Plastic package motor and electrical equipment provided with plastic package motor

A technology of plastic-encapsulated motors and installation positions, which is applied to electromechanical devices, electrical components, electric components, etc., can solve the problems of inability to install various loads, insufficient space for thermal protectors, etc., to avoid insufficient space, rich diversity, Avoid shedding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

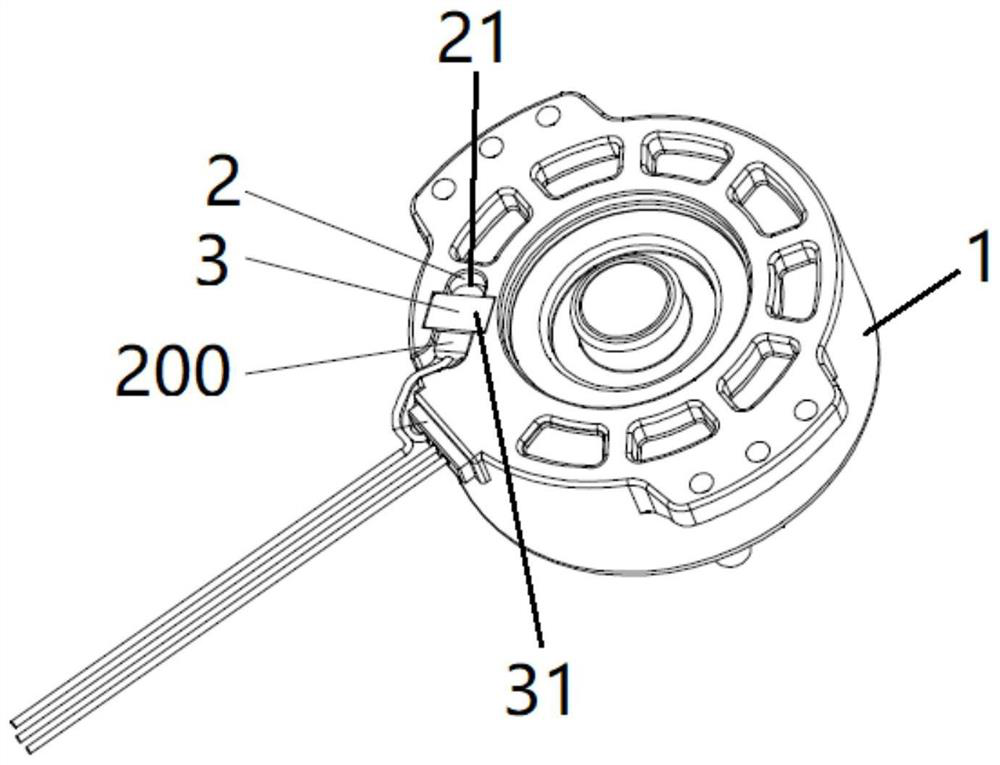

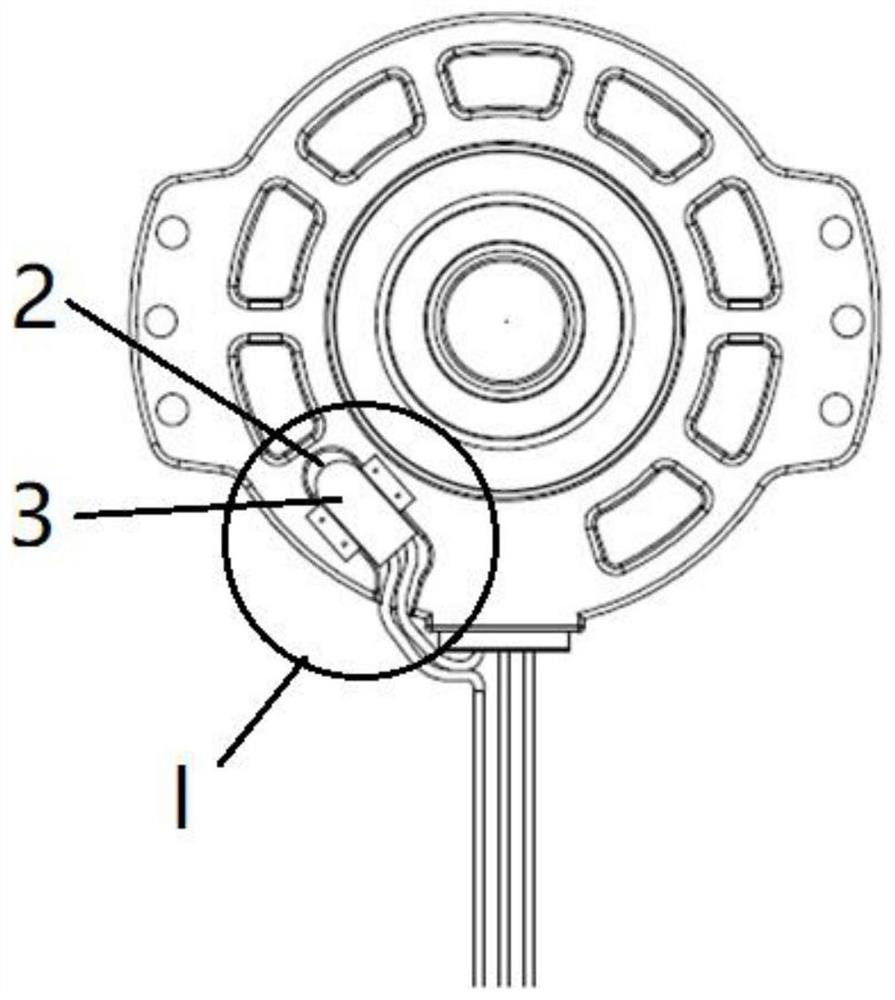

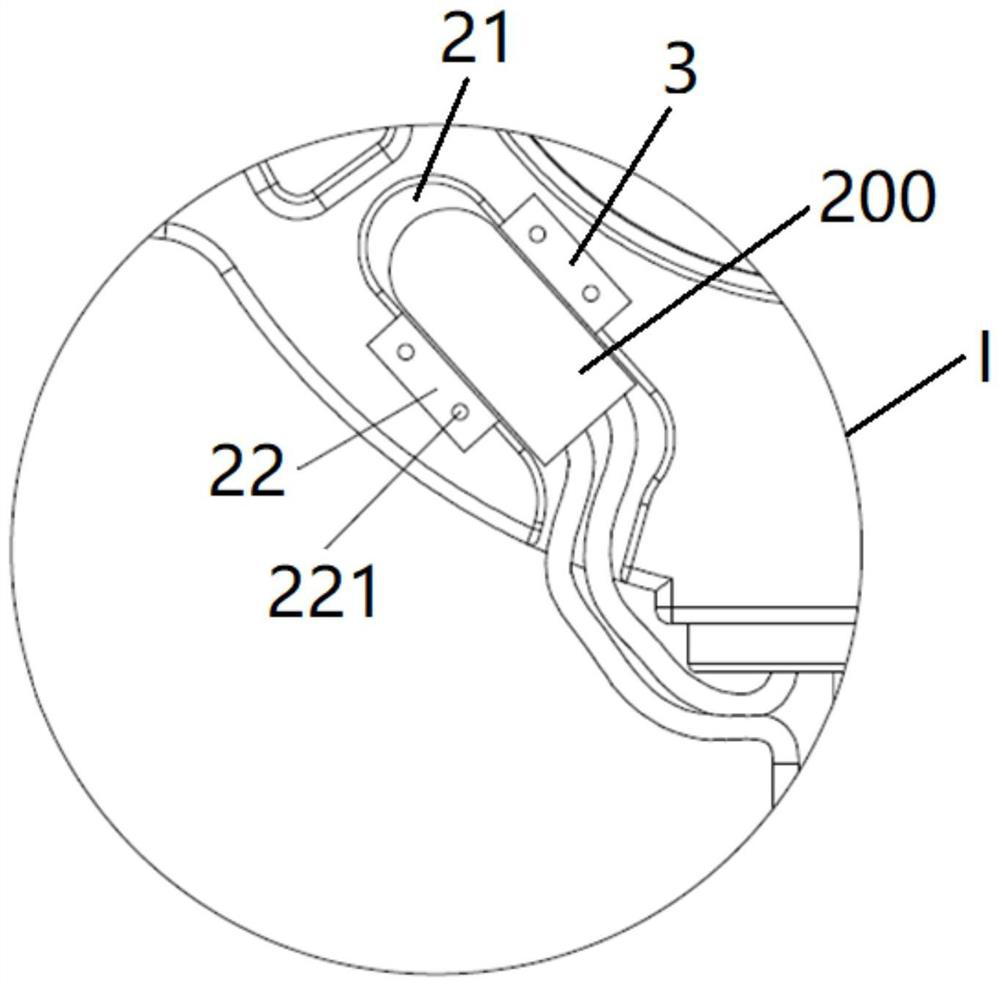

[0023] Such as Figure 1 to Figure 4 As shown, the figure schematically shows that the plastic-encapsulated motor includes a stator 1 , a thermal protector installation position 2 and a fastener 3 .

[0024] In the embodiment of the present invention, the installation position 2 of the thermal protector is arranged on the installation angle plane of the stator 1 .

[0025] The fastener 3 is covered on the thermal protector installation position 2, wherein the fastener 3 is intersected with the thermal protector installation 2, and the two ends of the fastener 3 extend through the thermal protector installation both sides of bit 2. Specifically, the thermal protector 200 of the plastic-encapsulated motor in the prior art is fixed by means of a bracket and the injection-molded stator, and is installed on one side of the injection-molded stator. However, due to different lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com