Patents

Literature

173results about How to "Hoisting safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

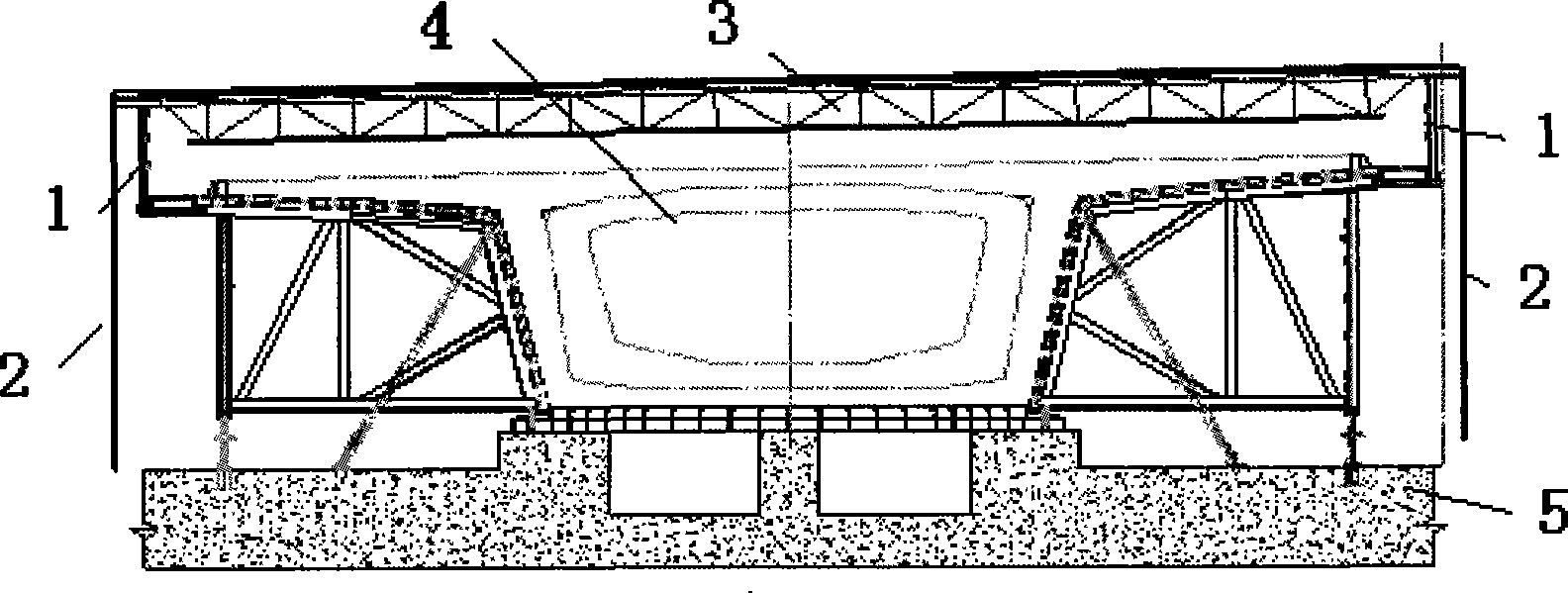

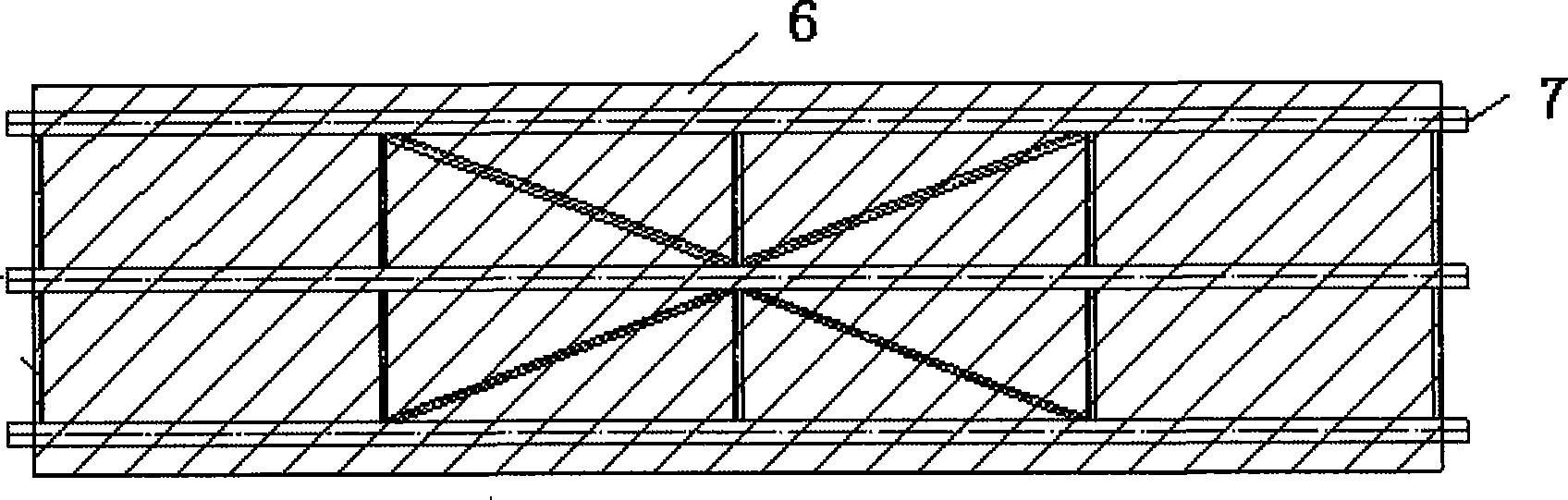

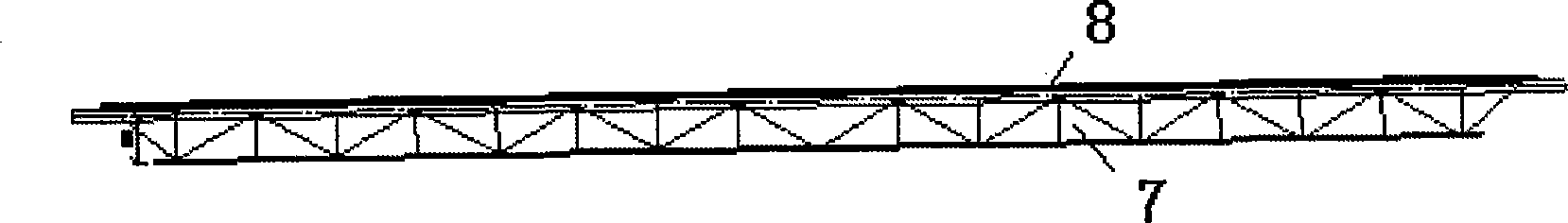

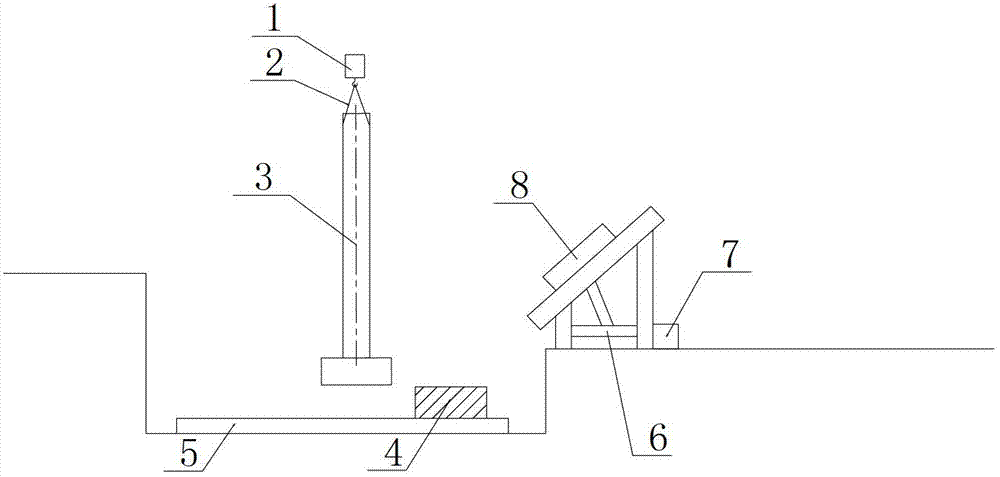

Precast beam maintaining apparatus and maintaining method

InactiveCN101244607ATight liftingHoisting safetyCeramic shaping apparatusTemperature measurementEngineering

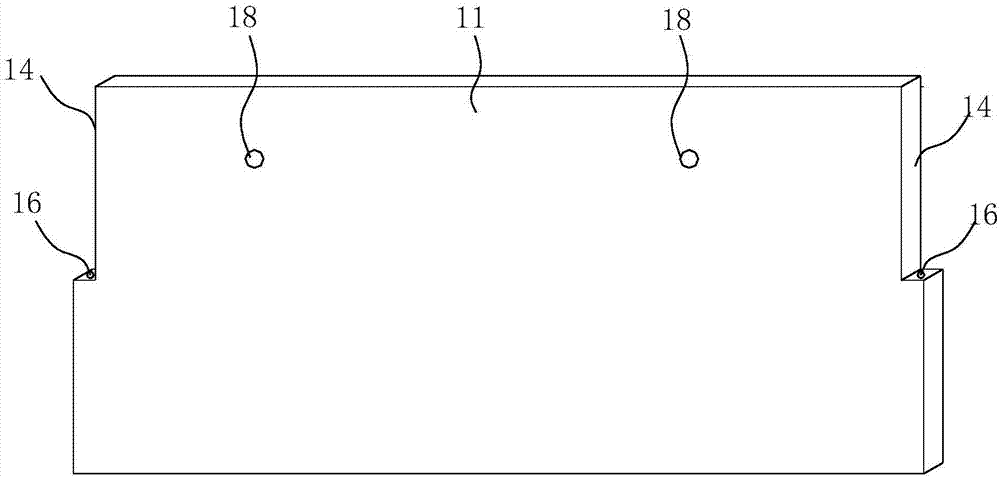

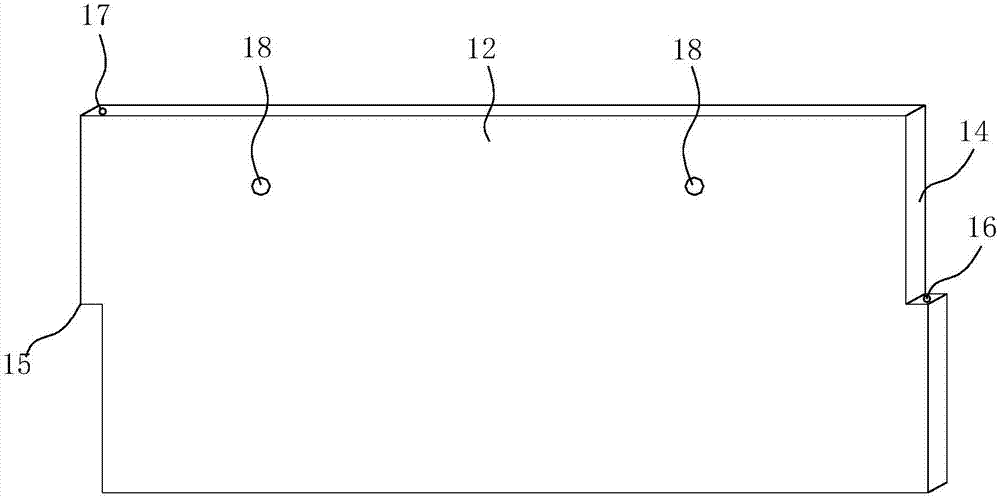

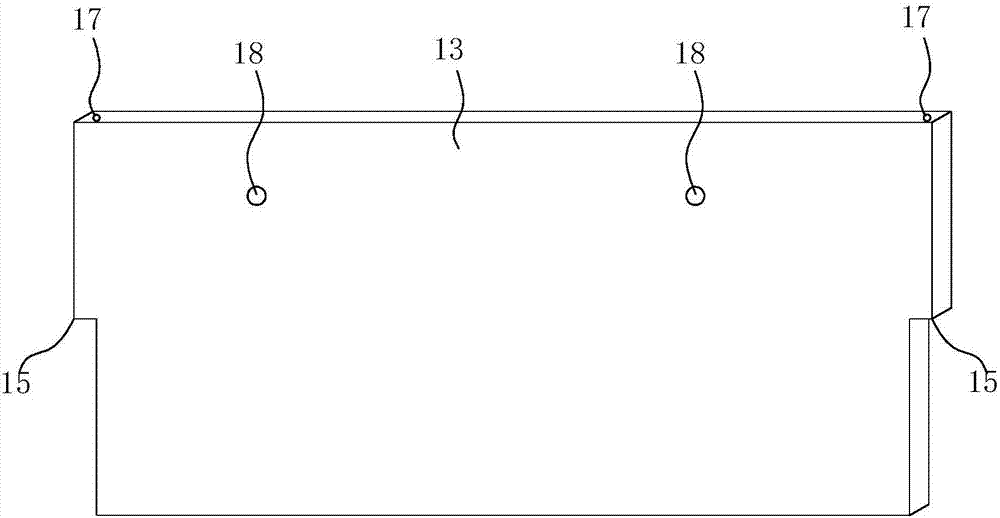

The invention relates to a curing device for a precast beam, which is characterized in that: a steaming shelf and a piece of tarpaulin covering around the shelf together form a curing shield; the shelf comprises a rigid framework and a cover plate, and a temperature control device and a humidifying device are arranged in the curing shield; the temperature control device comprises a temperature regulating device and a temperature measuring device. The invention also relates to the curing method for the precast beam, which is characterized in that: the moisture and temperature preservation curing temperature should be controlled between 30 and 35 DEG C, and water can be splashed on the concrete surface to maintain the moisture. The curing device and method for the precast beam in the invention has the advantages of convenient hoisting and mounting, small temperature difference inside and outside the concrete during curing, desirable development of the concrete strength, earlier time for removing the internal mold, faster construction speed, better construction efficiency, assurable precast quality of the box girder, and lower costs.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

