Patents

Literature

170results about How to "Reduce hoisting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

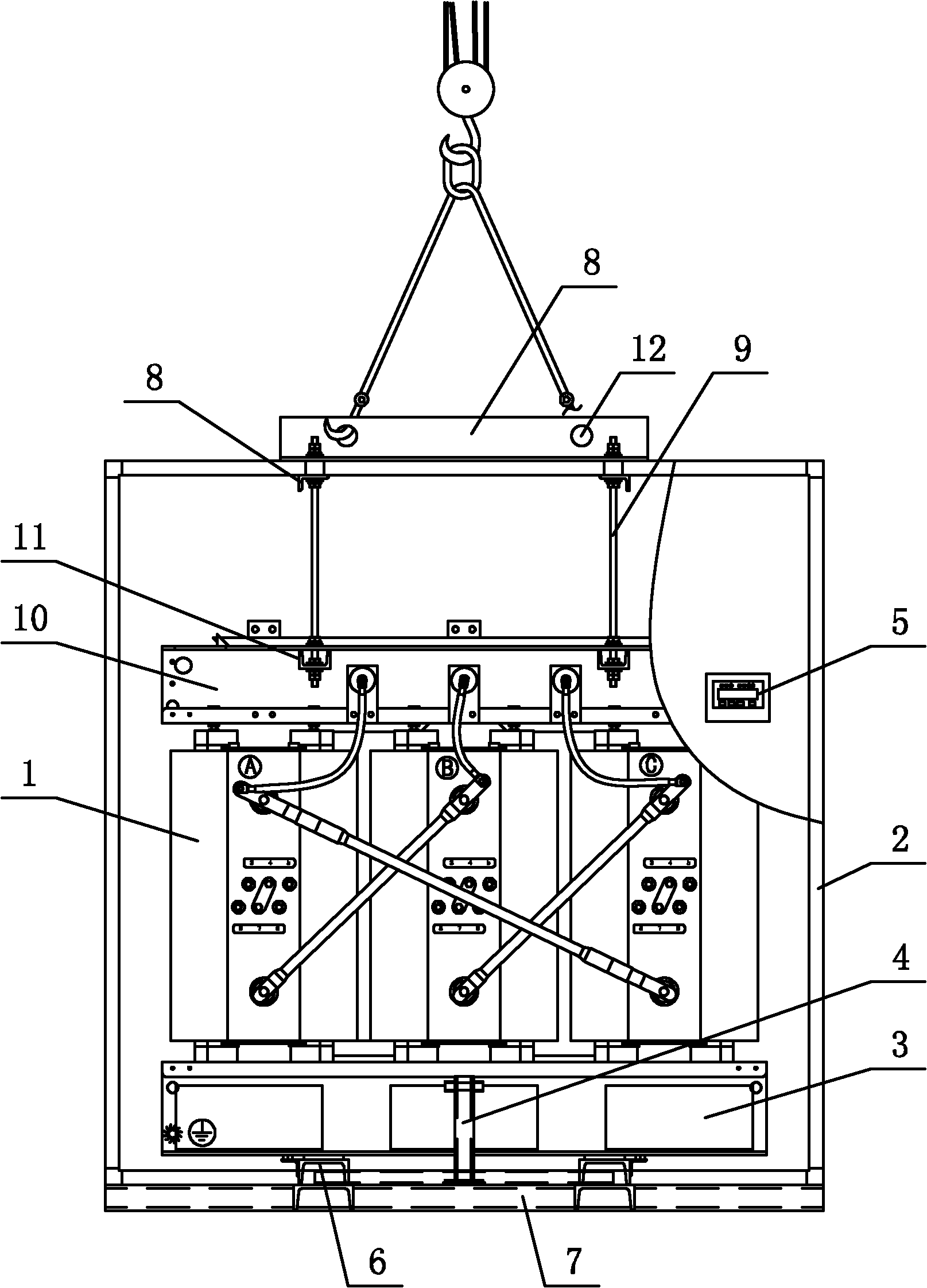

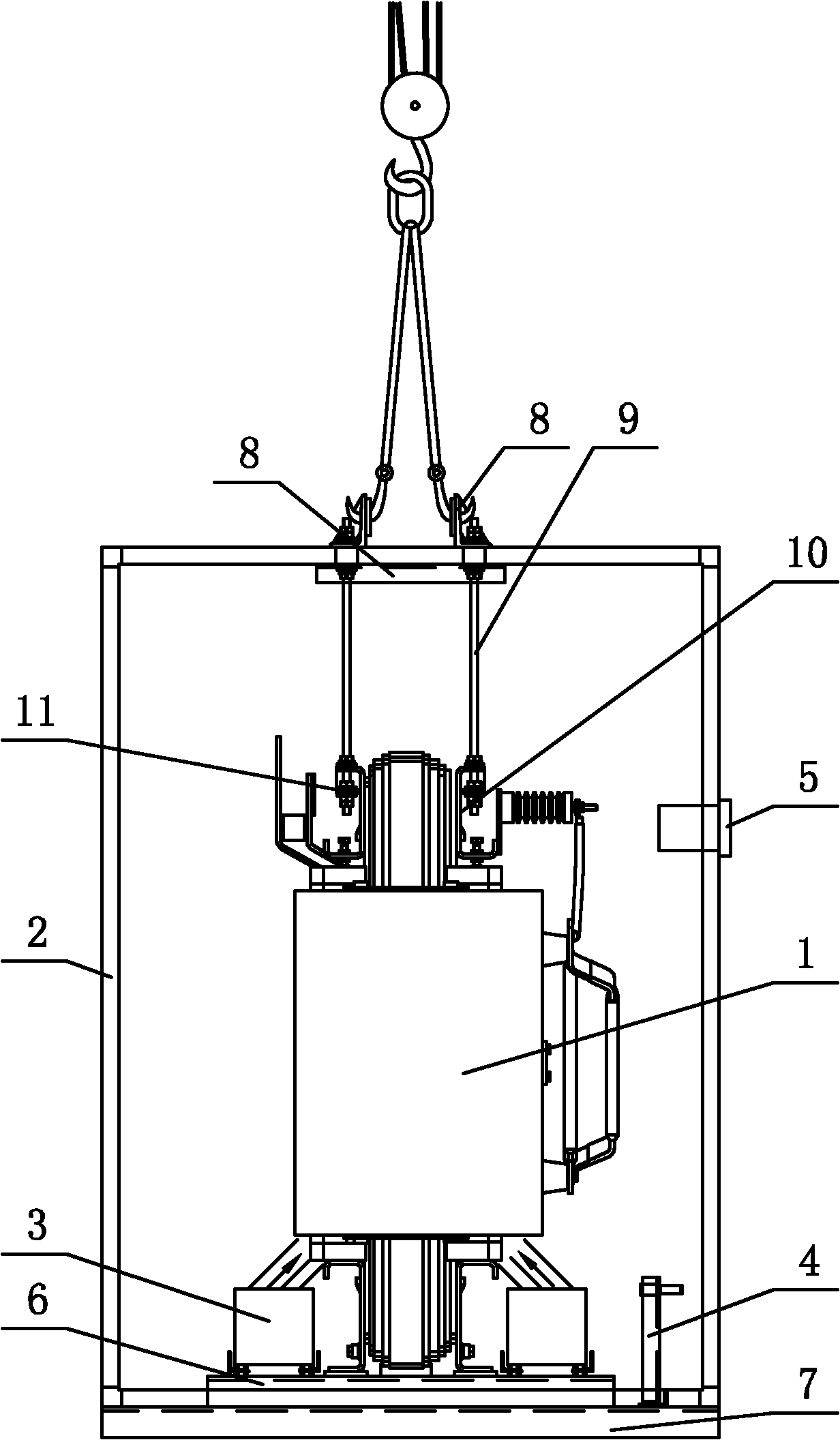

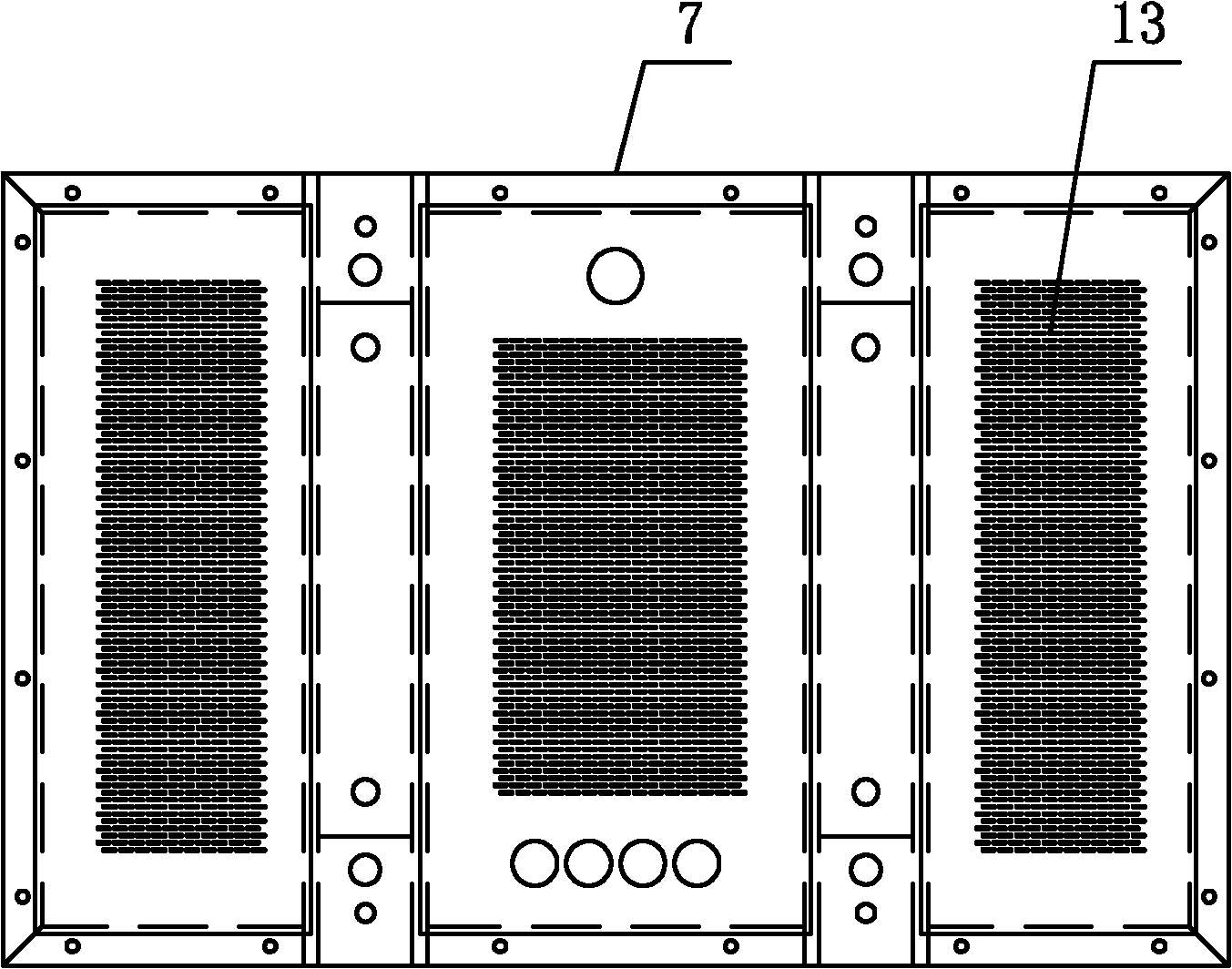

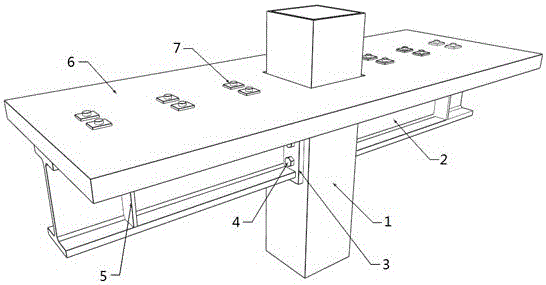

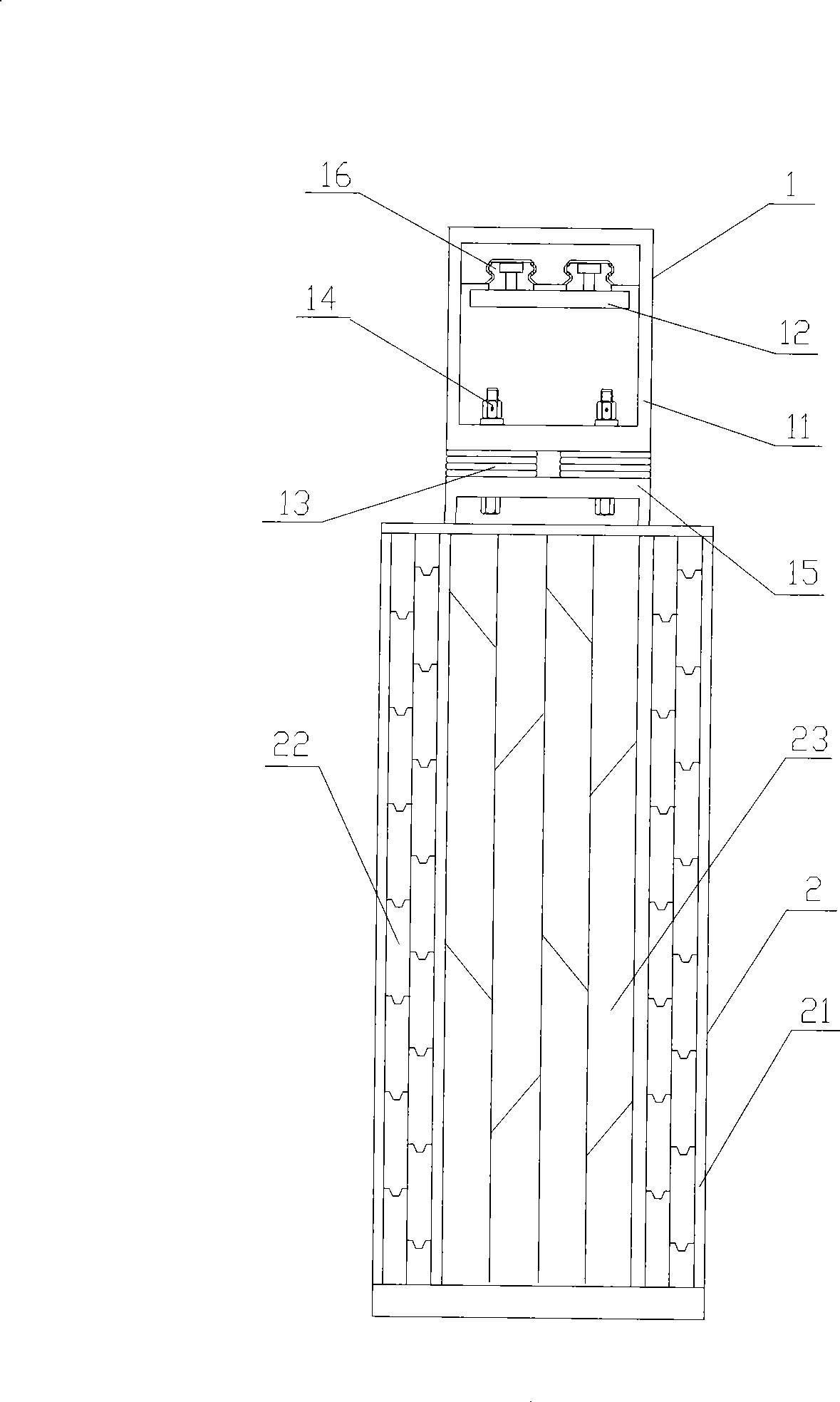

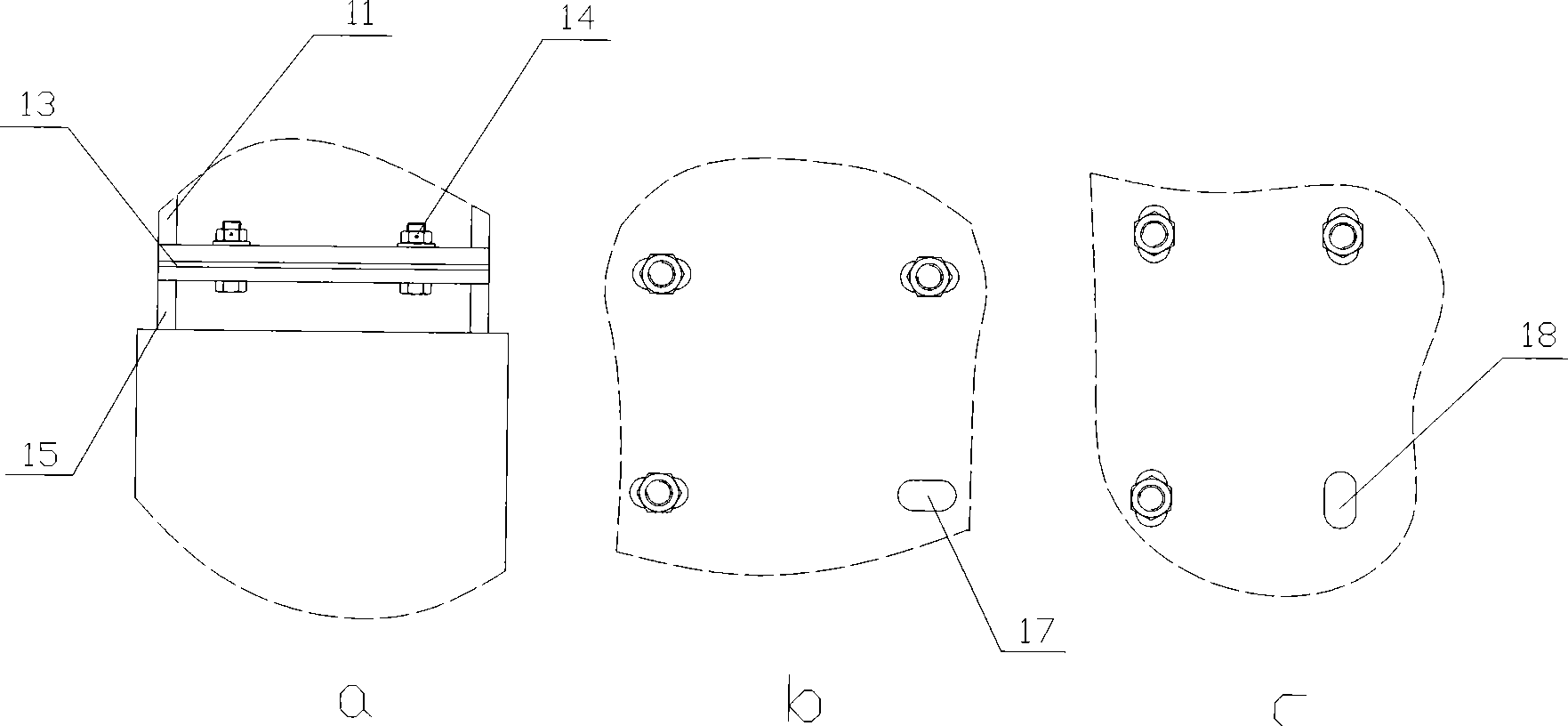

Dry type transformer

InactiveCN102054561AReduce the labor intensity of on-site installationReduce hoisting costsTransformers/reacts mounting/support/suspensionTransformers/inductances casingsChinese charactersTransformer

The invention relates to a dry type transformer which comprises a transformer body and a protective outer shell. A cooling air blower is arranged below the transformer body, a cable holder is arranged in front of the transformer body, a temperature controller is arranged on the protective outer shell, a supporting channel steel arranged below the transformer body is fixedly connected with a channel steel on the corresponding position of a base through bolts, the bottom of the protective outer shell covered at the outer side of the transformer body is fixedly connected with the base through studs, two hanging supports are respectively distributed at the inner side and the outer side of the top of the protective outer shell, the four hanging supports are arranged in the shape of Chinese character Jing, the lower ends of the four hanging screws passing through the hanging supports are connected with an upper clamping piece on the upper part of the transformer body, the connection part of the hanging screws and the upper clamping piece is provided with a reinforcing channel steel, and the hanging support at the outer side of the top of the protective outer shell is provided with lifting holes. The invention realizes the integral hoisting and transportation of the transformer and attachments, greatly lowers the installation labor intensity of the worker, saves time and labor, increases the efficiency of installation and reduces the cost of hoisting and transportation.

