Prefabricated member, structure column, shear wall, semi-prefabricated building structure and construction method thereof

A technology of building structure and construction method, which is applied in the direction of building structure and construction, can solve the problems of heavy weight of prefabricated parts, difficulty in popularizing prefabricated buildings, and difficulty in popularizing prefabricated buildings, and achieve weight reduction, convenient connection and Detection, convenient and reliable splicing and connectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

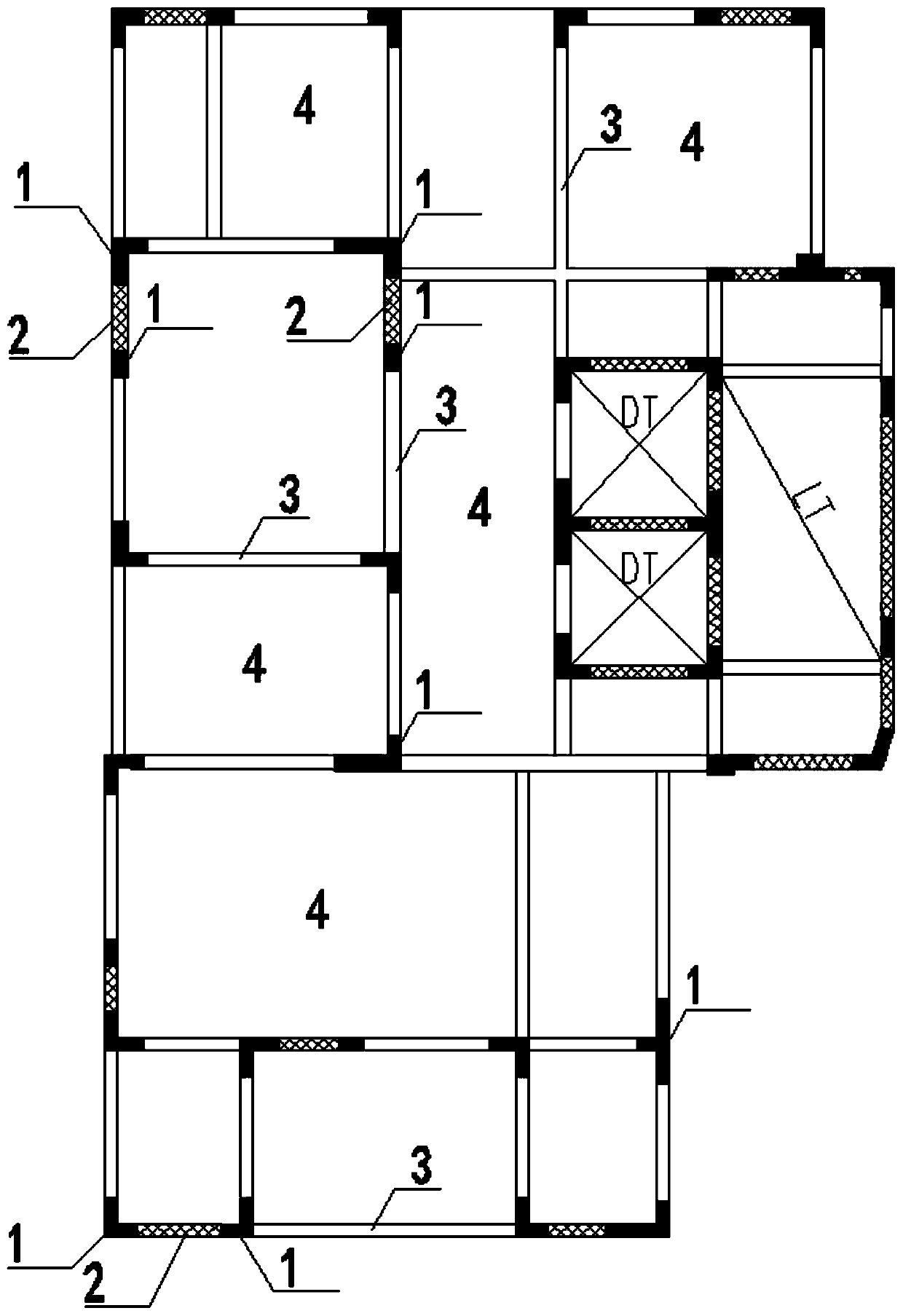

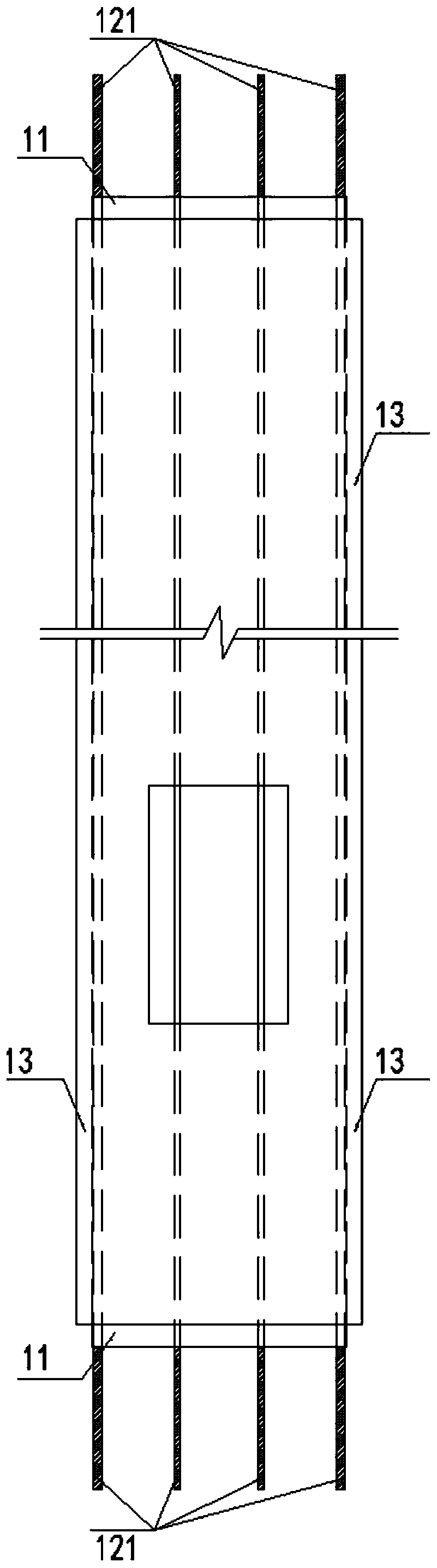

[0064] Such as Figure 1-12 As shown, the prefabricated part provided by the present invention includes a column formwork 11 and a steel skeleton 12. The steel framework 12 is arranged in the column formwork 11 and connected with the column formwork 11. On the column formwork 11 A beam connection hole 111 communicating with the inside of the structural beam 3 is provided at a position corresponding to the structural beam 3 .

[0065] The prefabricated part of this application has completed most of the template and steel bar installation processes, which reduces the weight of the components to be transported while maintaining the advantages of factory production, thereby reducing transportation costs and hoisting costs, and promoting the promotion of prefabricated buildings , the column formwork 11 on the prefabricated part has airtight constraint effect on the concrete, can improve the compressive strength of the concrete, is beneficial to reduce the section of the column and ...

Embodiment 2

[0076] Such as Figure 1-11 As shown, this embodiment discloses a structural column 1, which includes several sections of prefabricated parts as described in Embodiment 1, and also includes column cast-in-place parts. The prefabricated parts are vertically spliced and connected to each other vertically. The column cast-in-place parts are concrete solidification parts poured in the connected prefabricated parts.