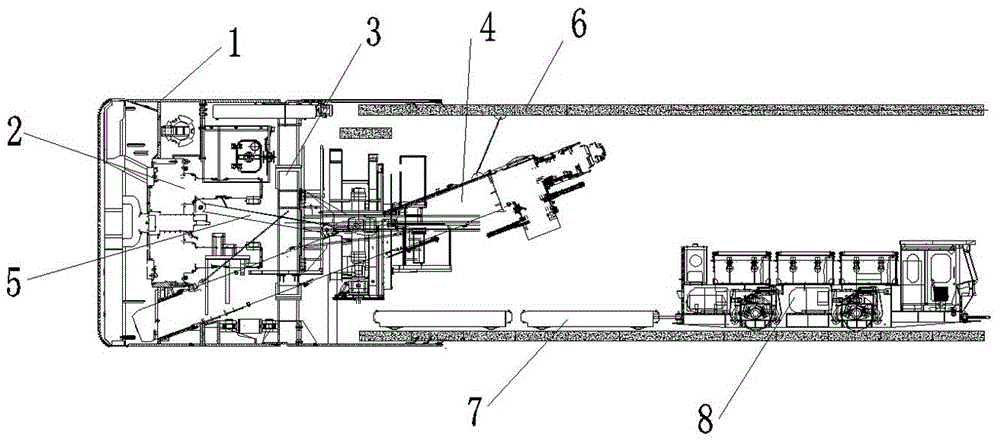

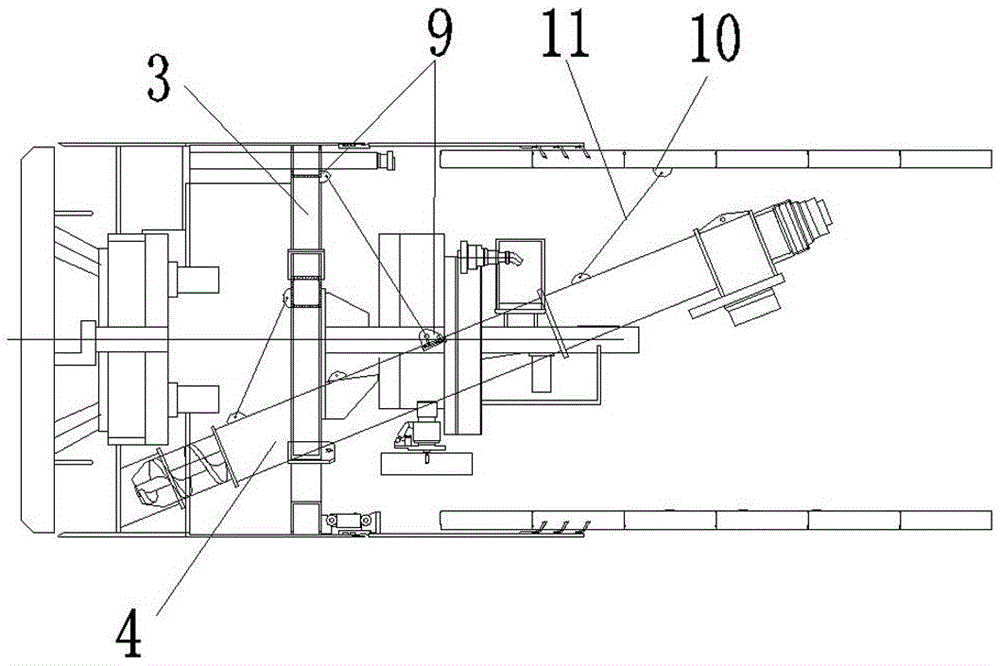

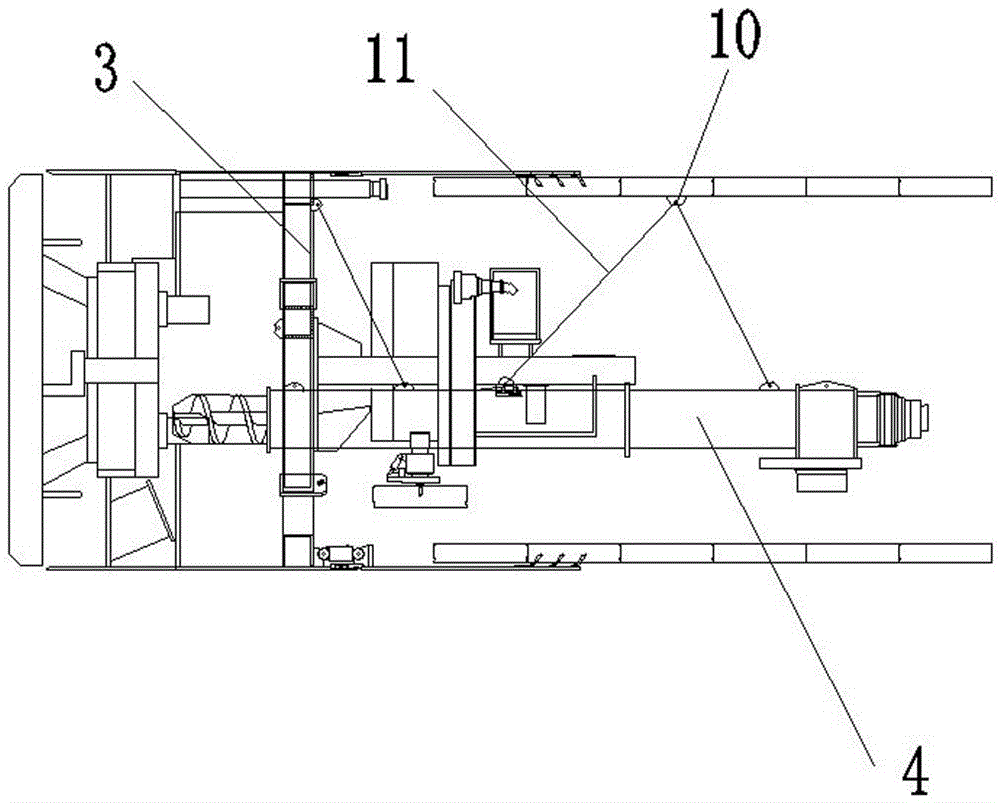

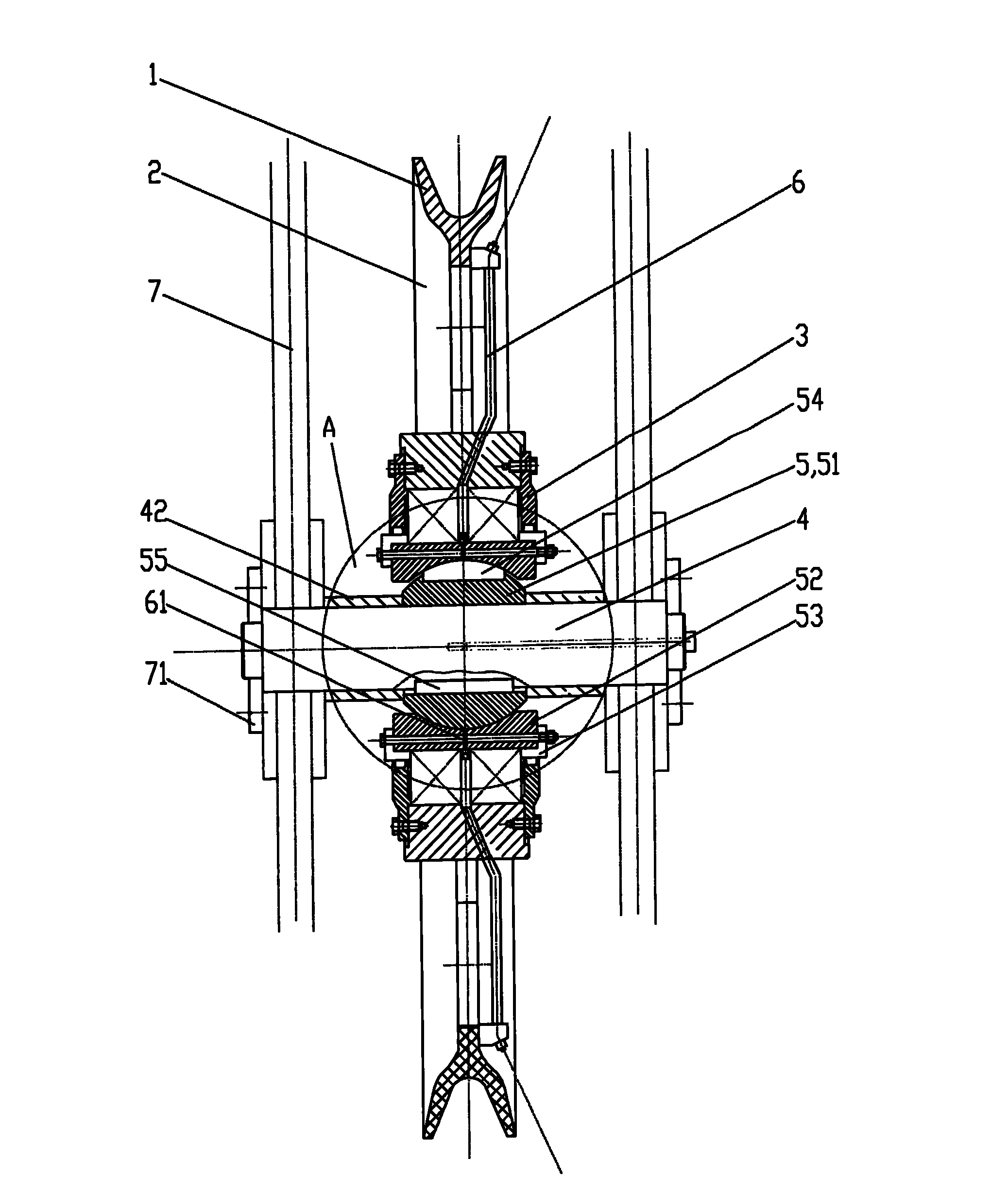

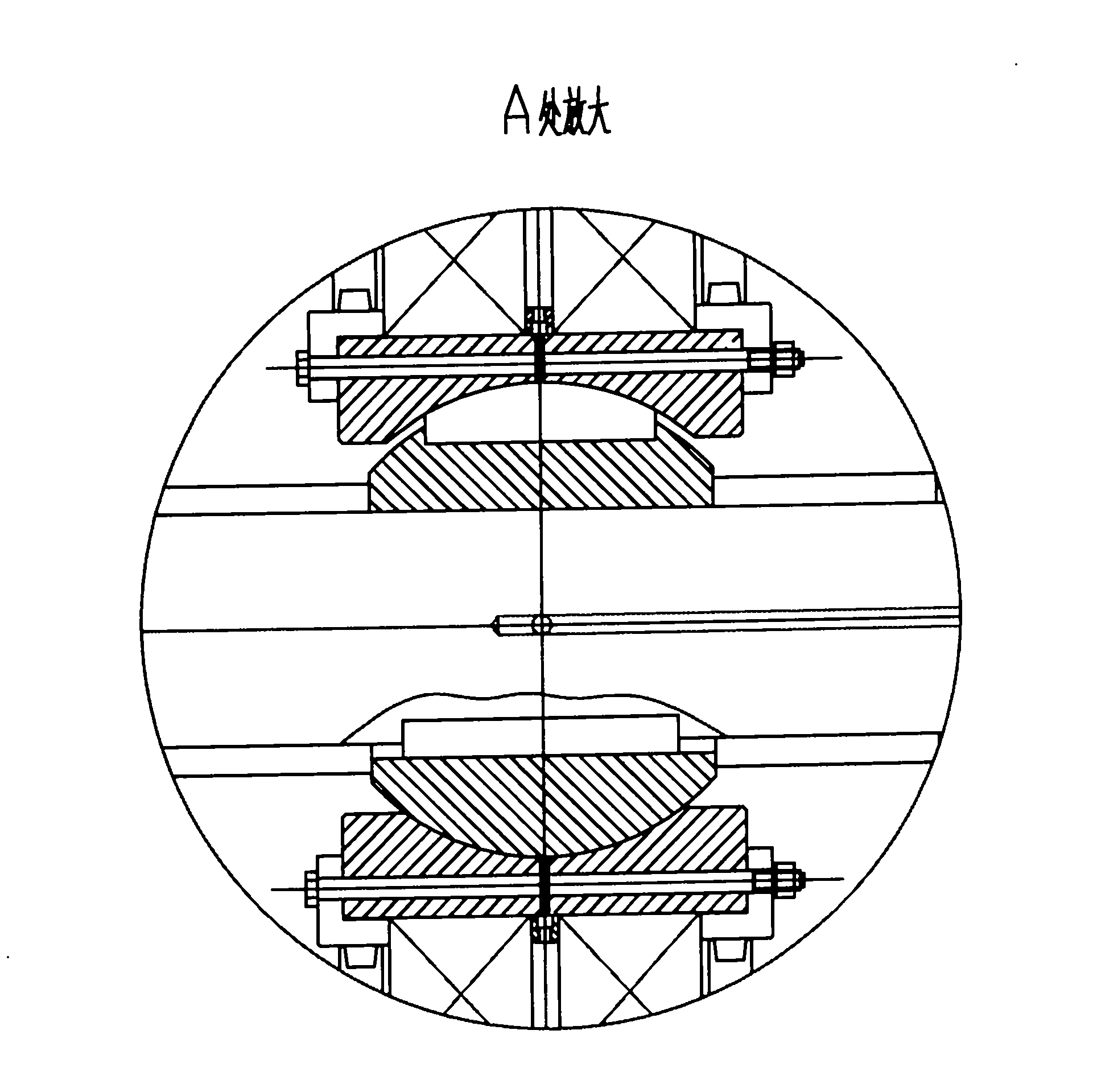

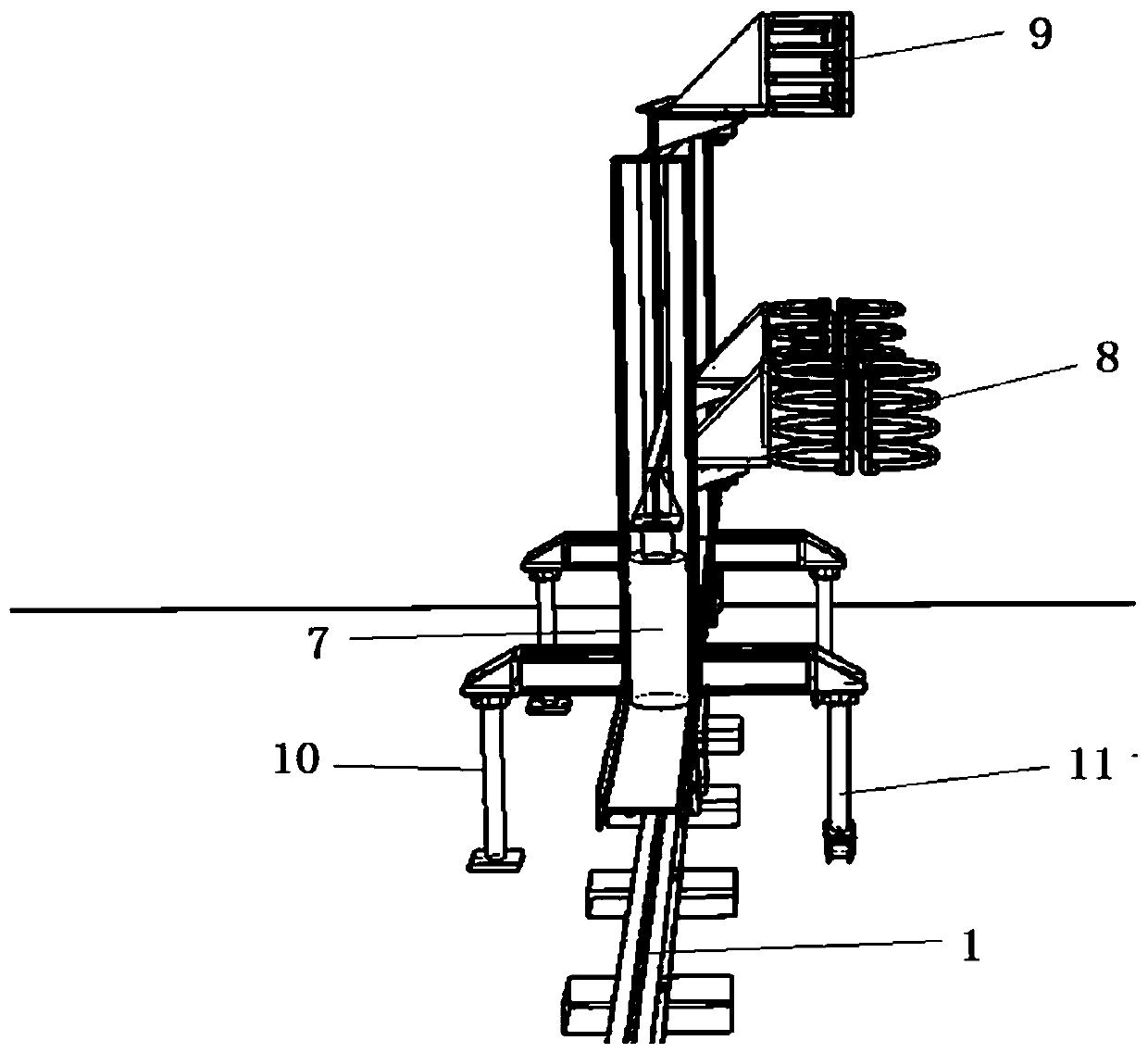

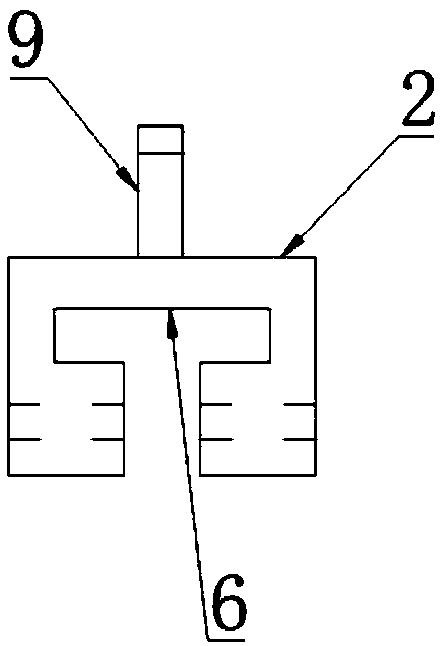

Method and device for in-tunnel demounting of master drive of shield tunneling machine

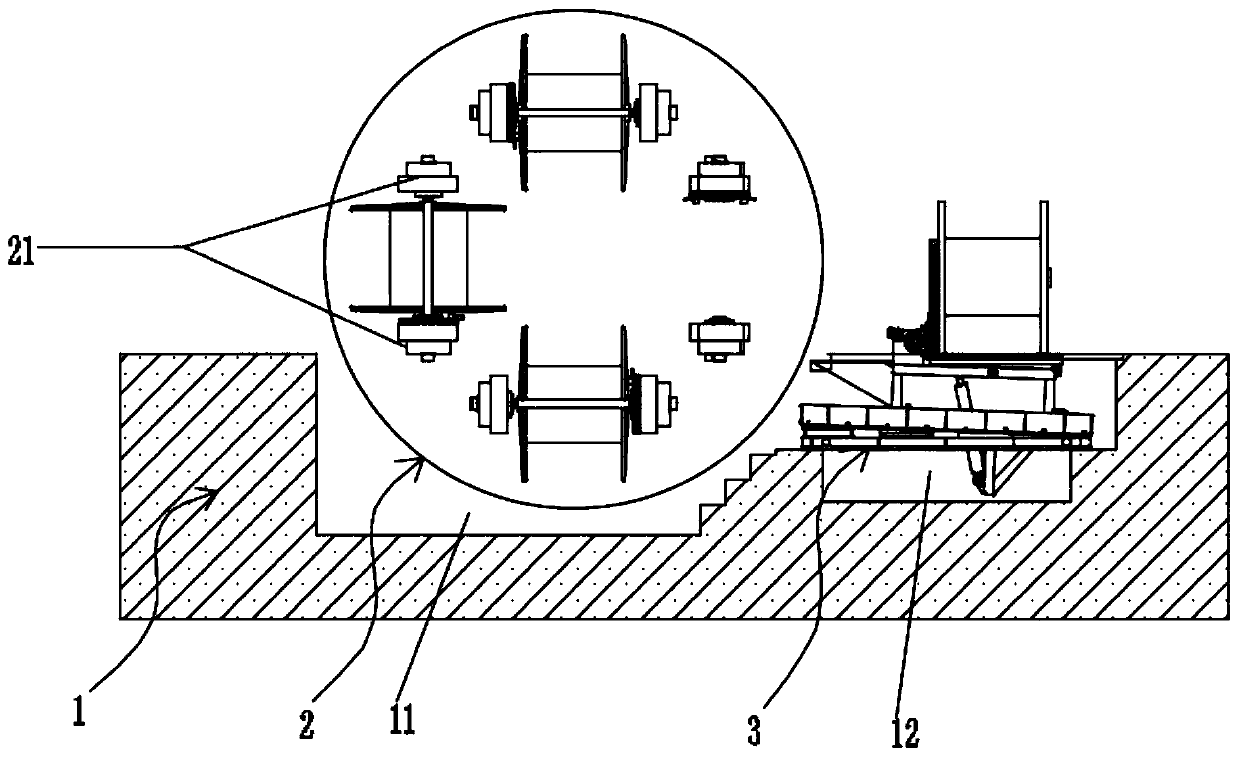

The invention belongs to the technical field of tunneling construction of shield tunneling machines for tunnels, particularly relates to a device for in-tunnel demounting of a screw conveyer of the shield tunneling machine and mainly provides a novel method and a novel device for demounting of a master drive of the shield tunneling machine. In order to realize in-tunnel mounting and demounting of the master drive of the shield tunneling machine and guarantee safety and effectiveness in in-tunnel assembly, maintenance and disassembly of the master drive of the shield tunneling machine, a device for in-tunnel demounting of the master drive of the shield tunneling machine is provided and comprises a shield, the master drive, the screw conveyer and a beam shaped as a Chinese character 'mi' meaning rice, the master drive is arranged at the front end of the shield, and the beam is arranged in the shield. A plurality of lifting lugs are welded to the beam, a lifting base point is arranged above the tail of the screw conveyer, and the lifting lugs on the beam and lifting lugs on the screw conveyer are connected. The method and the device for in-tunnel demounting of the master drive of the shield tunneling machine have the advantages that in-tunnel mounting and demounting of the master drive are realized effectively, in-tunnel mounting, demounting and maintenance of the master drive are facilitated, construction efficiency is improved, and hoisting and mounting of large structural parts can be realized safely.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

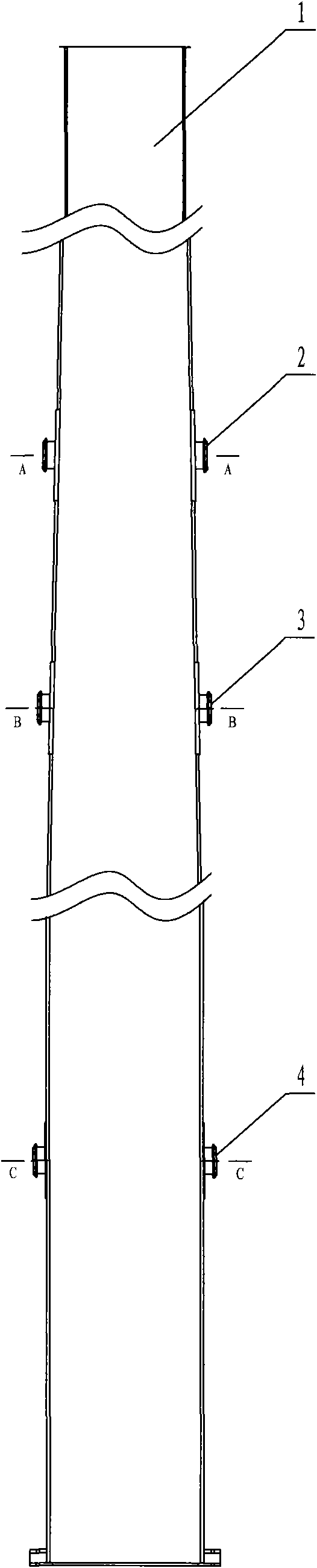

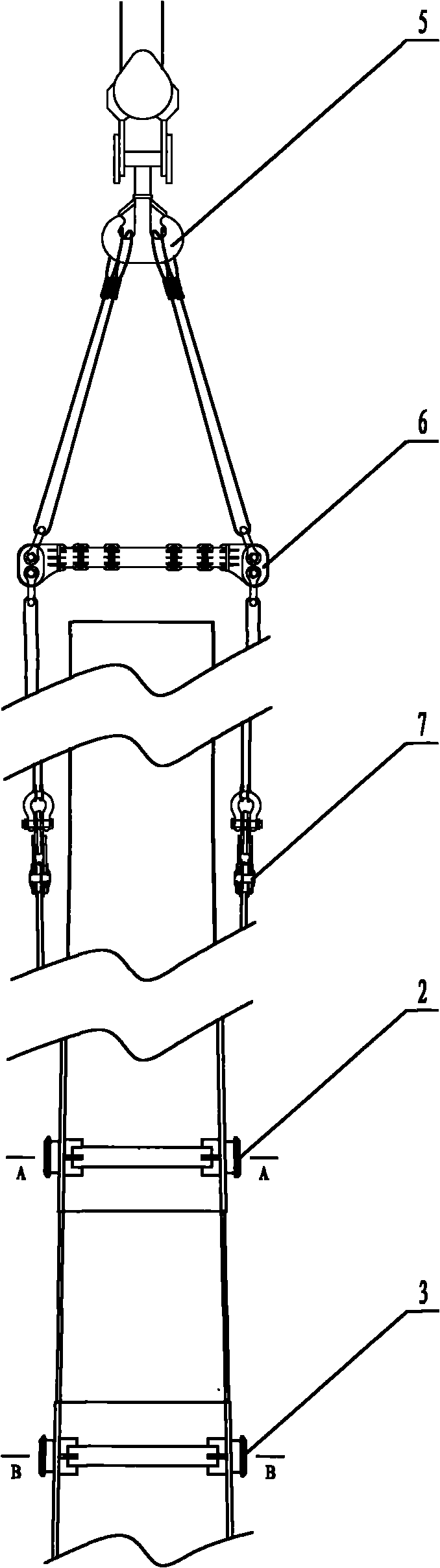

Hoisting method of thin-wall long and thin large-size equipment

InactiveCN101830393AStable hoistingHoisting safetyLoad-engaging elementsMarine engineeringLarge size

A hoisting method of thin-wall long and thin large-size equipment comprises the following steps of: arranging two upper groups of main lifting lugs I and two lower groups of main lifting lugs II on the thin-wall long and thin large-size equipment; arranging two sliding tail lifting lugs at the tail of the thin-wall long and thin large-size equipment, wherein the distance from the sliding tail lifting lugs to the bottom end is 0.14 time of total length; by using a formed integral steel wire rope hoisting system, lifting off a saddle by using a main hoist and an auxiliary hoist; after the saddle is removed, crowing, advancing and rotating by using the main hoist; crowing and rotating by a sliding tail hoist along with the main hoist; and when the elevation of the equipment reaches 70-75 degrees, gradually loosening a lifting hook by using the auxiliary hoist , rotating by using the main hoist after the equipment erects and hoists the equipment to the in-place orientation to be in place. The invention has the advantages of stable and safe hoisting process, 100 percent of quality integrity of the equipment and inner parts, less than 0.2 thousands of ratio of the deflection to the span length during the hoisting, stability, smoothness and safe operation in the whole hoisting process.

Owner:中国石化集团第五建设公司

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

Technological method for hoisting special large-sized equipment using rotary balance process

ActiveCN1850576AAddress site and space issuesShorten the construction periodLifting devicesCranesEngineeringWork time

The invention is about the process to hang the large device by the rotary balance method. It to fix the large device frame off-center to make a fulcrum to balance the frame gravitation and the hoister lifting force. The load of the hoister is much less than the gravitation of the frame, so the hoister can lift large device in the present workshop space. So it can decrease the working time and the cost.

Owner:SHANGHAI BAOYE GRP CORP

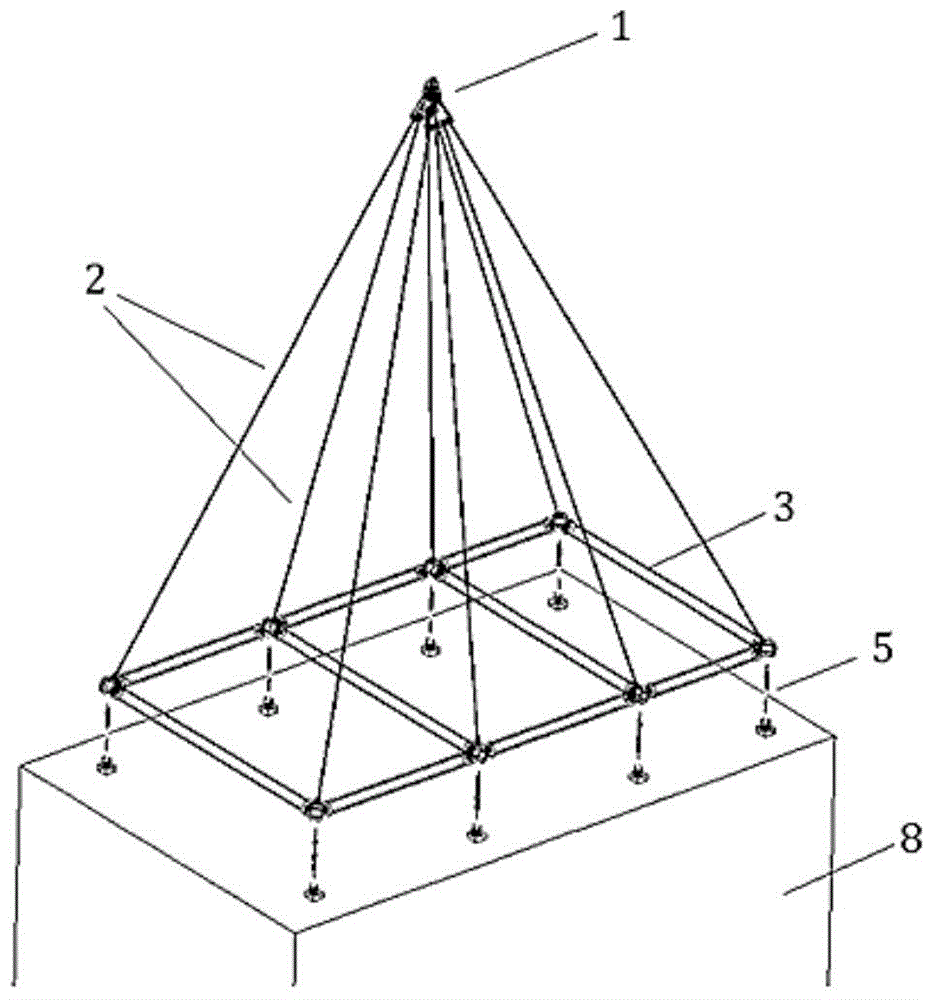

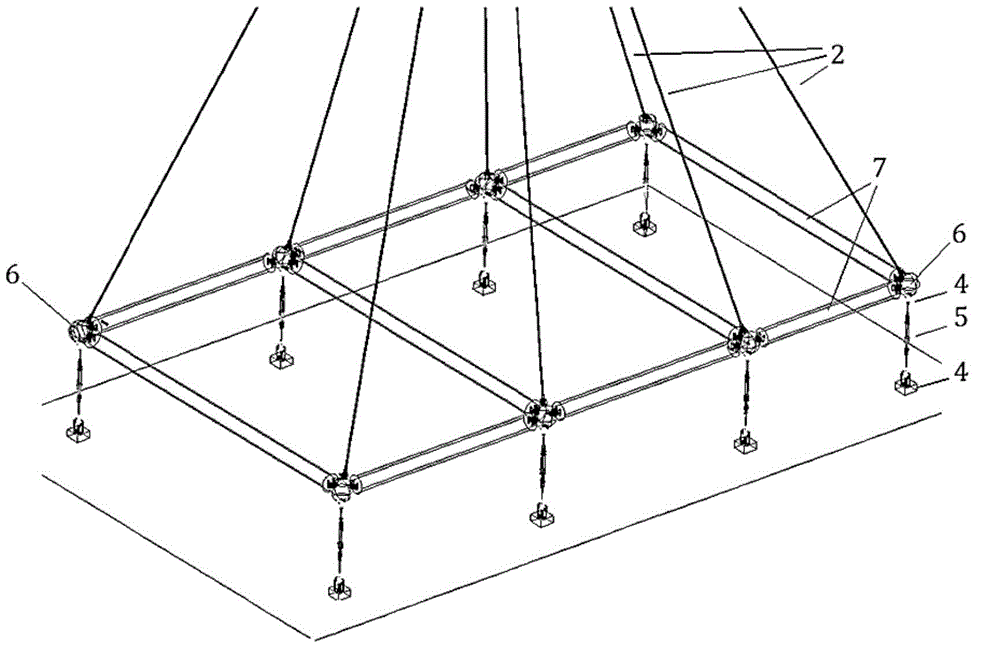

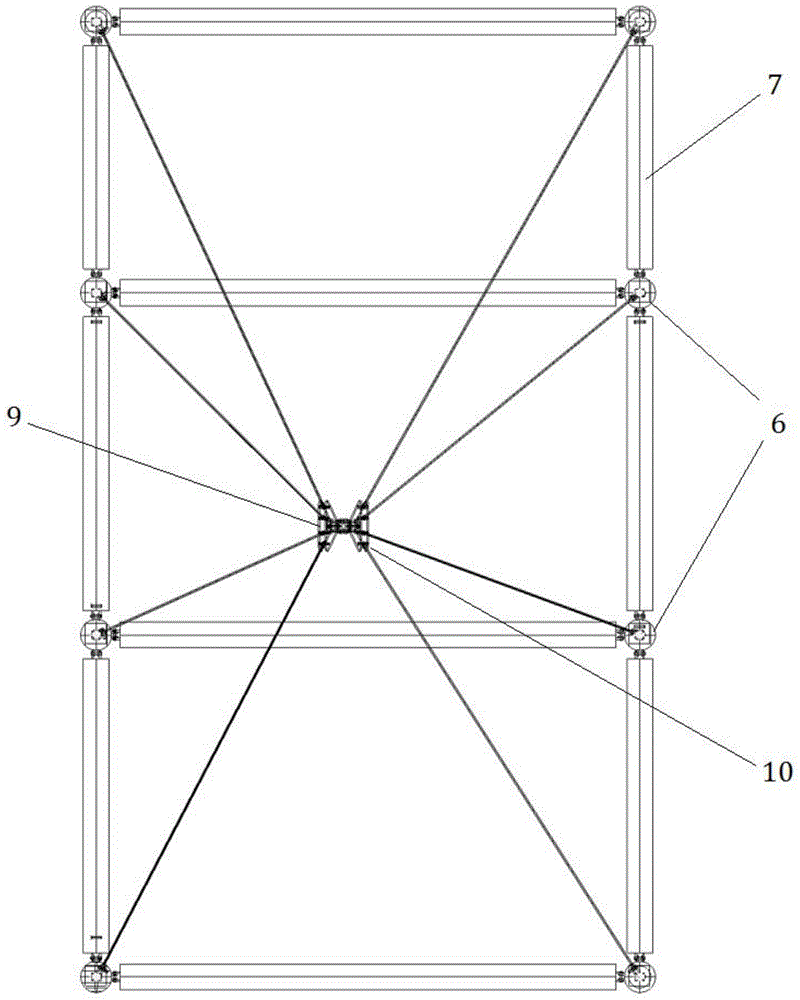

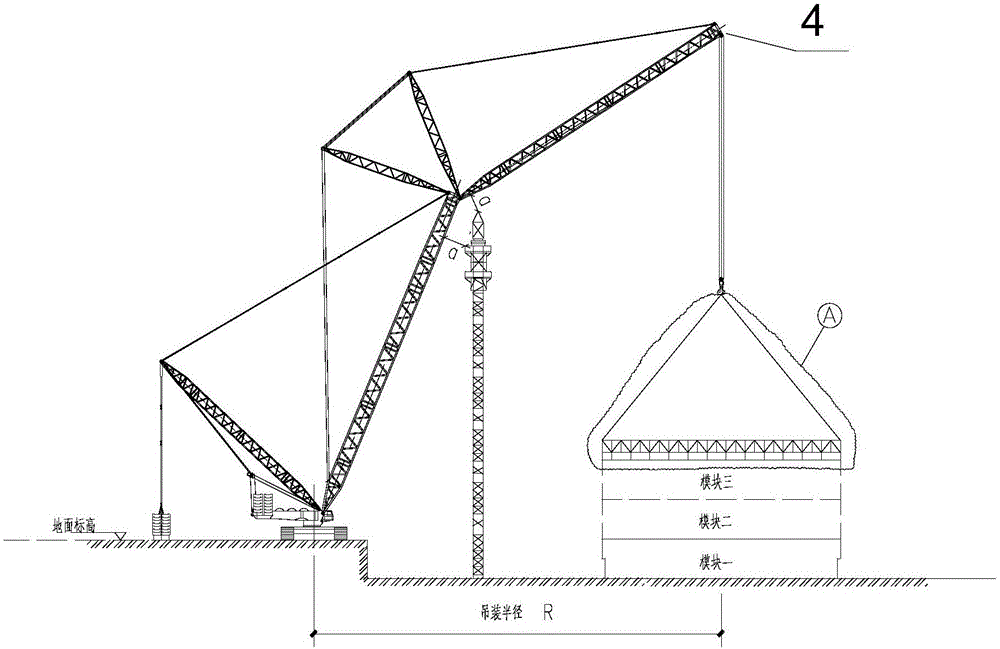

Special sling for hoisting extra-large structural modules for nuclear power plants

ActiveCN104649128AReduce your weightImprove effective transportation capacityLoad-engaging elementsNuclear powerWorking temperature

The invention discloses a special sling for the hoisting extra-large structural modules for nuclear power plants, which belongs to the field of mechanical engineering. The special sling comprises a distributor, multiple steel tube beams and multiple connecting nodes, wherein the steel tube beams are connected in pairs by the connecting nodes so as to form balancing beam frames, and the balancing beam frames are respectively connected with the distributor and a hoisting module; and the length of an upper hoist cable can be adjusted according to the position of the center of gravity of a lower hoisting module, so that the distributor is aligned at the center of gravity of the lower hoisting module in the up-and-down direction. According to the special sling, a hydraulic oil cylinder is adopted to be connected with a hanging bracket and hoisted objects, the appearance of the hydraulic oil cylinder is exquisite, the self weight of the hydraulic oil cylinder is reduced, but the hydraulic oil cylinder can bear a large force, and the hydraulic oil cylinder is made of 45# high-quality carbon steel, so that the hydraulic oil cylinder has the characteristics of fatigue resistance, impact resistance, non-magnetism, and the like; and the working temperature of the hydraulic oil cylinder can be minus 60-200 DEG C, so that after running for 6000 hours, the hydraulic oil cylinder with super-long service life has no fault. Therefore, the hanging bracket and the hoisted objects connected simply and conveniently, errors are easy to control, and the service life is long.

