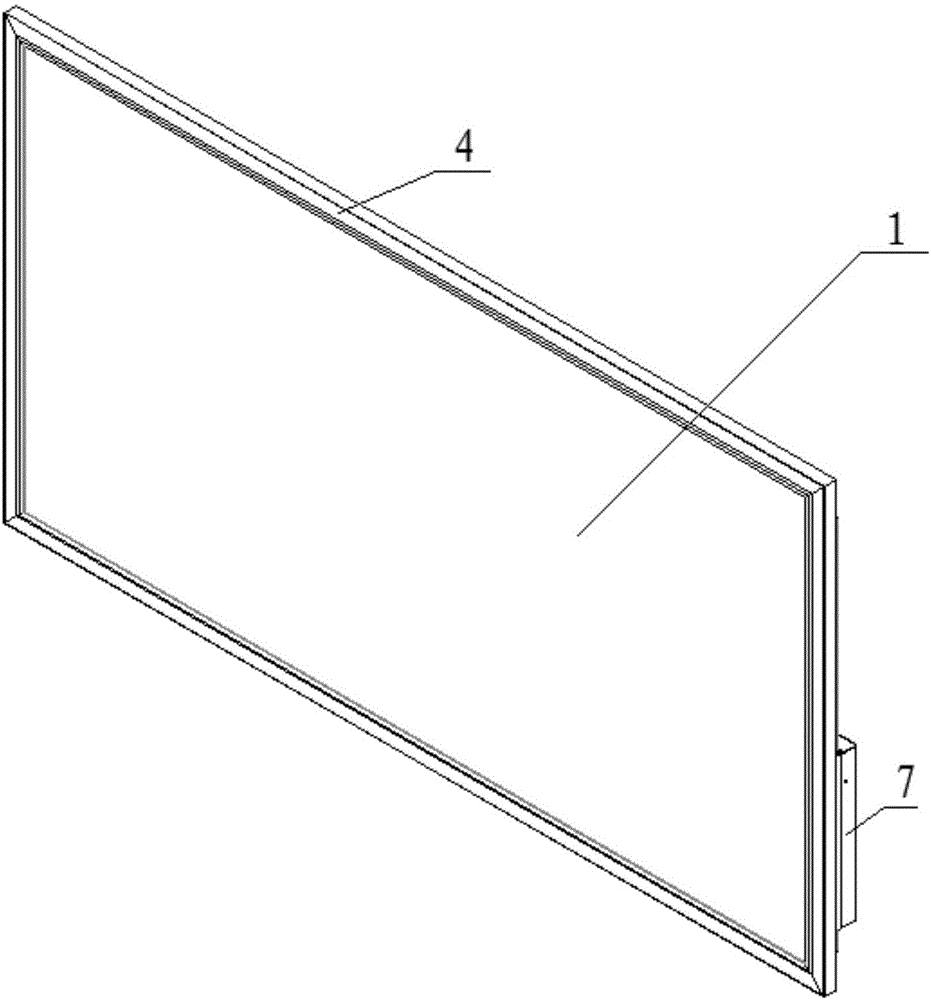

Wall-mounted heater and mural heater

InactiveCN106765477ASpeed up the flowAvoid excessive heatLighting and heating apparatusElectric heating systemElectricityHeating effect

The invention relates to the technical field of heater equipment, in particular to a wall-mounted heater and a mural heater. The wall-mounted heater comprises a heating panel, a heating plate and a back plate, wherein the back plate is of a groove-shaped structure; radiating holes are formed in an upper groove wall and a lower groove wall of the back plate; the heating panel is fixedly connected with the upper edges of the groove walls of the back plate; the heating plate is fixedly arranged in the groove of the back plate; a clearance is reserved between the groove bottom of the back plate and the heating plate; a clearance is also reserved between the heating plate and the heating panel; and the heating plate and the heating panel are electrically connected with a power supply. The mural heater comprises the wall-mounted heater and a mural, wherein the mural is fixedly arranged on the outer surface of the heating panel of the wall-mounted heater. The wall-mounted heater and the mural heater, provided by the invention, are excellent in heating effect, reduce the scald situation, are full-bodied in artistic atmosphere and also have the technical advantages of stable structure and high practicality.

Owner:HANGZHOU PAPABEAR TECH CO LTD

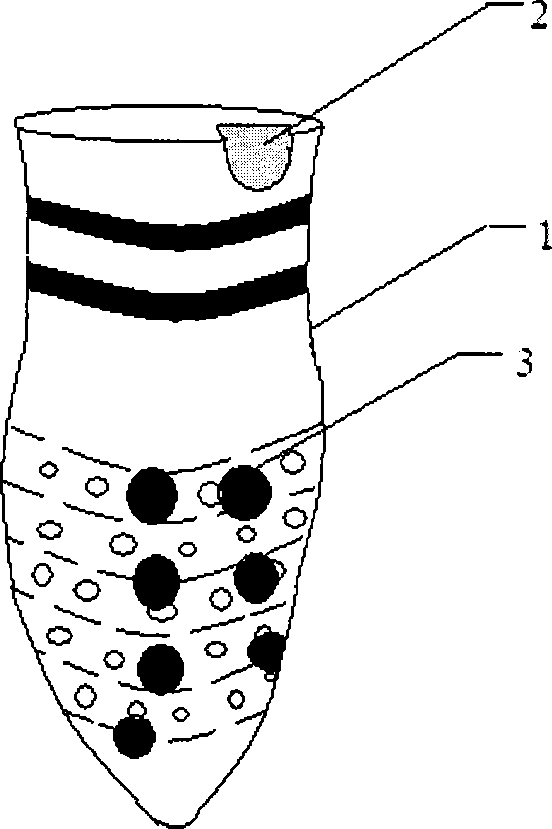

Visual storing method for long-term storage of DNA molecules and a device thereof

InactiveCN101532010AArtisticOrnamentalBioreactor/fermenter combinationsBiological substance pretreatmentsGenetic MaterialsDNA extraction

The invention relates to a visual storing method for long-term storage of DNA molecules and a device thereof. Currently, the long-term storage of the DNA molecules is mainly applied to the fields of practical medicine and scientific research so as to lead the DNA molecules to have artistic quality and appreciation and meet memory requirement and relevant reports have not been released currently. The invention is a visual storing method for long-term storage of DNA molecules and a device thereof; the method comprises the following steps: (1) DNA is extracted; and (2) sol-gel solution containing DNA is poured into a cavity of the storing device, vacuumization is carried out after the sol-gel solution is cooled and solidified and inert gas is charged and then the cavity is sealed. The invention leads the stored DNA to be visualized when in need under the premise of the stability of long-term stored genetic material, designs the storage space thereof into artistic modeling with personalized features, realizes the effect of using long-term stored genetic material for medicine and the like, simultaneously has artistic quality, appreciation and meets requirements of memory.

Owner:樊世斌 +1

Gold pigment for colored glazes and application method of gold pigment

The invention relates to a gold pigment for colored glazes and an application method of the gold pigment, and belongs to the technical field of colored glaze preparation. The gold pigment for the colored glazes is prepared by uniformly mixing 80KG of sodium hydroxide, 117KG of quartz sand, 2KG of borax, 16KG of sodium nitrate, 1KG of porcelain clay, 0.5KG of sodium fluorosilicate, 2KG of antimony oxide, 18KG of calcium carbonate, 1KG of potassium carbonate, 1KG of barium carbonate and 90g of 99.99% gold; then melting the mixture for 18 hours at 1400 DEG C to form a liquid state; performing water quenching, drying and crushing, and screening through a 120-mesh sieve; taking the screen underflow to obtain the gold pigment. The application method comprises the following steps of: taking a crystal material by using an iron rod, and rolling the iron rod on the gold pigment at a uniform speed to ensure that the gold pigment is uniformly covered on the surface of the crystal material; then rolling over a piece of pure silver paper, and performing tempering; finally, sleeving one more layer of the crystal material outside the gold pigment for molding. The gold pigment has a bright and shining overall effect, a prepared colored glaze is rich in coloring effect and is more ornamental and artistical, and the application method is simple and feasible.