Owner:济南西电特种变压器有限公司

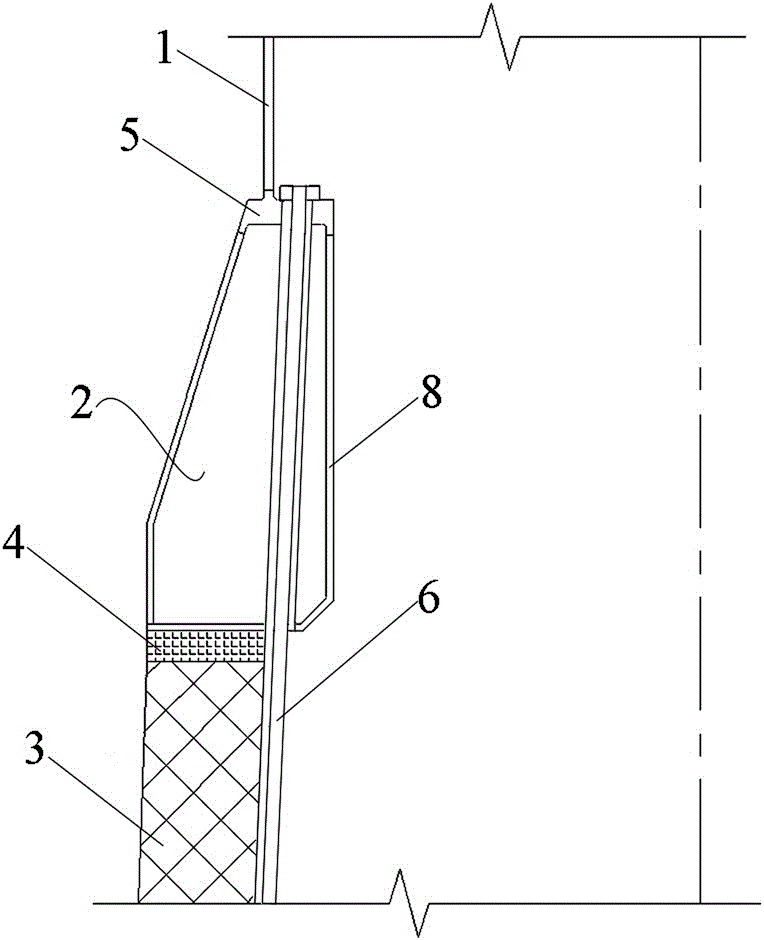

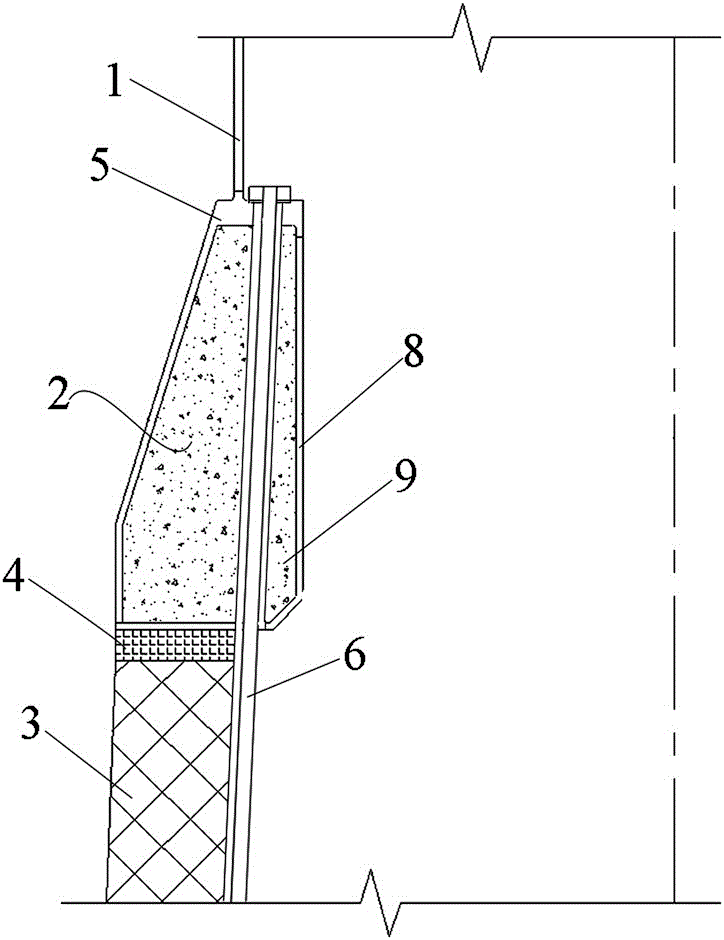

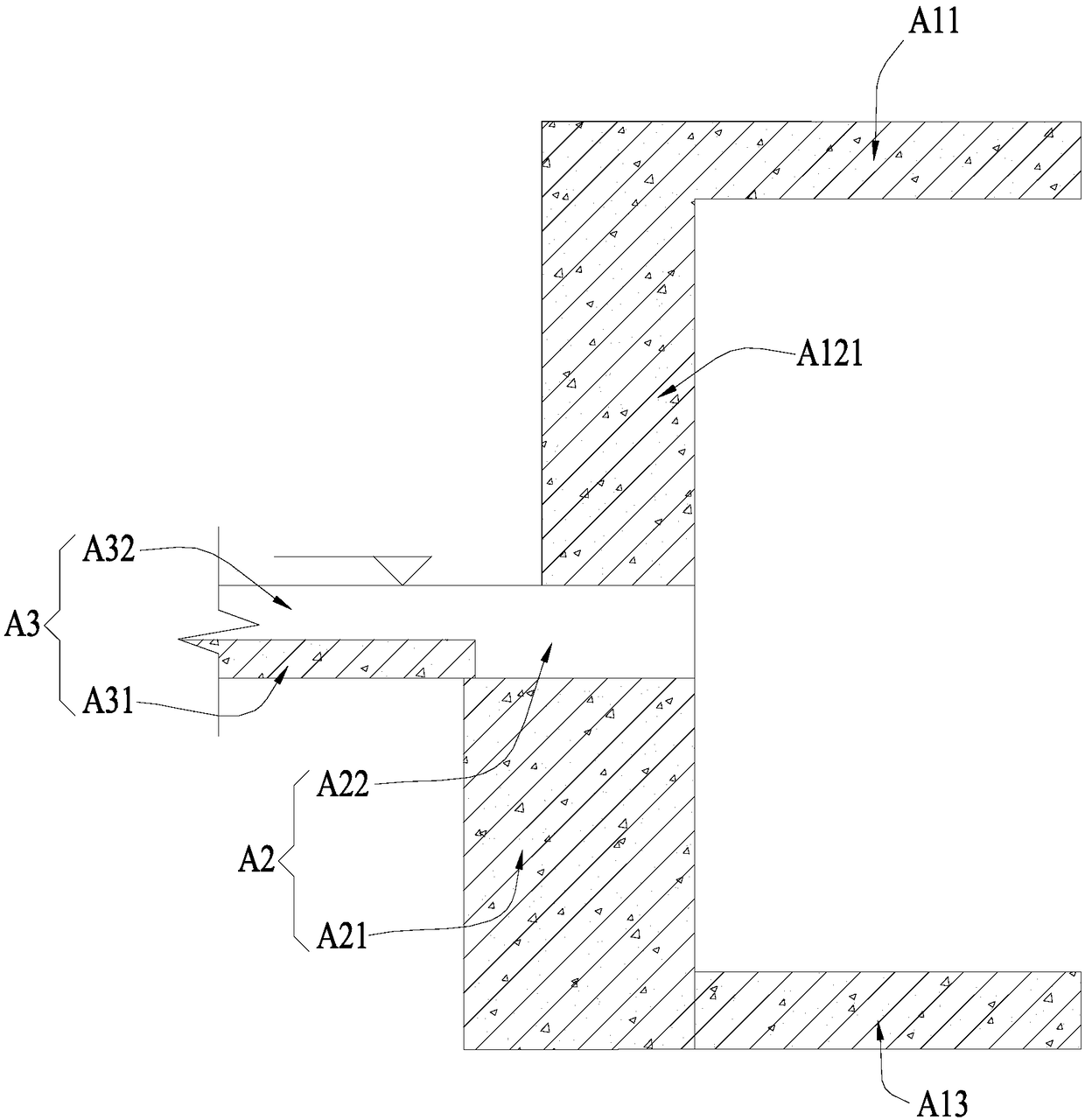

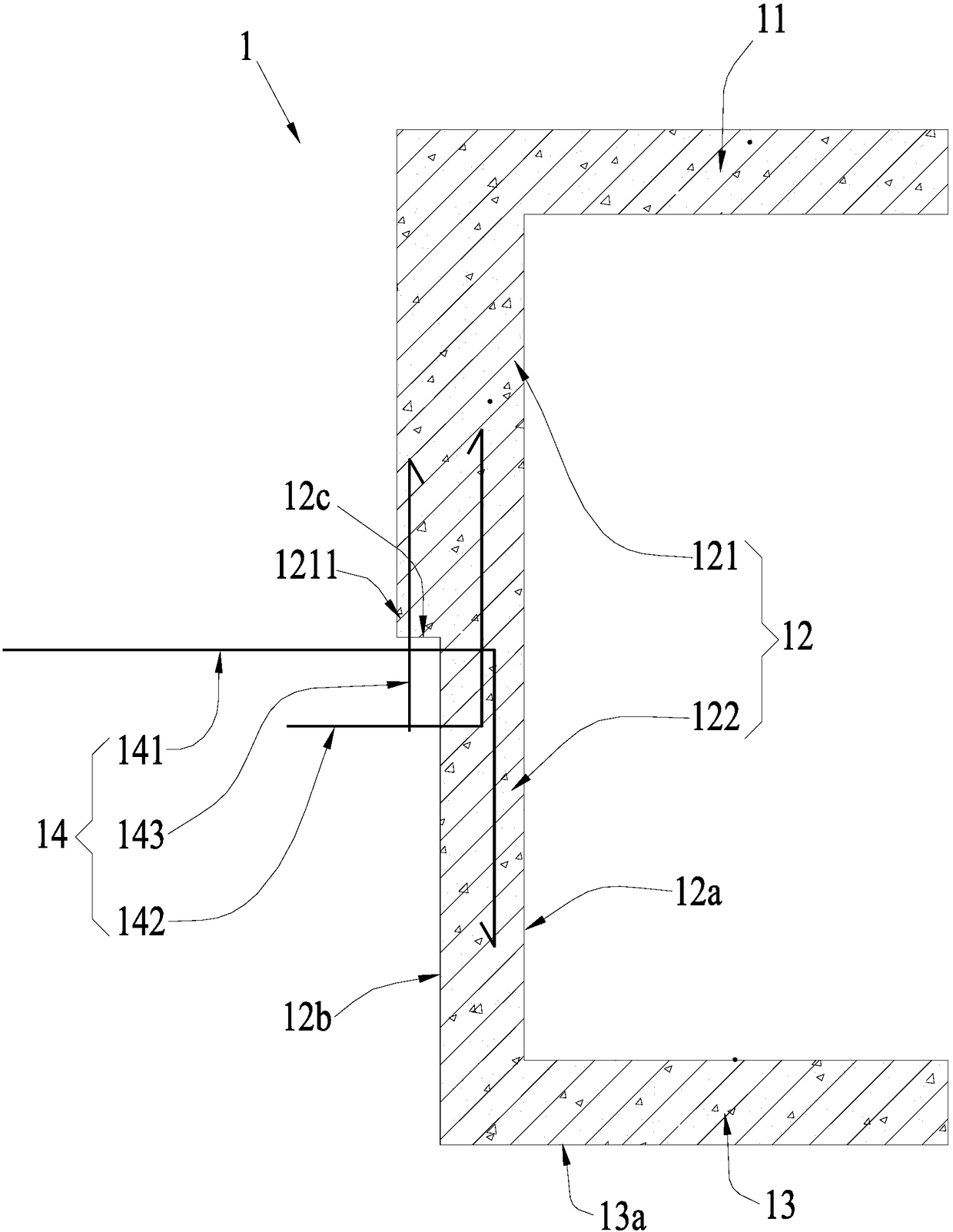

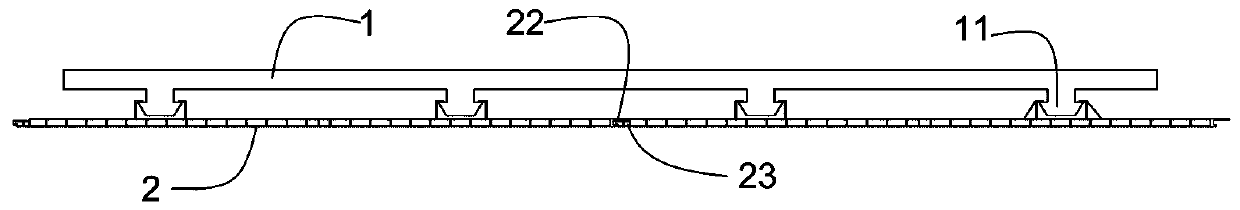

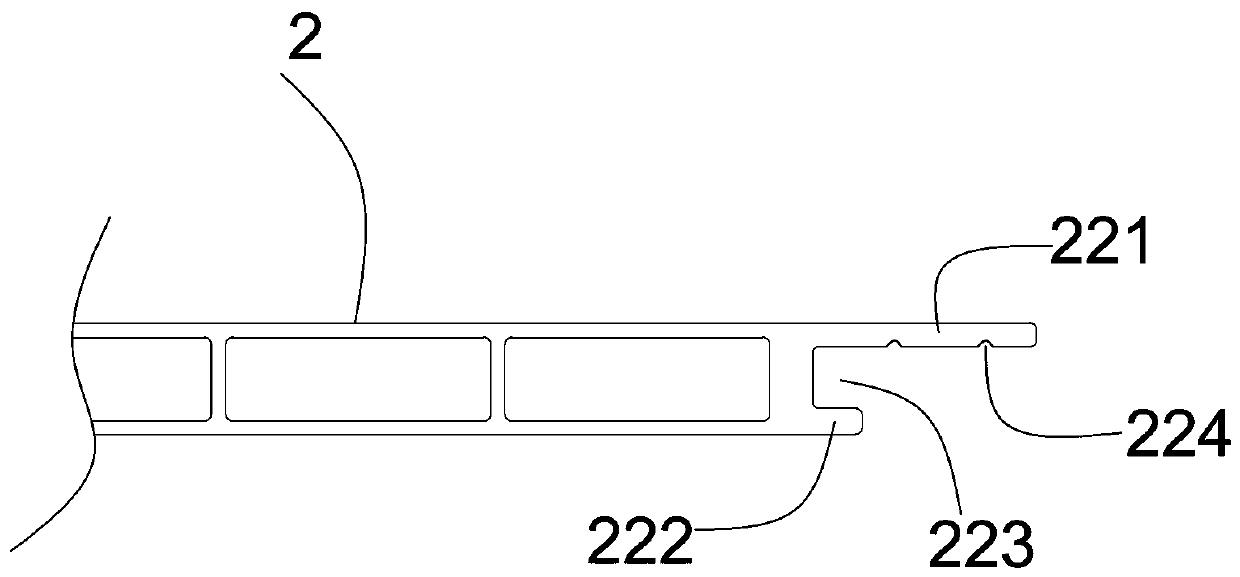

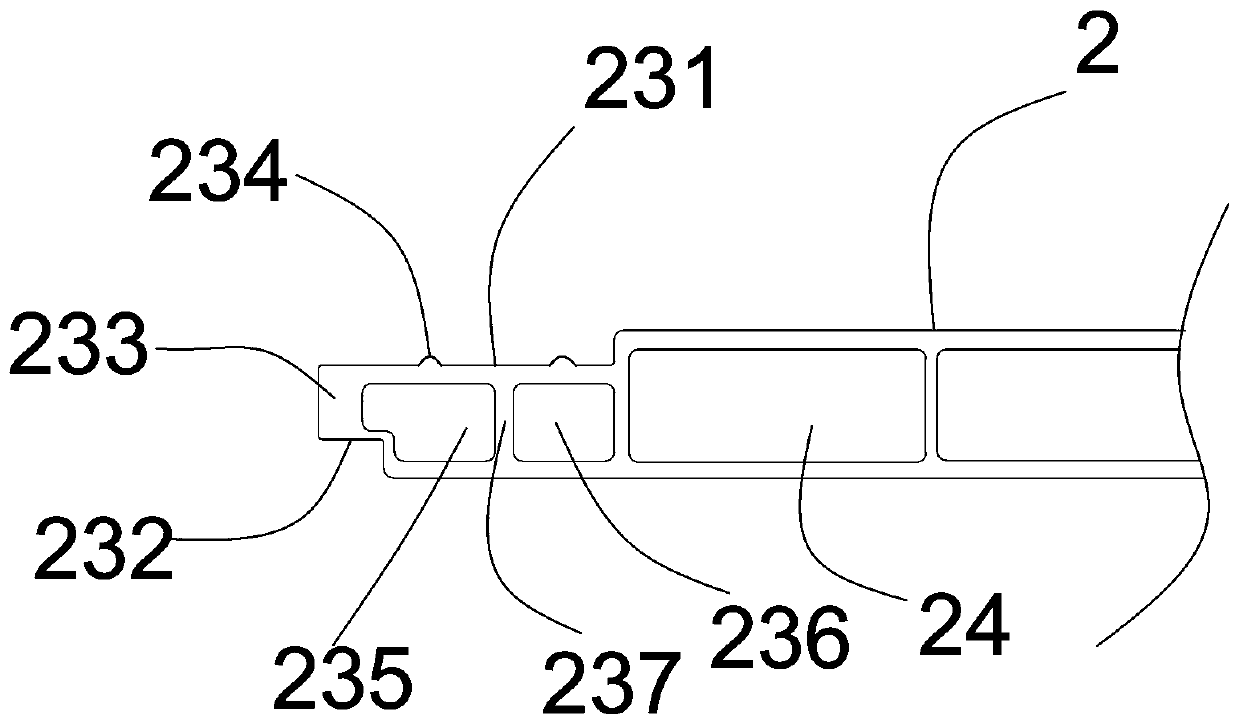

Assembled combining structure and mounting method thereof

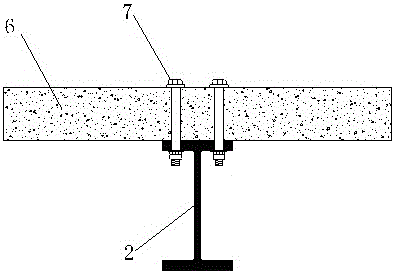

InactiveCN105735464AGood compression and bending resistanceReduce weightBuilding material handlingFlangeReinforced concrete slab

The invention relates to an assembled combining structure and a mounting method thereof. The assembled combining structure comprises a steel pipe and concrete combined column which is composed of a steel pipe and concrete filled in the steel pipe, an H-shaped steel frame is arranged on the side wall of the combined column, a reinforced concrete plate is arranged on a steel beam, a through hole allowing the combined column to penetrate is formed in the reinforced concrete plate, and the reinforced concrete plate is fixedly connected on an upper flange through a plurality of bolt shear-resistant connecting members. The assembled combining structure is simple and firm in structure and convenient to mount and transport.

Owner:FUZHOU UNIV

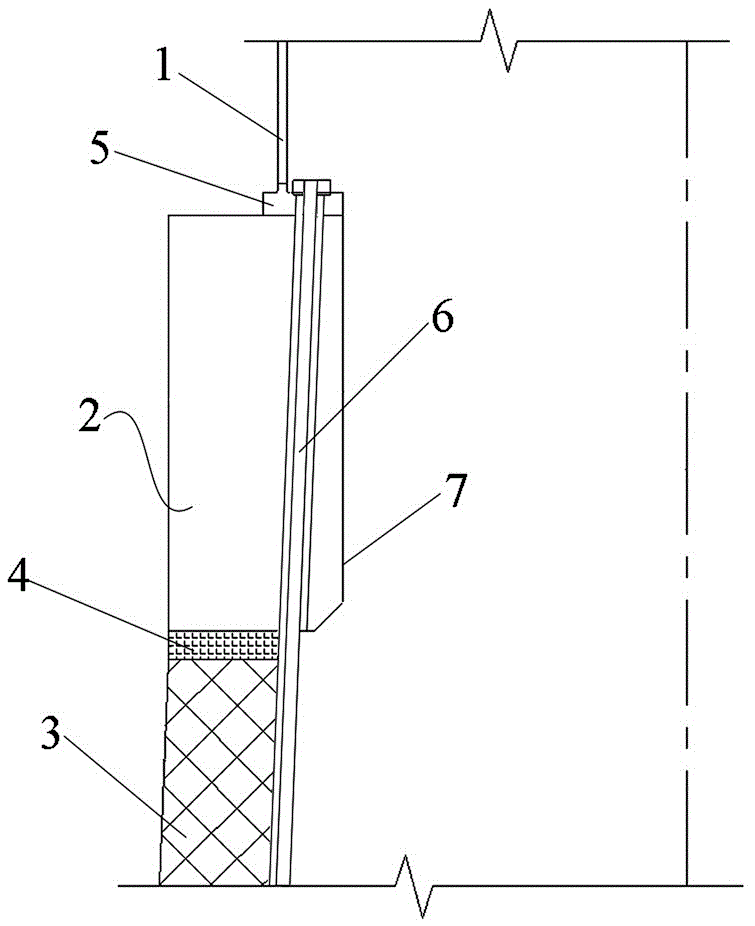

Steel sheet pile coefferdam structure and topdown construction method thereof

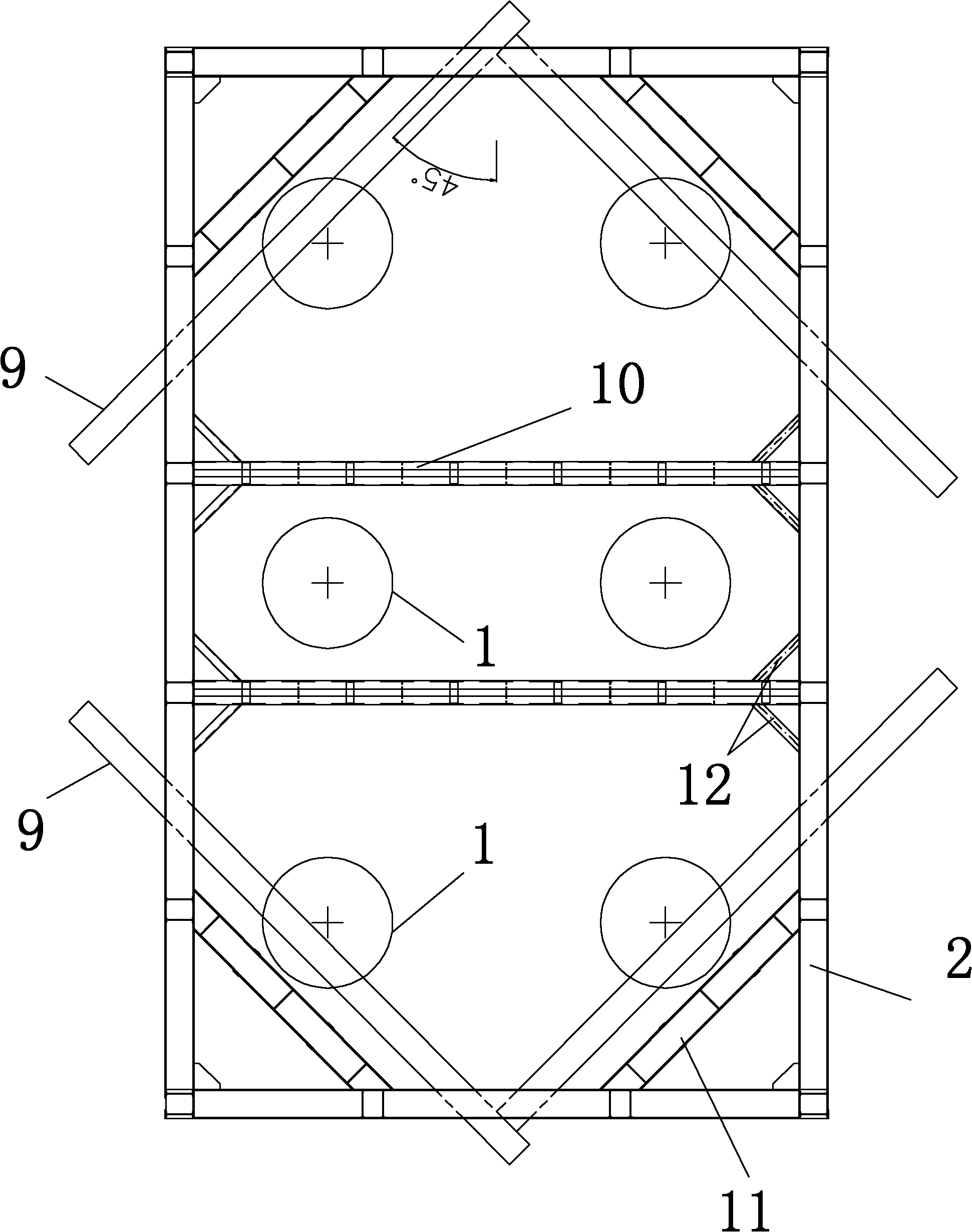

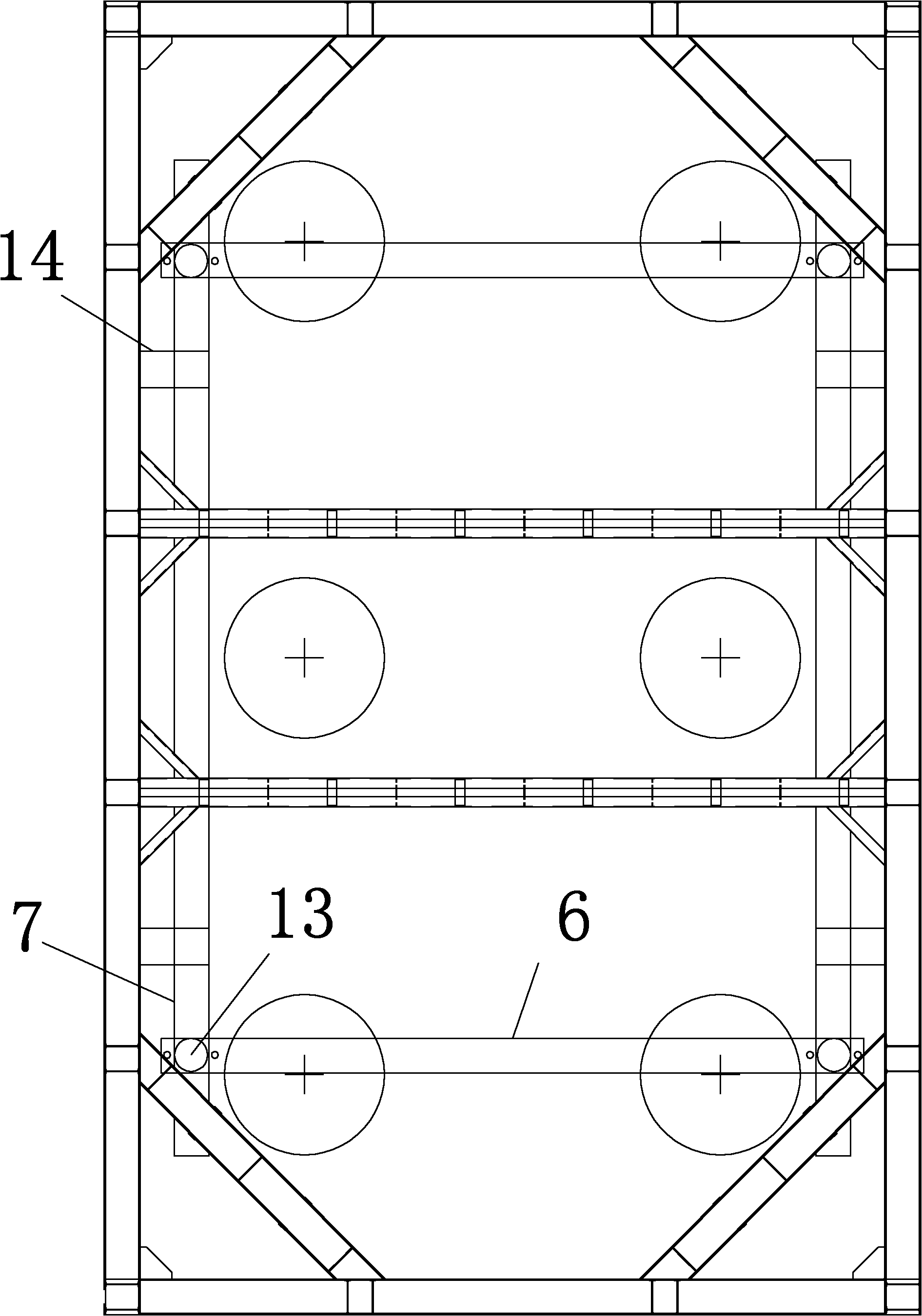

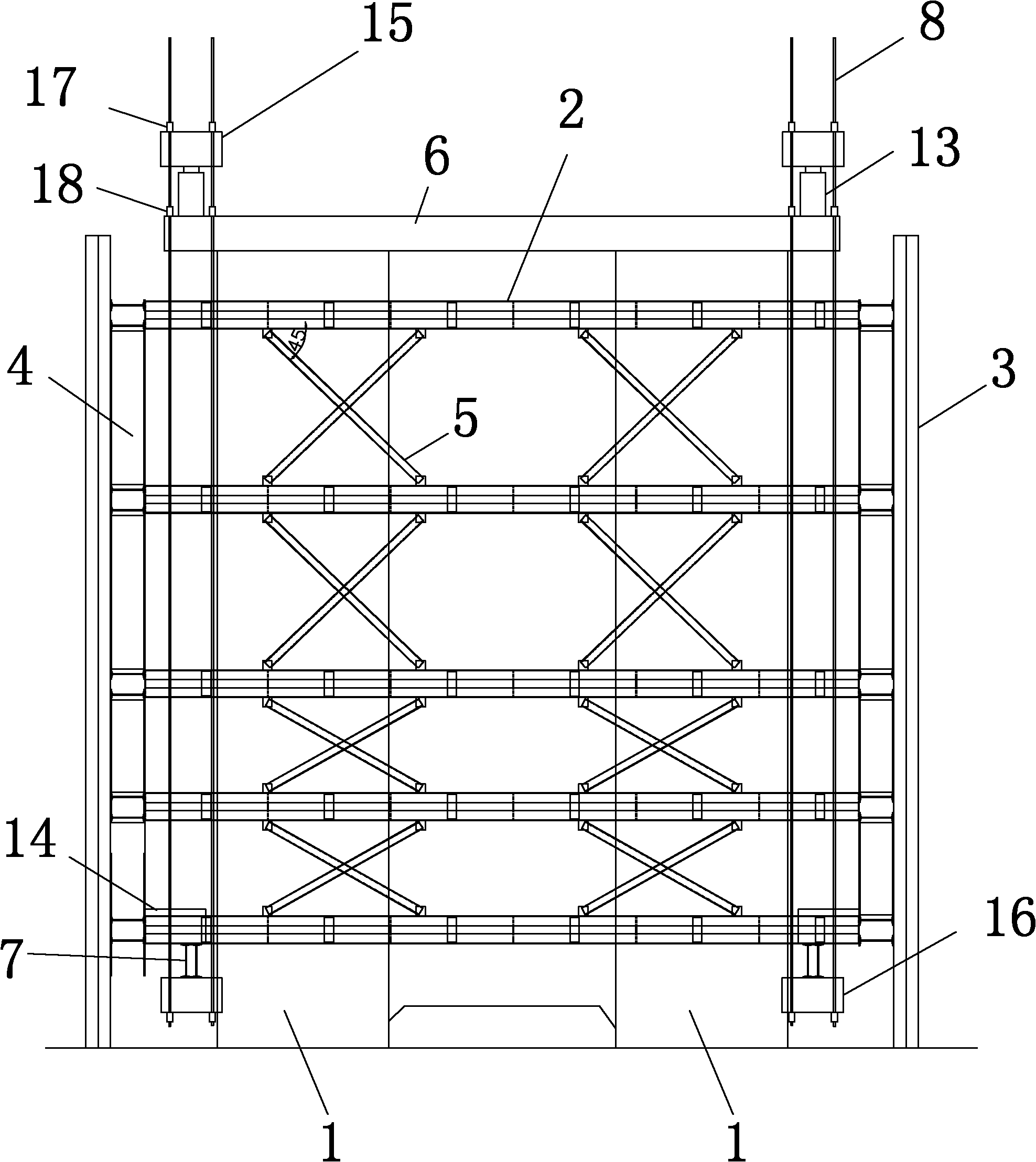

ActiveCN102191777ARealize intermittent decentralizationHigh positioning accuracyLifting devicesFoundation engineeringPurlinPile cap

The invention discloses a steel sheet pile coefferdam structure comprising a steel protecting canister, a plurality of layers of circuit purlins and steel sheet piles, wherein the steel sheet piles are inserted into the peripheries of the circuit purlins; the lower part of the steel protecting canister is welded with a bracket to form a temporary supporting platform; the circuit purlins at the upper layer and the circuit purlins at the lower layer are connected through a vertical rid and a bridging at 45 degrees; the top of the steel protecting canister is fixedly provided with an upper outrigger; the upper outrigger is provided with lifting equipment; and a lower outrigger is welded below the circuit purlins at the lowermost layer and lifted by a lifting rope of the lifting equipment. The invention also discloses a topdown construction method of the steel sheet pile coefferdam structure. In the invention, the circuit purlins, the vertical ribs and the bridging at 45 degrees are installed by utilizing a lifting system under the preconditions without using large-size lifting equipment or utilizing a large-scale prefabricating field, and therefore the quality and the stability of a steel sheet pile coefferdam are ensured; and a highrise pile cap of a pier inside water is constructed with lowest cost and smallest construction risk, therefore the feasibility and the economy of a construction technology of the steel sheet pile coefferdam inside water are enhanced.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