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD

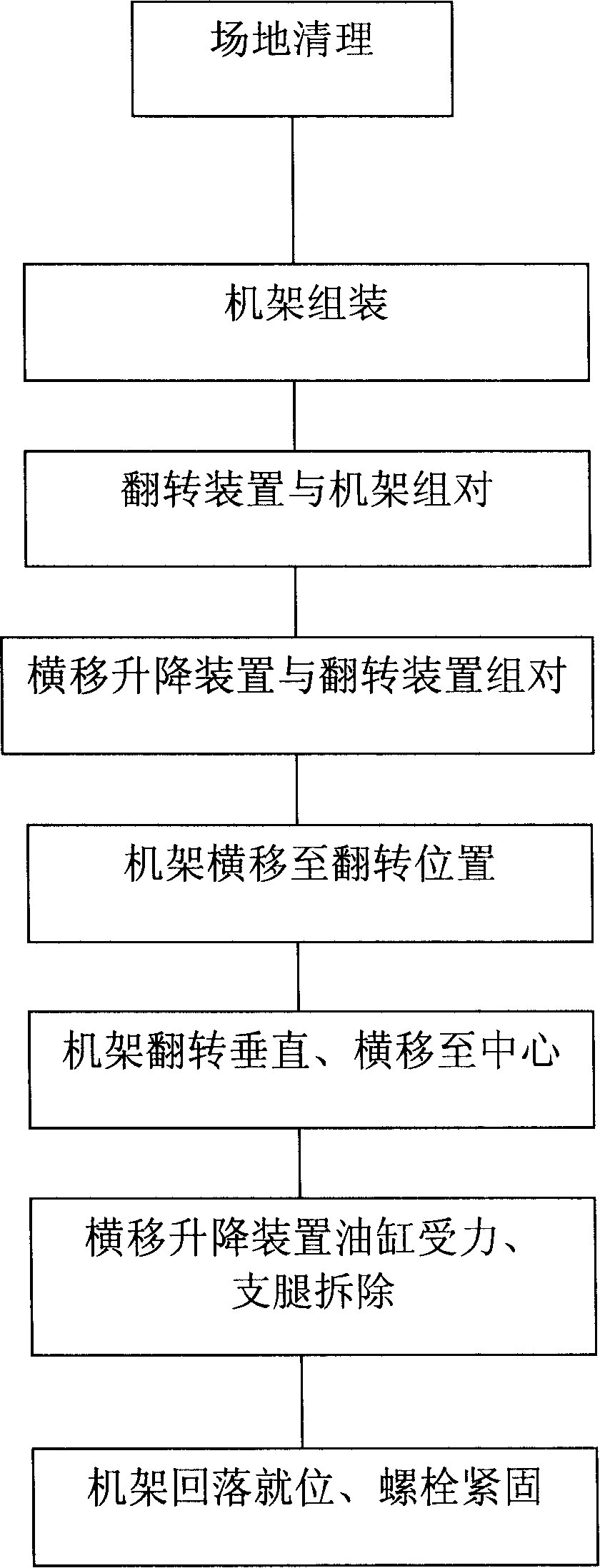

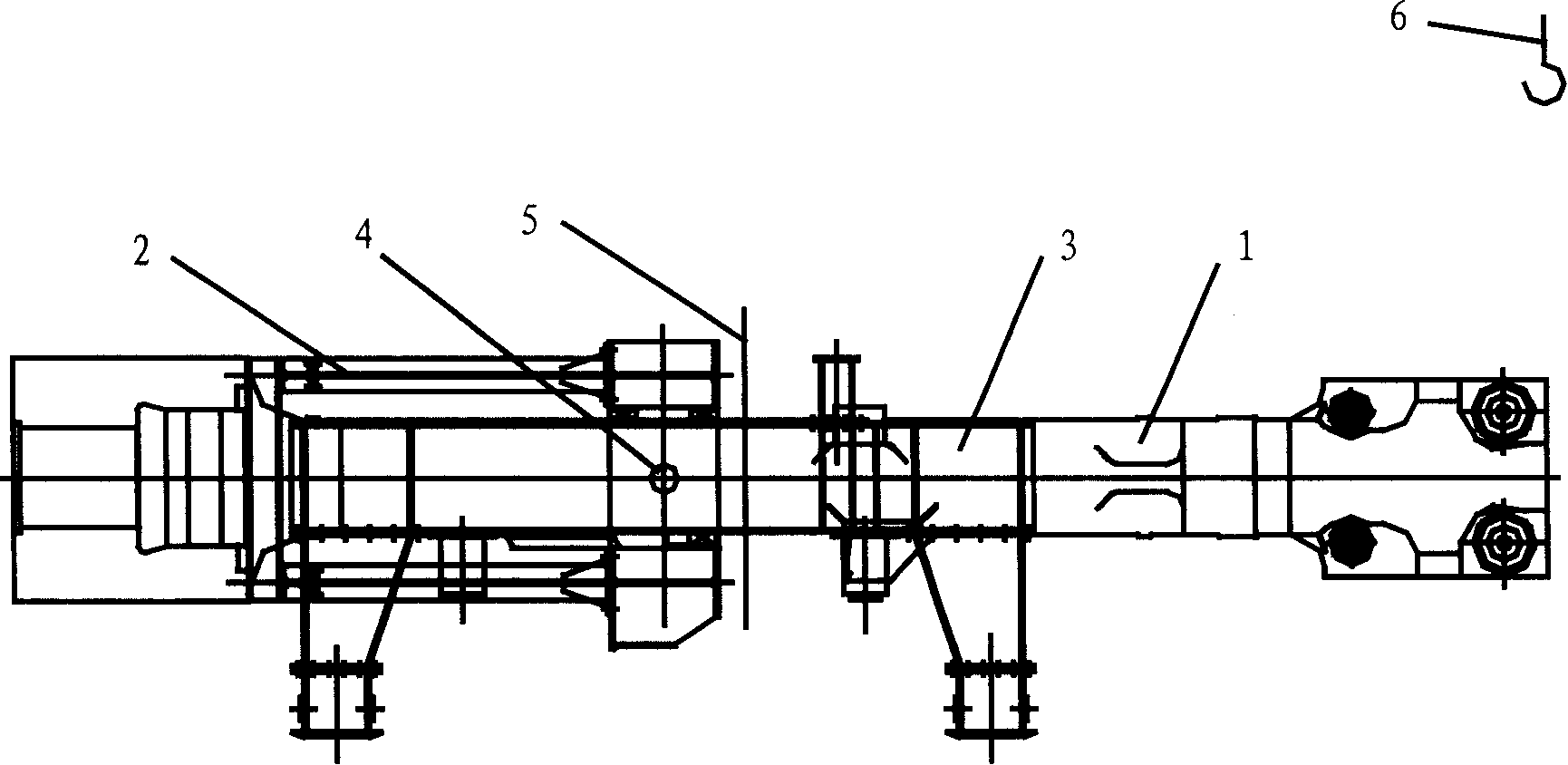

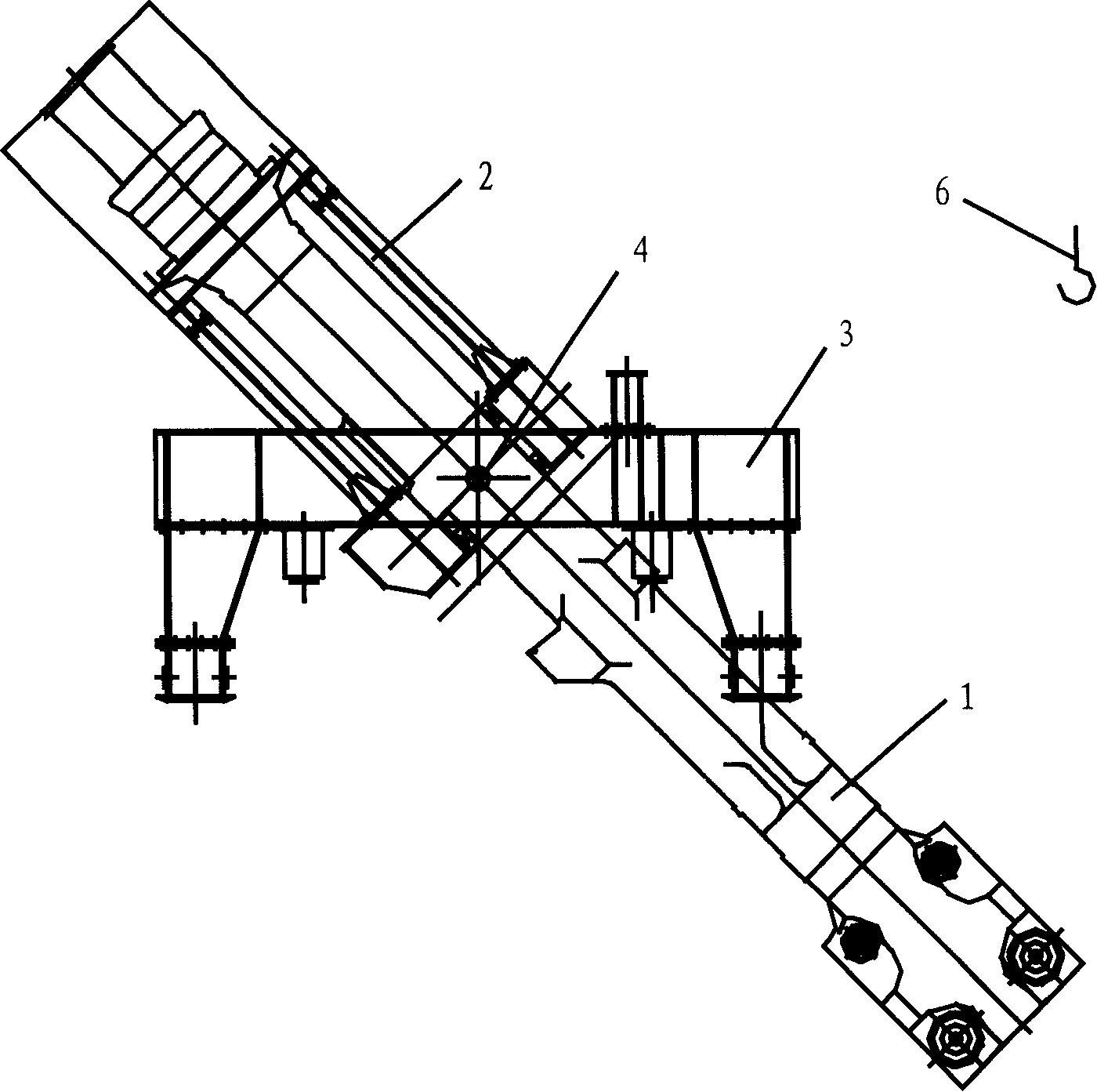

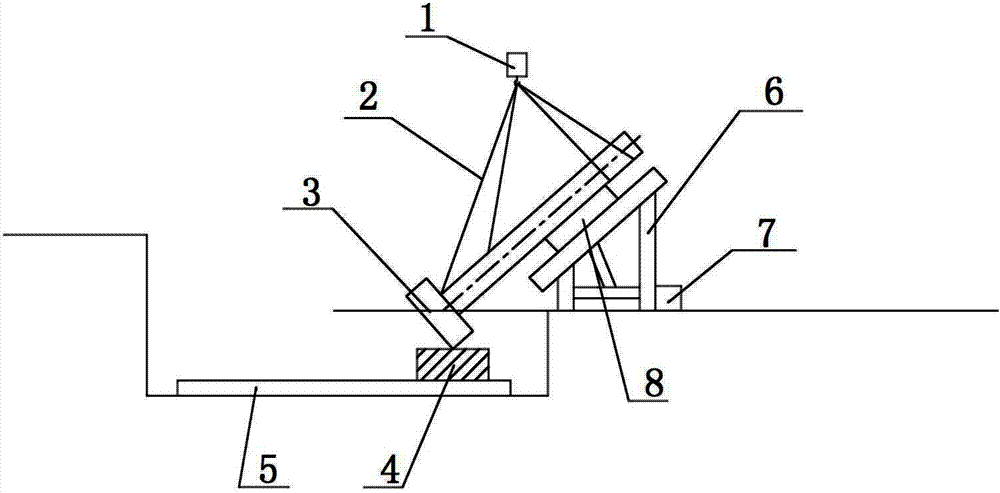

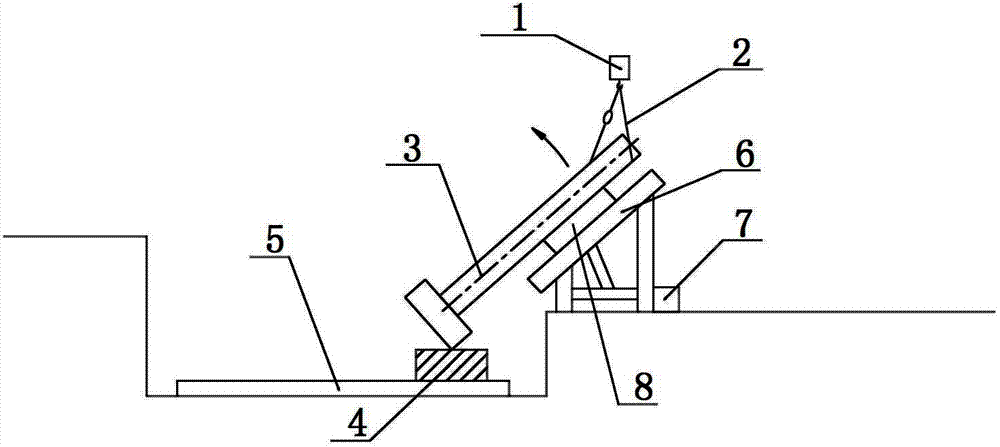

Method for hoisting rolling mill housing

InactiveCN102756975AOvercoming the Difficulty of Insufficient Lifting HeightHoisting safetyLoad-engaging elementsStrip millEngineering

The invention discloses a method for hoisting a rolling mill housing, which comprises the following steps: 1), before the rolling mill housing is hoisted, a housing support frame is fixed on a roll change carriage rail of a rolling mill; a stop block is arranged at the end, far away from the bottom plate of the rolling mill, of the roll change carriage rail; an inclined support panel is arranged on the housing support frame; sleepers are mounted on the bottom plate of the rolling mill; and the rolling mill housing in an inclined state is hoisted to the roll change carriage rail of the rolling mill in such a manner that the central line of the rolling mill housing is superposed on that of the rolling mill, the bottom of the rolling mill housing falls on the sleepers, and the upper part of the rolling mill housing falls on the inclined support panel; and 2), a sling is arranged at the upper end of the rolling mill housing; and the rolling mill housing is hoisted to be vertical and then hoisted to a preset position on the bottom plate of the rolling mill horizontally through a crane, and falls on the bottom plate of the rolling mill, so as to hoist the mill housing in place. According to the invention, the problem that the hoisting of the main hook of a crown block equipped in a construction site is insufficient can be solved, so as to ensure safe, smooth and reliable hoisting.

Owner:TIANJIN 20 CONSTR

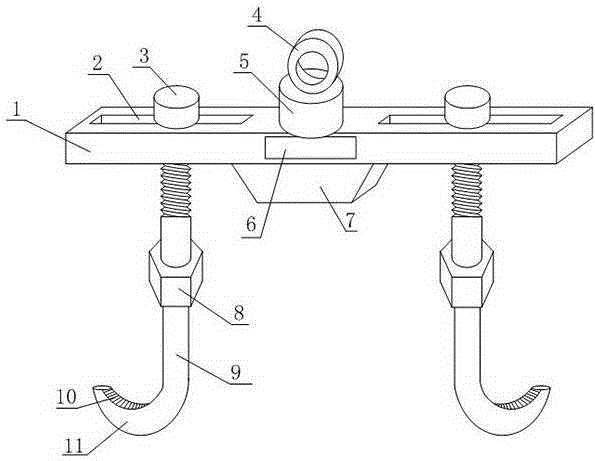

Reinforcing mesh sling and hoisting method for reinforcing mesh

ActiveCN104692227AHoisting safetySimple structureBuilding material handlingLoad-engaging elementsEngineeringRebar

The invention discloses a reinforcing mesh sling and a hoisting method for a reinforcing mesh. The reinforcing mesh sling comprises a retainer and multiple hooks used for hooking and hanging the reinforcing mesh, wherein the multiple hooks are arranged in multiple rows and multiple columns and fixed on the retainer, and the opening orientation of the hooks is the same. The reinforcing mesh sling disclosed by the invention is simple in structure, convenient to operate, safe and reliable in hoisting of the reinforcing mesh. The hoisting method for the reinforcing mesh disclosed by the invention is based on a hoisting method of the reinforcing mesh sling disclosed by the invention, therefore, the rapid and safe hoisting of the reinforcing mesh can be achieved.

Owner:CABR TECH CO LTD

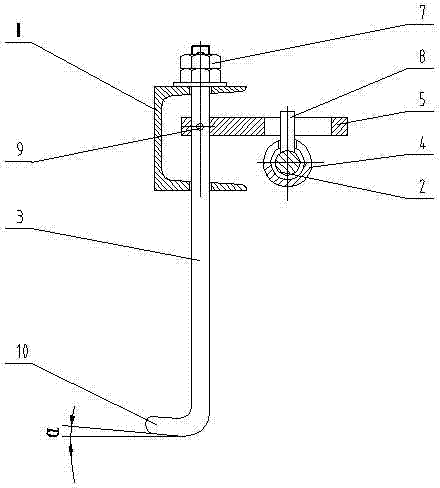

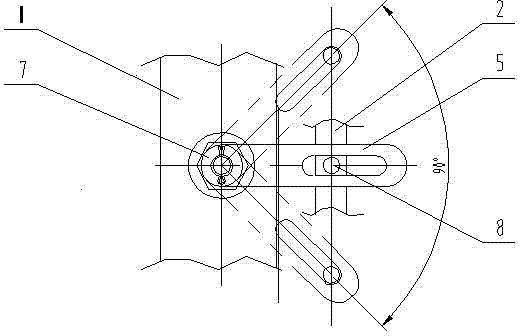

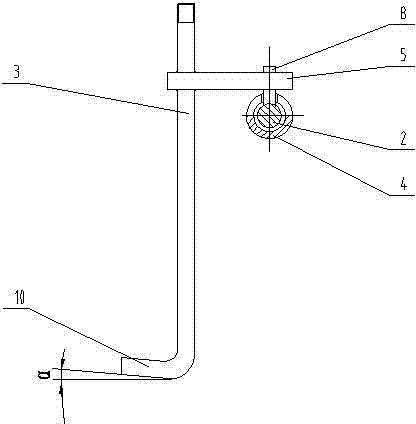

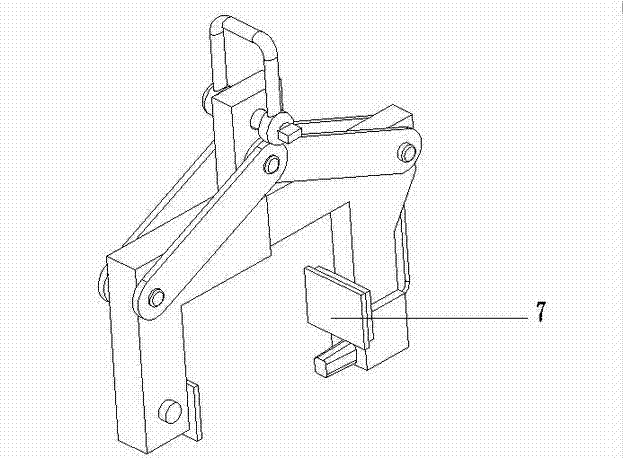

Lifting device for electrolytic copper plates

InactiveCN103539002APrevent slippageImprove work efficiencyLoad-engaging elementsStructural engineeringMechanical engineering

The invention relates to a lifting device for electrolytic copper plates. The lifting device is characterized in that through holes which are formed in equal intervals and are used for installing lifting hooks are formed in channel steel at the two sides of a triangular frame in a drilling manner, and the tops of the lifting hooks are fastened on the channel steel at the two sides of the triangular frame by means of nuts; swinging rods are fastened at the upper parts of the lifting hooks by positioning pins and are provided with long-strip channel holes; an included angle between a swinging rod and the horizontal plane of each of elbows at the lower ends of the lifting hooks is 135 degrees; the two ends of the triangular frame are provided with guide sleeves, and pushing rods parallel to the channel steel at the two sides of the triangular frame slide in the guide sleeves; the pushing rods are provided with vertical poking rods which are arranged at equal intervals; the poking rods are inserted into the long-strip channel holes and are matched with the long-strip channel holes in a sliding manner. In lifting, a crane puts down the triangular frame slowly, so that the elbows at the lower ends of the lifting hooks are inserted into gaps of the electrolytic copper plates which are arranged on a bracket at equal intervals, and further all the elbows are positioned below the left shaft end and the right shaft end of a hanging shaft of the electrolytic copper plates. The lifting device has the advantages that the operating efficiency is high, the electrolytic copper plates do not need to be hung by manual work in a one-by-one manner, the labor is saved and the lifting is safe and reliable.

Owner:江西江钨钴业有限公司

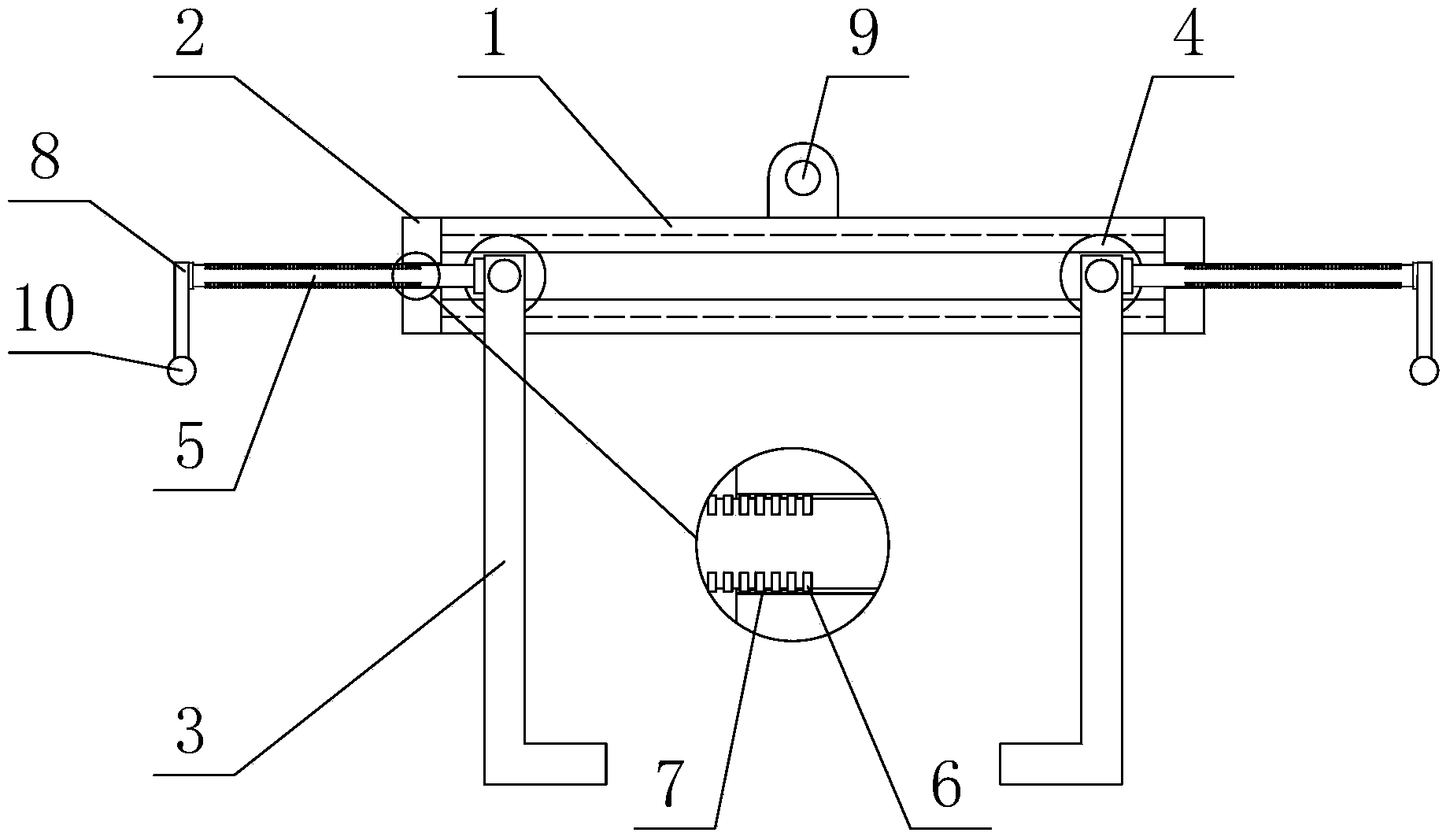

Steel coil hoisting tool

InactiveCN103626022AHoisting process safetyImprove hoisting efficiencyLoad-engaging elementsPush pullEngineering

The invention relates to a steel coil hoisting tool which comprises two parallel hoisting beams and end plates, wherein the end plates are used for connecting the two hoisting beams and are respectively positioned at both ends of the hoisting beams; each hoisting beam is a c-shaped steel with a long slot; the long slots of the two hoisting beams are opposite; two L-shaped hangers are arranged between the two hoisting beams; the L-shaped hangers are mounted between the two hoisting beams through rollers respectively embedded in the long slots of the two hoisting beams; two rollers are coaxial; through holes are respectively formed in the two end plates; push-pull rods in parallel to the hoisting beams are respectively inserted in the through holes; a plurality of latches are uniformly distributed on the push-pull rods in the axial direction; clamping grooves matched with the latches are formed in the inner sides of the through holes; the two push-pull rods are respectively connected with the two L-shaped hangers; handles perpendicular to the push-pull rods are mounted at the end parts outside the push-pull rods. The steel coil hoisting tool has the advantages of simple structure, convenience in use, firm structure, avoidance for damage to a steel coil, improvement on hoisting efficiency and elimination for potential safety hazards.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE

