Wax color dying product and production process thereof

A production process and product technology, applied in the field of batik dyeing products and their production processes, can solve the problems of single color tone, unable to meet diversified aesthetic needs, and less changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

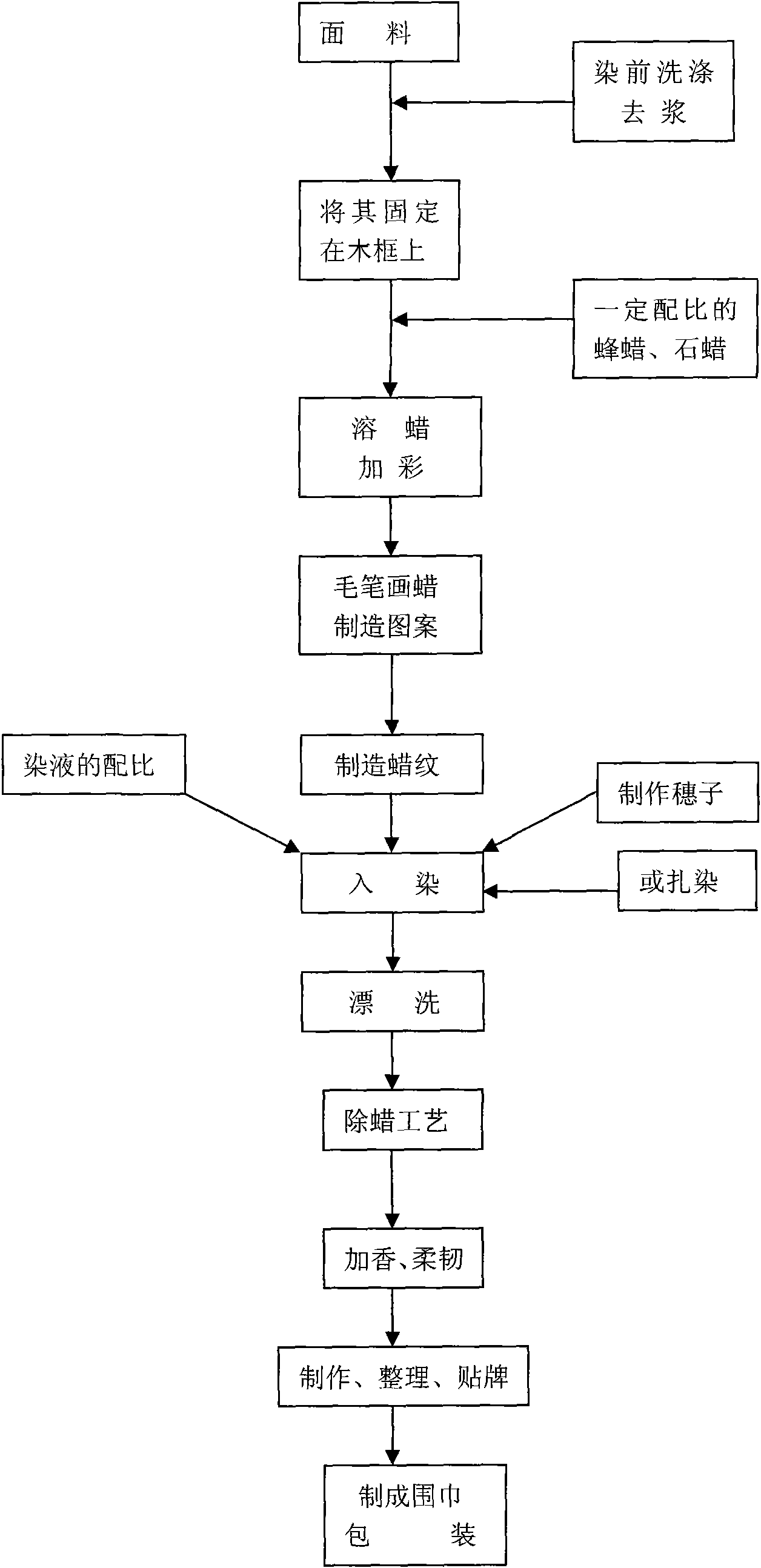

Image

Examples

Embodiment Construction

[0020] For a better description of the present invention, give the embodiment of the waxwork dyeing artwork of the silk weaving men's scarf:

[0021] 1. Fix the fabric: customize and tighten the fabric on the wooden frame;

[0022] 2. Wax painting: prepare paraffin wax and beeswax at a weight ratio of 3:1, and then heat and melt the wax with a heater. When the temperature of the wax liquid rises to 120°C to 130°C, dip the wax liquid with a brush to paint on the fabric. If the temperature of the wax liquid is too low, it will not be able to penetrate into the fabric, and will not have the effect of anti-dyeing; if the temperature of the wax liquid is too high, the wax will spread rapidly on the fabric when waxing, resulting in a thinner wax layer formed by the wax on the fabric , still does not have a good anti-staining effect.

[0023] 3. Manufacture of ice patterns: The wax-colored dyed products are processed by the ice cracking method, so that after the wax is cooled, crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com