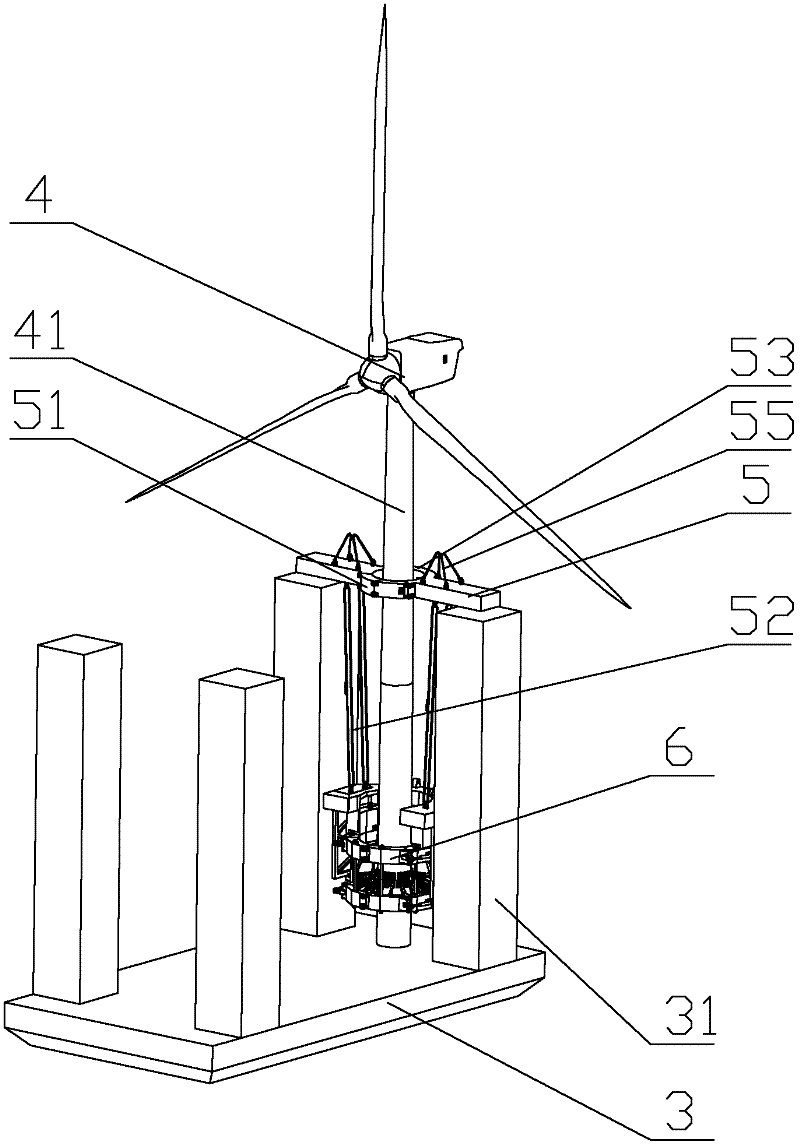

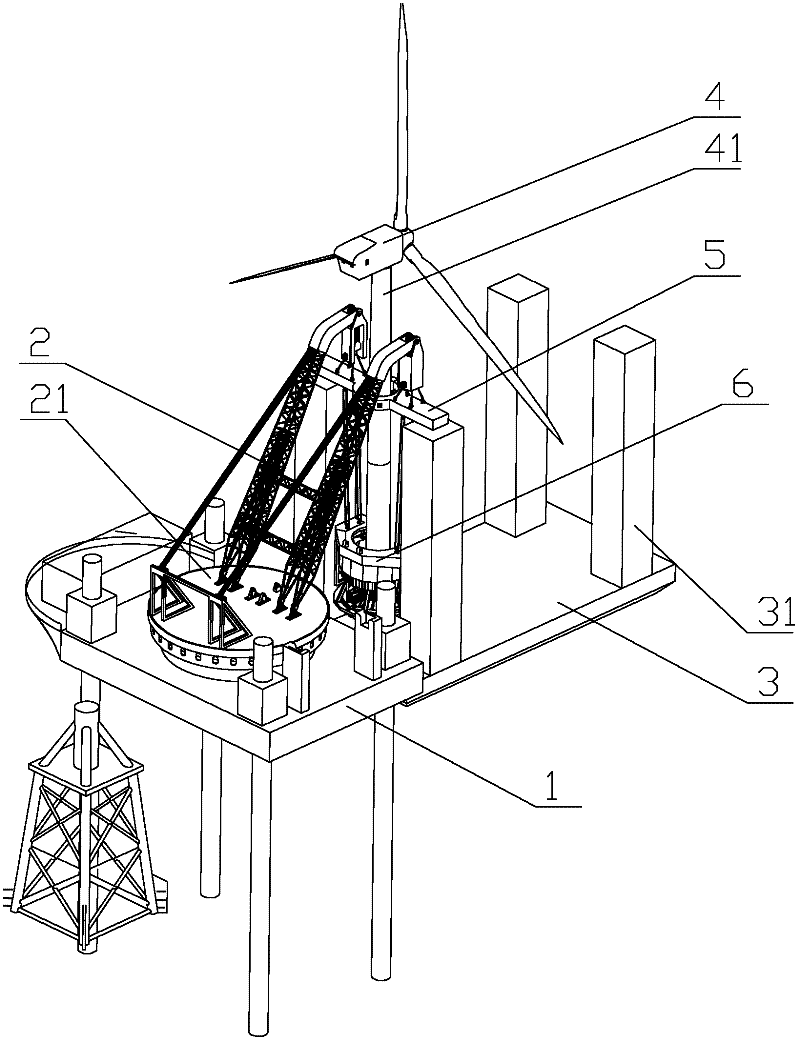

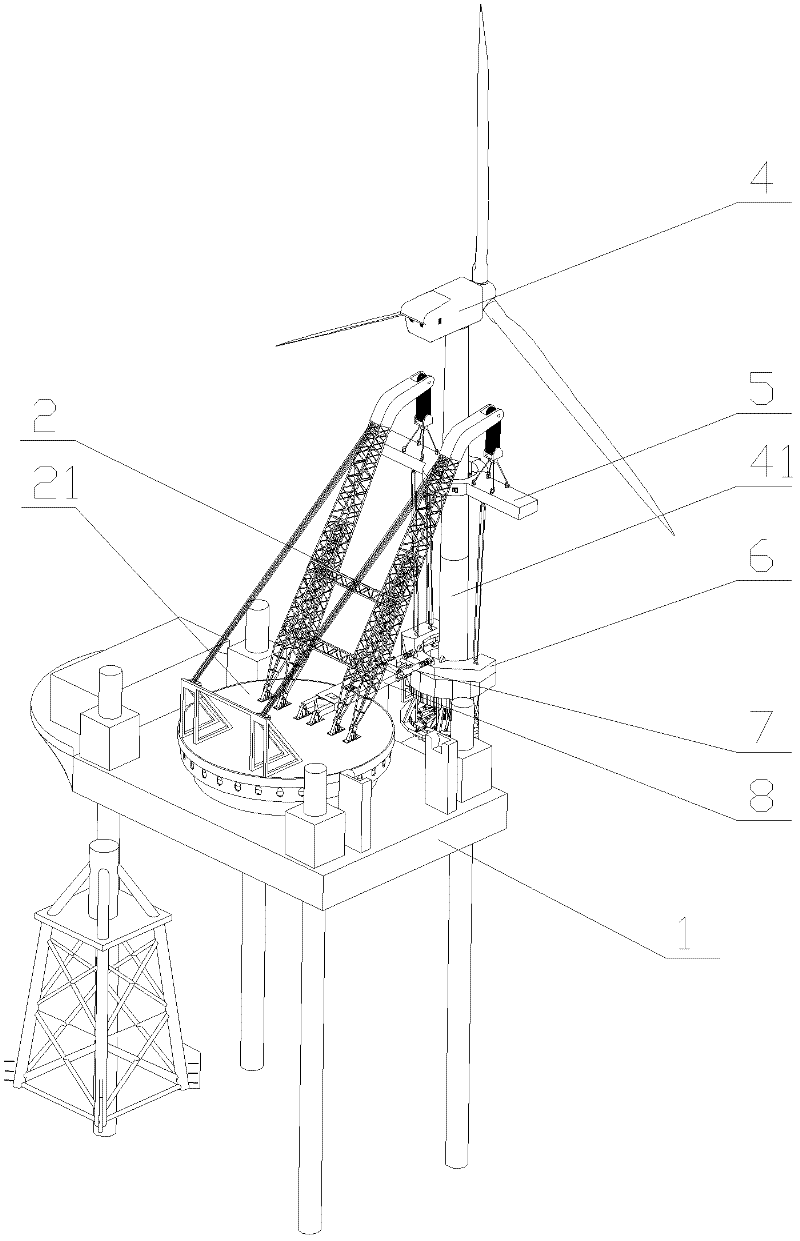

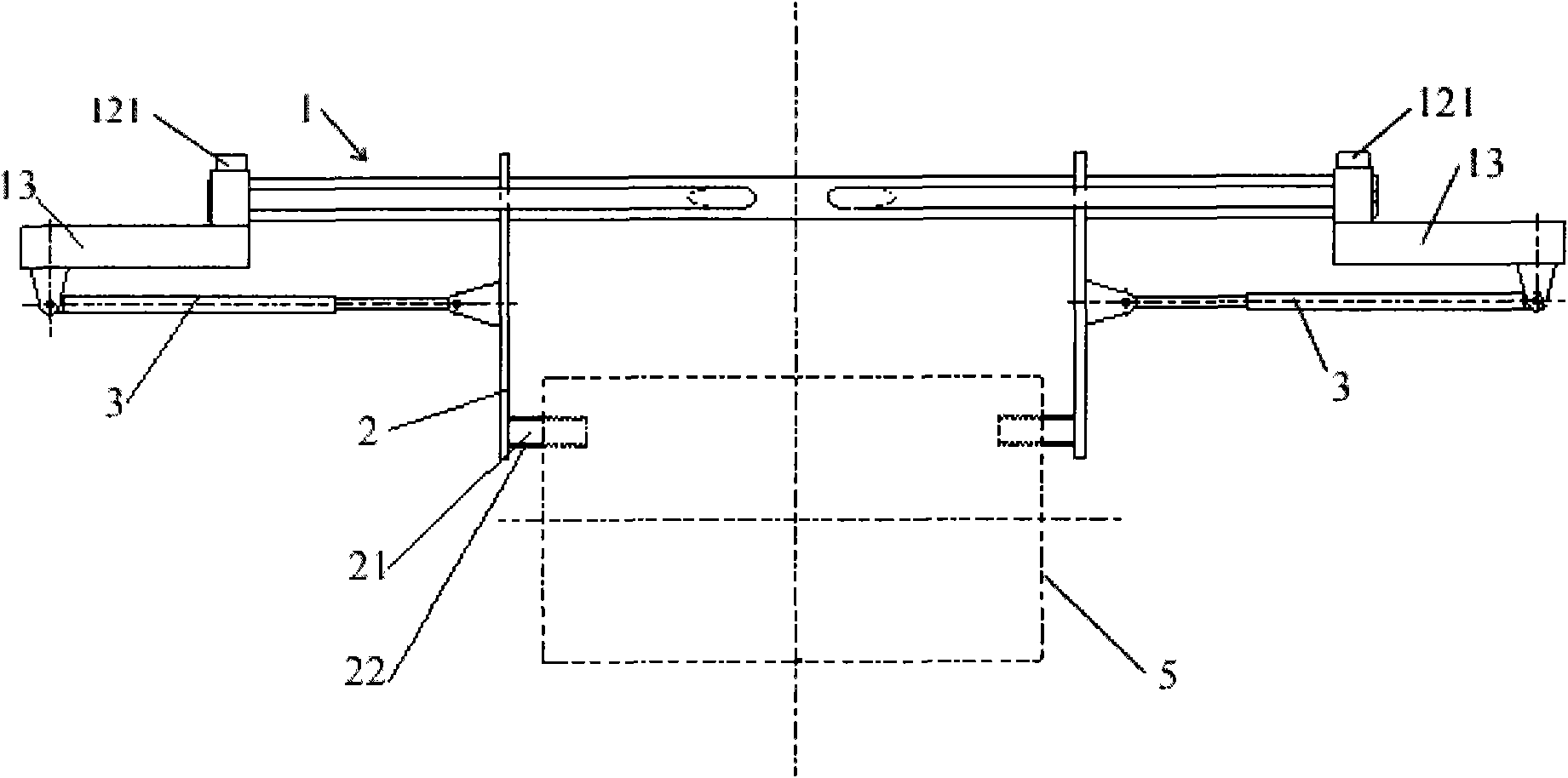

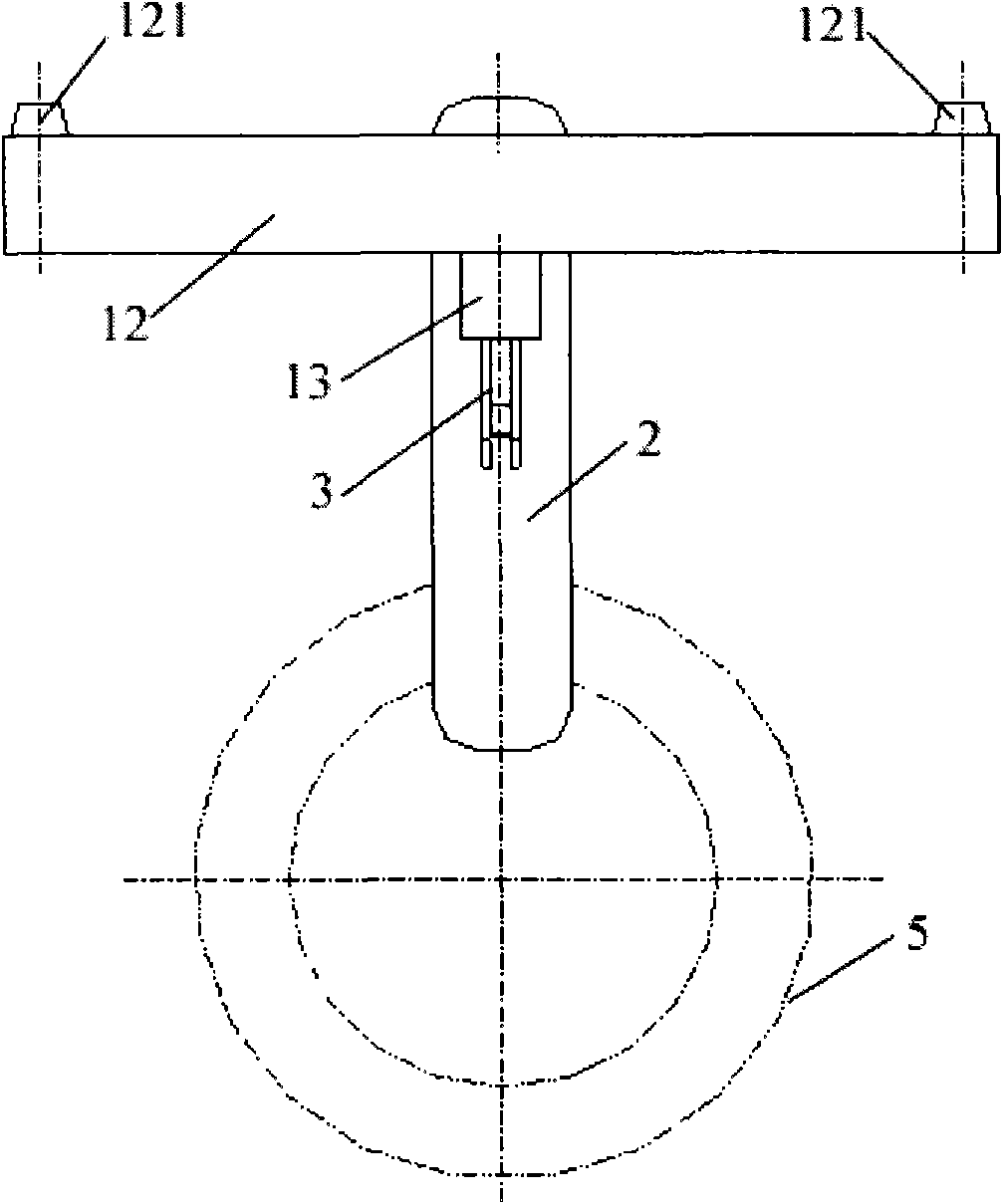

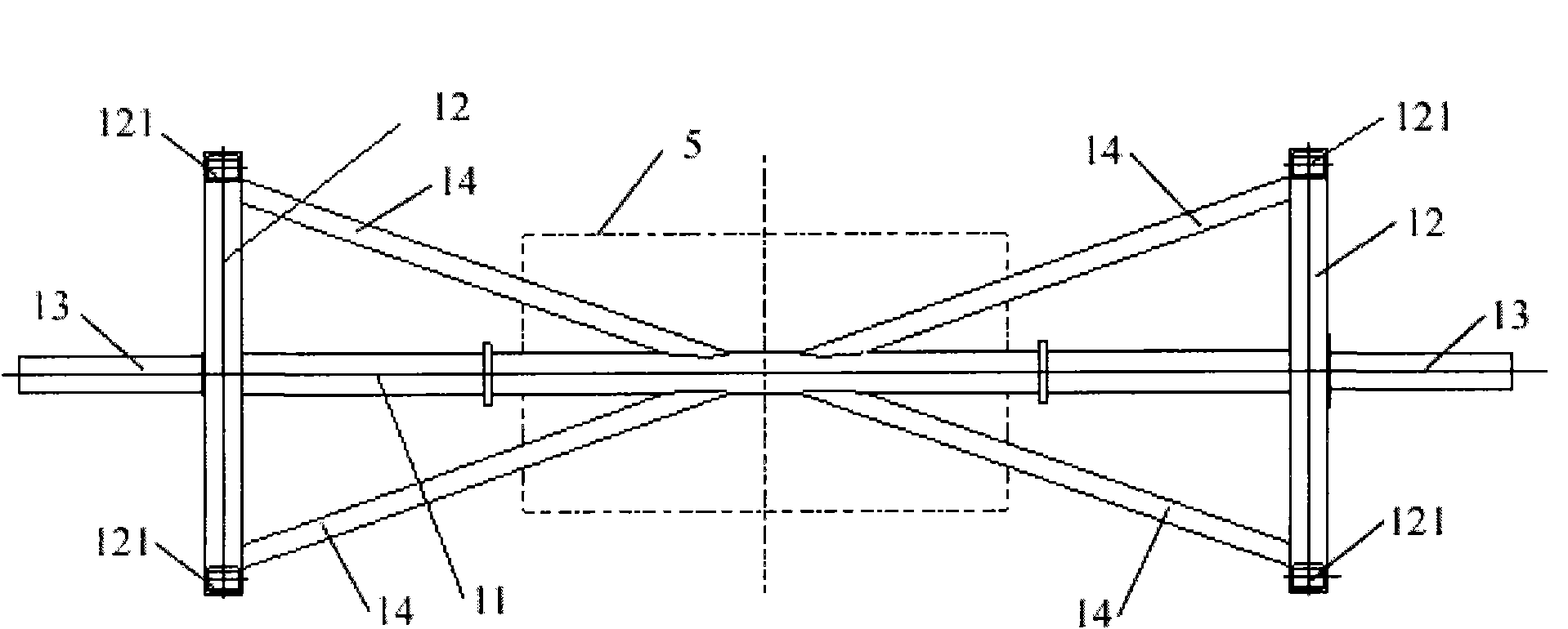

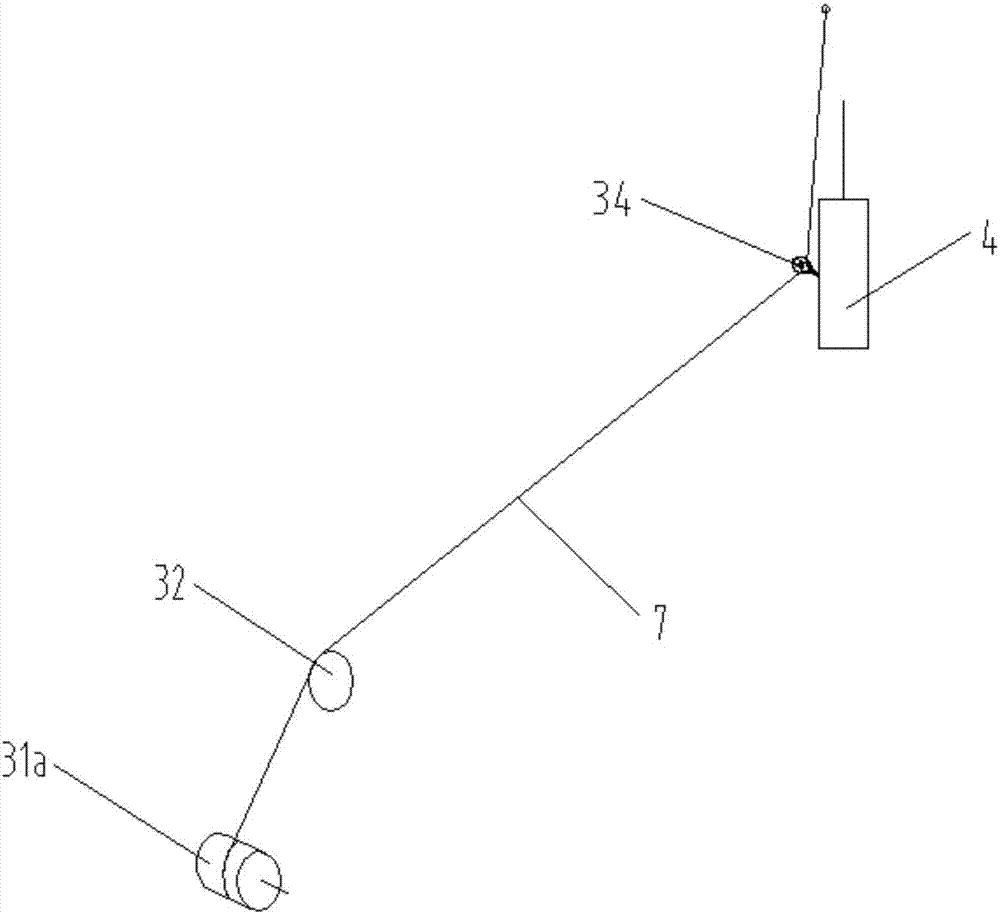

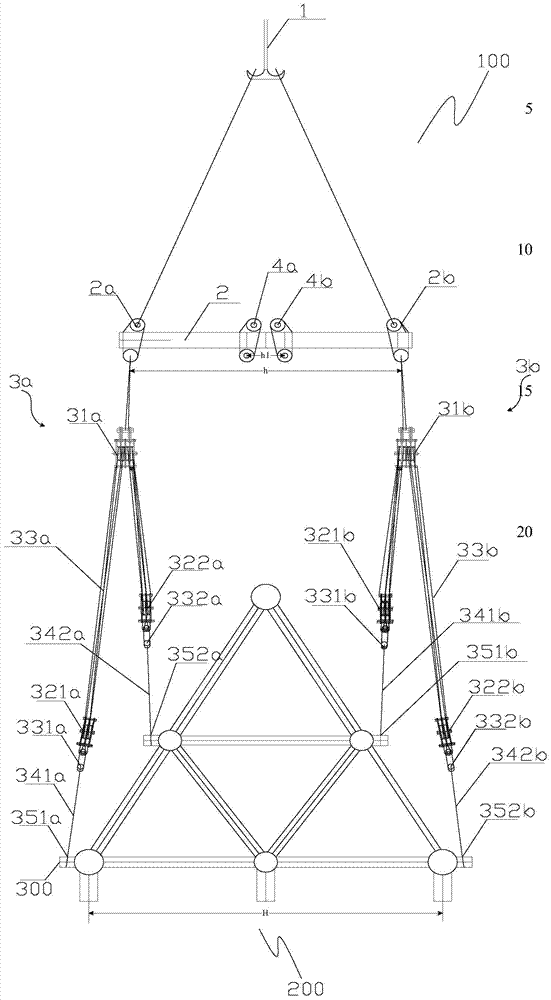

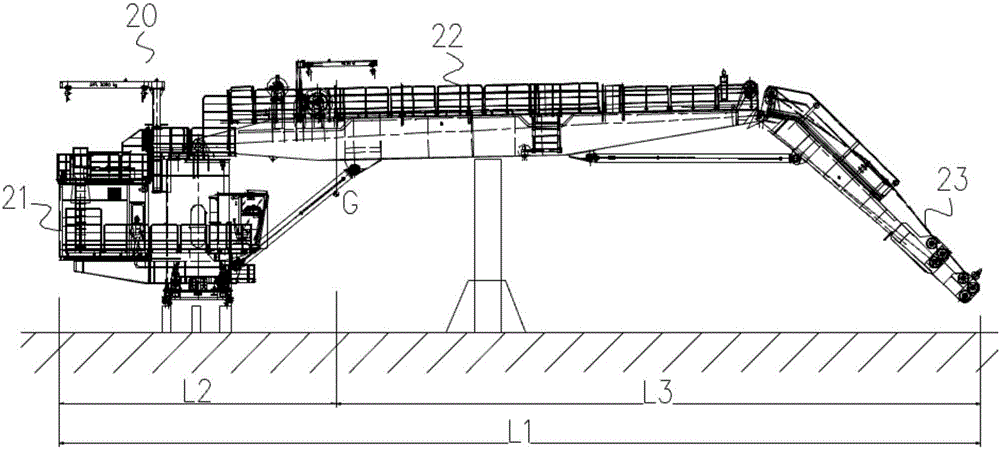

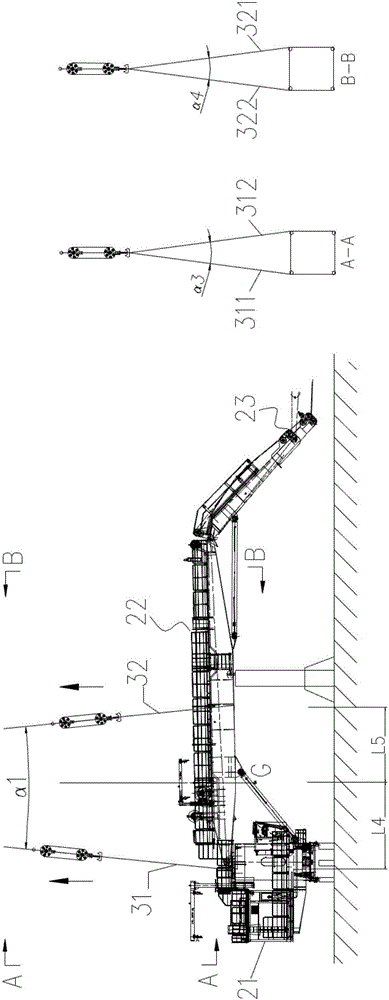

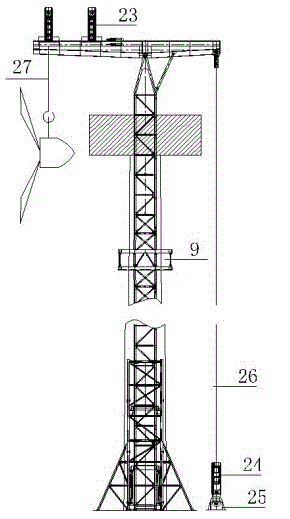

Integral hoisting equipment for offshore wind turbine

The invention discloses integral hoisting equipment for an offshore wind turbine. The integral hoisting equipment is used for integrally hoisting a wind turbine (4) on a transport ship (3) onto a wind turbine foundation through a crane (2) on an installation ship (1); fixing frames (31) are arranged on the transport ship (3); the wind turbine (4) is arranged between two adjacent fixing frames (31); the integral hoisting equipment for the offshore wind turbine comprises balance beams (5) supported on the two fixing frames (31), and a wind turbine lifting device (6) which is connected with the balance beams (5) through a rope (52); and a lockable follow-up device which can rotate and lock and can extend and retract along an axial direction is detachably hinged between a chassis (21) of the crane and the wind turbine lifting device (6). According to the hoisting equipment, an auxiliary platform is not needed to be arranged, the wind turbine can be transformed from flexible hoisting to rigid hoisting, stable butt joint between the wind turbine and the wind turbine foundation is realized, and bolt holes are stably centered and connected. Therefore, the hoisting process can be simplified, and the hoisting cost is reduced.

