Patents

Literature

33results about How to "Avoid running out of space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

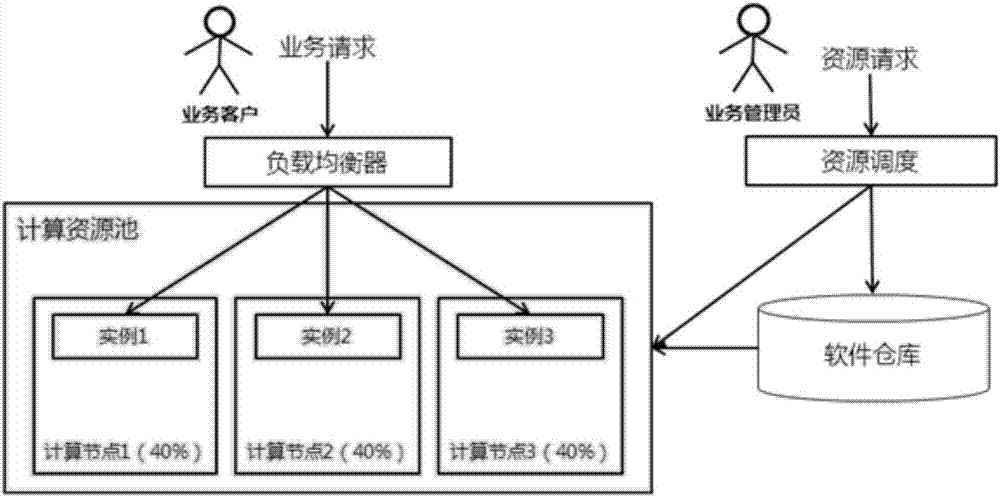

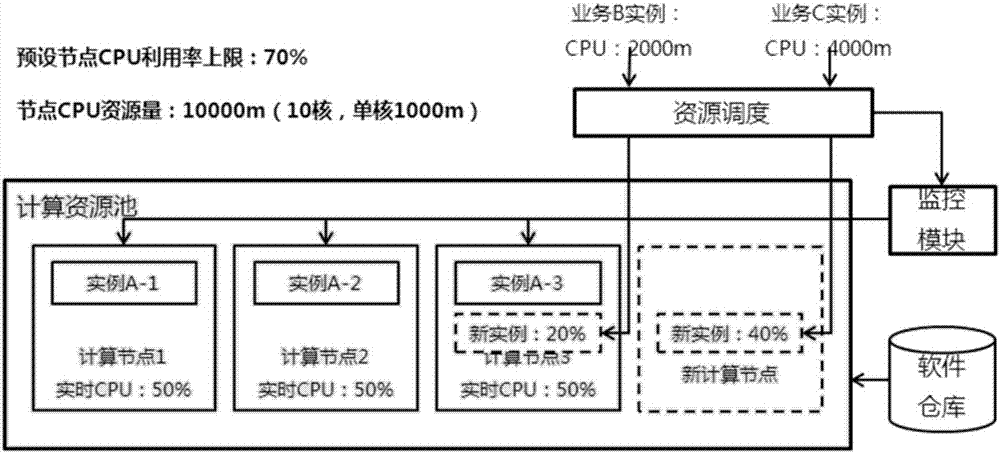

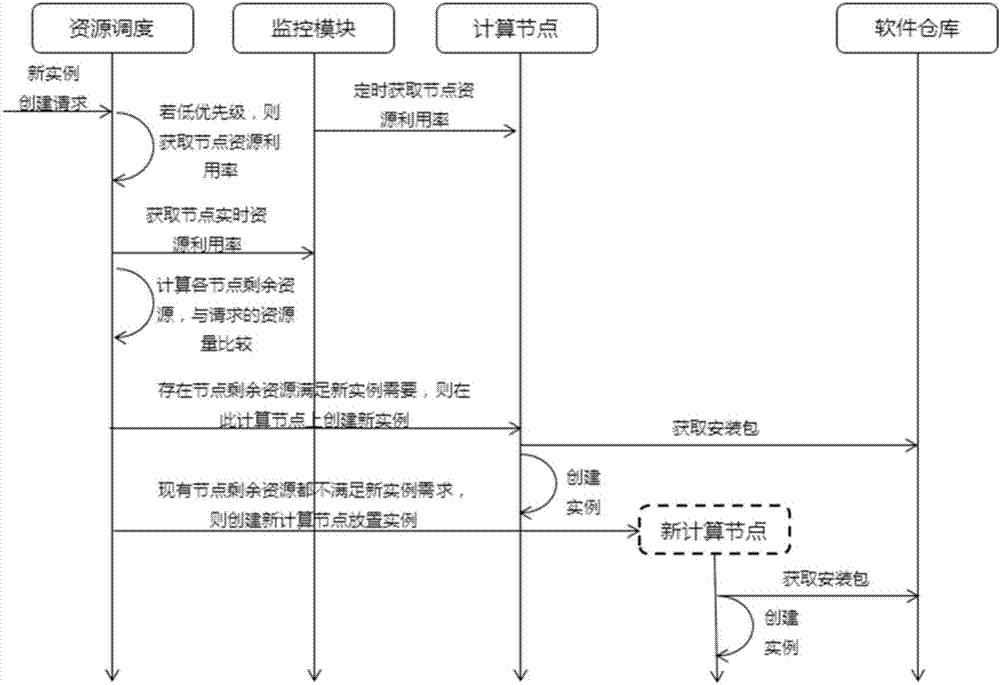

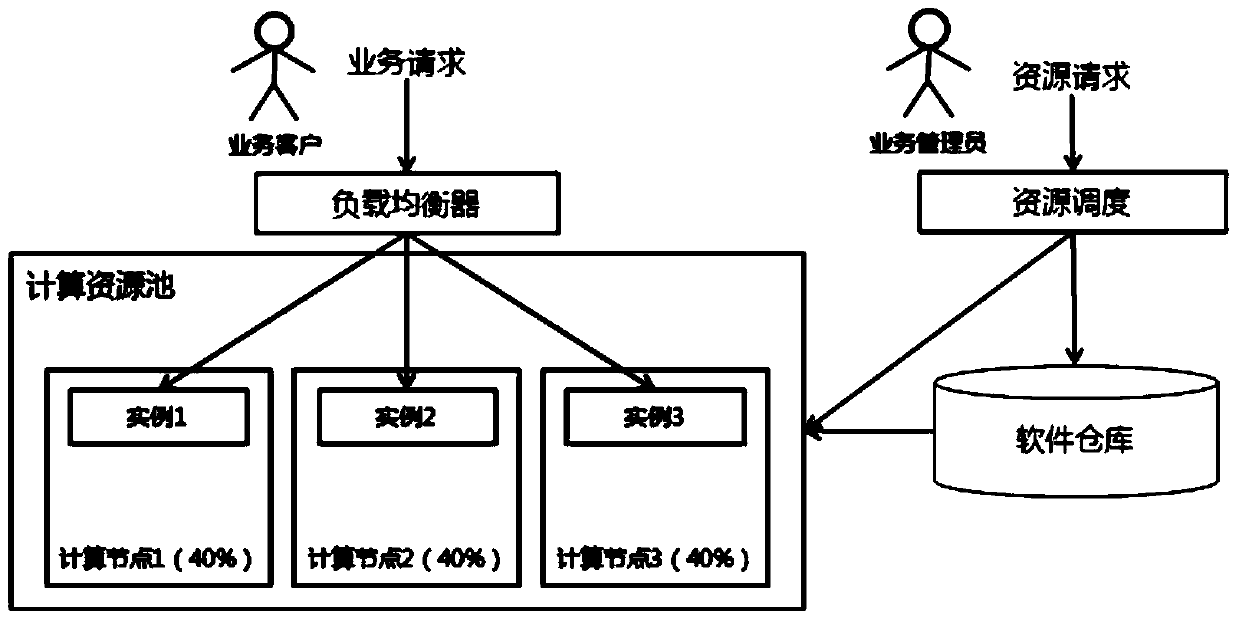

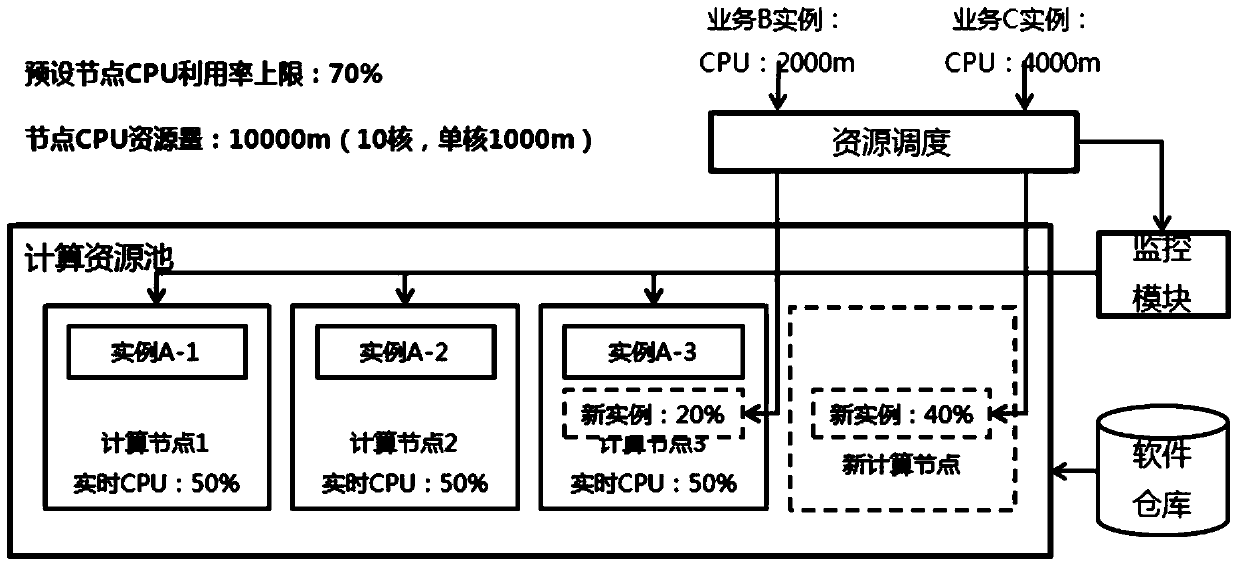

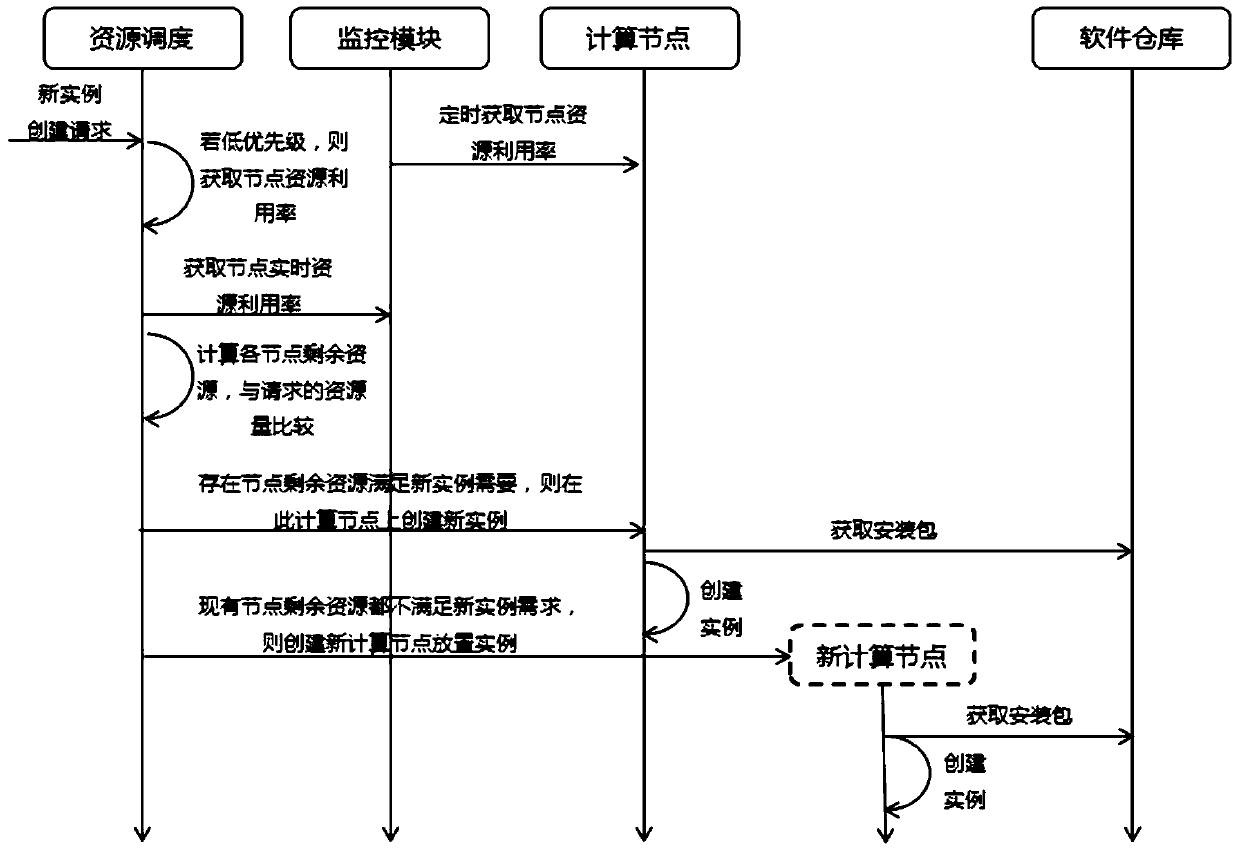

Method and device for regulating cloud computing resources

ActiveCN107040479AOptimizationReduce deficienciesData switching networksResource utilizationDistributed computing

The embodiment of the invention provides a method and device for regulating cloud computing resources, relates to the technical field of cloud computing, and used for reducing the quantity of computing nodes in a cloud computing platform by increasing remaining resources of the computing nodes, and improving the resource utilization rate. The method comprises the following steps: when a resource adjustment trigger condition is satisfied, selecting an object instance from an instance information table by a resource scheduling device; when a first business total resource quota is unchanged, adjusting the resource quota corresponding to each instance in a first business by the resource scheduling device, so that the resource quota of the object instance is decreased, and the resource quota corresponding to other instances except the object instance in the first business is increased; and transmitting a first request message to a load balancer by the resource scheduling device, so that the load balancer adjusts the weight corresponding to each instance in the first business according to the first request message, and the first request message comprises the adjusted resource quota corresponding to each instance in the first business.

