Method and device for in-tunnel demounting of master drive of shield tunneling machine

A main drive and shield machine technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of waste and inconvenience in disassembling the main drive, and achieve the effect of improving construction efficiency, occupying less space, and realizing disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

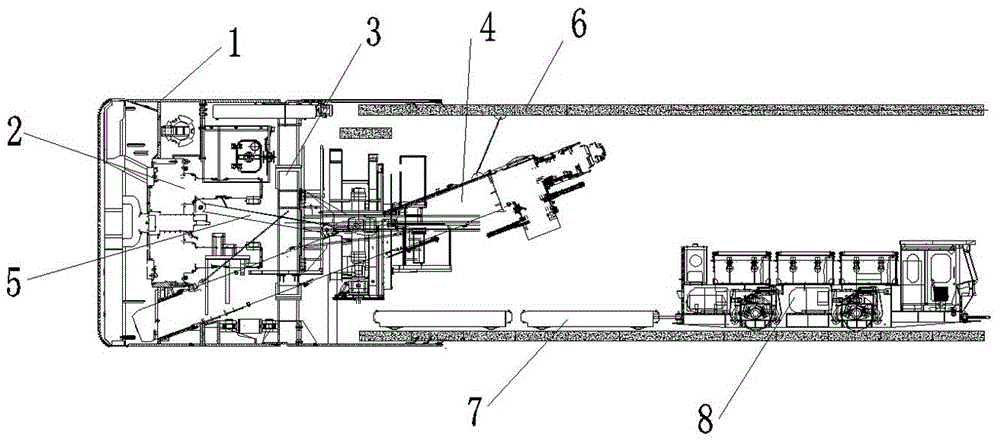

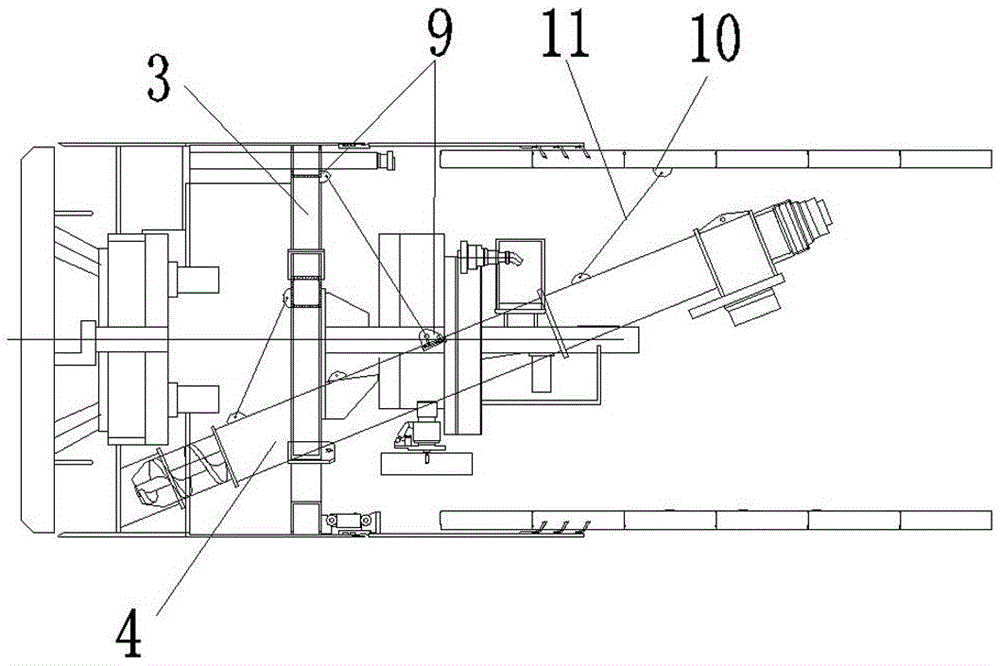

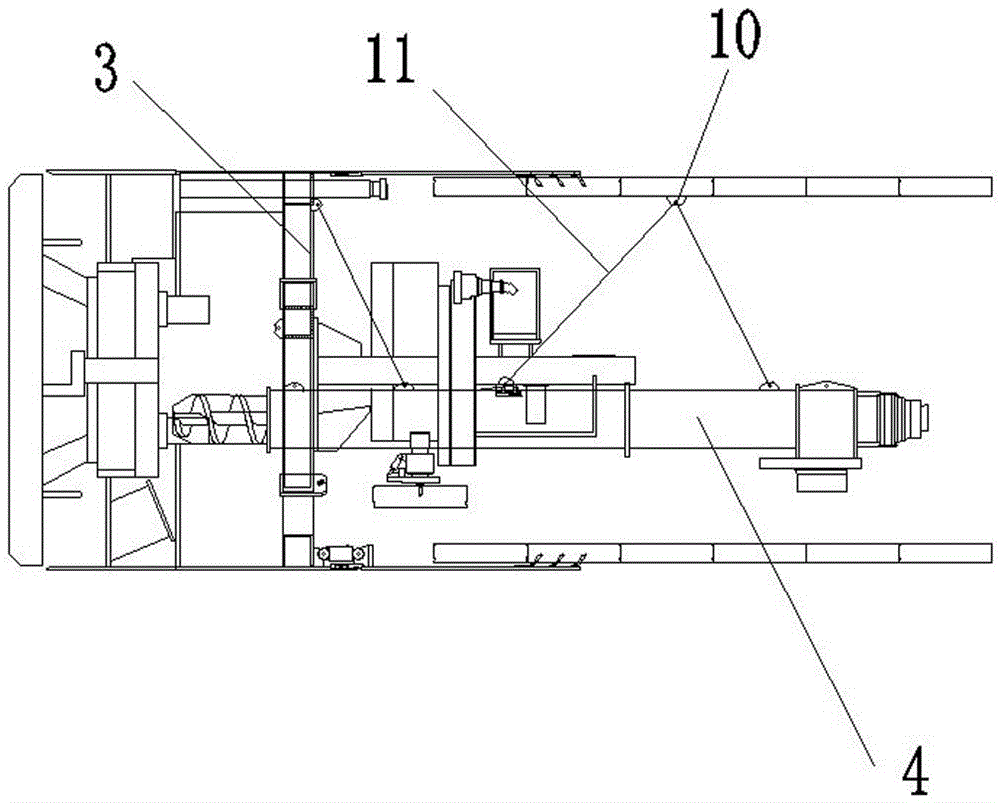

[0031] see figure 1 with figure 2 , provides a main driving device for removing the hole of a shield machine, including a shield body 1 and a main driving device 2 at the front end of the shield body, and a P-shaped beam 3 and a screw conveyor 4 arranged inside the shield body, wherein the main driving device 2 Connected with the screw conveyor 4 through the pull rod 5, a plurality of lifting lugs 9 are welded on the Pozir beam 3, and lifting lugs 9 are also arranged at the front end, the middle position and the tail of the screw conveyor. A hoisting base point 10 is arranged above the tail, wherein the upper lugs of the Pozir beam and the upper lugs of the screw conveyor, and the upper lugs of the screw conveyor and the hoisting base point are all connected to each other by hoisting equipment 11 .

[0032] The lifting base point 10 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com