Owner:ZIBO ZICHUAN ZHENHUA GLASS PROD

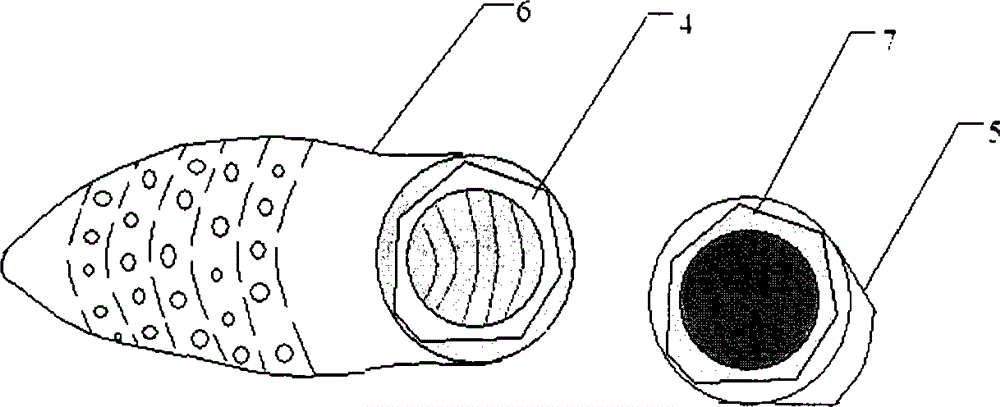

Manufacturing method of bamboo ancient egg-shaped and holed wind instrument

The invention discloses a manufacturing method of a bamboo ancient egg-shaped and holed wind instrument. The bamboo ancient egg-shaped and holed wind instrument comprises an instrument body, a blowing hole and sound producing holes, wherein the instrument body comprises an upper half and a lower half, the upper half is provided with an upper half connector, and the lower half is provided with a lower half connector. The manufacturing method includes: selecting a bamboo root, processing with high temperature, shaping, performing die assembly, opening the holes and decorating. The bamboo ancient egg-shaped and holed wind instrument has the advantages that the shapes of the manufactured instruments are different due to the fact that the instruments are made of natural materials; the range of the instrument ranges from low pitch 5 to high pitch 2, the instrument can also be forcibly manufactured into an instrument with the range ranging from high pitch 3 to high pitch 5, the tone of the instrument is graceful and pleasant to the ears, and playing requirements can be satisfied; ten finger holes include eight front holes and two rear holes, and sounds of several degrees can be blown in a bend-down and extensive manner; the instrument made of the bamboo root is attractive in appearance, artistic and pleasant in tone and conforms to playing standards; waste bamboo roots are reused, and sustainable development of economy is benefited; a person needs to uses breath, hands and the mouth to play the instrument, the functions of the whole body are mobilized, and the person can become ingenious and the physical and mental health of the person can be benefited if the person plays the instrument for a long time.

Owner:唐昭荣

A kind of processing method of high-tear-resistant transparent wrapping paper and wrapping paper product thereof

ActiveCN102268844AArtisticImprove anti-agingFlexible coversMechanical working/deformationPolypropyleneIndustrial engineering