Owner:HUAWEI TECH CO LTD

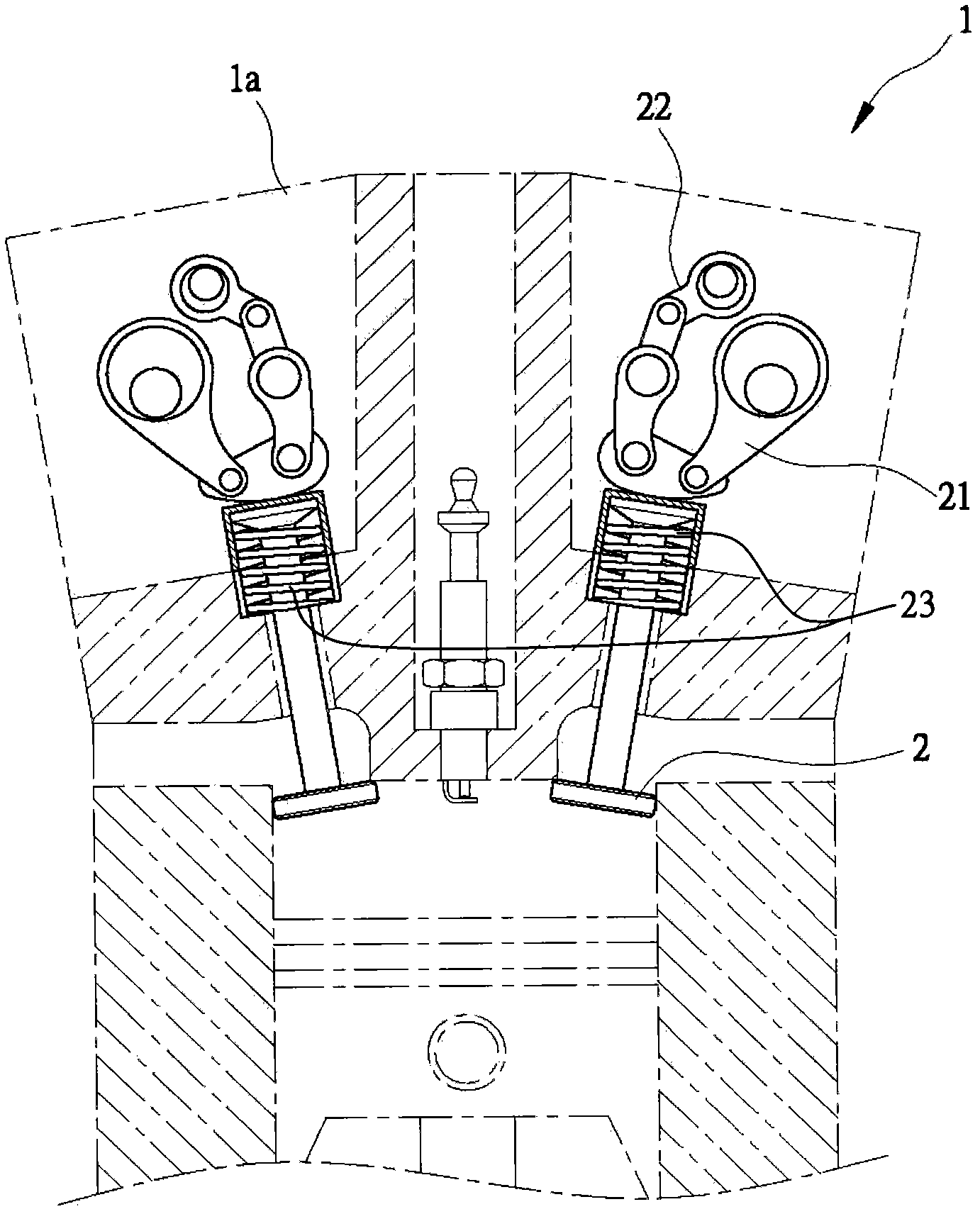

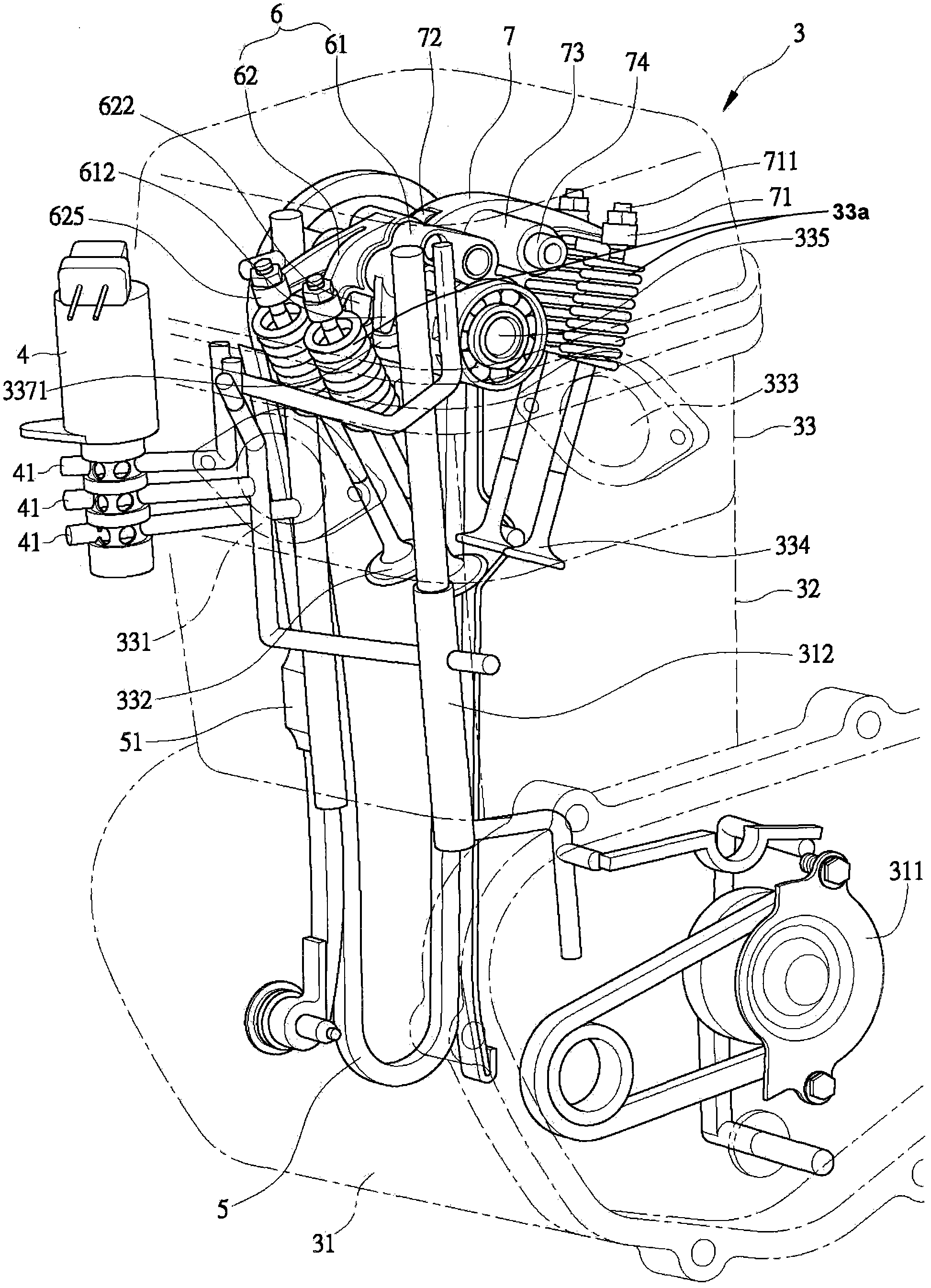

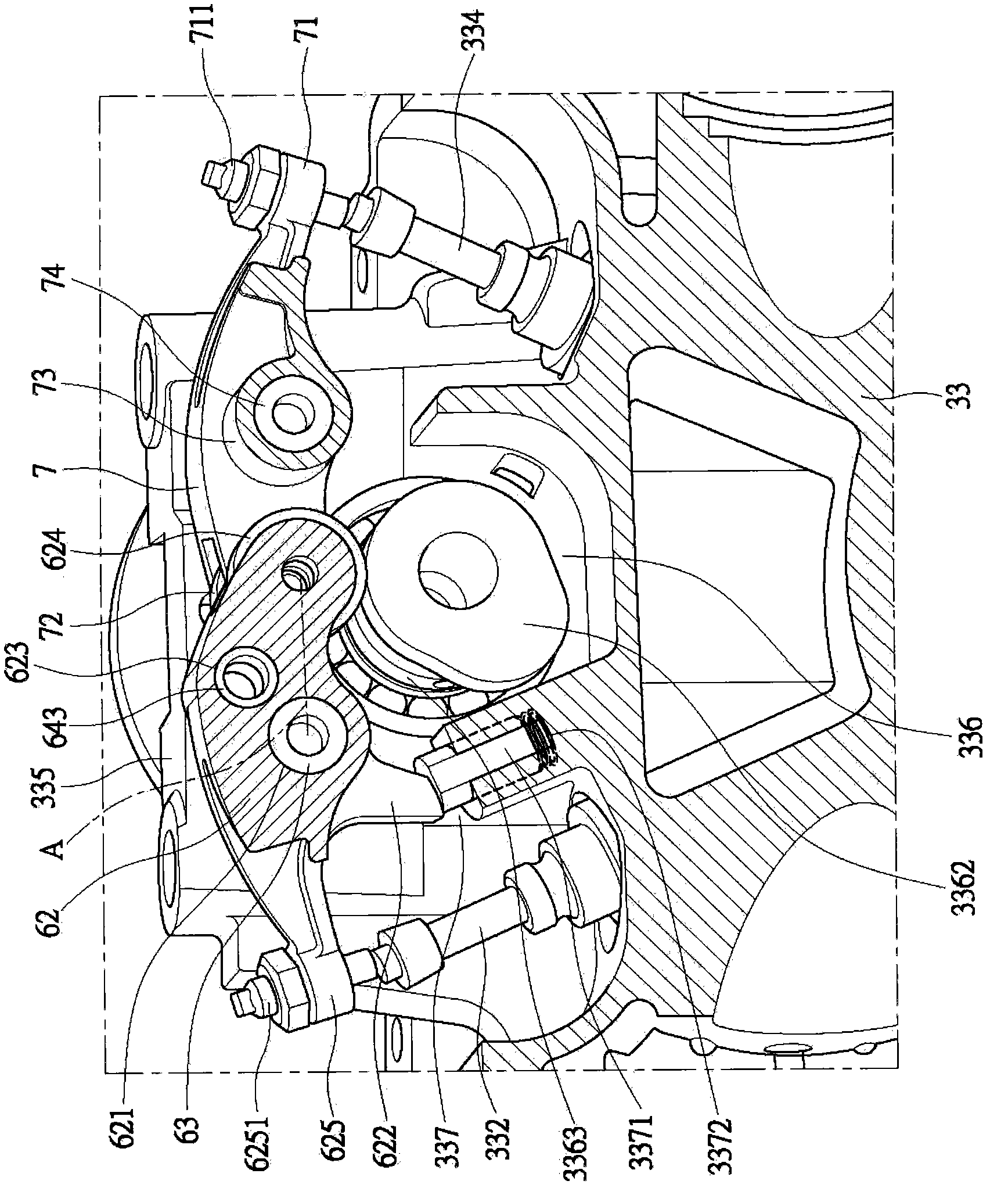

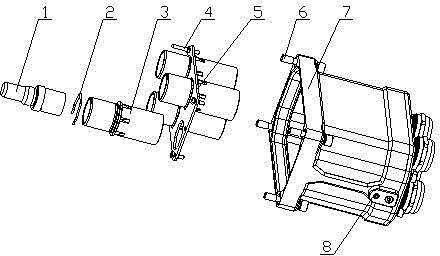

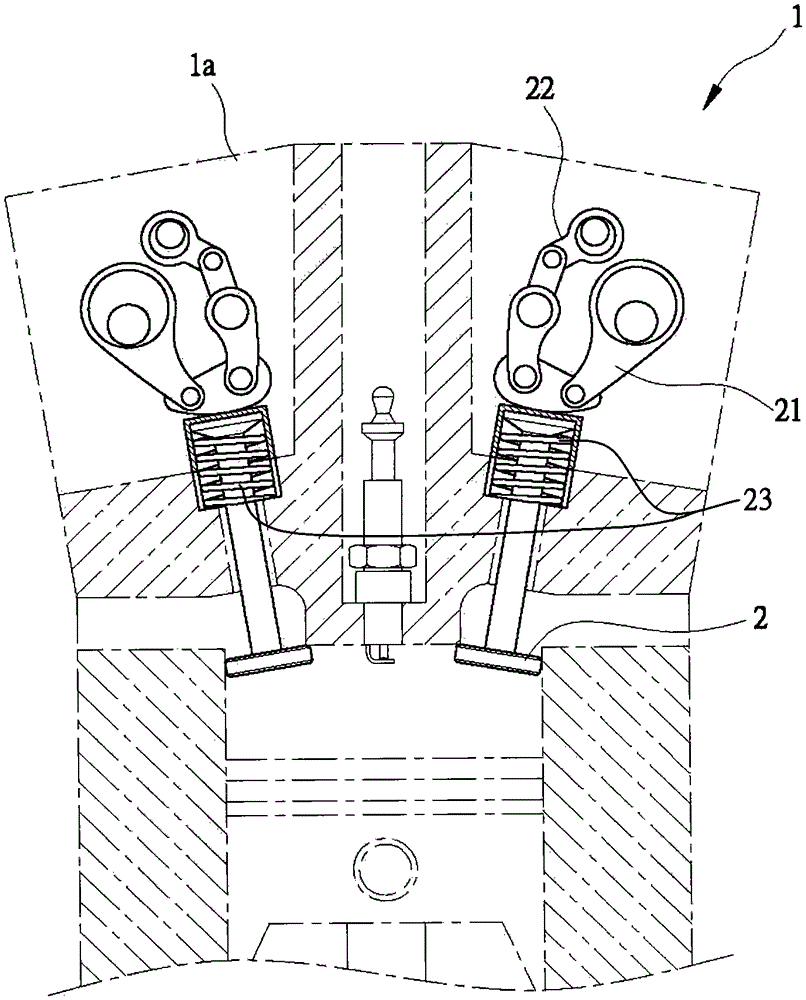

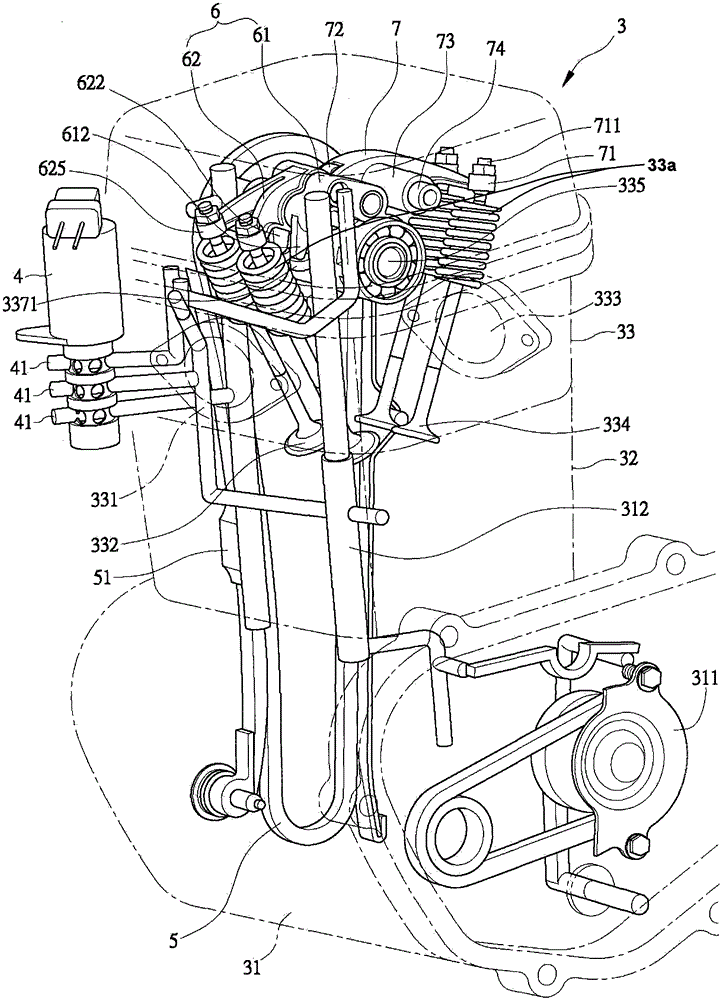

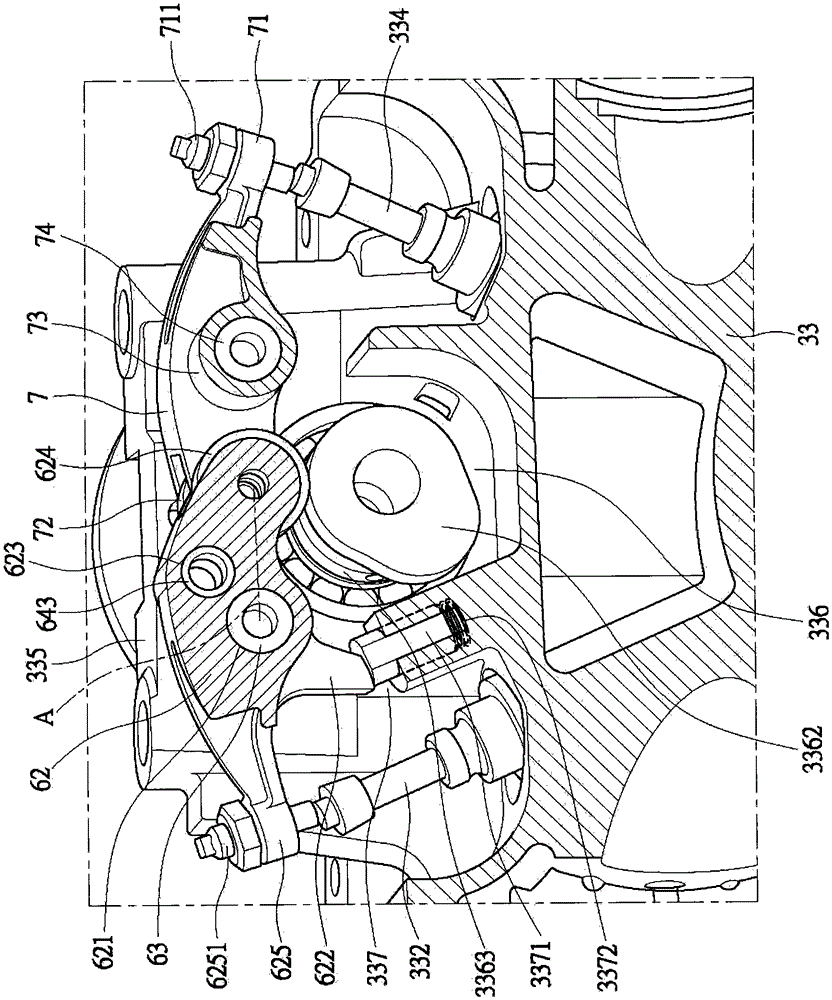

Variable vehicle lift mechanism of engine

InactiveCN102966390AInhibit wearSuppression lengthMachines/enginesLift valveHydraulic cylinderExhaust valve

The invention discloses a variable vehicle lift mechanism of an engine. An air intake / exhaust pier, an air intake / exhaust valve, a cam shaft base and a cam shaft are arranged on a cylinder head of the engine; a long air intake cam, a short air intake cam and an air exhaust cam are arranged on the cam shaft; an air intake valve rocker is provided with a high-opening degree rocker and a general-opening degree rocker; a roller of the high-opening degree rocker is contacted with the long air intake cam; a roller of the general-opening degree rocker is contacted with the short air intake cam; and a pressing part of the general-opening degree rocker is contacted with the air intake valve. The air intake / exhaust rocker is made from a light metal alloy materials, so that the rotation inert weight can be greatly reduced. A via hole of the high-opening degree rocker is communicated with a via hole of the general-opening degree rocker to form an oil hydraulic cylinder, so that the high-opening degree rocker and the general-opening degree rocker can be in respective swing or inter-moving state, the opening degree of the air intake valve is changed, and the engine can obtain the most proper power in both a low-speed operation state and a high-speed operation state.

Owner:KYMCO

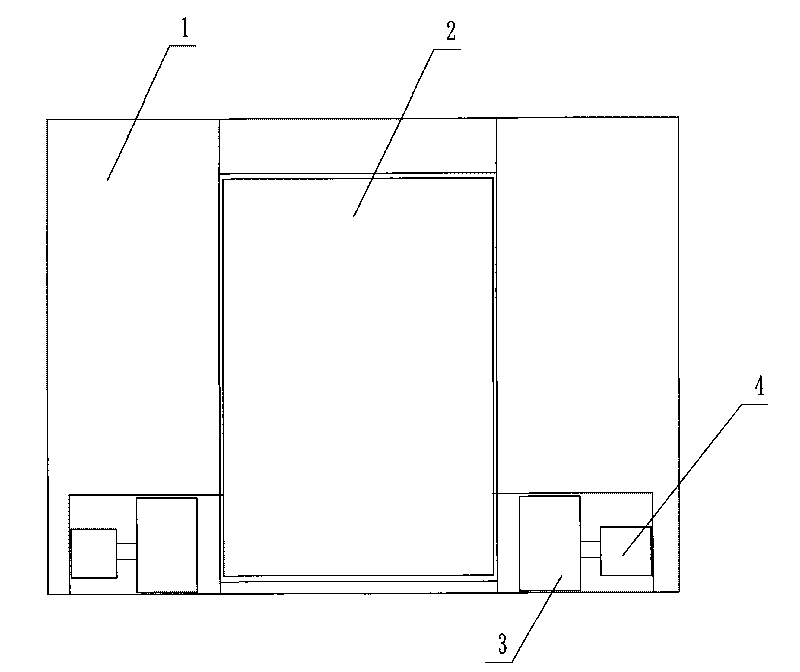

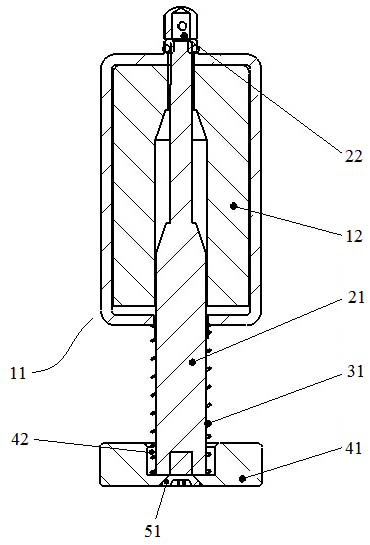

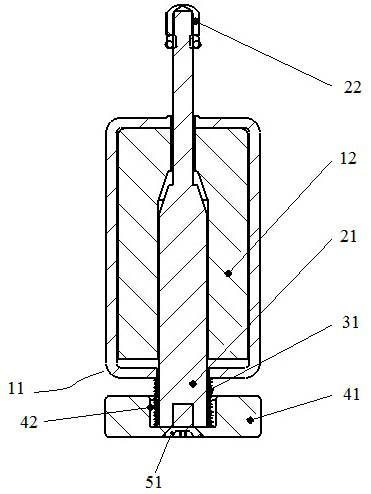

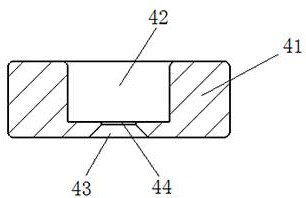

Remote automatic locking and unlocking device of reservoir strobe

InactiveCN101748709AAvoid economic lossAvoid running out of spaceBarrages/weirsControl systemElectro hydraulic

The invention discloses a remote automatic locking and unlocking device of a reservoir strobe, comprising a strobe vertical shaft, a strobe body, a locking block and a strobe control system, wherein the strobe control system is used for controlling the strobe; the locking block is also provided with an electric hydraulic mechanism; the locking block and the electric hydraulic mechanism are arranged at both edges of the strobe body; and the strobe control system can control the electric hydraulic mechanism to be put to and retreated from the locking block. The strobe control system controlling the strobe can not only remotely control the lifting of the strobe, but also modify the strobe control system when the remote automatic locking and unlocking device is installed and also remotely control the locking block, thereby removing the limit that a worker is necessary to move for locking in-place without needing the worker to reach a field for the operation of the strobe; and in addition, the remote automatic locking and unlocking device has the advantages of small equipment volume, simple distribution, simple transmission mode, low investment cost and convenient maintenance and is suitable for the condition of insufficient field equipment distribution space.

Owner:STATE GRID XINYUAN

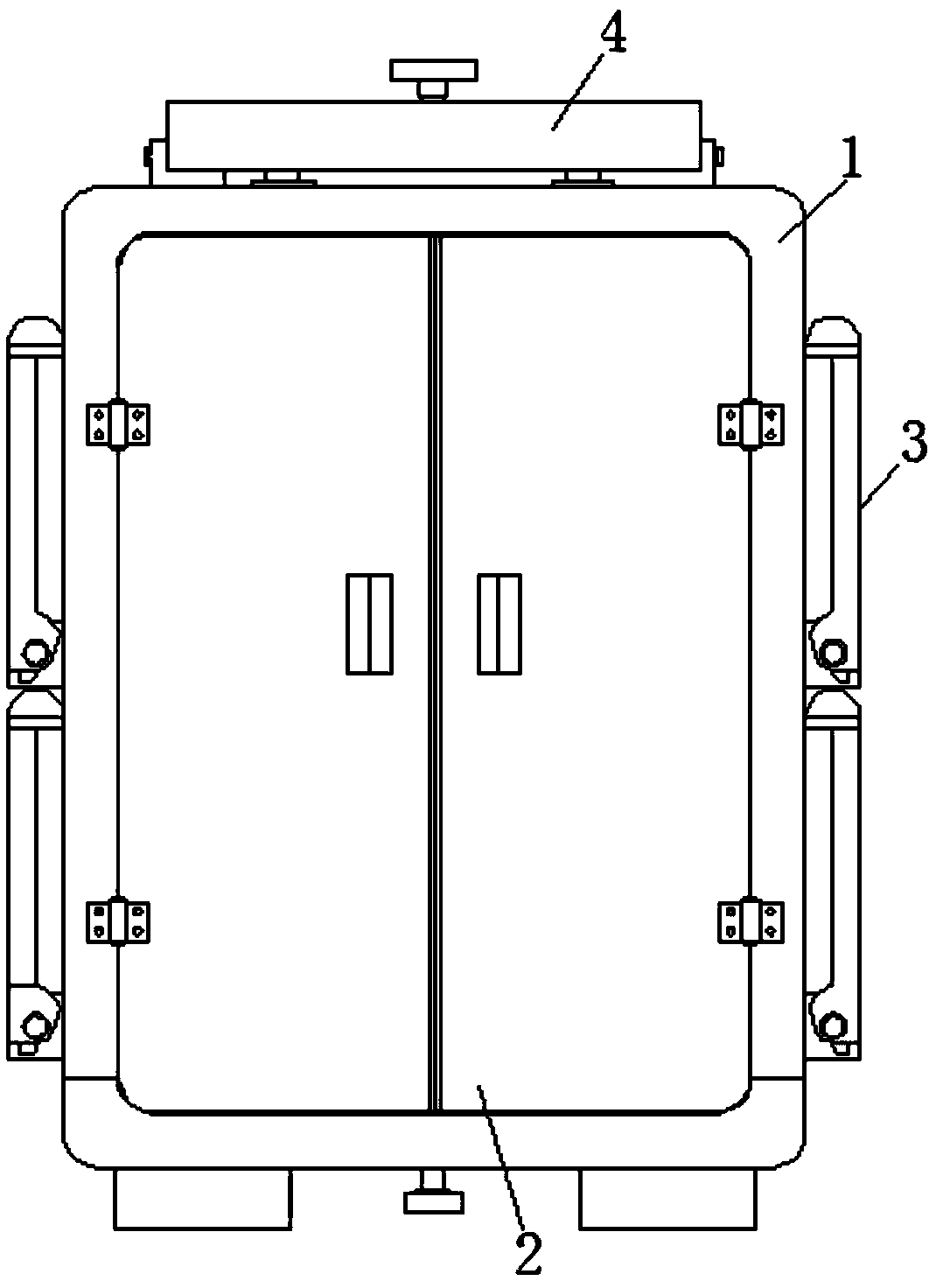

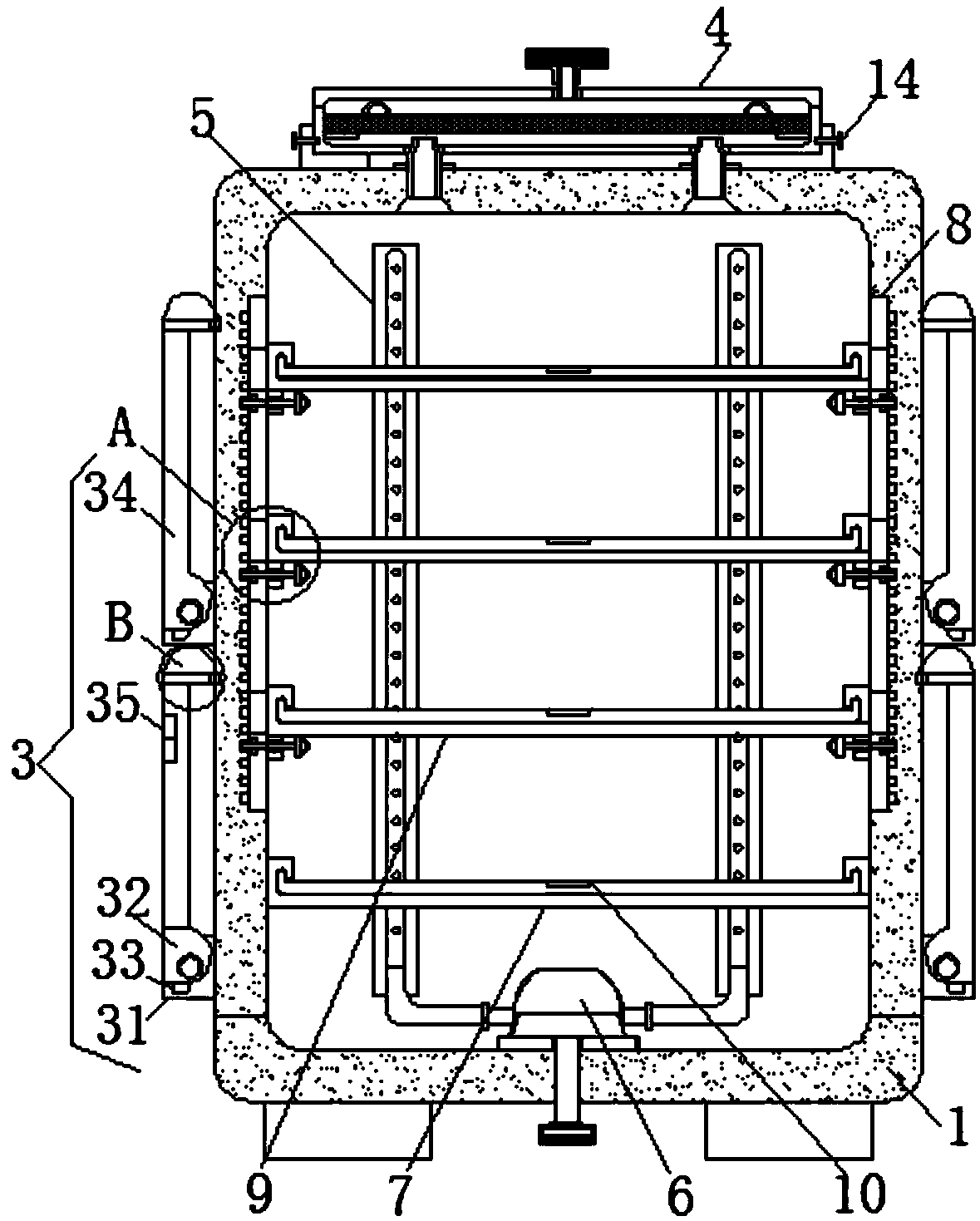

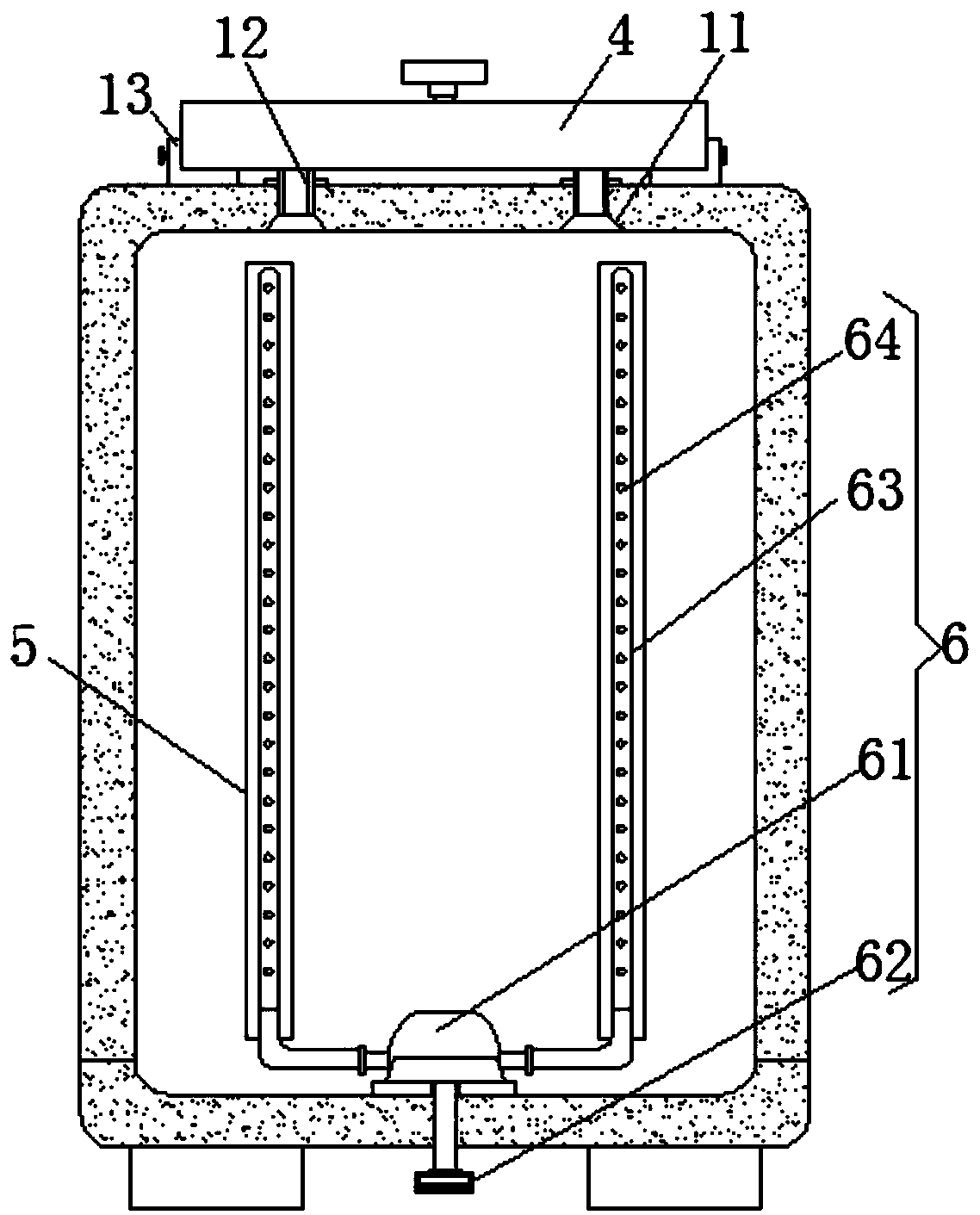

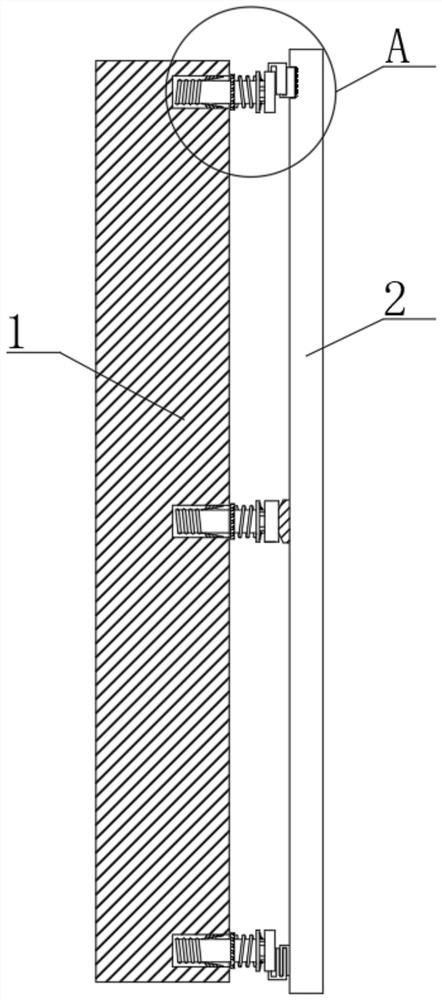

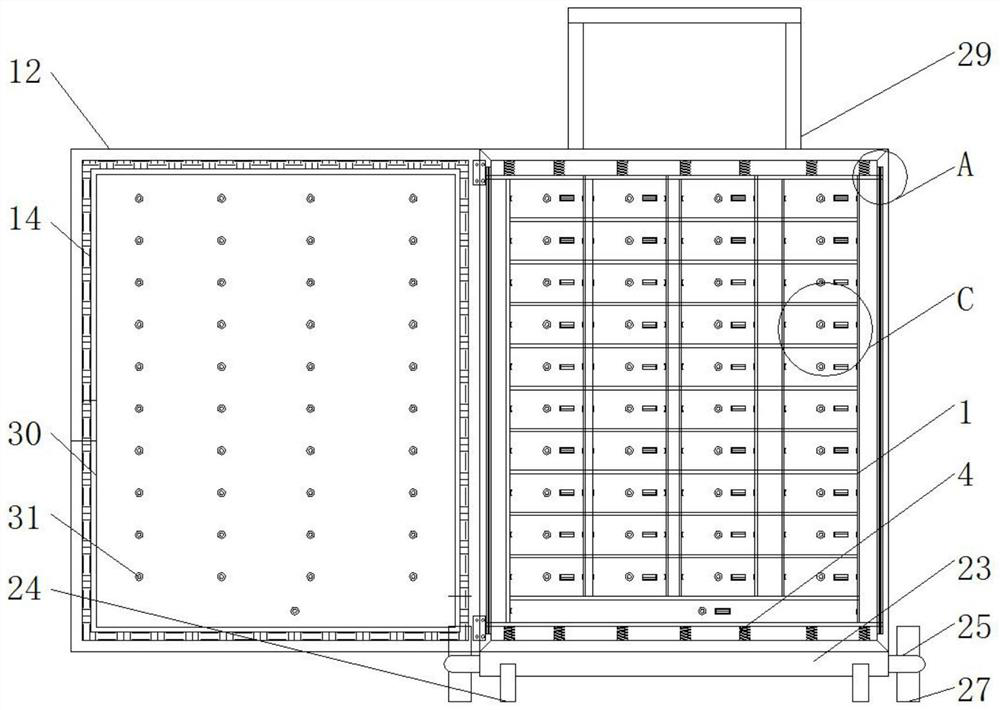

Household placement shoe cabinet

InactiveCN108618400ASolve problems that cannot meet the various needs of usersAvoid running out of spaceWardrobesGas treatmentEngineering

The invention relates to the technical field of household living equipment, and discloses a household placement shoe cabinet. The placement shoe cabinet comprises a cabinet body, sealing openable doors are movably connected to the two sides of the front surface of the cabinet body through hinges, and expansion devices are fixedly connected to the left and right side surfaces of the cabinet body; apurifying device is arranged at the top of the cabinet body, two mounting grooves are formed in the inner side wall of the front surface of the cabinet body, an air exhaust device matched with the mounting grooves is fixedly connected to the middle of the bottom of an inner cavity of the cabinet body, bottom frames are fixedly connected between the inner walls of the two sides of the cabinet body, sliding grooves are formed in the inner wall of the left and right sides of the cabinet body, adjusting devices are arranged between the two sliding grooves, and vent holes are formed in the top ofthe cabinet body. According to the placement shoe cabinet, through the arrangement and cooperation of the cabinet body, the sealing openable doors, the expansion devices, the purifying device, the airexhaust device, the bottom frames, the adjusting devices, communication pipes and L-shaped mounting blocks, the problem is effectively solved that existing household placement shoe racks cannot meetvarious demands of users.

