Assembly tool capable of replacing gearbox overhead without dismounting wind wheel

A technology for assembly tooling and gearboxes, applied in the field of assembly tooling, can solve the problems of no better solution for gearbox replacement, no advantages in timeliness and economy, and time-consuming and labor-intensive problems, so as to improve hoisting efficiency and avoid assembly Easy to build and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

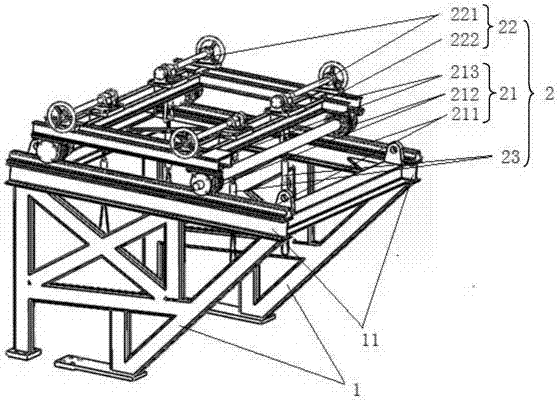

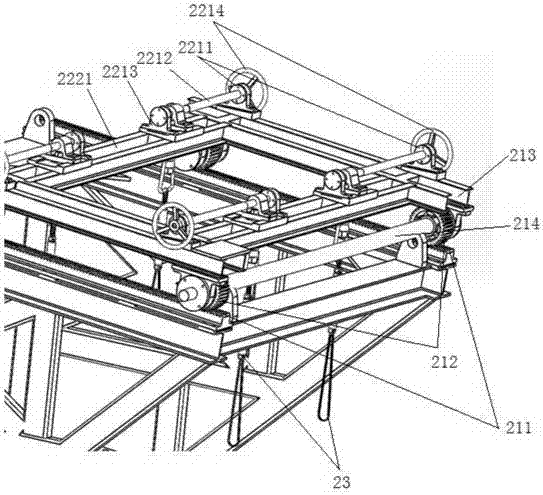

[0033] The present invention provides an embodiment of an assembly tool for replacing a gearbox in the air, such as Figure 1 to Figure 6 As shown, it includes a moving mechanism group 2 and a fixing mechanism 1 for supporting and fixing the moving mechanism group 2 . The moving mechanism group 2 includes an X-axis adjustment mechanism 21 , a Y-axis adjustment mechanism 22 and a Z-axis adjustment mechanism 23 .

[0034] The X-axis adjustment mechanism 21 includes at least two X-axis rails 211 arranged in parallel and at least four moving blocks 212 that can move on the X-axis rails and drive the moving mechanism group 2 to move. There are at least two X-axis rails 211 on each X-axis rail. For the moving block 212 , a connecting frame 213 parallel to the X-axis track 211 is connected between the two moving blocks 212 on the same X-axis track 211 .

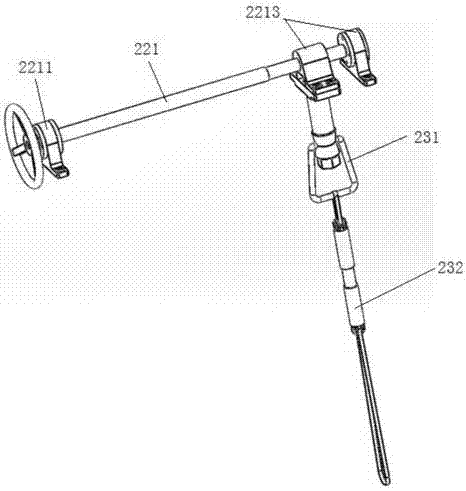

[0035] The Y-axis adjustment mechanism 22 includes two parallel support cross-frames 222 vertically connected to the two connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com