Construction method for single-piece hoisting of aluminum alloy vault of large vertical storage tank

A technology for vertical storage tanks and construction methods, which is applied in the field of hoisting and construction, and can solve problems such as high difficulty in safety and installation quality control, poor installation quality, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

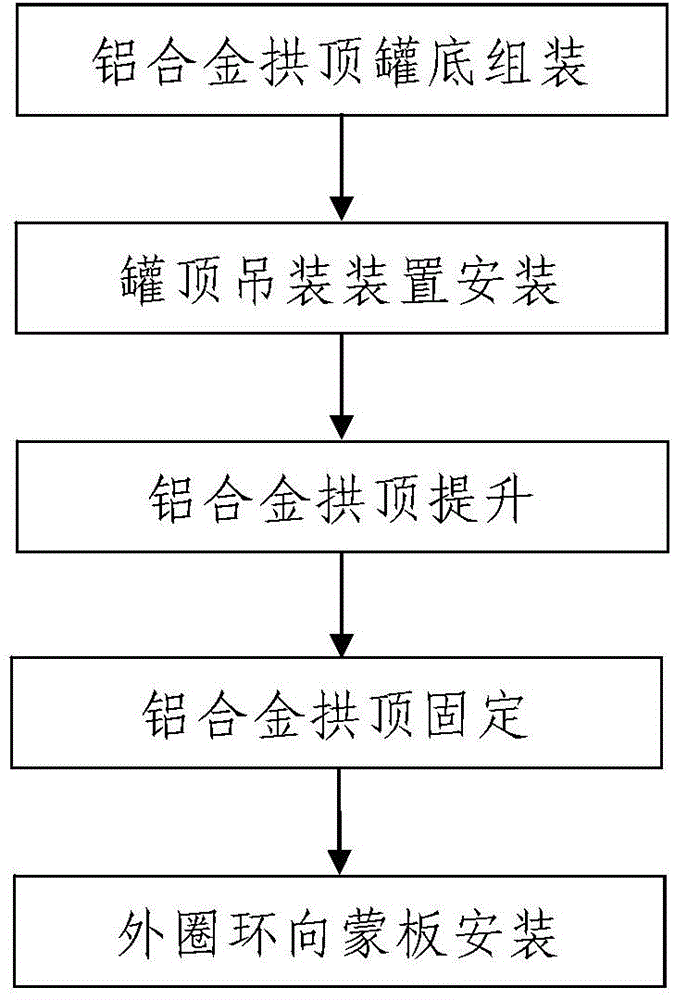

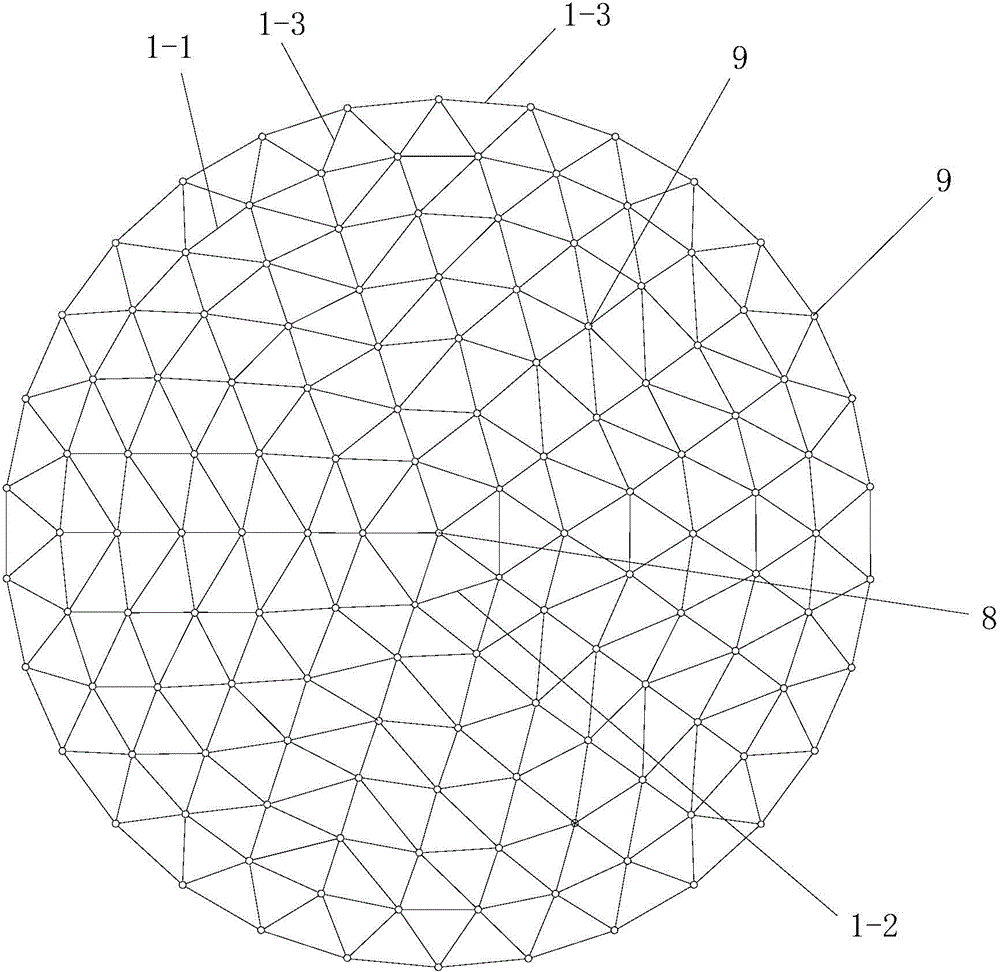

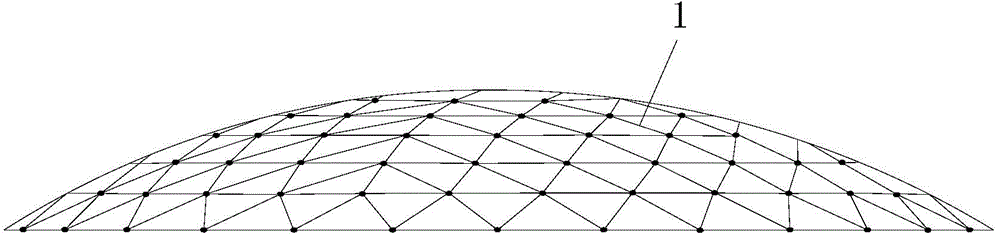

[0073] Such as figure 1 In the overall hoisting construction method of the aluminum alloy vault of a large vertical storage tank shown, the hoisted aluminum alloy vault 1 is fastened on the top of the large vertical storage tank and is located directly above the large vertical storage tank. The above-mentioned large vertical storage tank is a cylindrical storage tank arranged vertically and with an upper opening, the diameter of the cylindrical storage tank is Φ10m~Φ40m and its volume is not less than 5000m 3 . combine figure 2 with image 3 , the aluminum alloy vault 1 includes a support frame and a layer of external panels that are mounted on the support frame, and the support frame includes a central connecting piece that is arranged vertically and a plurality of layers that are arranged from the inside to the outside. The ring beams on the outside of the central connector, the multiple ring beams have the same structure and are all regular polygonal beams, the multiple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com