Owner:戚腾丹

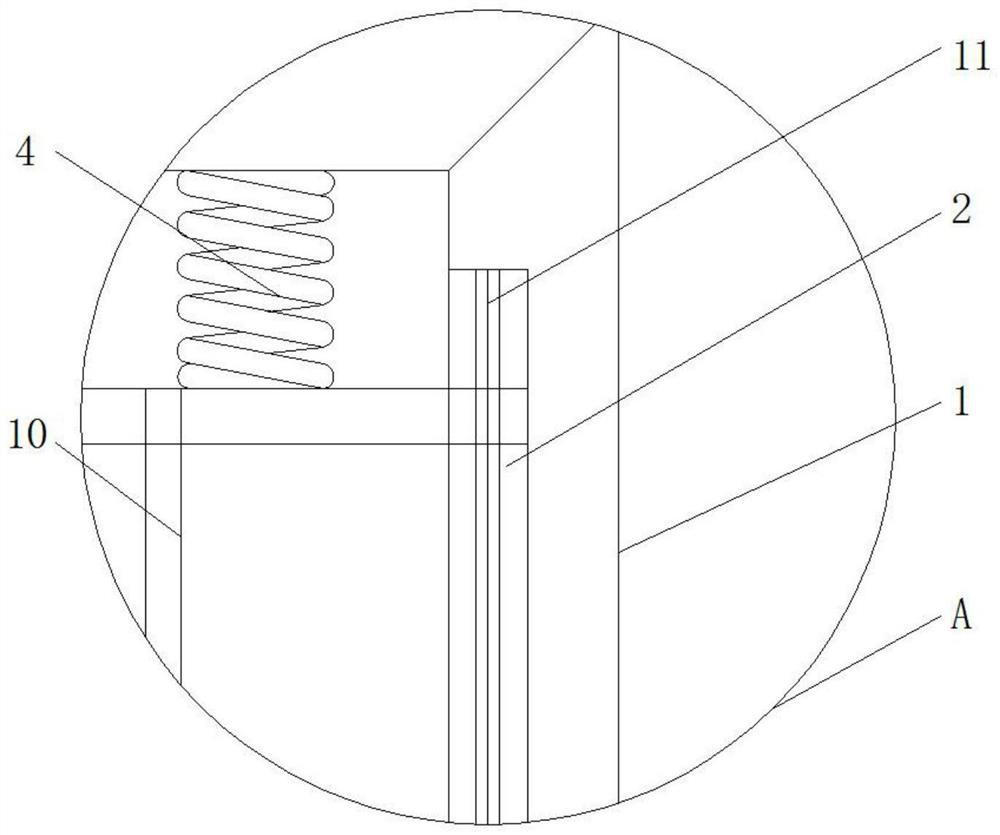

Assembly type mounting assembly of wall panel

PendingCN112064946AImprove functionalityAvoid running out of spaceCovering/liningsScrew threadMachining

The invention belongs to the technical field of wall panel connecting structures, and discloses an assembly type mounting assembly of a wall panel. The assembly type mounting assembly comprises a wallbody and a panel, a threaded hole is formed in the side face of the wall body, and a bolt is mounted in the threaded hole in a threaded manner. The outer surface of the part, located in the threadedhole, of the bolt is fixedly sleeved with an oblique clamping piece matched with the threaded hole in the reverse direction, and the outer surface of the part, located on the side face of the wall body, of the bolt is movably sleeved with a gasket. According to the assembly type mounting assembly of the wall panel, the oblique clamping piece is arranged on the outer side of the bolt, so that whenthe bolt is mounted, a clamping device between the bolt and the threaded hole does not need to be additionally mounted, machining is directly conducted during machining, the functionality of the structure is improved, and excessive extra steps are not needed; and by arranging a reverse clamping device and a compressed spring structure, the structure of an original bolt is changed, a connecting piece can still be additionally installed after the bolt is installed, and therefore the problem that when the original bolt is installed, the using space of a tool is insufficient can be solved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

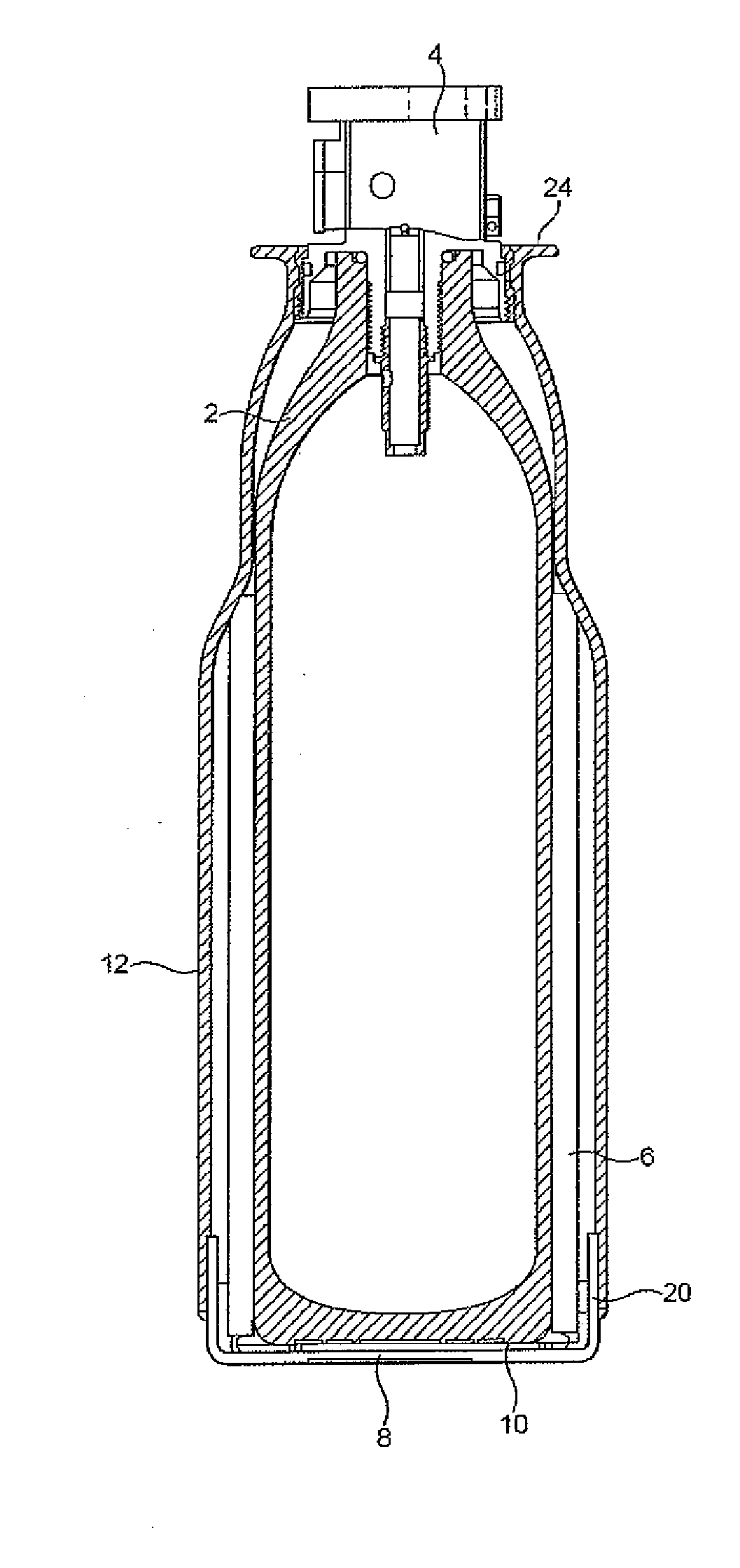

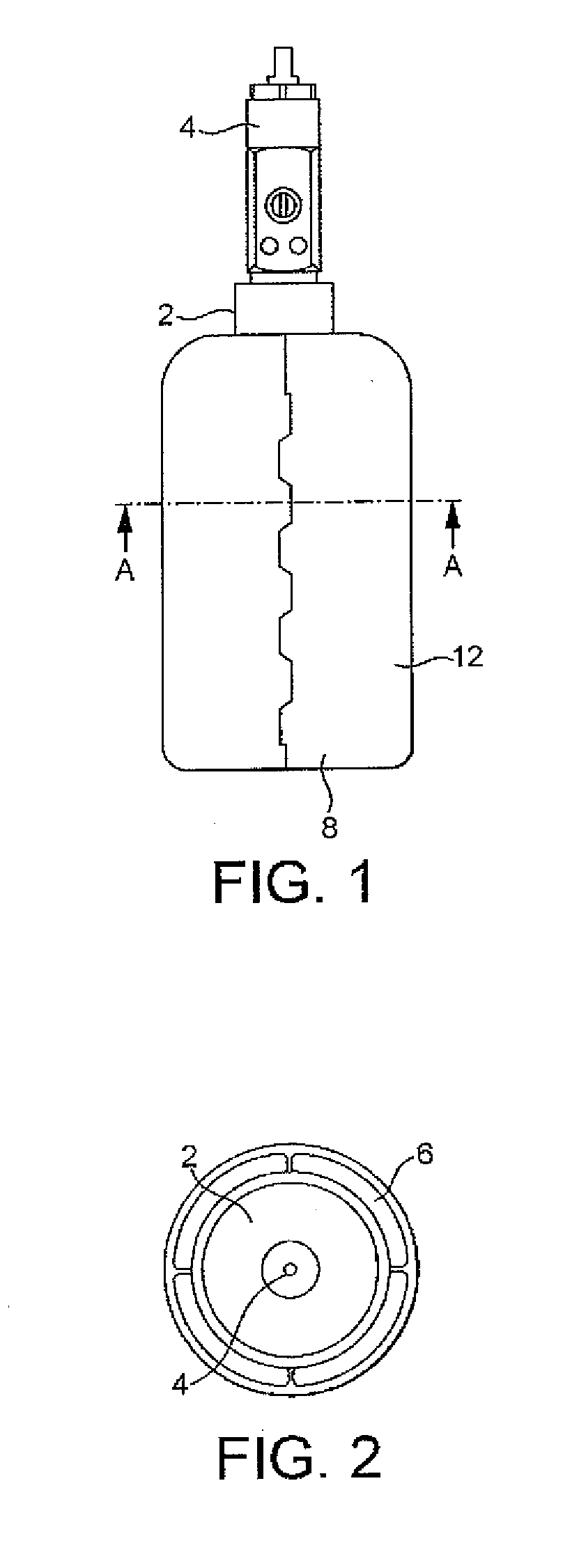

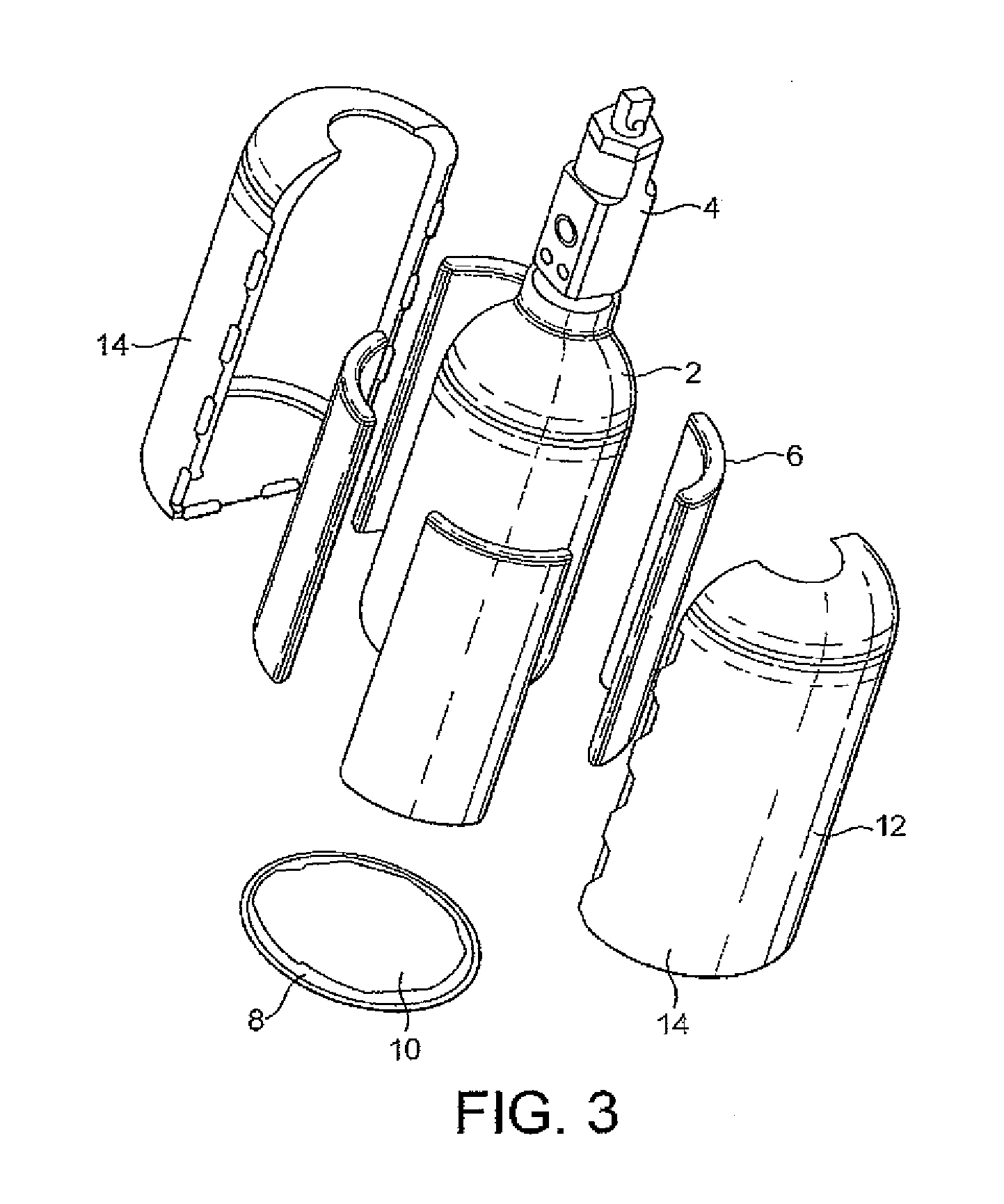

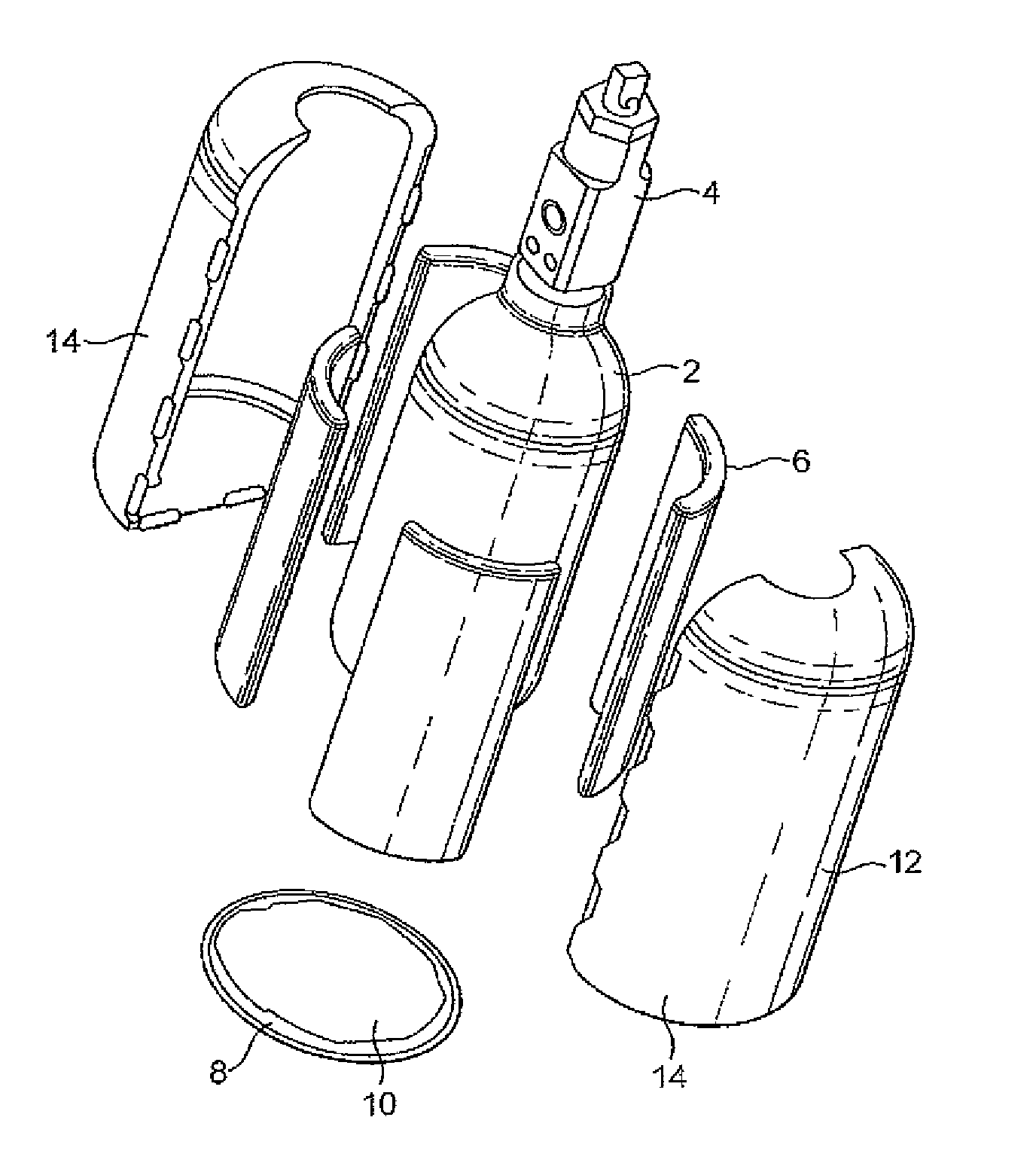

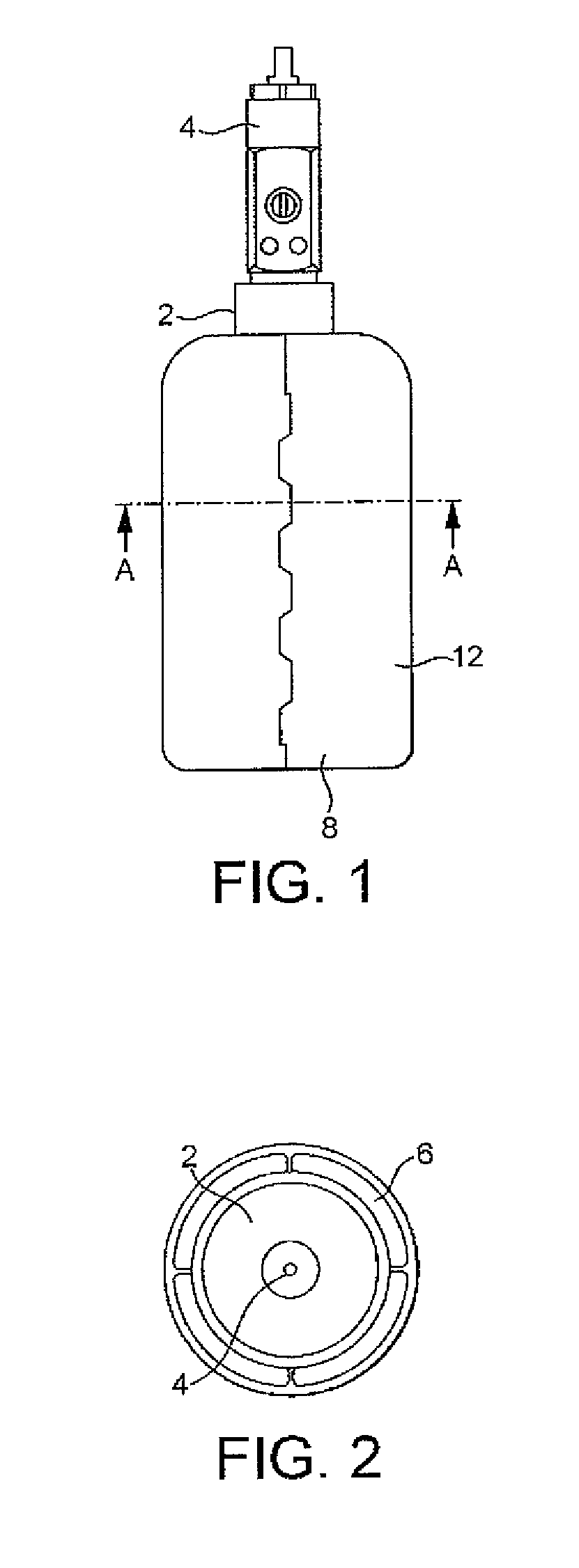

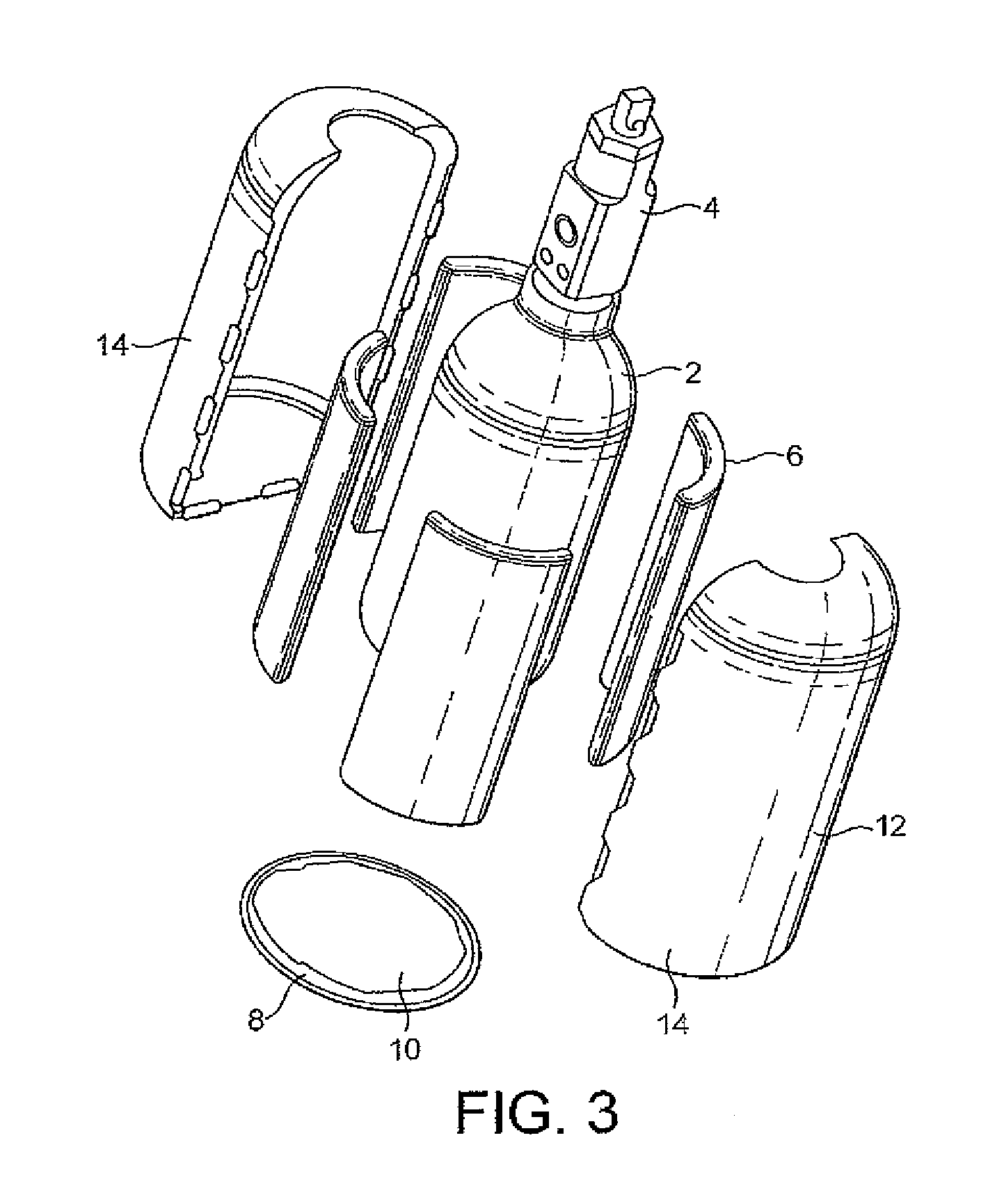

Gas storage apparatus

InactiveUS20120151943A1Easy to storeAvoid running out of spaceDomestic cooling apparatusLighting and heating apparatusGas phaseGas cylinder

A gas storage apparatus comprises a pressure vessel in the form of a cylinder, closed by a valve, containing a non-permanent gas having under its storage conditions a gas phase and a liquid phase. A jacket formed of plastics sachets surrounds and is in heat transfer relationship with the outer surface of the cylinder. The sachets define closed compartments containing a heat release substance which is liquid at 20° C. On opening the valve, the non-permanent gas is delivered from the cylinder. The liquid phase of the non-permanent gas absorbs heat from the heat release substance which undergoes fusion. The heat release substance may be water.

