Slabstone lifting appliance

A sling and slate technology, which is applied to load hanging components, transportation and packaging, etc., can solve the problems of inconvenience of sling distance adjustment, inconvenience for sling to be attached to the board, and the board is easy to bump, so as to achieve convenient and adaptable connection or disassembly. Good, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

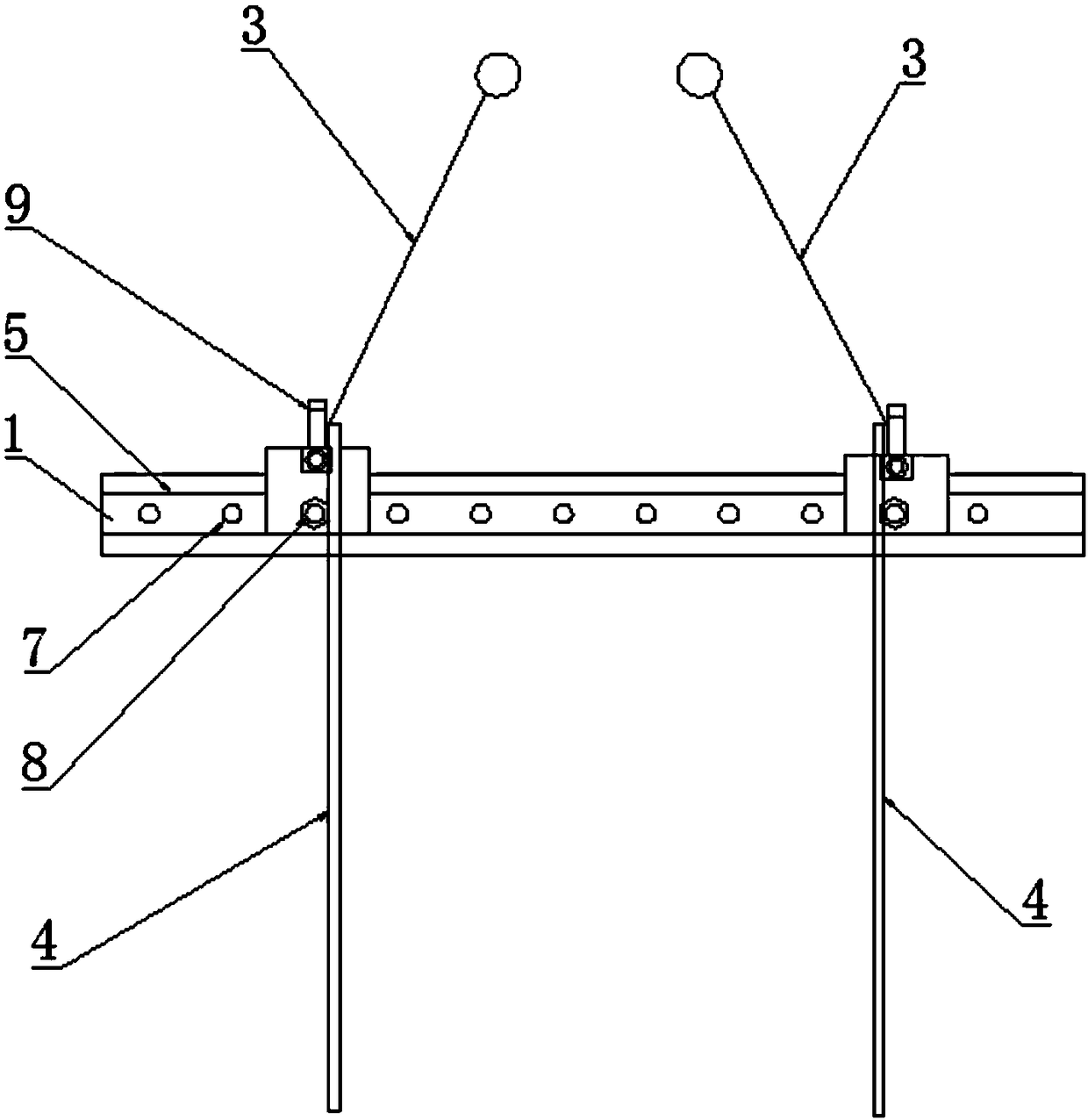

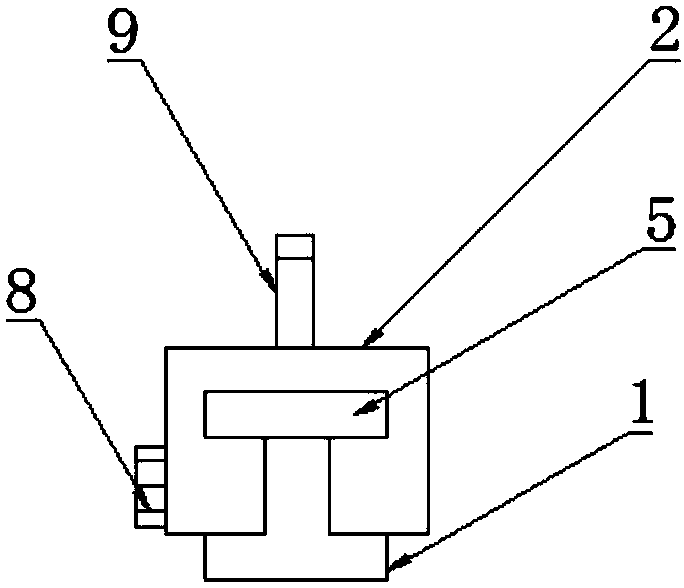

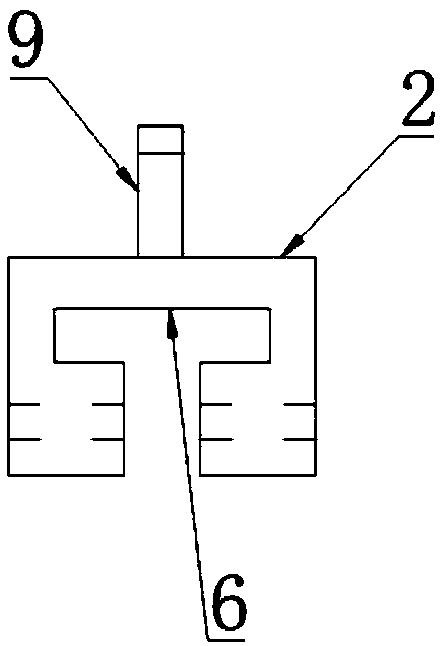

[0019] The specific embodiment of the present invention is like this: as Figure 1-4 As shown, a stone slab spreader includes a hanging beam 1. At least two sliding seats 2 that can slide along its long direction are sleeved on the upper part of the hanging beam 1. The guiding structure of vertical direction limit, there is also a positioning mechanism between the sliding seat 2 and the hanging beam 1 to fix the two; the sliding seat 2 is threaded with a lifting rope 3 and a sling 4 that can be placed on the plate; the sliding seat 2 can slide along the long direction of the suspension beam 1, and adjust the distance between the two sliding seats 2, so that the suspension belt 4 can be socketed with plates of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com