Owner:MINFENG SPECIAL PAPER

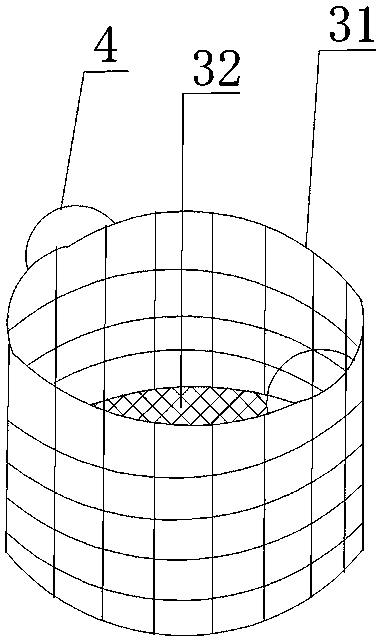

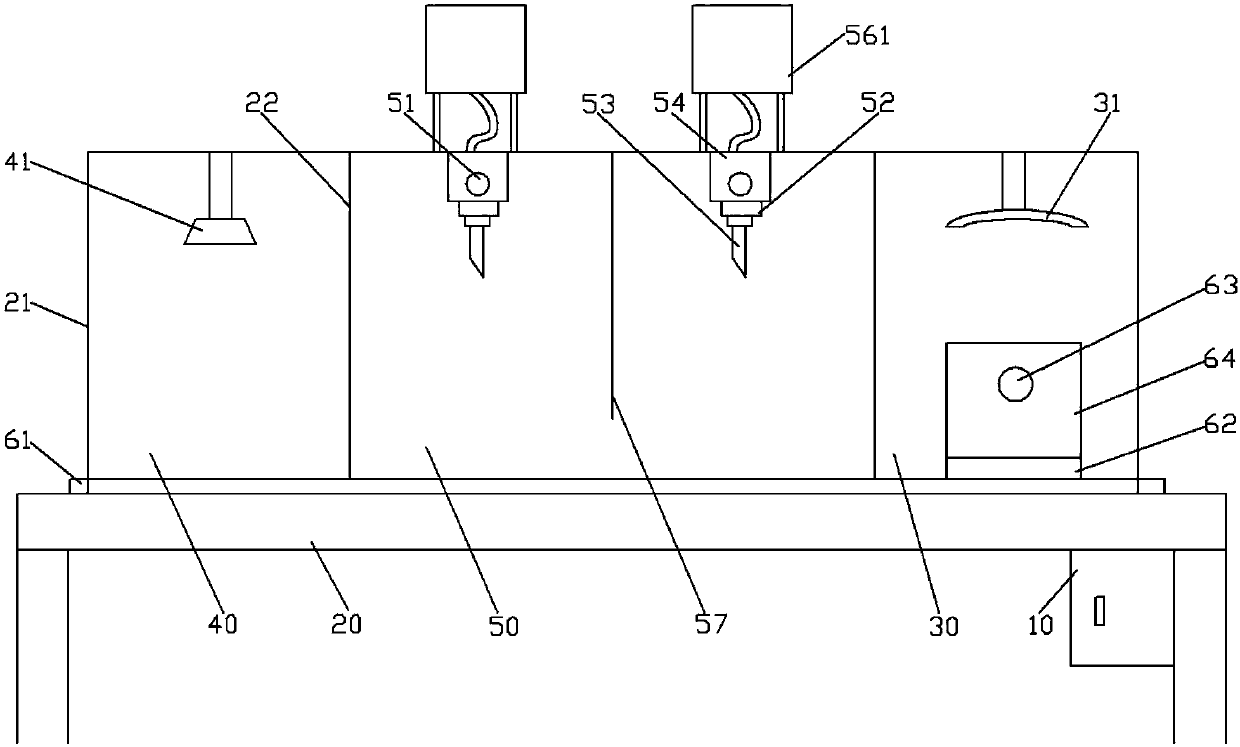

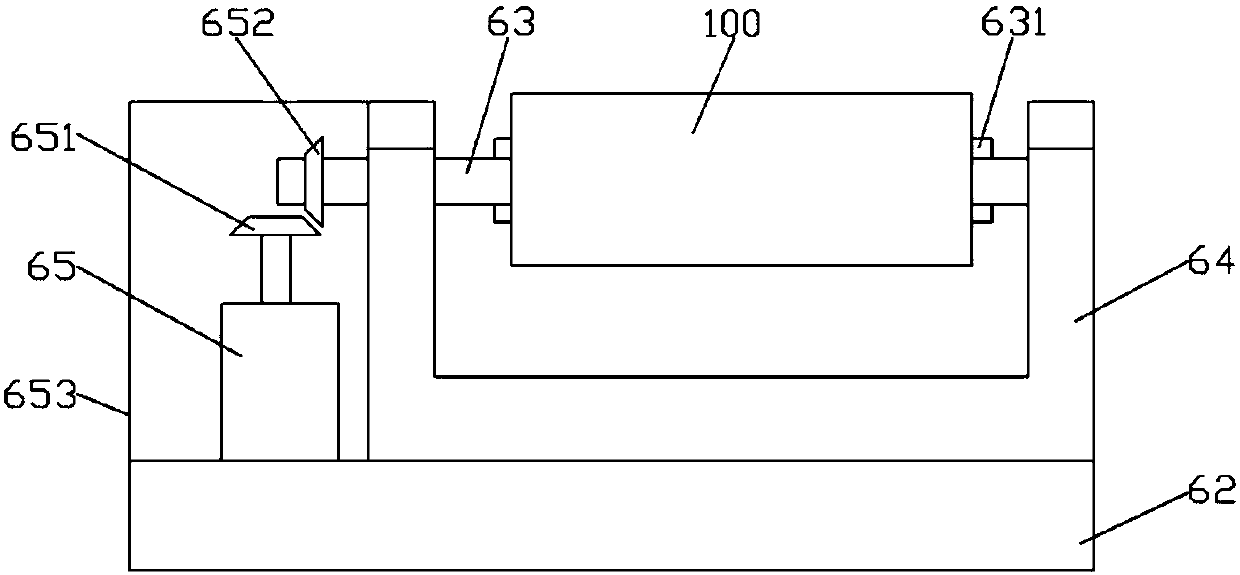

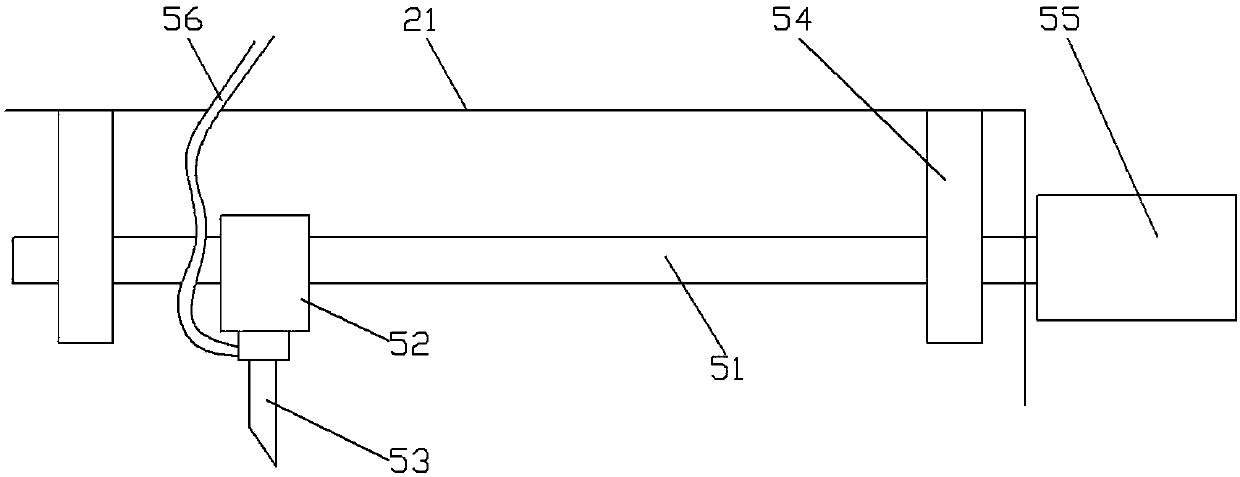

Tibet lamb skin space dyeing process and space dyeing device thereof

ActiveCN106320016ABroaden the field of applicationIncrease added valueLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringReagent

The invention discloses a Tibet lamb skin space dyeing process and a space dyeing device thereof. The process includes the steps of retanning, degreasing, dip dyeing, space dyeing and washing and drying. The process is characterized in that according to space dyeing, Tibet lamb skin obtained after dip dyeing and drying is hung on the space dyeing device, a space dyeing reagent and water are added into a dye liquor tank for heating to 65-70 DEG C, and then corresponding dyes are added for dyeing stage by stage. The space dyeing device thereof comprises a rack, the dye liquor tank is arranged at the bottom of the rack, a lifting rod is arranged on the rack, a movable platform is arranged at the upper end of the lifting rod, and multiple pieces of space dyeing toggling are installed below the movable platform; a lifting control mechanism is arranged above the rack and comprises a motor I, a transmission and a fixed pulley set, the motor I is connected with one end of the transmission through a belt, and the other end of the transmission is connected with the fixed pulley set through a chain. An auxiliary material and the space dyeing device are combined for dyeing, the process is simple, finished products with the art sense are obtained according to requirements, the color fastness of the products is high, layering is distinct, the application fields of the Tibet lamb skin are greatly widened, and the added value of the Tibet lamb skin is greatly increased.