Owner:LINDE AG

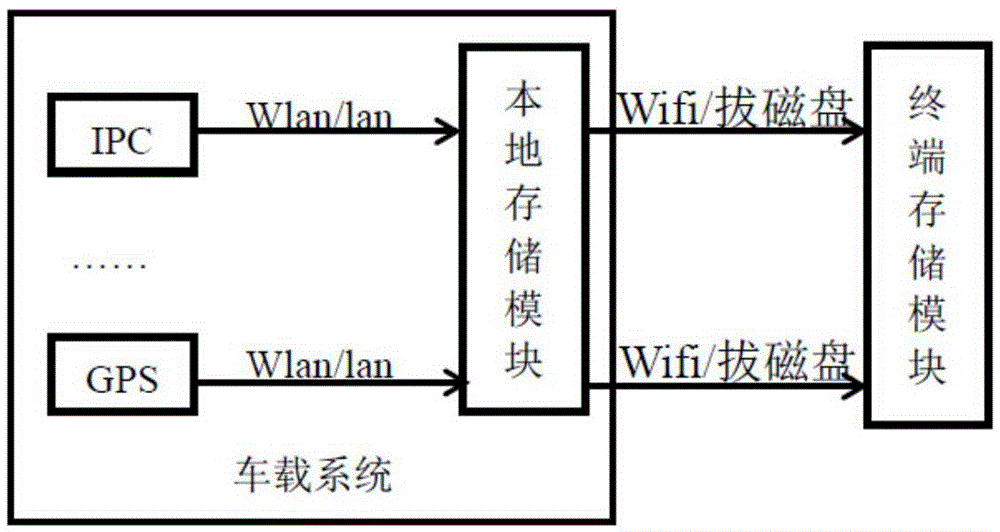

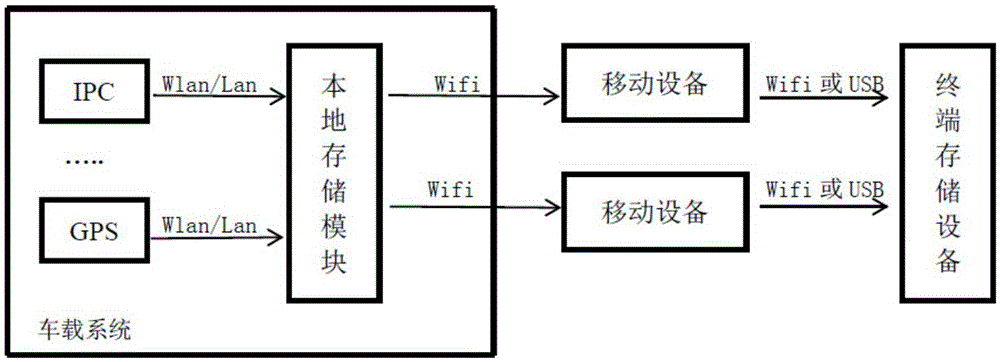

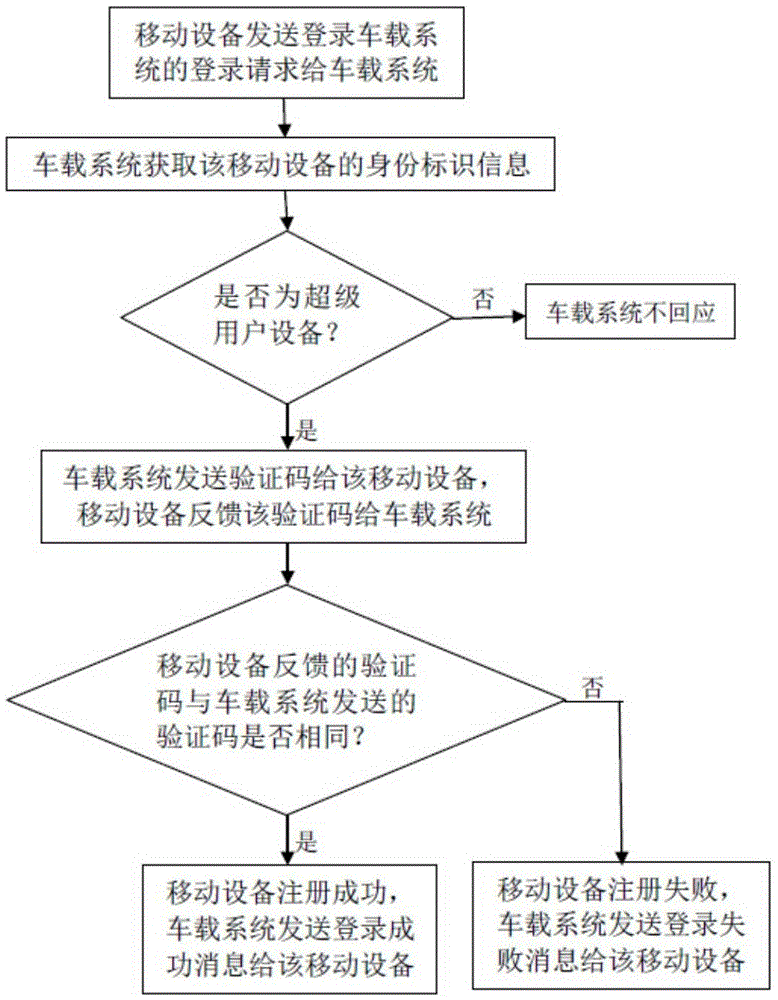

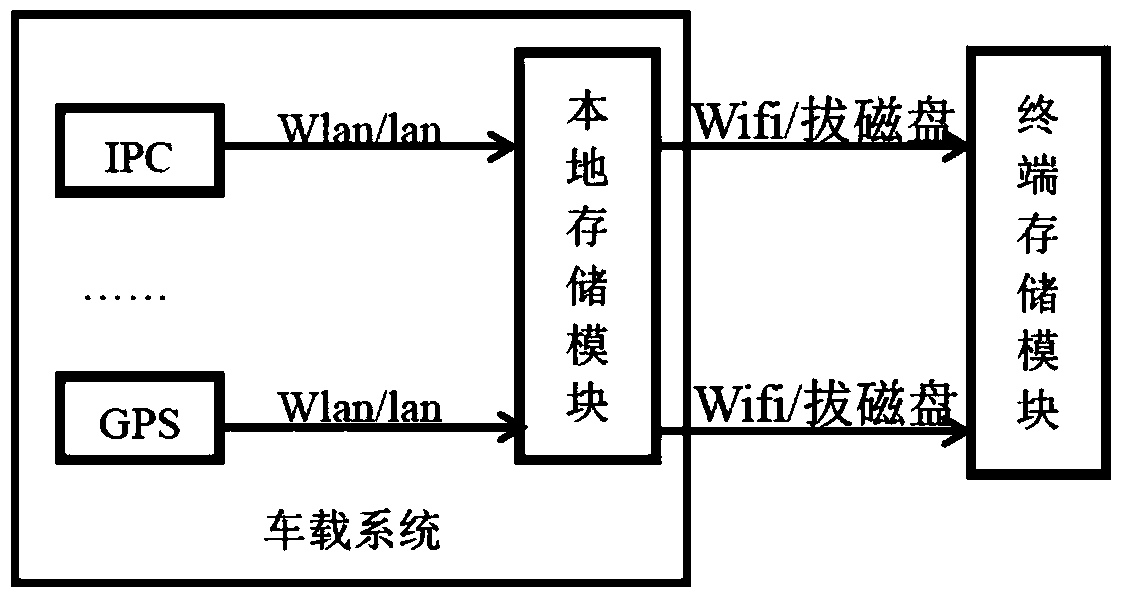

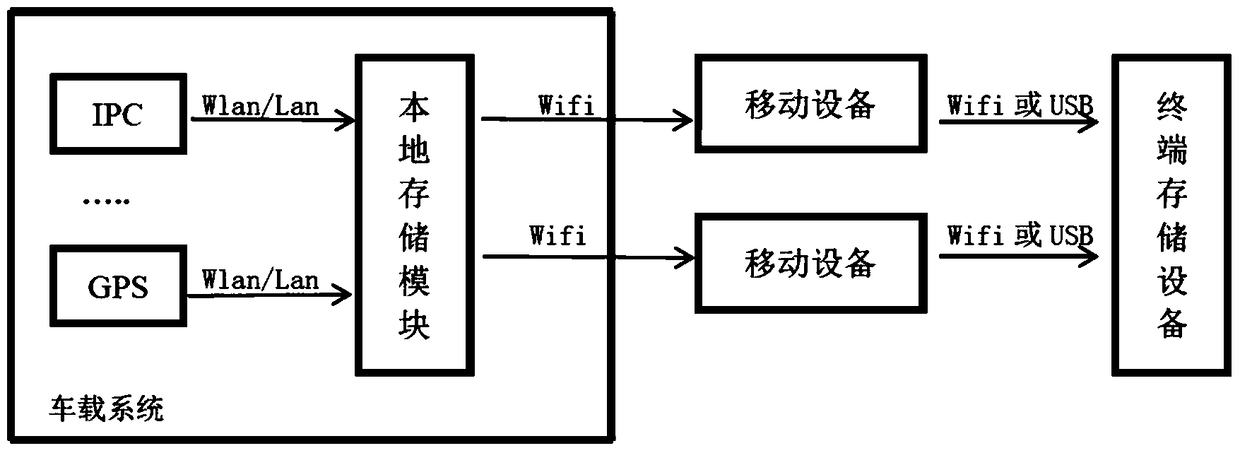

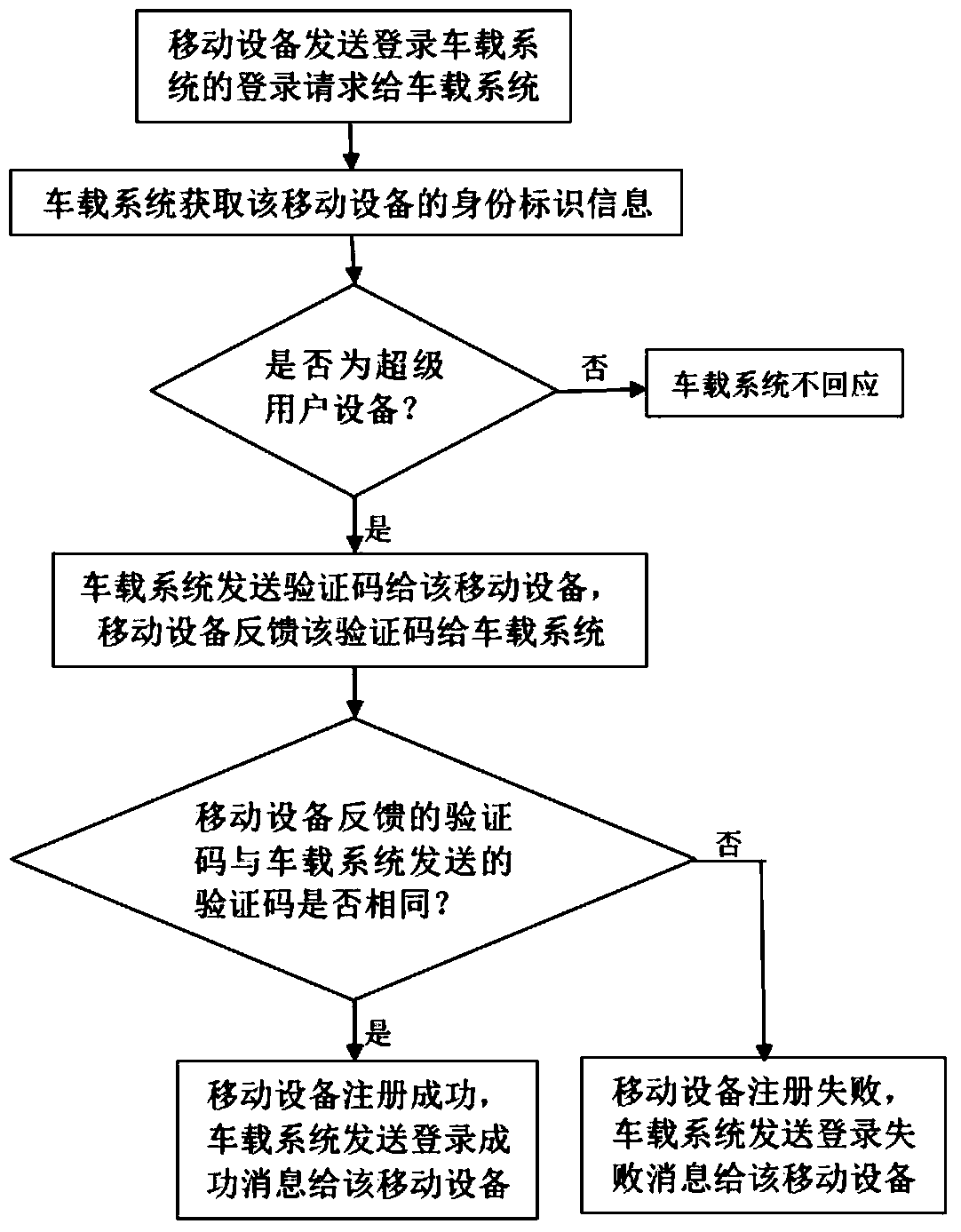

WiFi-based vehicle-mounted video automatic storage method and system

ActiveCN105554466AFlexible storageOptimize the transmission methodClosed circuit television systemsTransmissionData transmissionMobile device

The invention discloses a WiFi-based vehicle-mounted video automatic storage method and system. The method is characterized in that the access of a mobile device to a vehicle-mounted system is achieved through WiFi; the vehicle-mounted system acquires an available storage capacity of the current mobile device, and sends a vehicle-mounted video to the current mobile device according to the available storage capacity of the current mobile device; the size of the vehicle-mounted video sent by the vehicle-mounted system to the mobile device is no larger than the available storage capacity of the current mobile device; the received vehicle-mounted video is stored in a terminal storage device through the current mobile device. The WiFi-based vehicle-mounted video automatic storage method and system provided by the invention have the advantages that the vehicle-mounted video of the vehicle-mounted system is stored in the terminal storage device through the mobile device, so that the storage of the vehicle-mounted video is more flexible, the data transmission method is optimized, and the use is facilitated.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

Gas storage apparatus

InactiveUS8579146B2Avoid running out of spaceEasy to storeDomestic cooling apparatusLighting and heating apparatusGas cylinderGas phase

A gas storage apparatus comprises a pressure vessel in the form of a cylinder, closed by a valve, containing a non-permanent gas having under its storage conditions a gas phase and a liquid phase. A jacket formed of plastics sachets surrounds and is in heat transfer relationship with the outer surface of the cylinder. The sachets define closed compartments containing a heat release substance which is liquid at 20° C. On opening the valve, the non-permanent gas is delivered from the cylinder. The liquid phase of the non-permanent gas absorbs heat from the heat release substance which undergoes fusion. The heat release substance may be water.

Owner:LINDE AG

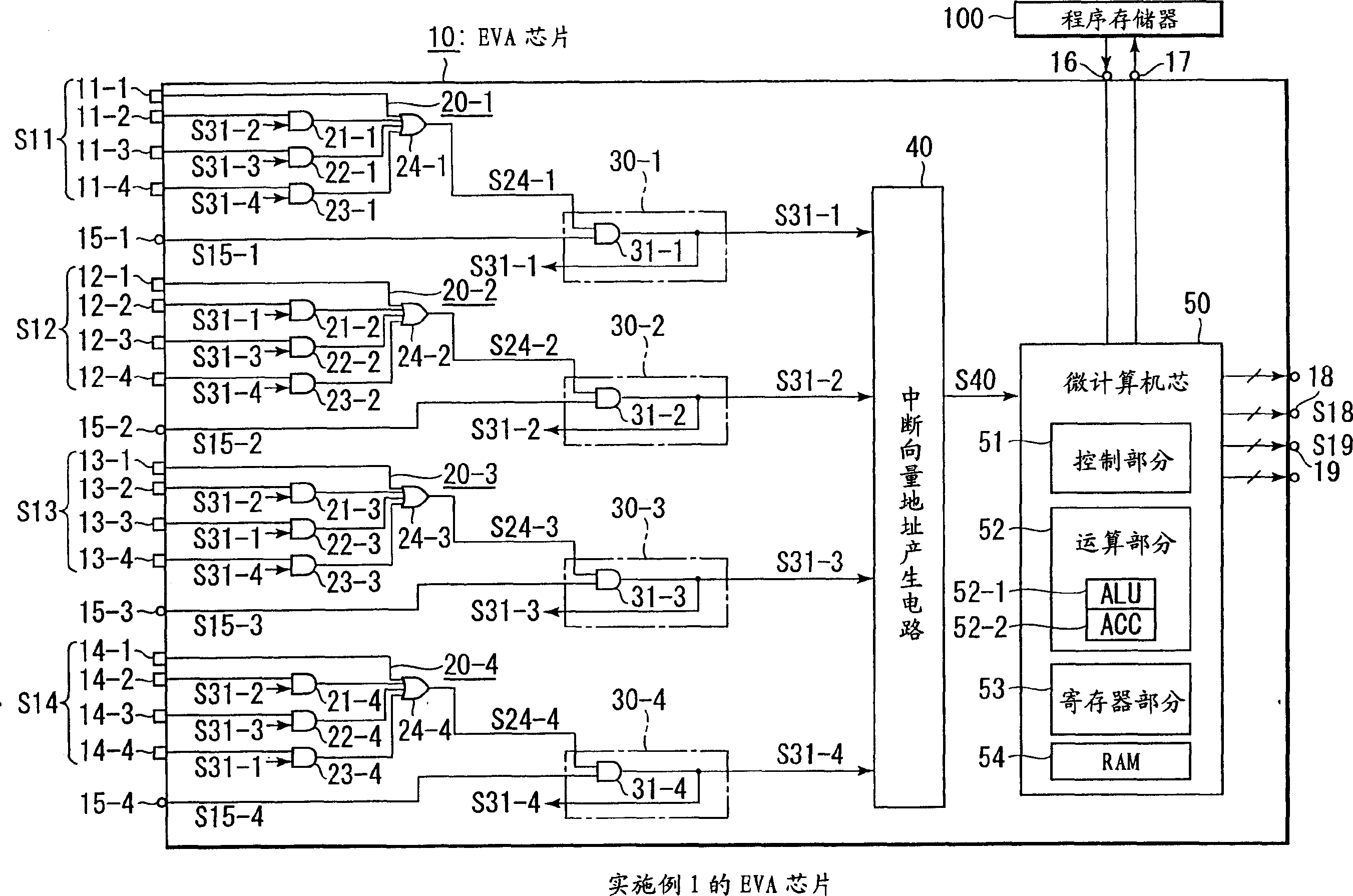

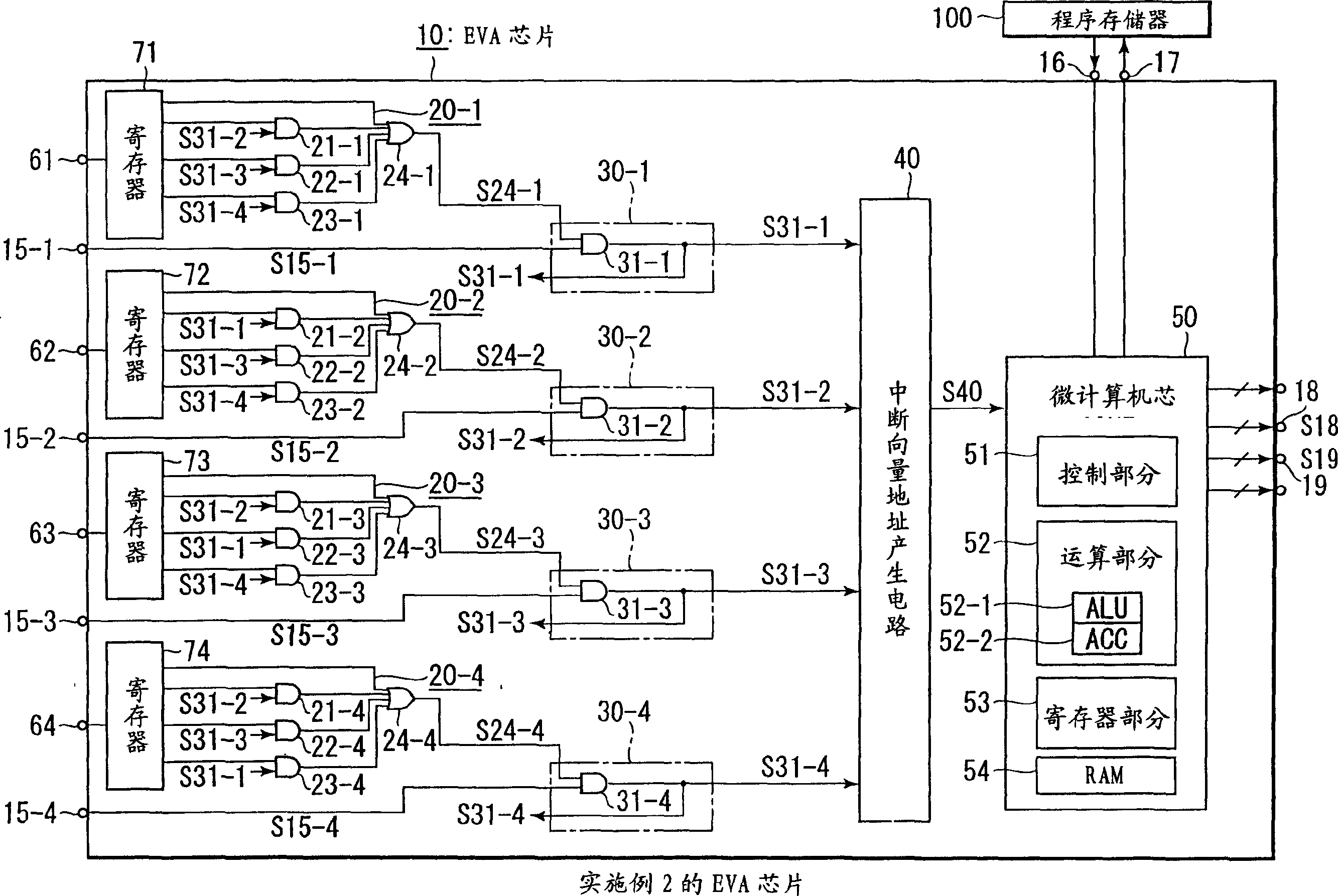

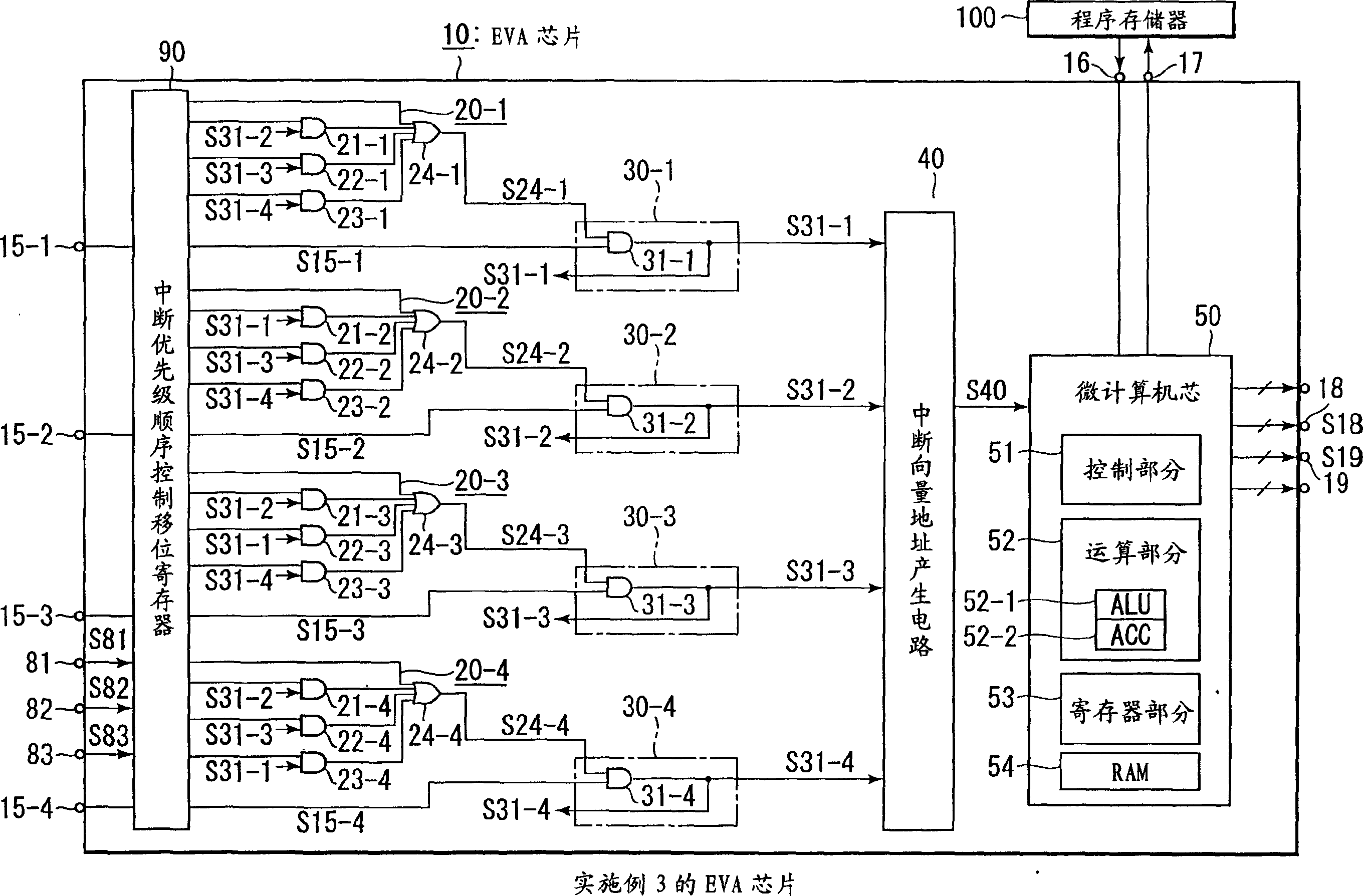

Evaluation chip

InactiveCN1673973AImprove convenienceLow costDetecting faulty computer hardwareSoftware testing/debuggingMicrocomputerLogical operations

An evaluation chip is disclosed whose interrupt priority order can be changed freely. A plurality of interrupt priority order determining circuits 20 - 1 to 2 - 4 perform a logical operation on a plurality of signals S 11 to S 14 used for interrupt priority order modifying control that are applied from outside and a plurality of interrupt signals S 31 - 1 to S 31 - 4 , and output interrupt modifying signals S 24 - 1 to S 24 - 4 . A plurality of interrupt modules 30 - 1 to 30 - 4 perform a logical AND operation on the plurality of signals S 24 - 1 to S 24 - 4 and a plurality of interrupt request signals S 15 - 1 to S 15 - 4 that are applied from outside, and output the signals S 31 - 1 to S 31 - 4 . An address generating circuit 40 encodes the plurality of signals S 31 - 1 to S 31 - 4 and generates interrupt vector addresses 40 . A microcomputer core 50 executes interrupt instructions that have been fetched from an external program memory 100 , based on the addresses S 40.

Owner:OKI ELECTRIC IND CO LTD

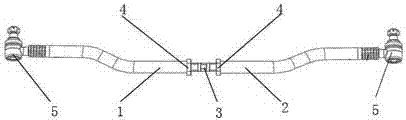

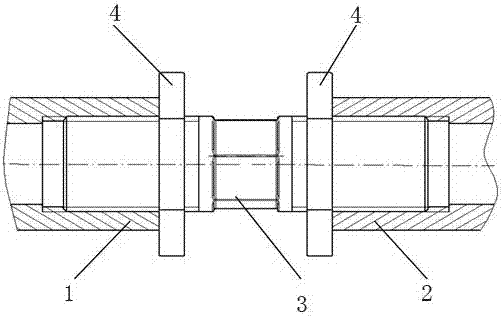

Steering tie rod with adjusting structure

PendingCN107284525AAvoid running out of spaceLarge operating spaceSteering linkagesStructural engineeringMechanical engineering

Owner:JIANGLING MOTORS

Electromagnetic shielding box

PendingCN113207272AIncrease fair usageReduced service lifeScreening casingsVibration suppression adjustmentsPhysicsEngineering

The present invention discloses an electromagnetic shielding box which comprises a box body, a circuit board, a sliding rail, a sliding rod, a box door, an electromagnetic switch group, a control rod, a placement box, a placement plate, a connection block group, a telescopic pull rod and a mounting plate, sliding grooves are formed in two sides of the interior of the box body, a wave disturbance device is embedded and fixed on the surface of the circuit board, and the sliding rail is fixed in a mounting frame through a hexagon bolt. The sliding rod penetrates through the two sides of the mounting frame, the sliding rod is fixed into the box body through a sliding groove, the top end and the bottom of the mounting frame are fixedly connected with the top end and the bottom of a damping spring, a second mounting groove is formed in the left side of the box door in a penetrating mode, and an electromagnetic shielding layer is fixedly embedded in the front of the box door; and the right side of the box body is movably connected with the left side of the box body through a hinge, the electromagnetic shielding box is provided with the wave disturbances, and the multiple wave disturbances are used for carrying out wave disturbing processing on electronic equipment in the independent containing boxes, so that wave disturbing signals are increased, and the electromagnetic shielding effect of the whole box body is sequentially improved.

Owner:东台市苏宝电磁屏蔽设备有限公司

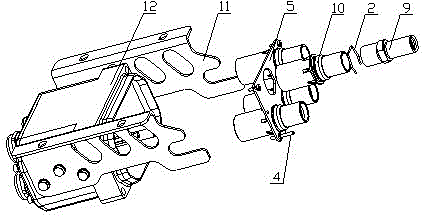

Foaming mold of PU headrest mold core connecting rod turnover mechanism

The invention relates to the technical field of foaming molds, and particularly discloses a foaming mold of a PU headrest mold core connecting rod turnover mechanism. The foaming mold comprises an upper mold, a lower mold, a mold core and the connecting rod turnover mechanism. The upper mold is connected with the lower mold. The mold core is arranged between the upper mold and the lower mold. Theconnecting rod turnover mechanism is arranged in the middle of the mold core and comprises a straight connecting rod, a bent connecting rod and a flat air cylinder. One end of the straight connectingrod is fixed to the center of the mold core through a first fixing seat, and the other end of the straight connecting rod is connected with the bent connecting rod. The bent connecting rod is connected with the flat air cylinder, and the flat air cylinder is fixed to the lower mold. The foaming mold is compact in structure, reasonable in layout and convenient to operate; operators can take products and clean the mold core conveniently; the connecting rod turnover mechanism is arranged in the center of the mold core, the mold core is stressed evenly and turned over synchronously; the problem that the drive stroke of the air cylinder is insufficient is avoided; and the air cylinder is arranged at the bottom of the lower mold, use space is reduced, and the problem that space in the mold is insufficient is effectively avoided.

Owner:NANTONG CHAODA EQUIP CO LTD

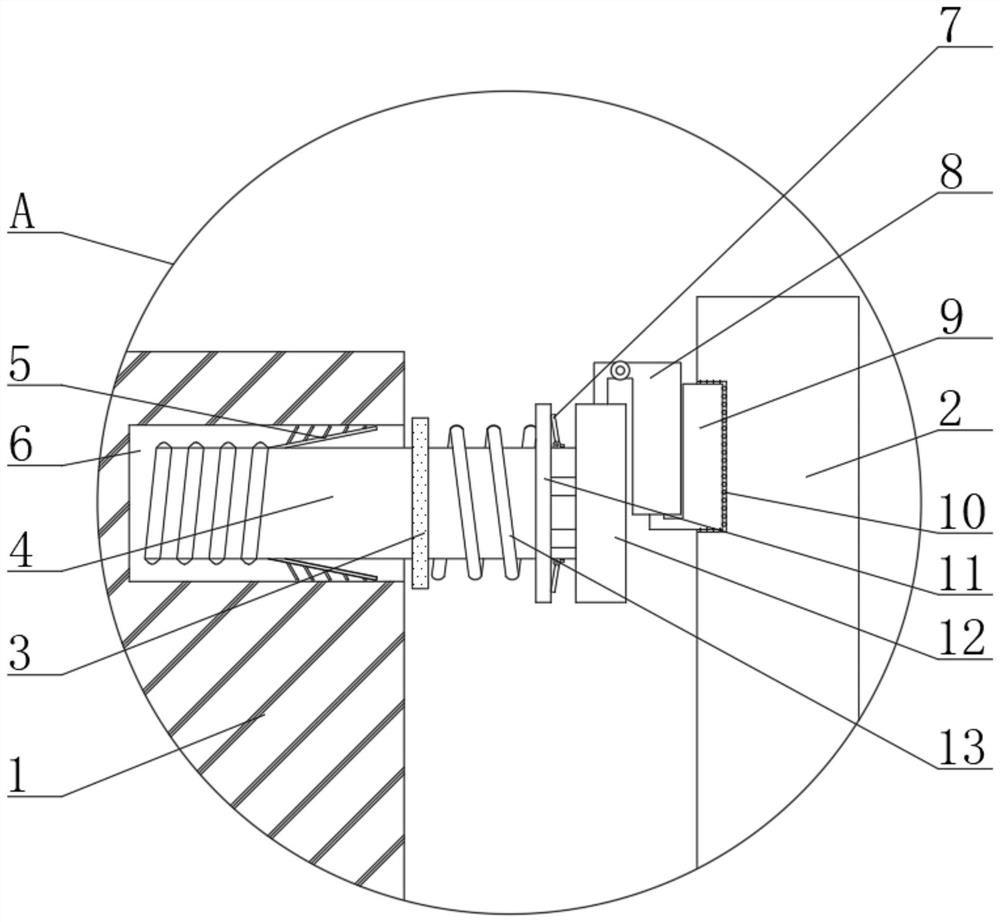

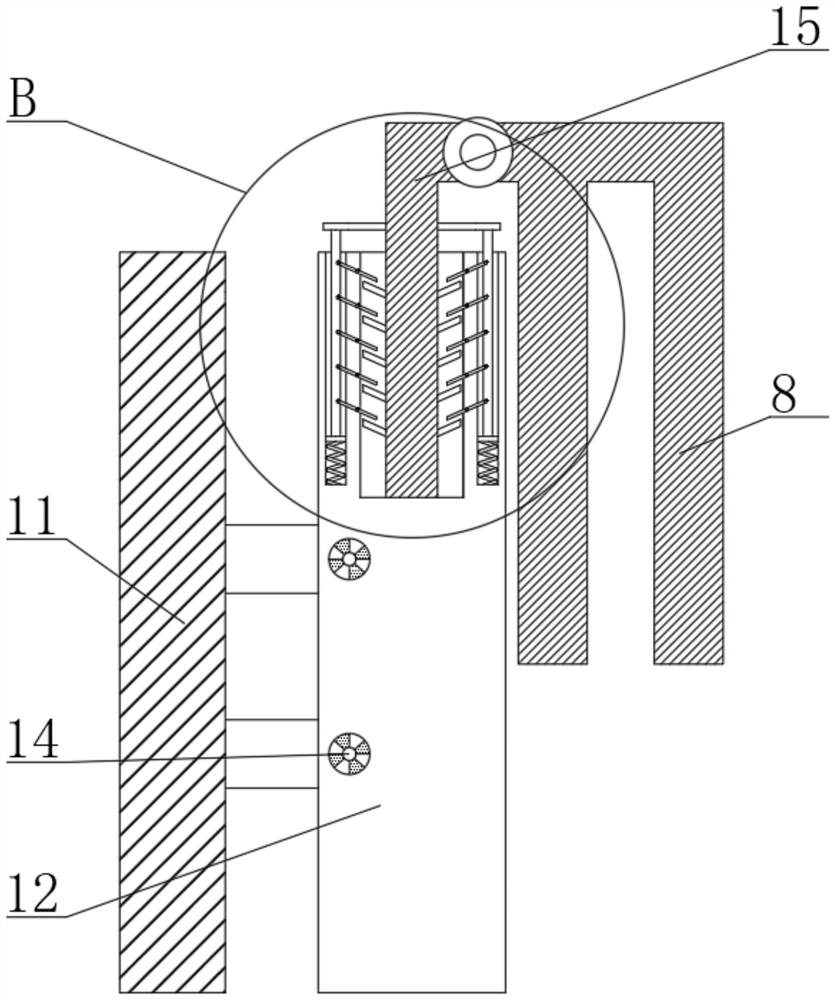

Combined multi-core high-voltage electric connector

InactiveCN104953299AFast connectionAccurately complete the connectionElectrically conductive connectionsTwo-part coupling devicesElectricitySelf locking

The invention discloses a combined multi-core high-voltage electric connector. The connector comprises plug seats and plugs, wherein a plurality of connection pins and jacks are arranged in each plug seat, error-proofing nails are arranged in the plug seats and the plugs, and positioning blocks are arranged on outer casings of the plug seats and the plugs. According to the combined multi-core high-voltage electric connector, multiplex circuits are integrated in a casing; an insulator adopts independent insulation to meet a high-voltage requirement; the insulator is fixed through a clamp spring structure and can be quickly detached; with the adoption of the error-proofing design, connection mistakes of the multiplex circuits is avoided; a contact element can realize self-locking positioning and does not need to be fixed by other parts; sliding chutes are adopted for positioning, and the plugs and the plug seats are connected in a guiding insertion manner.