Owner:SANY ELECTRIC CO LTD

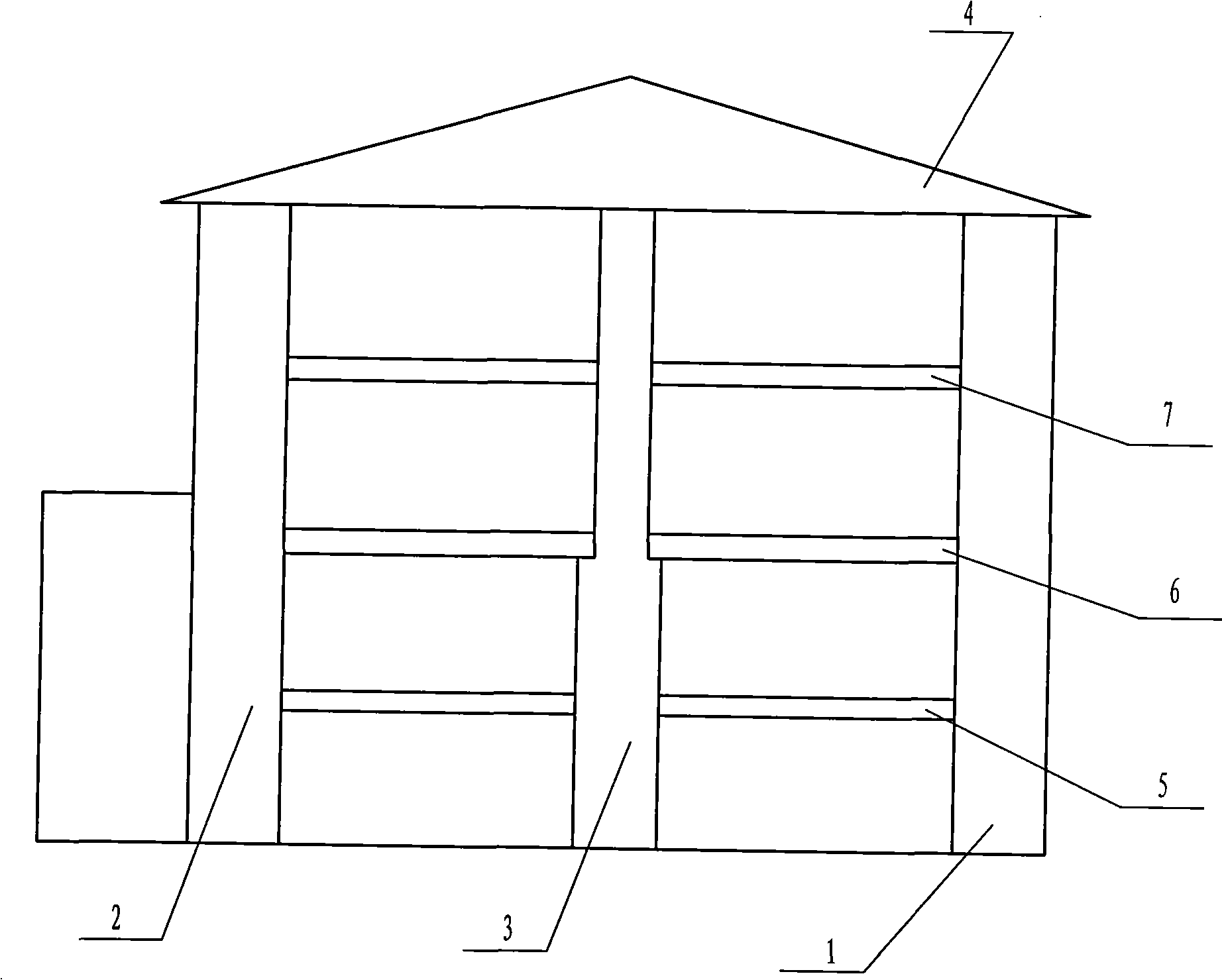

Reinforced concrete building top-down method construction process

InactiveCN101324088AGuaranteed structural constructionShorten the construction periodForms/shuttering/falseworksFoundation engineeringReinforced concreteSteel frame

The invention discloses a reinforced concrete building topdown method construction process, comprising the steps as follows: 1: the foundation, foundation and independent pile foundation construction is carried out; 2: a left supporting concrete column, a right supporting concrete column and a middle supporting concrete column of steel frame are established; 3: the areas between the left supporting concrete column and the middle supporting concrete column and areas between the right supporting concrete column and the middle supporting concrete column are used as hoisting passages of hoisting steel frame; each steel frame is hoisted onto the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; 4: all steel frames are hoisted on the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; after the connection and fixing operation, all steel frames are used as the roof of the reinforced concrete building; 5: in the roof, the indoor concrete frame structure is constructed. The method of the invention firstly constructs the side frame and the middle frame column structure, subsequently carries out the hoisting of the steel frame, and constructs the reinforced concrete structure in the clean area after the roof surface has no water, thus saving the construction period, reducing the cost, ensuring the safety hoisting, overcoming the effect of weather and ensuring the construction period and the construction quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

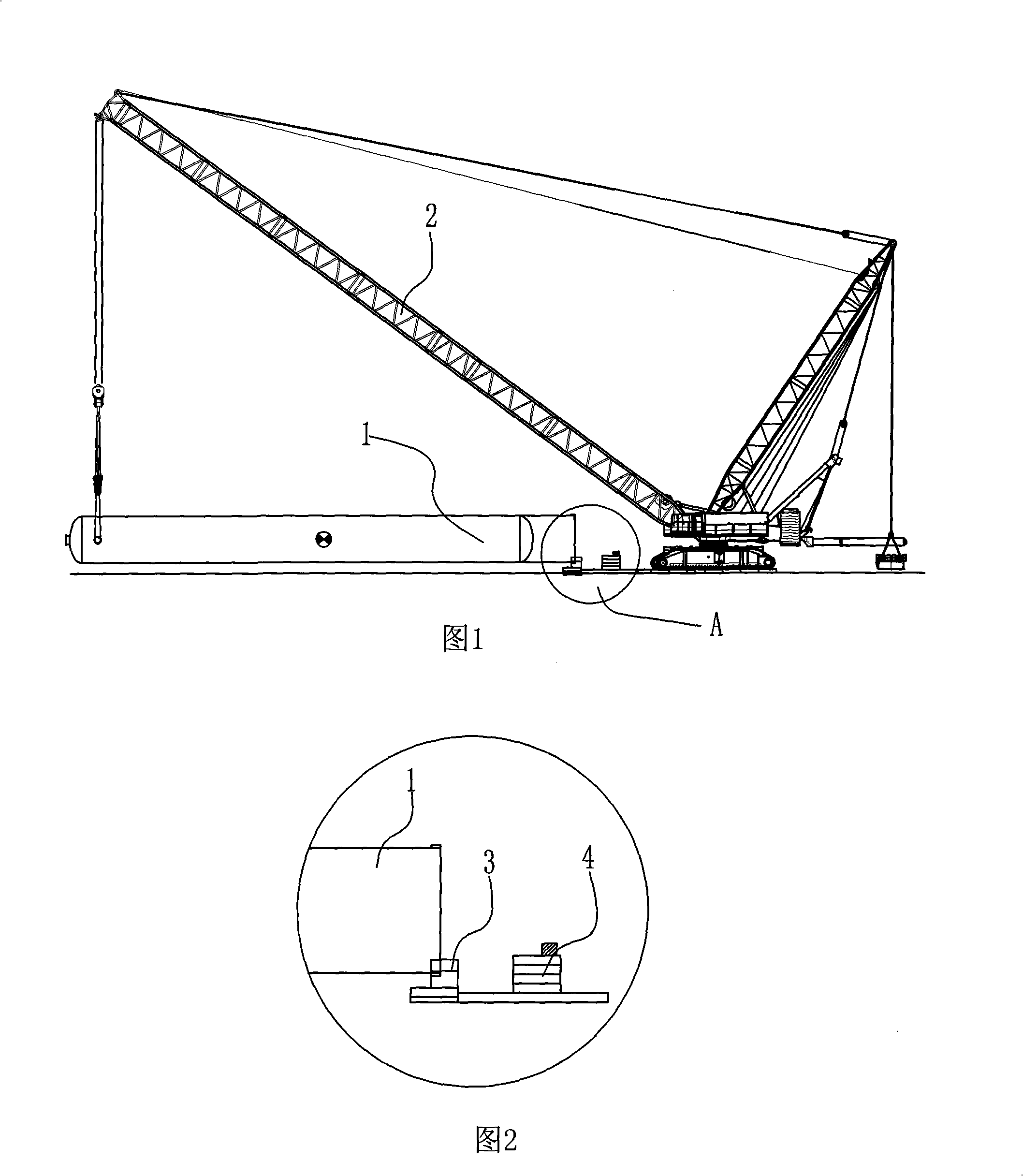

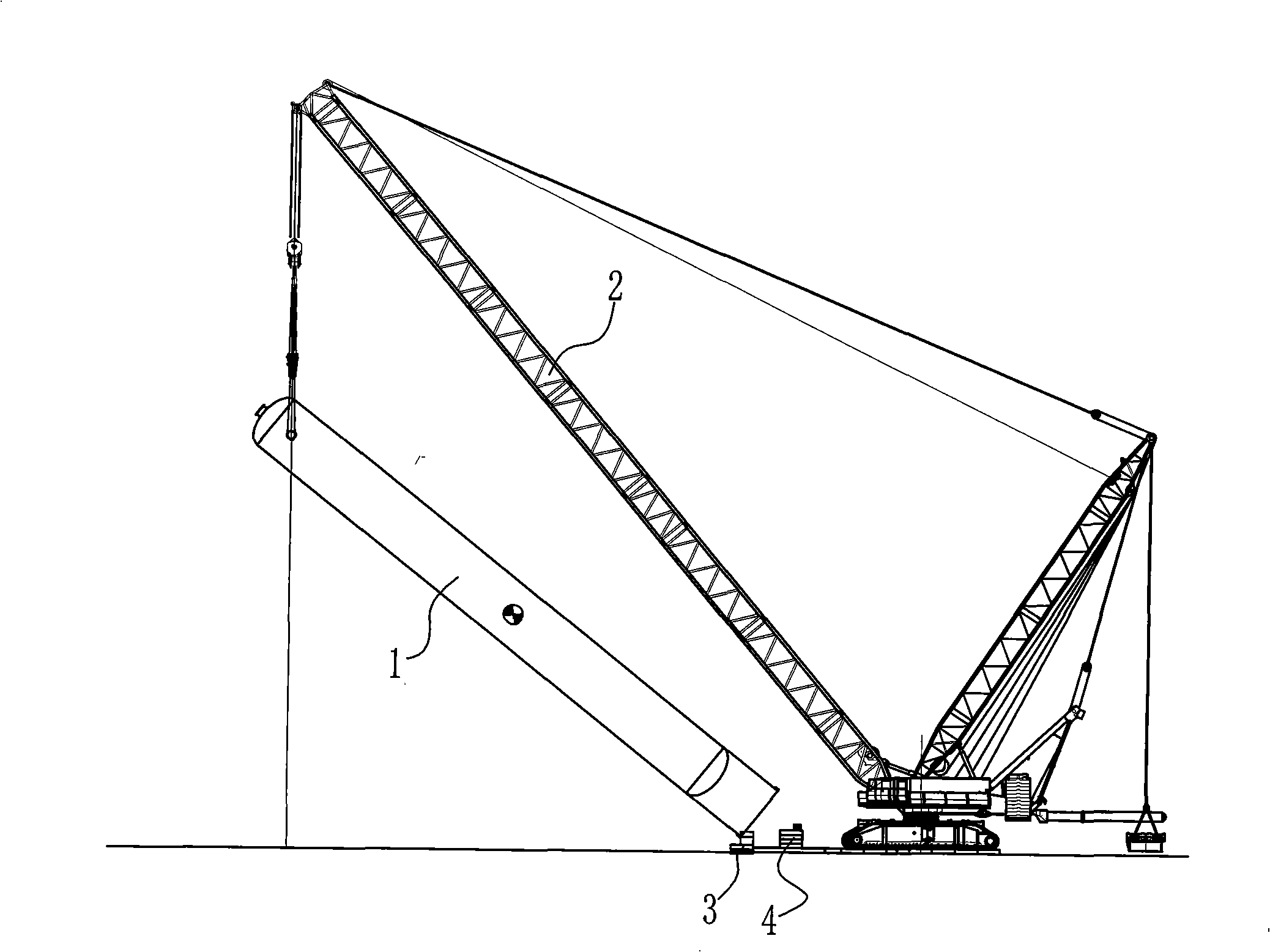

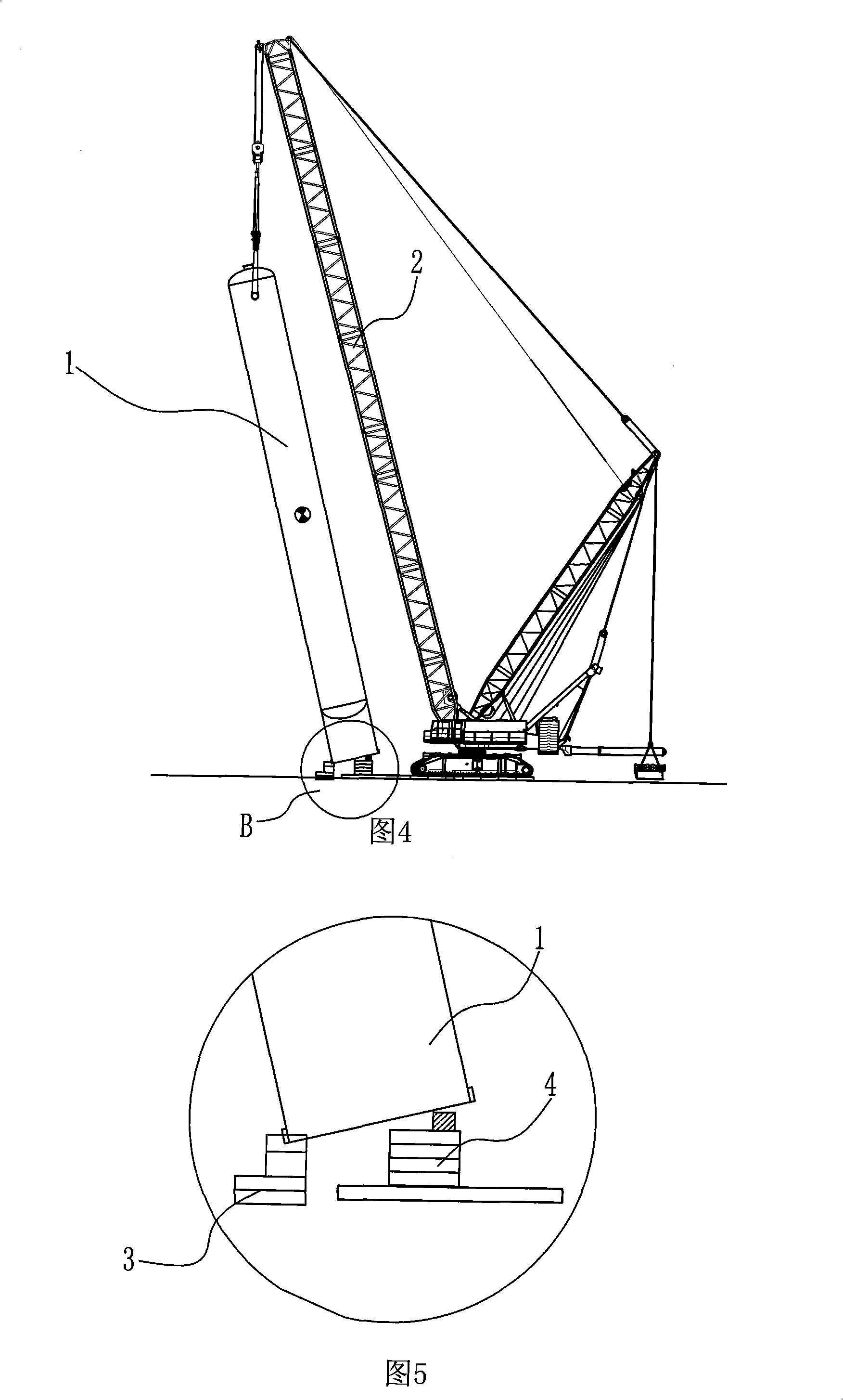

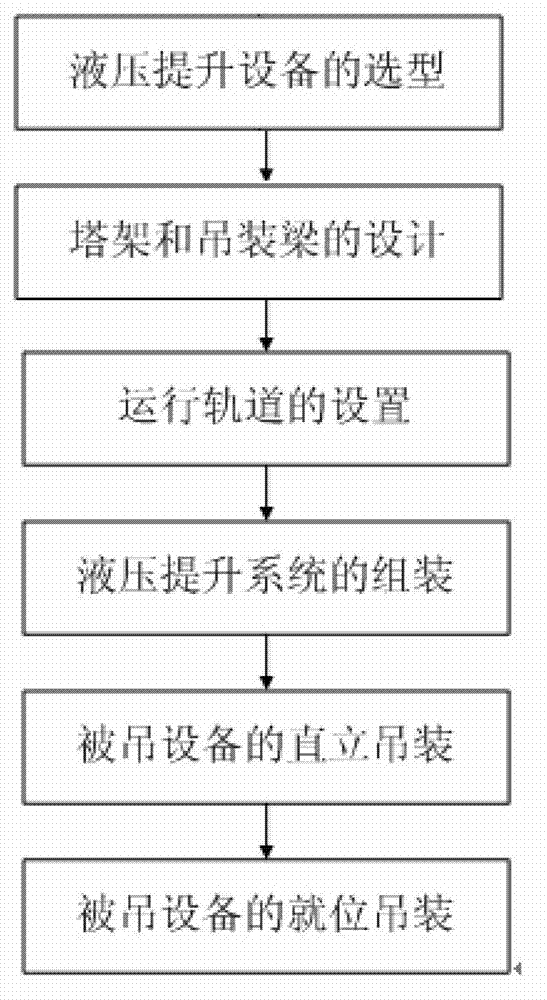

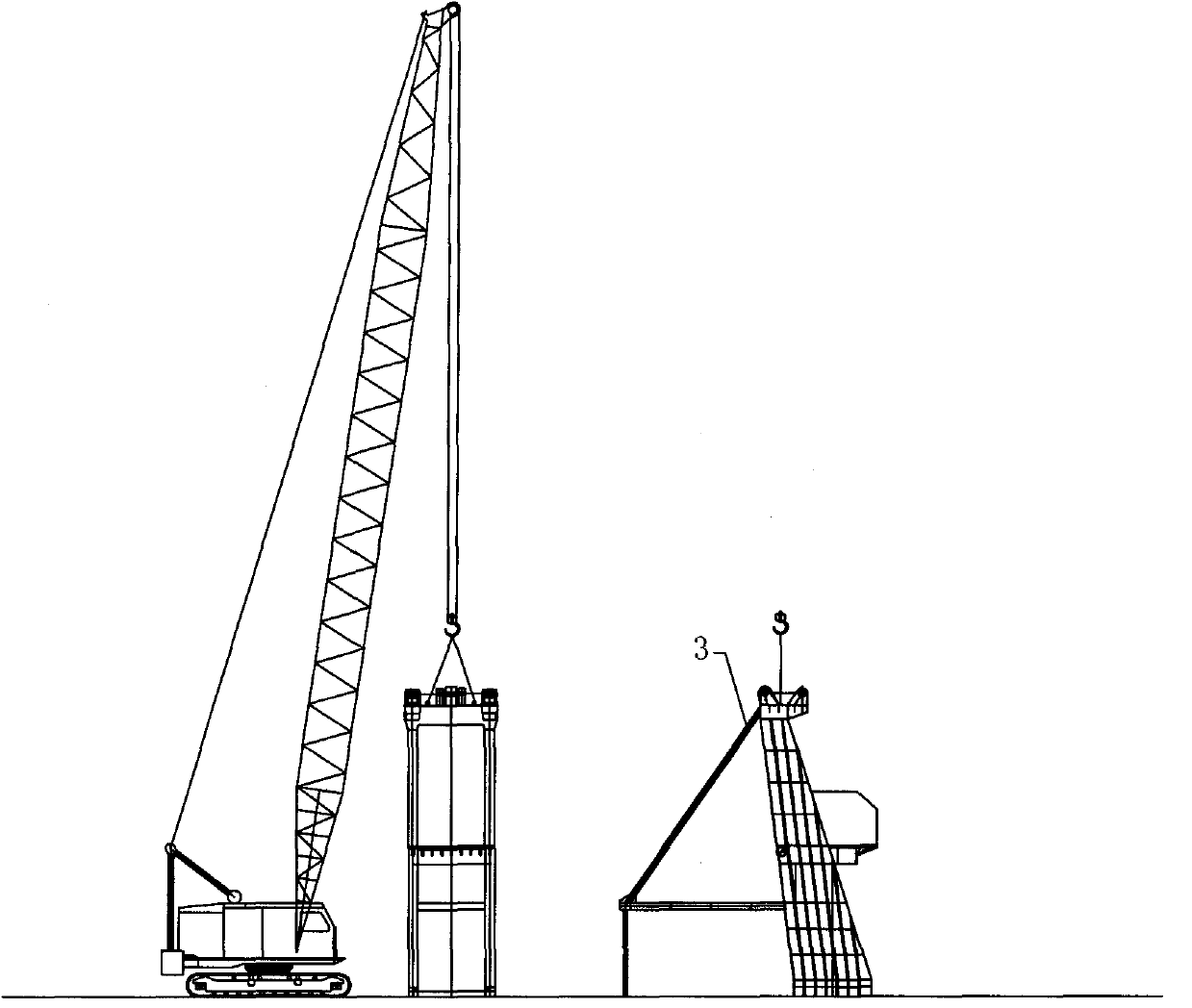

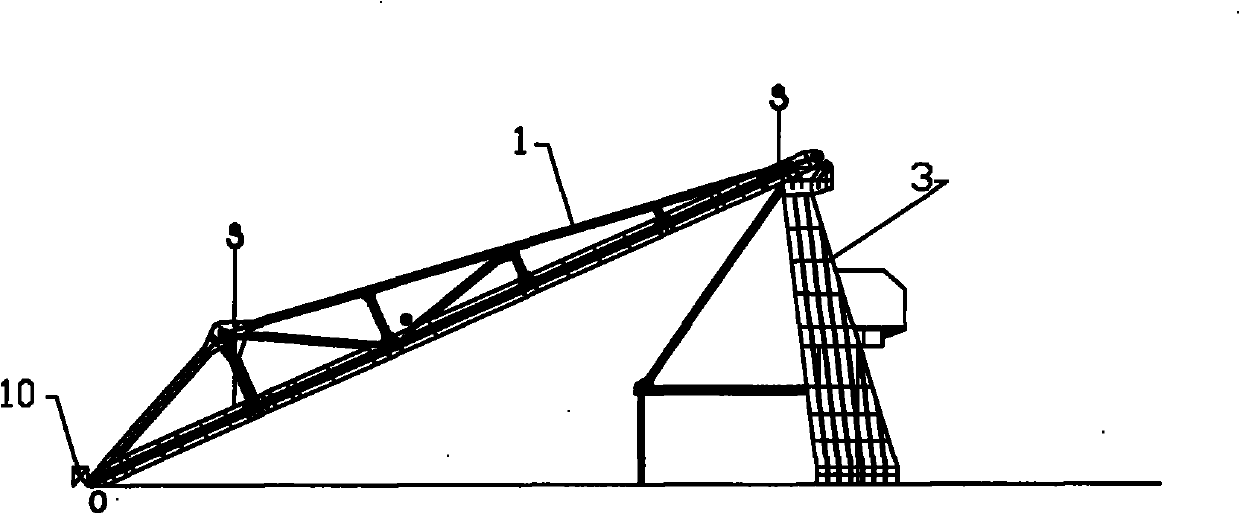

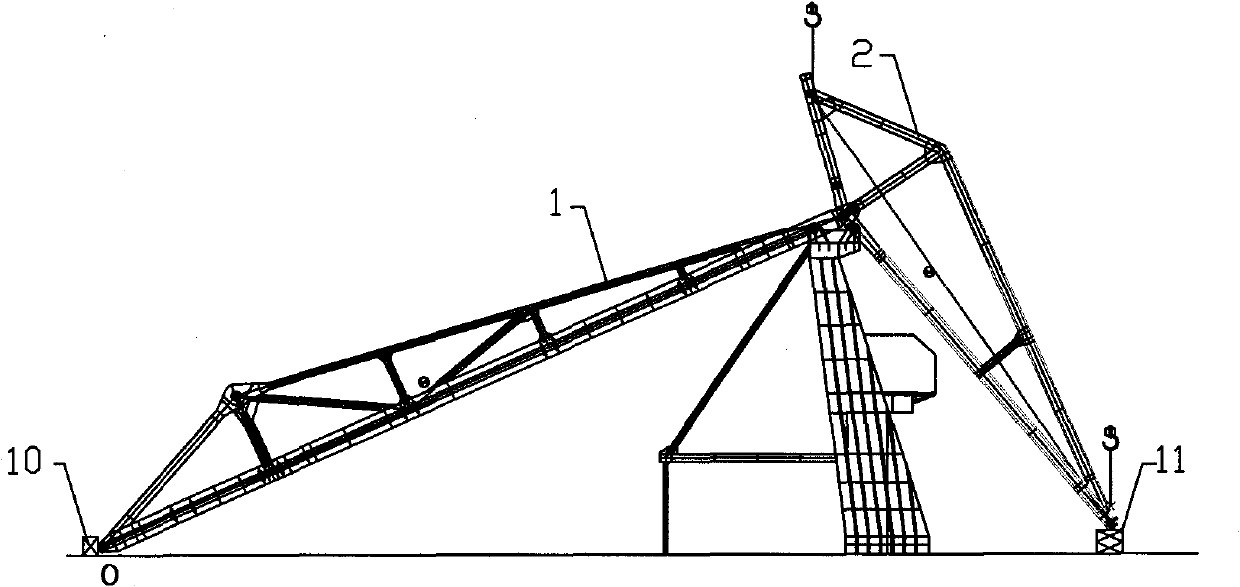

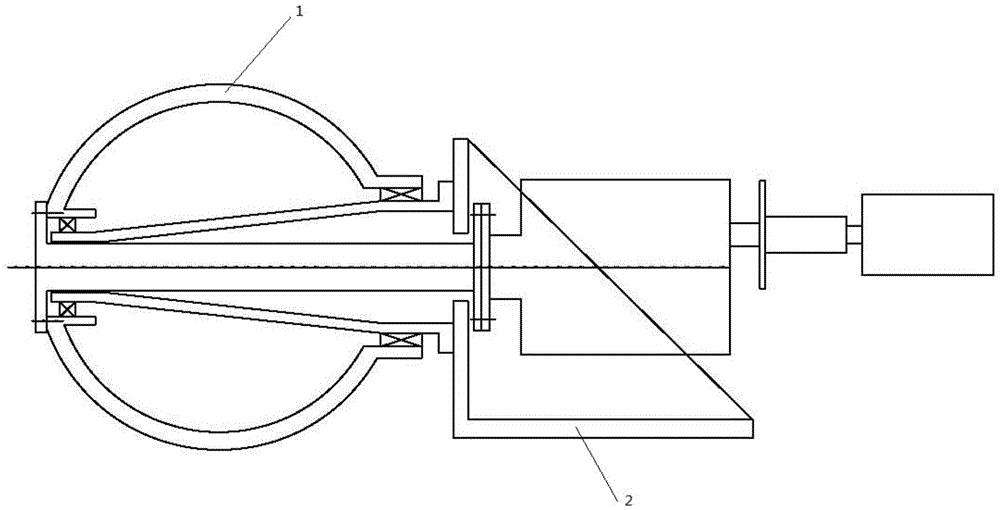

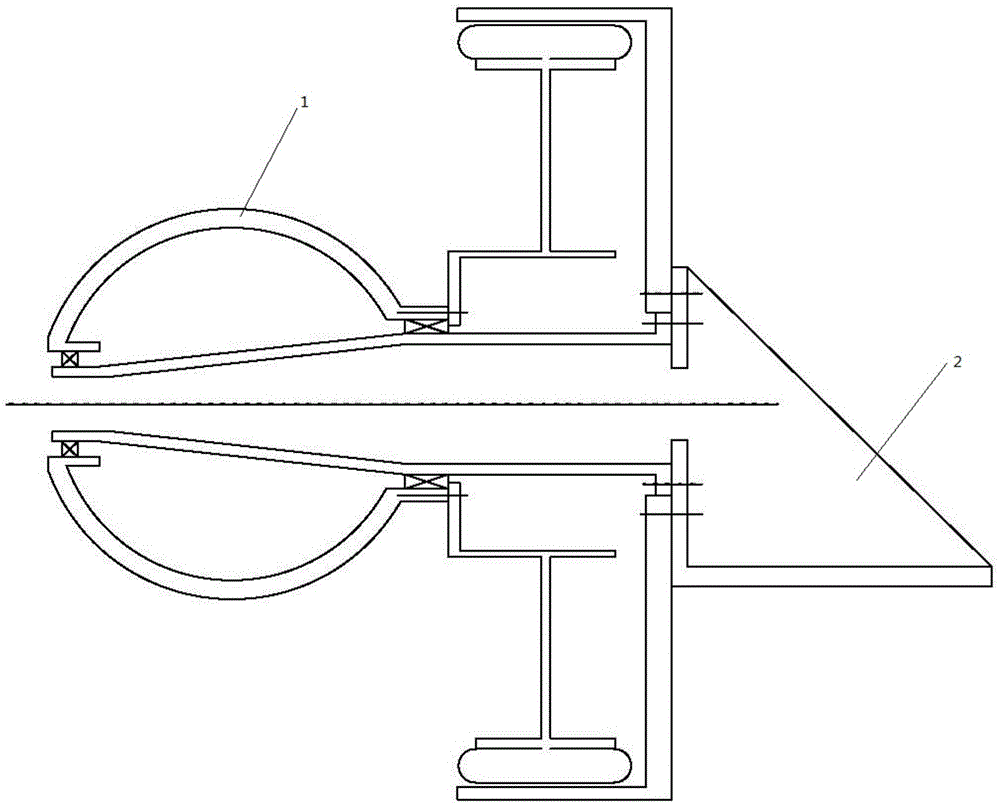

Turning hoisting method for vertical type apparatus

ActiveCN101513974AGood practical valueAvoid defectsLoad-engaging elementsCranesGravity centerIndustrial engineering

The invention relates to a turning hoisting method for the vertical type apparatus, characterized by comprising the following steps: a) the apparatus to be hoisted is unloaded according to the hoisting site condition and the hoisting machine station, and the tail of the apparatus faces to the hoisting machine; b) a rotating shaft system is arranged near to the tail of the apparatus, and a falling preventing device is arranged at the position where the apparatus arrive in the falling preventing angle; c) the lift hook of the hoisting machine is connected with the lifting point of the apparatus, which is located above the center gravity of apparatus; d) the hoisting machine lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the rotating shaft system and lift the apparatus step by step: e) the tail of the apparatus contacts with the falling preventing device when the apparatus arrive in the falling preventing angle position, the hoisting machine continuously lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the falling preventing device until the apparatus is completely vertical; f) the hoisting machine continuously lifts the lift hook to make the apparatus disengaged from the falling preventing device, the rotating shaft is removed; g) the operation radius of the hoisting machine is adjusted to be the positioning radius, then the apparatus is rotated to the base, the orientation is adjusted to position the apparatus. The hoisting method provided by the invention has no pulley set, no limitation to the lifting point orientation and simple operation.