Owner:NINGXIA WUZHONG JINGYI FUR PROD

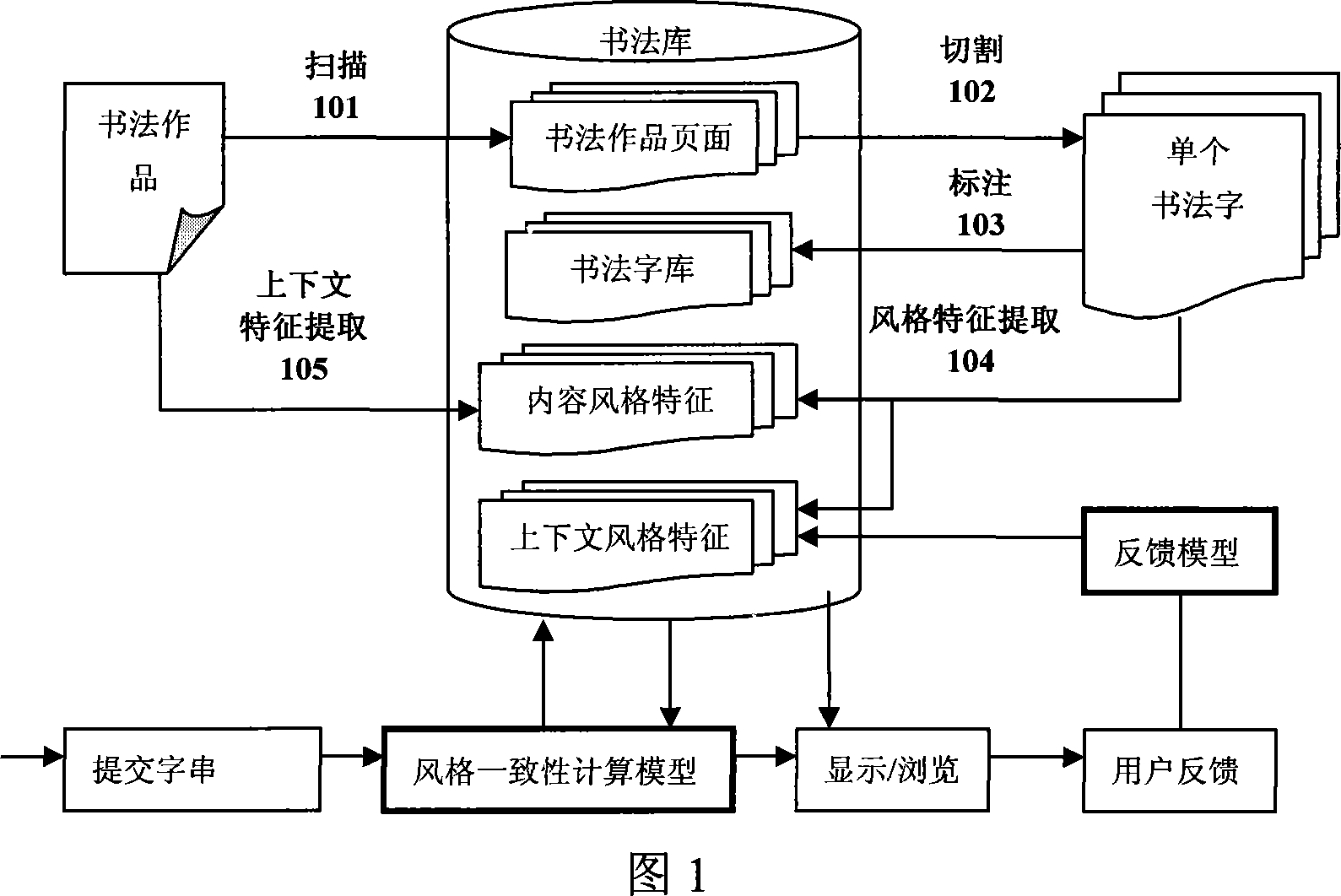

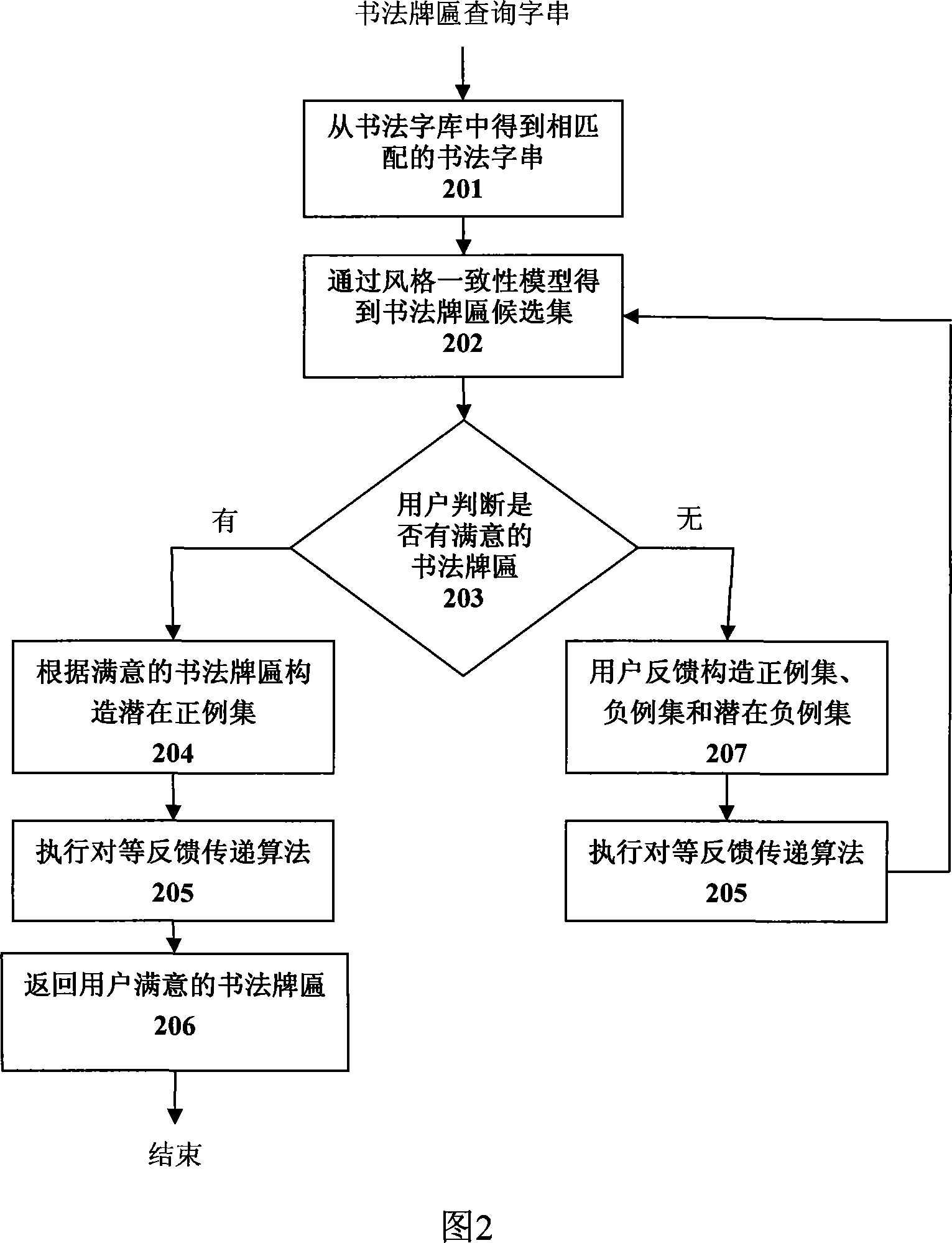

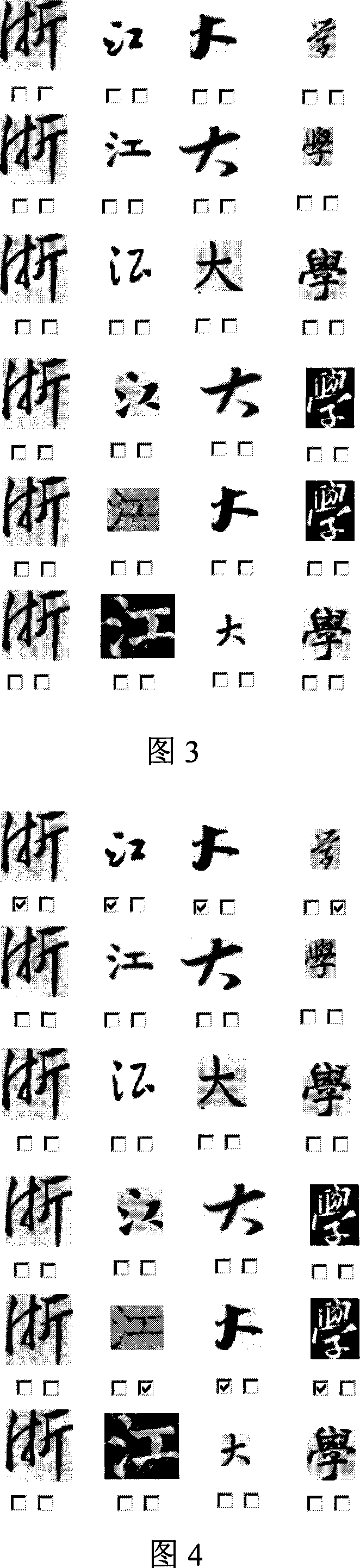

Computer aided calligraphy tablet design method

InactiveCN101236577APracticalMeet aesthetic standardsSpecial data processing applicationsAlgorithmComputer graphics (images)

The invention discloses a method of designing a calligraphic tablet assisted by a computer, which is characterized in that: firstly, the content style feature and the context style feature of calligraphic characters are combined as an expression mode of the style feature of the calligraphic characters, then the content style feature and the context style feature of calligraphic characters are extracted and fused based on the expression mode of the style feature of the calligraphic characters; the style similarity between calligraphic characters is calculated, then a style consistency computation module is used to acquire a calligraphic tablet candidate set; finally, the measurement of the calligraphic style is improved by a matchable feedback transfer algorithm. The method can overcome the limitation with a single feature as the calligraphic character style feature and define the calligraphic character style and calculate style similarity through fusing the bottom feature and the context feature of the calligraphic characters; the content style feature and the context style feature can be automatically extracted through the computer to ensure the generated calligraphic tablet have practicability; in the end, the method can improve the system performance through feedback so that the generated calligraphic tablet meet the aesthetical standard of people.

Owner:ZHEJIANG UNIV

Birch bark compound material and preparation method and application thereof

InactiveCN105111718AOvercome the inherent thinkingCorrosion resistantLayered productsPolyurethane adhesiveThermal insulation

The invention relates to a bark compound material and a preparation method and application thereof, in particular to a birch bark compound material and a preparation method and application thereof, and aims to solves the problems that utilization of birch bark by the prior art is low in efficiency, the birch bark has narrow application fields and the market is in shortage of cork barks. The birch bark compound material is composed of birch bark granules and polyurethane adhesive. The preparation method includes: 1, pretreating birch bark; 2, crushing and screening the birch bark; 3, performing mixing; and 4, performing forming and cutting. The birch bark compound material has the advantages of moisture resistance, electric insulation, heat preservation, thermal insulation, wear resistance, high comfort, high decorativeness and environmental friendliness and health. The invention is applicable to preparation and application of the birch bark compound material.