Owner:绵阳永贵电器有限公司

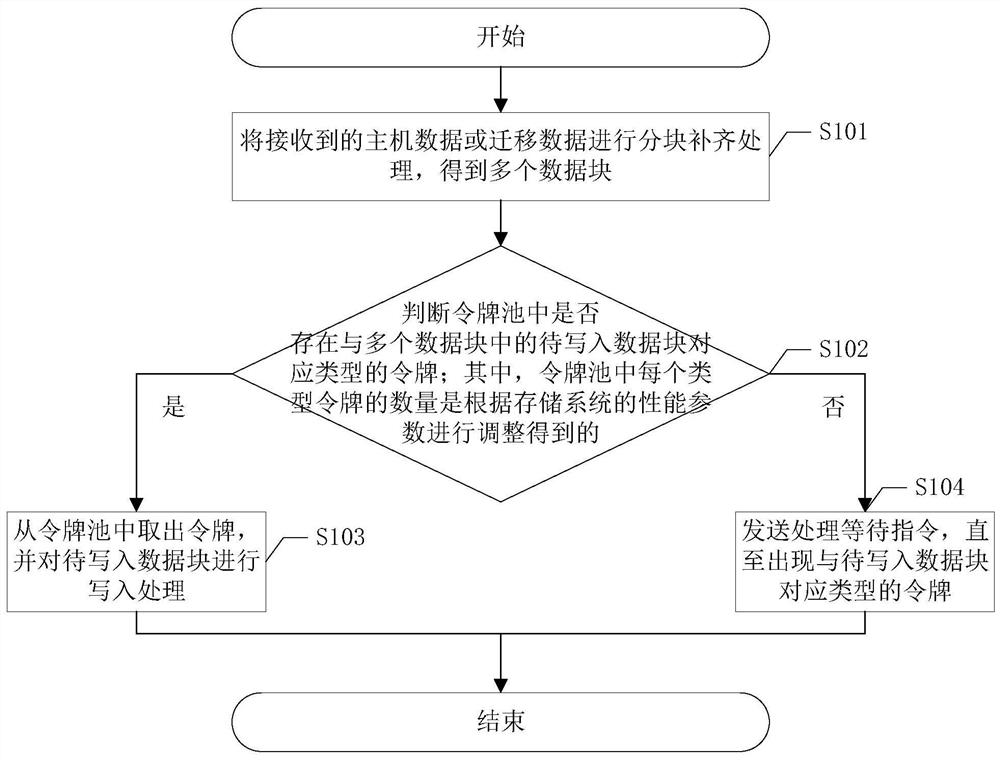

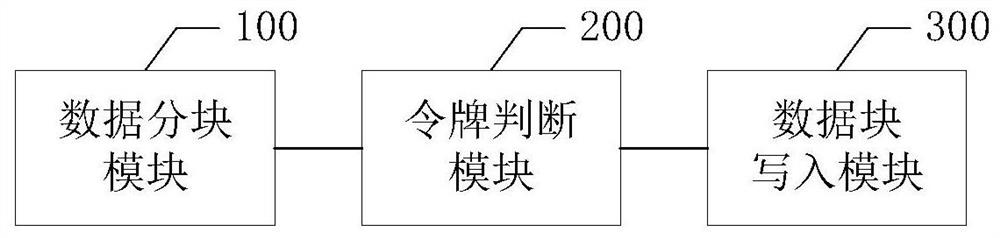

Data writing method of storage system and related device

PendingCN113031872AAdjust processing speedAvoid running out of spaceInput/output to record carriersPoolDatabase

The invention discloses a data writing method of a storage system, which comprises the following steps of: performing block completion processing on received host data or migration data to obtain a plurality of data blocks; judging whether a token of a type corresponding to a to-be-written data block in the plurality of data blocks exists in a token pool or not, wherein the number of each type of tokens in the token pool is obtained by adjusting performance parameters of the storage system; and if yes, taking out the token from the token pool, and performing write-in processing on the data block to be written in. By dividing the host data or the migration data into the plurality of data blocks and processing the to-be-written data blocks by using the tokens in the token pool, the data writing speed is controlled through the tokens, the problem that the storage space is exhausted is avoided, and the reliability of the storage system is improved. The invention further discloses a storage system, a server and a computer readable storage medium, which have the above beneficial effects.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

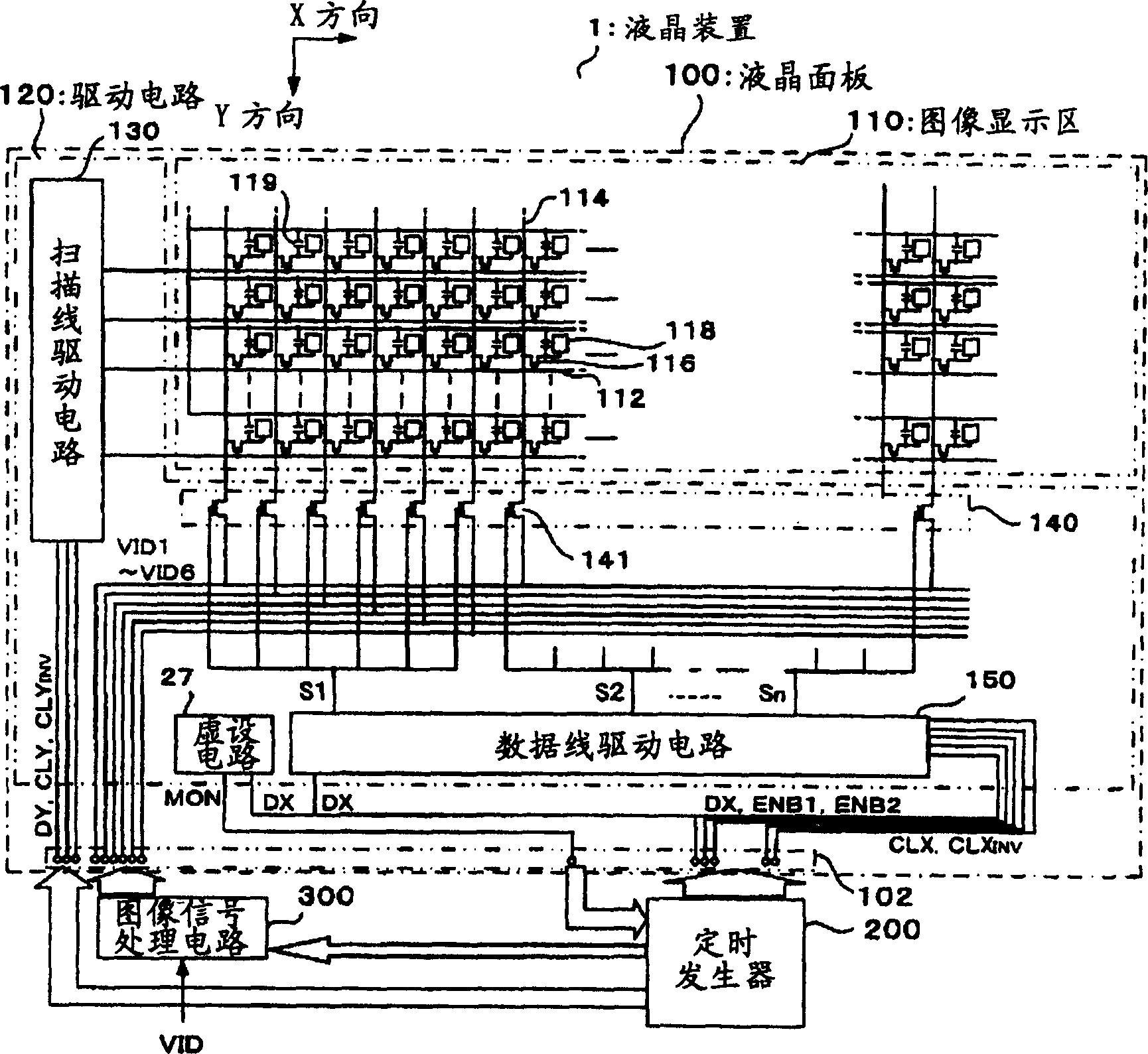

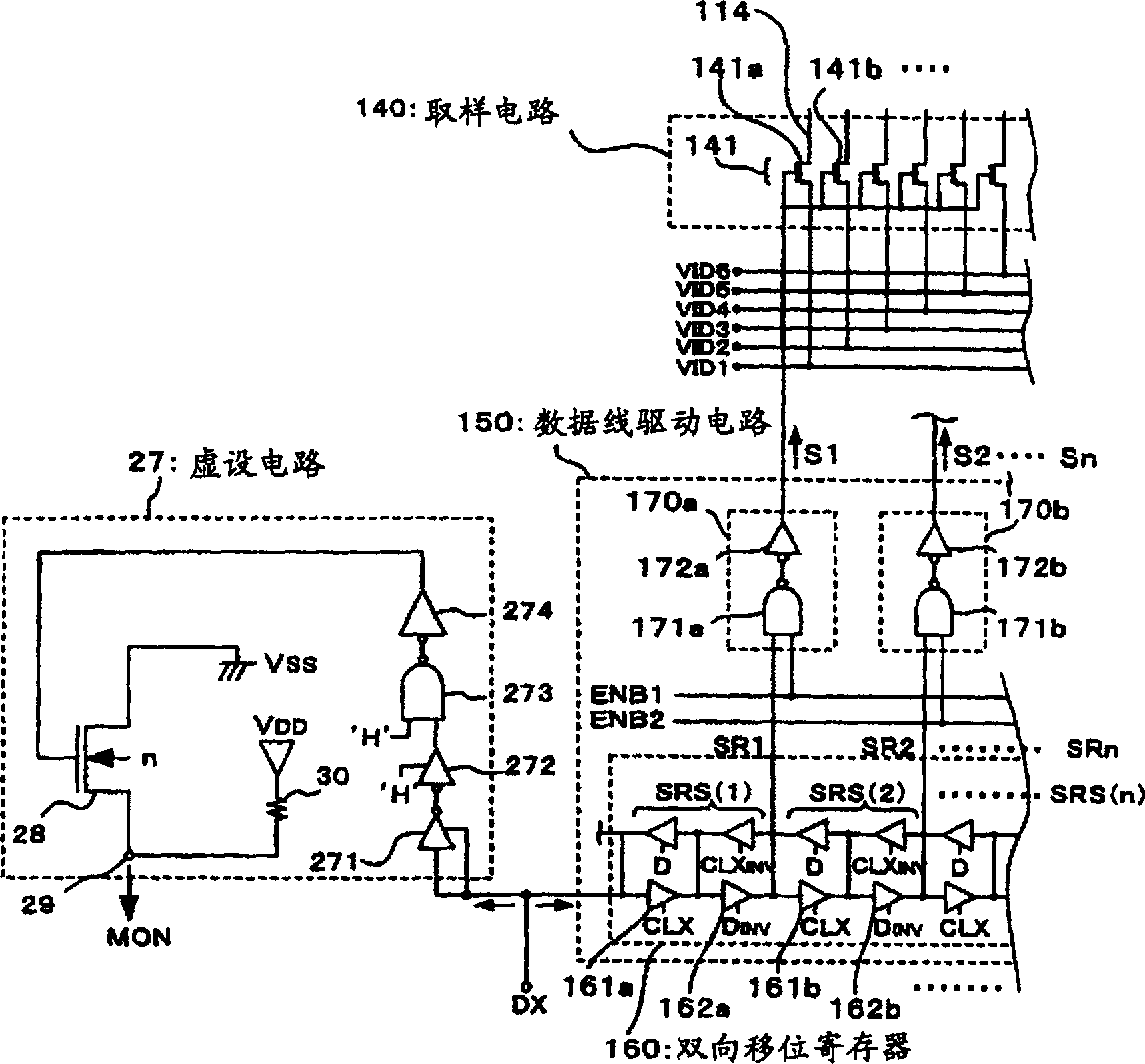

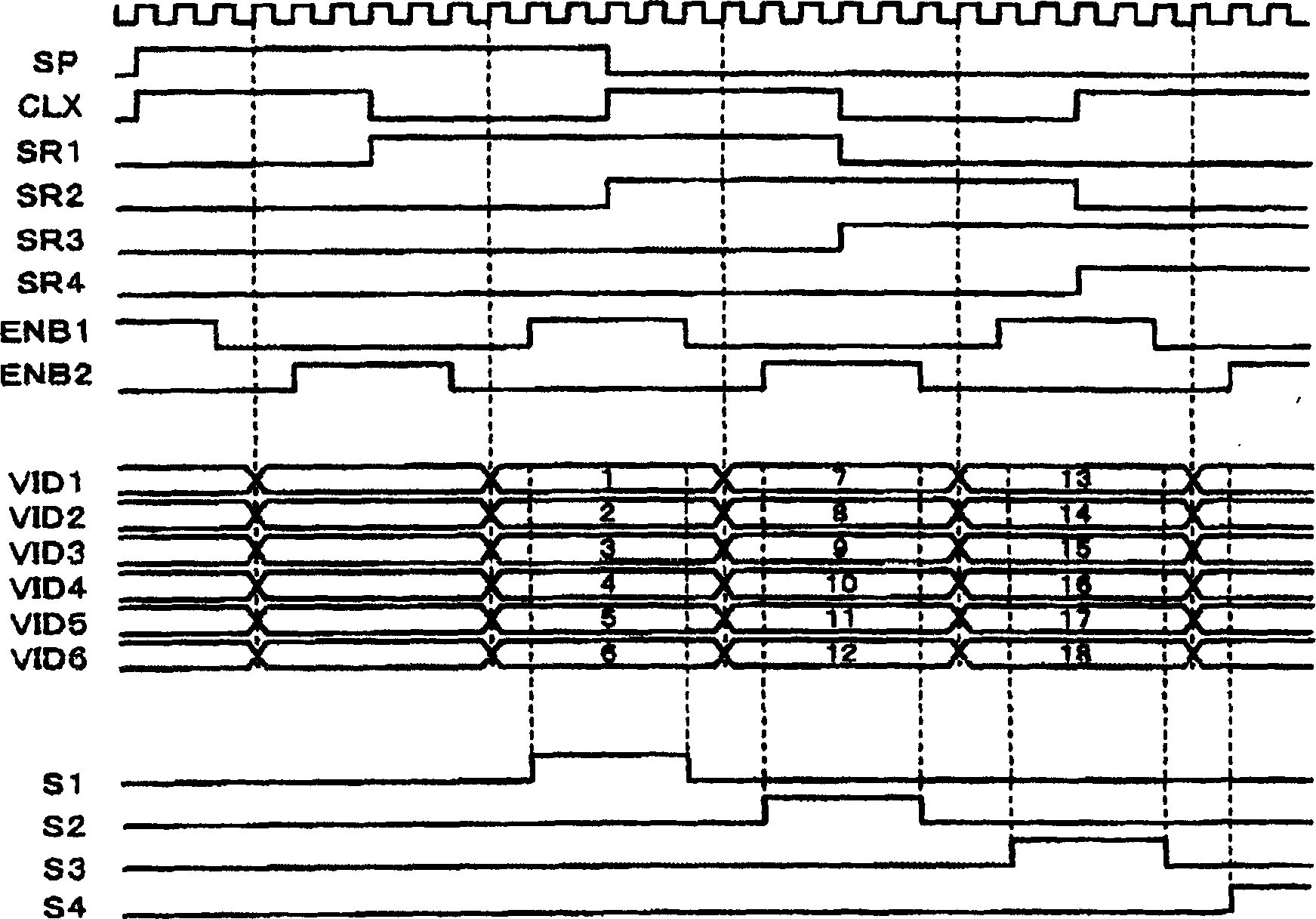

Electro-optical panel driving circuit, electro-optical device provided with electro-optical panel and driving circuit, and electronic apparatus provided with electro-optical device

ActiveCN1551091AMiniaturizationAvoid running out of spaceColor television with bandwidth reductionCathode-ray tube indicatorsShift registerSample image

An electro-optical panel driving circuit is provided on a substrate and includes a shift register circuit that sequentially outputs transfer signals, a buffer circuit that buffers the sequentially output transfer signals, a sampling circuit that samples image signals using the buffered transfer signals as sampling pulses and that supplies the sampled image signals to data lines, and a dummy circuit that simulates at least part of the buffer circuit and the sampling circuit. Delay signals indicating the amount of delay of the sampling pulses and generated by the dummy circuit are fed back to the shift register circuit so that the amount of delay is reduced. The buffer circuit, the sampling circuit, and the dummy circuit are provided on the substrate.

Owner:SEIKO EPSON CORP

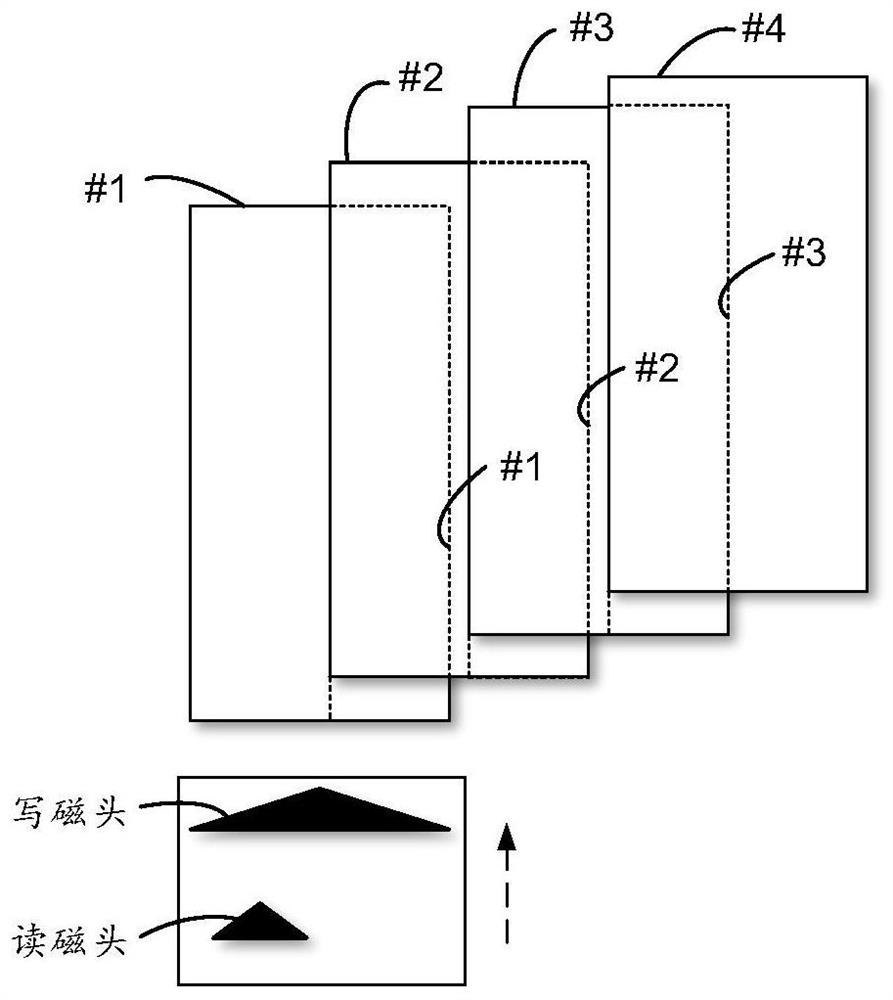

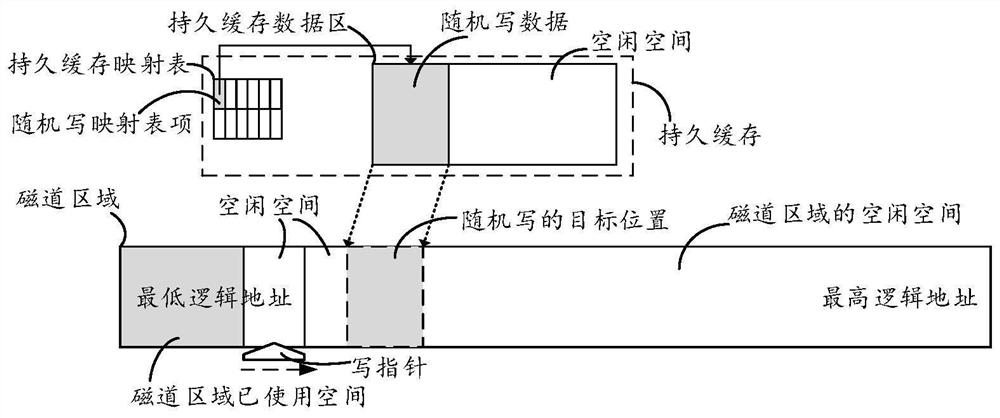

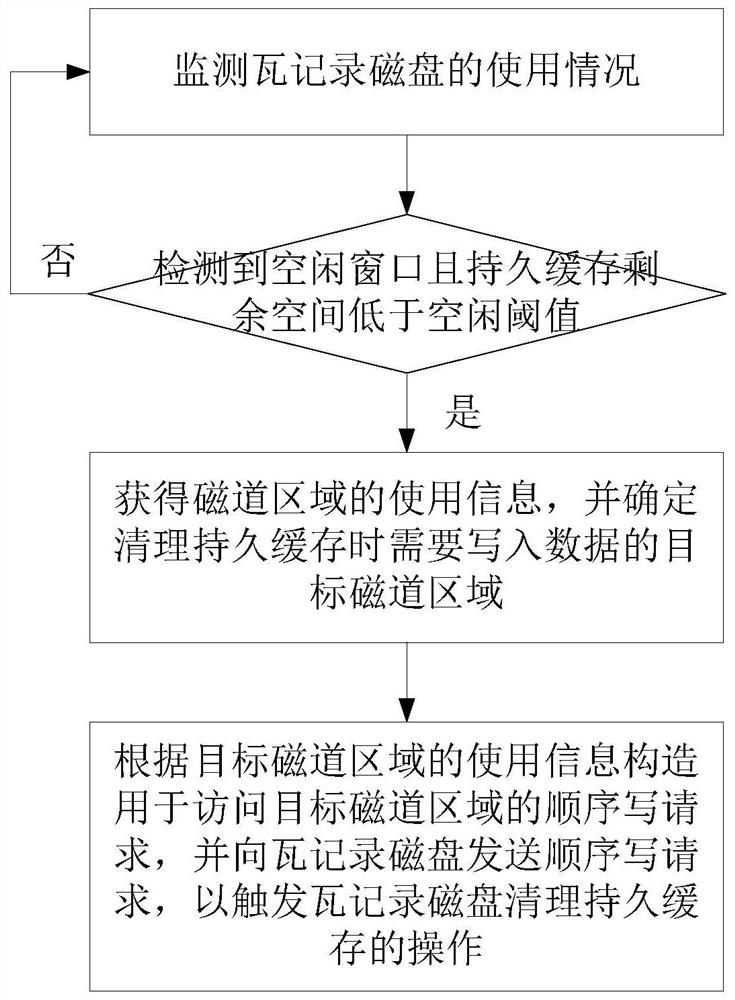

A Cleaning Method for Persistent Cache in Host-Aware Tile Recording Disk

ActiveCN109582222BReduce request response time fluctuationsAvoid running out of spaceInput/output to record carriersComputer hardwareIdle time

The invention discloses a method for cleaning a persistent cache in a host perceptual tile recording disk, which comprises the following steps: (1) monitoring the use condition of the tile recording disk, and if an idle window is detected and the residual space of the persistent caches is lower than a preset idle threshold value, turning to a step (2); (2) obtaining use information of the magnetictrack area, and determining a target magnetic track area needing to write data when the persistent cache is cleaned; And (3) constructing a sequential write request according to the use information of the target track area, and writing the sequential write request into the target track area to trigger the operation of cleaning the persistent cache of the tile recording disk. The data in the persistent cache can be actively cleaned by utilizing the idle time of the system, so that the performance of the tile recording disk sensed by the host is effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

