Prefabricated overhead steam heat preservation pipeline and production technology

A technology of steam insulation pipe and production process, which is applied in the direction of protecting pipelines through thermal insulation, thermal insulation, pipeline protection, etc., can solve the problems of easy corrosion, inconvenient construction, poor thermal insulation effect, etc., and achieves low production cost, convenient installation, Good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

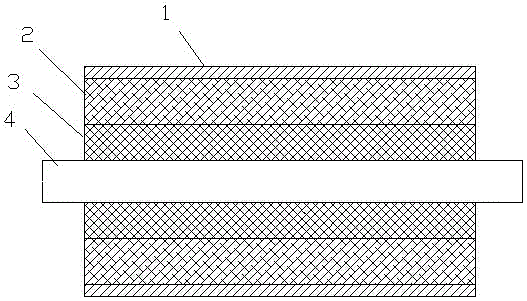

[0020] The prefabricated overhead steam insulation pipe of the present invention comprises a working steel pipe 4 , an inner insulation layer 3 , an outer insulation layer 3 and an outer protection pipe 1 .

[0021] As shown in the figure, the inner insulation layer 3 is wrapped around the outer periphery of the working steel pipe 4. The inner insulating layer 3 adopts a high-temperature resistant inorganic insulation layer.

[0022] As shown in the figure, the outer insulation layer 2 is wrapped around the outer periphery of the inner insulation layer 3, and the outer insulation layer 2 is an organic insulation layer. The organic insulation layer of an embodiment of the present invention uses polyurethane material as the insulation layer.

[0023] The present invention adopts a double thermal insulation structure combining a high-temperature-resistant inorganic thermal insulation layer and an organic thermal insulation layer. The high-temperature-resistant inorganic thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com