Method for three-dimensionally capturing and rotating micromechanical member by using ultrasonic radiation force

A micromechanical component, ultrasonic radiation technology, applied in microstructure technology, microstructure devices, chemical instruments and methods, etc., can solve the problems of microcomponent damage, controllable object limitation, unable to solve the problem of driving objects to rotate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

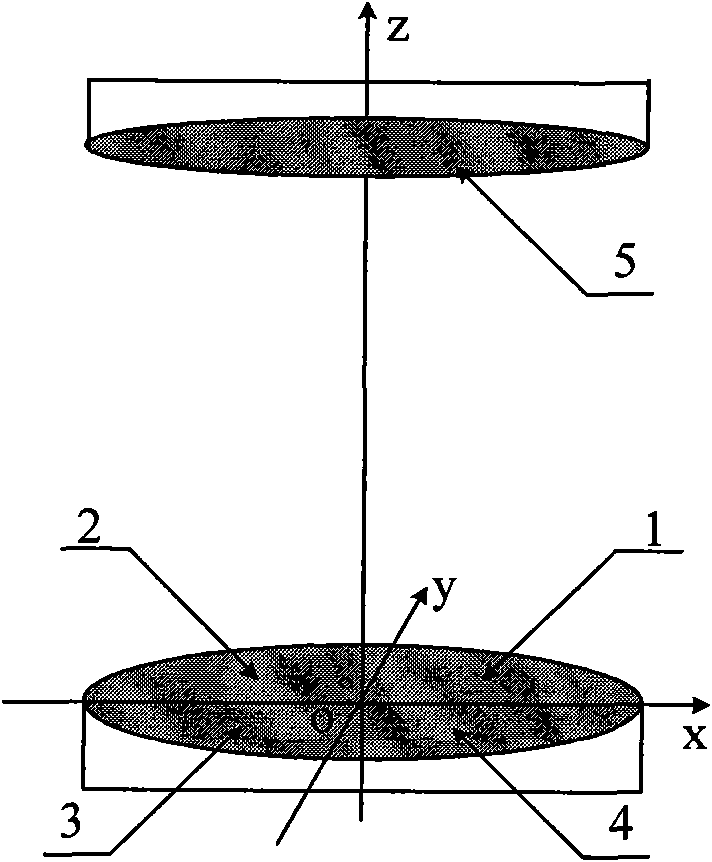

[0017] Such as figure 1 As shown, the present invention uses four identical plane quarter-circle fan-shaped ultrasonic transducers to form a complete circle, and controls the initial phases of the driving signals of the four transducers so that they are sequentially different by 90°. At this time, the four ultrasonic transducers The synthetic sound field of the transducer has a helical wavefront, and another planar circular ultrasonic transducer is arranged on the axis passing through the center of the circle and perpendicular to the plane where the circular surface is located, and its radiated sound wave propagation direction is the same as that of the four transducers mentioned above. The propagation direction is opposite, and the micro-components located in the interference superposition sound field of the four parallel transducers and the backpropagation transducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com