Structure and method for integrally breaking pile head of pile foundation

A technology of pile foundation and pile head, which is applied in the field of pile head integral removal structure of pile foundation, can solve the problems of pile foundation damage, time-consuming, major damage to main reinforcement, etc., so as to achieve a smooth pile head structure, avoid casualties, and avoid damage and damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

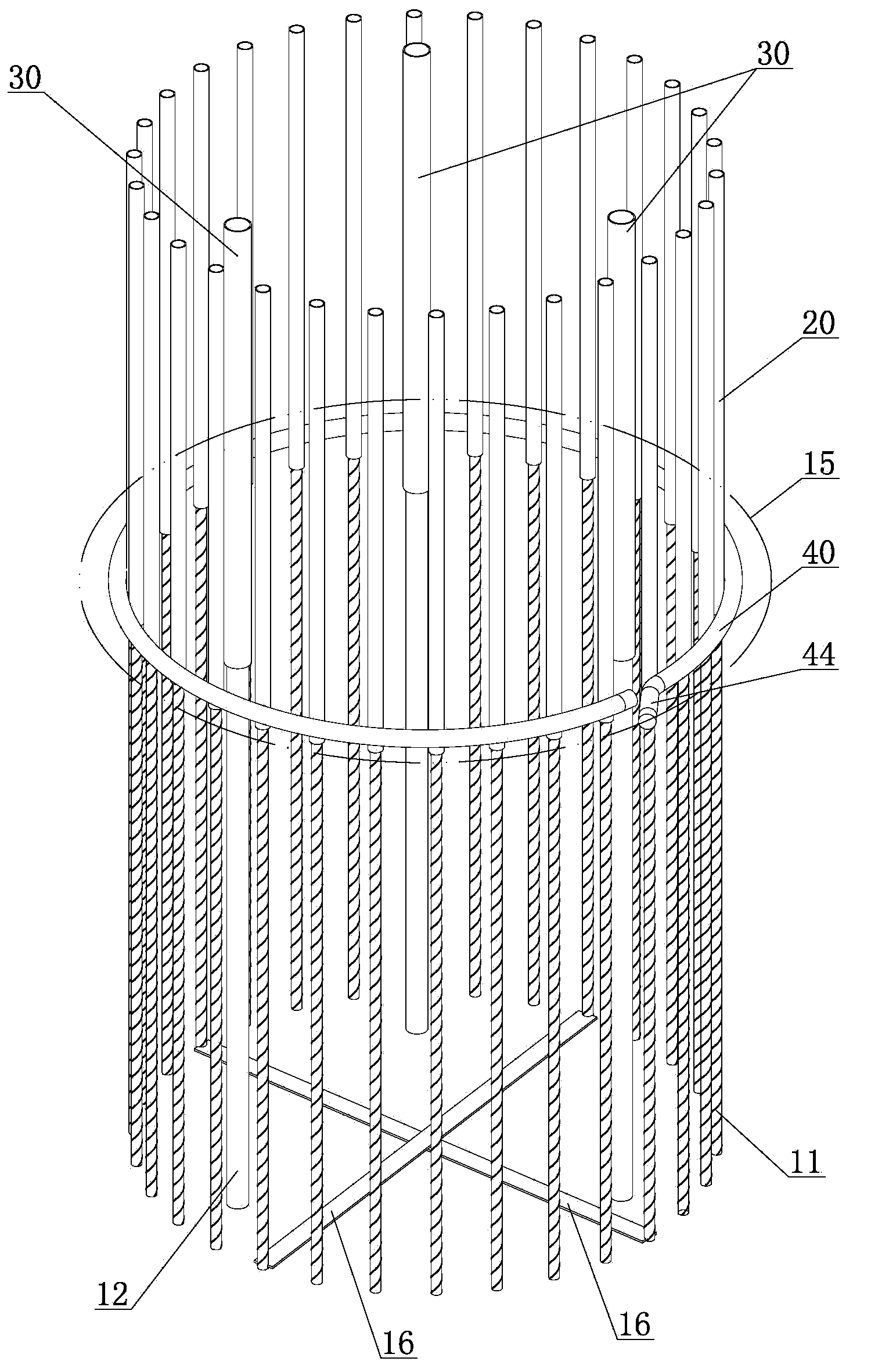

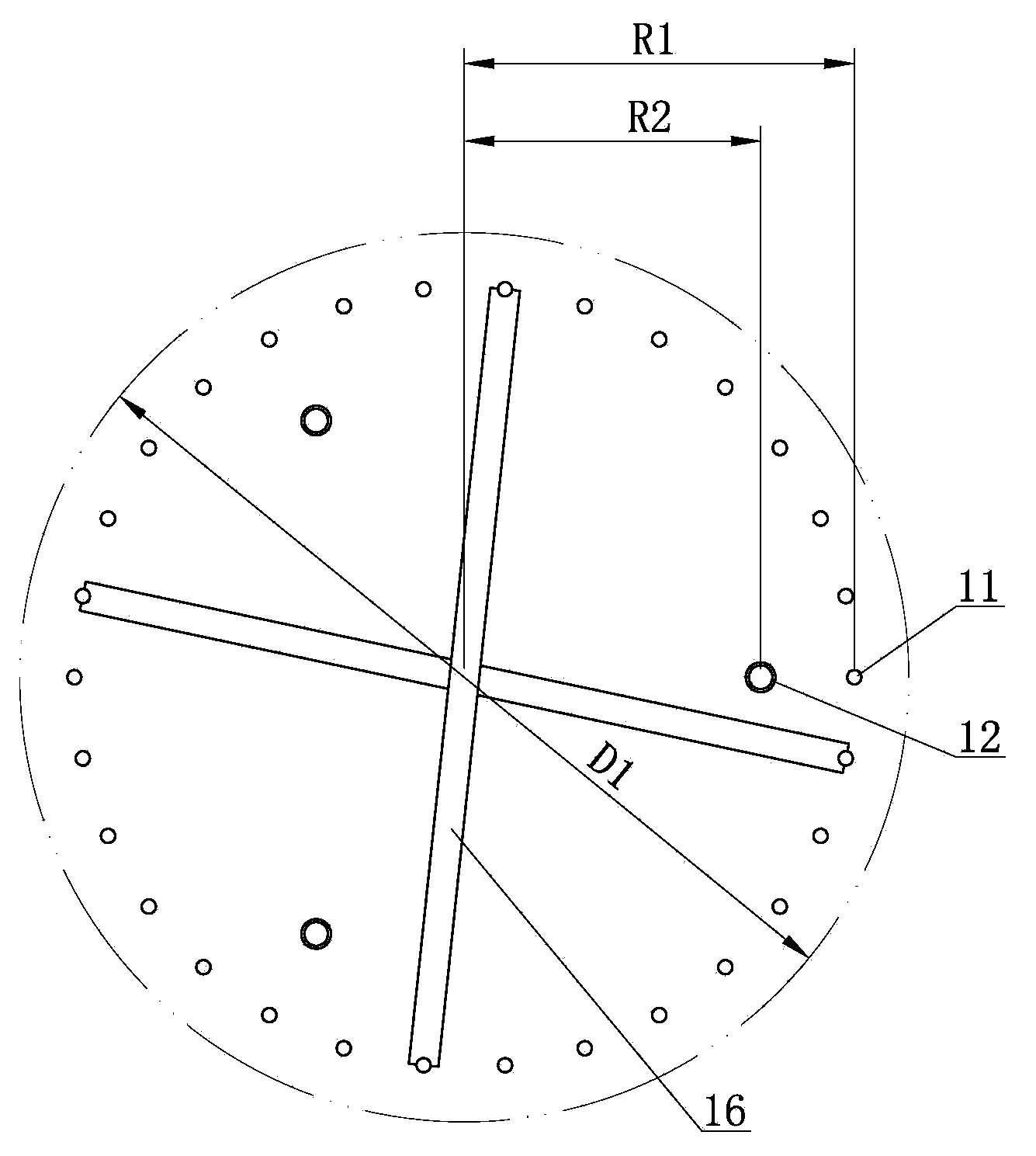

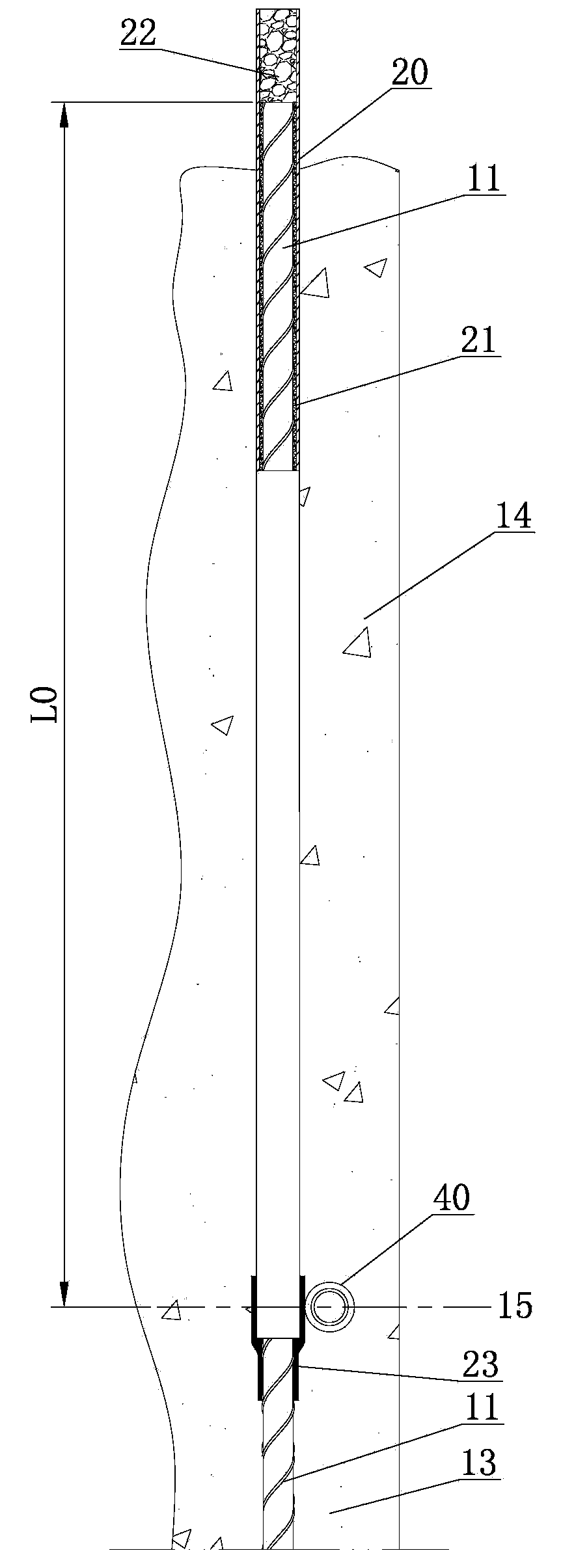

[0044] Such as Figure 1 to Figure 5 , a pile foundation pile head overall demolition structure, including the pile foundation and the steel cage main reinforcement 11 in the pile foundation, the acoustic measuring tube 12, after the pile foundation pouring is completed, the pile head of the