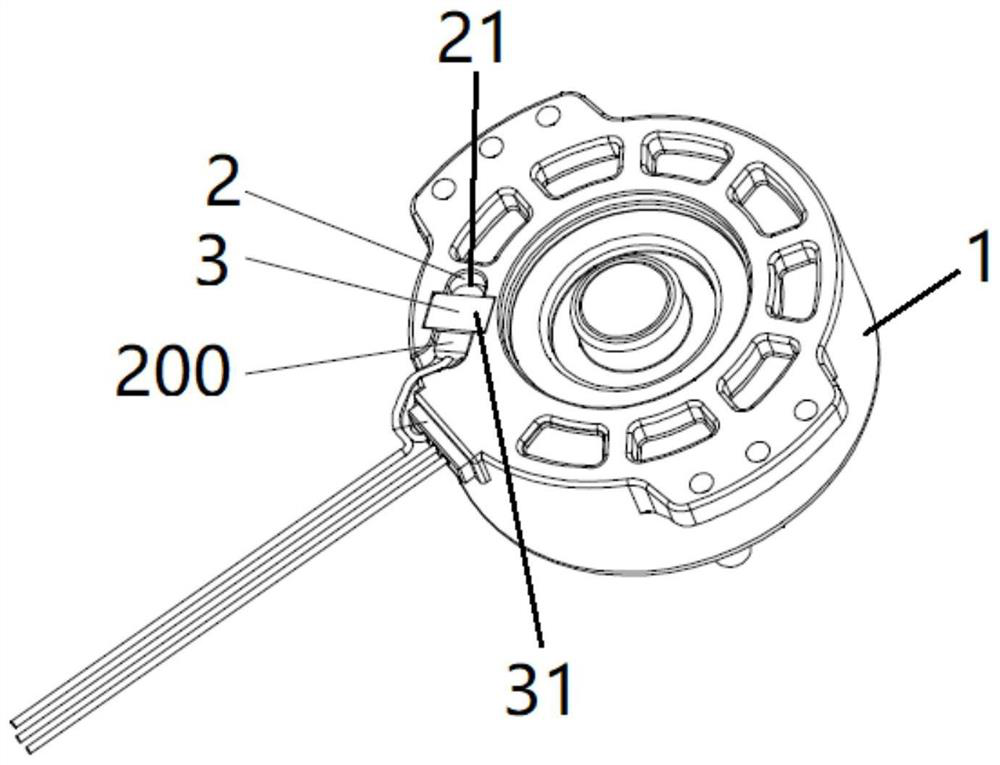

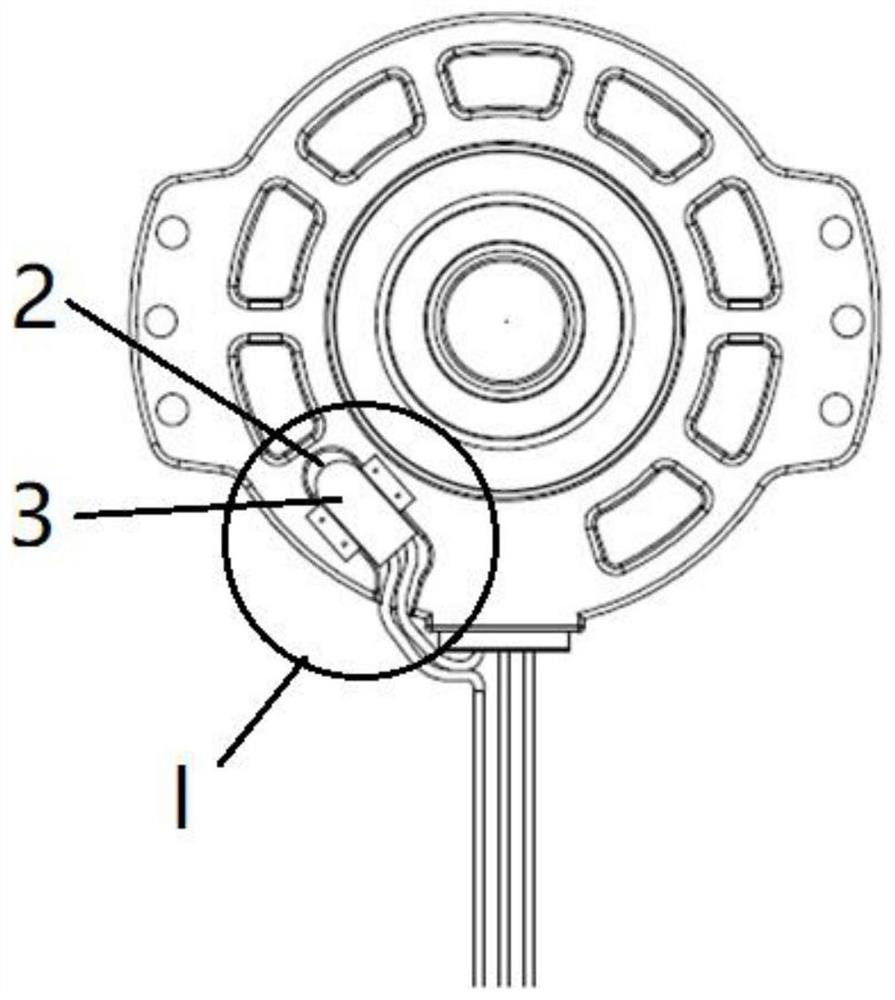

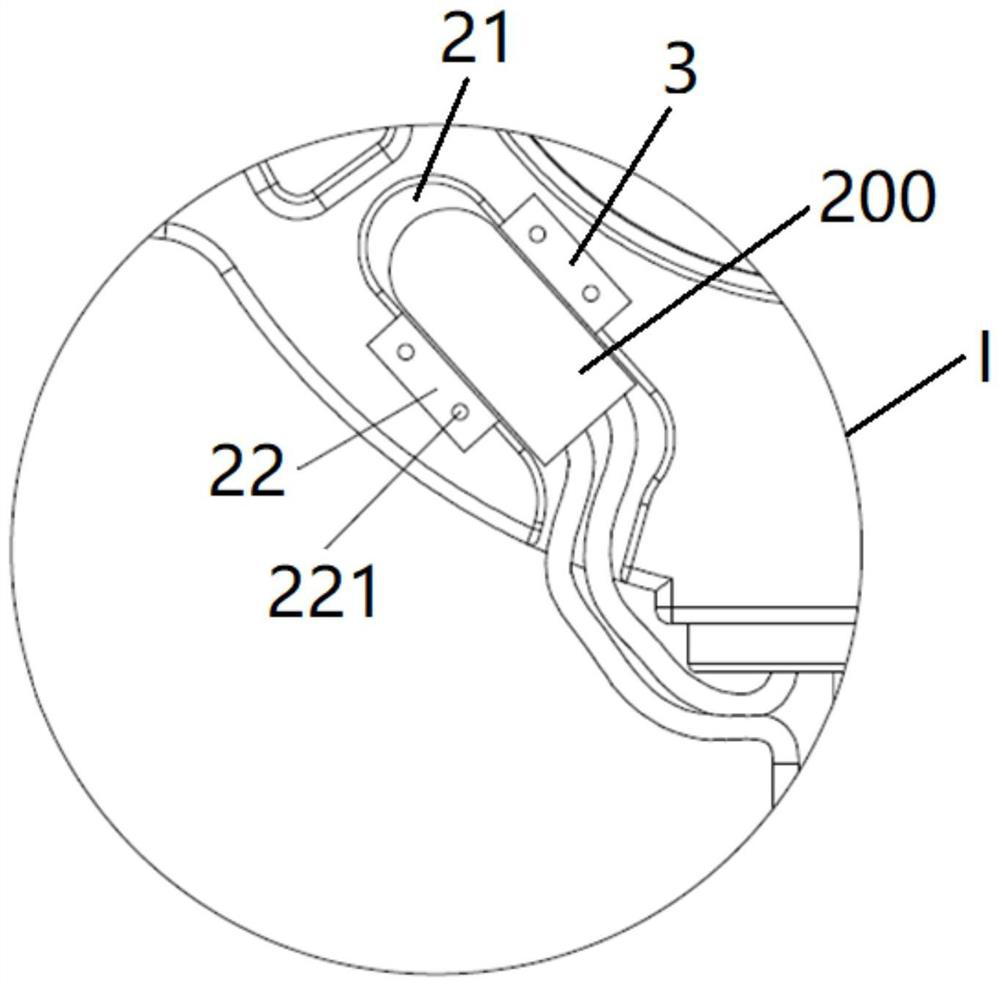

Plastic package motor and electrical equipment provided with plastic package motor

PendingCN111865001AAchieve installationAchieve fixationStructural associationElectric machineryElectrical equipment

The invention relates to a plastic package motor and electrical equipment provided with the plastic package motor, and the motor comprises: a thermal protector installation position which is disposedon an installation angle plane of a stator; a fastener which is arranged on the thermal protector installation position in a covering mode, wherein the fastener and the thermal protector installationposition are arranged in an intersecting mode, and the two ends of the fastener extend to penetrate through the two sides of the thermal protector installation position. The plastic package motor provided by the invention has the beneficial effect of avoiding the situation that a plurality of loads cannot be installed due to interference generated when the motor is installed because the space position of the thermal protector is insufficient.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

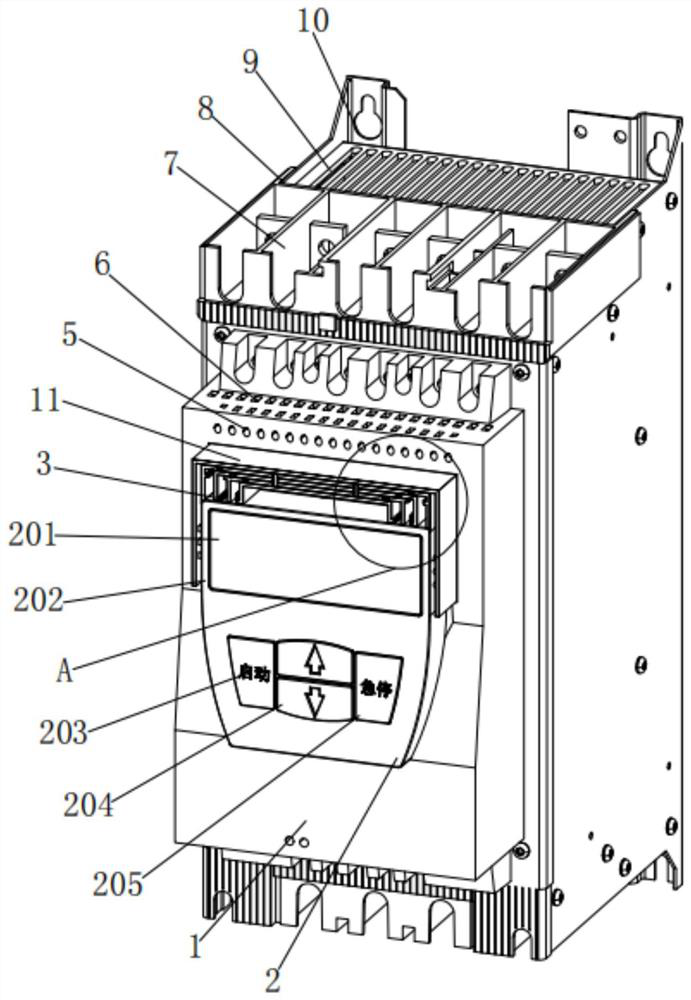

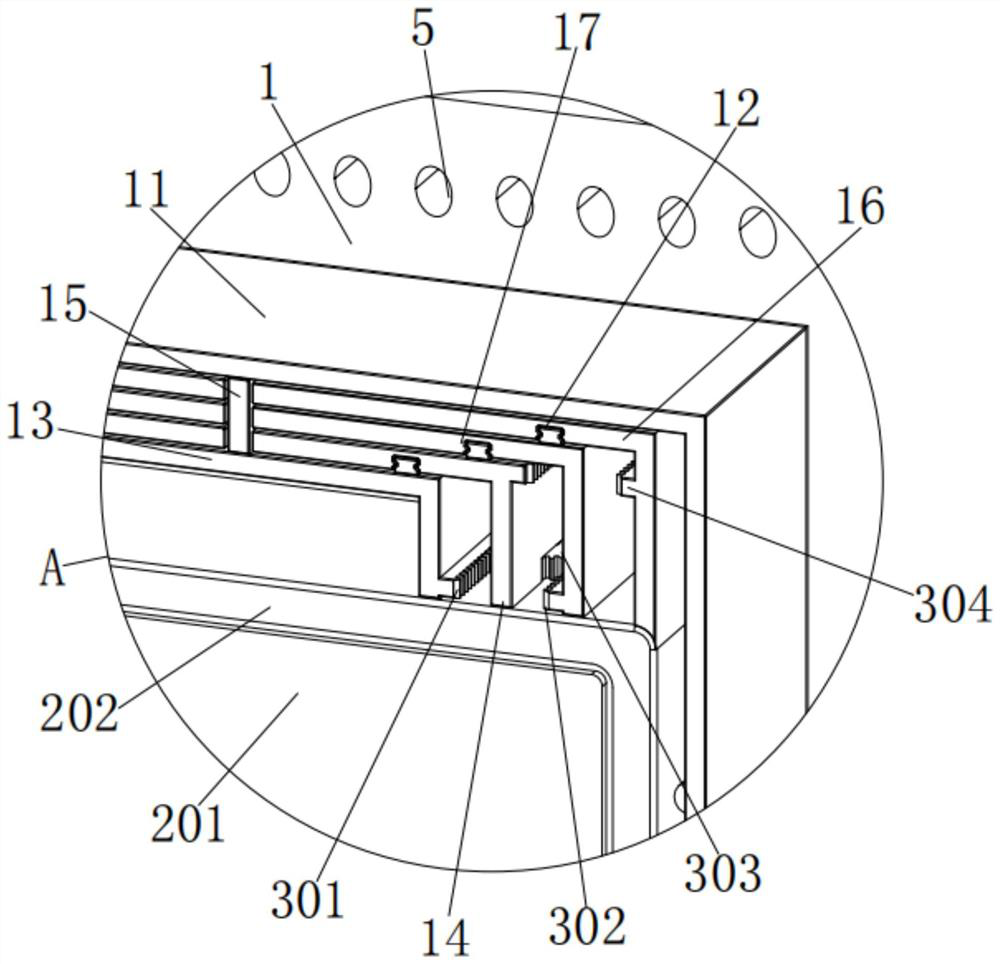

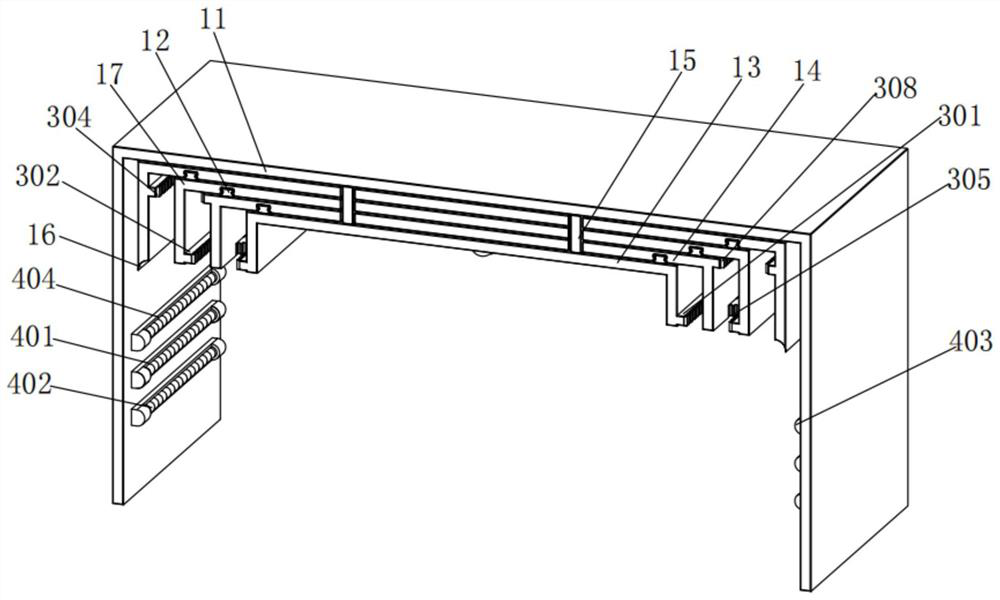

Motor soft starter of SPI communication display module

ActiveCN113613429AAvoid the problem that it is difficult to see the screen clearly due to strong light and no light blocking structureAvoid the problem of not being able to see the screen clearlyLighting elementsCasings/cabinets/drawers detailsElectric machineryControl theory

The invention discloses a motor soft starter of an SPI communication display module. The motor soft starter comprises a soft starter and wiring holes; a plurality of wiring holes are machined in the upper part of the soft starter; bolt holes are machined in the front sides of the wiring holes; a control assembly is mounted on the front side of the soft starter; and lighting assemblies are mounted on the two sides of the inner wall of a baffle plate. According to the motor soft starter of the SPI communication display module, through cooperation of a motor, an upper gear, a lower gear, a threaded rod, a cross beam, a third push plate, a second push plate, a first push plate and the baffle, an output shaft of the motor can drive the threaded rod to rotate, so that the threaded rod can drive the third push plate to move forwards through the cross beam, the actual moving distance of the first push plate is larger than the moving distance of the second push plate due to the influence of the lower gear; and the baffle can form a three-face enclosure on the outer side of the display module, and the problem that a screen is inconvenient to see clearly due to the fact that the soft starter is not provided with a light blocking structure due to strong light irradiation in the using process is solved.