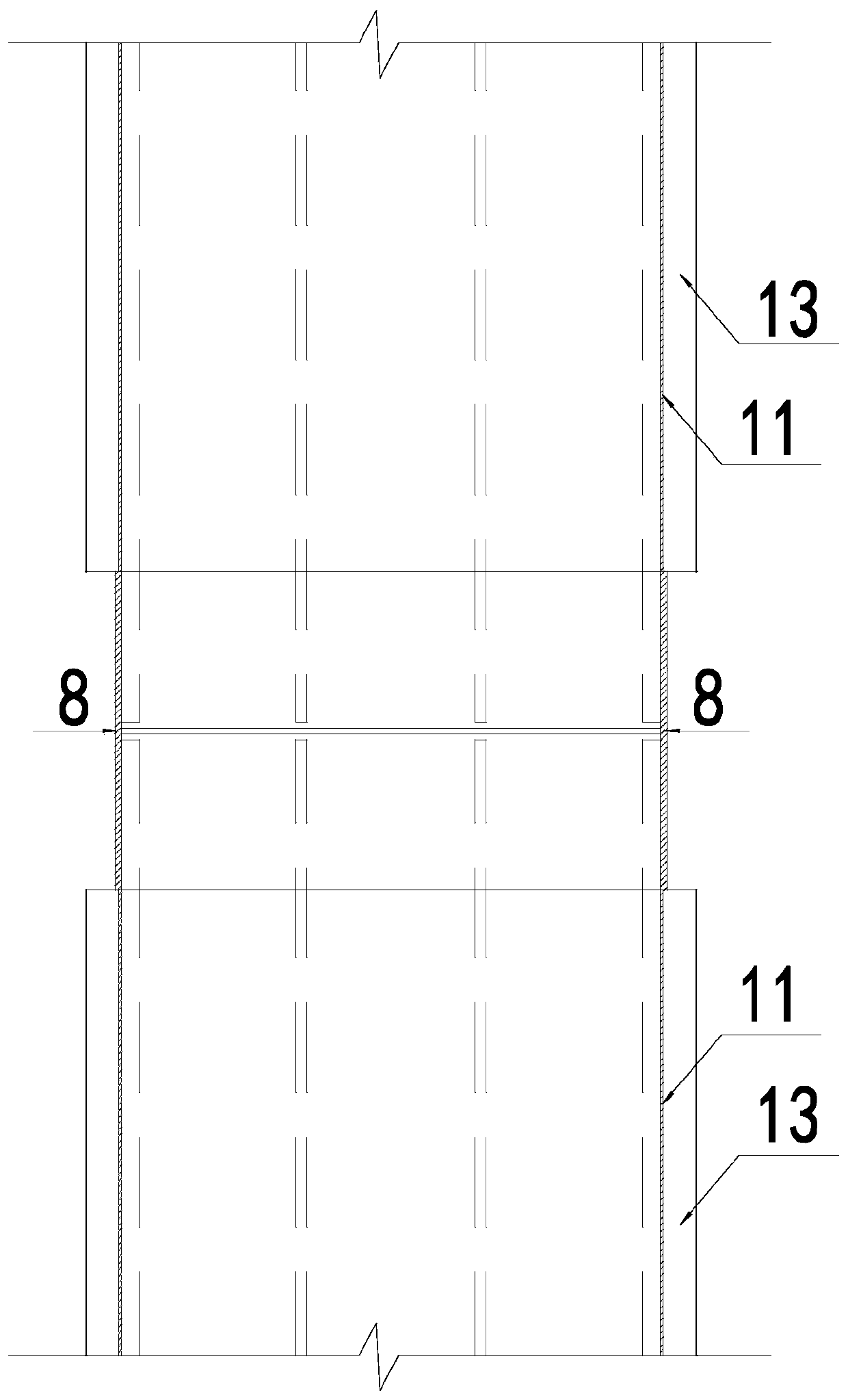

[0077] Such as figure 2 , 3 As shown, at the beginning, the two ends of the steel skeleton 12 respectively extend from the two ends of the column formwork 11 to the outside of the column formwork 11, and the vertical steel columns outside the prefabricated parts adjacent up and down The periphery of the bar 121 is provided with a connecting sleeve 8, and the connecting sleeve 8 communicates with the column mold sleeves 11 adjacent up and down.

[0078] In this embodiment, the connection set 8 is formed by welding the upper and lower adjacent column mold sets 11 ...

Embodiment 3

[0081] Such as figure 1 , 10 , 11, this embodiment discloses a shear wall 2, which includes a prefabricated wall skeleton 22 and the prefabricated part described in Embodiment 1. The prefabricated wall skeleton 22 is cross-shaped and arranged on adjacent prefabricated parts In between, the ends of the prefabricated wall frame 22 are connected to the prefabricated parts; post-cast walls with the prefabricated wall frame 22 as the skeleton are post-cast between the adjacent prefabricated parts.

[0082] In this embodiment, the shear wall 2 further includes at least two prefabricated wall panels 21, the prefabricated wall panels 21 are arranged parallel to each other, and the two ends of the prefabricated wall panels 21 are respectively connected to the adjacent prefabricated parts ; The prefabricated wall skeleton 22 is set in the wall space surrounded by the prefabricated wall panels 21 and the prefabricated parts, and the post-cast wall body 23 is a solidification element pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com