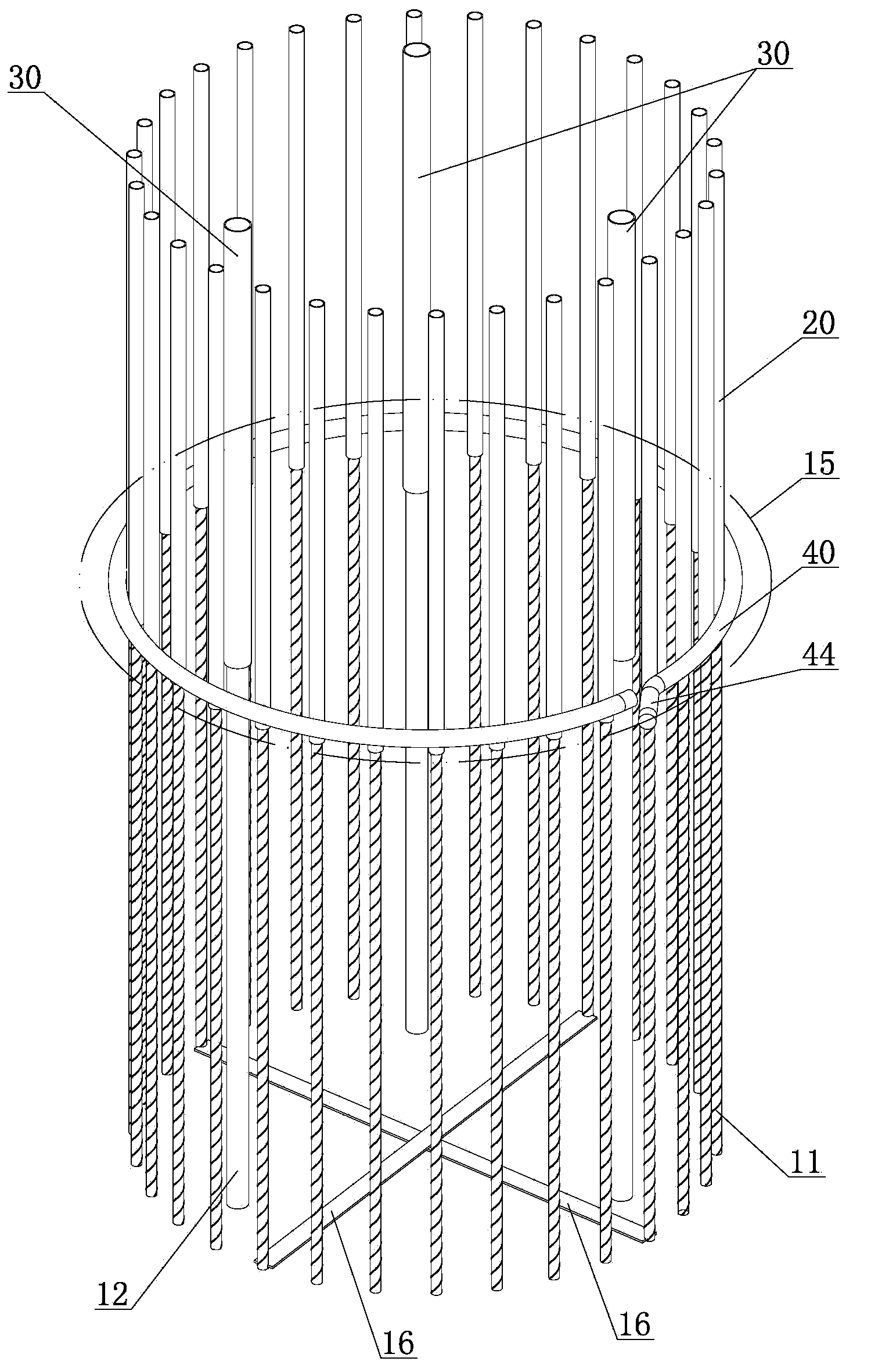

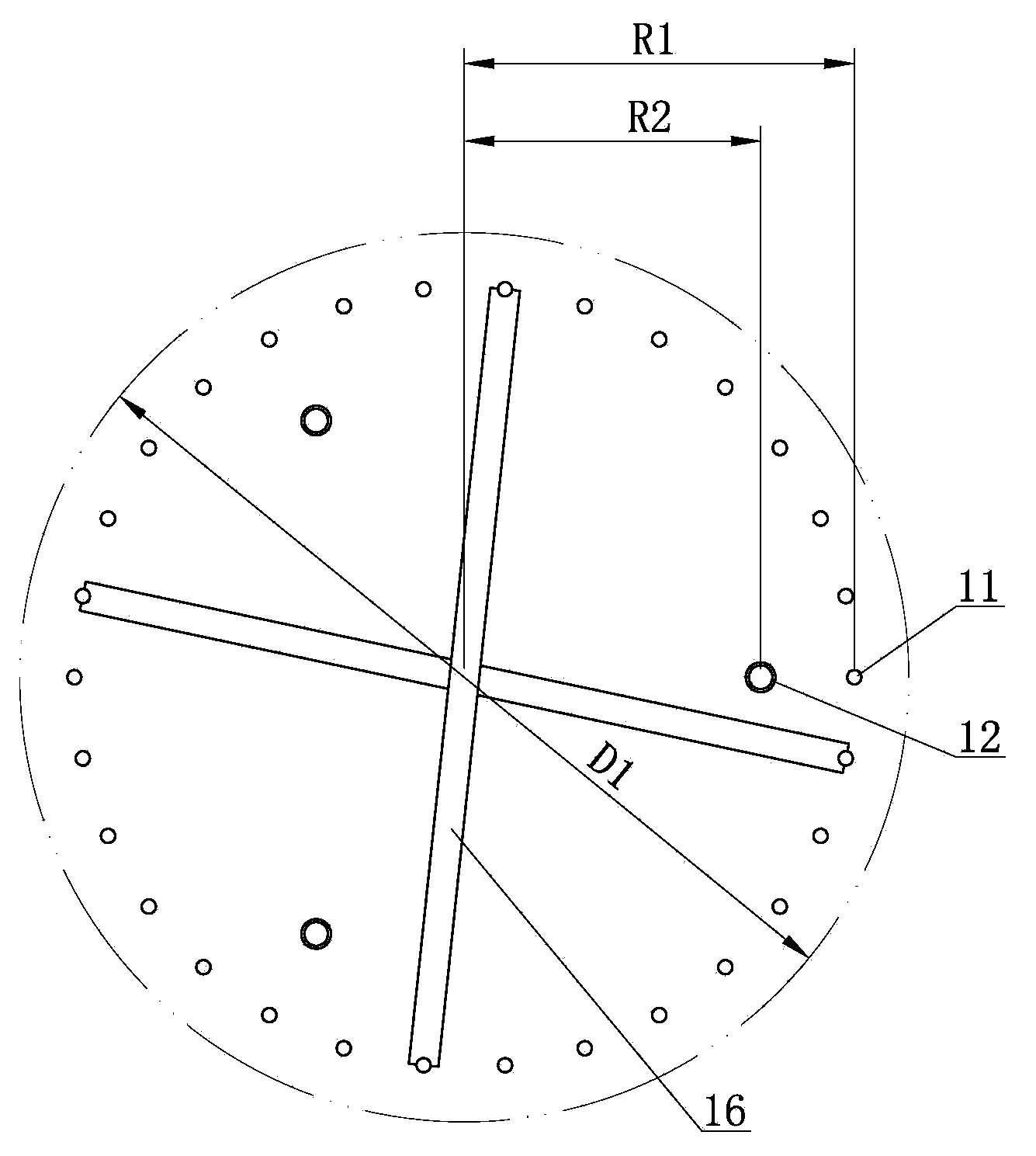

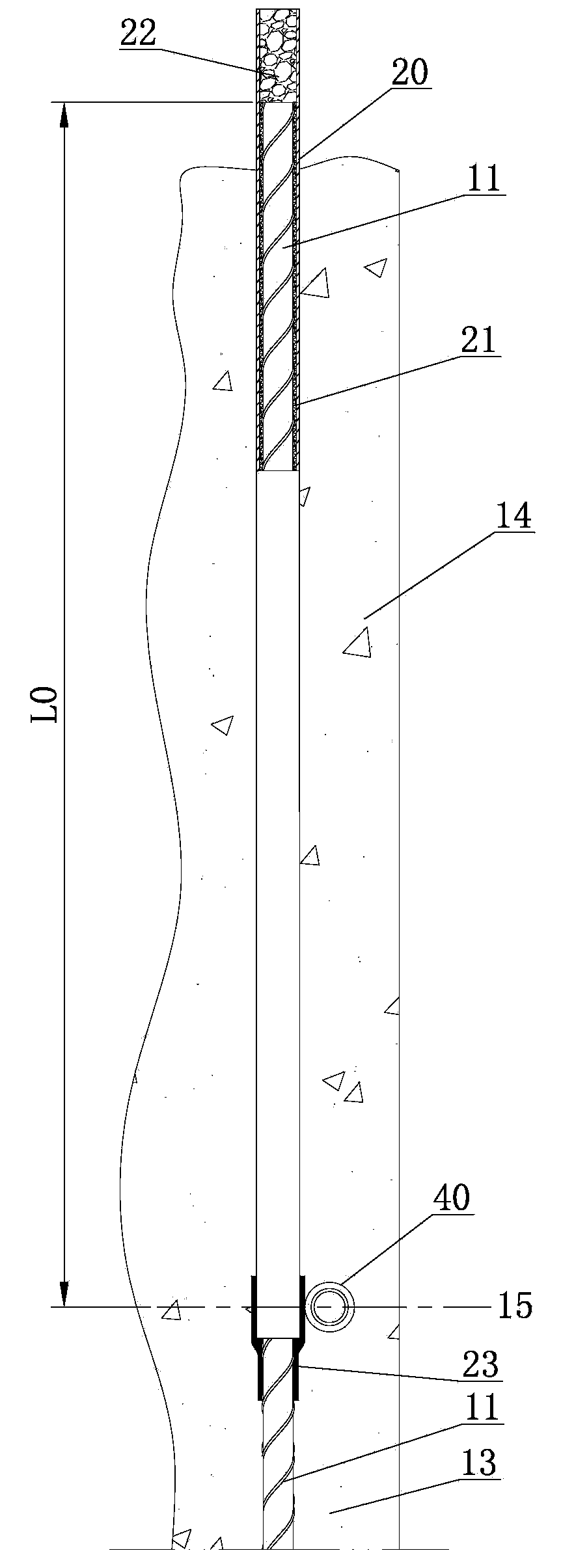

Structure and method for integrally breaking pile head of pile foundation

The invention relates to a structure and a method for integrally a breaking pile head of a pile foundation. The structure comprises the pile foundation, and main ribs of a reinforcement cage and sounding pipes, which are positioned in the pile foundation; main rib sleeves sleeve sections, higher than the top surface of a design pipe body, of the main ribs of the reinforcement cage; a gap is formed between the outer diameter of each main rib and the inner diameter of the corresponding main rib sleeve; a sounding sleeve is arranged on each sounding pipe in a sleeving manner; a separating pipe is arranged at the position of a pile head cutting line by encircling the main ribs of the reinforcement cage; the separating pipe comprises a flexible outer pipe and inner ribs inserted in an inner hole of the flexible outer pipe; after the pile foundation is cast, the inner ribs are pulled out of the separating pipe, separating holes are forming by drilling, separating wedges are inserted into the separating holes, and the pile foundation is knocked to enable the pile head and the top surface of the design pipe body to be separated. The structure and the method have the beneficial effects that the positions of the sounding pipes and the main ribs of the reinforcement cage in the pile foundation are not required to be searched any more, the main ribs are prevented from being damaged in the breaking construction; the pile head after breaking is flat in structure.

Owner:CCCC TUNNEL ENG

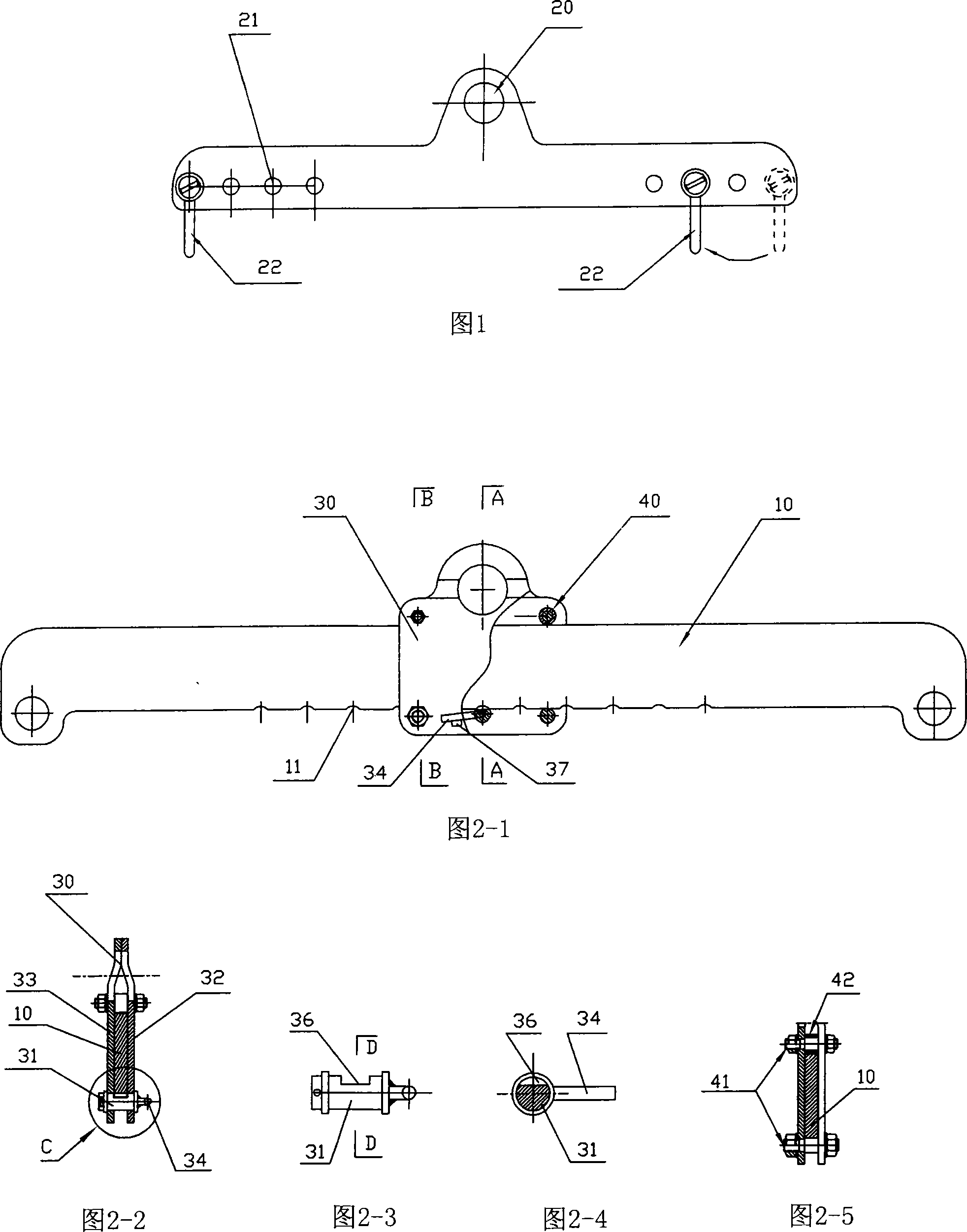

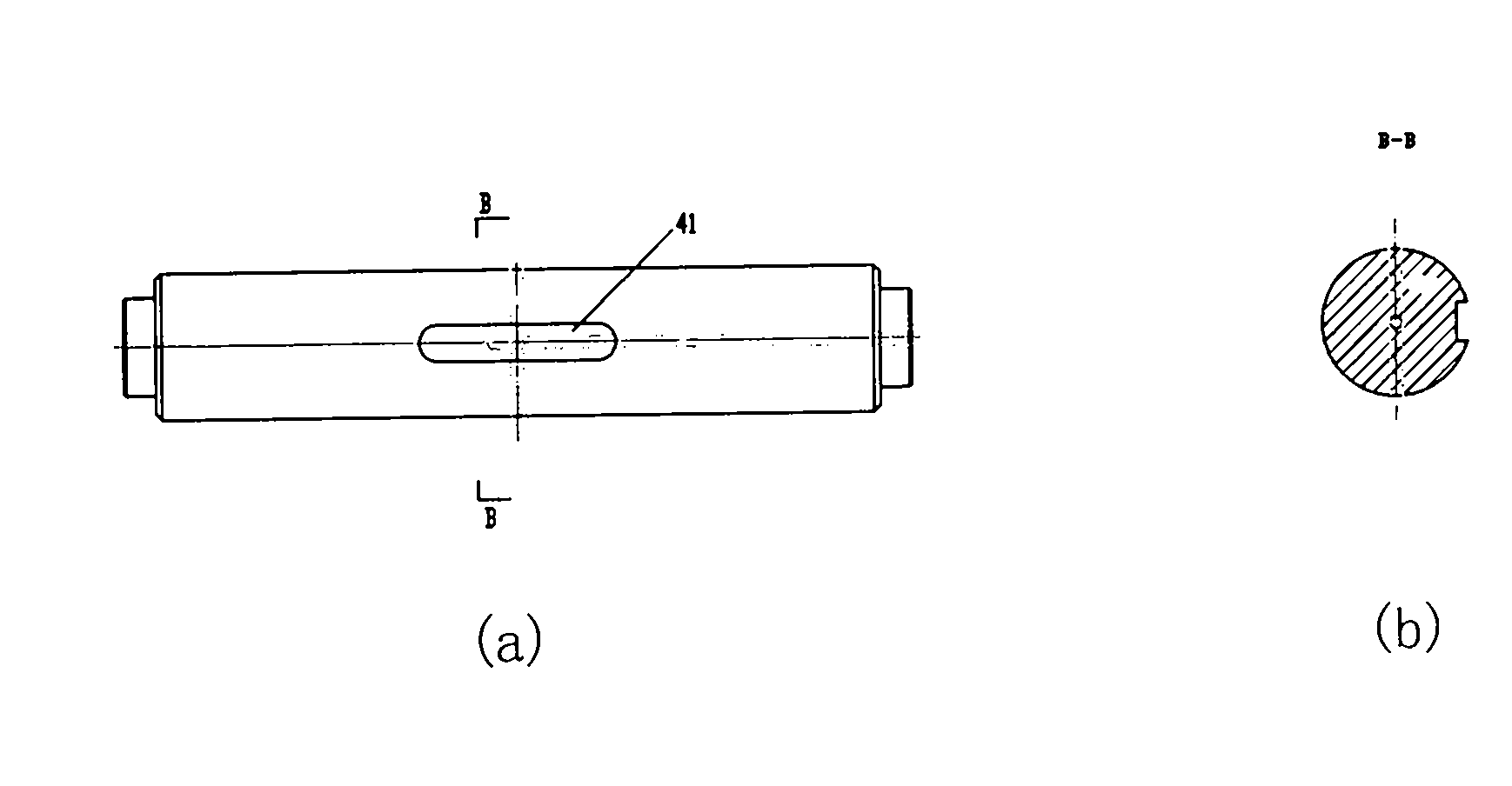

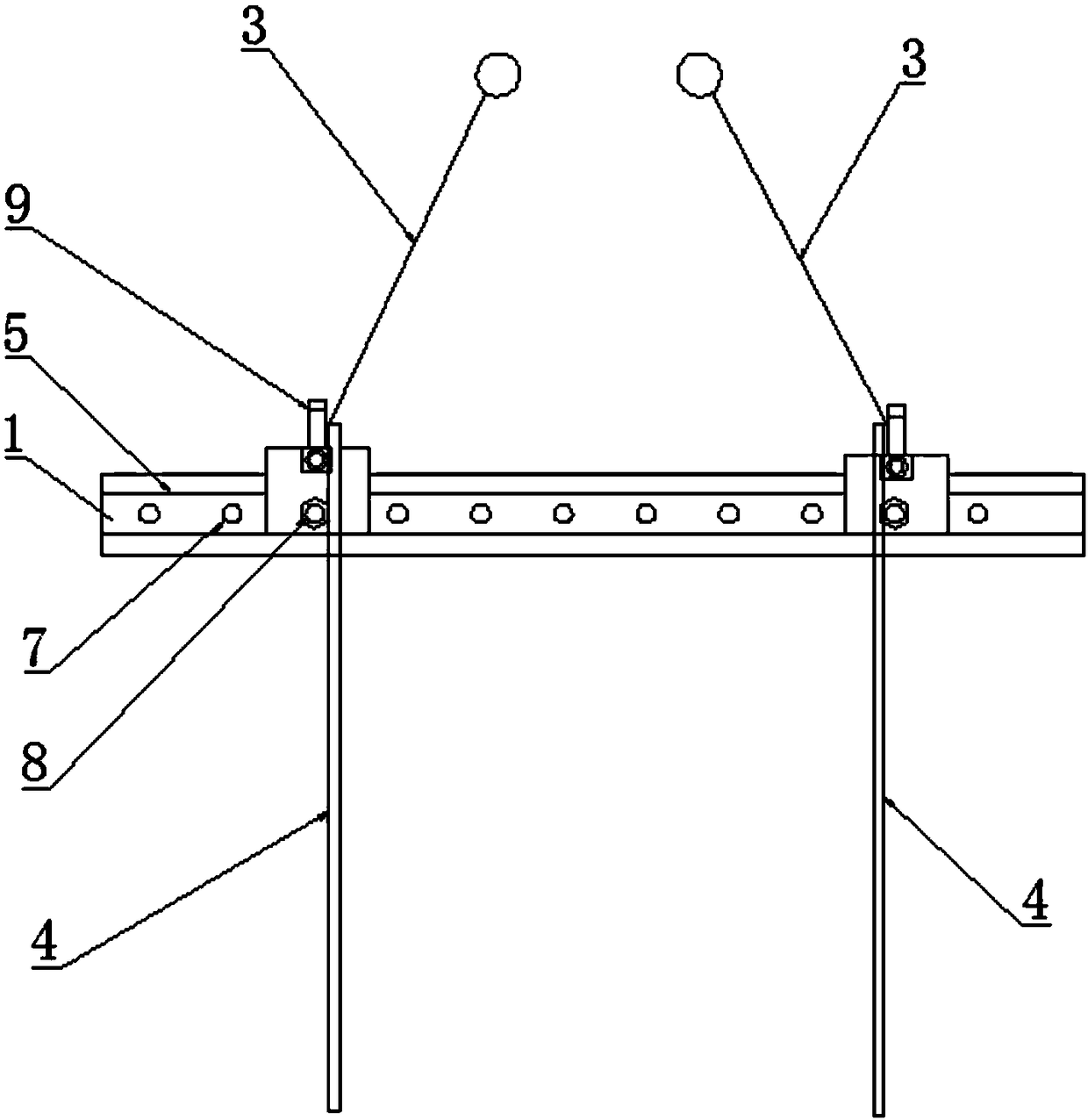

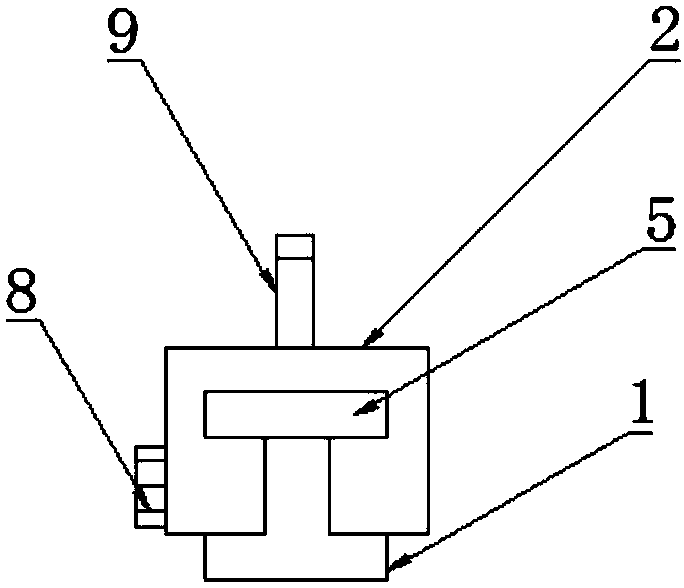

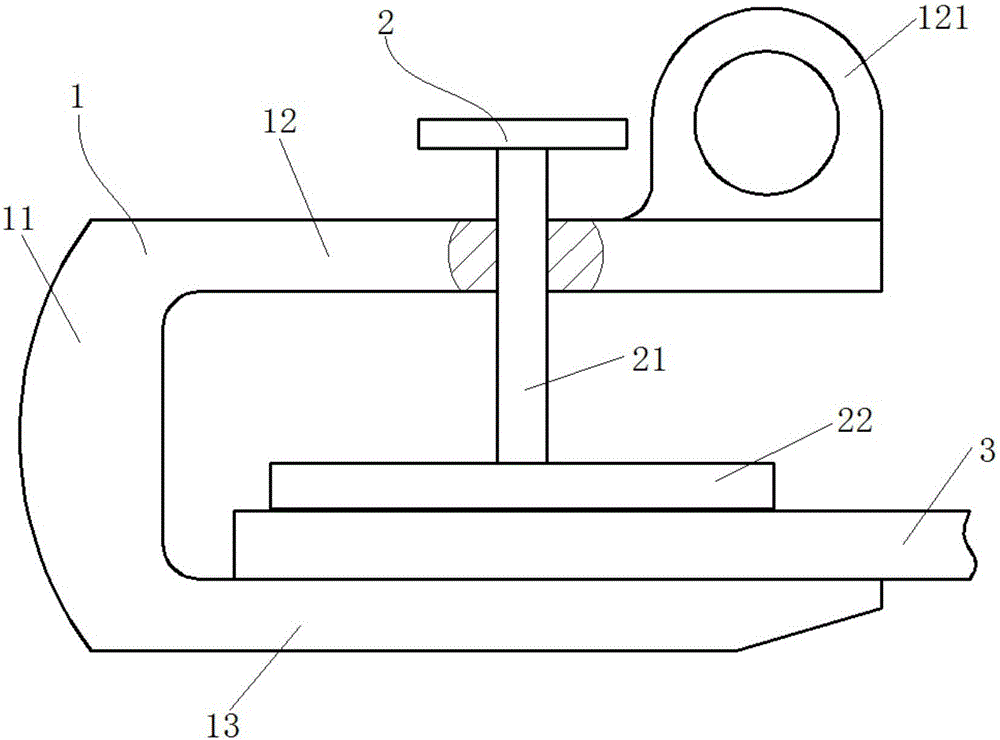

Sling with adjustable balanced type transverse beam

The invention discloses a spreader having an adjustable balanced beam, comprising a beam; a lower end of the beam is provided with a plurality of positioning troughs; the beam is connected with a balancing seat which is provided with a rolling mechanism in contact with the beam and a positioning shaft matching with the positioning troughs respectively. The balancing seat consist of a front and a back board which are arranged at the front and back ends of the beam; the positioning shaft passes through the front and back boards of the balancing seat; one end of the positioning shaft is provided with a handle, and the other end is provided with a fixed pin; the middle part of the positioning shaft is provided with a flute; the front board of the balancing seat is provided with a left and a right handle stop block. The rolling mechanism comprises a connecting shaft which connects the front and back boards of the balancing seat and a roller equipped on the connecting shaft. As the beam of the spreader provided by the invention is provided with the balancing seat which can move along the beam, heavy objects can be lifted easily, rapidly, safely and reliably by adjusting the position relationship between the balancing seat and the beam according to the gravity offset of the lifted heavy object.