Owner:郑宝环

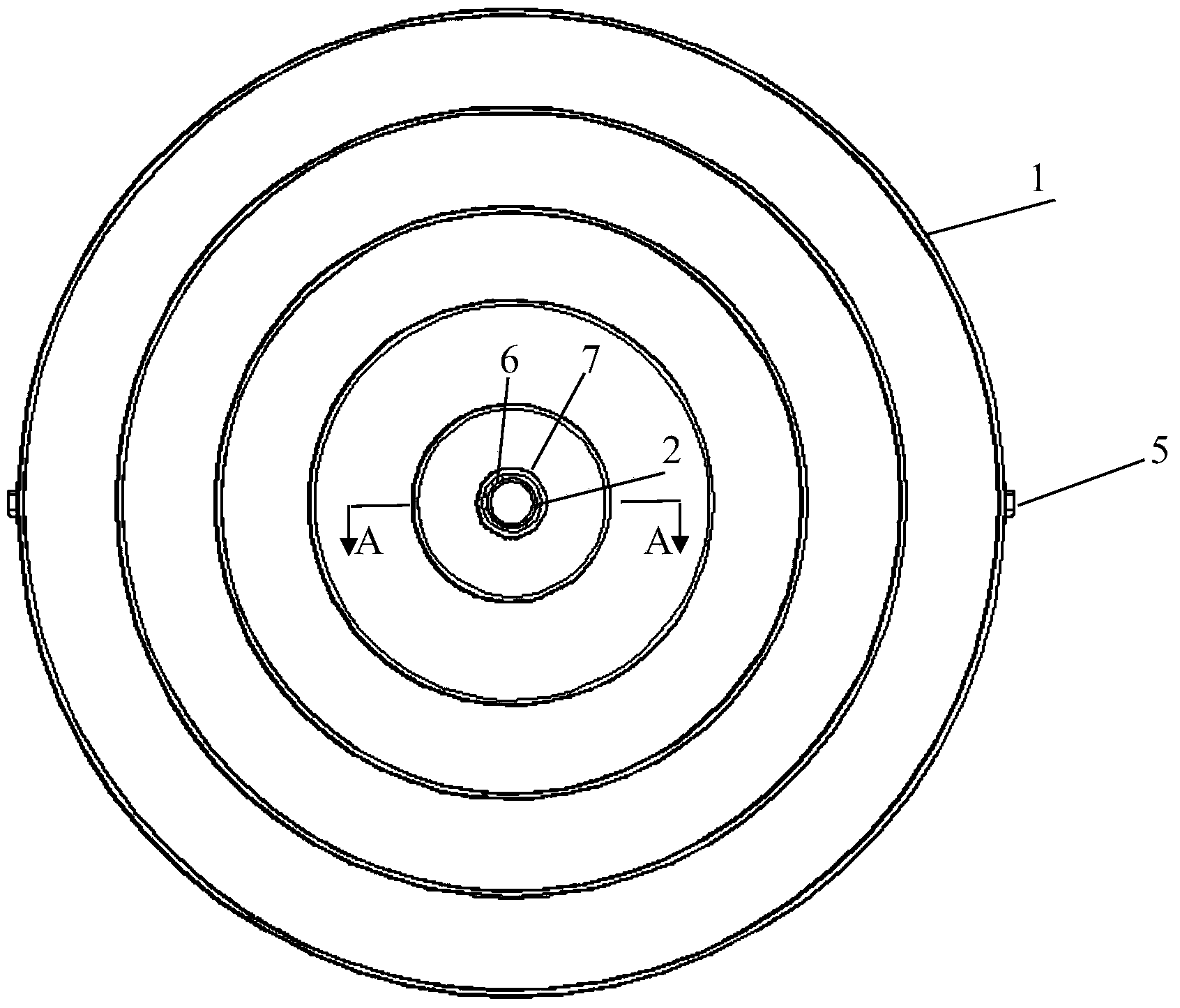

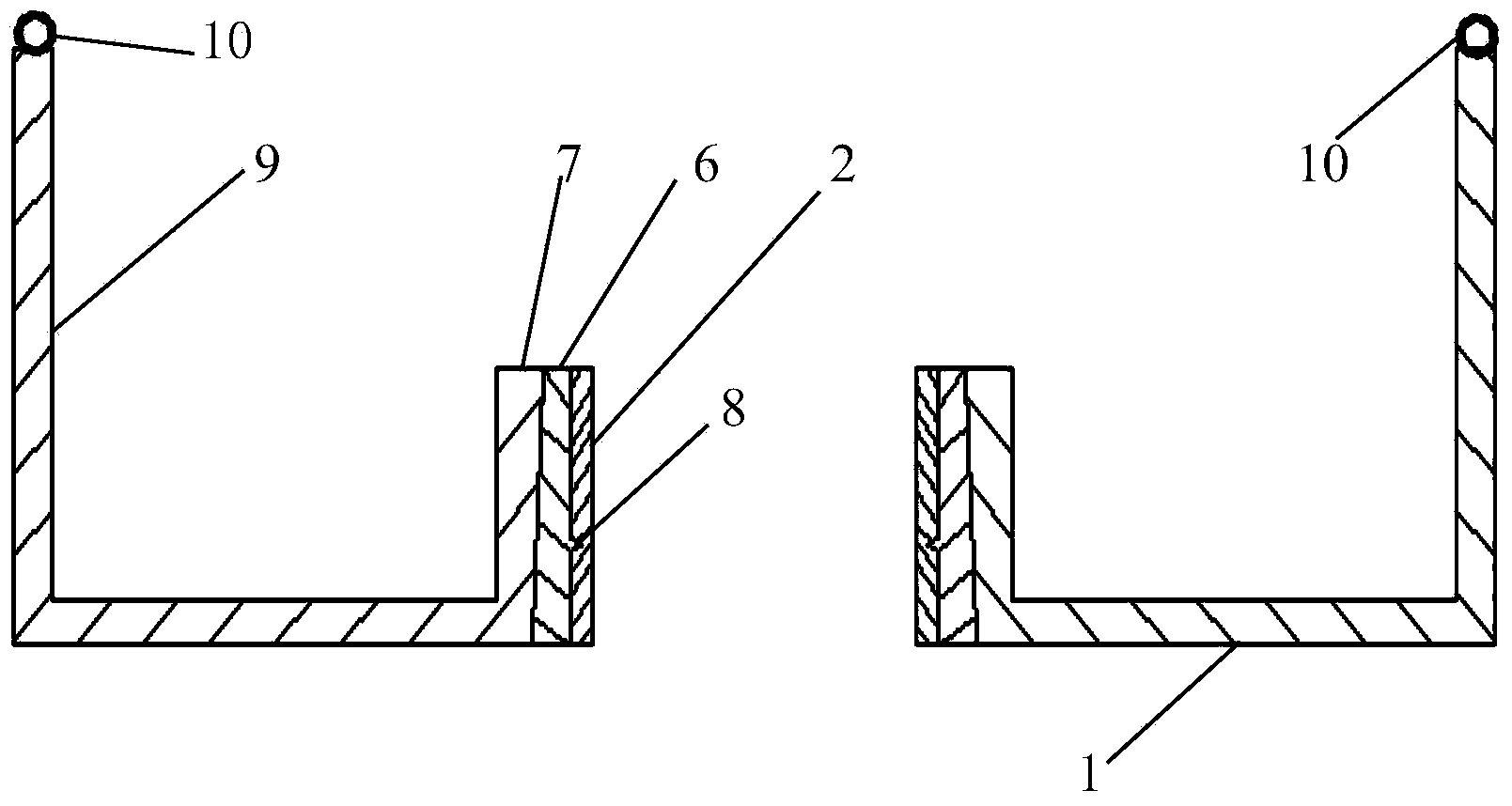

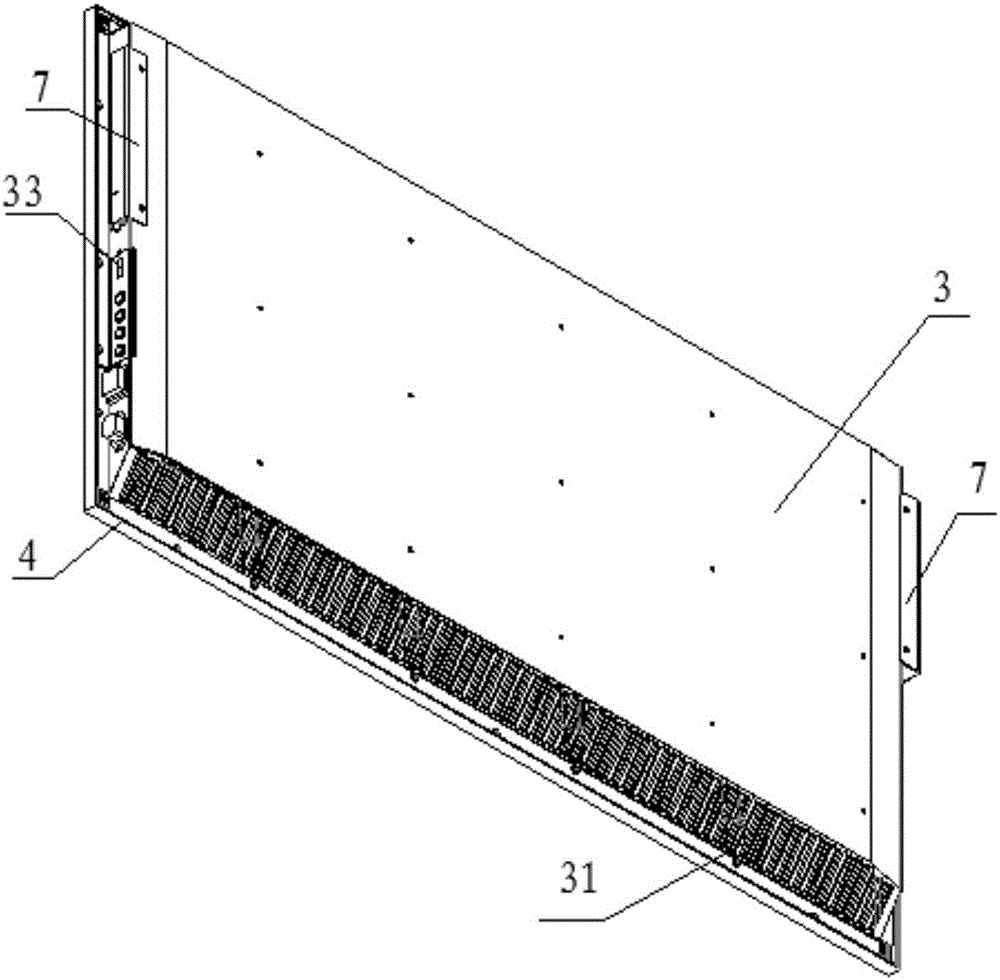

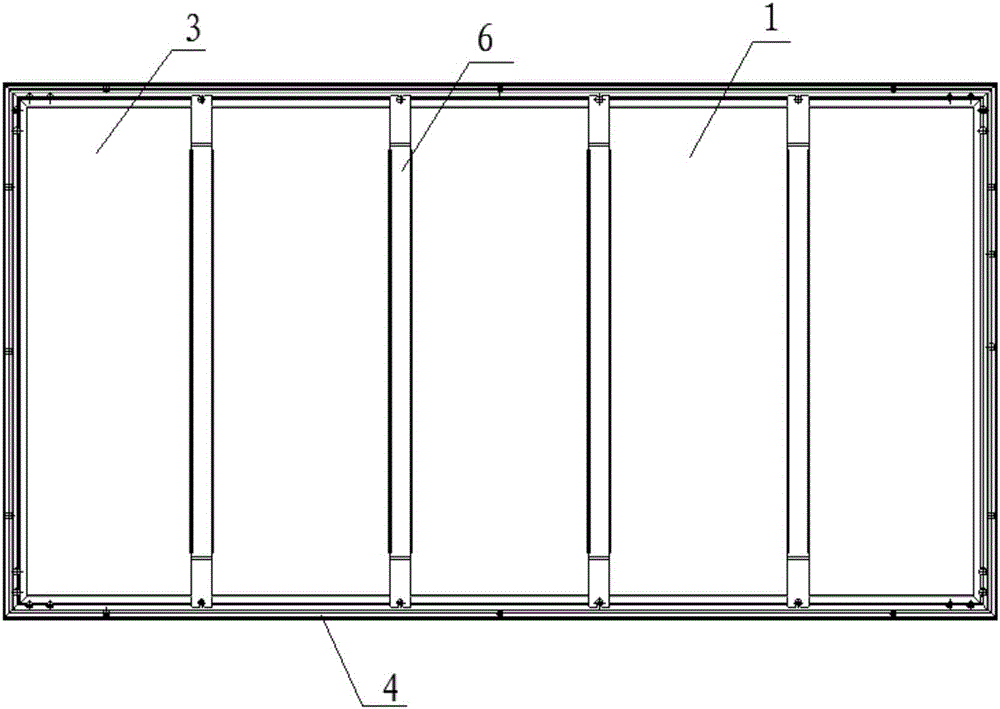

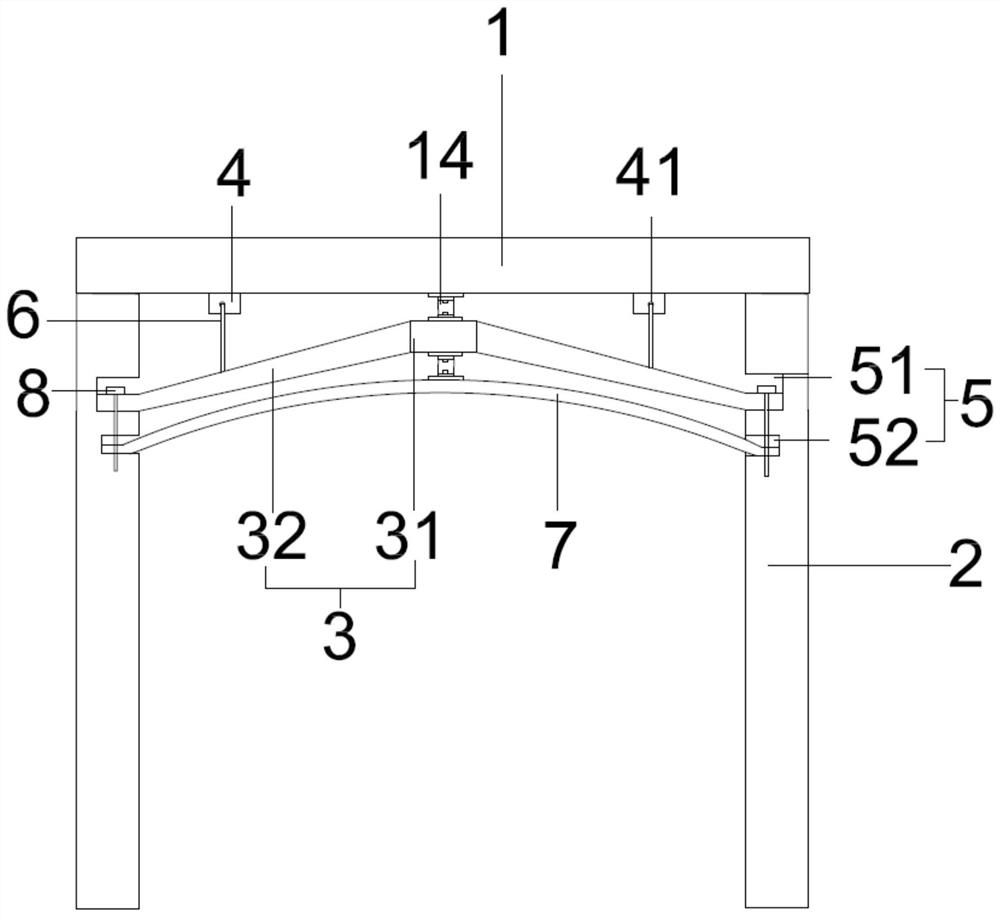

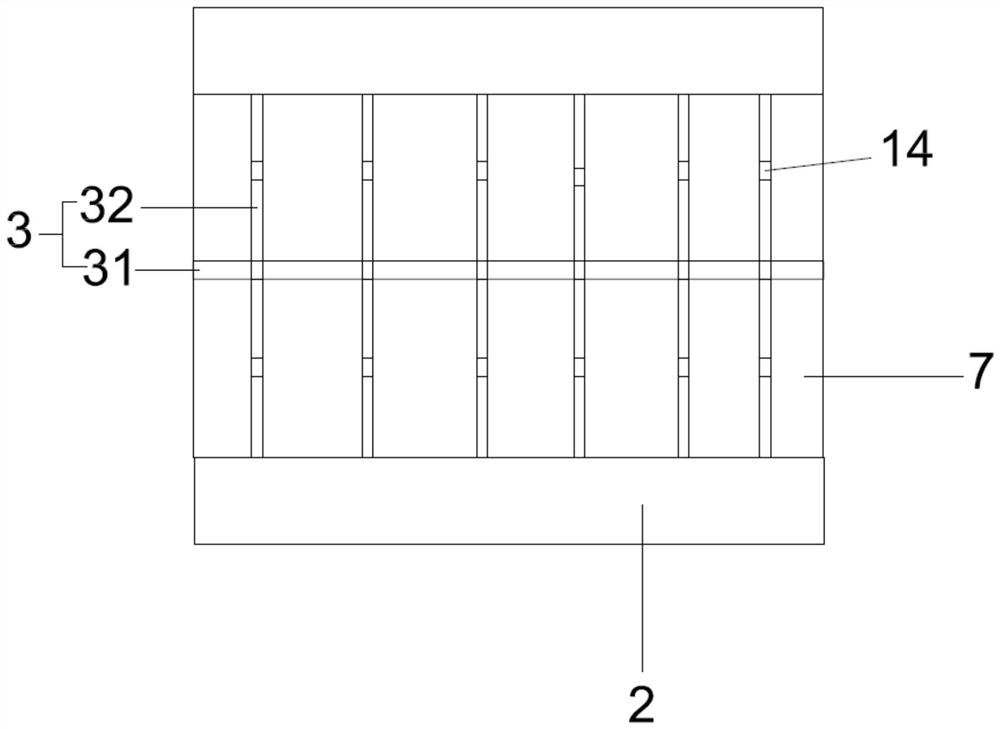

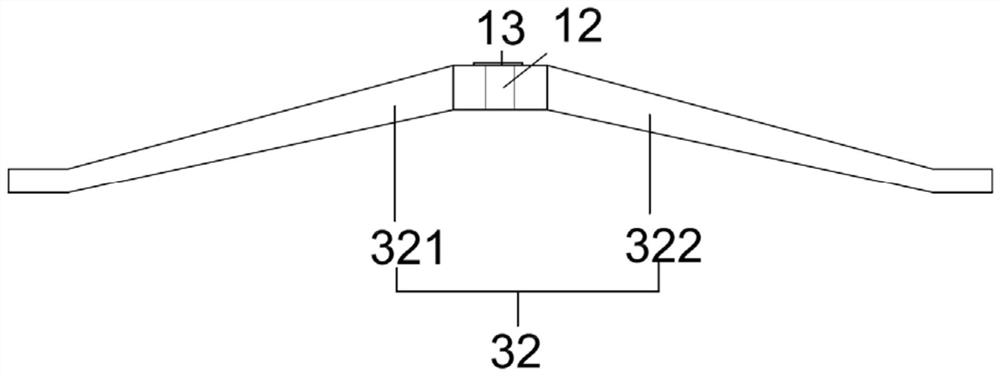

Arc-shaped space special-shaped wood veneer design structure and mounting method

The invention provides an arc-shaped space special-shaped wood veneer design structure. The arc-shaped space special-shaped wood veneer design structure comprises a top wall, side walls and a suspended ceiling framework. Grooves are formed in the side walls and comprise first grooves and second grooves, the suspended ceiling framework is arranged at the bottom of the top wall, and the suspended ceiling framework comprises a connecting frame and a supporting frame. Clamping grooves are formed in the two sides of the connecting frame. The supporting frame comprises a first supporting frame bodyand a second supporting frame body, the tops of the first supporting frame body and the second supporting frame body are clamped in the clamping grooves, and the bottoms of the first supporting framebody and the second supporting frame body are clamped in the first grooves. A wood veneer is arranged at the bottom of the suspended ceiling framework and extends towards the two sides to be clamped in the second grooves, and bolts sequentially penetrate through the supporting frame, the first grooves, the second grooves and the wood veneer to be fixed to the inner walls of the side walls. According to the arc-shaped space special-shaped wood veneer design structure, the fishbone-shaped suspended ceiling framework structure is adopted to replace a keel frame used by a traditional suspended ceiling conversion layer, the coordination of the whole space is improved, the cost is reduced, and the construction period is shortened.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