Owner:SINOPEC NINGBO ENG

Hanger for lifting tubes and lifting equipment with same

InactiveCN101857168AReduce hoisting costsOvercoming the problem of low hoisting efficiencyLoad-engaging elementsSteel tubeEngineering

The invention provides a hanger for lifting tubes and lifting equipment with the same. The hanger for lifting the tubes comprises a hanger frame and two opposite hooks, wherein at least one hook is slidably arranged on the hanger frame; and the hooks are provided with hooking parts which are matched with inner holes of the tubes. The hanger for lifting the tubes can conveniently lift steel tubes with different lengths, is safe to operate and has high lifting efficiency. The lifting equipment of the invention is provided with the hanger for lifting the tubes.

Owner:SANY GRP

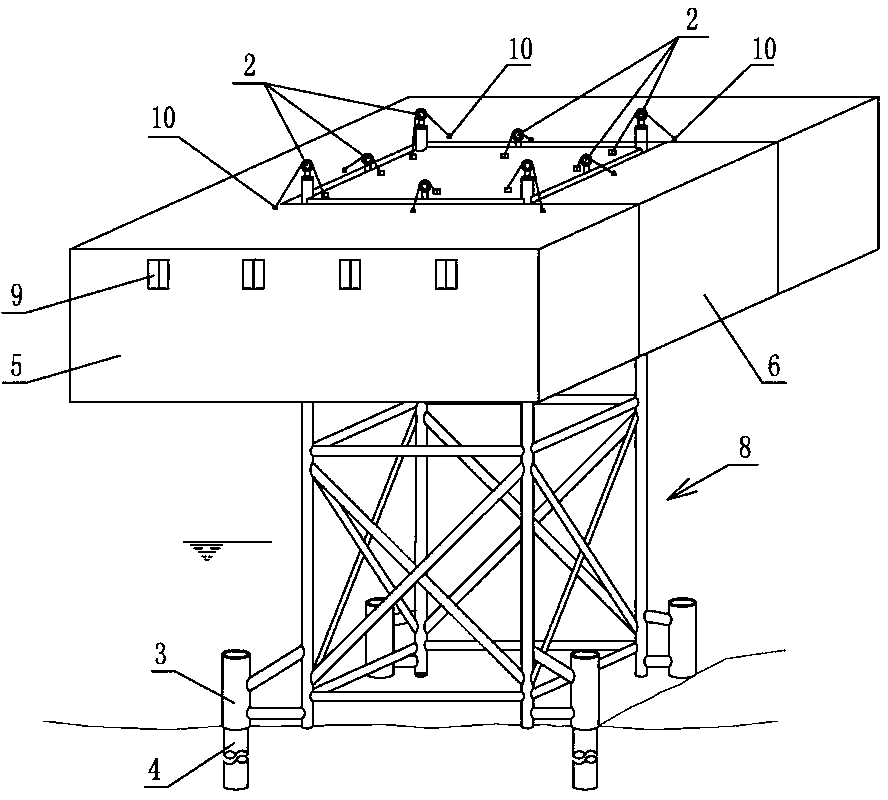

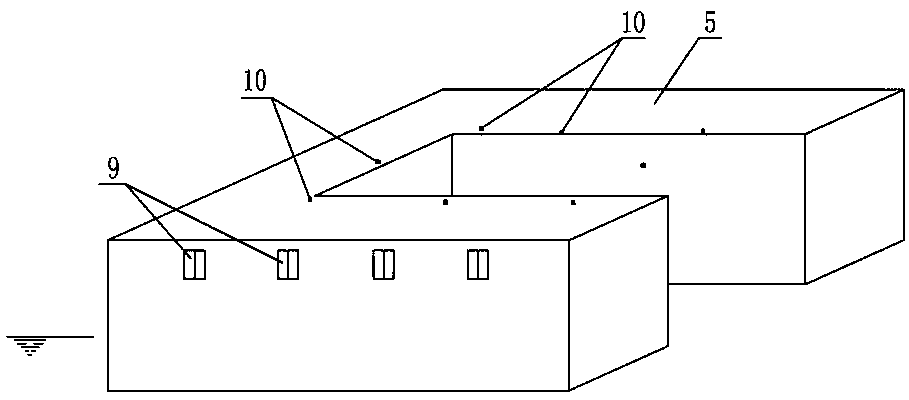

Self-installation type offshore booster station structure and installation method thereof

ActiveCN102936888AReduced requirements and lifting costsChance of reducing riskArtificial islandsUnderwater structuresPipe supportOffshore wind power

The invention relates to a self-installation type offshore booster station structure which is safe and high in efficiency, saves cost and has low requirements on ship machine equipment. The technical scheme is that the self-installation type offshore booster station structure comprises at least four steel piles which are vertically and regularly arranged, a guide pipe support fixedly installed above the steel piles and a booster station upper equipment assembly block installed on the guide pipe support, wherein the lower ends of the steel piles stretch deep into a supporting layer under a sea bed. The booster station structure is characterized in that a hoisting mechanism used for hoisting the upper equipment assembly block is arranged at the top end of the guide pipe support. The upper equipment assembly block is defined into an annular shape in splicing mode through a branch assembly block I and a branch assembly block II and is coaxially fixedly sleeved on the periphery of the guide pipe support. The structure is suitable for the field of ocean engineering like offshore wind power generation.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

In-situ spraying reparation method of horizontal aluminum busbar in electrolytic plant

InactiveCN102676970ASimple processing methodUnique process methodMolten spray coatingCoated surfaceElectrolysis

The invention relates to a reparation method of an aluminum busbar, in particular to an in-situ spraying reparation method of a horizontal aluminum busbar in an electrolytic plant. The method comprises firstly checking conditions of the busbar, performing leveling processing on the surface of the busbar, then performing preprocessing on the surface of the busbar to enable the preprocessed matrix surface to reach Sa 2.5-3.0 grade and to expose uniform metal natural color, performing rough processing on the surface of the busbar to enable roughness or riveting line depth of the surface to reach 40-80mu m, utilizing the electric arc spraying technology to spray a base layer and a working layer on the surface of the damaged busbar, finally utilizing a movable suspension milling cutter to mill the coating surface, and performing clean and smooth processing to complete the reparation of the horizontal aluminum busbar. The method can be achieved in the electrolytic plant, can effectively avoid interference of a strong magnetic field, reduces labor strength, has less consumption of labor and materials and simple and fast operation, can repair surface defects of the horizontal busbar serving as the upper structure of an aluminum cell, and can reproduce a repairing layer with excellent abrasion performance.

Owner:QINGTONGXIA ALUMINUM GRP +1

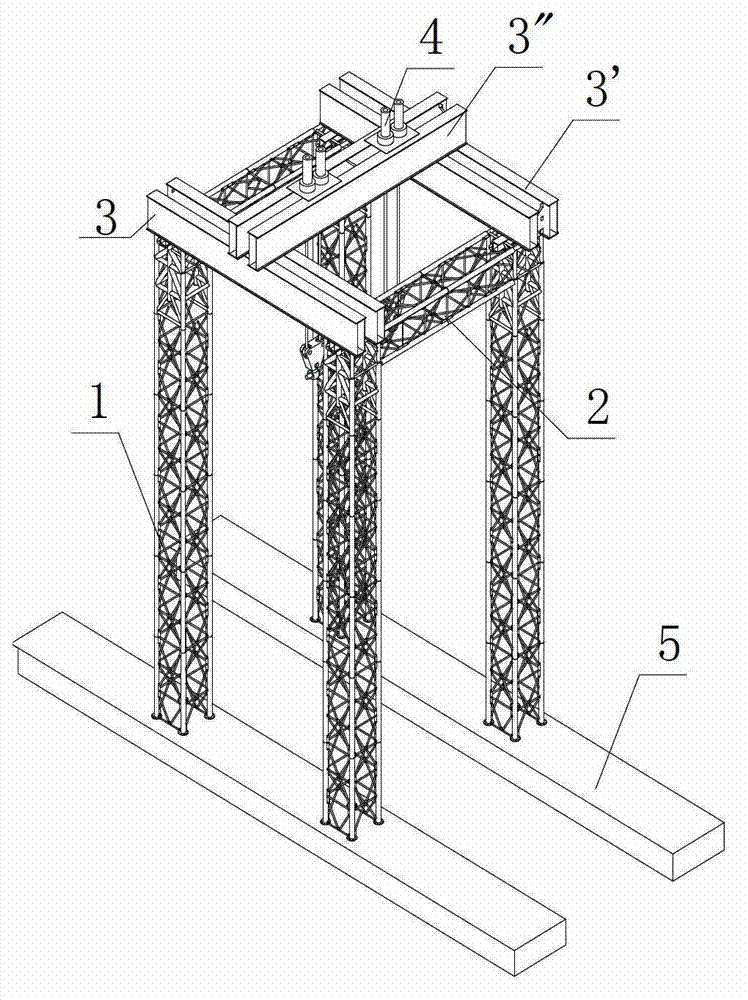

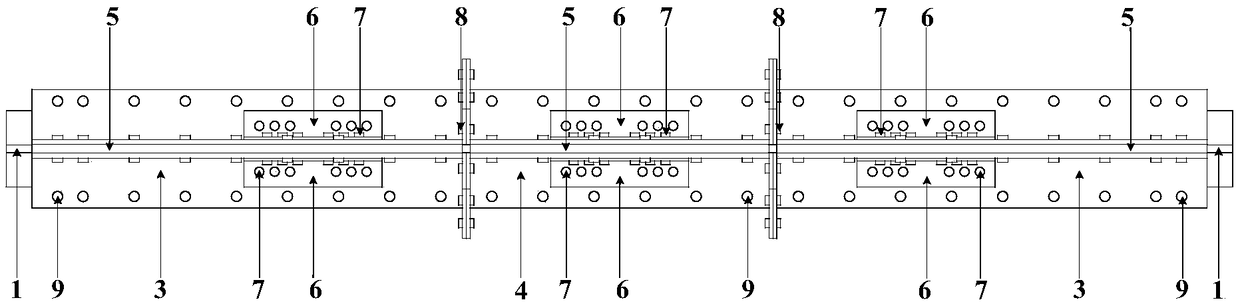

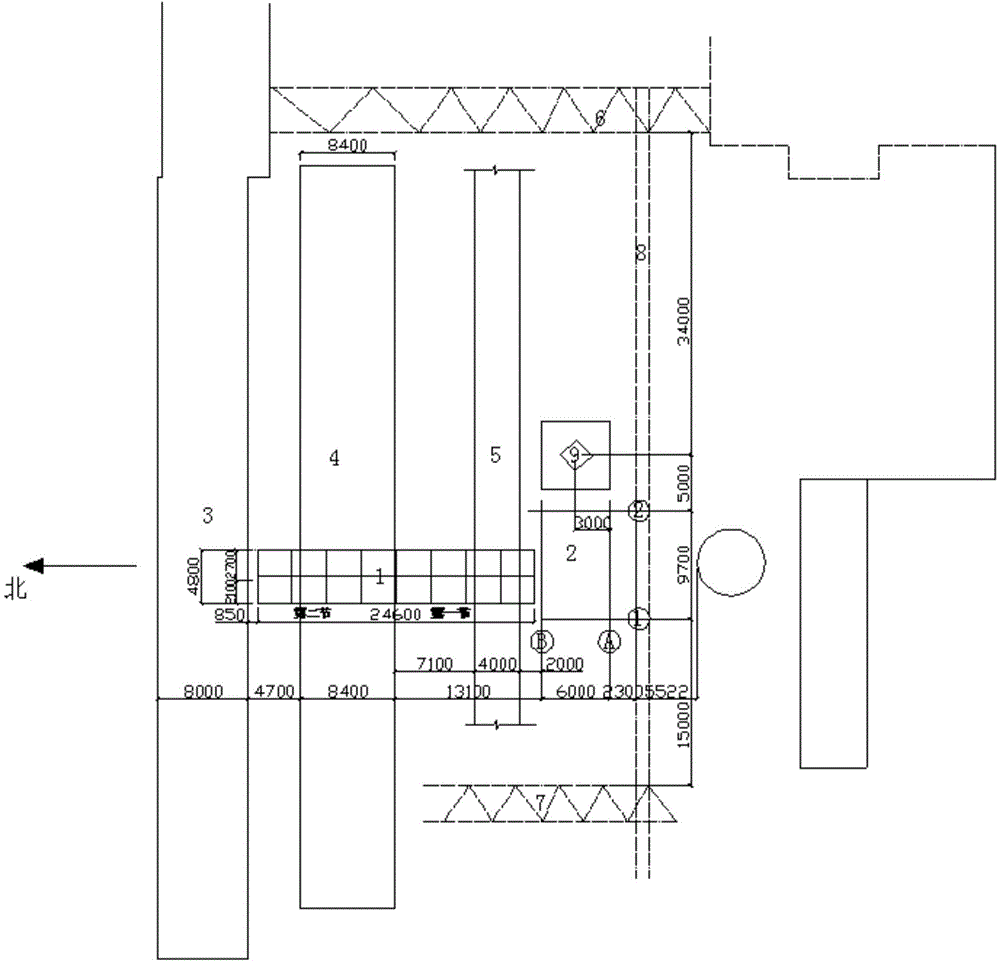

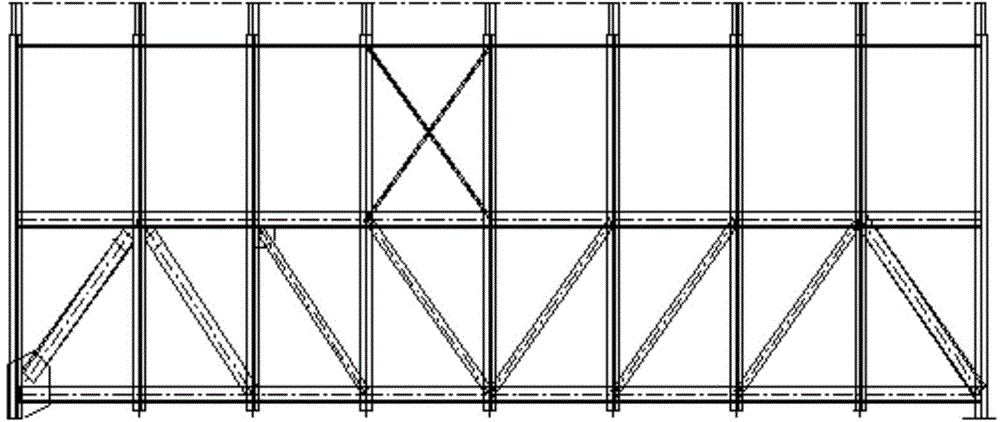

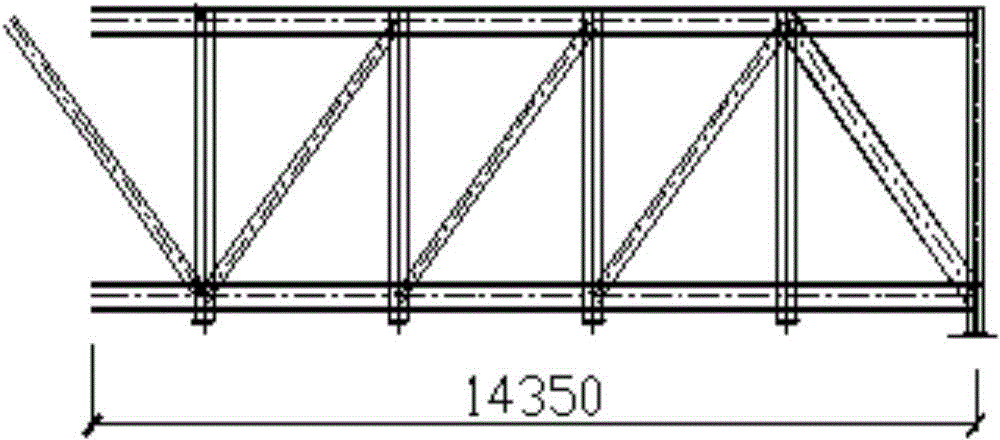

Integrally moving on-load hydraulic lifting system without mooring rope and lifting method

ActiveCN102786004AAccurate hoisting in placeStable and safe hoistingTrolley cranesTrolleysMarine engineeringTower

The invention relates to the field of lifting and hoisting, in particular to an integrally moving on-load hydraulic lifting system without a mooring rope and a lifting method. The integrally moving on-load hydraulic lifting system without the mooring rope comprises a tower and two parallel running rails, the tower comprises four vertical posts and connection crossbeams, and the two running rails are fixed on the ground. The bottom ends of the four vertical posts are arranged in the running rails so that the vertical posts can slide in the running rails. Two of the vertical posts are arranged on one of the running rails, and the other two vertical posts are arranged on the other running rail, the vertical posts on the two running rails correspond to each other, and the top ends of the corresponding vertical posts are connected through the connection crossbeams. The vertical posts and the connection crossbeams form the tower in the frame type structure. Without the mooring rope, the hydraulic lifting system can integrally move in long distance in an on-load manner, and lifting is safe and stable and economical.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

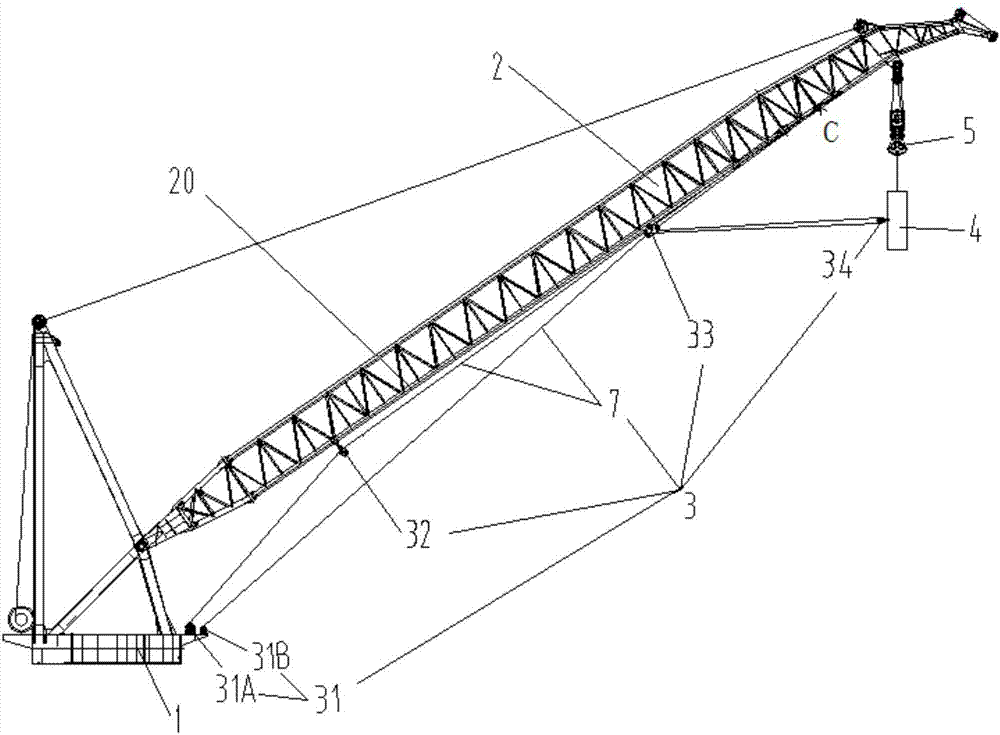

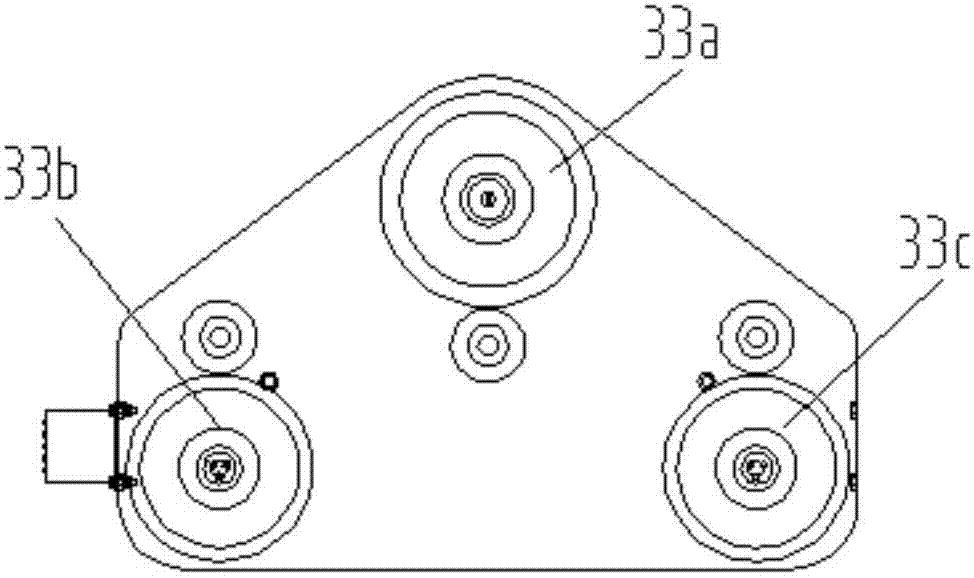

Moment hoisting method for three connecting rods of gantry crane

InactiveCN101792091AReduced performance requirements for maximum capacityReduce hoisting costsCranesControl theoryGantry crane

The invention discloses a moment hoisting method for three connecting rods of a gantry crane, which is characterized by comprising the following steps: 1) connecting hinged points between an arm frame and a fly-jib; 2) fixing relative positions between the arm frame and the fly-jib to form two connecting rods at the time; 3) hoisting the arm frame and a hinged end of a turntable of the crane to a turntable of the gantry crane and connecting hinged points between the arm frame and the turntable of the crane; 4) connecting a big pull rod and the upper end point of the fly-jib of the two connecting rods to form a three-connecting rod mechanism; and 5) integrally hoisting the three-connecting rod mechanism with the crane by taking the hinged point between the arm frame and the turntable of the crane as a rotating hinged point and taking the lower end point of the fly-jib of three connecting rods as a hoisting point so that the three-connecting rod mechanism is hoisted upwards around the rotating hinged point. The moment hoisting method for the three connecting rods of the gantry crane of the invention has low requirements on performance of the crane needing to be hoisted and can save hoisting cost.

Owner:GUANGZHOU WENCHUAN HEAVY IND

Hinge joint conversion type external prestressed concrete tower and construction method thereof

ActiveCN106121346AEliminates the possibility of vertical cracksEliminate potential safety hazardsDesign optimisation/simulationTowersPre stressEngineering

The invention provides a hinge joint conversion type external prestressed concrete tower and a construction method thereof. The hinge joint conversion type external prestressed concrete tower comprises a common prestressed concrete tower barrel and an external prestressed strand arranged tightly attached to the inner wall face of the common prestressed concrete tower barrel. A prestressed anchoring region annular beam is arranged on the upper end face of the common prestressed concrete tower barrel. A steel tower barrel is arranged on the upper end face of the prestressed anchoring region annular beam. An anti-torsion-deformation buffering support is arranged between the prestressed anchoring region annular beam and the common prestressed concrete tower barrel. The prestressed anchoring region annular beam and the steel tower barrel are connected through a flange fixed to the bottom of the steel tower barrel. The external prestressed strand penetrates the prestressed anchoring region annular beam and the flange from bottom to top and then is fixed through an anchorage device. By the adoption of the hinge joint conversion type external prestressed concrete tower, the common prestressed concrete tower barrel at the lower portion can only bear the vertical pressure transmitted by the prestressed anchoring region annular beam, the possibility that the common prestressed concrete tower barrel at the lower portion vertically cracks under the effect of the eccentric prestress of an anchoring region is eliminated, and potential safety hazards of an external prestressed concrete wind power tower are eliminated.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Floating crane cargo stabilizing device

The invention discloses a floating crane cargo stabilizing device which comprises a rotating platform, a cantilever crane supported on the rotating platform, and a cargo stabilizing mechanism arranged on the rotating platform and the cantilever crane. The cargo stabilizing mechanism comprises cargo stabilizing guide winches, a cargo stabilizing guide pulley, a cargo stabilizing pulley yoke, a cargo stabilizing guide cargo pulley and cargo stabilizing steel wire ropes, the cargo stabilizing guide winches are arranged on the rotating platform, the cargo stabilizing guide pulley is arranged in the position, close to the bottom, of a cantilever crane lower chord, a lifting hook is arranged on the lower side of the upper part of the cantilever crane, a sling load is tied in the lifting hook, the cargo stabilizing pulley yoke is arranged on the cantilever crane lower chord and located between the cargo stabilizing guide pulley and a fixing frame which is arranged in the position, close to the lifting hook, of the lower side of the upper part of the cantilever crane, the cargo stabilizing guide cargo pulley is arranged on the sling load, the cargo stabilizing steel wire ropes are arranged among the cargo stabilizing guide winches, the cargo stabilizing guide pulley, the cargo stabilizing pulley yoke and the cargo stabilizing guide cargo pulley optionally in a penetrating winding mode. According to the floating crane cargo stabilizing device provided by the invention, when sling loads of different sizes are lifted to different lift heights, cargo stabilizing can be achieved by converting different rope winding modes.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

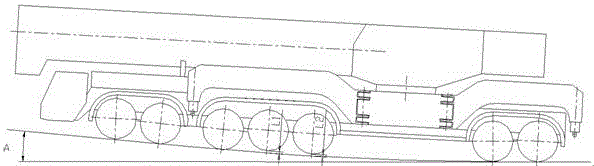

Modular flexible chassis, application thereof and crane thereof

ActiveCN106698210AWide range of usesEasy maintenanceServomotorsServometer circuitsModularityComputer module

The invention discloses a modular flexible chassis, application thereof and a crane thereof, and belongs to the field of crane equipment. The chassis consists of multiple modules with different functions; all the modules adopt different combination and connection modes to realize flexibility and modularization of a vehicle body; the assembled chassis is high in ground self-adaptability; the chassis comprises a driving control driving module positioned at an advancing end, support bearing modules connected with the driving control driving module, a crane operation module arranged between the support bearing modules, and a driven driving module positioned at a tail end; the support bearing modules include a front support bearing module and a back support bearing module; the crane operation module is positioned between the front and back support bearing modules; the driving control driving module is connected with the front support bearing module; and the driven driving module is connected with the back support bearing module. Compared with a traditional structure, the modular flexible chassis has such multiple functions as high ground self-adaptability, multiple purposes, convenience to maintain and high power.