Owner:天津重钢机械装备股份有限公司

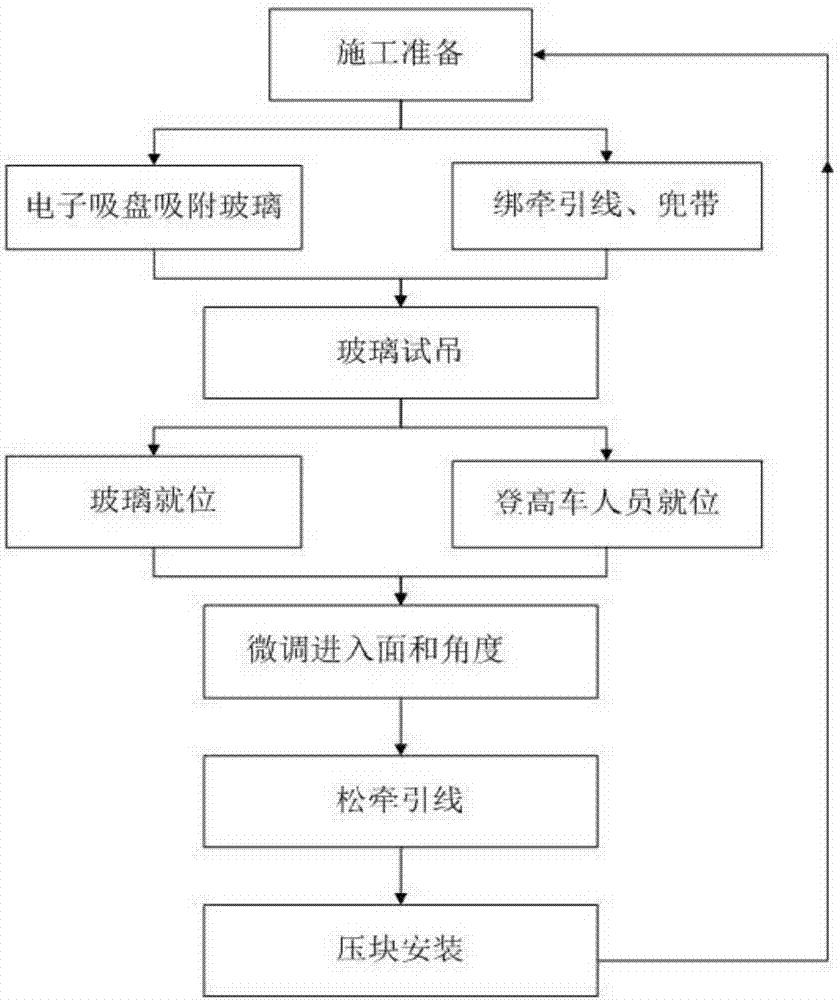

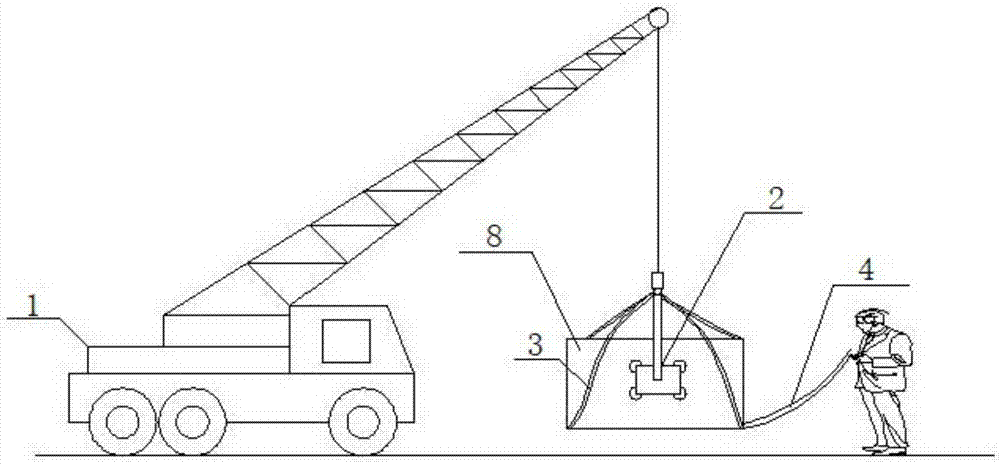

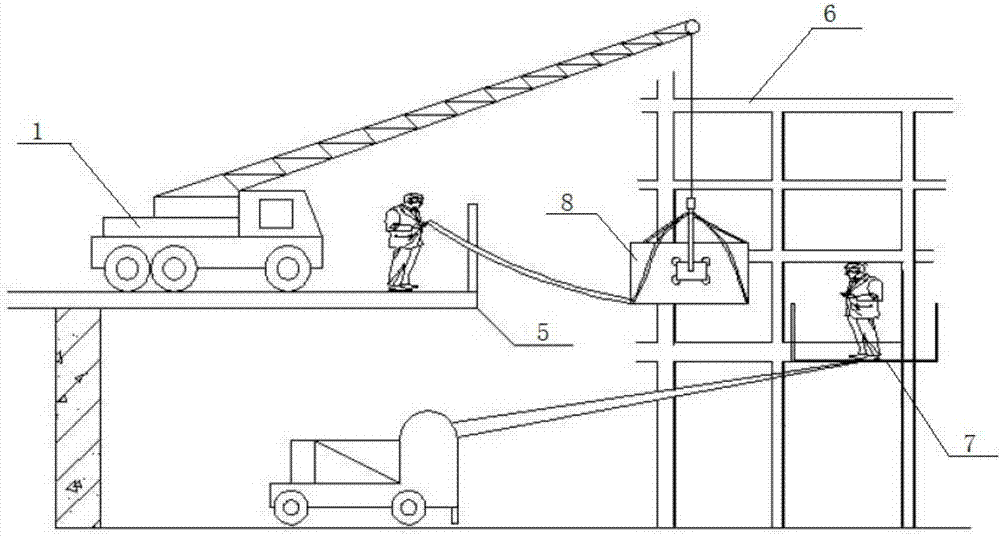

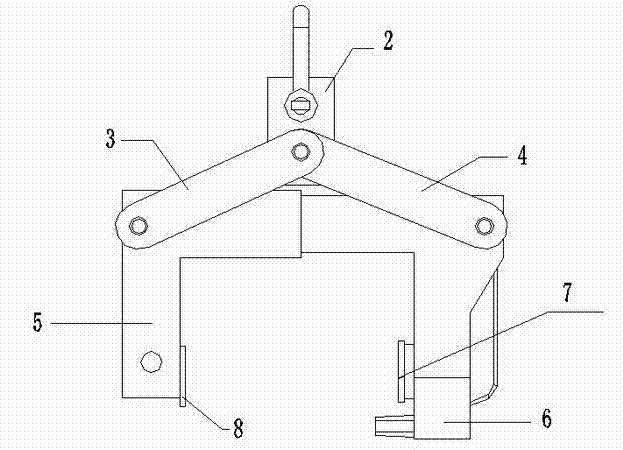

Super large curved surface glass curtain wall mechanical installation method

InactiveCN107503454AEasy to control the angleEasy to installWallsBuilding material handlingSUSPENDING VEHICLEEngineering

The invention discloses a super large curved surface glass curtain wall mechanical installation method. The super large curved surface glass curtain wall mechanical installation method comprises the following steps of construction preparation, suction of the glass through an electronic suction cup, binding of a haulage rope and a basket strap, trial suspending of the glass, setting of glass in place and setting of ladder truck personnel in place, fine tuning of the glass, loosening of the haulage rope and installation of a press block. By utilizing the electronic suction cup to suck the glass, most of the weight of the glass is borne by a crane and the suction cup, the manual work at the carrying place of the glass is reduced, the ladder truck is a novel introduced machine and can conveniently adjust the height and the angle, only operating personnel stands on the ladder truck, the weight of the glass is not borne, the stress of people and materials is divided, and the method is safer and more efficient.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Dedicated sling for concrete duct piece

The invention discloses a dedicated sling for a concrete duct piece, which comprises a hand ring. The hand ring is fixed on a mounting plate; one end of a first hoisting and shrinking plate and one end of a second hoisting and shrinking plate are respectively connected to the mounting plate; the other end of the first hoisting and shrinking plate is connected with a first forceps holder; the other end of the second hoisting and shrinking plate is connected with a second forceps; a baffle is arranged inside the vertical tail end of the first forceps holder; a clamp is arranged inside the vertical tail end of the second forceps holder; and the horizontal end of the second forceps holder is arranged in the horizontal end of the first forceps holder in a penetrating manner to axially slide. According to the dedicated sling for the concrete duct piece, the duct piece which is under the horizontally-arranged state can be hoisted, a hoisting process is safe, simple and easy to realize, a great quantity of manpower and hoisting material can be saved, and potential safety hazards are eliminated.