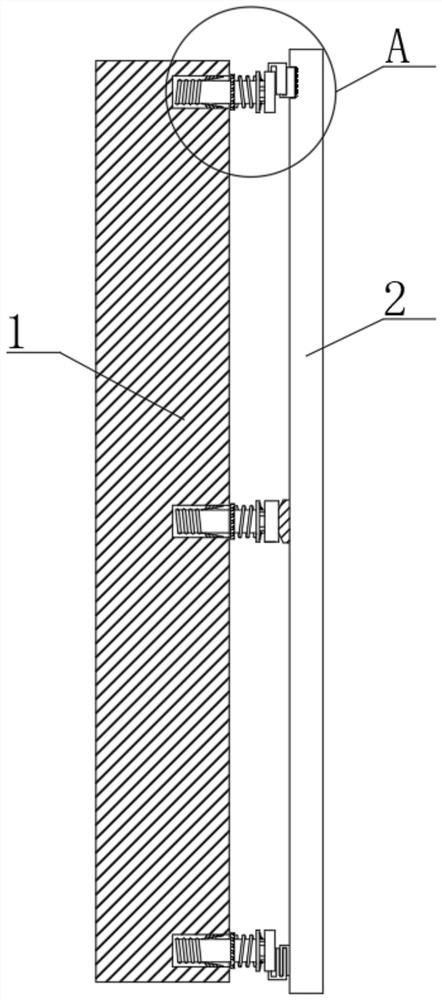

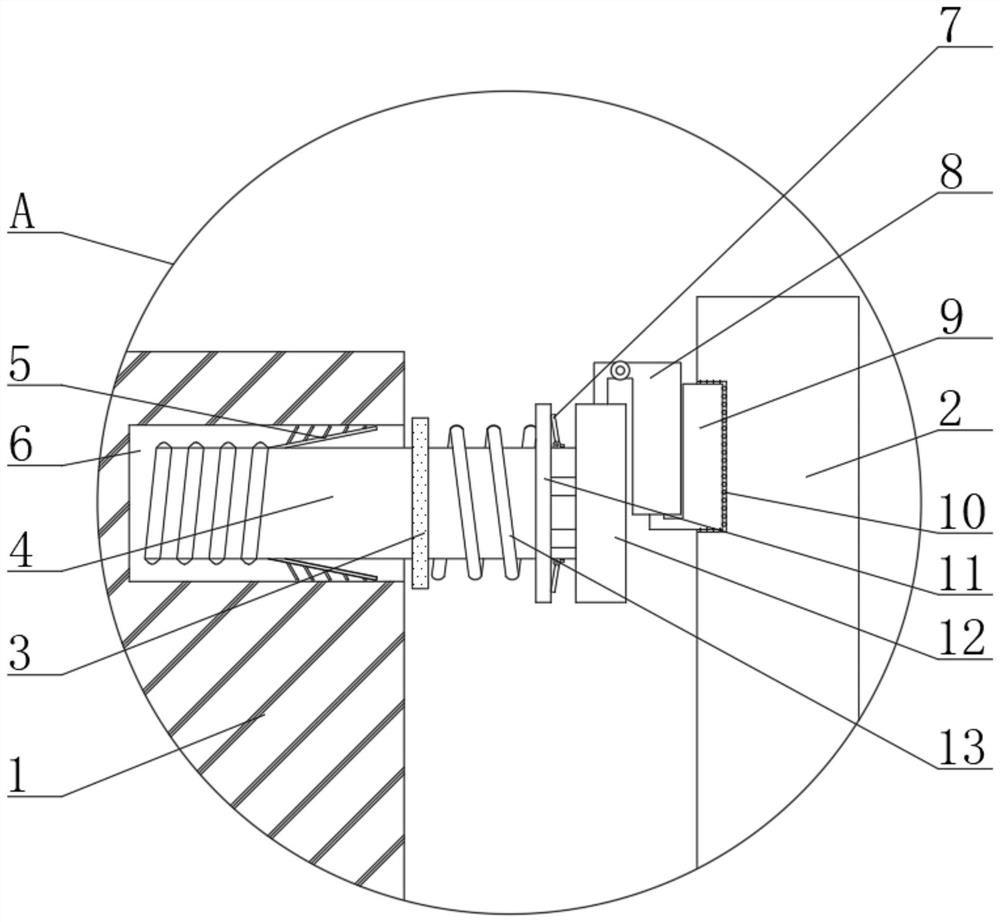

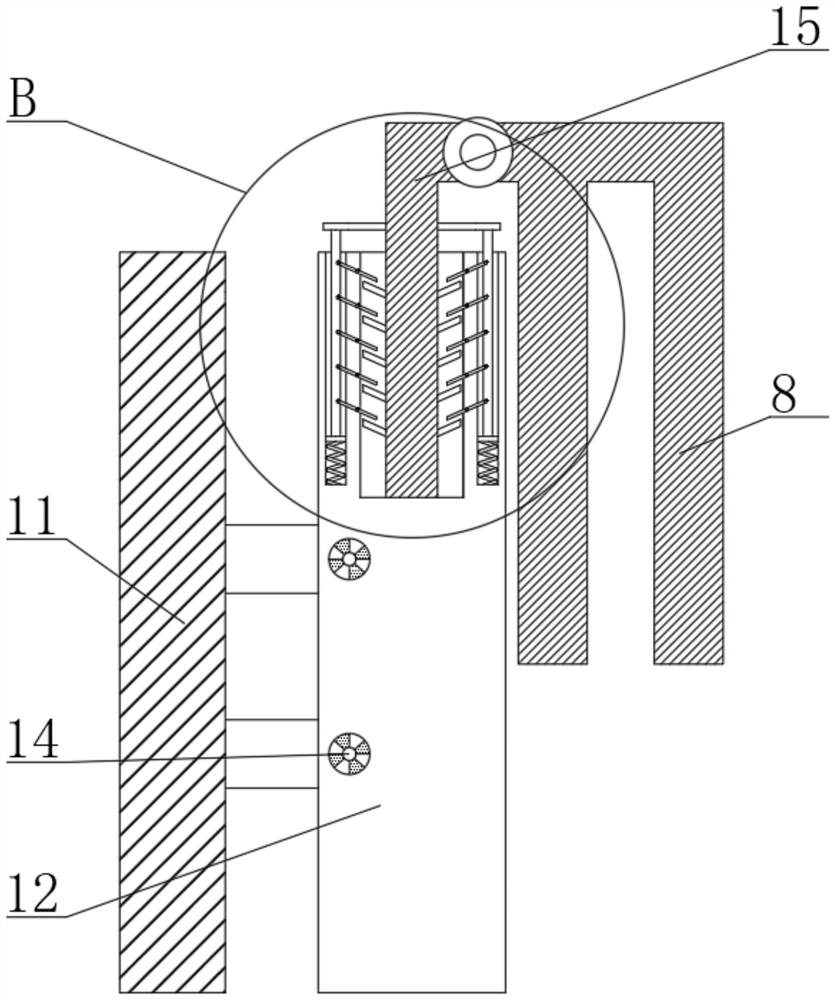

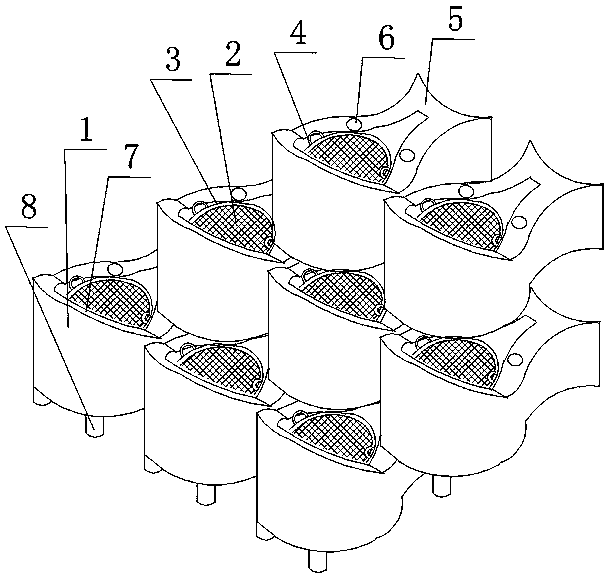

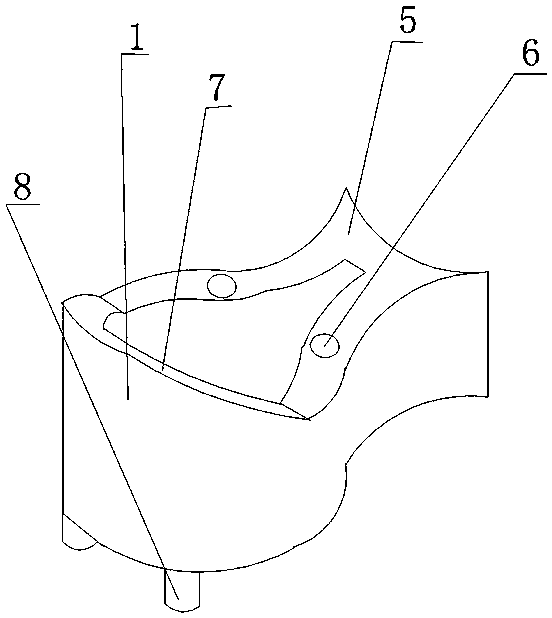

Assembly type mounting assembly of wall panel

PendingCN112064946AImprove functionalityAvoid running out of spaceCovering/liningsScrew threadMachining

The invention belongs to the technical field of wall panel connecting structures, and discloses an assembly type mounting assembly of a wall panel. The assembly type mounting assembly comprises a wallbody and a panel, a threaded hole is formed in the side face of the wall body, and a bolt is mounted in the threaded hole in a threaded manner. The outer surface of the part, located in the threadedhole, of the bolt is fixedly sleeved with an oblique clamping piece matched with the threaded hole in the reverse direction, and the outer surface of the part, located on the side face of the wall body, of the bolt is movably sleeved with a gasket. According to the assembly type mounting assembly of the wall panel, the oblique clamping piece is arranged on the outer side of the bolt, so that whenthe bolt is mounted, a clamping device between the bolt and the threaded hole does not need to be additionally mounted, machining is directly conducted during machining, the functionality of the structure is improved, and excessive extra steps are not needed; and by arranging a reverse clamping device and a compressed spring structure, the structure of an original bolt is changed, a connecting piece can still be additionally installed after the bolt is installed, and therefore the problem that when the original bolt is installed, the using space of a tool is insufficient can be solved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Finishing method for improving lamination degree of coating and crust leather

The invention relates to the technical field of leather making chemistry and engineering and provides a finishing method for improving the lamination degree of a coating and crust leather. According to the finishing method, non-ionic polyurethane resin without charges and a non-ionic oil wax auxiliary agent are selected as main body materials of a finishing agent; the surface tension of a finishing agent is reduced so that the leveling property and the permeability are improved; a technology is balanced and primary and secondary aspects in each phase and each operation are grasped; the lamination degree of the coating and the crust leather is improved; an ideal thin film is formed on the surface of the crust leather through the finishing agent and a shell is not easy to form after the coating is repeatedly bent or stretched; the non-ionic oil wax auxiliary agent has good filling and covering effects and can be used for improving the flatness and fineness of a particle surface of the crust leather; injuries on the particle surface of the crust leather are covered; the grading rate and utilization rate of the crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

Processing method for leather block floor

ActiveCN105034672AAffect aestheticsReduced service lifeOrnamental structuresFlooringComputer scienceBlocking layer

A processing method for a leather block floor includes the following steps that 1, a digital block type drawing is evenly divided into multiple square pattern blocks of the same specification; 2, leather leftover materials in various colors are cut into small leather square blocks of the same specification and in different colors; 3, the small leather square blocks in the corresponding colors are placed in small checks of a template in a right-side up mode according to the pattern content of each square pattern block and the arranging mode of the digital blocks in different colors in the square pattern blocks; 4, all the small leather blocks on the same leather block layer are transferred to the next processing position through one piece of transfer sticker; 5 gaps between the small leather square blocks are filled with glue, a leather layer of the floor is formed after the glue is dried and solidified, and then the transfer sticker is torn off; 6, the back face of the leather layer is polished and flattened; 7, numbers are given to all the leather layer blocks and correspond to the numbers of the digital blocks of the drawing; and 8, the leather layer is pasted to a floor base layer through glue. The floor processed through the method is attractive and abundant in pattern and good in comfortableness.