Owner:XUZHOU HEAVY MASCH CO LTD

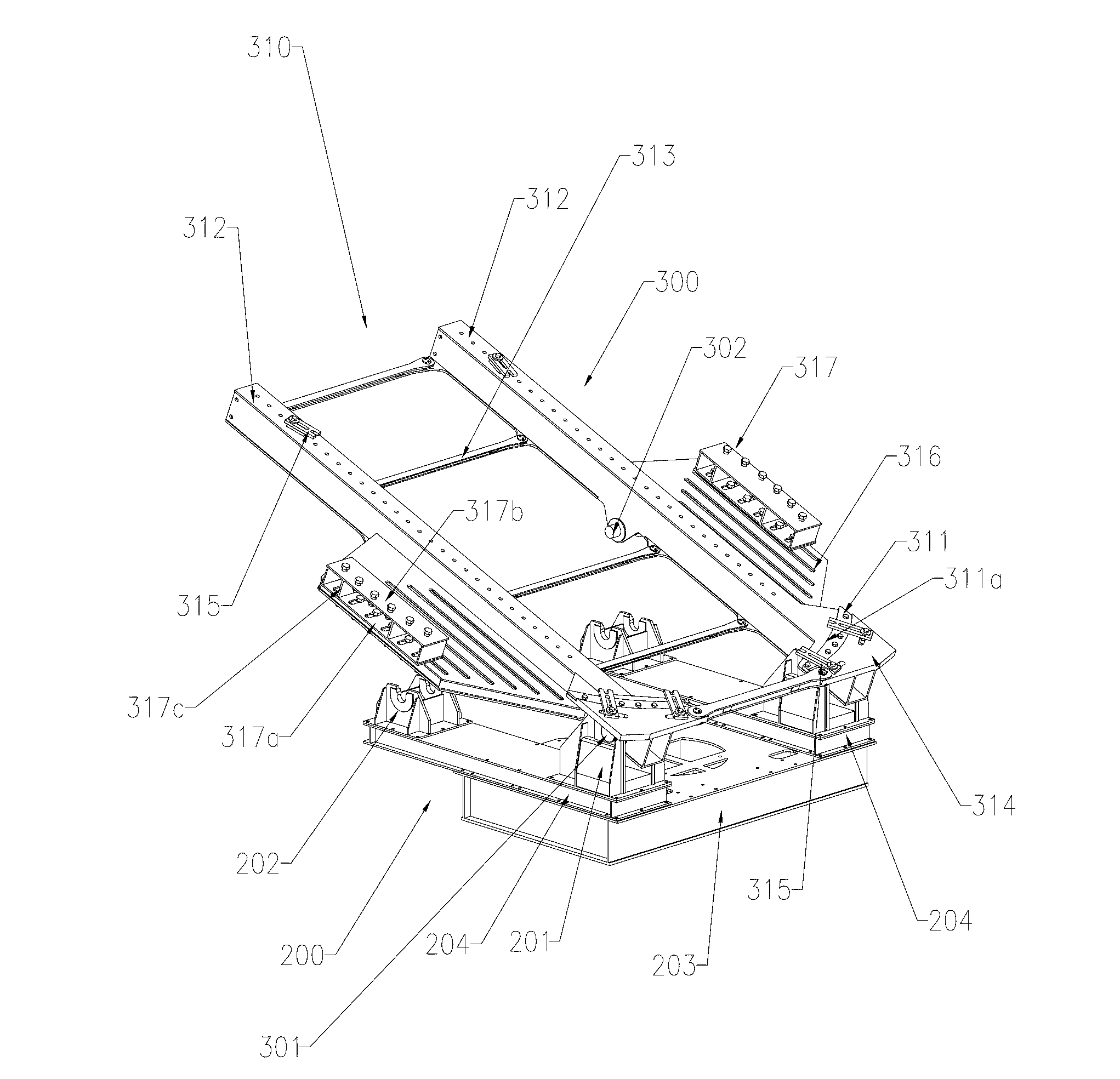

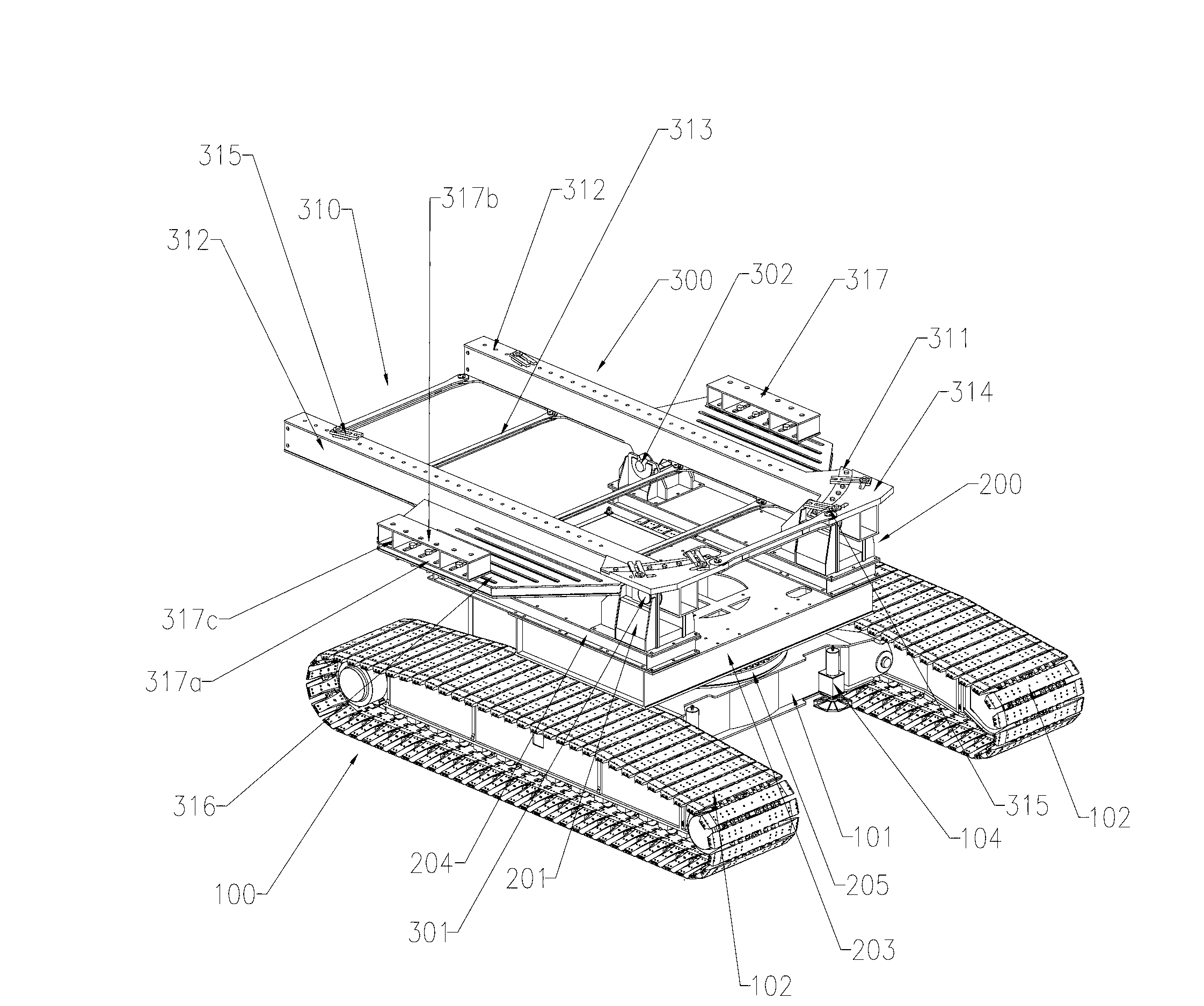

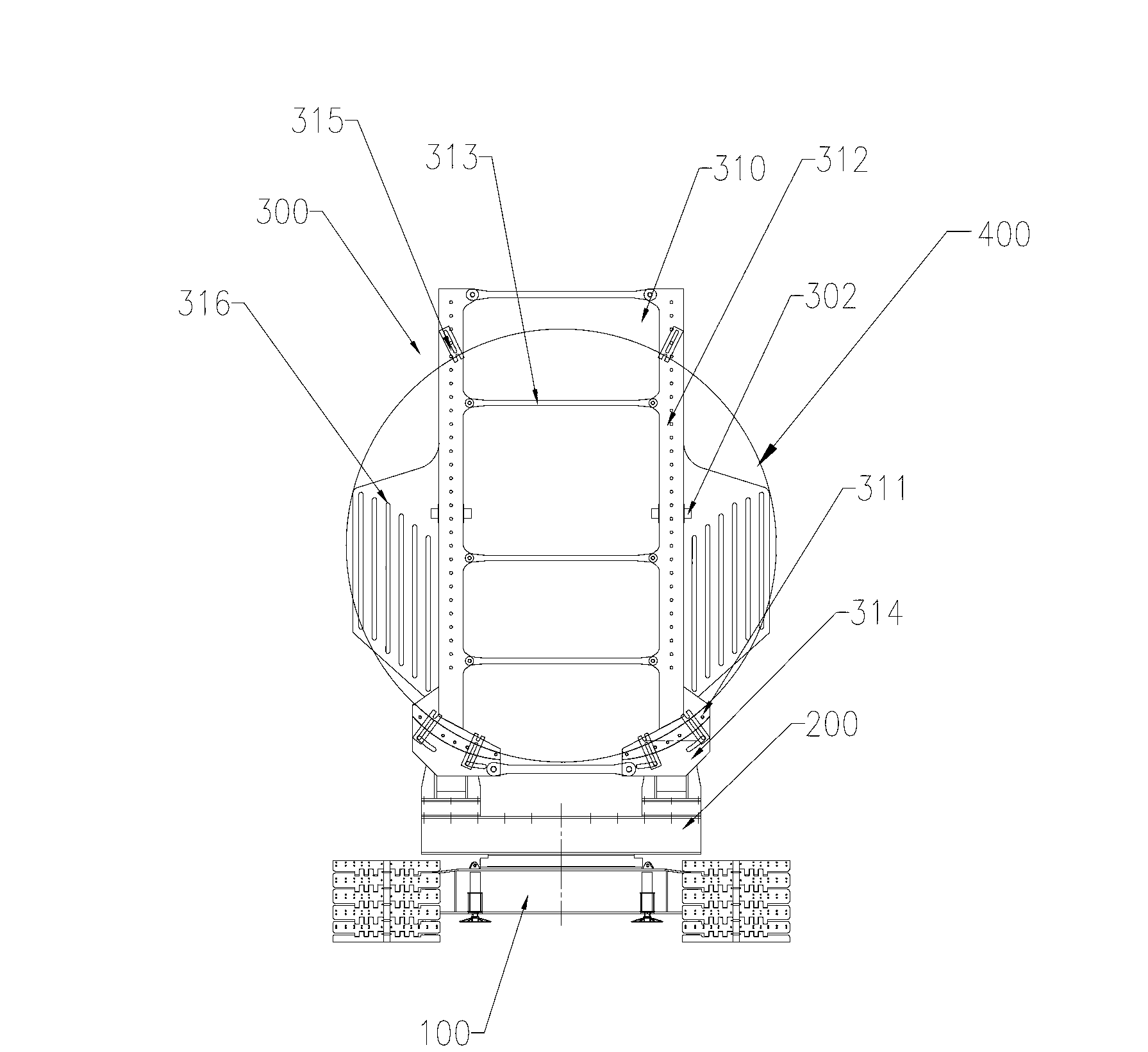

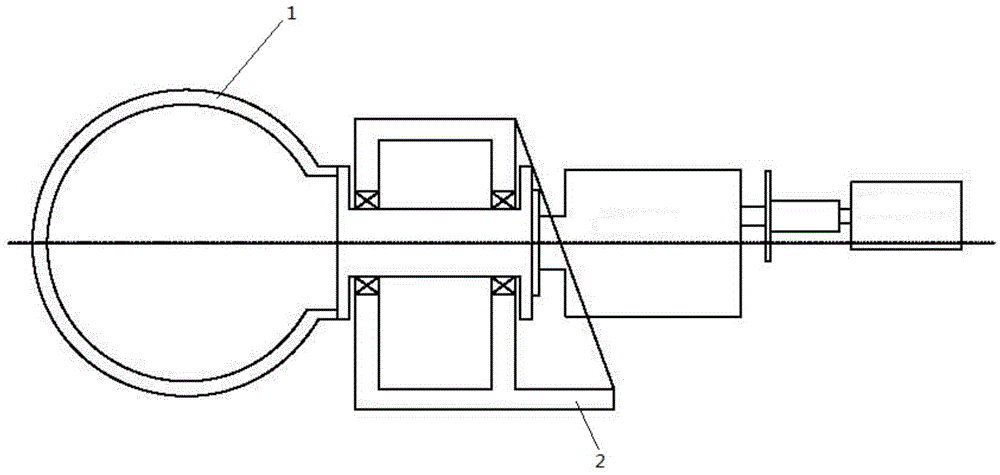

Tail dragging device used for hoisting equipment, tail dragging vehicle and equipment hoisting method

ActiveCN103010952AControl synchronizationReduce hoisting costsLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a tail dragging device used for hoisting equipment, a tail dragging vehicle provided with same, and an equipment hoisting method for tail dragging through the provided tail dragging vehicle. The tail dragging device comprises a supporting mechanism (200) and a rotating mechanism (300), wherein the rotating mechanism (300) is rotatably and detachably installed on the supporting mechanism (200), and the supporting mechanism (200) comprises a front supporting seat (201); and the rotating mechanism (300) comprises a supporting frame (310), wherein a rotating shaft (301) is installed at the bottom of the supporting frame (310) and supported on the front supporting seat (201), and the supporting frame (310) can rotate between the horizontal position and the vertical position around the rotating shaft, and comprises a first support member (311) mutually matched with equipment (400) for supporting the equipment when the supporting frame is in the vertical position. The tail dragging vehicle comprises the tail dragging device and a travelling mechanism. The provided tail dragging vehicle can save the hoisting cost and has better versatility.

Owner:ZOOMLION HEAVY IND CO LTD

Wind driven generator, wind driven generator set and installation method thereof

ActiveCN105649885AReduce the difficulty and cost of hoistingAchieve connectionWind motor assemblyWind motor supports/mountsWind drivenAutomotive engineering

The invention provides a wind driven generator, a wind driven generator set and an installation method thereof. The wind driven generator comprises a stator and a rotor coating the stator, and further comprises a driving part connected with the rotor and driving the rotor to axially move. The wind driven generator can reduce the lifting difficulty.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

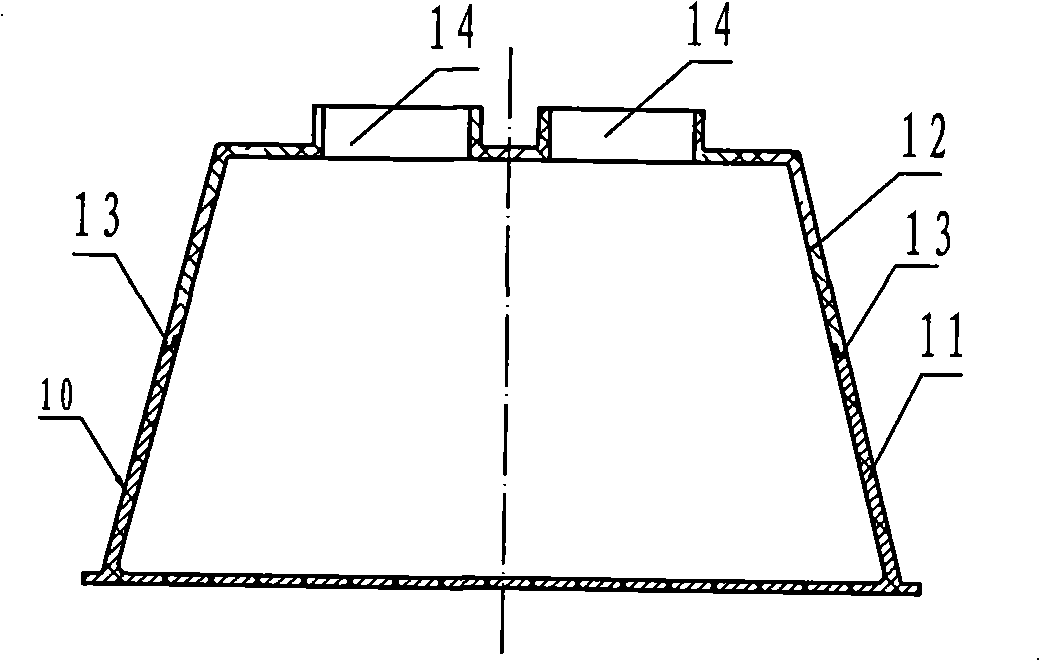

Radiation-retarding door body structure and mounting method thereof

InactiveCN101469596ASave steel plate material and transportationNo leakage hazardRadiation protectionLayered productsSteel platesEngineering

The present invention provides a radiation protection door structure which includes: door hanging device including hanging upper frame, guide way, fixed bolt and hanging lower frame; a groove that coordinates with the guide way is set on the upper end-face of the hanging upper frame and a circular hole is set on the lower end-face; a circular hole is set on the upper end-face of the hanging lower frame; the fixed bolt locks by passing through circular hole on lower end-face of the hanging upper frame and circular hole on the upper end-face of the hanging lower frame; the door includes: van-type frame, lead layer and boron containing polyethylene layer; the inner layer of the door is boron containing polyethylene layer, outer layer is lead layer and the outside of the lead layer is covered by van-type frame. The advantages are: a great volume of steel plate material and transport, hoisting cost is saved.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Self-balance hoisting tool and hoisting method for specially-shaped component

The invention provides a self-balance hoisting tool and a hoisting method for a specially-shaped component, belongs to the technical field of building construction, and aims to solve the problems that two cranes are required to hoist the specially-shaped component and hoisting points are required to be replaced in the prior art. The self-balance hoisting tool for the specially-shaped component comprises a hoisting hook, a hoisting beam and two pulley blocks, wherein a hoisting lug is arranged at each of the two ends of the hoisting beam and is connected with the hoisting hook through a steel wire rope; each pulley block comprises a first fixed pulley, two second fixed pulleys and a cable; each first fixed pulley is connected with the corresponding hoisting lug through the steel wire rope; in each pulley block, one end of the cable sequentially penetrates through one of the second fixed pulleys, the first fixed pulley and the other second fixed pulley; a hoisting ring is arranged at each of the two ends of each cable. According to the self-balance hoisting tool and hoisting method, the hoisting period can be effectively shortened, and the hoisting cost is reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

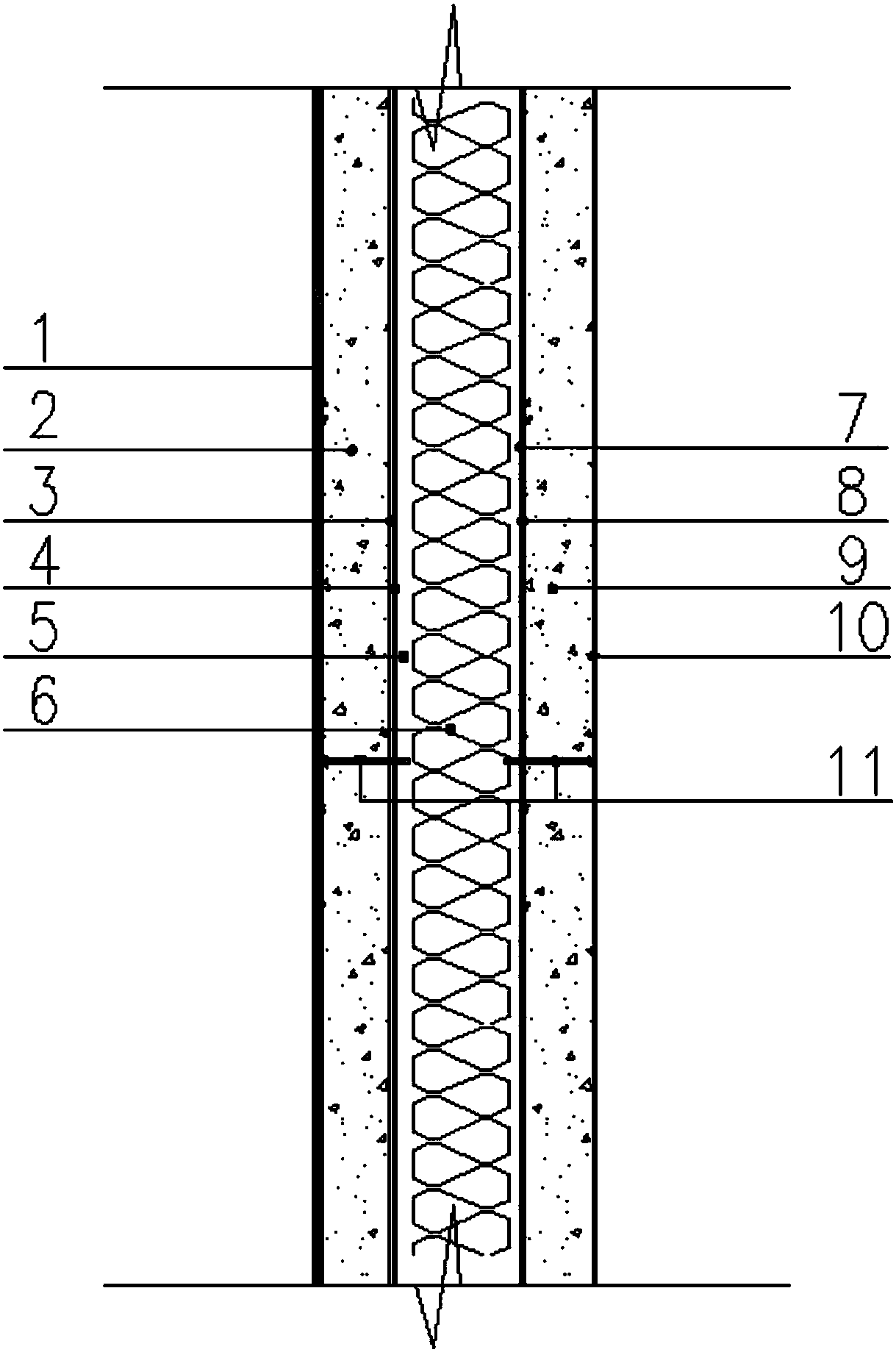

Fabricated light steel keel wall body suitable for building and construction technology

PendingCN107859213AImprove sound insulationImprove thermal insulation and energy savingWallsThick plateEngineering

The invention belongs to the technical field of fabricated light steel keel enclosure wall bodies of buildings and construction and discloses a fabricated light steel keel wall body suitable for a building and a construction technology. The fabricated light steel keel wall body suitable for the building comprises a wall surface anti-cracking and waterproof material composite layer and the like. AnALC board base layer with the thickness being 50-200 mm is arranged on the right side of the wall surface anti-cracking and waterproof material composite layer, and a damping and sound-insulating material layer with the thickness being 1.2-19 mm is arranged on the right side of the ALC board base layer with the thickness being 50-200 mm. A heat-insulating material layer with the thickness being 2-15 mm is arranged on the right side of the damping and sound-insulating material layer with the thickness being 1.2-19 mm, and a light steel keel wall frame is arranged on the right side of the heat-insulating material layer with the thickness being 2-15 mm. The light steel keel wall frame is filled with a heat-insulating material with the thickness being 30-140 mm, and a heat-insulating materialwith the thickness being 2-15 mm is arranged on the right side of the light steel keel wall frame. A sound-insulating material with the thickness being 1.2-19 mm is arranged on the right side of theheat-insulating material with the thickness being 2-15 mm, and an ALC board with the thickness being 50-200 mm is arranged on the right side of the sound-insulating material with the thickness being 1.2-19 mm. A facing layer is arranged on the right side of the ALC board with the thickness being 50-200 mm.

Owner:武汉麦特建筑科技有限公司

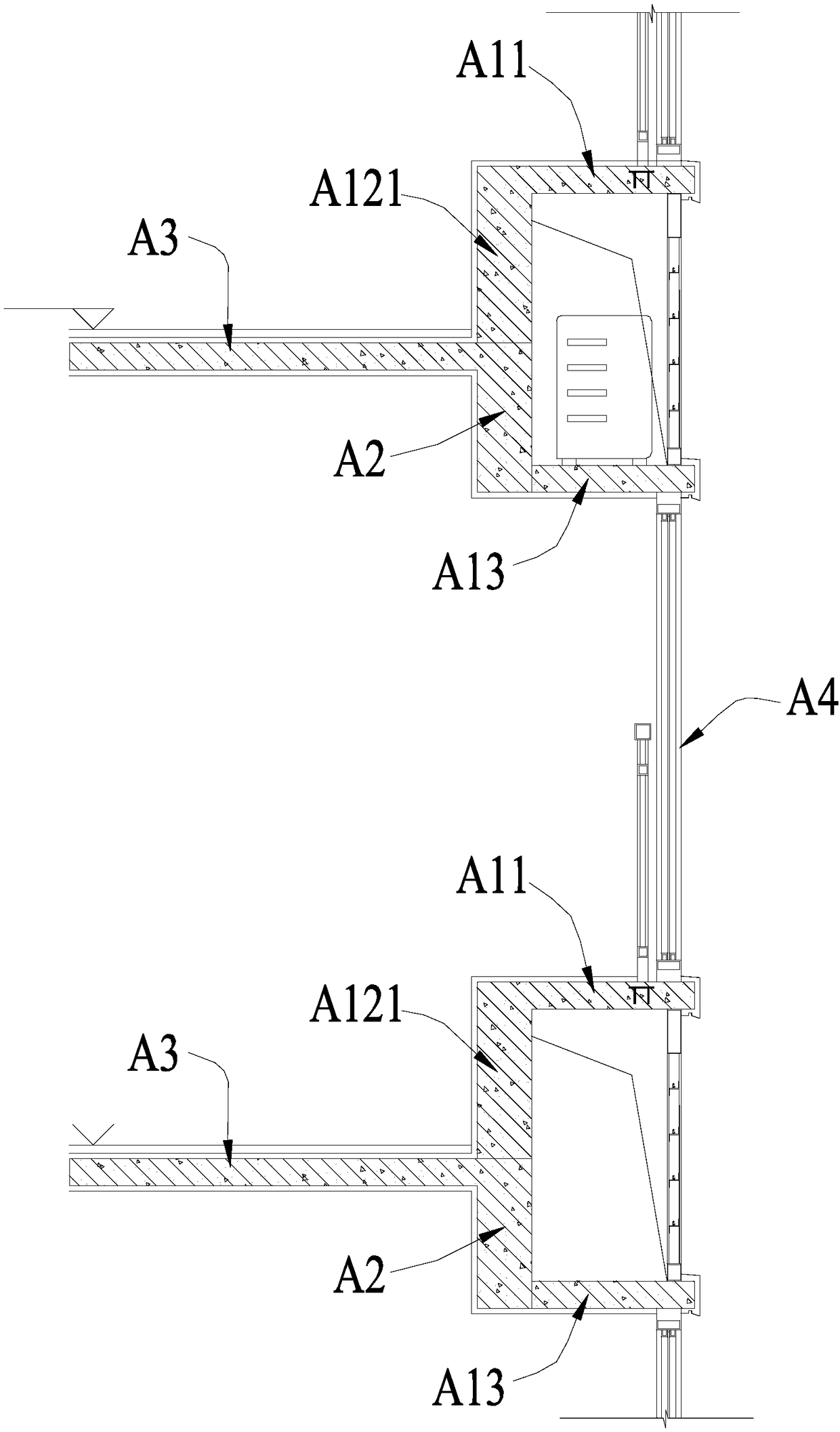

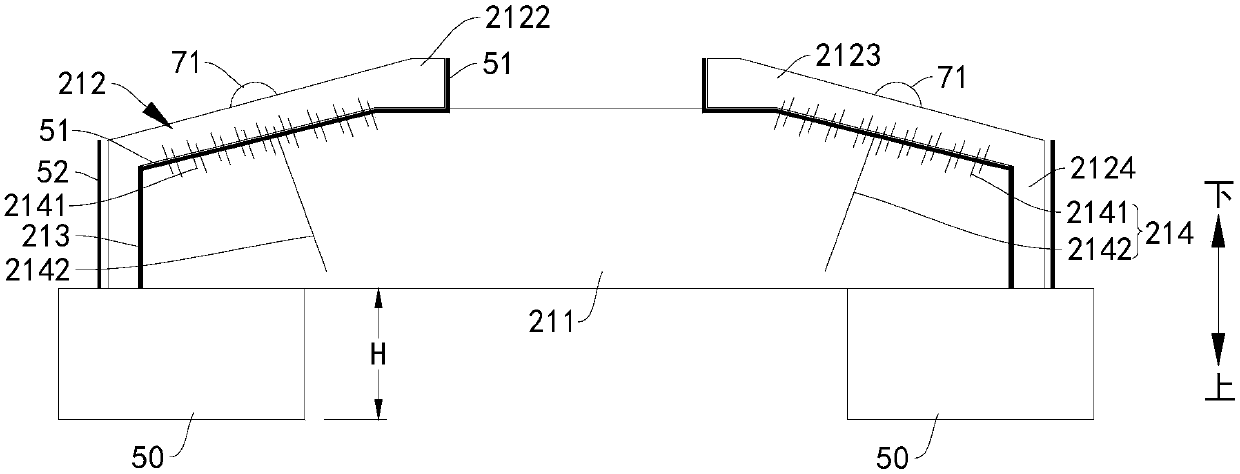

Prefabricated bay window component, assembly type bay window panel point construction and construction method thereof

PendingCN108316466AEnsure structural safetyFirmly connectedBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a prefabricated bay window component, an assembly type bay window panel point construction and a construction method thereof. The prefabricated bay window component is a reinforced concrete prefabricated component which is integrally cast and molded. The prefabricated bay window component comprises a first plate part, a second plate part and a third plate part, wherein a lug boss is formed in the upper part of the second part component relative to the lower part and is protruded toward the inner side of the second plate part; the first plate part and the third plate part are connected with the outer side of the second plate part; the first plate part is located above the third plate part; the second plate part is connected with an anchoring part used for connectinga building main body; the first plate part is used as a bay windowsill bottom plate; the upper part of the second plate part is used as a bay windowsill lower wall; the third plate part is used as a bay windowsill top plate. Through the prefabricated bay window component, the assembly type bay window panel pointconstruction and the construction method thereof, the occurrence of long-length specially-shaped prefabricated components in the bay window panel point construction is avoided under the precondition that the structure safety of the assembly type bay window panel point structure is ensured; the difficulties and the costs for producing, transporting and hoisting all the prefabricated components in the assembly type bay window panel point construction can be reduced.