Owner:卧龙电气南阳防爆集团工业驱动有限公司

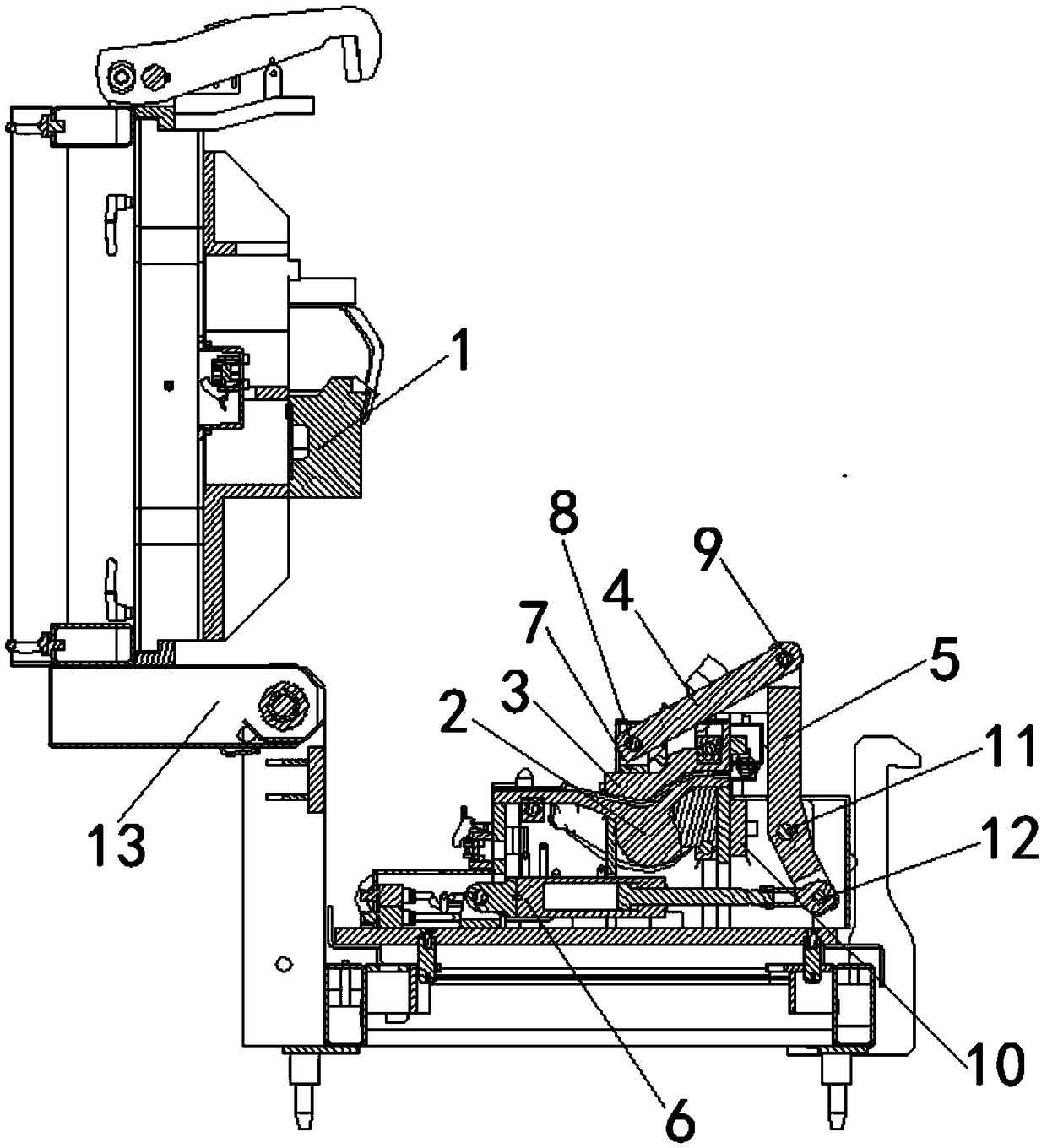

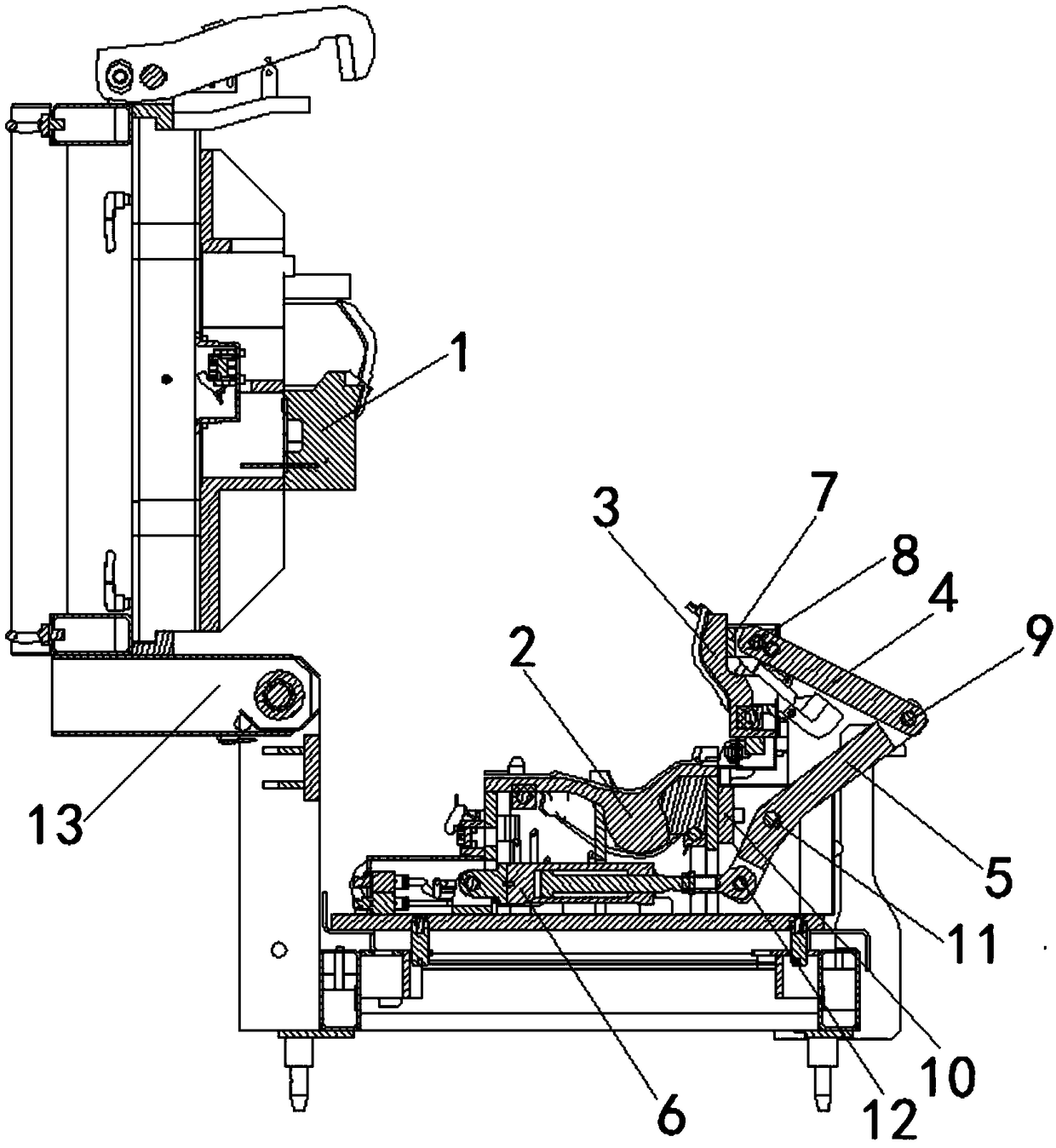

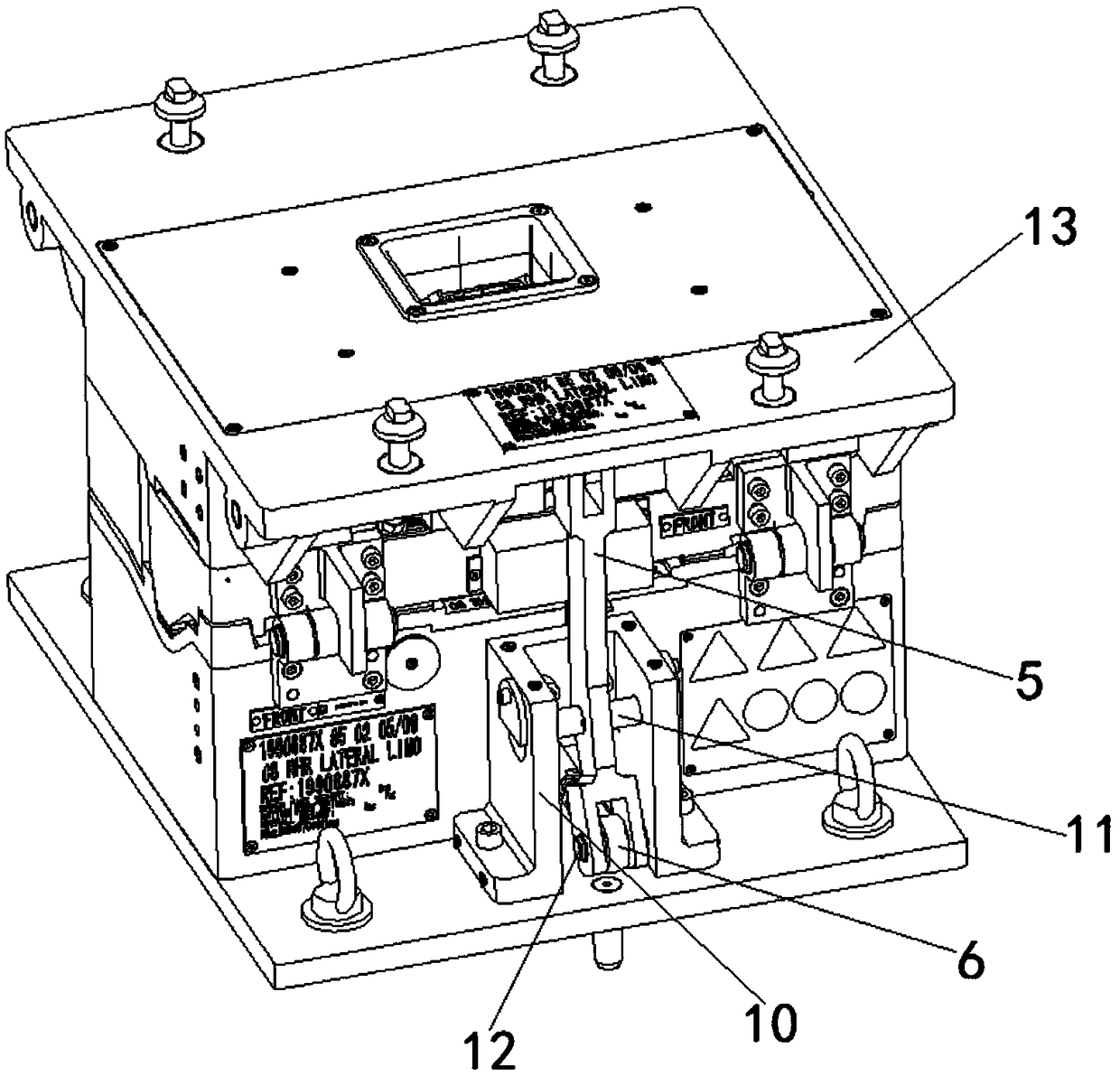

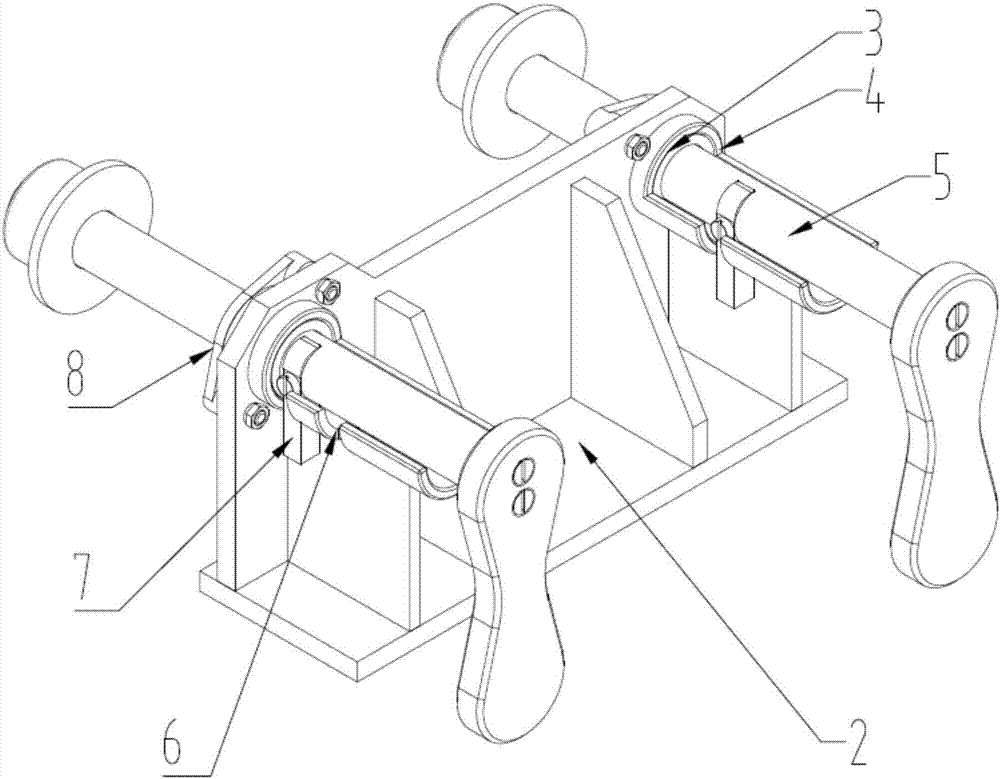

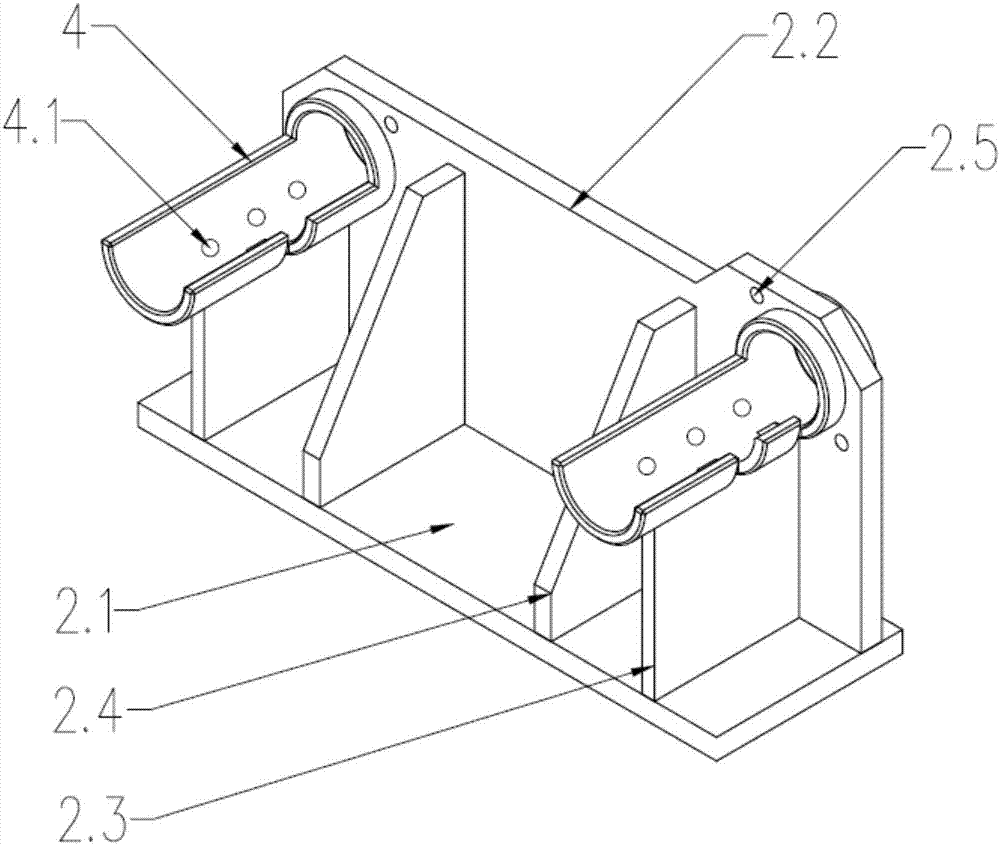

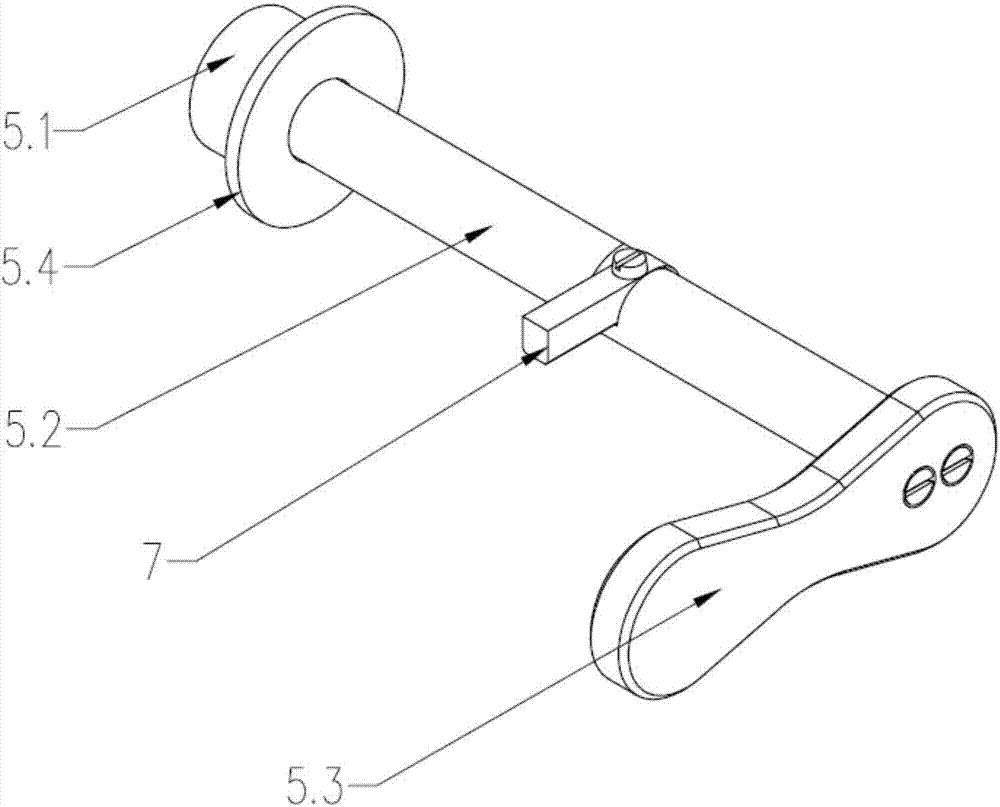

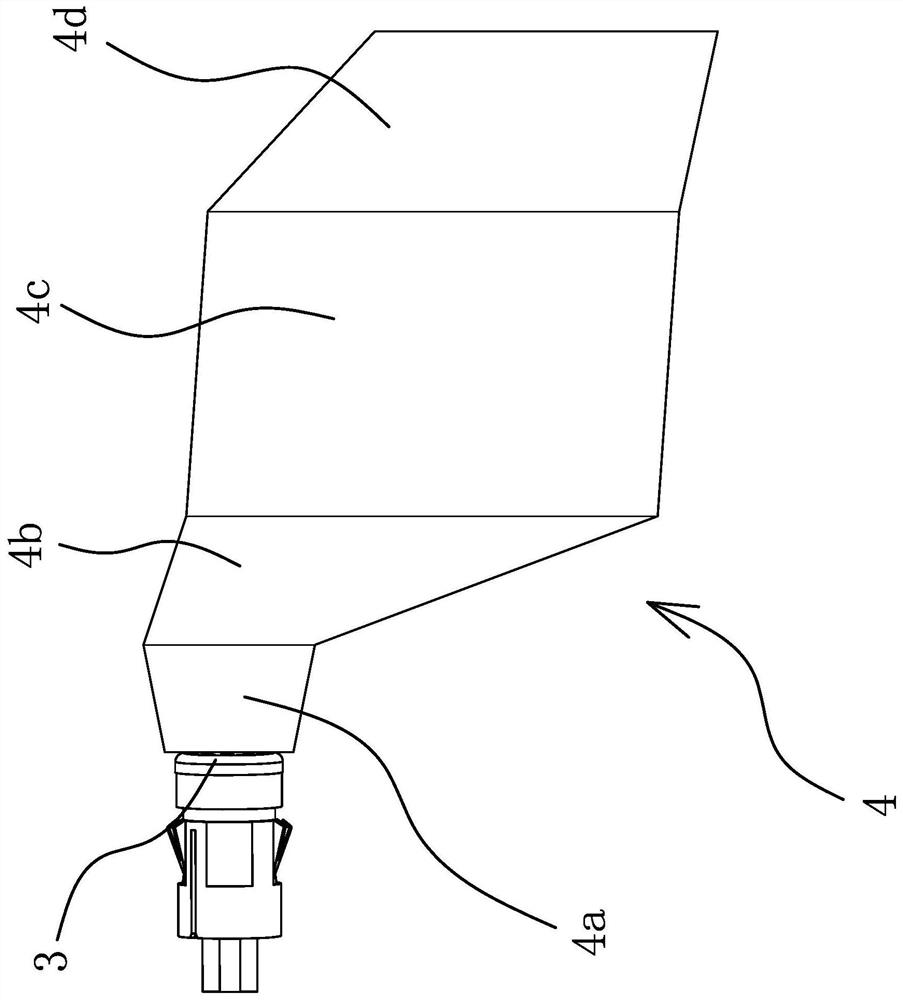

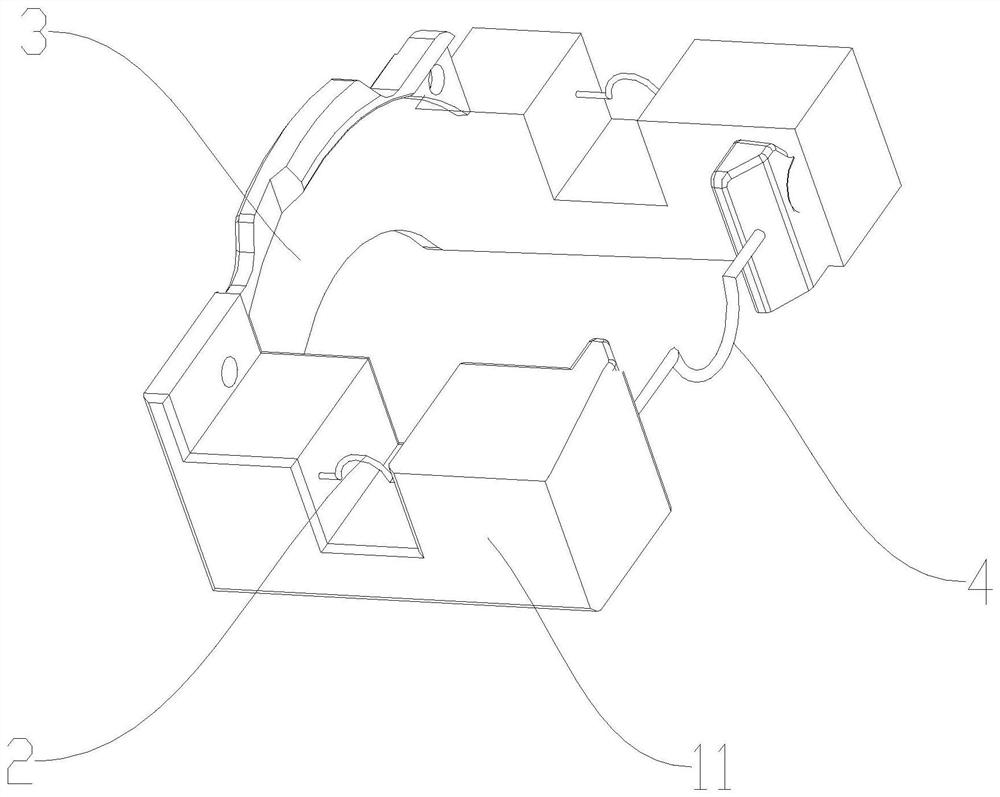

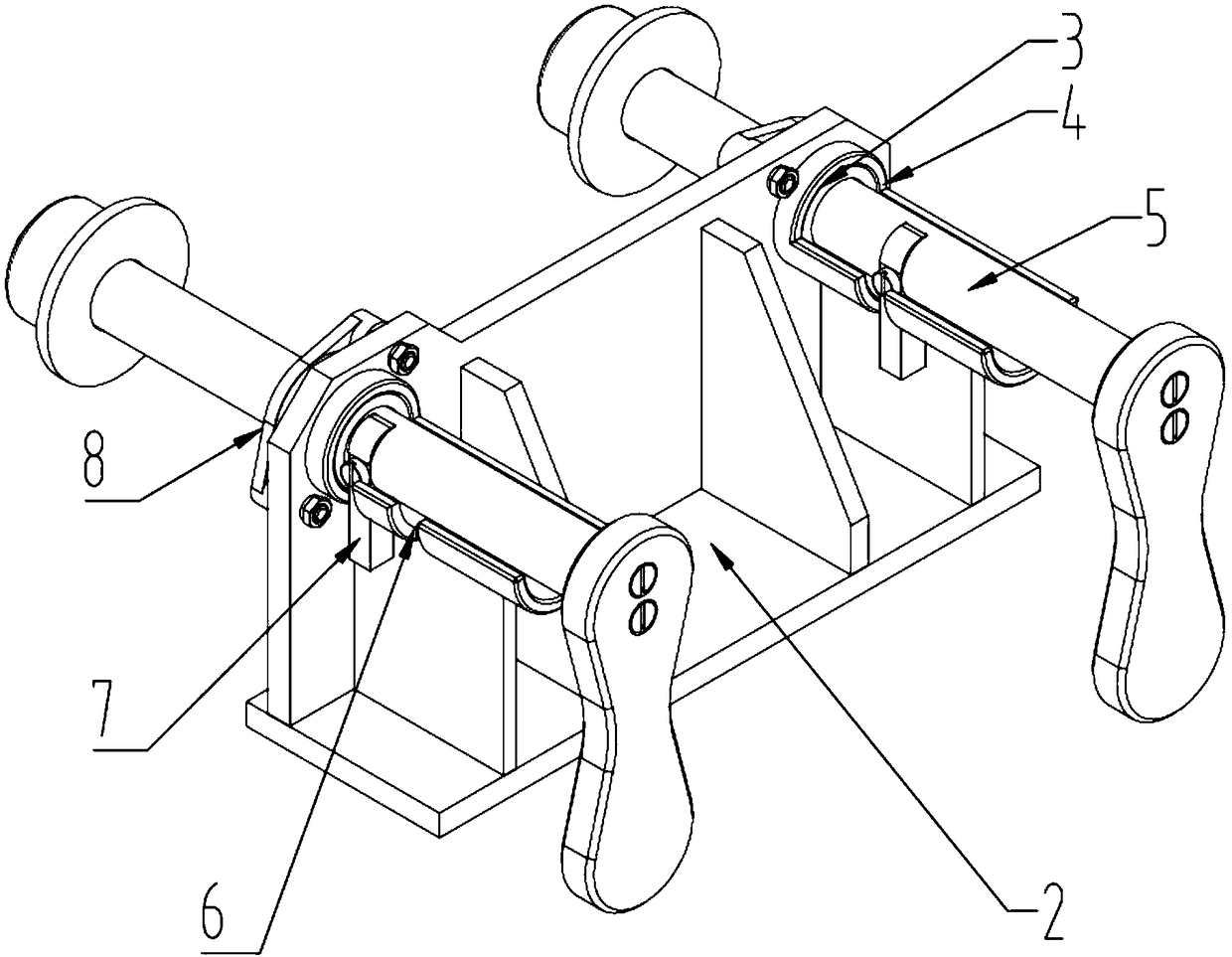

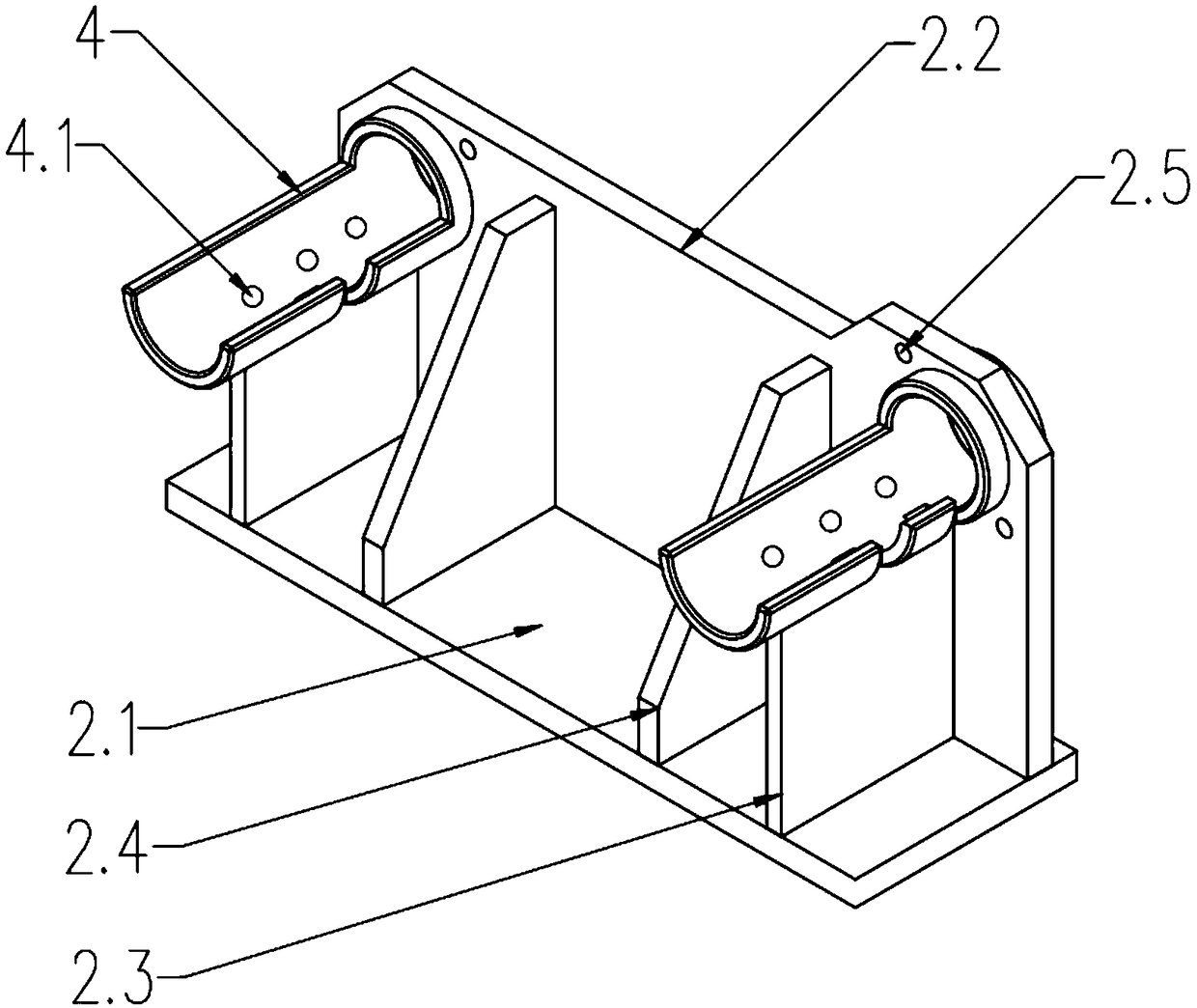

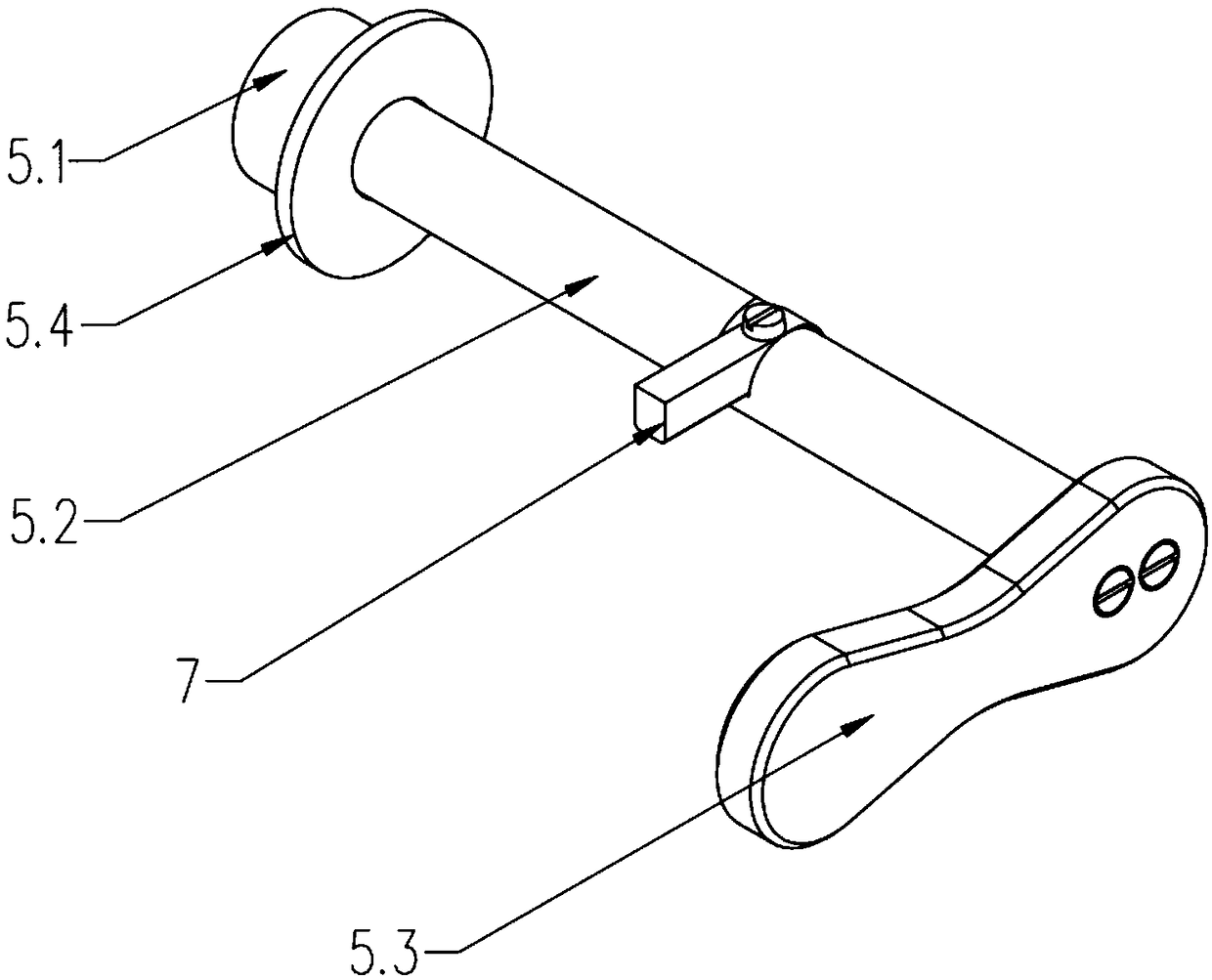

Side locking device for lifting appliance on electrophoresis conveying line

ActiveCN106968006AAvoid running out of spaceAvoid accumulationElectrophoretic coatingsSemi openElectrophoresis

The invention relates to a side locking device for a lifting appliance on an electrophoresis conveying line. By adoption of the side locking device, a novel locking method is provided for a vehicle provided with front lifting lugs suspended on the rear portion. The whole locking device is mounted on two side beams of the lifting appliance through a locking support. The locking device specifically comprises the locking support. Mounting bases are arranged at the two ends of the locking support through mounting holes. One end of each mounting base is of a sleeve structure, and the other end of each mounting base is of a semi-open sleeve structure. The two ends of the locking support penetrate through the mounting bases and provided with locking pin assemblies. A concave clamping groove is formed in one side of each mounting base. Clamping tongues are arranged on the locking pin assemblies, clamped in the concave clamping grooves and tightly matched with the concave clamping grooves. By adoption of the locking device, a traditional locking way that only a bottom supporting beam is locked is eliminated, the locking device is more suitable for the current situation of micro-surfaces and mixed-line production of cars, the phenomenon that the traditional locking device is prone to being covered with paint is avoided fundamentally, and the use intensity is reliable.