Owner:SHANGHAI MIPAI FLOOR MFG

Self-stabilization fish scale pit type ecological baffle wall

InactiveCN108570965AEasy to replaceAchieve self-stabilityBreakwatersQuaysEngineeringMechanical equipment

The invention discloses a self-stabilization fish scale pit type ecological baffle wall. The ecological baffle wall comprises baffle wall units, wherein cavities which longitudinally run through the baffle wall units are formed in the middles of the baffle wall units and are internally sleeved with ecological replacement tanks for planting plants, nutrient for supplying nutrients to the plants ispaved in the ecological replacement tanks, locking bulges are symmetrically arranged on two side walls of the bottom surfaces of the front parts of the baffle wall units, and locking grooves are symmetrically formed in two side walls of the top surfaces of the middles of the baffle wall units and are matched with the locking bulges; and the baffle wall units are arrayed in a fish scale manner oneby one so as to form the ecological baffle wall, the adjacent baffle wall units on the upper and lower layers are arranged in a staggered manner, and the locking bulges of the baffle wall unit on theupper layer stretch into the locking grooves of the baffle wall unit on the lower layer so as to form limiting connection. Compared with the prior art, the self-stabilization fish scale pit type ecological baffle wall has the advantages that the self-stability is good, the construction is simple, large-size mechanical equipment is not required, the ecological baffle wall can resist corrosion, hasgood greening effect and can well meet the biodiversity, a hydrophilic observation platform can be provided for residents, a self-rescue life way is provided for drowning people, and the water ecological functions of ecological protection slopes are realized.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Dyeing device and dyeing method for fabric

ActiveCN107761281ASmudge effect is obviousDark colorTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsProgrammable logic controllerEngineering

The invention discloses a dyeing device for a fabric. The dyeing device comprises a conveying mechanism, a PLC (Programmable Logic Controller), a worktable and a housing, wherein the conveying mechanism comprises a conveying belt, a mounting block, a mounting frame and a rotating shaft; a spraying head is arranged in a fog wet cavity; a plurality of spraying holes are uniformly formed in the bottom of the spraying head; the spraying head is connected with a steam generator; a blowing head is arranged in a drying cavity, and is connected with a blower; a spray dyeing mechanism is arranged in each dyeing cavity, and comprises a translation screw rod, a translation screw nut and a pressure spray head; each pressure spray head is connected with a corresponding dye tank. By using the dyeing device disclosed by the invention, the fabric can be dyed in a diversified manner; dyed patterns are attractive and not single, avoid repetition and have fashion sense.

Owner:JIAXING WANYUAN FASHION

Intaglio printing process for printing decorative pattern

The gravure printing method for printing decorative pattern is characterized by that said method incldues the following steps: gravure plate-making for decorative pattern, using gravure press to print UV printing ink on the card paper, then using UV light to cure, the described pattern is the patterns of pit pattern (imitation metal etch), dioptric pattern, wrinkle, ice flower and corellite pattern, then using chemical etching or electronic plate-making process to make plate and print, also can make composite plate on printing roller. Said invention adopts single-sheet gravure press and web gravure press, the card paper can be gold can paper, silver card paper or card paper with colour, and its printing ink is UV gravure decorative printing ink.

Owner:潘治平 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com