Owner:CCCC SHEC FOURTH ENG

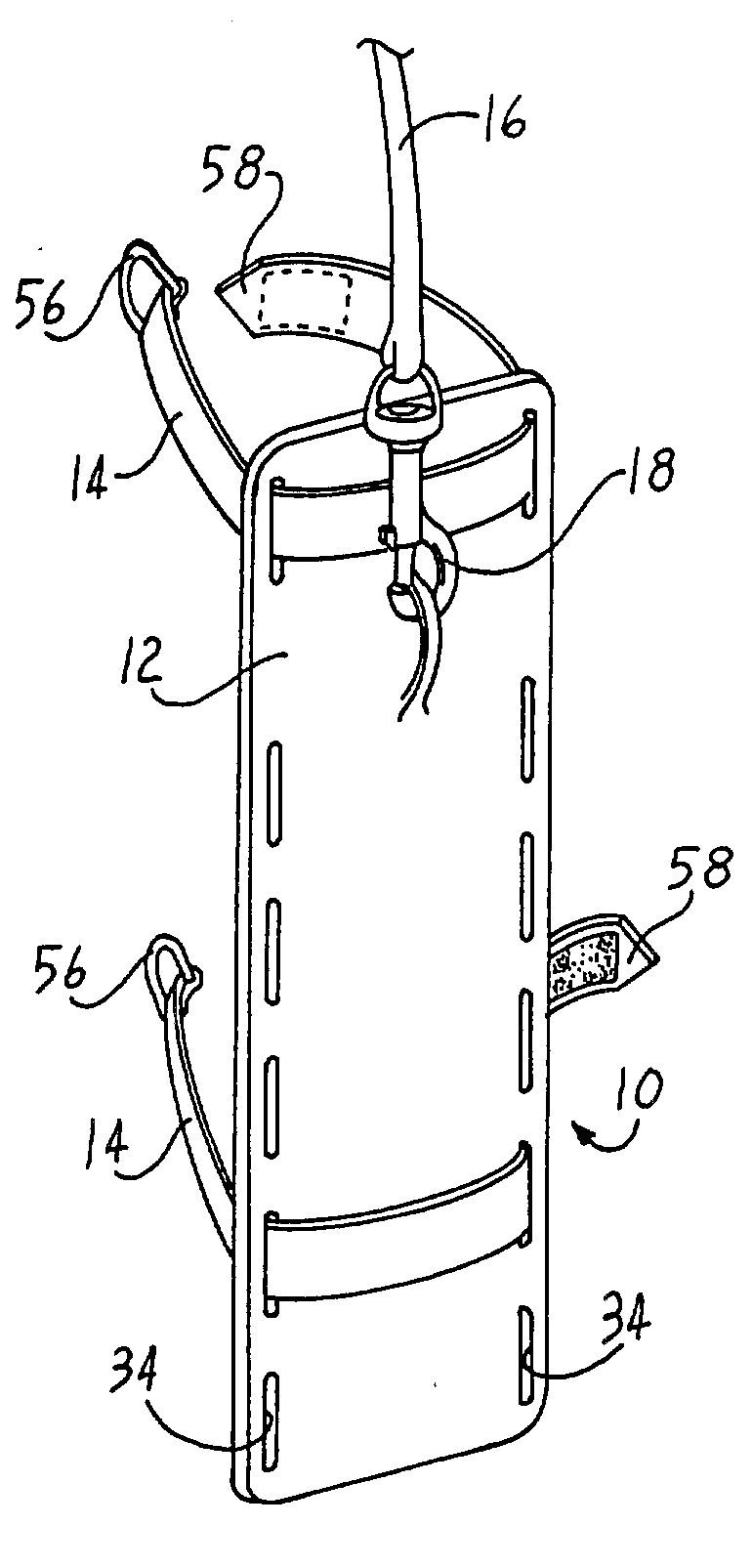

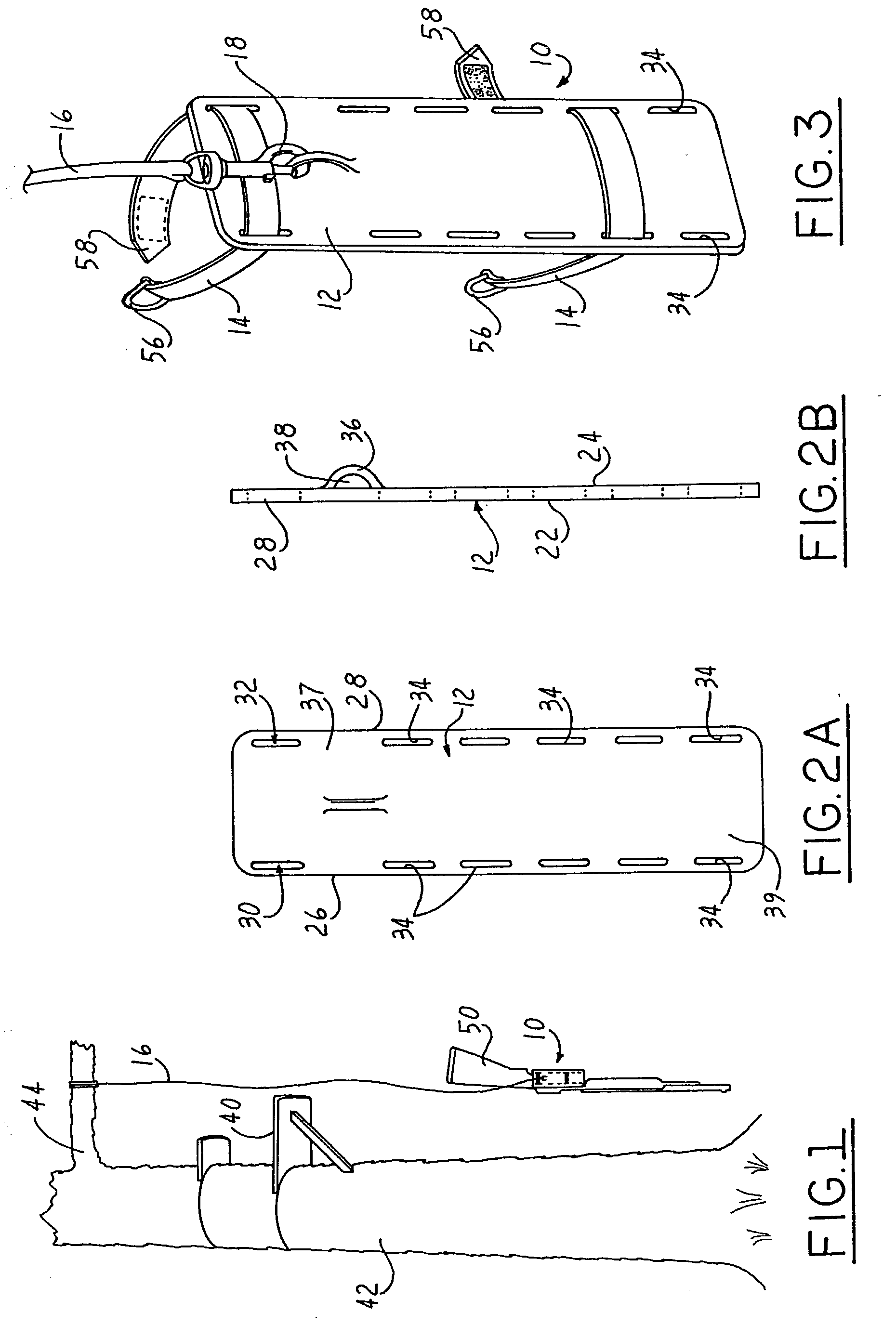

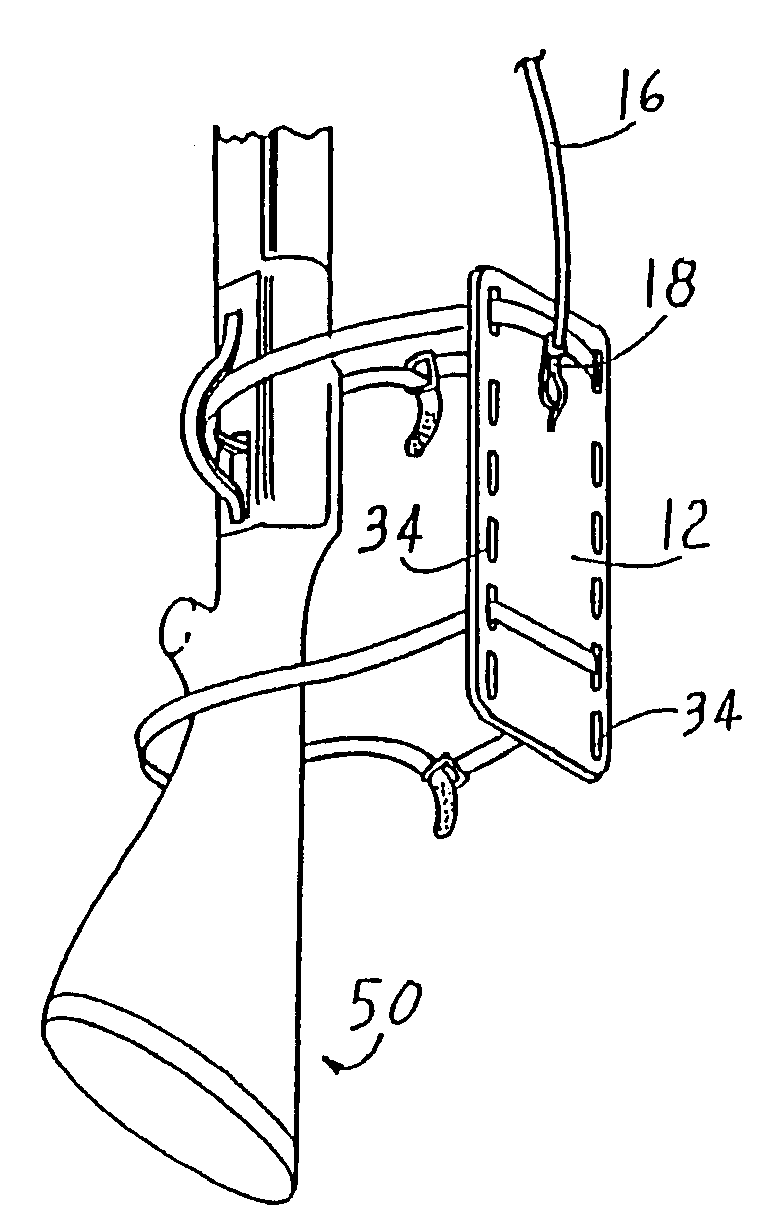

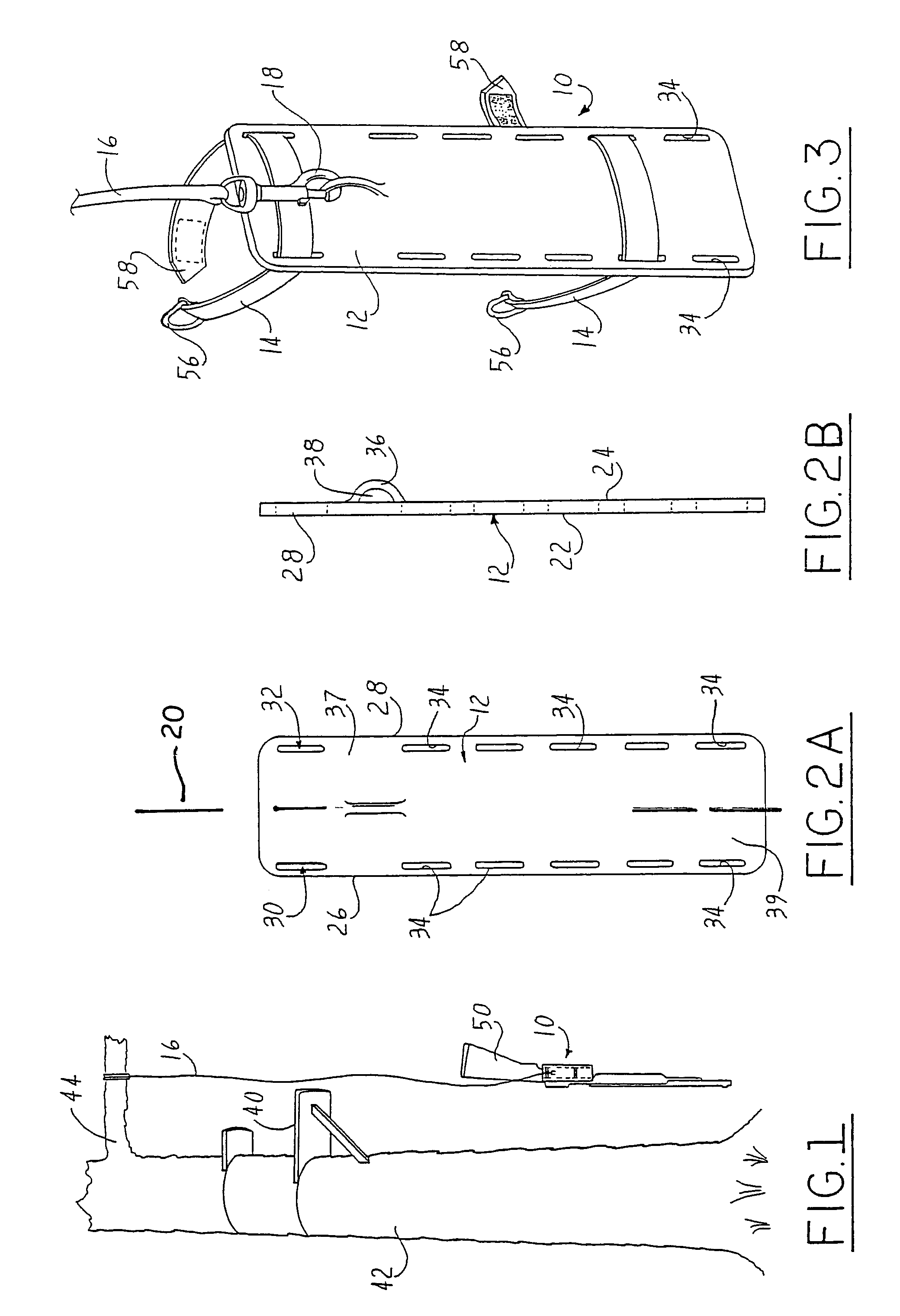

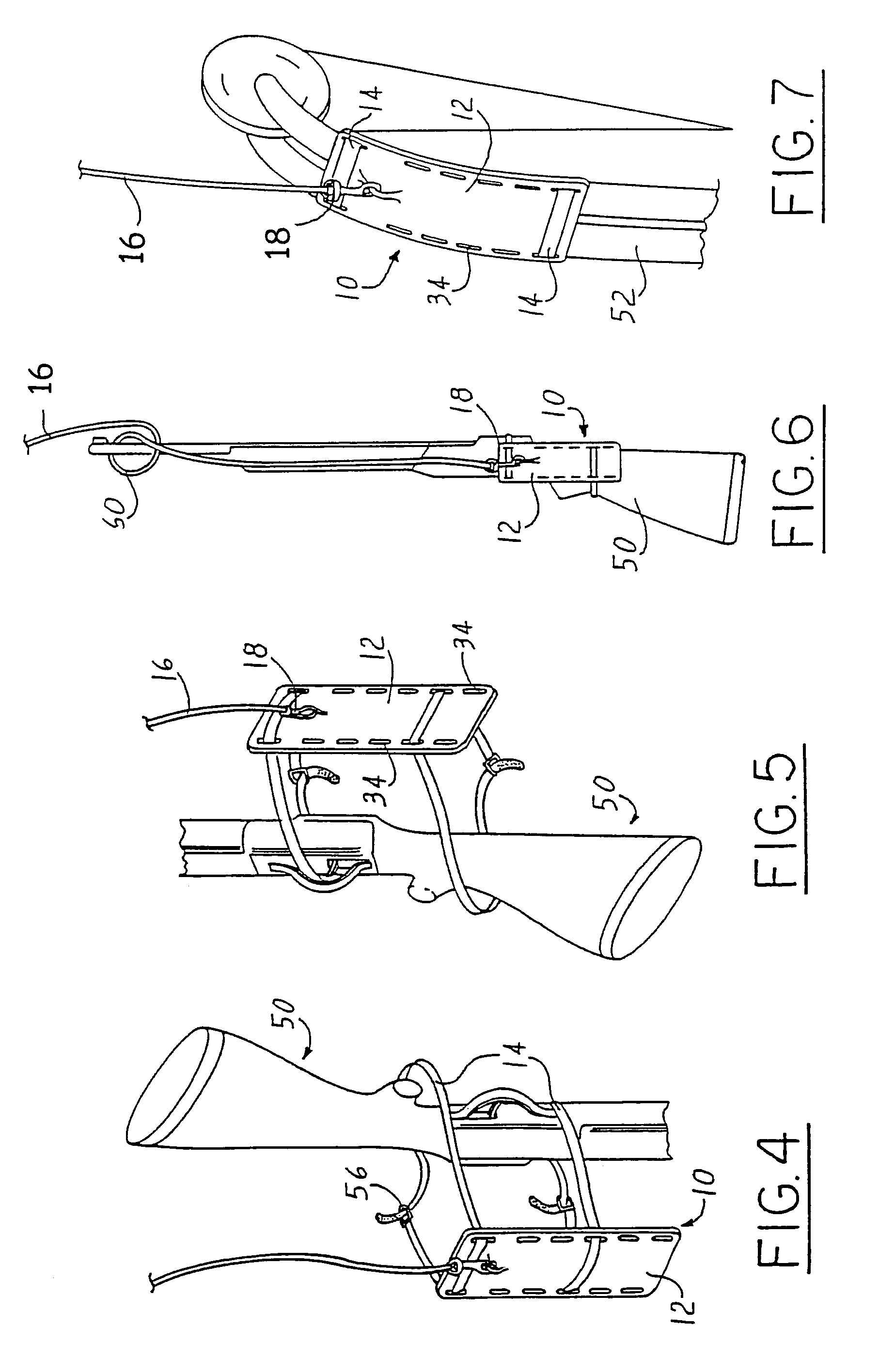

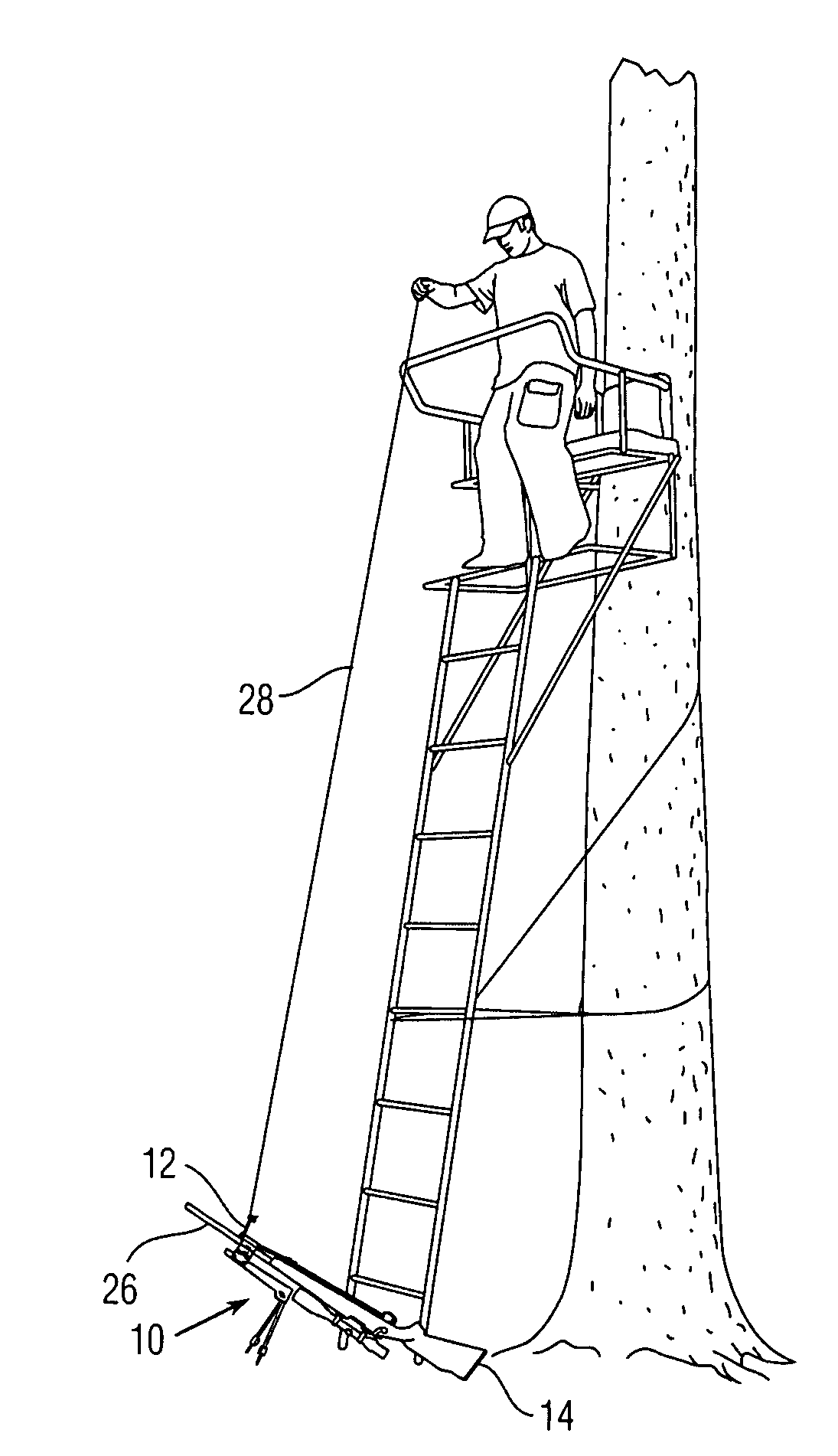

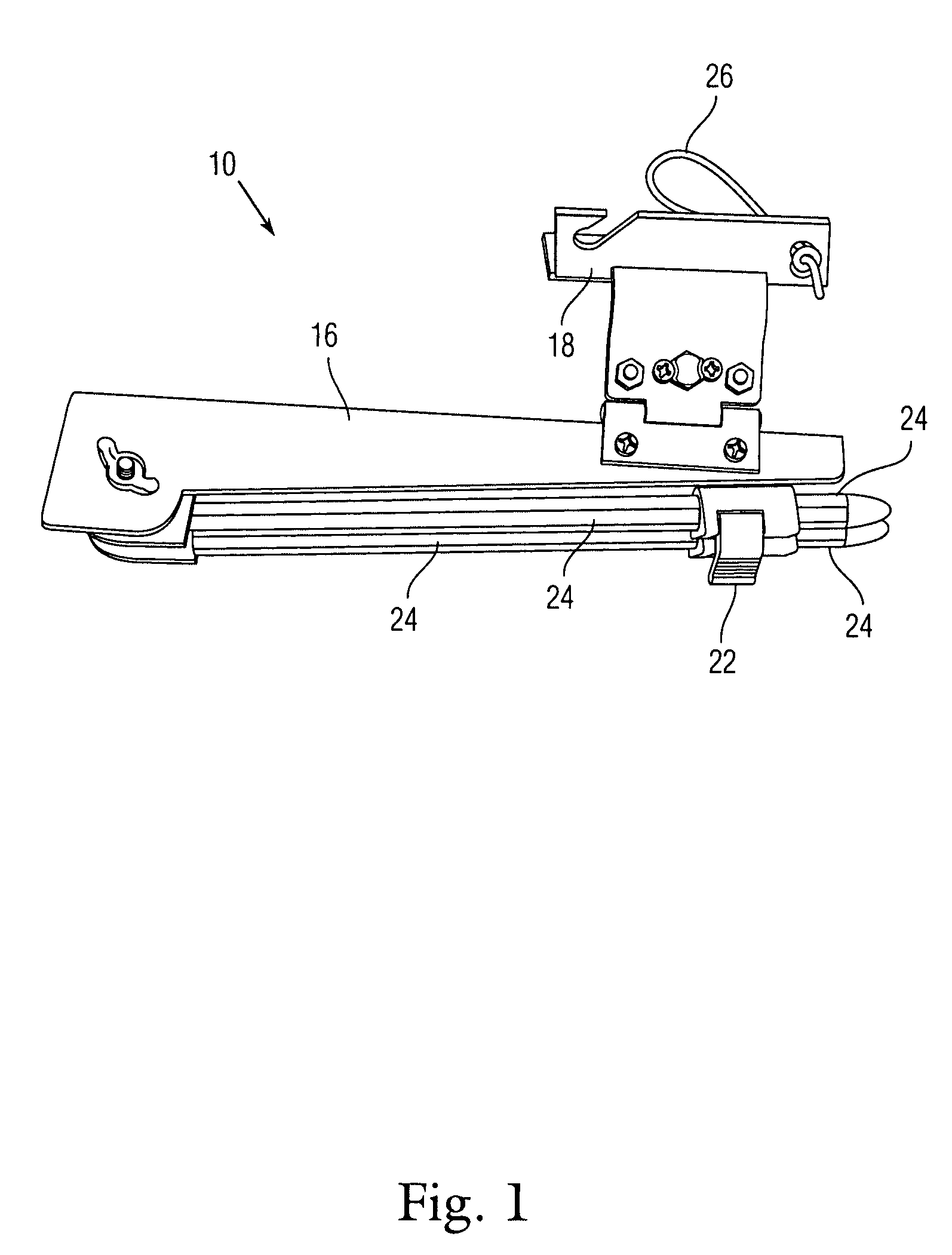

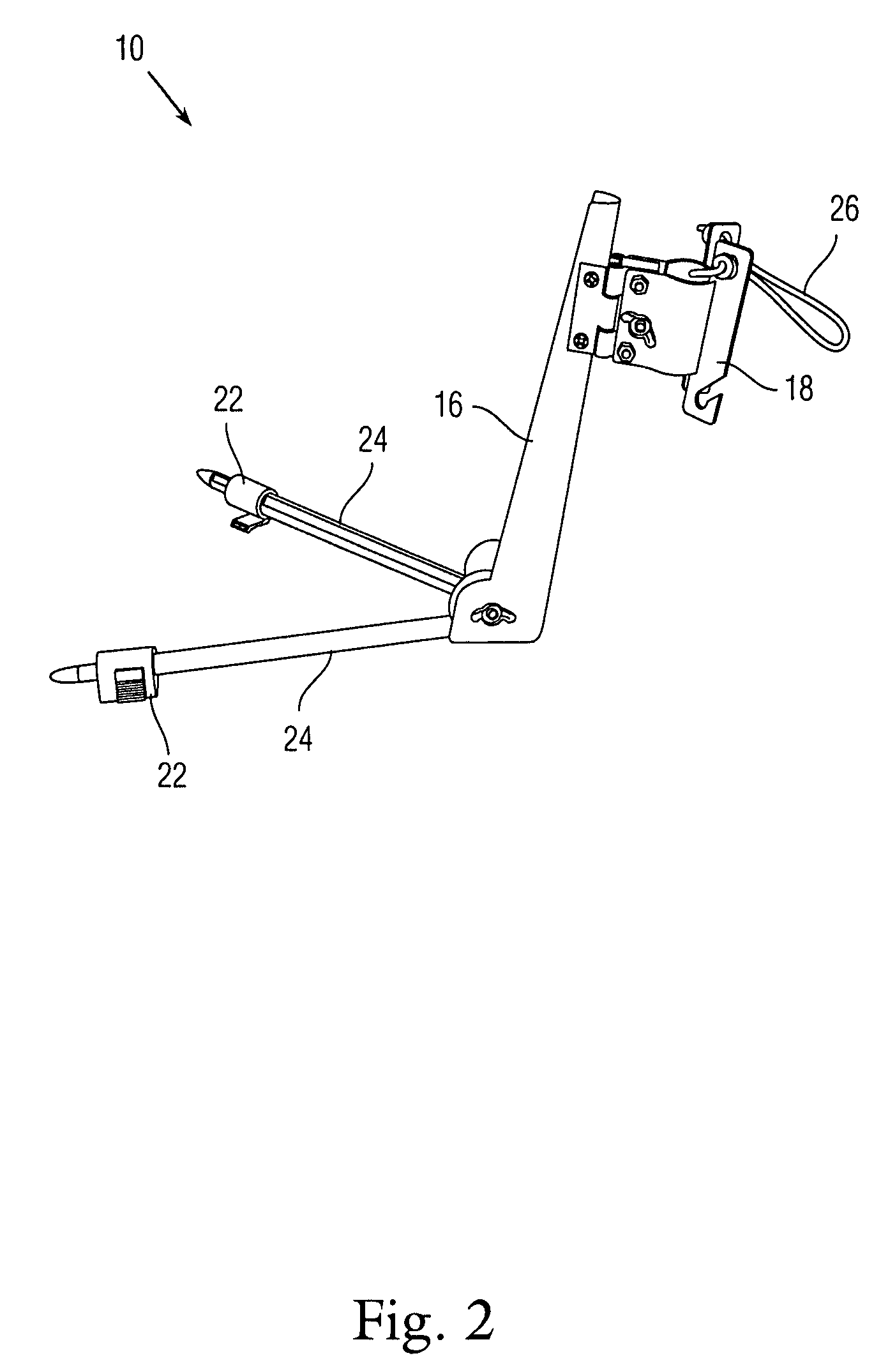

Gun gurney

The gurney is for lifting firearms, such as shotguns, rifles, archery bows and hunting equipment to an elevated hunting position. The gurney includes a molded urethane fixture or base member with slots longitudinally aligned along the longitudinal edges thereof. A lifting catch is provided on the rear surface of the fixture near the upper end portion thereof. The catch is centrally located. A pair of Velcro straps are provided which extend through pairs of laterally aligned slots that best fit each firearm. The Velcro straps are wrapped around the firearm and secured. A lifting cord with a snap hook on one end is attached to the lifting catch. The other end of the cord is attached to a tree limb or elevated platform or tree stand in a clear area and secured at a predetermined height that will prevents the firearm, archery bow or equipment from hitting the ground. Once the hook is attached to the catch on the fixture, the firearm, archery bow or equipment is ready to be safely hoisted.

Owner:LUKAS JAY J

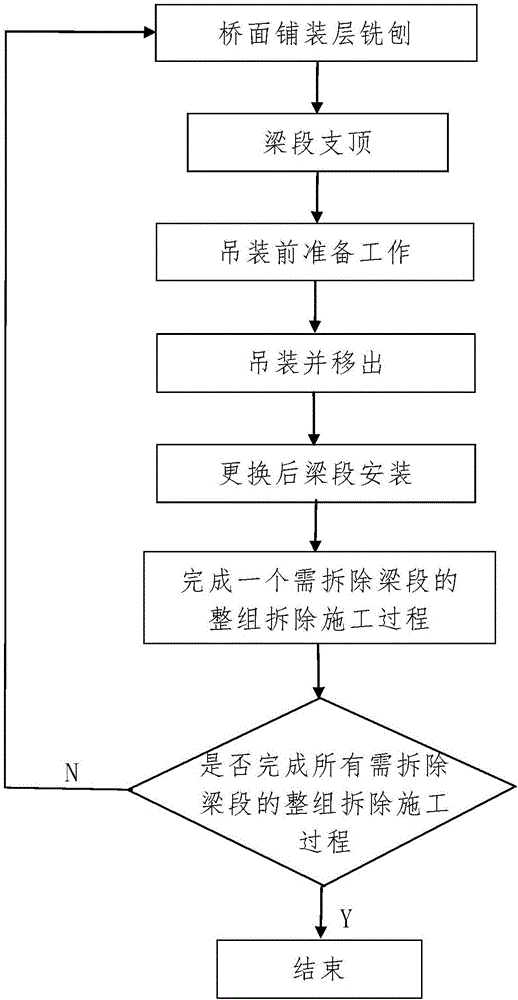

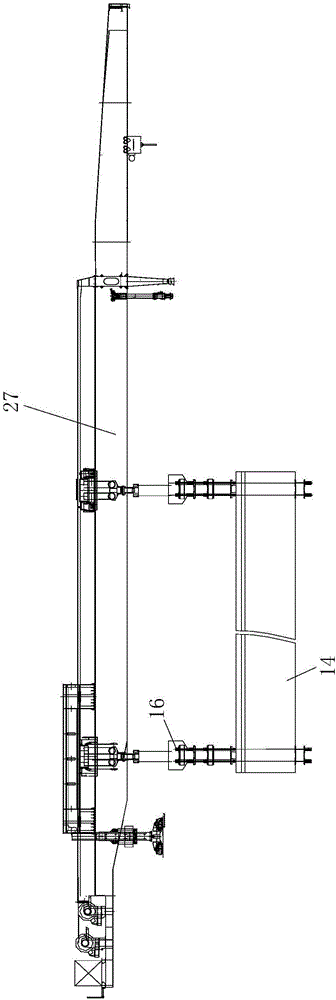

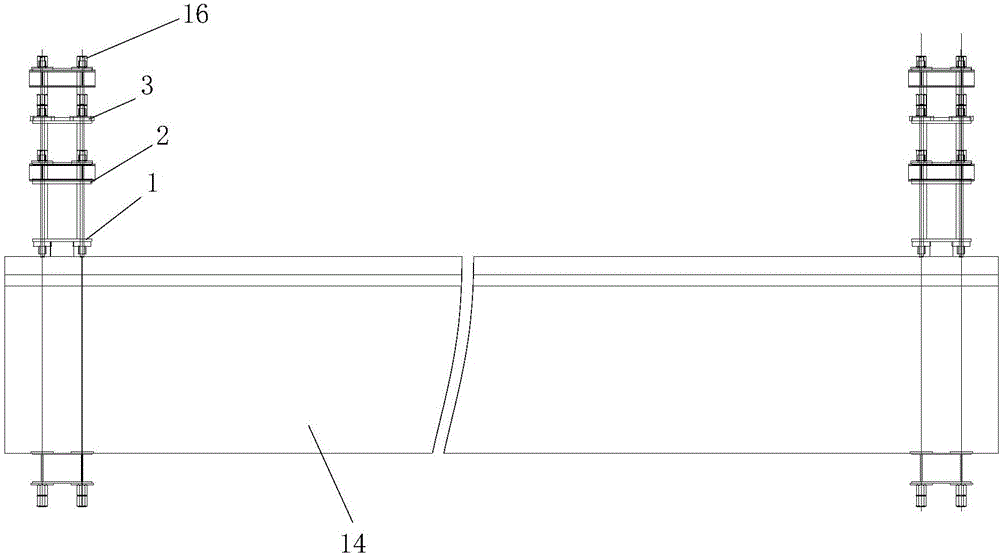

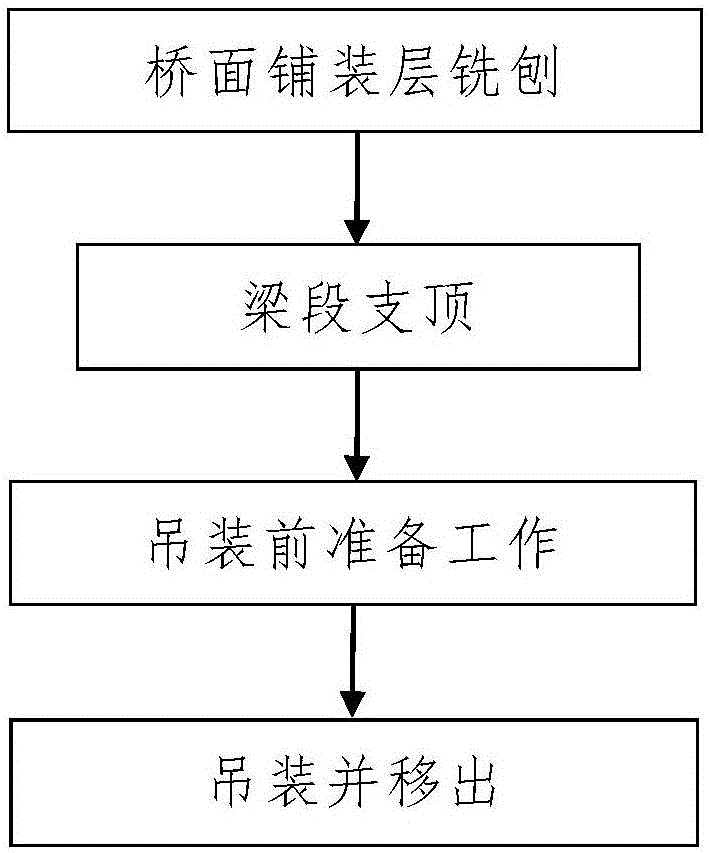

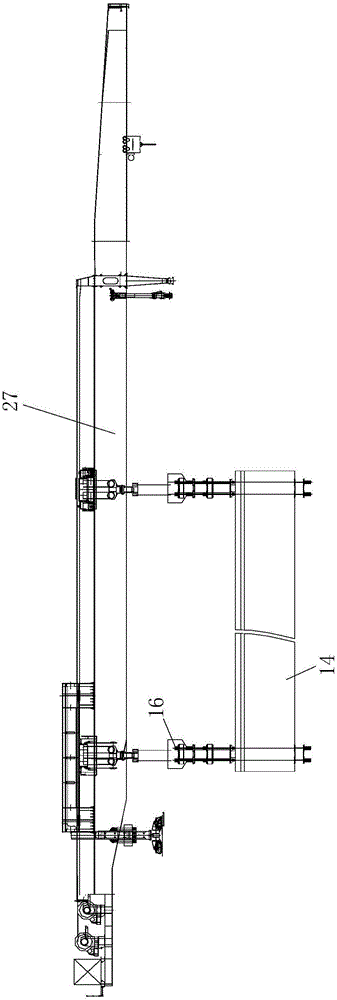

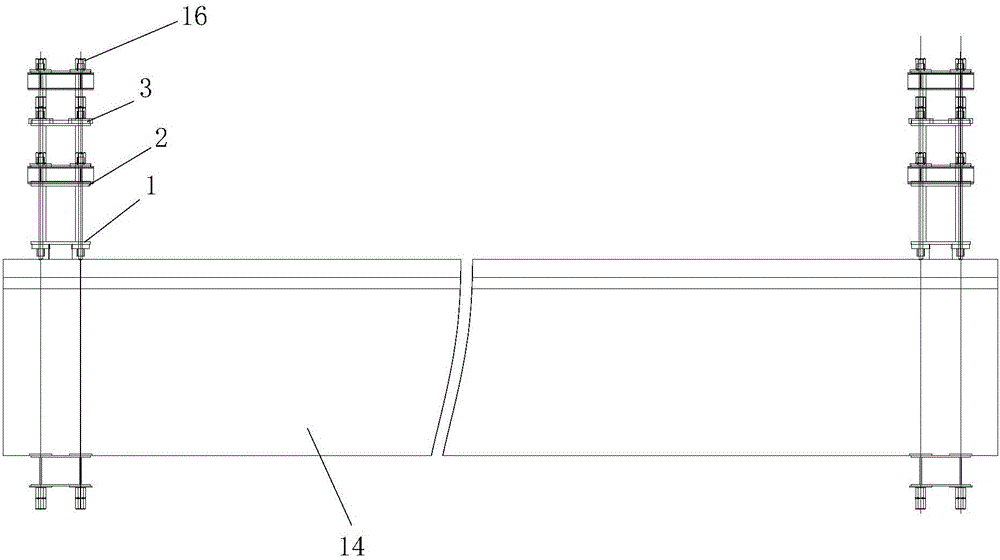

Crossing existing line bridge girder dismounting method

ActiveCN106284109ASimple stepsReasonable designBuilding repairsBridge strengtheningBridge deckRailway line

The invention discloses a crossing existing line bridge girder dismounting method. A dismounted bridge girder is a girder crossing an existing railway line and is formed by splicing a plurality of girder segments to be dismounted from front to back. During complete set dismounting construction of any segment to be dismounted, the process comprises the following steps that firstly, a bridge deck pavement is milled, specifically, the bridge deck pavement of the girder segment constructed currently is milled; secondly, the girder segment is jacked up, specifically, the girder segment constructed currently is horizontally jacked upwards through a vertical jacking device, so that the girder segment constructed currently is separated from two supporting piers; thirdly, preparation operation before hoisting is conducted; and fourthly, the girder segment constructed currently is horizontally hoisted upwards through a bridge girder erection machine and moved to the outer sides of the two supporting piers. The method is simple in step, reasonable in design, easy and convenient to construct and good in application effect, the complete set dismounting construction process of the crossing existing line bridge girder can be completed easily, conveniently and rapidly, and the construction process is safe and reliable, the construction period is short, and the method is economic and practical.

Owner:中铁二十局集团第三工程有限公司

Gun gurney

Owner:LUKAS JAY J

Jib-type crane pulley device

The invention discloses a jib-type crane pulley device which comprises a pulley and a pulley shaft. The pulley comprises a rim with a U-shaped rope groove, a hub, a spoke and a swinging mechanism, wherein the spoke is connected with the rim and the hub, the swinging mechanism comprises an inner ball, a steel ring and a positioning sleeve, the inner ball is sleeved in an inner ring of the steel ring, the ball center of the inner ball is superposed on the circle center of the steel ring which is fixedly connected with the hub by the positioning sleeve, and the inner ball is provided with a pulley shaft hole matched with the pulley shaft which penetrates through the pulley shaft hole of the inner ball of the swinging mechanism and is in rotating connection with the inner ball. When the jib-type crane pulley device is in use, the pulley can wholly swing along with the inclination direction of a hoisted object to constantly keep a force position kept in the center of the pulley so that the rope groove can not be deformed due to unbalanced force, a steel wire is prevented from jumping to cause danger, the deformation of the pulley is effectively lessened in the use process, and the pulley has prolonged service life and is safe to hoist.

Owner:CHANGZHOU CHANGKUANG HOISTING MACHINERY

Generator rotor hoisting air gap monitoring and protecting device

ActiveCN113607071AReduce laborReduce work intensityOptical rangefindersUsing optical meansControl engineeringControl theory

The invention discloses a generator rotor hoisting air gap monitoring and protecting device. The device comprises a protecting device for collision sensing feedback of a rotor; a monitoring communication module which is used for receiving and processing feedback information of the protection device and sending an instruction to a report warning module; the report warning module which is used for receiving an instruction of the monitoring communication module and giving an alarm; a distance measuring module which is used for measuring a distance between the rotor and the bottom of the pit; a feedback display module which is used for receiving and processing feedback information and simulating and displaying the hoisting process and state of the rotor through a 3D graph; and a power supply guarantee module used for providing power. The protection device achieves protection and monitoring in a limited gap between a rotor and a stator, through cooperation of all modules, the number of used workers is greatly reduced, equipment protection is simple, safe and effective, hoisting monitoring covers all parts without hidden danger, equipment extrusion and collision alarm is timely, normal position operation is visual and visual, the hoisting process is synchronously displayed, and the walking bottom of the hoisting part can be monitored; safety of personnel and equipment is ensured, and hoisting is simple and quick.

