Impeller aligning method of wind turbine generator system

A technology for wind turbines and impellers, which is applied in the assembly of wind turbines and wind power generation. It can solve the problems of broken blades, long hoisting hours, and high safety factor, and achieve the effects of convenient installation and reduced site requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

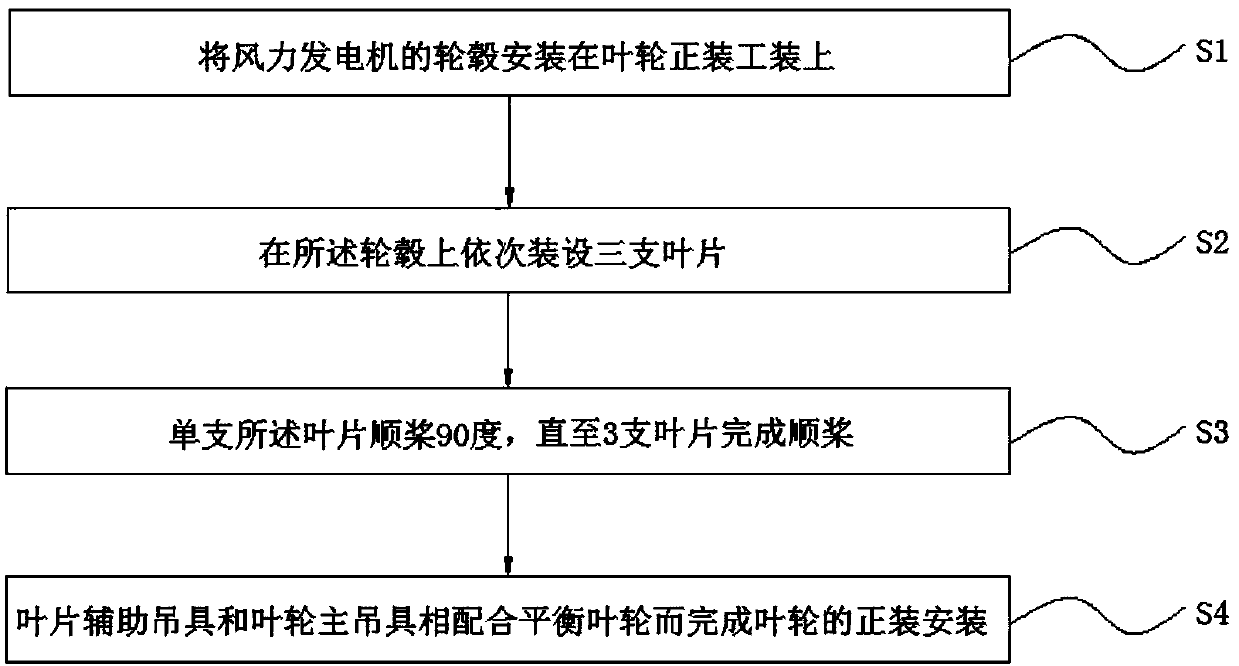

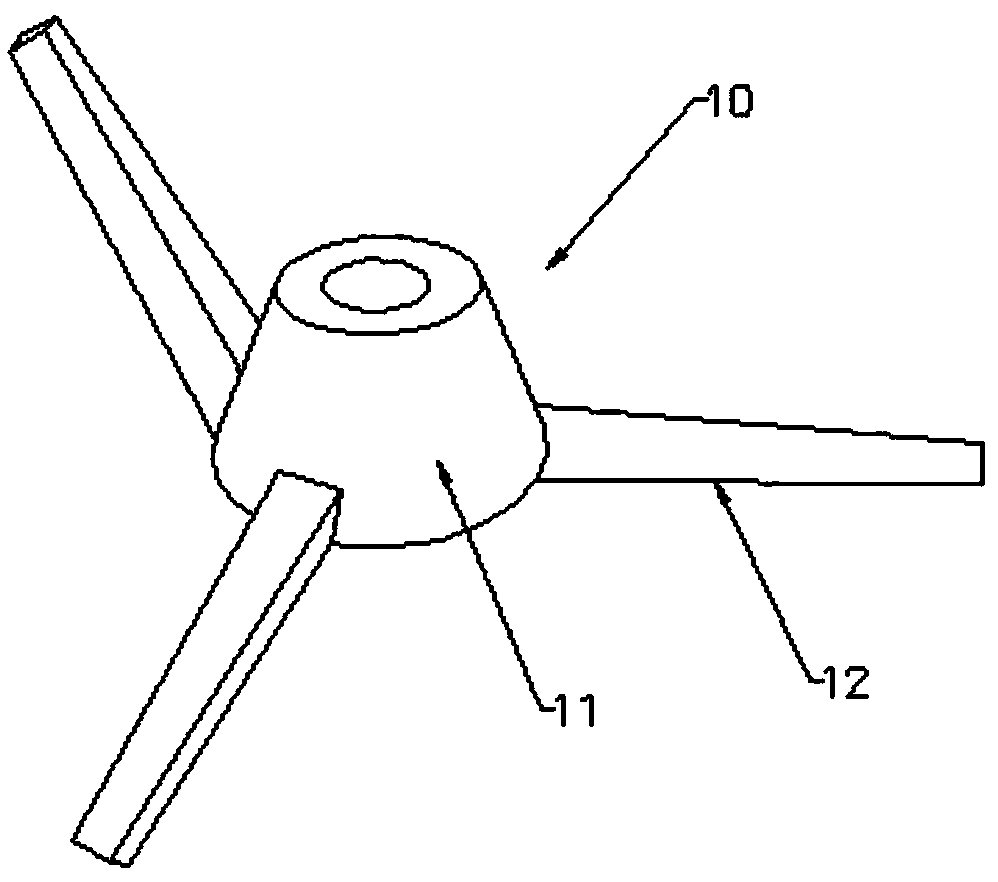

[0017] Such as figure 1 As shown, a schematic flow chart of a wind turbine impeller installation method, in this embodiment, the impeller installation equipment is used, and the impeller installation equipment includes the auxiliary blade spreader, the blade trailing edge protector, the impeller main spreader and the impeller installation tooling, And the wind turbine impeller installation method includes the following steps: S1: install the hub of the wind generator on the impeller installation tooling; S2: install three blades on the hub in sequence, first, by adjusting the position of the center of gravity of the blade auxiliary hanger to the The line connecting the center of gravity of the blade is perpendicular to the blade, and the blade trailing edge protector is installed on the blade trailing edge of the blade; secondly, the blade auxiliary sling is fixed on the blade trailing edge of the blade to lift the blade; again, Rotate the blades, and finally, install the blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com