pile foundation is from the design pile body top surface and the pile The foundation is separated, and the position of the design pile body top surface of the pile foundation is the cutting line 15 of the pile head. The pile foundation is a reinforced concrete cylinder with a diameter of D1=1500mm. The reinforcement cage is equipped with 30 main reinforcements. The main reinforcement is a steel reinforcement with a diameter of 25mm. The main reinforcement is distributed along the circumference of the pile foundation cylinder. The radius of the distribution circle at the center of the main reinforcement is R1=690mm; There are 3 acoustic tubes distributed symmetrically to the center line of ...

Embodiment 2

[0065] A pile foundation pile head overall removal method, the method adopts a kind of pile foundation pile head overall removal structure of embodiment 1, the pile head of the pile foundation is separated from the pile foundation from the design pile body top surface, the design pile of the pile foundation The position of body top surface is pile head cutting line; The step of described method comprises:

[0066] a. Determine the lengths of the main reinforcement casing and acoustic measurement casing according to the positions of the upper end of the reinforcement cage main reinforcement and the pile head cutting line of the pile foundation. The design requires that the main reinforcement is 1000mm higher than the top surface of the pile body (i.e., higher than the cutting line of the pile head), the upper end of the main reinforcement casing is 75mm higher than the upper end of the main reinforcement, and the lower end of the main reinforcement casing is 25mm lower than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com