Owner:大唐互联科技(武汉)有限公司

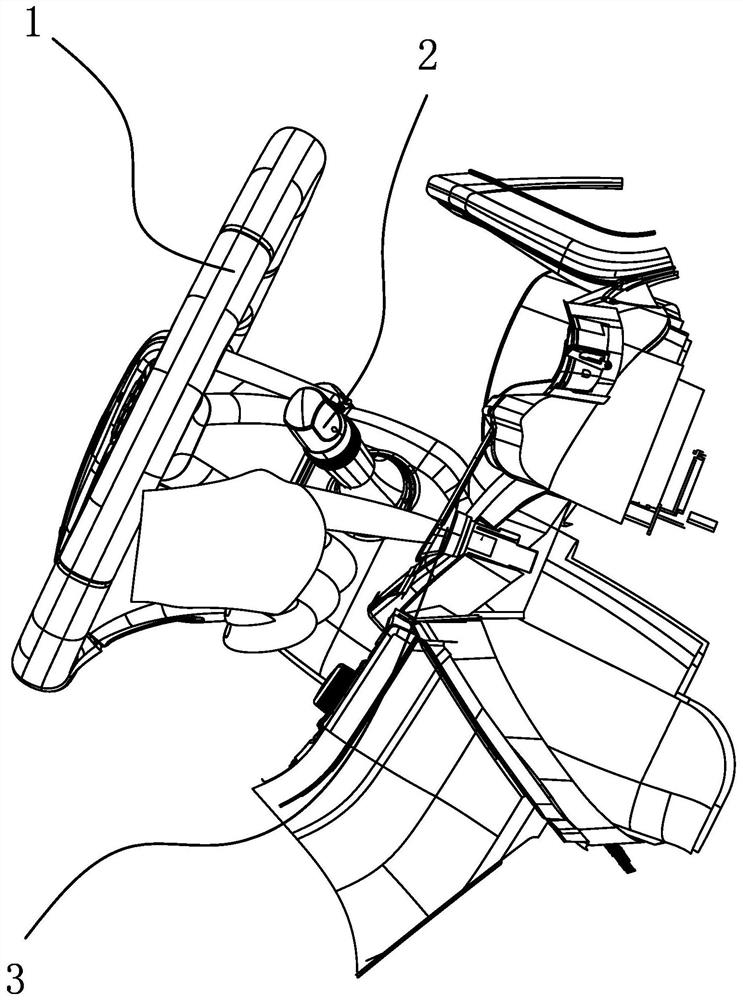

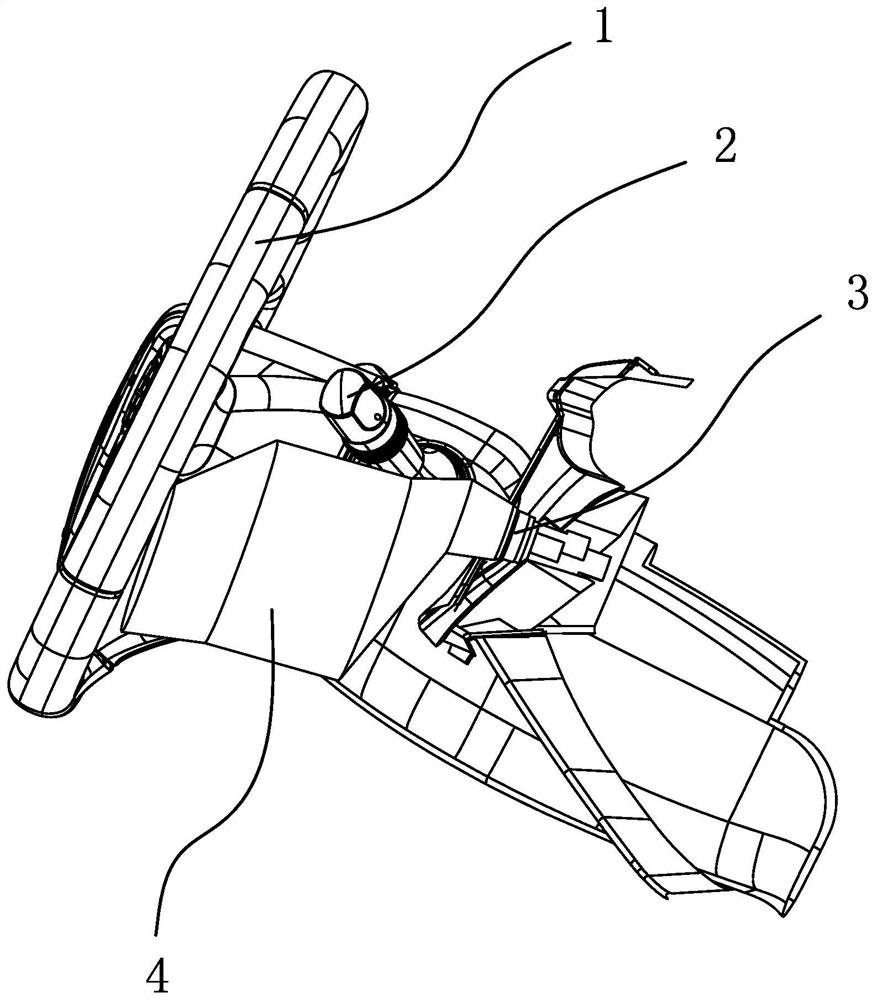

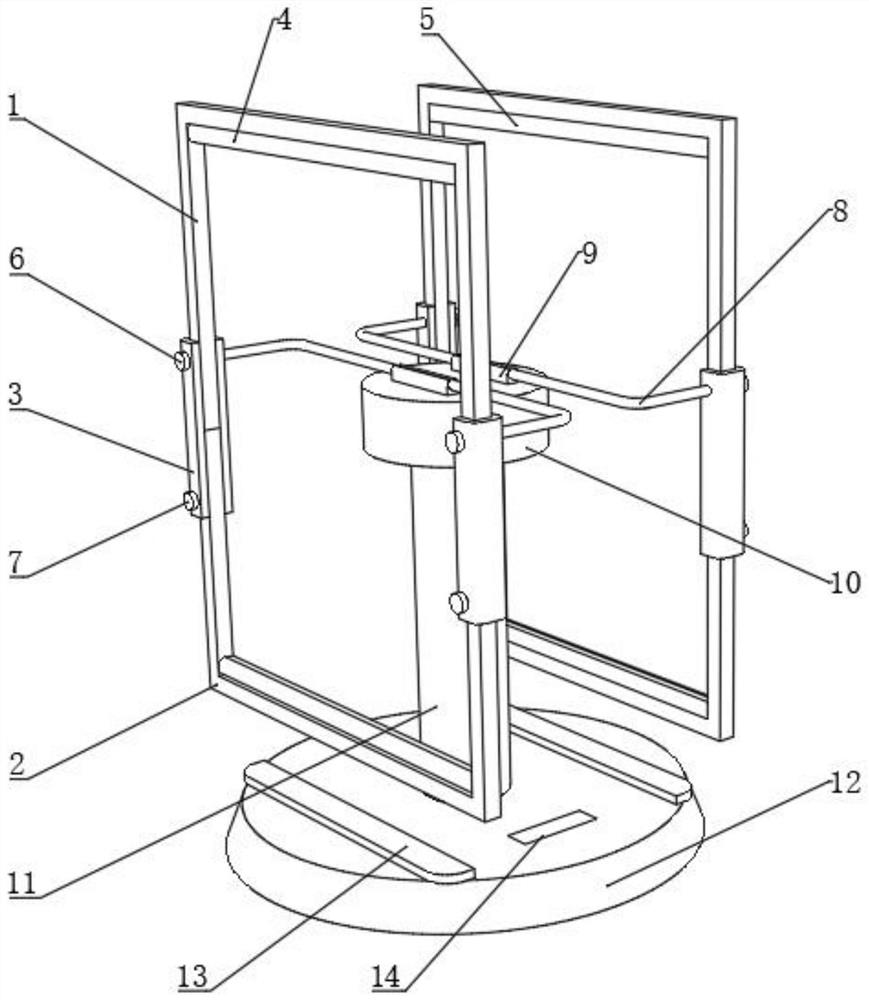

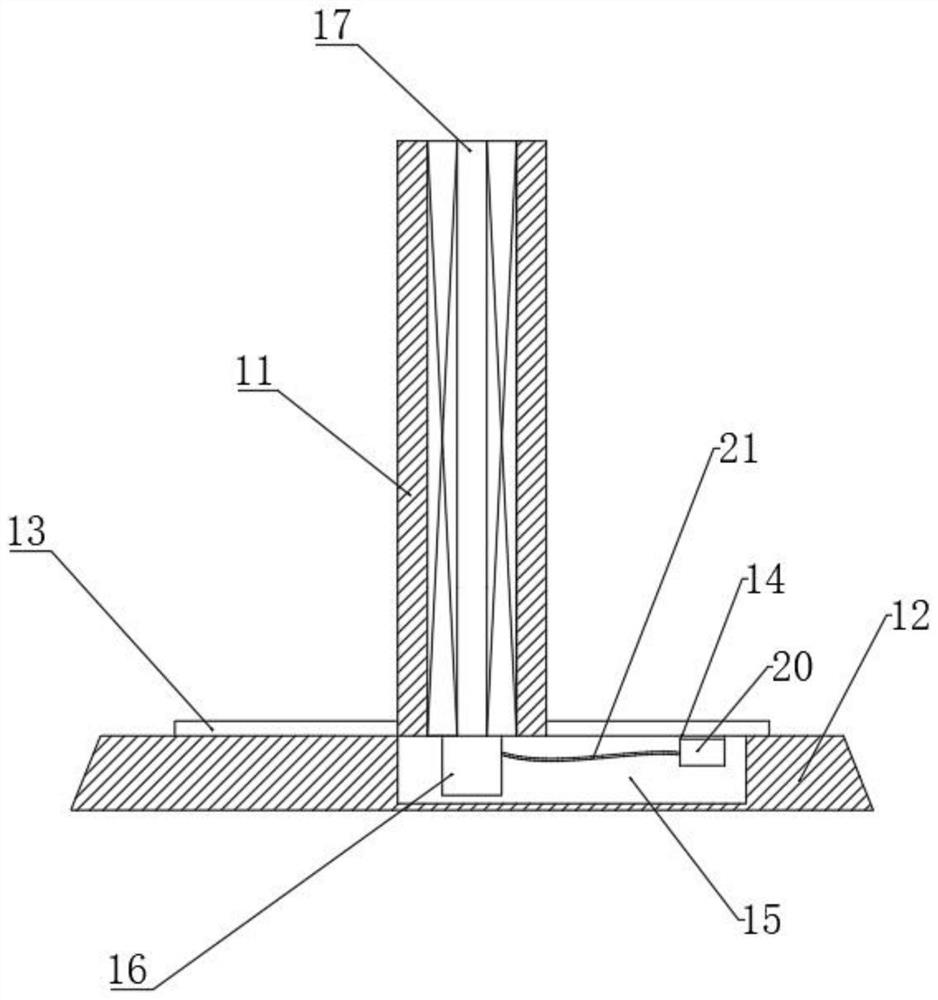

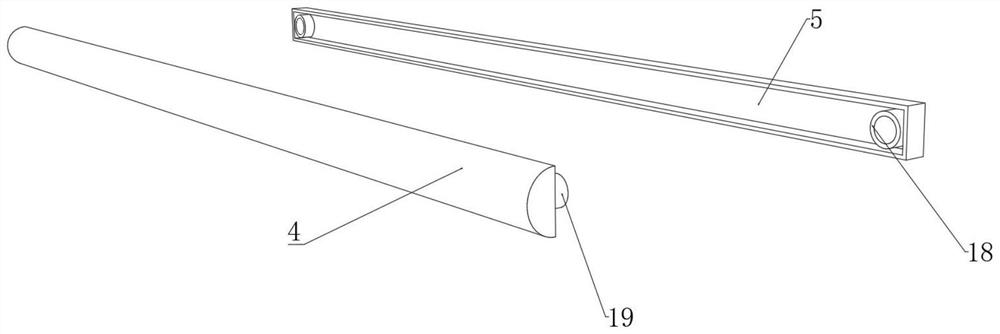

A method for checking the operating space of a car one-button start switch

ActiveCN106980714BReduce development costsReasonable arrangementGeometric CADDesign optimisation/simulationLittle fingerControl engineering

The invention provides a verification method for operation space of a one-key starting switch of an automobile and belongs to the field of automobile design technology. Through the method, the problems of long verification cycle, high cost and low efficiency of an existing one-key starting switch are solved. The verification method comprises the steps that A, a switch operation envelope comprising a first verification body, a second verification body, a third verification body and a fourth verification body is made, wherein the first verification body is a tubular envelope simulating an index finger area state, the second verification body is a tubular envelope simulating middle finger, ring finger and little finger released and clenched area states, the third verification body is a tubular envelope simulating a palm area state, and the fourth verification body is a tubular envelope simulating a wrist area state; and B, the one-key starting switch is verified through the switch operation envelope. Through the verification method, whether the arrangement of the one-key starting switch is reasonable and whether surrounding operation space is appropriate can be analyzed at a vehicle modeling CAS stage, the verification cycle is shortened, and modeling development cost is saved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Roll screen display device capable of displaying in multiple directions

PendingCN113178148AImprove stabilityPrevent lack of spaceBoardsElectric machineryStructural engineering

The invention discloses a roll screen display device capable of displaying in multiple directions, and belongs to the field of roll screens, the roll screen display device capable of displaying in multiple directions comprises a pair of upper frames, lower frames are slidably connected to the lower ends of the upper frames, connecting boxes are fixedly connected to the inner walls of the upper ends of the upper frames and the inner walls of the lower ends of the lower frames, and clamping boxes are clamped to the front ends of the connecting boxes; sleeve frames are slidably connected to the left and right ends of the upper frame and the lower frame, upper rotating rods and lower rotating rods are in threaded connection to the front ends of the sleeve frames, auxiliary rods are fixedly connected to the rear ends of the sleeve frames, pipe clamping grooves are clamped to the outer ends of the auxiliary rods, and rotating frames are fixedly connected to the lower ends of the pipe clamping grooves. The display device is characterized in that the motor in the base frame drives the rotating shaft and the rotating frame to rotate, so that the upper frame and the lower frame which are connected with the rotating frame rotate, slow-circulation 360-degree rotation of content displayed by the whole roll-up banner is effectively achieved, and people in more directions can receive content information.

Owner:NANTONG ZHONGFA DISPLAY EQUIP CO LTD

Opening electromagnet of spring operating mechanism

ActiveCN112927981ASlow downGuaranteed working lengthHigh-tension/heavy-dress switchesAir-break switchesMechanical engineeringElectromagnet

The invention relates to an opening electromagnet of a spring operating mechanism. The opening electromagnet of the spring operating mechanism comprises: an electromagnet main body which is internally provided with a coil; a movable iron core arranged in the coil in a penetrating manner; a reset spring used for driving the movable iron core to retreat so as to reset the movable iron core; and a delay counterweight fixed on the rear end surface of the movable iron core and is used for increasing the motion mass of the movable iron core so as to reduce the action speed of the movable iron core. The delay counterweight is provided with a spring stop surface, and the spring stop surface is flush with the end face of the rear end of the movable iron core and is used for supporting the end portion of the reset spring. According to the scheme, the opening time of the operating mechanism can be easily controlled.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

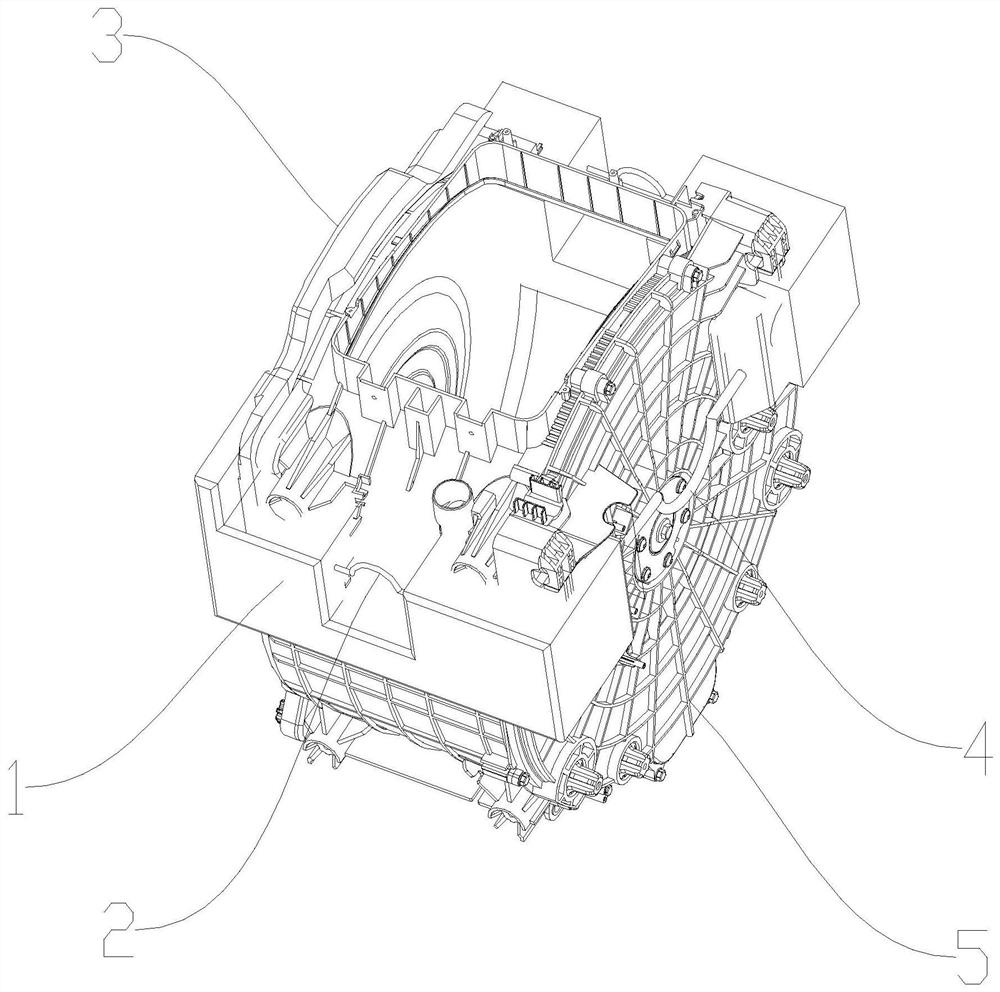

Clothes processing equipment

ActiveCN109505095BIncrease flexibilityEasy to installOther washing machinesTextiles and paperLaundryMechanical engineering

The invention belongs to the technical field of laundry processing equipment, and aims to solve the problem that in the existing laundry processing equipment, installing a counterweight on an outer cylinder results in a limited installation position of an installation member for installing the outer cylinder. To this end, the present invention provides a laundry processing device, which includes a box body and an outer cylinder, and the laundry treatment equipment also includes a counterweight member arranged on the outer tube and a connecting link between the counterweight member and the box body. Install components. In the present invention, by installing the installation member on the counterweight member of the drum, the interference between the installation member and the counterweight member in the structural arrangement of the laundry processing equipment is avoided, so that the installation position of the installation member will not be affected by the counterweight configuration. The limitation of the installation position of the components improves the flexibility of the arrangement of the installation components, and at the same time facilitates the installation of the counterweight components to a certain extent, avoiding the situation that the installation space of the counterweight components is insufficient.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

A side locking device for electrophoretic transmission line spreader

ActiveCN106968006BAvoid running out of spaceAvoid accumulationElectrophoretic coatingsSemi openElectrophoresis

The invention relates to a side locking device for a lifting appliance on an electrophoresis conveying line. By adoption of the side locking device, a novel locking method is provided for a vehicle provided with front lifting lugs suspended on the rear portion. The whole locking device is mounted on two side beams of the lifting appliance through a locking support. The locking device specifically comprises the locking support. Mounting bases are arranged at the two ends of the locking support through mounting holes. One end of each mounting base is of a sleeve structure, and the other end of each mounting base is of a semi-open sleeve structure. The two ends of the locking support penetrate through the mounting bases and provided with locking pin assemblies. A concave clamping groove is formed in one side of each mounting base. Clamping tongues are arranged on the locking pin assemblies, clamped in the concave clamping grooves and tightly matched with the concave clamping grooves. By adoption of the locking device, a traditional locking way that only a bottom supporting beam is locked is eliminated, the locking device is more suitable for the current situation of micro-surfaces and mixed-line production of cars, the phenomenon that the traditional locking device is prone to being covered with paint is avoided fundamentally, and the use intensity is reliable.

Owner:大唐互联科技(武汉)有限公司

Rapid manufacturing process for preassembled power distribution room and GRC shell

InactiveCN113738164AMaintenance period is sufficientGood strength and structureCeramic shaping apparatusBuilding constructionsRebarProcess engineering

The invention discloses a rapid manufacturing process for a prefabricated power distribution room and a GRC shell. The rapid manufacturing process comprises various sizing customized molds and an assembly type process. The manufacturing process comprises the following steps of manufacturing a standard component reinforcing mesh, namely scientifically designing a reinforcing mesh, stirrups, riveting reinforcing steel bars and binding; mold closing the standard component, specifically, mold closing a positioning pin, fixing and pre-burying the embedded part at a designed position by using a screw; stirring, specifically, in a full-automatic large-scale stirring station, setting a ratio and stirring time according to environmental conditions; pouring; maintaining, specifically, opening the mold after steam curing, standing after natural maintaining, and standing in a maintaining period; splicing, specifically, splicing through an assembly type process and a flexible number combination concept, after drawing is conducted, flashes are treated firstly, adopting bolt connection for splicing, tensioning two components to the maximum extent to enable a gap is infinitely small, and filling the combination face of the components with special structural adhesive; and performing surface treatment; According to the manufacturing process, long-distance transportation of finished products is not needed, different-place splicing is achieved, the working efficiency is greatly improved, and damage to the products caused by long-distance transportation is reduced.

Owner:张建川

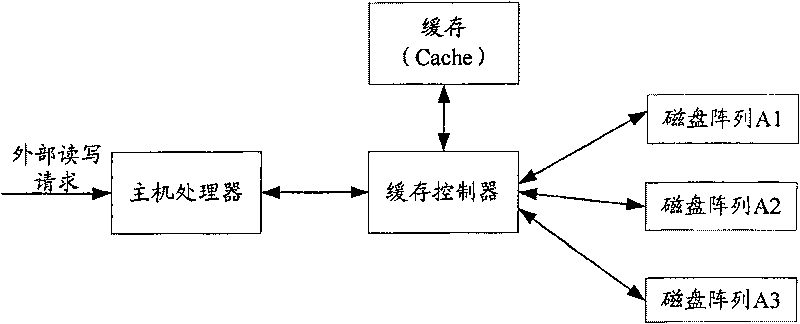

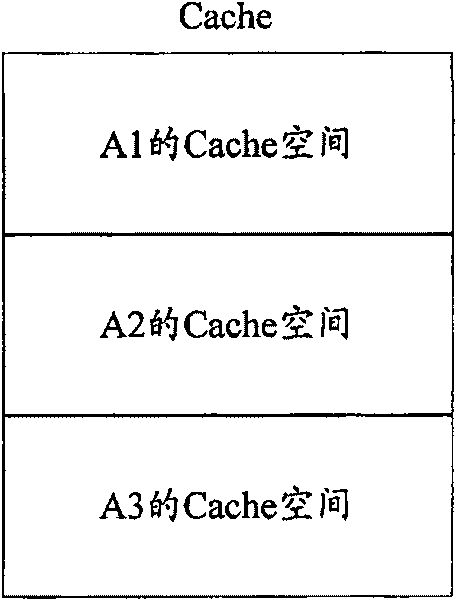

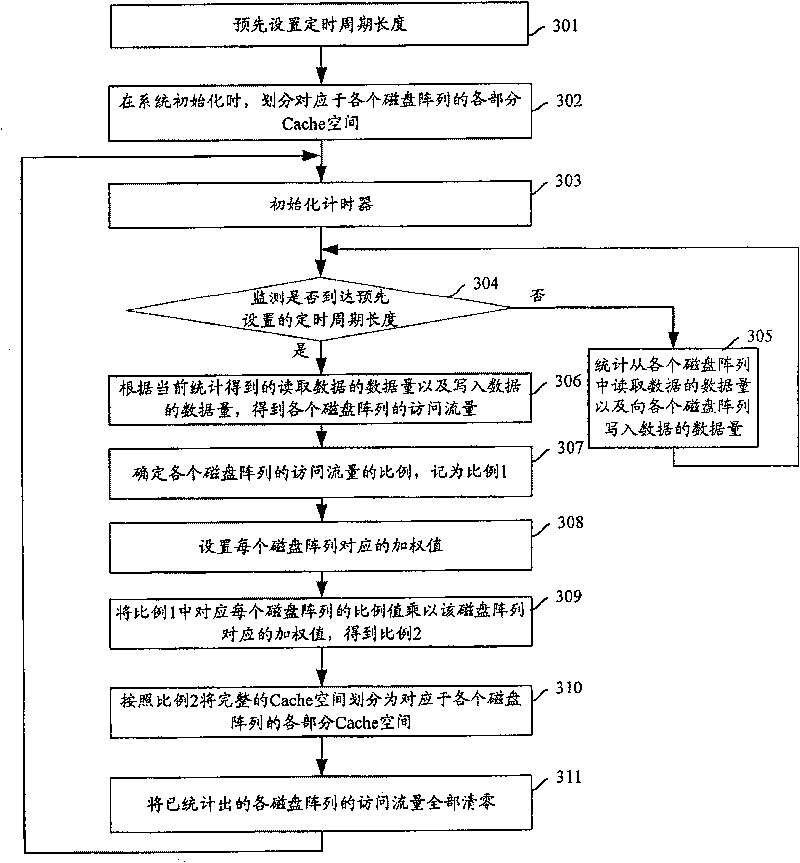

Method and apparatus for dividing buffer memory space and buffer memory controller thereof

InactiveCN101135994BImprove hit rateImprove access efficiencyMemory adressing/allocation/relocationStore-and-forward switching systemsTraffic capacityTime segment

The method comprises: counting the flow rate accessing each disk array in a preset time interval; according to the flow rate accessing each disk array in the time interval, resizing the space of each Cache respectively corresponding to each disk array. The apparatus thereof comprises a host computer processor and a buffer controller.

Owner:NEW H3C TECH CO LTD

A method and device for cloud computing resource adjustment

ActiveCN107040479BOptimizationReduce deficienciesData switching networksResource utilizationDistributed computing

Embodiments of the present invention provide a method and device for adjusting cloud computing resources, which relate to the technical field of cloud computing and are used to reduce the number of computing nodes in a cloud computing platform and improve resource utilization by increasing the remaining resources of computing nodes. When the trigger condition for resource adjustment is satisfied, the resource scheduling device selects the target instance from the instance information table; when the total resource quota of the first service remains unchanged, the resource scheduling device adjusts the target instance corresponding to each of the instances in the first service A resource quota, so that the resource quota of the target instance is reduced, and the resource quotas corresponding to other instances in the first service other than the target instance are increased; the resource scheduling device sends a first request to the load balancer message, so that the load balancer adjusts the weight corresponding to each of the instances in the first service according to the first request message, and the first request message includes the weight of each of the instances in the first service The corresponding adjusted resource quota.

Owner:HUAWEI TECH CO LTD

WiFi-based automatic storage method and system for car video recording

ActiveCN105554466BFlexible storageOptimize the transmission methodClosed circuit television systemsTransmissionData transmissionMobile device

The invention discloses a WiFi-based vehicle-mounted video automatic storage method and system. The method is characterized in that the access of a mobile device to a vehicle-mounted system is achieved through WiFi; the vehicle-mounted system acquires an available storage capacity of the current mobile device, and sends a vehicle-mounted video to the current mobile device according to the available storage capacity of the current mobile device; the size of the vehicle-mounted video sent by the vehicle-mounted system to the mobile device is no larger than the available storage capacity of the current mobile device; the received vehicle-mounted video is stored in a terminal storage device through the current mobile device. The WiFi-based vehicle-mounted video automatic storage method and system provided by the invention have the advantages that the vehicle-mounted video of the vehicle-mounted system is stored in the terminal storage device through the mobile device, so that the storage of the vehicle-mounted video is more flexible, the data transmission method is optimized, and the use is facilitated.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

Engine variable valve lift mechanism

InactiveCN102966390BInhibit wearSuppression lengthMachines/enginesLift valveHydraulic cylinderExhaust valve

The invention discloses a variable vehicle lift mechanism of an engine. An air intake / exhaust pier, an air intake / exhaust valve, a cam shaft base and a cam shaft are arranged on a cylinder head of the engine; a long air intake cam, a short air intake cam and an air exhaust cam are arranged on the cam shaft; an air intake valve rocker is provided with a high-opening degree rocker and a general-opening degree rocker; a roller of the high-opening degree rocker is contacted with the long air intake cam; a roller of the general-opening degree rocker is contacted with the short air intake cam; and a pressing part of the general-opening degree rocker is contacted with the air intake valve. The air intake / exhaust rocker is made from a light metal alloy materials, so that the rotation inert weight can be greatly reduced. A via hole of the high-opening degree rocker is communicated with a via hole of the general-opening degree rocker to form an oil hydraulic cylinder, so that the high-opening degree rocker and the general-opening degree rocker can be in respective swing or inter-moving state, the opening degree of the air intake valve is changed, and the engine can obtain the most proper power in both a low-speed operation state and a high-speed operation state.

Owner:KYMCO

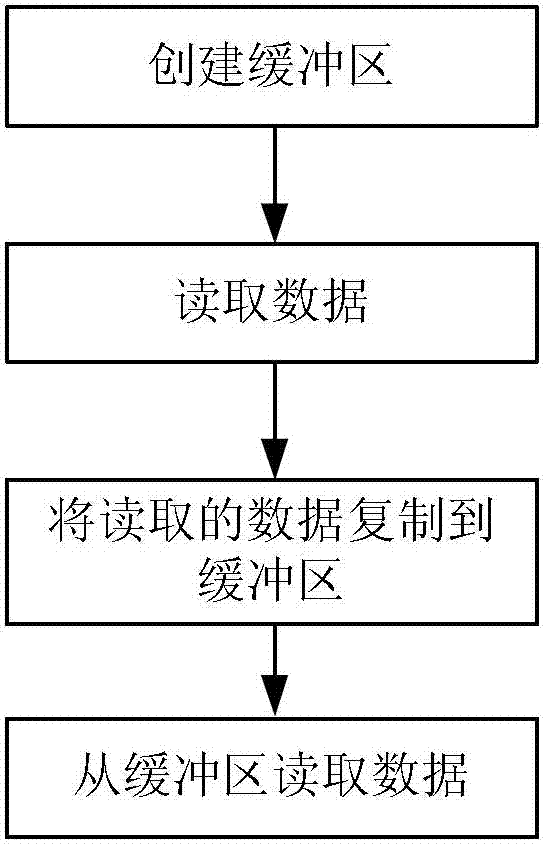

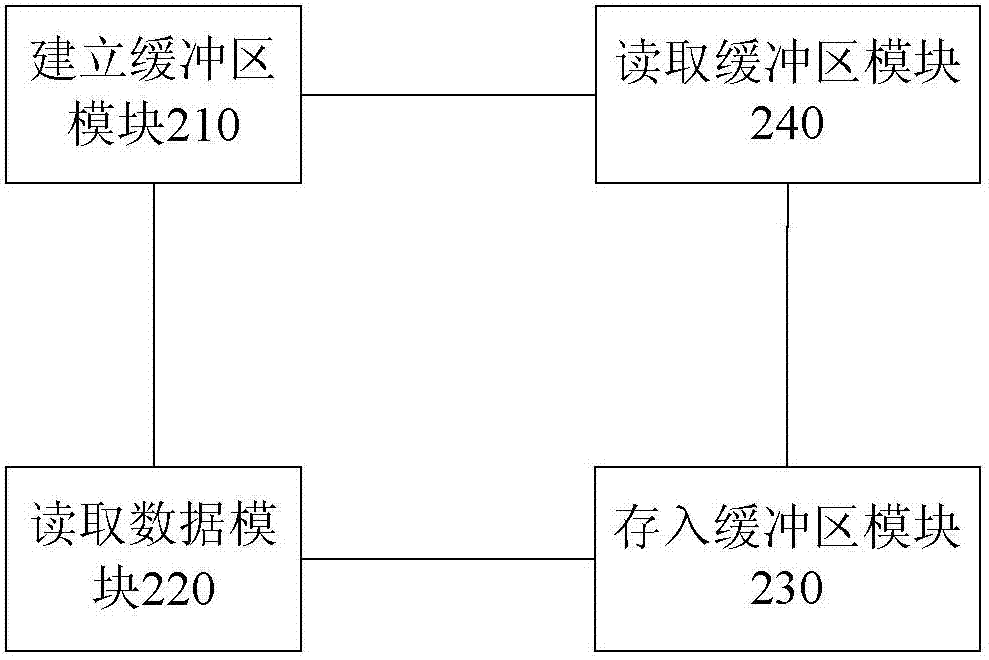

Data buffering method and device under condition of limited resources

InactiveCN102902520AAvoid running out of spaceImprove performanceSpecific program execution arrangementsLimited resourcesParallel computing

The invention provides a data buffering method under the condition of limited resources, comprising the steps of building only one buffer zone; obtaining data by using an original program interface; copying the obtained data to the buffer zone; and accessing the data from the buffer zone. The invention also provides a data buffering device under the condition of the limited resources, comprising a buffer zone building module for building only one buffer zone, a data reading module for obtaining the data by using the original program interface, a buffer zone storing module for copying the data read by the data reading module to the buffer zone and a buffer zone reading module for accessing data from the buffer zone. According to the technical scheme of the invention, only one buffer zone is adopted, so that the problem that multi-buffer zone space is insufficient under the condition of the limited resources is avoided and the program performance is improved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com