Owner:广东省建工设计院有限公司

Manufacturing method of bridge pier

ActiveCN110656574AReduce adverse effectsThe connection structure is stable and reliableCeramic shaping apparatusBridge structural detailsArchitectural engineeringPier

The invention discloses a manufacturing method of a bridge pier. The manufacturing method of the bridge pier comprises the following steps of obtaining a pier stud prefabricated part and a capping beam prefabricated part, wherein a pier stud prefabrication chamber extending in the axial direction is formed in the pier stud prefabricated part; a capping beam prefabrication chamber is formed in thepier stud prefabricated part; a connecting rib extending upwards is arranged on the pier stud prefabricated part; the pier stud prefabricated part is placed on a mounting surface; concrete is injectedinto the pier stud prefabrication chamber from an opening in the upper end of the pier stud prefabrication chamber to be cured to form a pier stud concrete layer; the capping beam prefabricated partis mounted at the upper part of the pier stud prefabricated part, and the connecting rib is enabled to extend into the capping beam prefabrication chamber; and concrete is injected into the capping beam prefabrication chamber to be cured to form a capping beam concrete layer connected with the pier stud concrete layer and the connecting rib. According to the manufacturing method of the bridge pierdisclosed by the embodiment of the invention, the site construction procedure is simple, the construction speed is increased, the construction safety is enhanced, adverse effect of a traditional fullcast-in-situ process on traffic environment is avoided, and moreover, the connection between a pier stud and a capping beam is firmer.

Owner:BYD CO LTD

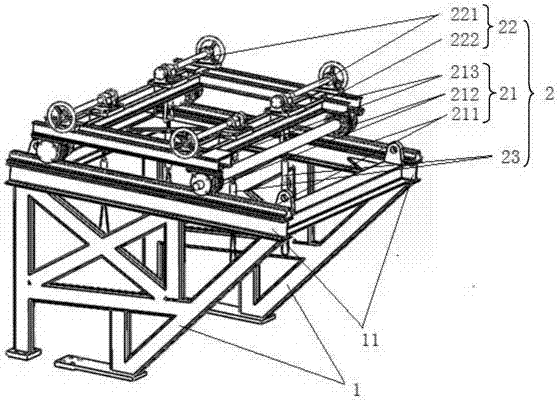

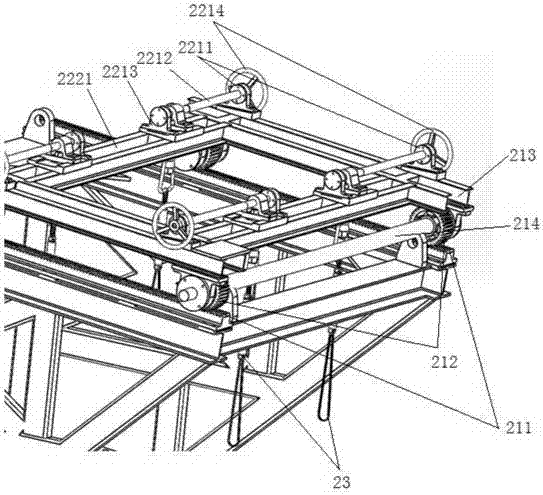

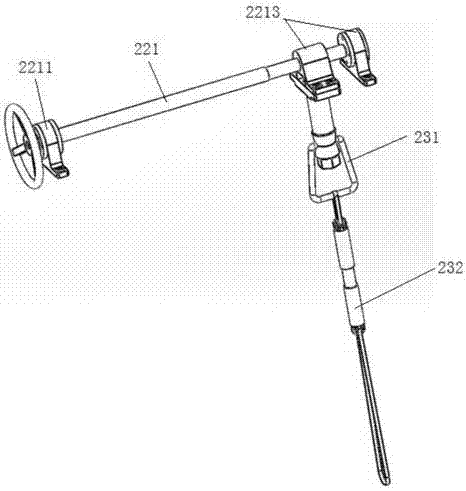

Assembly tool capable of replacing gearbox overhead without dismounting wind wheel

ActiveCN107140536AImprove hoisting efficiencyHoisting safetyMachines/enginesWind energy generationEngineeringMechanical engineering

The invention discloses an assembly tool capable of replacing a gearbox overhead without dismounting a wind wheel, and belongs to the assembly field. The assembly tool comprises a mobile mechanism group and a fixing mechanism used for supporting and fixing the mobile mechanism group, wherein the mobile mechanism group comprises an X-axis regulating mechanism, a Y-axis regulating mechanism and a Z-axis regulating mechanism; the X-axis regulating mechanism comprises at least two X-axis rails which are arranged in parallel and at least four mobile blocks capable of moving on the X-axis rails, and a connecting frame is arranged between every two mobile blocks; the Y-axis regulating mechanism comprises two parallel supporting transverse frames which are perpendicularly connected with the two connecting frames; a Y-axis slide slot is formed in each supporting transverse frame; a lead screw structure is arranged at each of two ends of each Y-axis slide slot; the Z-axis regulating mechanism comprises an adjustable connector which is connected on a mobile part for connecting and fixing a to-be-assembled object; and the X-axis rails are arranged on a supporting longitudinal beam on the upper part of the fixed mechanism. According to the assembly tool disclosed by the invention, the position and speed of the gearbox are precisely controlled through three dimensions, so that the purpose of replacing the gearbox overhead without dismounting the wind wheel is achieved, and therefore, lifting efficiency is improved.

Owner:GUODIAN UNITED POWER TECH

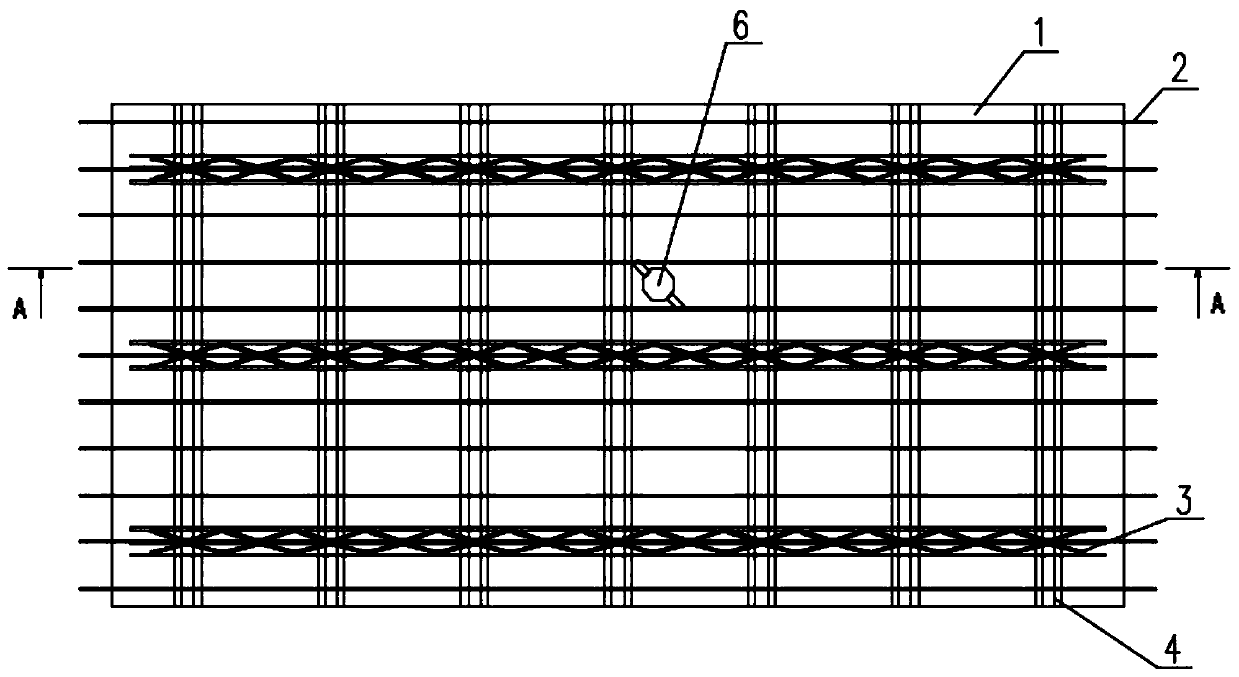

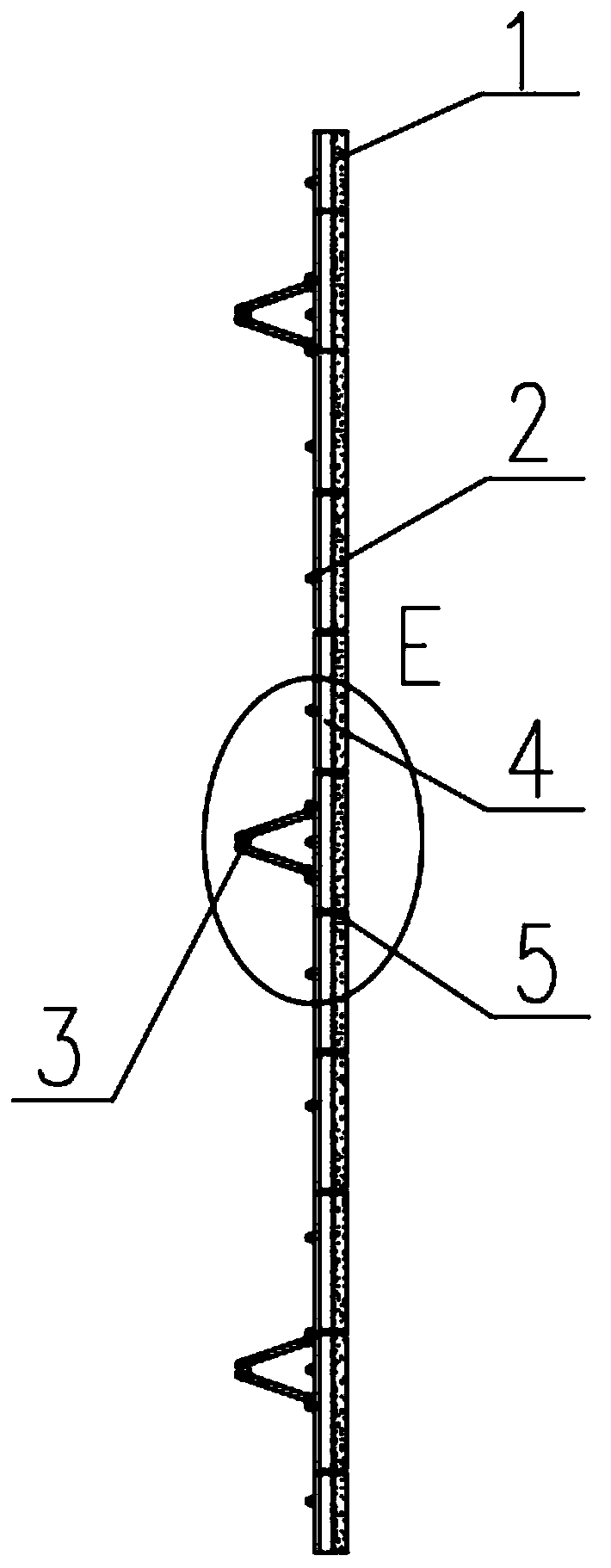

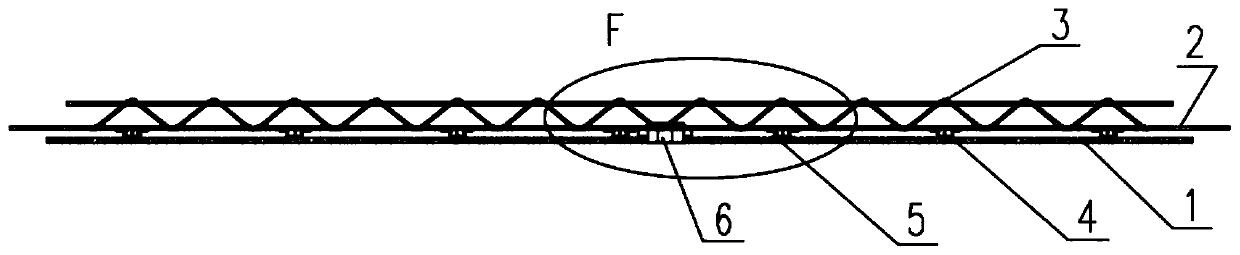

Prefabricated composite floor component

The invention discloses a prefabricated composite floor component which comprises high-precision dismounting-free form boards, combined formed steel bar products and connecting screws. The bottom faceof a floor is formed by the multiple high-precision dismounting-free form boards, rectangular grooves are adopted by the single faces of the high-precision dismounting-free form boards to achieve galling, the combined formed steel bar products are placed above the bottom face of the floor and are connected together through n-shaped profile steel, the open sides of the n-shaped profile steel are connected to the bottom faces of the combined formed steel bar products, concrete is poured after the closed sides of the n-shaped profile steel are connected with the galling faces of the rectangulargrooves of the floor through connecting screws, and a prefabricated is formed. Reserved wire box wire pipes are arranged on the high-precision dismounting-free form boards and in the combined formed steel bar products. According to the prefabricated composite floor component, the concept is ingenious, the structure is compact and reasonable, prefabricated parts are thin and light, lifting and transporting are facilitated, cost is reduced, by means of the design of the dismounting-free form boards, workloads are reduced, and the requirement for high levelness of a combined beam is guaranteed.

Owner:高慧静

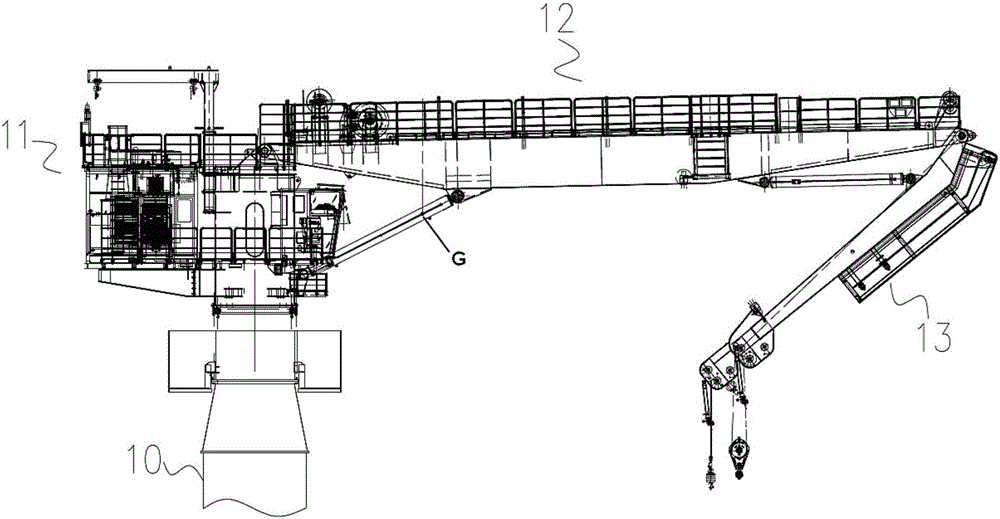

Lifting process of upper structure of FPSO crane

ActiveCN105947910AShorten the installation cycleReduce hoisting costsLoad-engaging elementsCranesButt jointGravity center

The invention discloses a lifting process of an upper structure of a FPSO crane. The lifting process comprises the following steps: (S1) a main lifting rope set is mounted on the upper structure; a first lifting rope set is positioned on the left side of the gravity center G by 6834 mm; and a second lifting rope set is positioned on the right side of the gravity center G by 6834 mm; (S2) a first adjusting rope and a second adjusting rope are mounted on the upper structure; (S3) the upper structure is wholly lifted, and an included angle between a main lifting arm and a joint lifting arm is adjusted in air, so that an original included angle between the main lifting arm and the joint lifting arm is reduced from an obtuse angle to 75 degrees; and (S4) the upper structure is in butt joint. The lifting process of the upper structure of the FPSO crane lifts the upper structure of the crane as a whole part, reduces the lifting times, can control and adjust the levelness of a flange at the bottom of an operation platform by only adjusting a folding angle of the joint lifting arm in air in the whole lifting process, reduces the mounting period and the lifting cost of the crane, and reduces potential safety hazards in aerial operations.

Owner:广州文冲船舶修造有限公司

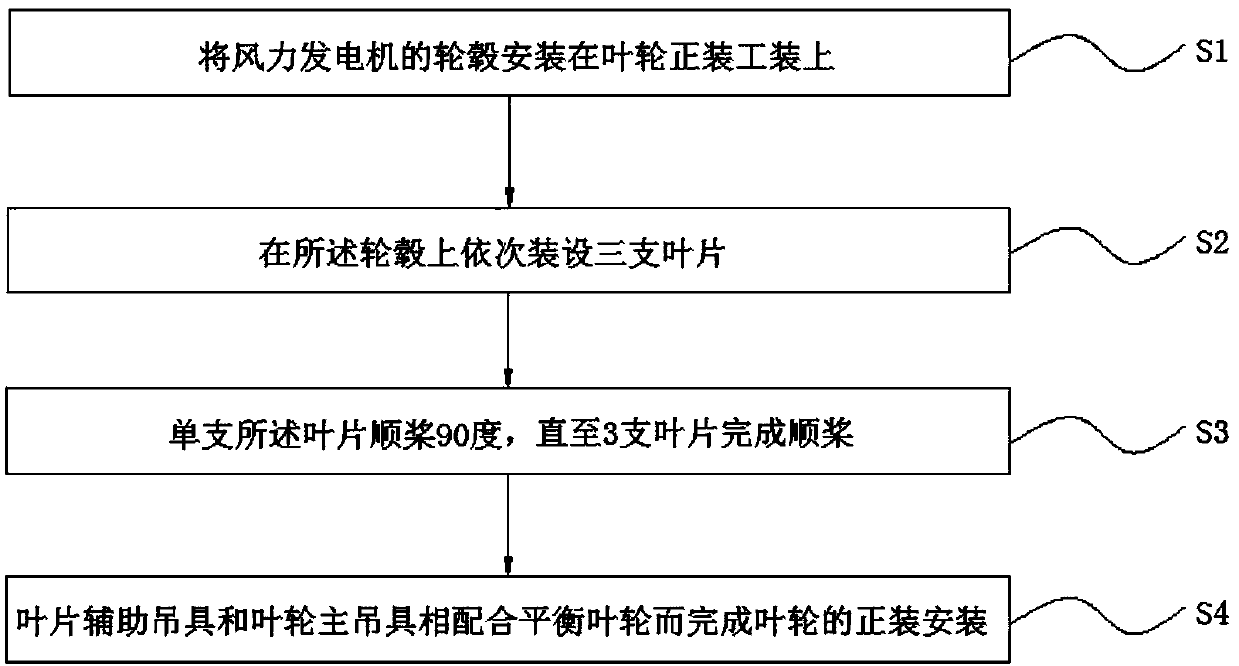

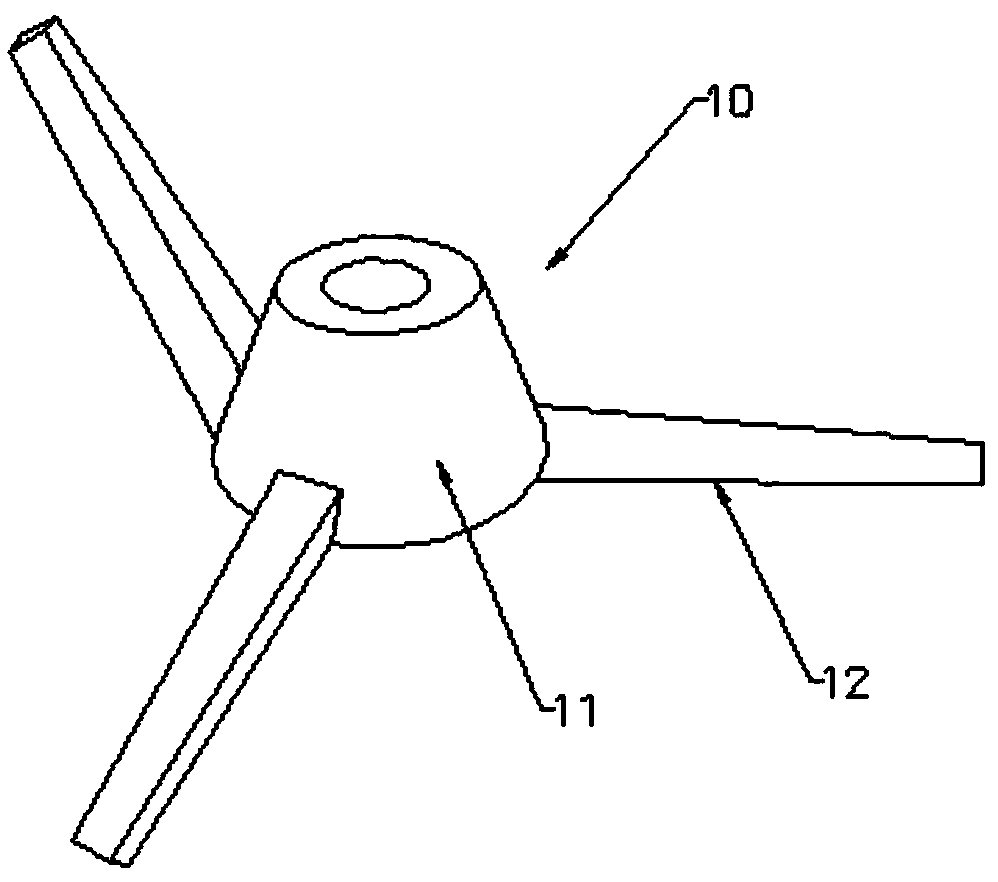

Impeller aligning method of wind turbine generator system

InactiveCN107676229AReduce breakageReduce riskWind motor assemblyWind energy generationWind drivenImpeller

The invention provides an impeller aligning method of a wind turbine generator system, and belongs to the technical field of wind turbine generator systems. The impeller aligning method of the wind turbine generator system comprises the following steps: (S1) a hub of a wind driven generator is mounted on an impeller aligning tool; (S2) three blades are mounted on the hub in sequence; connecting lines between the gravity center positions of blade auxiliary lifters and the gravity center positions of the blades are perpendicular to the blades; blade back edge protectors are mounted in the bladeback edge positions of the blades; the blade auxiliary lifters lift the blades through fixing in the blade back edge positions of the blades; and the blades are rotated and mounted on the hub; (S3) single blade is feathered by 90 degrees until three blades are feathered; and (S4) the blade back edge position of one blade is fixed through the blade auxiliary lifters; the hub is fixed through an impeller main lifter; and the blade auxiliary lifters and the impeller main lifter are matched to balance the impeller to finish the aligning installation of the impeller. The lifting time and the lifting cost can be reduced; and meanwhile, the blade rupture and deformation risks can be reduced.

Owner:NANJING ZHONGREN ENERGY TECH

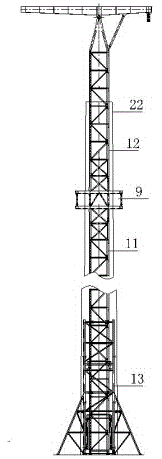

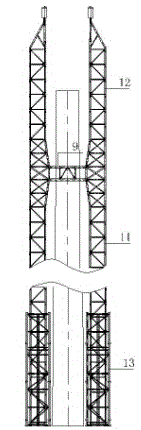

Wind generator tower self-elevating translation hoist hoisting system

The invention discloses a wind generator tower self-elevating translation hoist hoisting system. The system comprises a hoisting device, a top structure, a tower rack structure and a ground anchor device, the hoisting device comprises a hoisting arm, an end beam, hydraulic hoisting racks, a lifting oil cylinder, lifting beams and lifting steel strands, the top structure comprises supporting legs, a supporting oil cylinder, a pin roll 1 and a top ring beam, the tower rack structure comprises a pedestal, tower standard knots and tower rack top knots, the ground anchor device comprises an oil cylinder bottom anchor, a ground anchor oil cylinder, a ground anchor embedded part and a ground anchor steel strand, the system also comprises an elevating device, the elevating device comprises sleeve racks, an elevating oil cylinder, a lower ring beam, a lower latch, an upper ring beam, an upper latch and tower guiding rollers. The system has the advantages of high automation degree, self-elevating installation of a tower rack, and stabilization of a hoisting tower cylinder and a fan, and solves the problems of long cycle, large workload and high cost of fan hoisting using large-tonnage crawler cranes and truck cranes at present.