Owner:THREE GORGES HI TECH INFORMATION TECH CO LTD +1

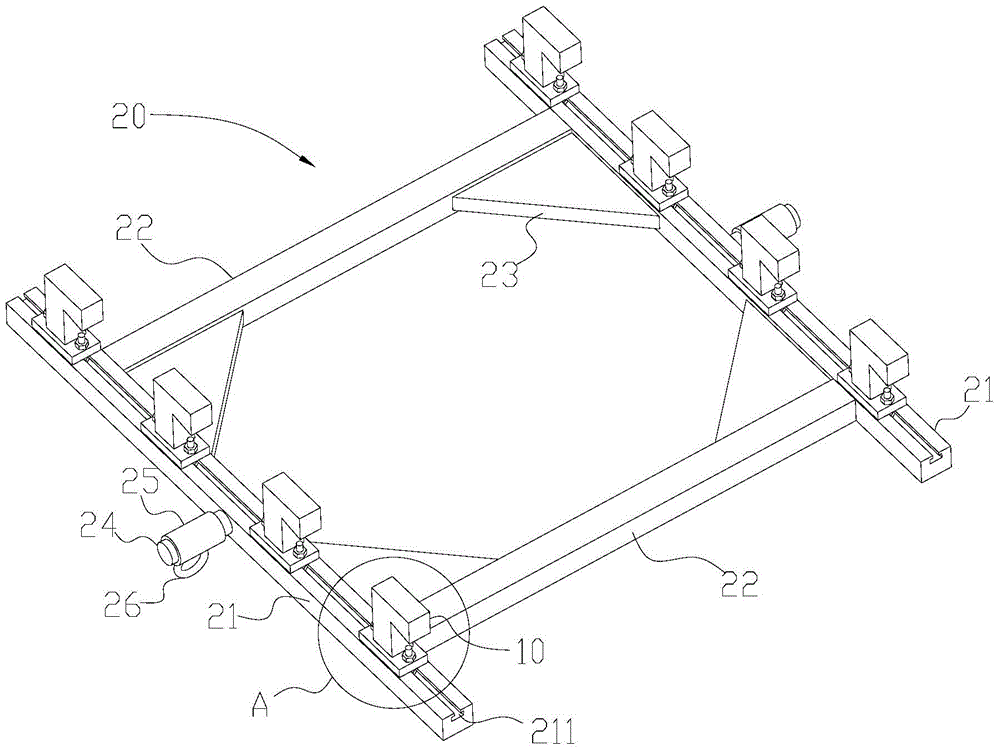

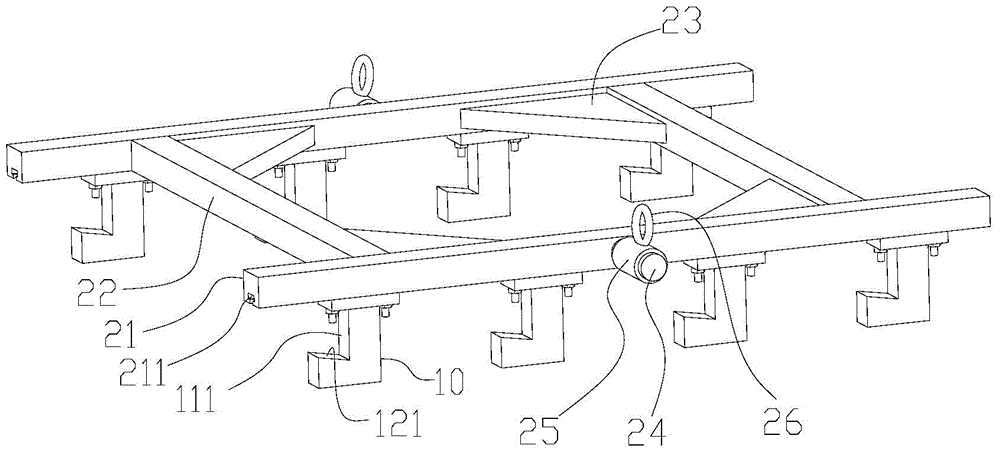

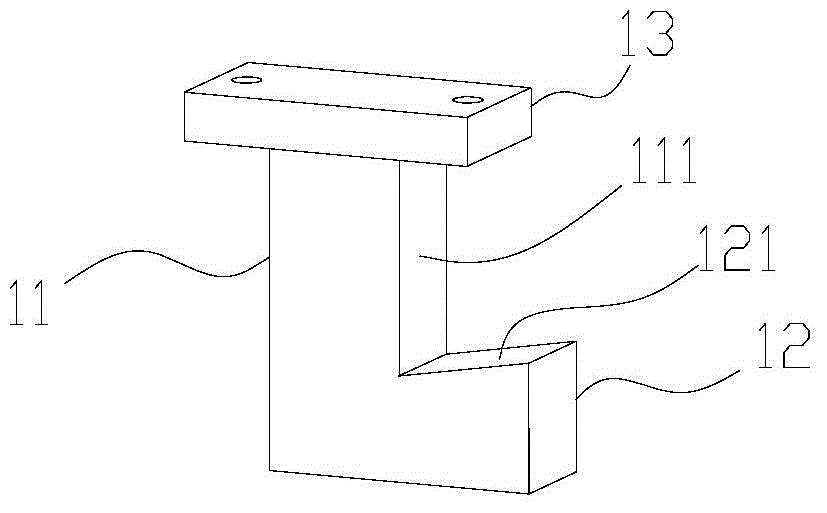

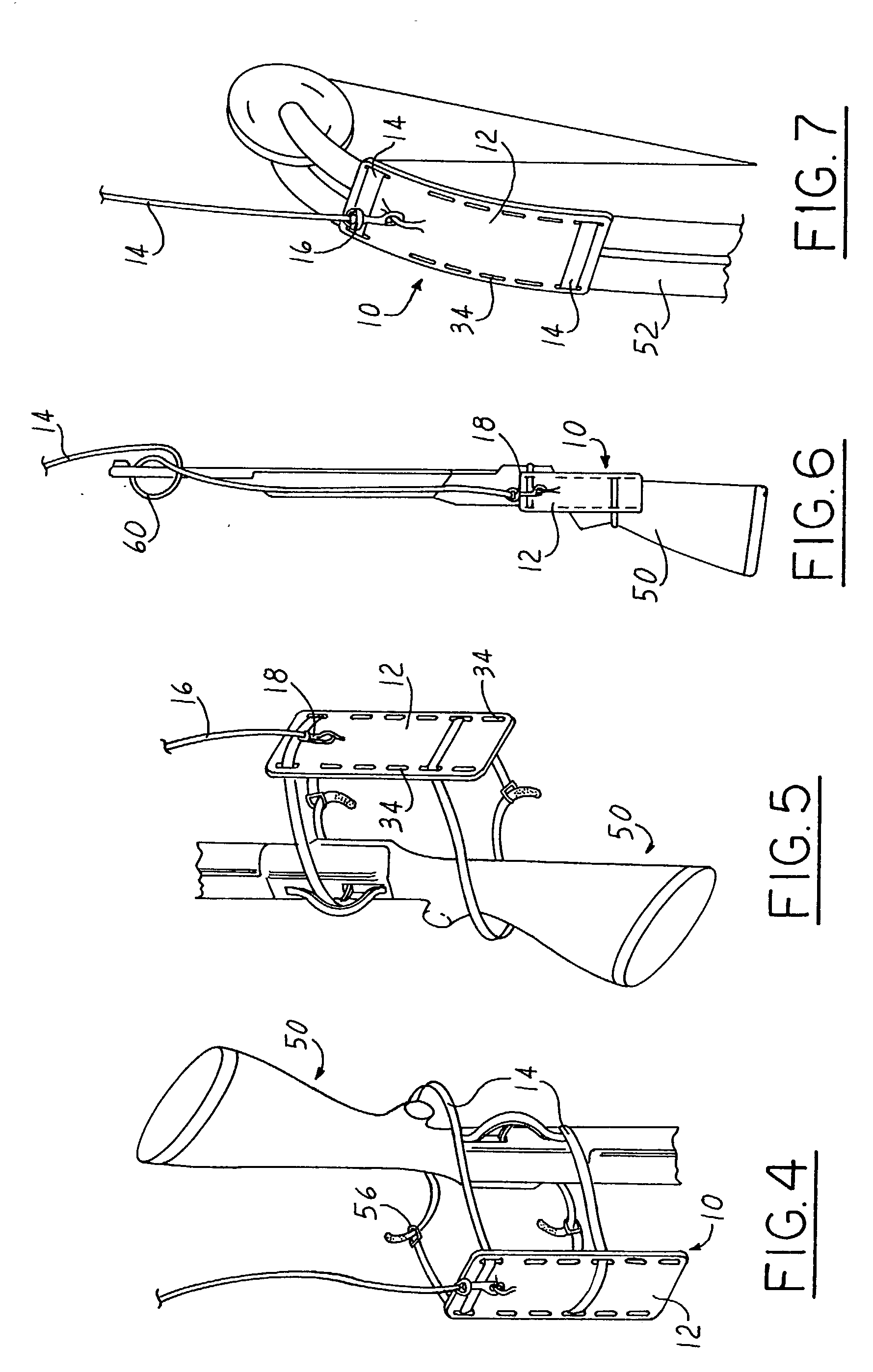

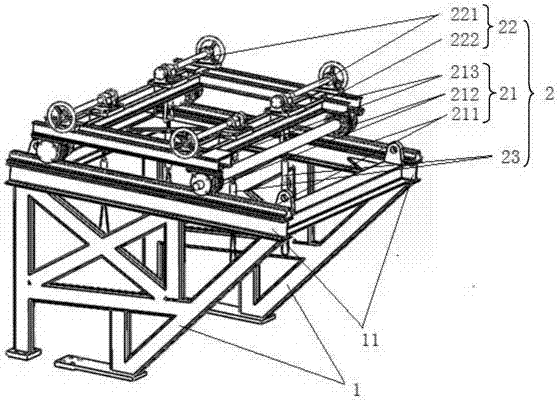

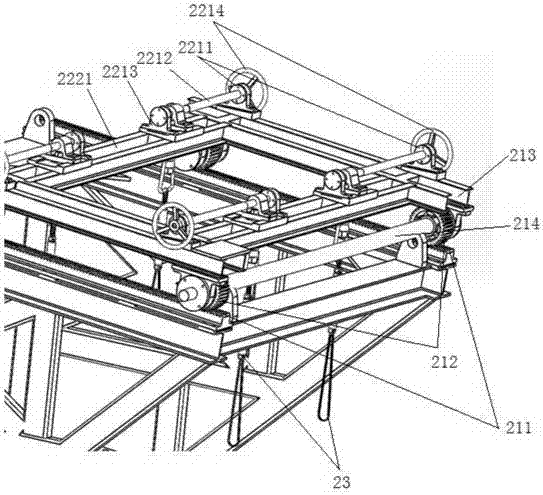

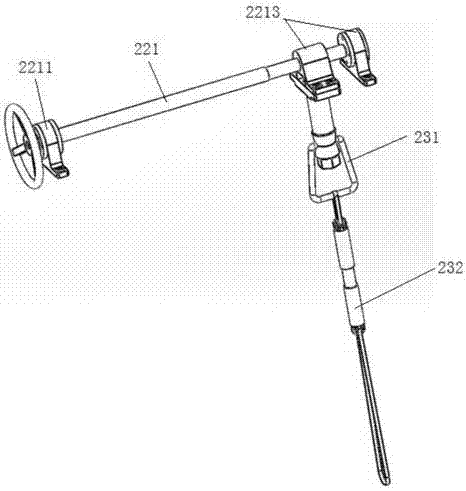

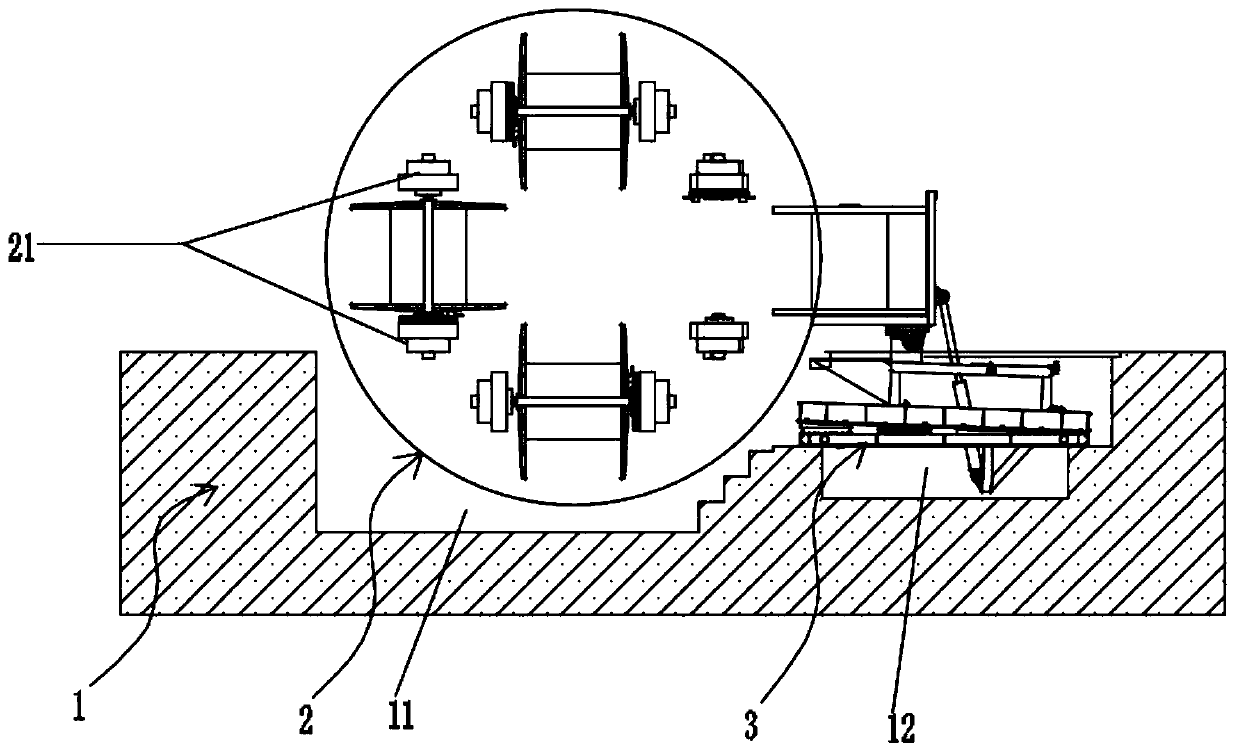

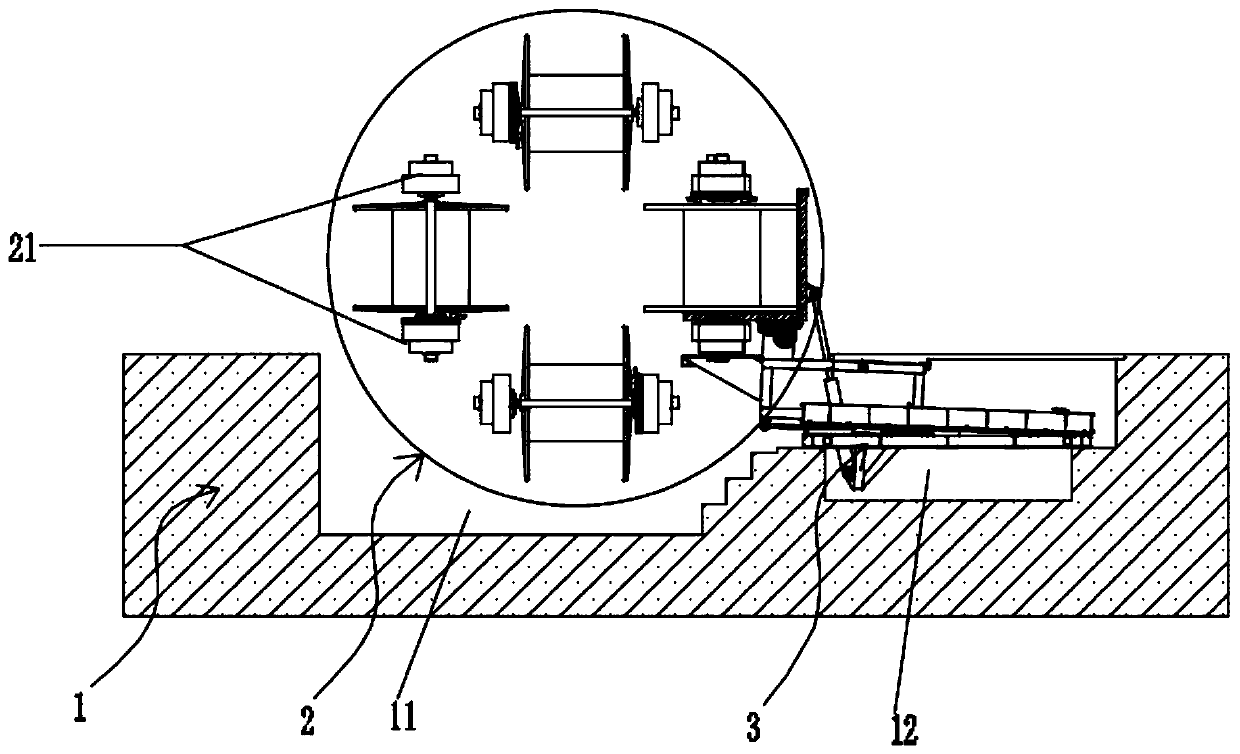

Assembly tool capable of replacing gearbox overhead without dismounting wind wheel

ActiveCN107140536AImprove hoisting efficiencyHoisting safetyMachines/enginesWind energy generationEngineeringMechanical engineering

The invention discloses an assembly tool capable of replacing a gearbox overhead without dismounting a wind wheel, and belongs to the assembly field. The assembly tool comprises a mobile mechanism group and a fixing mechanism used for supporting and fixing the mobile mechanism group, wherein the mobile mechanism group comprises an X-axis regulating mechanism, a Y-axis regulating mechanism and a Z-axis regulating mechanism; the X-axis regulating mechanism comprises at least two X-axis rails which are arranged in parallel and at least four mobile blocks capable of moving on the X-axis rails, and a connecting frame is arranged between every two mobile blocks; the Y-axis regulating mechanism comprises two parallel supporting transverse frames which are perpendicularly connected with the two connecting frames; a Y-axis slide slot is formed in each supporting transverse frame; a lead screw structure is arranged at each of two ends of each Y-axis slide slot; the Z-axis regulating mechanism comprises an adjustable connector which is connected on a mobile part for connecting and fixing a to-be-assembled object; and the X-axis rails are arranged on a supporting longitudinal beam on the upper part of the fixed mechanism. According to the assembly tool disclosed by the invention, the position and speed of the gearbox are precisely controlled through three dimensions, so that the purpose of replacing the gearbox overhead without dismounting the wind wheel is achieved, and therefore, lifting efficiency is improved.

Owner:GUODIAN UNITED POWER TECH

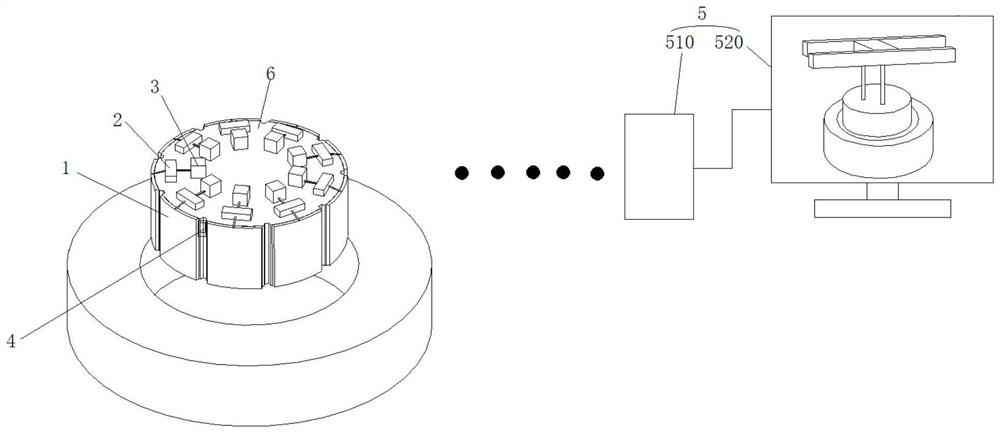

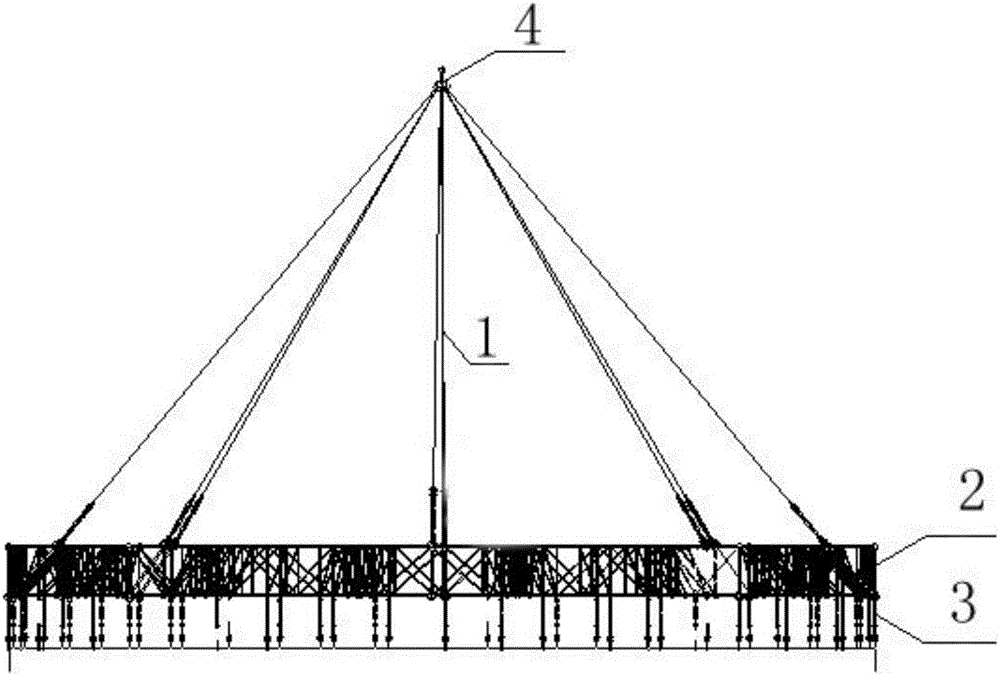

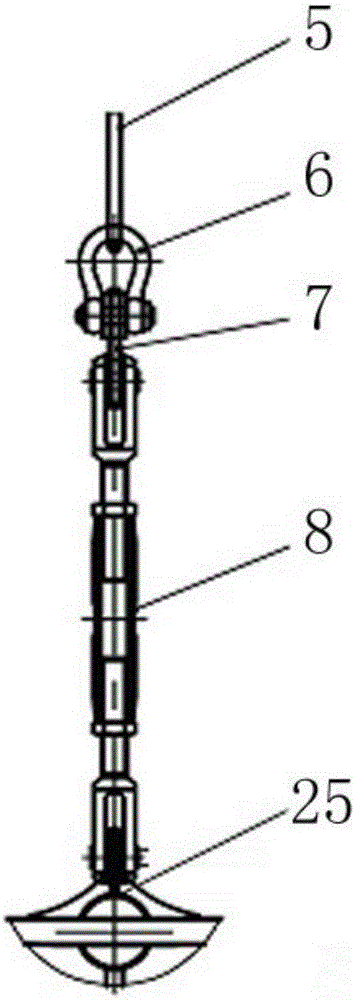

System for hoisting steel lining module of nuclear power station

ActiveCN106395605AStructural stability and safetyHoisting process safetyLoad-engaging elementsEngineeringNuclear power plant

The invention discloses a system for hoisting the steel lining module of a nuclear power station. The system comprises an upper hoisting cable tool system, a truss hoisting tool and a lower hoisting cable tool system; in the upper hoisting cable tool system, an adjustable length connection way formed by a main steel wire rope, a flat shackle, a connecting pulling plate and an adjustable pulling rod is adopted between the truss hoisting tool and a hoisting machine hoisting hook; and in the lower hoisting cable tool system, a space-adjustable flexible connection way formed by a turnbuckle, a steel wire rope ring, a circular ring plate, an upper shackle and a lower shackle is adopted between the truss hoisting tool and a module hoisting point. The system guarantees structure stability and hoisting process safety during the hoisting of the steel lining module, working at heights during the construction of a containment steel lining of the nuclear power station is reduced, the intersection of time and space during the construction with concrete is reduced, the construction cycle of the nuclear power station is shortened, and the economic benefit is improved; and moreover, convenient and fast construction of hoisting tools for hoisting during the hoisting of the steel lining module is facilitated.

