Preparation device of environment-friendly alloy new material alloy bar for food mechanical part

A technology for food machinery and preparation devices, which is applied to the parts of grinding machine tools, grinding drive devices, metal processing equipment, etc., can solve the problems of inconvenient grinding, poor grinding effect, grinding errors, etc. effect, improved gripping effect, improved stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

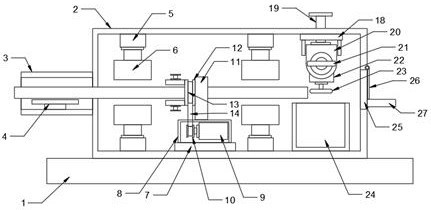

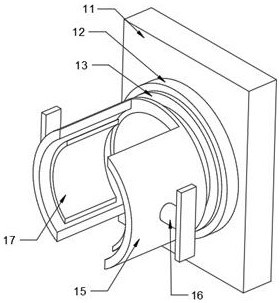

[0023] see Figure 1~4 , in an embodiment of the present invention, a device for preparing an environmentally friendly alloy new material alloy rod for food machinery parts, comprising a bottom plate 1, a processing box 2 and a polishing sheet 23, the upper end of the bottom plate 1 is equipped with a processing box 2, and the middle part of the left end of the processing box 2 Be provided with fixed tube 3, fixed tube 3 inboard bottom end is equipped with support plate 4, processing box 2 inboard left end is provided with telescopic motor 5, telescopic motor 5 front end is equipped with fixed plate 6, and fixed plate 6 inboard is equipped with fixed cylinder 29, fixed A turret 30 is installed on the inner side of the cylinder 29, and a roller 31 is installed in the middle of the turret 30; four telescopic motors 5 and four fixed plates 6 are arranged, which are divided into two groups and installed on the left and right sides of the fixed frame 11 and are symmetrical about the...

Embodiment 2

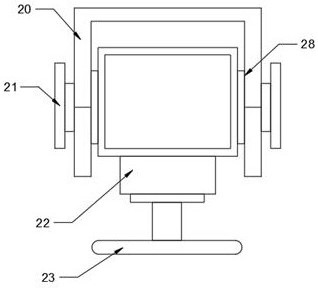

[0027] In an embodiment of the present invention, a device for preparing an environmentally friendly alloy new material alloy rod for food machinery parts includes a bottom plate 1, a processing box 2 and a polishing sheet 23. Fixed pipe 3 is arranged, and support plate 4 is installed on the inner bottom end of fixed pipe 3, and telescopic motor 5 is arranged on the left end of processing box 2, and fixed plate 6 is installed on the front end of telescopic motor 5, and fixed cylinder 29 is installed on the inboard of fixed plate 6, and fixed cylinder 29 inboards are equipped with a turret 30, and the middle part of the turret 30 is equipped with a roller 31; the upper end of the right side of the processing box 2 is equipped with a limit frame 18, and the middle part of the limit frame 18 is equipped with a second threaded rod 19, and the bottom of the second threaded rod 19 A support frame 20 is installed at the end, a knob 21 is installed on the outside of the support frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com