Owner:QINGDAO SINOSTRO TECH CO LTD

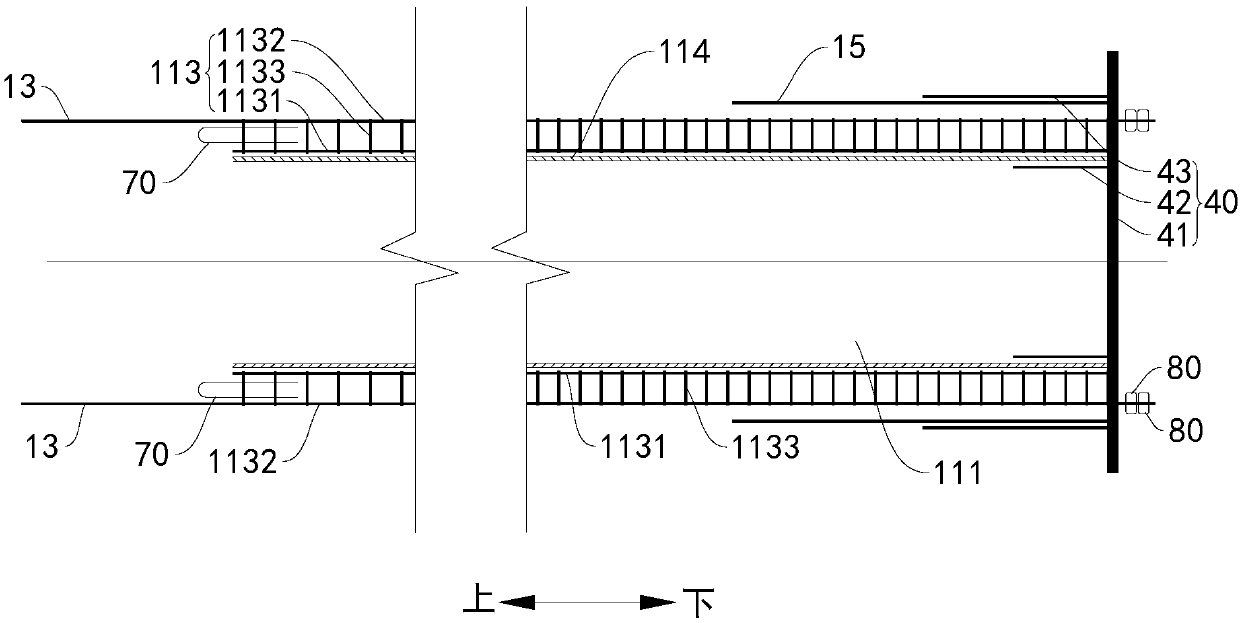

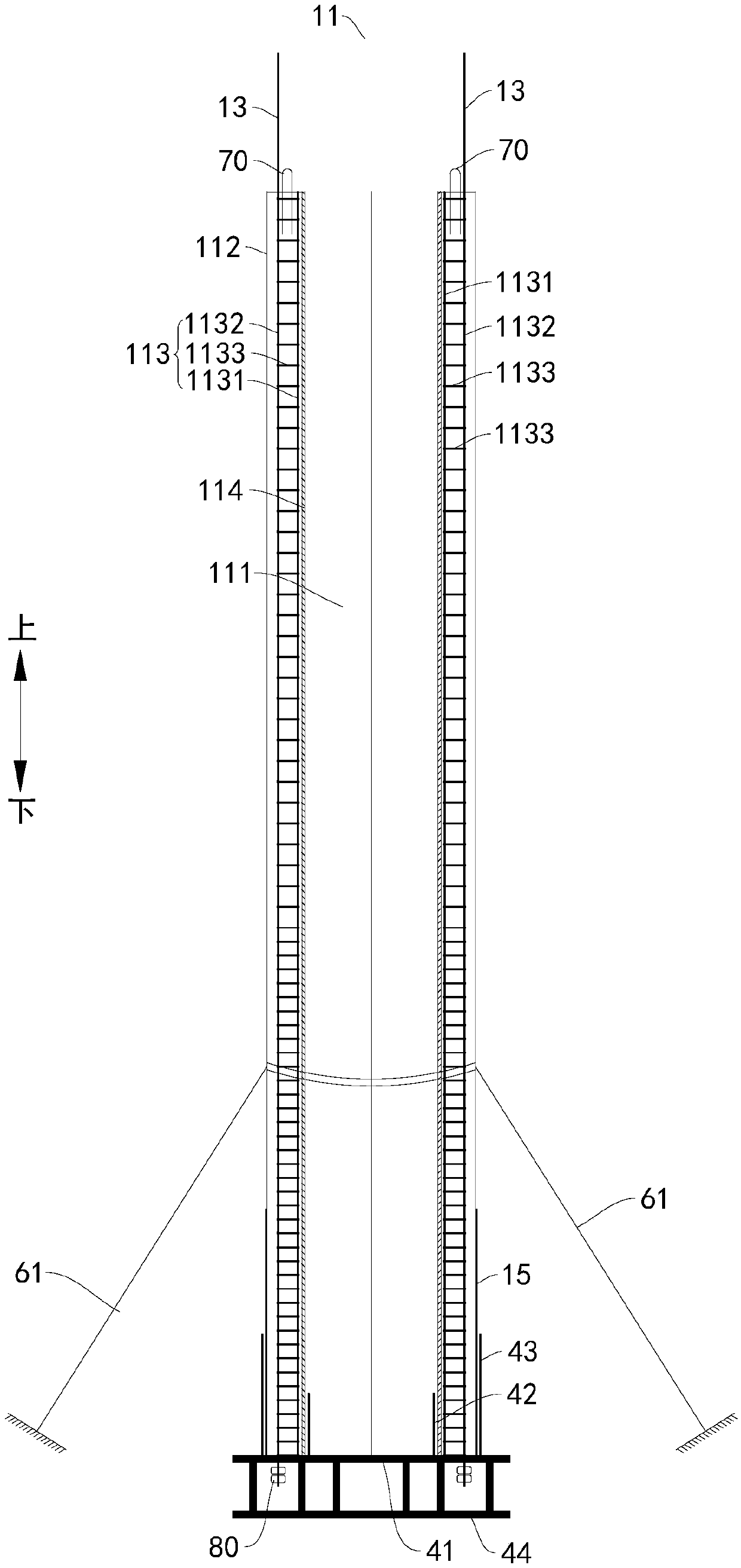

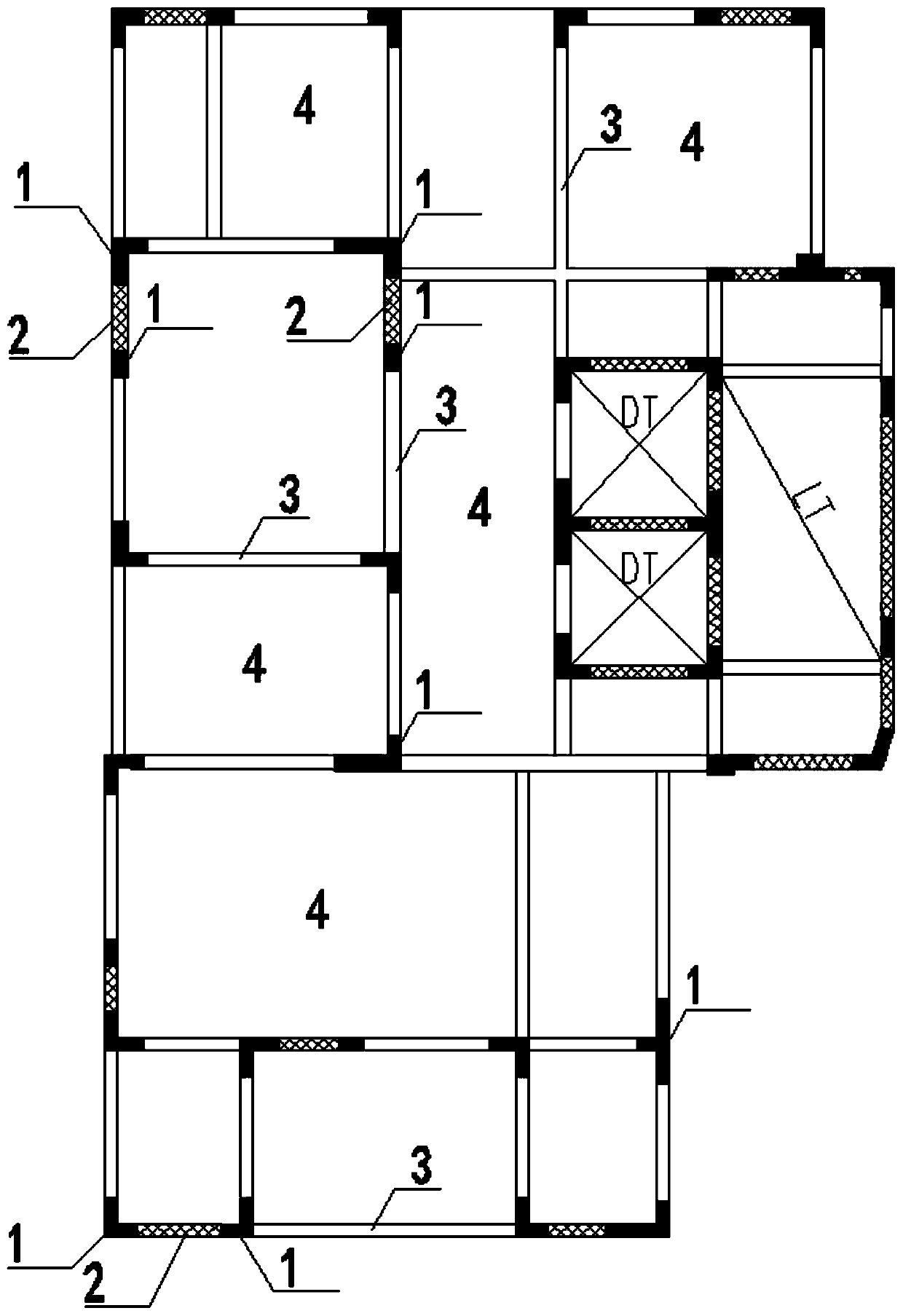

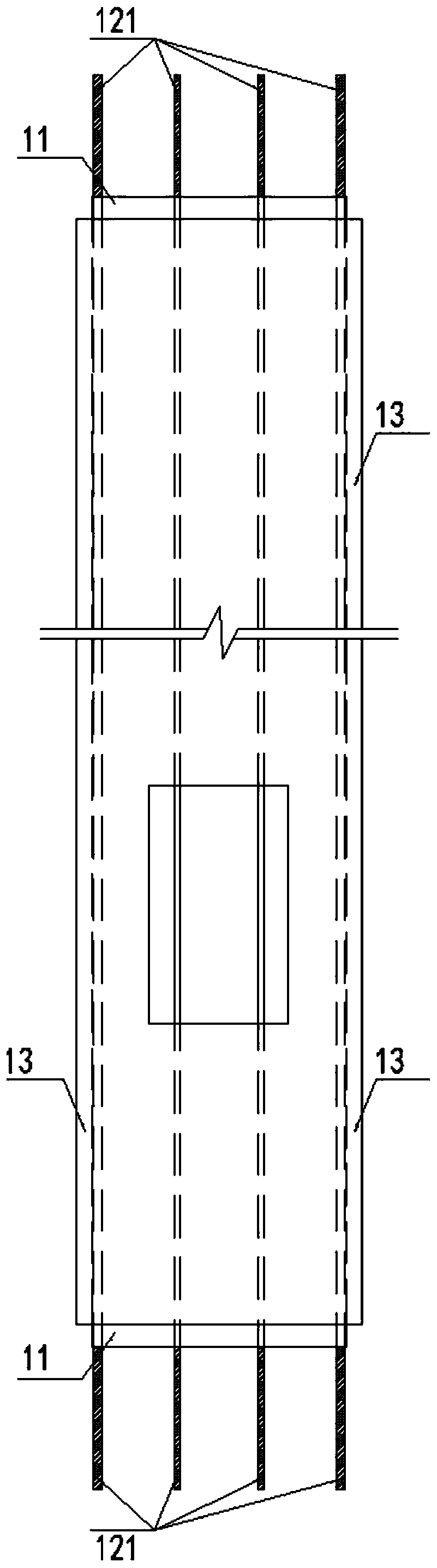

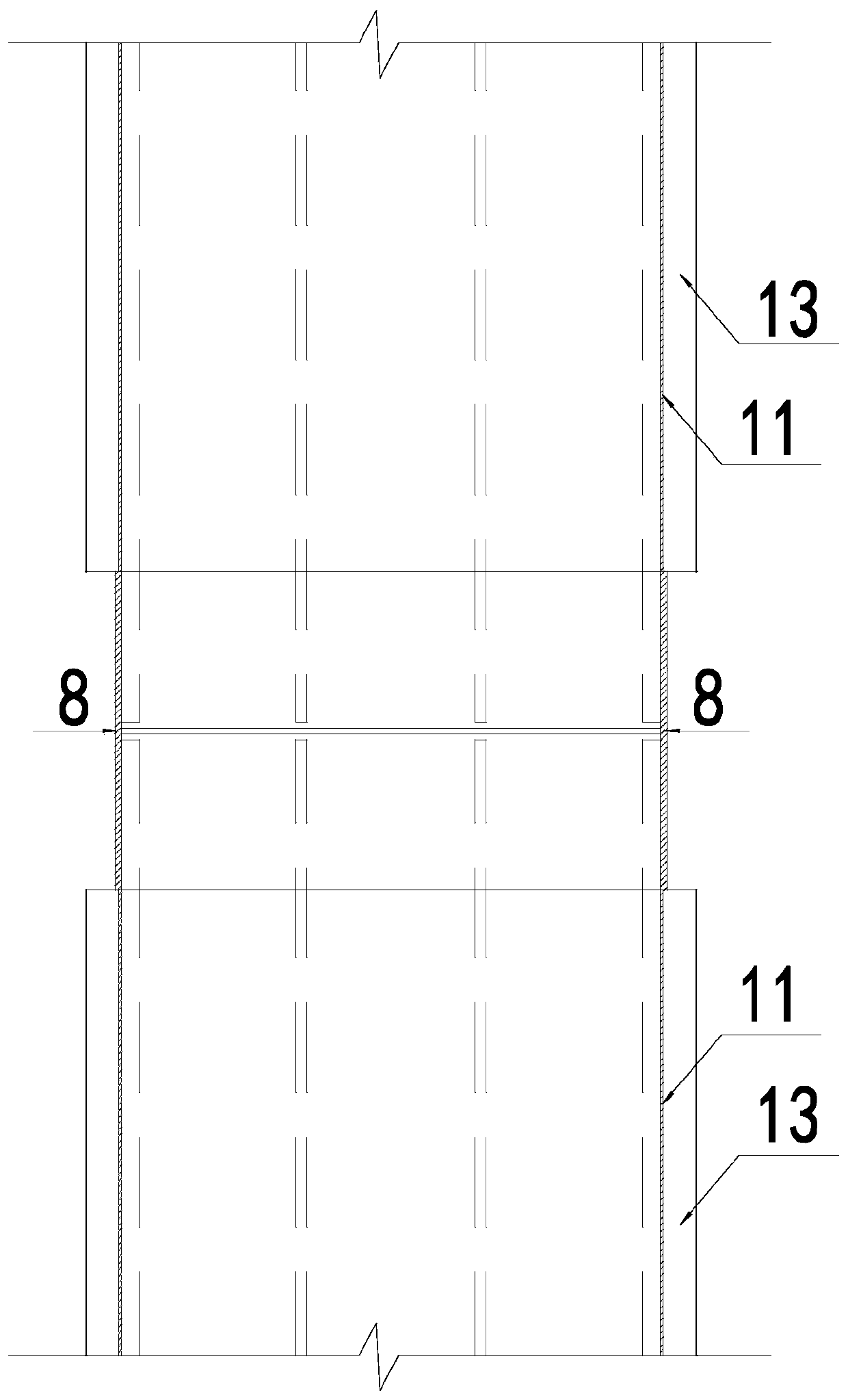

Prefabricated member, structure column, shear wall, semi-prefabricated building structure and construction method thereof

PendingCN111088848AReduce shipping costsReduce hoisting costsBuilding constructionsFloor slabArchitectural engineering

The invention relates to the technical field of prefabricated buildings, in particular to a prefabricated member, a structure column, a shear wall, a semi-prefabricated building structure and a construction method thereof. The prefabricated member comprises a columnar die sleeve and a steel framework, wherein the steel framework is arranged in the columnar die sleeve and is connected with the columnar die sleeve; and a structural opening connected with a beam is formed in the columnar die sleeve. The prefabricated member is produced in a factory, and the mounting procedure of most die plates and rebars is finished; and in addition, a cavity is formed in the columnar die sleeve, so that the advantages of keeping industrialized production while greatly reducing the weight of the prefabricated member are realized. The semi-prefabricated building structure comprises the structure column and / or the shear wall, a prefabricated groove beam and a prefabricated floorslab. After assembling, concrete is synchronously poured in the cavity, and a beam and plate overlapping layer in the prefabricated member to form a structural system with excellent integrality. The prefabricated member has theadvantages of being convenient in construction, reliable in connection, reduced in cost, and similar to stress of the existing structural system and facilitates popularization of a prefabricated building.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

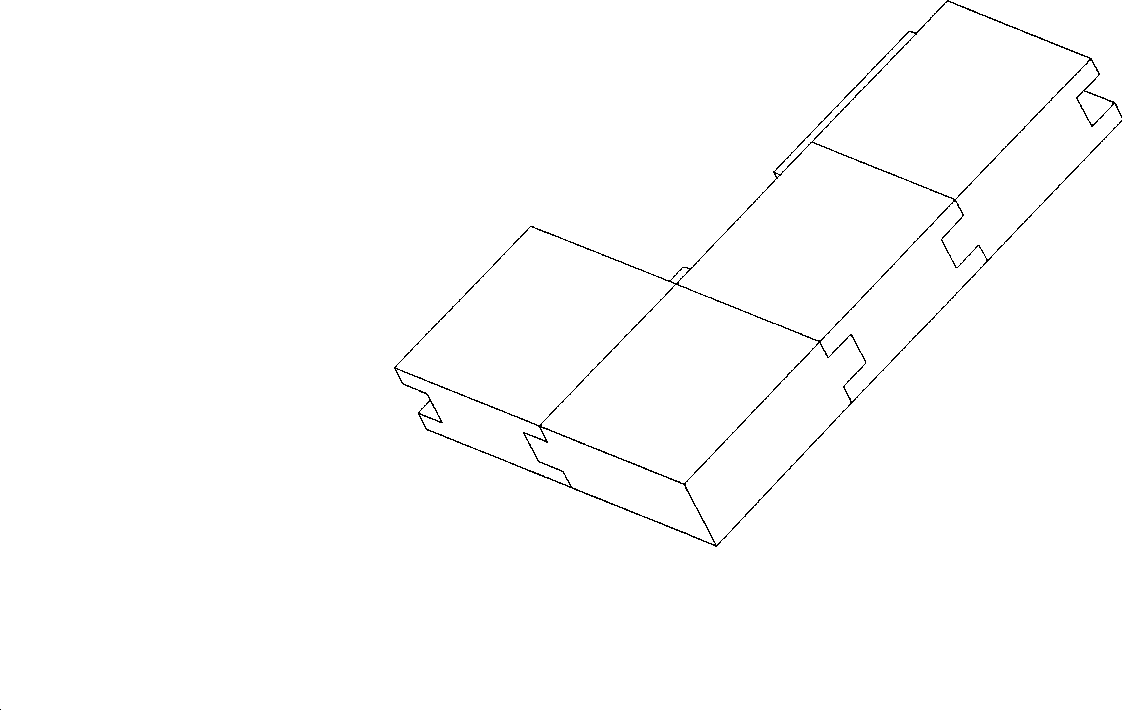

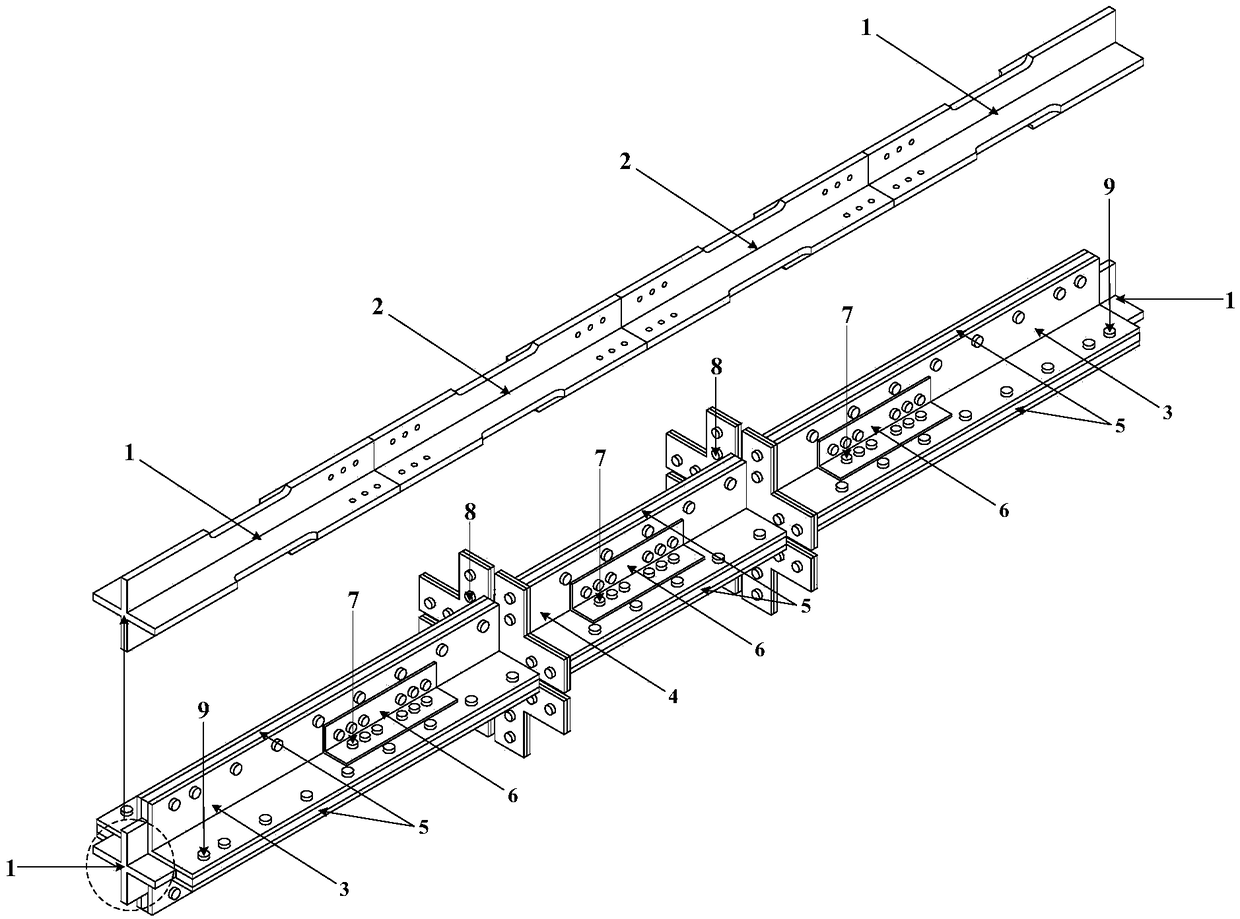

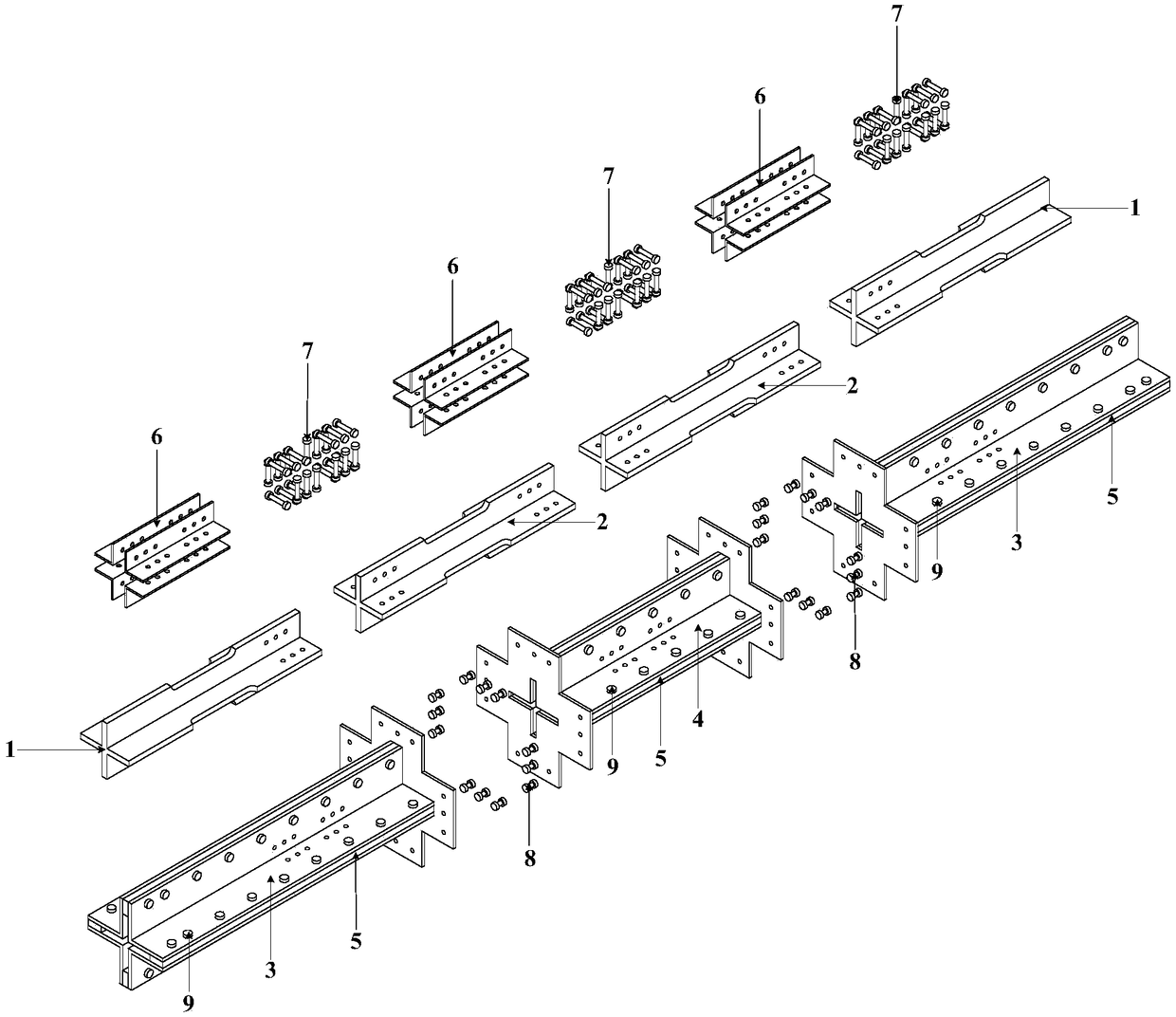

Fully assembled segmented anti-buckling supporting member with crossed cores capable of being directly replaced

ActiveCN108708469ALow costEasy and fast repair workProtective buildings/sheltersShock proofingEngineeringCore component

The invention relates to a fully assembled segmented anti-buckling supporting member with crossed cores capable of being directly replaced, and belongs to the field of structural engineering. The anti-buckling supporting member is composed of two edge section crossed core components, n middle section crossed core components, two edge section assembled-type peripheral constraining devices, (n-1) middle section assembled-type peripheral constraining devices, 4(n+1) core outer side L-shaped connecting members, a first high-strength bolt group and a second high-strength bolt group. Based on a component segmented assembled-type designing concept, an ultra-long ultra-heavy anti-buckling supporting member is divided into a plurality of sections to overcome the inconveniences of long and heavy components during the processing, transporting and installing processes. The core outer side L-shaped connecting members and the core components are arranged to tightly jack and transmit axial force in segments, weakening areas are arranged on the core components to achieve plasticity damage control, the releasing and replacing of damaged cores can be achieved without dismantling the peripheral constraining devices from the anti-buckling supporting members by the above arrangements, and post-quake repairing operation is optimized.

Owner:BEIJING UNIV OF TECH

Grouping and air-pairing installation method for corridor

ActiveCN104060838AEasy to group splicingFlexible useBuilding material handlingTerrainArchitectural engineering

The invention discloses a grouping and air-pairing installation method for a corridor, and relates to a high-altitude installation method of a steel structure. The grouping and air-pairing installation method comprises the installation steps: carrying out detailed composition on the terrain of a site and the positions of surrounding buildings, and determining main factors restricting the lifting of the corridor; determining the type and the position of a tower crane; dividing the lower layer of the M-2 corridor into two sections for installation; carrying out corridor pairing; assembling parts of the corridor. The grouping and air-pairing installation method disclosed by the invention has the advantages that in a construction area, the operating radius of the tower crane is large, the use is flexible, the long-term use can be achieved, the steel-structure construction is carried out in the areas with narrow construction sites and disadvantage for working of large lifting equipment, and convenience is brought for grouped splicing of the large steel structure. The grouping and air-pairing installation method disclosed by the invention also has the advantages that the problem that long-term matching and construction of the lifting equipment are needed due to the limitation to the construction site can be effectively solved, the use is flexible, and the use expense of the large lifting equipment is reduced; multiple constructions can be matched for optimizing other construction projects during the use period, so that the efficiency is improved.

Owner:BEIJING SHOUGANG CONSTR GROUP

Extruding type material ceiling structure and installation method

The invention discloses an extruding type material ceiling structure and an installation method. The extruding type material ceiling structure structurally comprises a keel and top plates. The keel isprovided with multiple clamping and protruding parts used for fixing the top plates in a clamping and inserting manner, and multiple clamping grooves used in cooperation with the clamping and protruding parts to achieve clamping and inserting fixing are formed in the top plates. First connecting parts and second connecting parts which are cooperatively used and are used for connecting the adjacent top plates are arranged at the two ends of the top plates, the keel and the top plates are of extruding type structures, and multiple hollow through holes are formed in the top plates. Splicing andlifting between the top plates and between the top plates and the keel are achieved in a clamping and inserting manner, a traditional rivet screwing manner is avoided, the lifting cost is greatly reduced, and in addition, the lifting efficiency is effectively improved; the top plates and the keel obtained through an integrated extruding preparing process are light in structure and convenient to install and transport, meanwhile, the extruding size specification is stable, and the extruding type material ceiling structure and the installation method are suitable for large-scale batched production. Use of other lifting parts is not needed, and certain lifting processes are reduced.

Owner:ZHEJIANG YASHA DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com