Owner:CHINA NUCLEAR IND 24 CONSTR

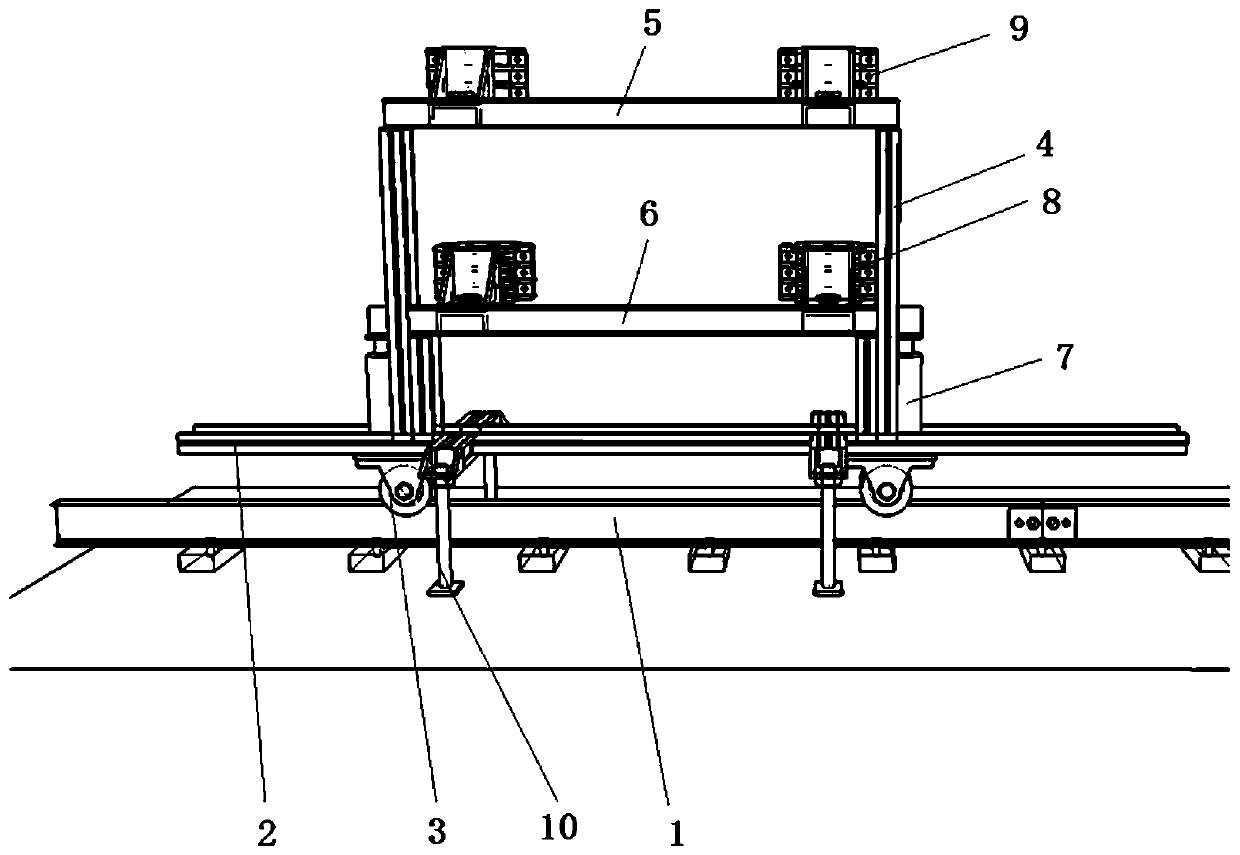

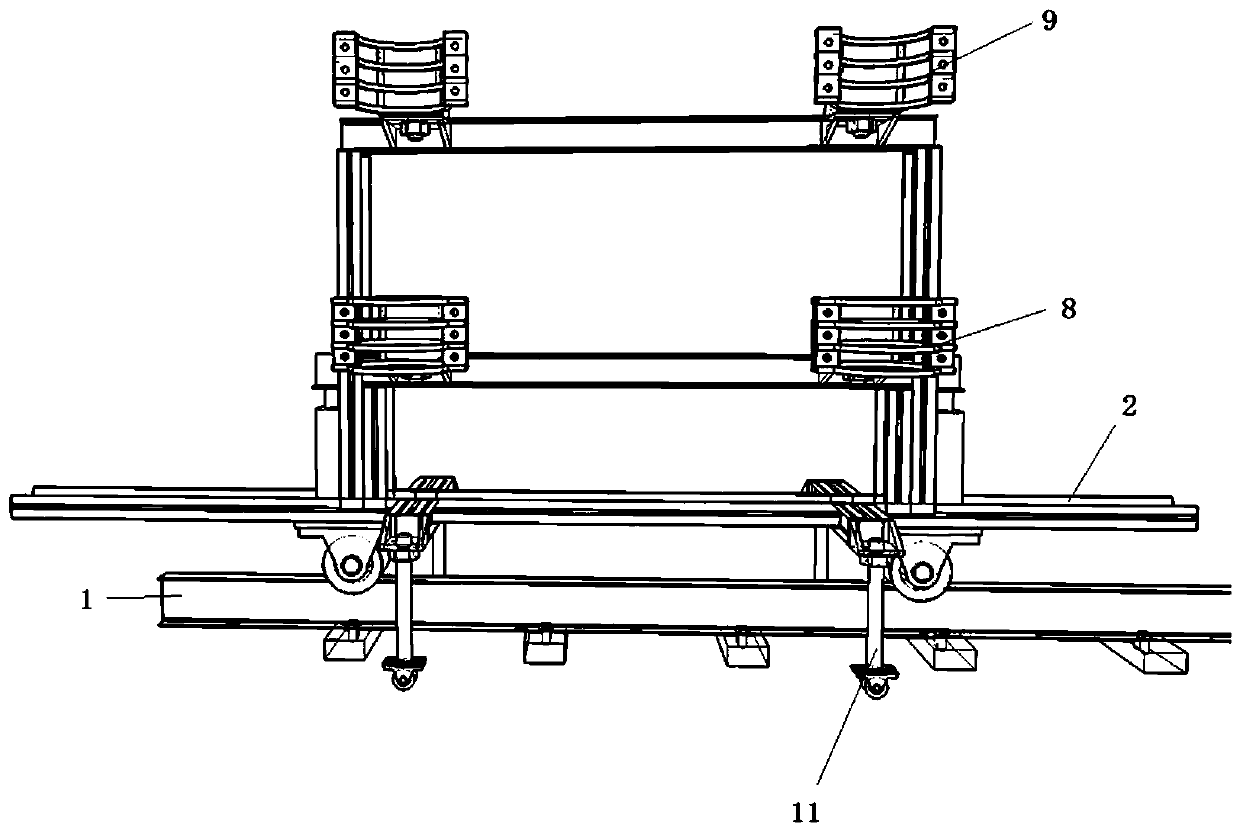

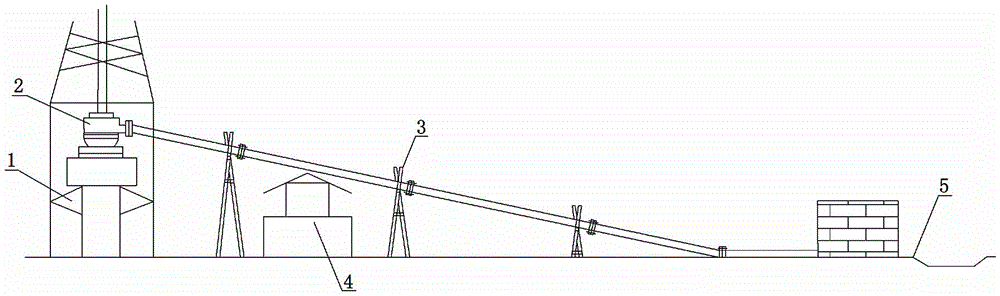

Rail type traction system for hoisting transportation

PendingCN111038940AEasy to assembleStrong applicabilityLifting framesMechanical conveyorsAutomotive engineeringTraction system

The invention relates to a rail type traction system for hoisting transportation. The system comprises a rail and is characterized in that a traction tool car is arranged on the rail, the traction tool car comprises a base and a steel wheel set located at the lower portion of the base, the steel wheel set is arranged on the rail, and the system has the characteristics that a supporting stand column is arranged on the base, a fixed cross beam is arranged on the upper portion of the supporting stand column, a jacking cross beam is arranged in the middle of the supporting stand column, the jacking cross beam is connected with a jacking device and driven by the jacking device to do lifting motion, a connecting structure is arranged on the jacking cross beam and used for being connected with aconveyed object, an adjustable fixing support and an adjustable pulley support are arranged at the bottom of the base, the adjustable fixing support is used for supporting the traction tool car when the traction tool car stops, and the adjustable pulley support is used for supporting the traction tool car when the traction tool car moves. The traction system can meet the working condition requirements of transverse movement, vertical hoisting transportation and the like, the influence of limiting the system by a working site is small, a rail system is suitable for various site environments, and the hoisting method is safe, reliable, stable, feasible and advanced in technology.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Device for safely raising and lowering a rifle between the ground and an elevated stand

InactiveUS7594351B1Good adhesionHoisting safetyCartridge extractorsAmmunition loadingEngineeringRifle

A device to be removably attached to a rifle or weapon to safely hoist and lower the weapon to and from an elevated stand. The device has a pair of legs which, together with the butt of the weapon, form a tripod to support the weapon while it is on the ground. A method for using the device.

Owner:WALKER SAMUEL E

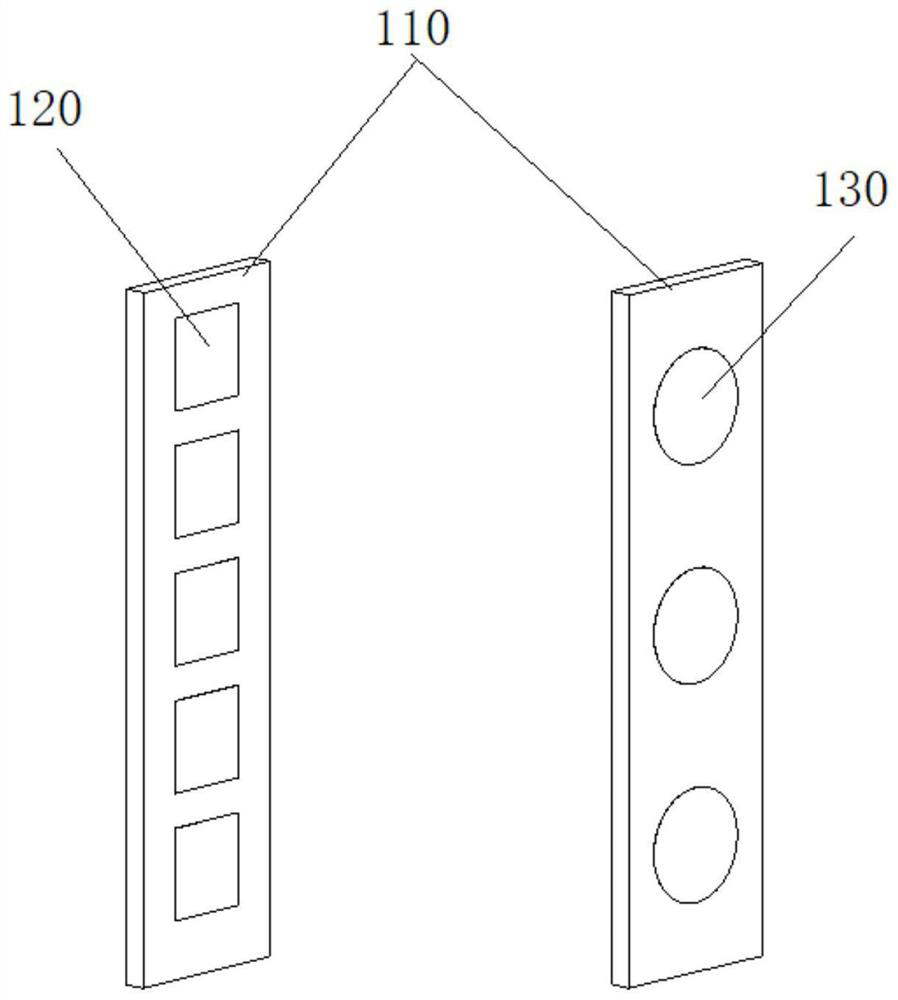

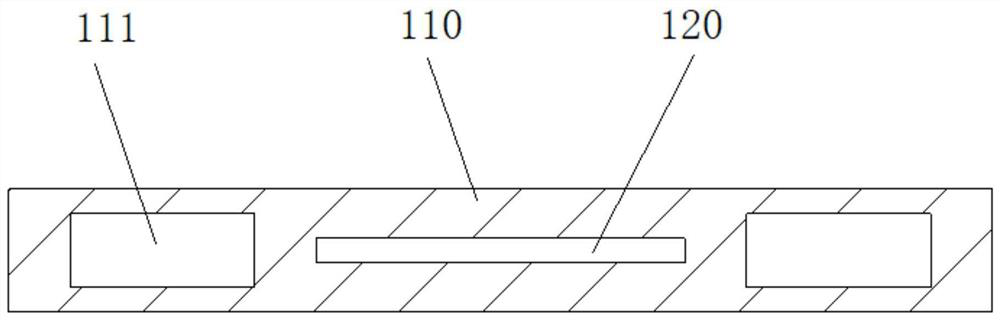

Prefabricated bearing platform form and mounting method thereof

PendingCN107443550ALabor savingSave raw materialsMould separation apparatusFoundation engineeringSocial benefitsBrick

The invention discloses a prefabricated bearing platform form and a mounting method thereof. The prefabricated bearing platform form comprises a plurality of plate bodies which are in sequential matched end-to-end connection, wherein upper concave tongue-and-groove openings or lower concave tongue-and-groove openings are formed in two sides of the plate bodies, and the upper concave tongue-and-groove openings and the lower concave tongue-and-groove openings are matched with each other; and when the plate bodies are in matched connection with the adjacent plate bodies, the upper concave tongue-and-groove openings in the plate bodies are spliced with the lower concave tongue-and-groove openings of the adjacent plate bodies. The mounting method of the prefabricated bearing platform form comprises the following steps: pouring of a bedding layer of a bearing platform; lofting of the bearing platform; hoisting and splicing of the plate bodies; axis location; elevation review, back-filling treatment; and pouring of the bearing platform after back-filling and compacting. The prefabricated bearing platform form replaces a brick membrane, shortens the foundation construction period, can effectively save the labor force and raw materials particularly for foundations with tight schedules and poor foundation soil qualities, decreases cost and increases benefits, and has good economic benefits and social benefits.

Owner:佛山市万科置业有限公司

Lateral coil feeding device for cable former

PendingCN109850688AEasy to install manuallyEasy to useFilament handlingCable/conductor manufactureMoving framePiston rod

The invention discloses a lateral coil feeding device for a cable former. The lateral coil feeding device comprises a cement face, a cable former body and a coil feeding mechanism. The cement face isprovided with a first groove and a second groove. The coil feeding mechanism is arranged in the second groove and comprises a coil feeding framework, a moving frame, a triangle fixing frame, a first air cylinder piston rod, a fixing base, an L-shaped rack, a wire coil and a second air cylinder piston rod. A hollow portion is arranged on the coil feeding framework. One end of the second air cylinder piston rod is fixedly connected with the coil feeding framework. The other end of the second air cylinder piston rod is fixedly connected with the moving frame. According to the lateral coil feedingdevice, by means of the first air cylinder piston rod, the L-shaped rack can be driven to rotate on the fixing base, thus the wire coil is driven to rotate by 90 degrees, by arranging the second aircylinder piston rod, the moving frame can be pushed to slide horizontally, the wire coil reaches the designed position to be installed manually, manual installing is convenient, use is convenient, andhoisting is safer compared with a traditional technology.

Owner:HEFEI SMARTER TECH GROUP CORP

Slabstone lifting appliance

The invention discloses a slabstone lifting appliance which comprises a lifting beam, wherein the upper part of the lifting beam is sleeved with at least two sliding seats capable of sliding along thelength direction of the lifting beam; a guide structure, which is capable of vertically limiting the sliding seats and the lifting beam, is arranged between the sliding seats and the lifting beam; apositioning mechanism is also arranged between the sliding seats and the lifting beam to fix the sliding seats and the lifting beam; a lifting rope and a lifting tape capable of sleeving a slab penetrate through each sliding seat. According to the slabstone lifting appliance disclosed by the invention, by adjusting the space between the two sliding seats, the lifting tape can sleeve the slabs different in length so as to realize high adaptability and convenient adjustment; the sliding seats are firmly connected with the lifting beam, and thus the lifting is safe; moreover, connection or disassembly is convenient to facilitate replacement; the slabs different in width can be lifted, and thus the application range is wide.

Owner:广西钟山县天顺石材有限公司

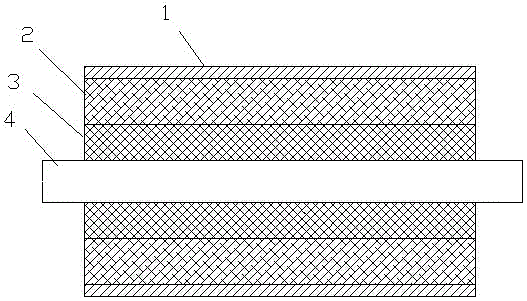

Prefabricated overhead steam heat preservation pipeline and production technology

InactiveCN105156768ALight in massImprove anti-corrosion performanceThermal insulationPipe protection by thermal insulationEngineeringSteel tube

The invention discloses a prefabricated overhead steam heat preservation pipeline and a production technology and belongs to the technical field of steam heat preservation pipeline equipment and production methods. The prefabricated overhead steam heat preservation pipeline and the production technology are used for improving the heat preservation effect and corrosion resistance of an overhead steam heat preservation pipe and are convenient to construct. The adopted technical scheme is as follows: the internal insulating layer of the prefabricated overhead steam heat preservation pipeline is a high-temperature-resistant inorganic insulating layer, the external insulating layer of the prefabricated overhead steam heat preservation pipeline is an organic insulating layer, the external protecting pipe of the prefabricated overhead steam heat preservation pipeline is a galvanized air pipe, the internal insulating layer wraps the periphery of a working steel pipe, the external insulating layer wraps the periphery of the internal insulating layer, and the external protecting pipe sleeves the external insulating layer. The prefabricated overhead steam heat preservation pipeline, disclosed by the invention, breaks through the traditional heat preservation structure, adopts the dual heat preservation structure of the combination of the high-temperature-resistant inorganic insulating layer and the organic insulating layer, is innovation for steam heat preservation pipelines, effectively solves the problems that the traditional steam heat preservation pipeline is inconvenient to construct, poor in heat preservation effect, easy to corrode and the like, is simple and practical in production technology, can effectively reduce the production cost, ensures the product quality, and has great popularization and application value.

Owner:河北君业科技股份有限公司

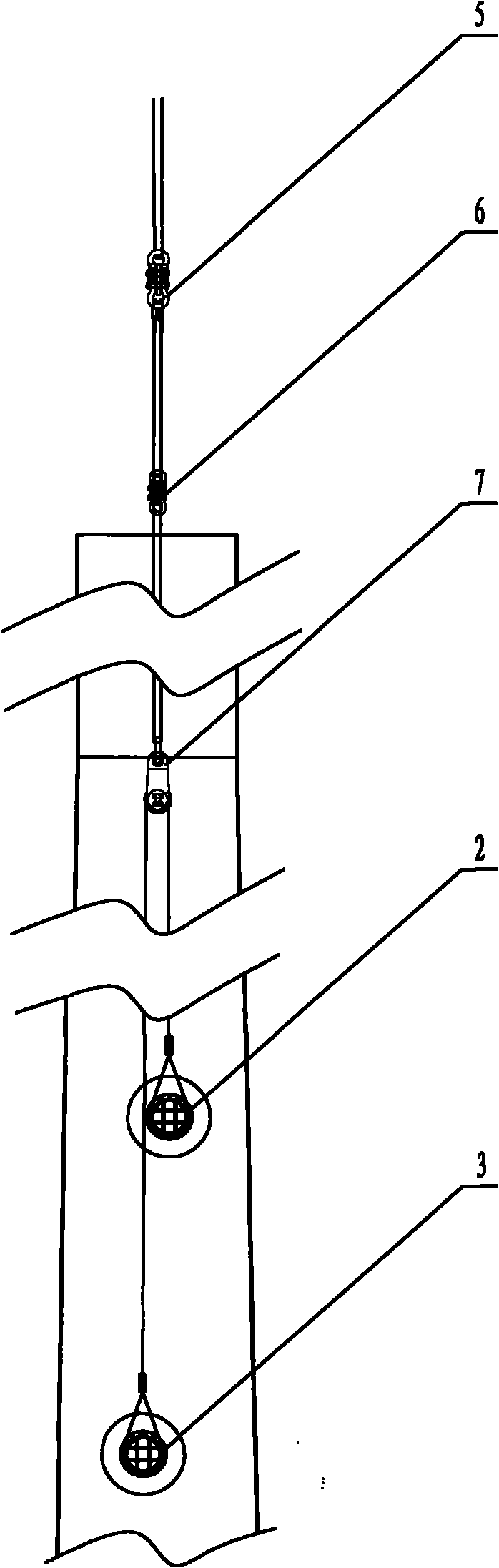

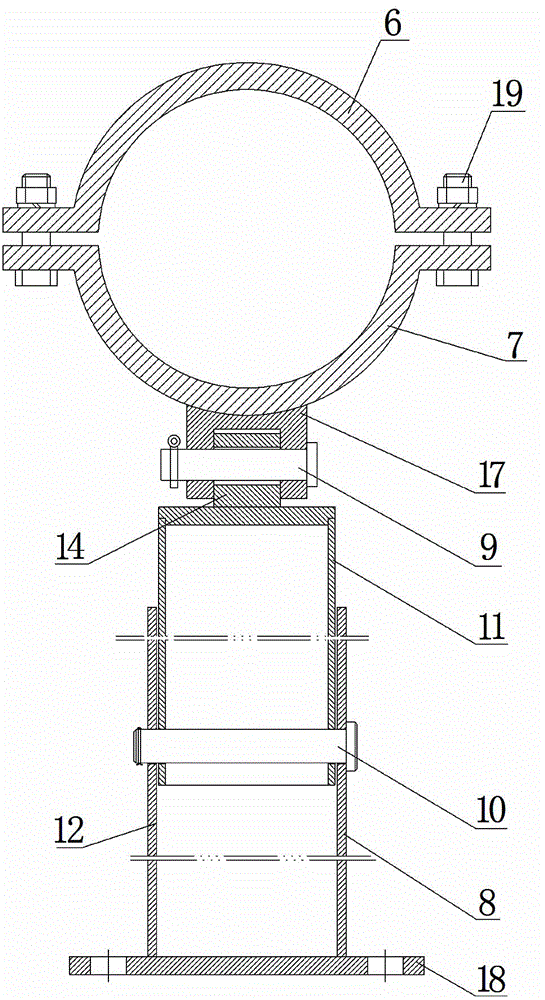

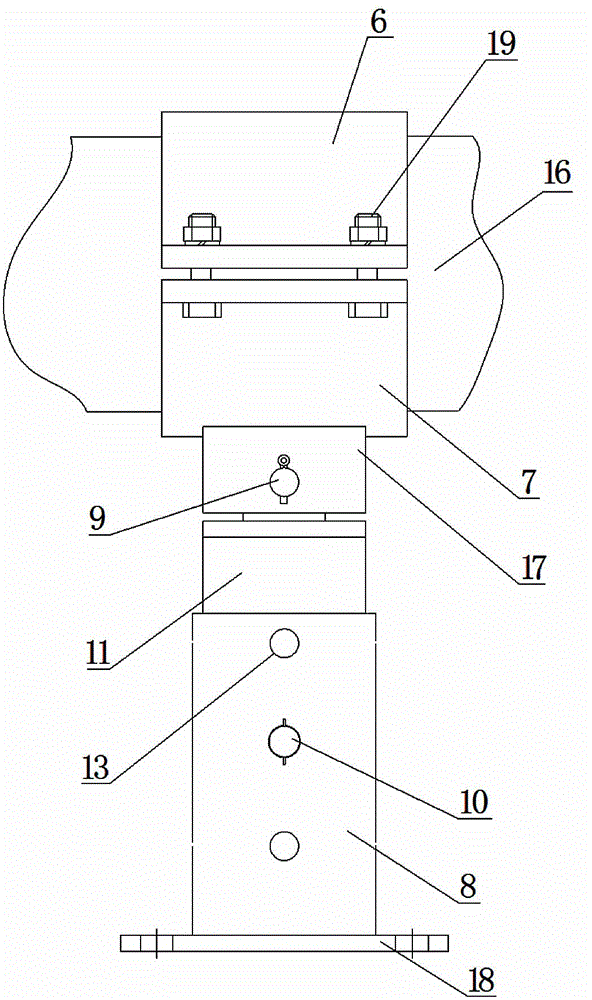

Novel supporting device for gas drilling sand draining pipe

The invention discloses a novel supporting device for a gas drilling sand draining pipe. The novel supporting device comprises an upper pressing sleeve (6), a lower supporting sleeve (7), a supporting base (8) and a height adjusting sleeve (11). A plurality of through holes I (13) penetrating through the supporting base (8) are formed in the cylindrical surface of the supporting base (8) in the length direction of the supporting base (8). A plurality of through holes II (15) penetrating through the height adjusting sleeve (11) are formed in the cylindrical surface of the height adjusting sleeve (11) in the length direction of the height adjusting sleeve (11). The height adjusting sleeve (11) is fixed into a cavity (12) through a height fixing pin (10) which penetrates through any through hole I (13) and the corresponding through hole II (15). The upper pressing sleeve (6) is fixed to the lower supporting sleeve (7) through connecting bolts (19). The bottom of the lower supporting sleeve (7) is further provided with a single-hole hinge support (17). The novel supporting device has the advantages that the mounting difficulty is lowered, the construction time is shortened, the suspension stability is improved, and safety and reliability are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Safety hoisting tool for large-sized pump bodies applied to petroleum transportation

The invention discloses a safety hoisting tool for large-sized pump bodies applied to petroleum transportation. The safety hoisting tool comprises a balance plate and pothooks, wherein a weighting block is arranged at the upper end of the middle part of the balance plate; a hoisting ring is arranged at the upper end of the weighting block; the balance plate is provided with clamping notches at the two ends of the weighting block along the axial direction; the pothooks are arranged in the clamping notches of the two ends; each pothook comprises a fixture block clamped at the upper end of the clamping notch and a pothook rod connected to the fixture block and passing through the clamping notch; a locknut is sleeved on the pothook rod; a thread segment matched with the locknut is arranged at the upper end of the pothook rod; and pothook bodies are arranged at the lower ends of the pothook rods. The safety hoisting tool has the beneficial effects that the interval between the pothooks can be adjusted according to the pump bodies of different sizes, thereby meeting the hoisting of the pump bodies of different sizes, after hoisting, the pothooks are locked through the locknuts, do not shift and are safe for the pump bodies, and the safety hoisting tool is stable in structure on the whole during hoisting, does not cause the rotation of the pump bodies and is good in hoisting safety and stability.

Owner:黄霞

Goods lifting device

ActiveCN105883596AImprove versatilityFirmly connectedLoad-engaging elementsIndustrial engineeringLifting equipment

The invention discloses a goods lifting device and relates to the technical field of goods lifting. The goods lifting device comprises a lifting open-mouth clamp and a clamping handle, wherein the lifting open- mouth clamp comprises a first clamping plate, a second clamping plate and a third clamping plate, the second clamping plate is fixedly connected with the first clamping plate, the third clamping plate is fixedly connected with the first clamping plate, and an accommodating part for lifted goods is formed between the two opposite side surfaces of the second clamping plate and the third clamping plate; and the clamping handle comprises a screw and a pressing plate, the screw is vertically fixedly connected with the pressing plate, the screw is in thread connection with the second clamping plate, and through rotating the screw, the lifted goods are clamped between the pressing plate and the third clamping plate. The goods lifting device has the advantages that the lifted goods are clamped between the clamping handle and the third clamping plate by the goods lifting device, lifting equipment is directly connected with the lifting device, and the goods lifting device is convenient to connect, great in universality and particularly suitable for the lifting of thin plate type goods.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com