Super large curved surface glass curtain wall mechanical installation method

A technology of curved glass and installation method, applied in the direction of walls, building components, buildings, etc., can solve the problems of unrealistic installation, high risk, large glass curtain wall panels, etc., to achieve convenient height and angle, reduce labor, and hoisting safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

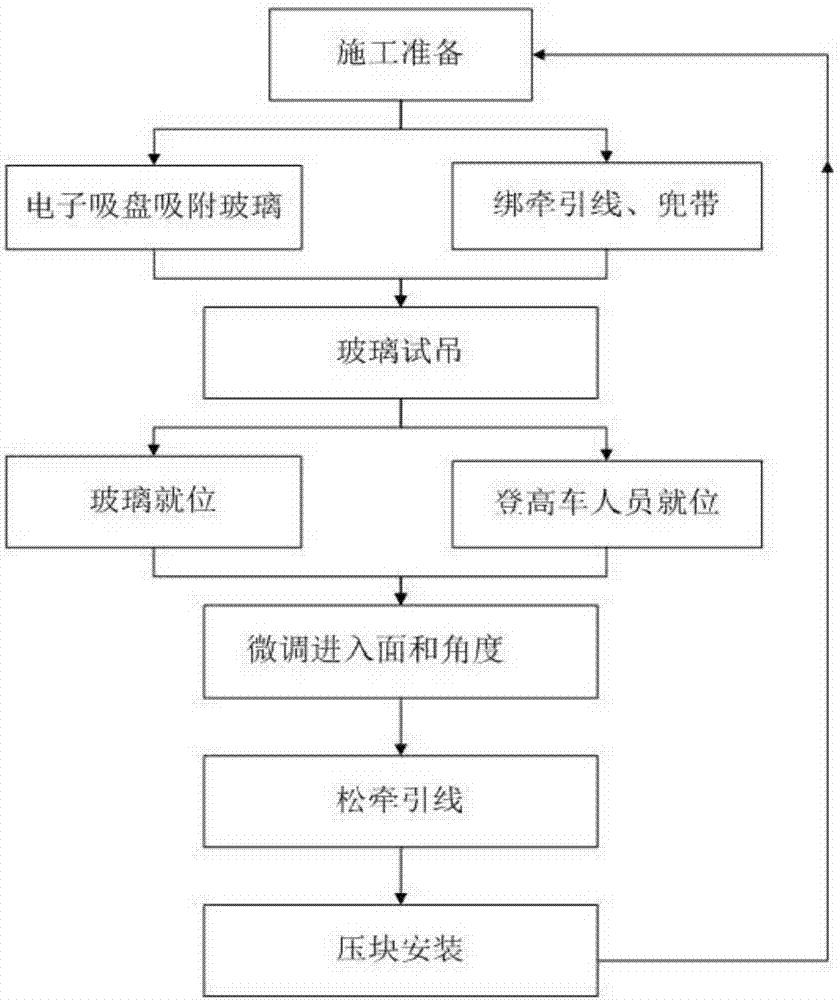

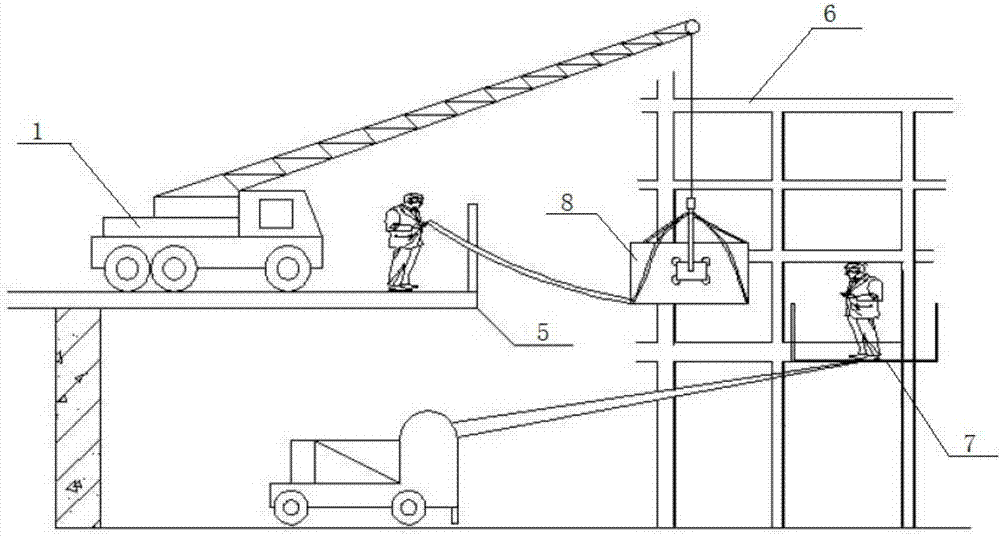

[0027] Embodiment 1: as figure 1 The flow chart of the mechanized installation method of super-large curved glass curtain wall includes the following steps: construction preparation → electronic suction cup absorbs glass and binds traction rope, belt → glass test hoisting → glass is in place and climbing car 7 personnel are in place → glass fine-tuning → Loosen the traction rope → Install the pressing block.

[0028] The specific construction method is as follows:

[0029] (1) Construction preparation

[0030] After the inspection of the machinery and equipment entering the site is completed, the layout of the site shall be reasonably arranged according to the actual situation to ensure the smooth progress of the construction. Arrange the glass to be transported, specify the route of the machine and clean up the keel.

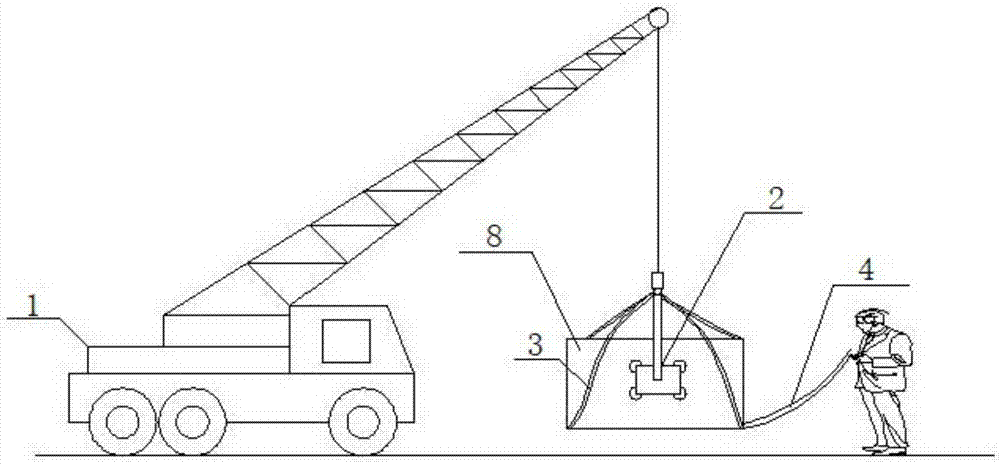

[0031] (2) Electronic sucker absorbs glass and binds traction rope and belt

[0032] Such as figure 2 As shown, determine the glass 8 to be transported, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com